Page 1

Installation Instructions

www.amico.com

Light-duty Monitor Arm (LMA)

Page 2

Preface

IMPORTANT, PLEASE READ CAREFULLY

Thank you for your purchase with Amico Accessories Inc.

This unit is designed for long lasting performance, provided that the end user complies with assembly and maintenance

procedures. This Instruction Manual is your guide to ensure that you get the best performance out of the equipment.

Amico Accessories Inc. is not responsible for any damage as a result of (but not limited to) abuse and other problems

that may be a direct or indirect result of failure to comply with the instructions provided in this manual.

Please Note These Key Words and Symbols:

WARNING Steps where extra care should be taken to prevent injuries and damage.

NOTE Steps that point out helpful information.

Medical Facility Responsibilities

Preventive maintenance checks must be performed regularly to maintain the quality and performance of this product.

Any parts that may be broken, missing, worn, distorted or contaminated in any way should not be used and all aected

parts should be replaced immediately. Should the necessity of any repair be suspected, please contact your local

distributor or call 1.877.264.2697.

2 Amico Accessories Inc.

Page 3

Contents

Section 1: Product Specications 4

Section 2: Installation Preparation 5

Section 3: Installation on Mounting Platform

Mounting to MRS (Monitor Rail System) 6

Mounting to VRS (Vertical Rail System) 7

Mounting on the Wall 8

Mounting on the Desk: Clamp Mount Assembly 9-10

Mounting on the Desk: Over Existing Grommet 10-11

Section 4: Device Installation

Device Conguration Recommendations 12

Cable Management 13

Section 5: Adjustments 14

Section 6: Maintenance And Troubleshooting

Preventive Maintenance 15

Troubleshooting 15

Cleaning 16

Section 7: Product Classication 17

Warranty 18

Notes 19

www.amico.com 3

Page 4

SECTION 1: Product Specications

FOLDED POSITION

4" [10.16 cm]

5" [12.7 cm]

16" [40.64 cm]

EXTENDED POSITION

NOTE:

L - LONG POST

S - SHORT POST

24" [60.96 cm]

Features

• Ideal for applications where only occasional adjustment is needed

• Available with or without extension

• Ideal for monitors 8-17 lbs (3.6-7.7 kg)

• Cable management made easy

• Screens can be mounted in landscape or portrait orientation

• Multiple mounting options available

7" [17.78 cm]

1" [2.54 cm]

11" [27.94 cm]

FOLDED POSITIONEXTENDED POSITION

3" [7.62 cm]

L= 13" [33.02 cm]

S= 6" [15.24 cm]

5" [12.7 cm] Height

Adjustment for

Long Post Only

5" [12.7 cm]

3" [7.62 cm]

0.39" - 2.95"

[0.99 cm - 7.49 cm]

0.39" - 2.95"

[0.99 cm - 7.49 cm]

SURFACE MOUNTING DETAIL

4 Amico Accessories Inc.

Page 5

SECTION 2: Installation Preparation

Installation, Tools and Part Requirements

• HEX key sizes: 2.5 mm; 1/8" (3.2 mm), 5 mm; 6 mm

• Philips Head Screwdriver size: #3

• 1/2" (12.7 mm) Socket wrench

WARNING It is the installer’s responsibility to ensure all components are properly assembled and installed

using the provided instruction manual.

WARNING Using improperly sized screws may damage your display. If spacers are required, be sure to use

correctly sized screws. Properly sized screws will easily and completely thread into the display mounting holes.

WARNING Exceeding weight capacities can result in severe personal injury or damage to equipment. It is

the installer’s responsibility to ensure the combined weight of all components does not exceed the weight

capacity of 8-17 lbs (3.6-7.7 kg).

WARNING Allowing any part of the component cables to be caught between movable parts can result in

serious personal injury or damage to equipment.

WARNING The arm will spring upward and may cause personal injury or equipment damage when the

monitor is removed, due to the change in weight. Secure the arm rst by lifting the arm to be in the fully UP

position when monitor is removed.

WARNING The mounting platform must be strong and stable enough for supporting the monitor as well as

the arm.

WARNING Verify that rails have been installed in accordance with Amico rail installation instructions. Rail

failure with mounted devices can cause serious injury and equipment damage.

WARNING Do not position the LMA above a patient.

WARNING It shall be the responsibility of the hospital, its consultants and/or contractors to determine if

the mounting surface is adequate to safely mount the specic instrument. This includes the selection of

appropriate fasteners and the proper installation, REGARDLESS OF WHAT IS SUPPLIED WITH YOUR LMA. See rail

instructions for specic wall channel guideline information.

WARNING DO NOT attempt to mount/remove the LMA from the rail when loaded with any instrument.

WARNING To prevent mounting adapter from sliding down the rail, ensure that all set screws are fastened

to the tightest possible position. Serious injuries could result if the set screws are not properly fastened.

