Page 1

Approval and Installation Booklet

Rigid Stationary Ceiling Column

www.amico.com

Page 2

ABOUT US

Amico Corporation has been a leading manufacturer of Medical Equipment since 1974, selling its products through a global distribution channel from three manufacturing facilities in Canada and the U.S.

With a track record of exceeding expectations, Amico is dedicated to developing and manufacturing the

most advanced medical equipment for the industrial and global Health Care Industry. With over 9 di erent divisions, Amico products o er a total hospital solution.

2 Amico Pipeline

Page 3

Table of Contents

Product Description 3

Cleaning 3

Inspection and Testing 3

Elevation View 4

Device and Accessory Chart 5

Device Placement (Bottom View) 6

Electrical Diagram (Bottom View) 7

Mounting Plate to Outlet Detail 8

Mounting Information 9

Typical Location View 10

Notes 11

2 Amico Pipeline

Page 4

Product Description

The Rigid ceiling column shall be an Amico Alert-1 series.

The shroud is made of 16 gauge stainless steel with a # 4 satin nish consisting of a: removable access panel, stainless steel ceiling collar and a heavy gauge steel mounting plate.

All electrical services are provided by means of EMT metal conduits and gas services are type L, oxygen cleaned copper

pipes. Standard dimensions are 12” X 12” [304.8 mm x 304.8 mm].

NOTE: Nitrogen is type K oxygen cleaned copper pipe.

NOTE: Electrical devices are pre-wired to electrical junction box at the mounting plate, unless other wise stated.

Gases will be manifolded for single point connections to the source. All pipes will extend 8” from the top of mounting plate.

Cleaning

The Amico Outlets are factory cleaned for oxygen service. Exposed surfaces of the outlet may be cleaned with a

mild detergent solution or wiped with a disinfectant commonly used in patient rooms that is compatible with plastics,

anodized aluminium and die cast zinc.

Inspection and Testing

Medical Gas Outlets should be inspected periodically or at least once a year. The test should be in accordance with

NFPA 99 “Gas and Vacuum systems”, or CSA Z7396.1-06 “Non ammable Medical Gas Piping System”.

Test for leaks: Ensure that no leaks exist, with or without the adapter inserted.

Test for Indexing: Only a mating gas speci c adapter should insert smoothly into the outlet, latch and be retained.

Test for Flow:

- Gas Outlets: 120 l/min (4.2 scfm) @ 345 kPa (50 psi), maximum allowable pressure drop is 28 kPa (4 psi).

- Nitrogen Outlet: 400 l/min (14.1 scfm) @ 1,250 kPa (180 psi), maximum allowable pressure drop is 70 kPa (10 psi).

- Vacuum Outlet: 30 l/min (1.1 scfm) @ 54 kPa (16 inHg), maximum allowable pressure drop is 13 kPa (4 inHg).

Refer to the appropriate standards for the proper way of performing the ow test.

NOTE: The Amico medical gas and vacuum outlets meet and exceed these requirements at the time of manufacture. However piping source capacity, sizing and restrictions may prevent outlets from attaining these values.

www.amico.com 3

Page 5

Elevation View

To accommodate di erent ceiling heights, Amico Corporation has standardized three di erent variations.

Please select the required nominal column height below:

L1= Nominal Column Height

30” (762mm)

36” (914.4mm)

42” (1066.8mm)

Ceiling Height:

Column Height

Floor Clearance:

Ceiling Height

L1

Ceiling

Height

Floor Clearance

78" [1981.2mm]*

Quantity

Finished Floor Line

* Recommended Floor Clearance

NOTE: Custom heights are available at an additional cost. Please contact Amico for pricing.

Approval Signature Date Phone No.