Contact Amico Accessories Inc. to discuss solutions not covered in this manual at 1.877.264.2697

www.amico.com 5

Page 6

SECTION 3: Installation on Mounting Platform

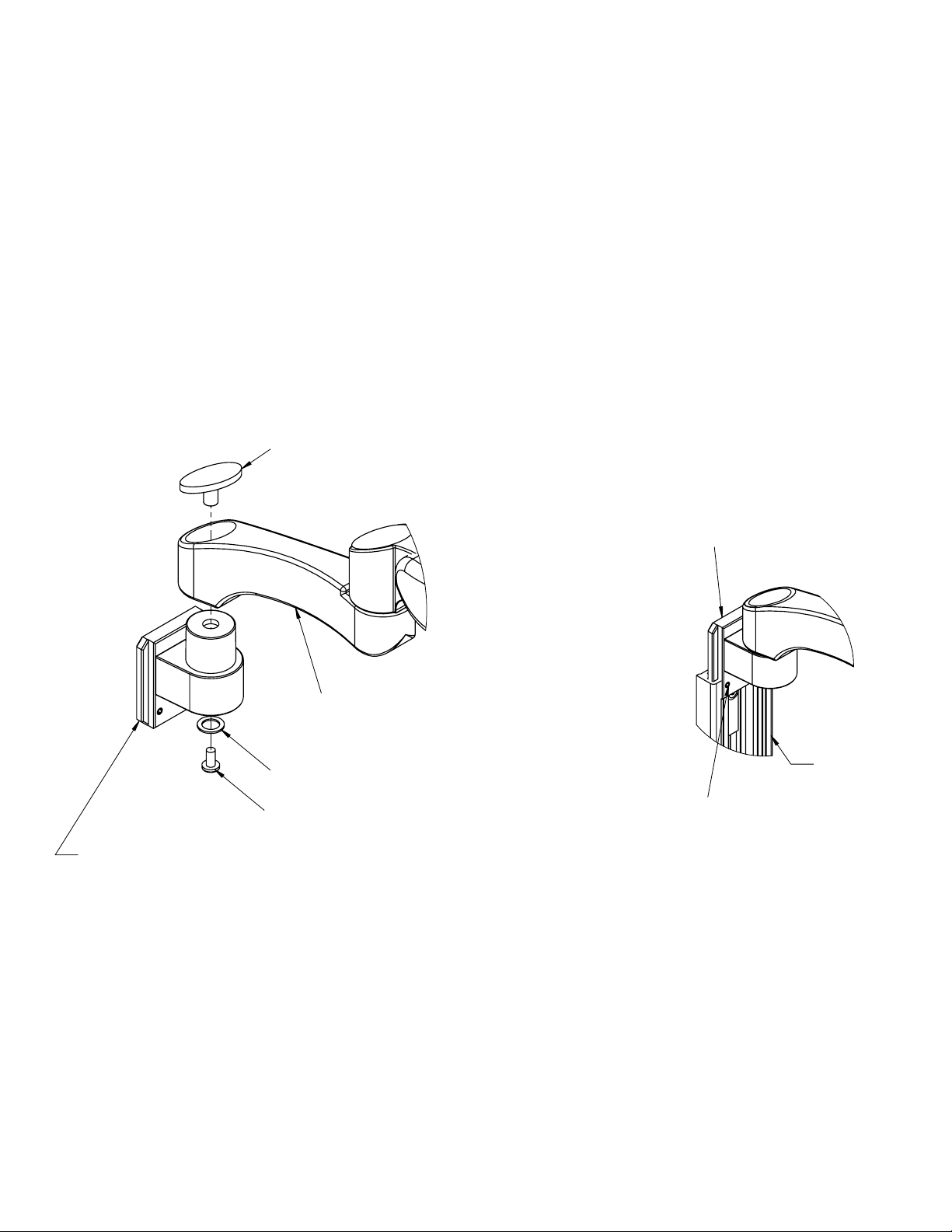

X-LMA-(MON/MON-B)-ADA

X-LMA-(VRS-/VRS-B)-ADA

SCREW

(PART OF X-LMA-01-01)

WASHER

(PART OF X-LMA-01-01)

CAP

(PART OF X-LMA-01-01)

X-LMA-VRS-ADA/

X-LMA-VRS-B-ADA

CAP

CUSTOMER

85 Fulton Way

Richmond Hill, Ontario

L4B 2N4, Canada

Toll Free: 1.877.264.2697 (T)

PROJECTION

X-LMA-MON-ADA/

X-LMA-MON-B-ADA

MRS RAIL

2 X H-SSCP-1420-05

2 X H-1420-LNUT-NYL

X-GTA-KNOB/

X-GTA-KNOB-B

Figure 1

HR-CONV-PIN

X-SSM-VERT-ADA

Figure 2

2 X HR-CONV-PIN

X-GTA-KNOB/

X-GTA-KNOB-B

2 X H-CAP-14-B

CUSTOMER

FOR USE WITH: LMA-__-(MON/MON-B)-__, LMA-__-(VRS/VRS-B)-__

PROJECT 394

X-LMA-(VRS-/VRS-B)-ADA

X-LMA-(MON/MON-B)-ADA

Slide X-LMA-(MON/MON-B)-ADA into the

1.