4 Amico Pipeline

Page 6

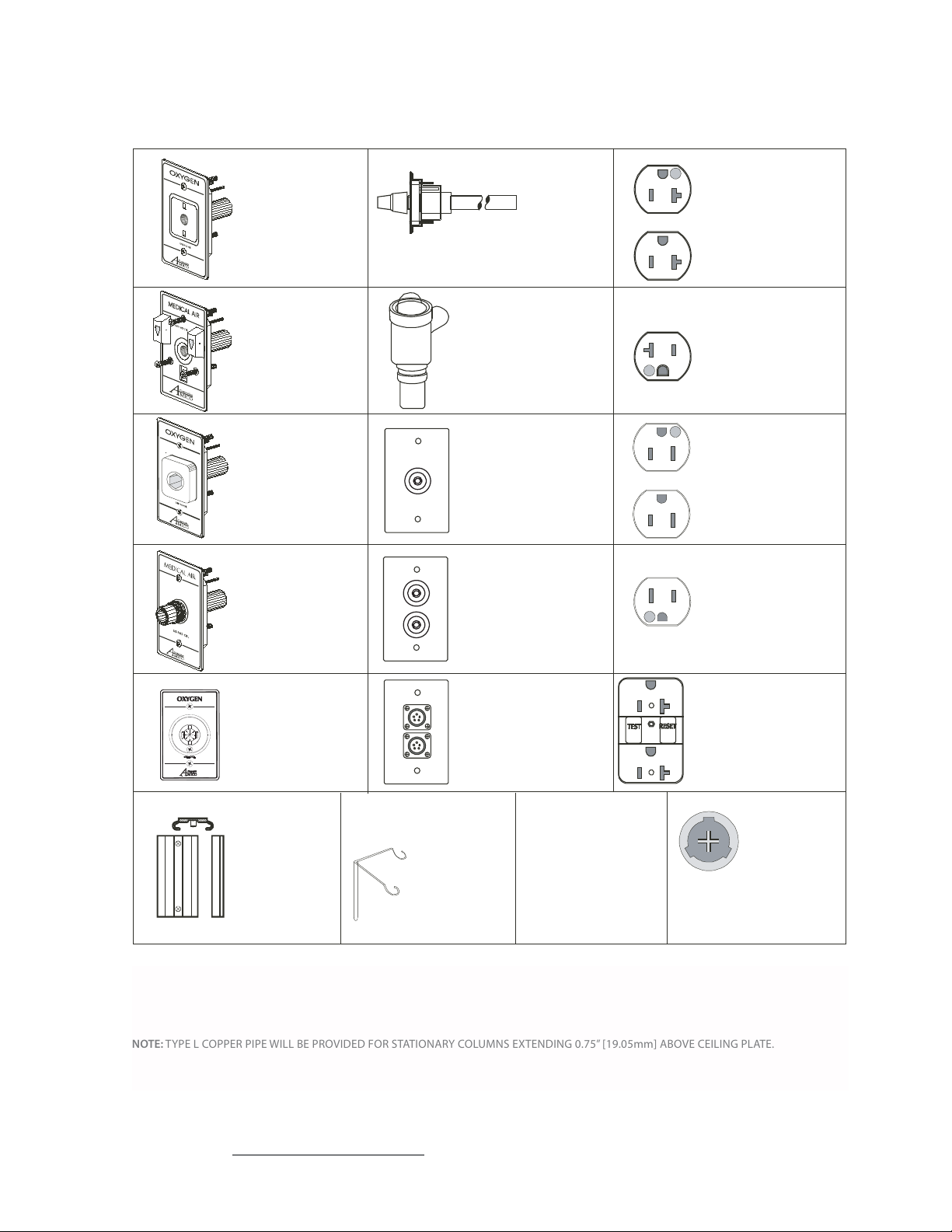

Device and Accessory Chart

*QD

XXX

Ohmeda / Medaes

Compatible

CH

XXX

Chemetron

Compatible

PB

XXX

Puritan-Bennett

Compatible

*DI

XXX

DISS

PE

Ceiling Column

Passive Evacuation

(19mm/33mm)

IMP

Passive Evacuation

with Impedance

V al ve (19mm /2 2mm)

(Side Mount Only)

GJ

Ground Jack

Receptacle

Single Hampden

(SLR-3)

GREEN

GJ2

Ground Jack

Receptacle

Dual Hampden

(SLR-3)

GREEN

E9-RED

E10-IVO.

Duplex Receptacle

8300-HG

125V/20a

(US / International)

E11-RED

E12-IVO.

Single Receptacle

8310-HG

125V/20a

(US / International)

E5-RED

E6-IVO.

Duplex Receptacle

8200-HG

125V/15a

(CAN / International)

E7-RED

E8-IVO.

Single Receptacle

8210-HG

125V/15a

(CAN / Internatio

nal)

E13-RED

E14-IVO.

Oxequip

Compatible

SL

OX

XXX

Monitor Jack

Duplex

(5-pin shown)

Amphenol Model

10-825806-05S

97-14S-5S

IV

MJ

E13C-RED

E14C-IVO.

Ground Fault Circuit

Interrupter

(C = Canadian)

DJ

DP

Data - Telephone

Vacuum

Bottle Slide

ALL ELECTRICAL DEVICES ARE HUBBELL BRAND

NOTE: CARBON DIOXIDE OUTLETS ARE NOT AVAILABLE IN PURITAIN-BENNETT. NITROGEN OUTLETS ARE ONLY AVAILABLE IN DISS.

NOTE: TYPE L COPPER PIPE WILL BE PROVIDED FOR STATIONARY COLUMNS EXTENDING 0.75” [19.05mm] ABOVE CEILING PLATE.