MRS rail.

Once the arm is positioned at the desired

2.

height, tighten 2 x H-SSCP-1420-05.

Turn 2 x X-GTA-KNOB/X-GTA-KNOB-B to loosen 2 x HR-

1.

CONV-PIN. Tilt and guide the 2X HR-CONV-PIN into the

opening of the VRS rail (Figure 1).

Ensure the flange on the X-SSM-VERT-ADA is properly

2.

aligned with the rail. Position to desired height before

tightening 2 x X-GTA-KNOB/X-GTA-KNOB-B. (Figure 2)

Lock the 2 x X-GTA-KNOB/X-GTA-KNOB-B with 2 x H-1420-

3.

LNUT-NYL and 2 x H-CAP-14-B. (Figure 3)

Mounting to MRS (Monitor Rail System):

1. Assemble LMA to X-LMA-(MON/MON-B)-ADA by placing LMA onto X-LMA-(MON/MON-B)-ADA and securing with

the screw through washer, X-LMA-(MON/MON-B)-ADA, LMA, and into cap, using #3 Philips head screwdriver (as

shown in the gure on the left below).

2. Slide X-LMA-(MON/MON-B)-ADA into the MRS rail (as shown in the gure on the right below).

3. Once the arm is positioned at the desired height, tighten two of the parts labeled H-SSCP-1420-05 in the

diagram below with a 1/8" (3.2 mm) HEX key.

Figure 1

(PART OF X-LMA-01-01)

WASHER

(PART OF X-LMA-01-01)

SCREW

(PART OF X-LMA-01-01)

X-LMA-MON-ADA/

X-LMA-MON-B-ADA

LMA-__-(_____)-__

6 Amico Accessories Inc.

Page 7

SECTION 3: Installation on Mounting Platform

F

DETAIL F

SCALE 1 : 5

HR-CONV-PIN

DETAIL P

SCALE 2 : 5

2 X HR-CONV-PIN

X-GTA-KNOB/

X-GTA-KNOB-B

2 X H-CAP-14-B

CUSTOMER

X-LMA-(VRS-/VRS-B)-ADA

Turn 2 x X-GTA-KNOB/X-GTA-KNOB-B to loosen 2 x HR-

1.

CONV-PIN. Tilt and guide the 2X HR-CONV-PIN into the

opening of the VRS rail (Figure 1).

Ensure the flange on the X-SSM-VERT-ADA is properly

2.

aligned with the rail. Position to desired height before

tightening 2 x X-GTA-KNOB/X-GTA-KNOB-B. (Figure 2)

Lock the 2 x X-GTA-KNOB/X-GTA-KNOB-B with 2 x H-1420-

3.

LNUT-NYL and 2 x H-CAP-14-B. (Figure 3)

F

DETAIL F

SCALE 1 : 5

2 X H-CAP-14-B

2 X H-1420-LNUT-NYL

X-GTA-KNOB/

X-GTA-KNOB-B

Figure 1

DETAIL P

SCALE 2 : 5

Figure 2

2 X HR-CONV-PIN

X-GTA-KNOB/

X-GTA-KNOB-B

2 X H-CAP-14-B

CUSTOMER

X-LMA-(VRS-/VRS-B)-ADA

F

DETAIL F

SCALE 1 : 5

DETAIL P

SCALE 2 : 5

2 X HR-CONV-PIN

X-GTA-KNOB/

X-GTA-KNOB-B

2 X H-CAP-14-B

CUSTOMER

N

DETAIL N

SCALE 2 : 5

X-LMA-(VRS-/VRS-B)-ADA

CUSTOMER

Mounting to VRS (Vertical Rail System):

1. Assemble LMA to X-LMA-(VRS/VRS-B)-ADA by placing LMA onto X-LMA-(VRS/VRS-B)-ADA and securing with the

screw through washer, X-LMA-(VRS/VRS-B)-ADA, LMA, and into cap, using #3 Philips head screwdriver (as shown

in Figure 2 below).

2. Turn two X-GTA-KNOB-X-GTA-KNOB-B to loosen two HR-CONV-PIN. Tilt and guide the two HR-CONV-PIN into the

opening of the VRS rail (Figure 3).

3. Ensure the ange on the X-SSM-VERT-ADA is properly aligned with the rail. Position to desired height before

tightening two X-GTA-KNOB/X-GTA-KNOB-B (Figure 3).

4. Lock the two X-GTA-KNOB/X-GTA-KNOB-B with two H-1420-LNUT-NYL using a 1/2" (12.7 mm) socket wrench and

cover with two H-CAP-14-B (Figure 3).