Stai nless Steel

IV Hook

(Duplex only)

Communication Jack or

Duplex Receptacle

(Provision Only)

DP - Duplex Receptacle

Provision

Twist-Lock

Receptacle

Hubble 23000-HG

125V/20a

TL

Approval Signature Date Phone No.

www.amico.com 5

Page 7

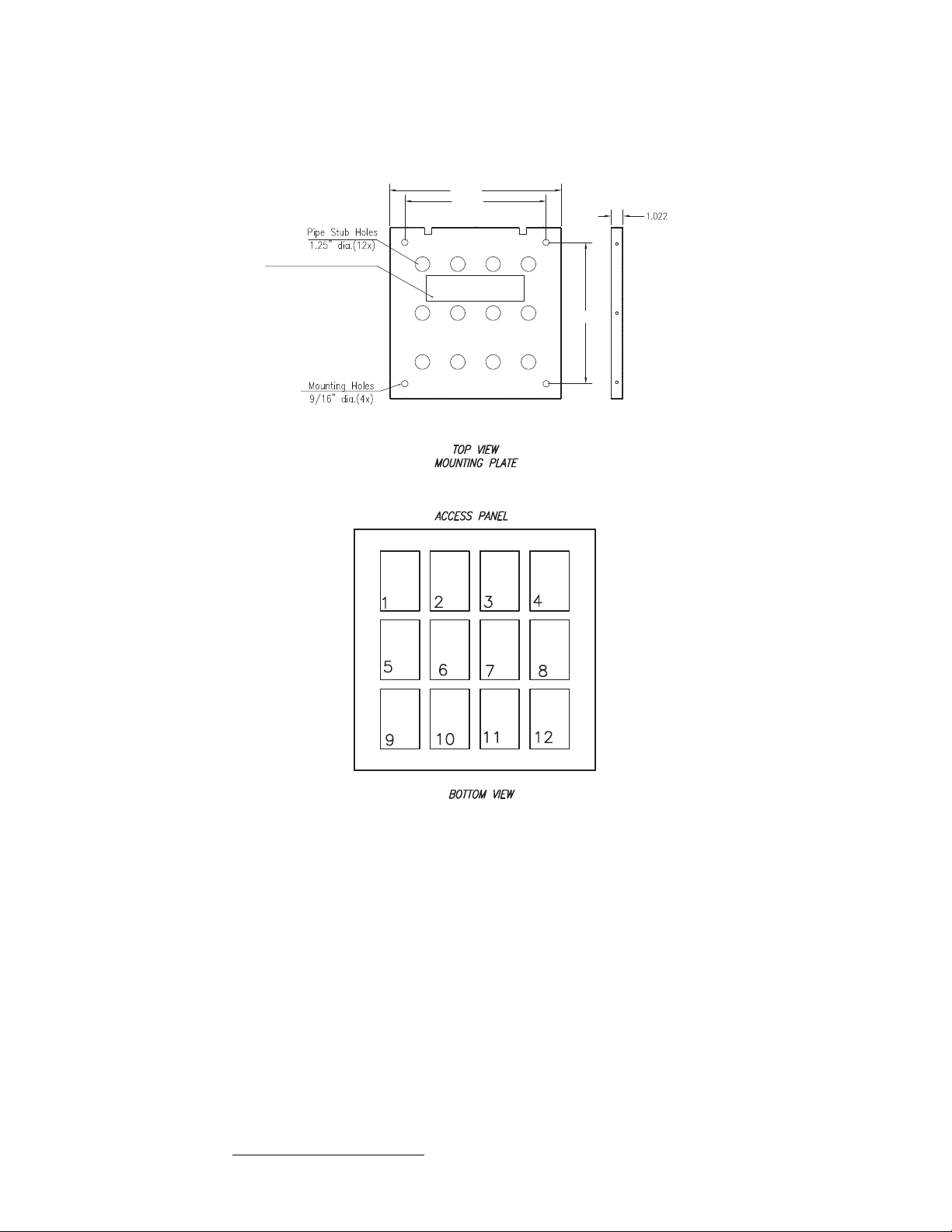

Device Placement (Bottom View)

Please fill the devices that you require for your application.

(Specify by using the symbols on Page 5 of this Approval Booklet.)