Figure 2

CAP

(PART OF X-LMA-01-01)

X-LMA-VRS-ADA/

X-LMA-VRS-B-ADA

WASHER

(PART OF X-LMA-01-01)

SCREW

(PART OF X-LMA-01-01)

X-SSM-VERT-ADA

Figure 3

www.amico.com 7

Page 8

SECTION 3: Installation on Mounting Platform

*** Repeat 1 to 3 for the other hole on X-LMA-WAL-ADA***

H-PHMS-1420-212

LMA-__-(_____)-__

CAP

(PART OF X-LMA-01-01)

WASHER

(PART OF X-LMA-01-01)

SCREW

(PART OF X-LMA-01-01)

X-LMA-WAL-ADA

2 X WASHER

(PART OF X-LMA-WAL-ADA)

2 X H-PHMS-1420-212

CUSTOMER

X-LMA-WAL-ADA

LMA ASSEMBLY

www.amico.com

PROJECTION

LMA ASSEMBLY

85 Fulton Way

Richmond Hill, Ontario

L4B 2N4, Canada

Toll Free: 1.877.264.2697 (T)

Tel: (905) 763.7778

Fax: (905) 763.8587

THIS PRINT IS PROPERTY OF AMICO ACCESSORIES

AND IS LOANED IN CONFIDENCE SUBJECT TO RETURN

UPON REQUEST AND WITH THE UNDERSTANDING THAT

PRIVATE AND CONFIDENTIAL

PART NO:

DESCRIPTION:

Mounting on the Wall

1. Drill a 1/2" (12.7 mm) hole at the desired mounting height. Hold metal channel of H-SNPTOG-1420 at alongside

plastic straps and slide channel through hole. Minimum clearance behind the wall is 1-7/8" (47.6 mm). See

Figure 4.1.

2. Hold ends of straps between thumb and forenger and pull toward you until channel rests ush behind the wall.

Slide plastic cap along straps with other hand until ange of cap is ush with the wall. See Figure 4.2.

3. Snap straps at wall by pushing side to side and snapping o straps level with ange of cap. See Figure 4.3.

*** Repeat steps 1 to 3 for the other hole on X-LMA-WAL-ADA ***

4. Place X-LMA-WAL-ADA over ange. Insert H-PHMS-1420-212 with #3 Philips head screwdriver and tighten until

ush against item, then stop, as shown in Figure 4.4.

5. Assemble LMA to X-LMA-WAL-ADA by placing LMA onto X-LMA-WAL-ADA and securing with the screw through

washer, X-LMA-WAL-ADA, LMA, and into cap, using #3 Philips head screwdriver (as shown in Figure 5).

Figure 4

Figure 5

8 Amico Accessories Inc.

Page 9

SECTION 3: Installation on Mounting Platform

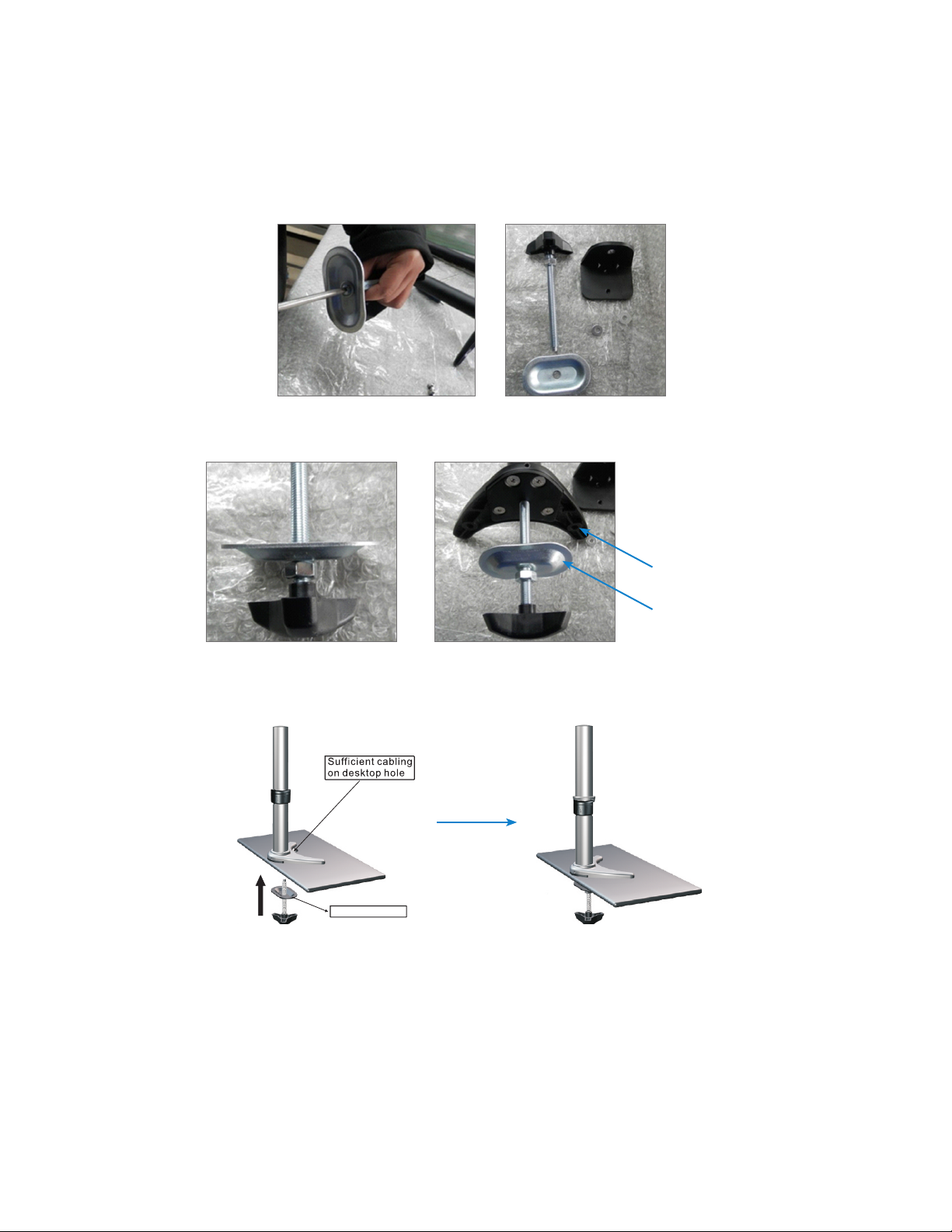

Mounting on the Desk: Clamp Mount Assembly

For Use With: LMA-__-DSK-L-__/LMA-__-DSK-S-__

WARNING It is recommended that the desk clamp be clamped to the side or rear of desktop surface. This

assembly is suitable for square edged desks only. It is the user’s responsibility to make sure the desk structure to

which this clamp is attached can support the combined weight of all components.

1. Adjust the height of the desk clamp to suit desktop surface.

0.39'' - 2.95''

(9.9 mm - 75 mm)

2. Place the plastic gasket cushion as shown.

3. Place the desk clamp on top of the desk in the desired position and ensure the clamp opening is facing towards

the edge of the desktop. Turn the handle to tighten by hand to ensure that the desk clamp fully contacts the

desktop surface and is secure.

www.amico.com 9

Page 10

SECTION 3: Installation on Mounting Platform

pressure plate

Mounting on the Desk: Clamp Mount Assembly

4. Loosen the collar and adjust the height as desired before installing and tightening the Light Monitor Arm.

Mounting on the Desk: Over Existing Grommet

1. Remove six screws from the existing plate.

2. Secure the grommet plate to the base plate with four screws as shown below.

2.5 mm HEX key

10 Amico Accessories Inc.

Grommet Plate

Base Plate

Page 11

SECTION 3: Installation on Mounting Platform

Mounting on the Desk: Over Existing Grommet

3. Remove the screw from the gripping plate as shown below.

4. Insert the gripping plate into bolt and tighten into base plate as shown below.

Base Plate

Gripping Plate

5. Unscrew the pressure plate and bolt from the base and sandwich desktop surface as shown. Turn and tighten by

hand to ensure that the grommet clamp pressure plate fully contacts the desktop surface and is secure.