Nitrogen Control Panel

Yes

No

Location of Nitrogen Control Panel

Side A

Side B

Side C

Side D

Please Specify Outlet Language

US

CAN

FRENCH

SPANISH/US

SPANISH/ISO

Gas Legend

Oxygen = O

Medical Air = A

Vacuum = V

Nitrous Oxide = 2

Nitrogen = N

Carbon Dioxide = C

Positions 1 - 12 = Medical Gas Outlets

Posititions A1 - D5 = Electrical and/or communication devices

NOTE:

1. Two electrical/communication/medical gas devices cannot be placed together at any corner.

WAGD (US) = W

AGSS (Canada) = E

Instrument Air = I

2. Maximum of 2 D5 provisions only.

3. The Nitrogen Control Panel will occupy three spaces of the bulkhead (E.G. A2 to A4).

Approval Signature Date Phone No.

6 Amico Pipeline

Page 8

Electrical Diagram (Bottom View)

____ gauge

____ gauge

_______________________

_______________________

10 gauge

Green

*Please Select One of the Following:

Amico r

ecommended circuit schedule based on layout

Custom circuit schedule. Please specify on circuit chart

Receptacle Type:

US/CAN

*BRITISH (simplex only)

*GERMAN (simplex only)

*Please specify electrical details:

Type of wire:

THHN XHHW RW90

NOTE:

1. Two electrical/communication/medical gas devices

cannot be placed together at any corner.

Circuit Chart

AWG Wire Gauge: Wire Color:

10 & 12 LIVE/HOT

10 & 12 NEUTRAL

10 GROUND

Isolated Power

Please select one of the following

All receptacles shall be mounted with

ground pin “DOWN”

All receptacles shall be mounted with

ground pin “UP” (Default)

2. If type of wire & gauge is not specified, Amico

will use the following:

For US/International

LIVE/HOT - 12 Ga. THHN Wire Black

NEUTRAL - 12 Ga. THHN Wire White

GROUND - 10 Ga. THHN Wire Green

For Canada

LIVE/HOT - 12 Ga. RW90 Wire Black

NEUTRAL - 12 Ga. RW90 Wire White

GROUND - 10 Ga. RW90 Wire Green

3. Conduit: 1/2” [12.7mm] rigid EMT.

3/4" rigid EMT for low voltage provision.

4. All conduits and wires will extend a minimum of12”

[304.8mm] above nish column for connection

to riser plate.

5. A pull-string will be provided to be connected by

others for all ground jacks and data provision.

6. British or German Receptacle cannot be positioned

side by side ie: A1 and A2.

Approval Signature Date Phone No.

www.amico.com 7

Page 9

Mounting Plate to Outlet Detail

11.880”

10.00”

Access Panel

Electrical Termination Box

2.0” x 9.0”

10”

NOTE:

1. Gases will be manifolded for single point connections from source.

2. All pipes will extend 8” from the top of mounting plate.

3. Pipe stubs diameters are:

- 3/4” dia. for vacuum, WAGD, and AGSS (Type L)

-1/2” dia. for medical air, oxygen, and nitrous oxide (Type L)

-1/2” dia. for nitrogen (Type K)

4. Exact locations of gas terminations on mounting plate will be determined after receiving the booklet.

Approval Signature Date Phone No.

8 Amico Pipeline

Page 10

Mounting Information

STRUCTURAL

CEILING

FINISHED CEILING

10"

[254mm]

6" [152.4mm]

RECOMMENDED

12" [304.8mm] SQUARE

MOUNTING PLATE

15-5/8" [396.88mm] SQUARE

CEILING COVER FIELD

MOUNTED

1/2" 12.7mm THREADED

ROD TYP. OF 4 BY OTHERS

ANTI-SWAY

SUPPORT STRUCTURE

(SUPPLIED BY OTHERS)

NOTE:

1. All labour and material for installation of mounting plate to mounting structure supplied by others.

2. Installer has nal responsibility for the strength and stability of the mounting structure that is supplied by others.

3. Mounting plate is xed to the column and cannot be pre-shipped.

4. Mounting plate to be mounted ush with nished ceiling.

5. Mounting structure supplied by others.

6. Gas pipes extend 8” above the column.

Approval Signature Date Phone No.

www.amico.com 9

Page 11

Typical Location View

3’ - 4’

[914.4 - 1219.2mm]

3’ - 4’

[914.4 - 1219.2mm]

3’ - 4’

[914.4 - 1219.2mm]

3’ - 4’

[914.4 - 1219.2mm]

10 Amico Pipeline

Approval Signature Date Phone No.

Page 12

www.amico.com

Amico Architectural | www.amico.com

85 Fulton Way, Richmond Hill

Ontario, L

4B 2N4, Canada

71 East Industry Court, Deer Park

NY 11729, U.S.A

Toll Free Tel: 1.877.264.2697

Toll Free Fax: 1.866.440.4986

Tel: 905.763.7778

Fax: 905.763.8587

Email: info@amico.com

C US LISTED

ac_instal_maint_rigid_retr_stnry_col PRINTED FEB 12

Loading...

Loading...