pressure plate

6. Refer to “Mounting on the Desk: Clamp Mount Assembly” step 4 on page 10 for collar adjustment and Light

Monitor Arm installation

www.amico.com 11

Page 12

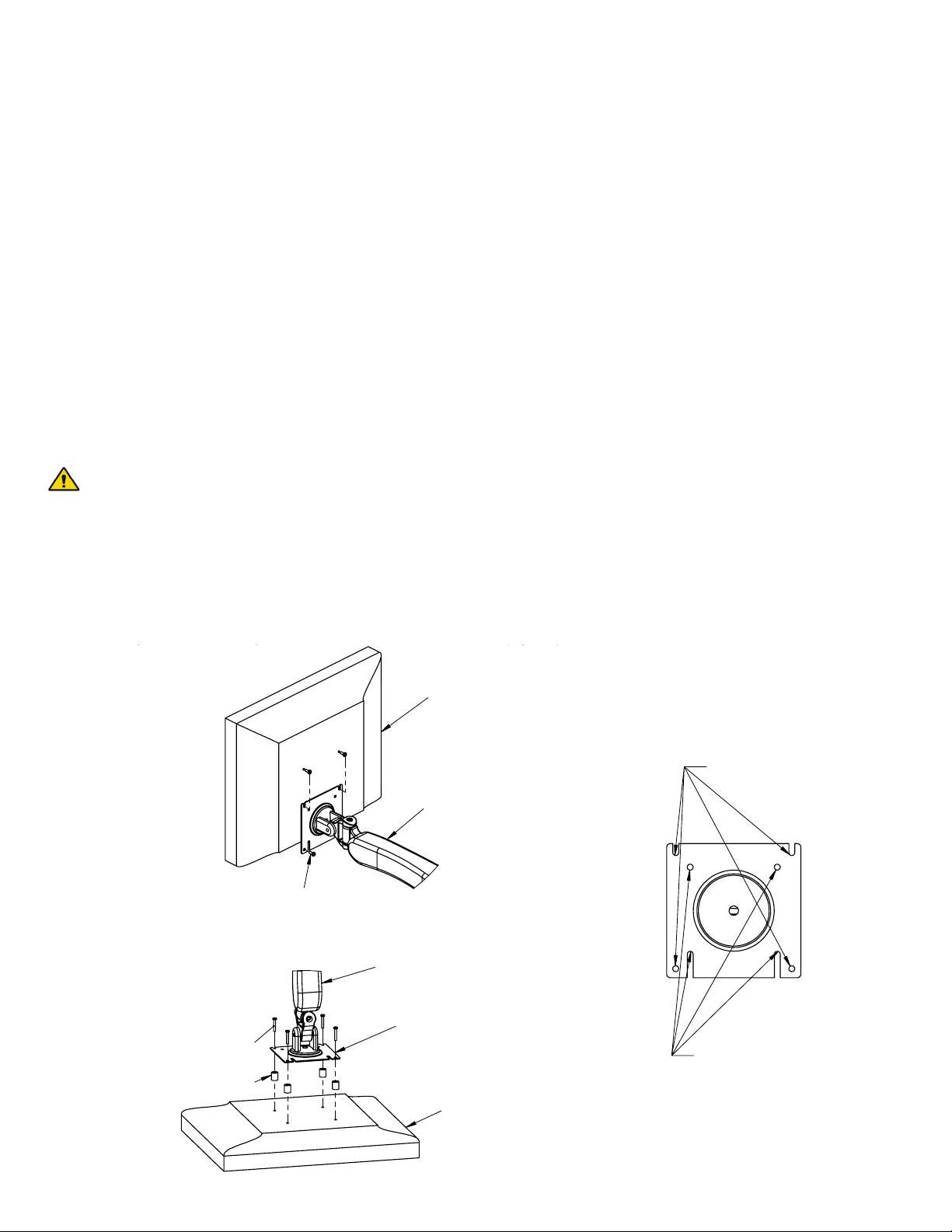

SECTION 4: Device Installation

D

DETAIL D

SCALE 1 : 7

CUSTOMER

MONITOR

(NOT PROVIDED)

4 X M4 screws

(PART OF X-LMA-01/02-01)

LMA-__-(_____)-__

LMA-__-(_____)-__

MONITOR

(NOT PROVIDED)

X-FIT-VSA-PLT

(PART OF LMA-__-(_____)-__

4 X Longer M4 screws

(PART OF X-LMA-01/02-01)

4 X spacers

(PART OF X-LMA-01/02-01)

CUSTOMER

FOR USE WITH: LMA-__-(_____)-__

Determine the monitor configuration. VESA 75 (75 mm x 75 mm M4 thread) or VESA 100 (100 mm x 100 mm M4 threads) and if spacers are required.

1.

VESA 100 configuration: 2 x M4 screws are partially threaded into the top 2 holes at the back of the monitor. The monitor can then be hung up

2.

on the X-FIT-VSA-PLT through the two slots at the top. Insert 2 more screws through the X-FIT-VSA-PLT 100 mounting holes at the bottom

and tighten all screws. (Figure 1)

VESA-75 configuration: Rotate X-FIT-VSA-PLT so the 2 slots for the VESA-75 configuration are located at the top. (Figure 3) Partially thread two screws

3.

into the top 2 holes at the back of the monitor. The monitor can then be hung up on the VESA Head through the two slots at the top. Insert 2

more screws through the VESA-75 mounting holes at the bottom and tighten all screws. (Figure 1)

When removing the monitor, the monitor arm and the monitor should be placed at the highest position. Remove the 2 bottom screws

4.

from the VESA plate, loosen the top 2 screws, and lift the monitor off the VESA plate.

If spacers are required, for both VESA 75 and VESA 100 monitor configurations, place the monitor down on a protective surface. Align and tighten

5.

4x Longer M4 screws through X-FIT-VSA-PLT and spacers into monitor. (Figure 2)

PROJECT 394

Holes for VESA 100 pattern

Holes for VESA 75 pattern

DESCRIPTION:

PART NO:

SCALE:

DRAWN BY:

CHECKED BY:

SHT.

OF

DRAWING NO:

NTS

4

11

PRIVATE AND CONFIDENTIAL

THIS PRINT IS PROPERTY OF AMICO ACCESSORIES

AND IS LOANED IN CONFIDENCE SUBJECT TO RETURN

UPON REQUEST AND WITH THE UNDERSTANDING THAT

NO COPIES ARE TO BE MADE WITHOUT THE CONSENT

OF AMICO ACCESSORIES

ALL RIGHTS TO DESIGN OR INVENTION ARE RESERVED

DATE:

DATE:

JT

2014-05-26

EC

2014-06-10

85 Fulton Way

Richmond Hill, Ontario

L4B 2N4, Canada

Toll Free: 1.877.264.2697 (T)

Tel: (905) 763.7778

Fax: (905) 763.8587

LMA ASSEMBLY

LMA-__-(_____)-__

20140526-E2900

PROJECTION

www.amico.com

CUSTOMER

Holes for VESA 100 pattern

Device Conguration Recommendations

1. Determine the monitor conguration and if spacers are required. The monitor conguration will be either VESA

75 (75 mm x 75 mm M4 thread) or VESA 100 (100 mm x 100 mm M4 threads).

2. For VESA 100 conguration: two M4 screws are partially threaded into the top two holes at the back of the

monitor. The monitor can then be hung up on the X-FIT-VSA-PLT through the two slots at the top. Insert two

more screws through the X-FIT-VSA-PLT 100 mounting holes at the bottom and tighten all screws (Figure 4).

3. For VESA-75 conguration: Rotate X-FIT-VSA-PLT so the two slots for the VESA-75 conguration are located at the

top (Figure 6). Partially thread two screws into the top two holes at the back of the monitor. The monitor can

then be hung up on the VESA head through the two slots at the top. Insert two more screws through the VESA75 mounting holes at the bottom and tighten all screws (Figure 4).

WARNING When removing the monitor, the monitor arm and the monitor should be placed at the highest

position. Remove the two bottom screws from the VESA plate, loosen the top two screws and then lift the

monitor o the VESA plate.

4. If spacers are required, for both VESA 75 and VESA 100 monitor congurations, place the monitor down on a

protective surface. Align and tighten four longer M4 screws through X-FIT-VSA-PLT and spacers into monitor

(Figure 5).

Figure 4

MONITOR

(NOT PROVIDED)

Figure 6

Holes for VESA 100 pattern

4 X M4 screws

(PART OF X-LMA-01/02-01)

LMA-__-(_____)-__

Figure 5

12 Amico Accessories Inc.

Holes for VESA 75 pattern

Page 13

SECTION 4: Device Installation

Cable Management

www.amico.com 13

Page 14

SECTION 5: Adjustments

Adjustment Procedure 1

1. Adjust the screw clockwise for heavier loads and counter-clockwise for lighter loads for counterbalance as

shown in the detailed view below, with a 5 mm HEX key.

2. Tighten or loosen the appropriate screw as shown below to adjust the monitor’s position accordingly. For

swivelling, use a 5 mm HEX key. For tilting, use a 6 mm HEX key.

WARNING Do not loosen top screw. Doing so may cause the head assembly to fall o.

Top screw

Adjustment Procedure 2

1. To adjust the tension on the movement of the arm, tighten or loosen the screw in the appropriate joints as

shown in the detailed view below using a 2.5 mm HEX key.

14 Amico Accessories Inc.

Page 15

SECTION 6: Maintenance and Troubleshooting

Preventive Maintenance

WARNING LMA requires periodic inspection and maintenance to perform optimally and achieve maximum

operation life.

WARNING The intervals shown are recommended. Maintenance schedules should be more frequent for

higher use areas.

Area Maintenance

VESA Adapter

1

2

3

• Check if the adapter plate and the monitor are securely attached. Ensure the four screws on the

mounting plate(s) are fastened to the tightest possible position.

• Visually inspect for any signs of grinding and gapping.

MRS Rail Mount Adapter

• Ensure the two set screws on the channel are fastened to the tightest possible position.

Swivel Joint

• Ensure screw on bottom of joint is fastened to the tightest possible position using a #3 Philips head

screwdriver.

• Ensure set screw at back of joint is tightened. Use a 2.5 mm HEX key to tighten as needed.

Troubleshooting

Symptom Possible cause Solution

Too easy or too dicult to tilt the monitor

up and down

Too easy or too dicult to utilize the

portrait/landscape feature

The entire arm is rocking slightly when in

use

• Excessively loosened or tightened

hardware

• Weight of the monitor is not compatible

with the arm

• Damaged hardware • Please contact Amico Accessories Inc.

Period

(Month)

4

1

1

• Adjust respective screws to control the

correct movement

• Please contact Amico Accessories Inc.

Length of the extension arm is at an angle

Extension arm is not secure or it is rocking

slightly

Arm is too dicult to maneuver with the

monitor

Arm falls to the lowest position on its own

when monitor is attached

Excessive gapping or angling at joints of

arm

• Loosened/damaged hardware

• Damaged extension arm

• Weight of the monitor exceeds the load

rating

• Counterbalance is not adjusted properly

for devices

• Damaged hardware or other physical

damage

• Equipment is too heavy

• Perform preventive maintenance

• Check all screws are secured

• Please contact Amico Accessories Inc.

• Please contact Amico Accessories Inc.

• Adjust for the correct counterbalance

• See section 4: adjustment procedure

• Check device mounted for weight

compatibility. If problem persists

contact Amico Accessories Inc.

If the above solutions do not solve your symptoms or you are in need of parts/hardware, please contact Amico

Accessories, 1.877.264.2697

www.amico.com 15

Page 16

SECTION 6: Maintenance and Troubleshooting

Cleaning

WARNING: The cleaning chemicals and methods below are not meant for controlling any infections. It shall

be the responsibility of the hospital or the hospital’s infection control ocer to sanitize the equipment.

WARNING: Please do not spray any chemical directly onto the arm. Apply onto a soft cloth and wipe clean

to prevent chemicals getting into the internal components of the arm.

The mounting assembly may be cleaned with most mild, non-abrasive solutions commonly used in the hospital

environment (e.g. diluted bleach, ammonia, or alcohol solutions). The surface nish will be permanently damaged by

strong chemicals and solvents such as acetone and trichloroethylene. Steel wool or other abrasive material should never

be used.

Damage caused by the use of unapproved substances or processes will not be warranted. It is recommended that you

test any cleaning solution on a small area of the LMA that is not visible to verify compatibility.

Never submerge the LMA and do not allow liquids to enter it. Wipe any cleaning agents o the LMA immediately using

a water-dampened cloth. Dry the arm thoroughly after cleaning.

Acetone

No Acetone

Acetone is a colorless,

mobile, ammable liquid

No Trichloroethylene

Trichloroethylene is a chlorinated

hydrocarbon commonly used as

an industrial solvent.

Trichloroethylene

16 Amico Accessories Inc.

Page 17

SECTION 7: Product Classication

LMA - - -01

01

With 7" (177.8 mm)

Extension

02

Without Extension

Grommet/Desk Clamp Mount, Short

Grommet/Desk Clamp Mount, Long

DSK-S

6" (152.4 mm)

DSK-L

13" (330 mm)

WAL

Direct Wall Mount

MON

Monitor Channel

VRS

Amico Vertical Direct Mount

www.amico.com 17

Page 18

Accessories

Warranty Policy

Amico Accessories Inc. warrants all mounting accessories to be free from defects in material and workmanship for a period of

twelve (12) months from the date of shipment. Within this period Amico Accessories Inc. will repair or replace any part which is

proven to be defective.

Amico Accessories Inc. will warrant its materials to be free from defect for an additional period of four (4) years, ve (5) years

from the date of shipment. Within this period, Amico Accessories Inc. will replace any part at no charge, which is proven to be

defective. Shipping and Installation costs after the rst twelve (12) months will be borne by the customer.

This warranty is valid only when the product has been properly installed according to Amico Accessories Inc. specications, used

in a normal manner and serviced according to factory recommendations. It does not cover products that are not manufactured

by Amico Accessories Inc. It does not cover failures due to damage which occurs in shipments or failures which resulted from

accidents, misuse, abuse, neglect, mishandling, alteration, misapplication or damage that may be attributable to acts of God.

Amico Accessories Inc. shall not be liable for incidental or consequential damages resulting from use of equipment.

All claims for warranty must rst be approved by Amico Accessories Inc. A valid Return Goods Authorization (RGA) number must

be obtained from Amico Accessories Inc. prior to commencement of any service work. Warranty work, which has not been pre-

authorized by Amico Accessories Inc., will not be reimbursed.

AMICO ACCESSORIES INC. DOES NOT HONOR VERBAL STATEMENTS CONCERNING THE WARRANTY.

The distributor and/or dealer are not sanctioned to create verbal warranties about the product described in this agreement. Any

statements will not be honored or be made part of the agreement of sale. This document is the nal complete and exclusive

terms of the agreement.

THIS WARRANTY IS INCLUSIVE AND REPLACES ALL OTHER WARRANTIES.

Amico Accessories Inc. shall not, under any circumstances be liable for incidental or consequential damages including, but not

limited to, prot, loss of sales or injuries to person(s) or property. Correction of noncompliance as noted above will result in

completion of all liabilities of Amico Accessories Inc., whether based on agreement, neglect or changed materials, designs or

specications without notice.

All claims for warranty must rst be approved by Amico Accessories Inc. Service Department: accessories@amico.com

or 1.877.264.2697). A valid Return Goods Authorization number must be obtained from Amico Accessories Inc. prior to

commencement of any warranty claim.

Page 19

Notes

www.amico.com 19

Page 20

www.amico.com

Amico Accessories Inc. | www.amico.com

85 Fulton Way, Richmond Hill

Ontario, L4B 2N4, Canada

71 East Industry Court, Deer Park

NY 11729, U.S.A.

Toll Free Tel: 1.877.264.2697

Toll Free Fax: 1.866.440.4986

Tel: 905.763.7778

Fax: 905.763.8587

Email: info@amico.com

AAIMLMA 10.16.2014

Loading...

Loading...