Page 1

Lx \ Ls Series II

AC Power Source

Programming Manual

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email:

Domestic Sales: domorders.sd@ametek.com

International Sales: intlorders.sd@ametek.com

Customer Service: service.ppd@ametek.com

Web: www.programmablepower.com

March 2011 Document No. 7004-981 Rev. S

Page 2

Page 3

Page 4

Refers to:

Lx Series AC Power Source/Analyzers - Series II

Ls Series AC Power Sources - Series II

Models:

Single chassis: 3000Lx, 4500Lx, 6000Lx

Multiple chassis: 9000Lx/2, 12000Lx/2, 13500Lx/3, 18000Lx/3

Single chassis: 3000Ls, 4500Ls, 6000Ls

Multiple chassis: 9000Ls/2, 12000Ls/2, 13500Ls/3, 18000Ls/3

Manual revision: S

Copyright © 2003-2010 AMETEK Programmable Power

Page 5

About AMETEK

AMETEK Programmable Power, Inc., a Division of AMETEK, Inc., is a global leader in the design

and manufacture of precision, programmable power supplies for R&D, test and measurement,

process control, power bus simulation and power conditioning applications across diverse

industrial segments. From bench top supplies to rack-mounted industrial power subsystems,

AMETEK Programmable Power is the proud manufacturer of Elgar, Sorensen, California

Instruments and Power Ten brand power supplies.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromechanical

devices with annualized sales of $2.5 billion. The Company has over 11,000 colleagues working

at more than 80 manufacturing facilities and more than 80 sales and service centers in the United

States and around the world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc.

Other trademarks, registered trademarks, and product names are the property of their respective

owners and are used herein for identification purposes only.

Notice of Copyright

Lx\Ls Series II AC Power Source, Programming Manual

Inc. All rights reserved.

© 2010 AMETEK Programmable Power,

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER, INC.

(“AMETEK”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR

EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL,

WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH

INFORMATION WILL BE ENTIRELY AT THE USER’S RISK, AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH,

ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE

TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED AMETEK CONTENT

IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION, WHICH IS POSTED AT

WWW.PROGRAMMABLEPOWER.COM.

Date and Revision

March 2011 Revision S

Part Number

7004-981

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email: sales@programmablepower.com

service@programmablepower.com

Web: www.programmablepower.com

i

Page 6

This page intentionally left blank.

ii

Page 7

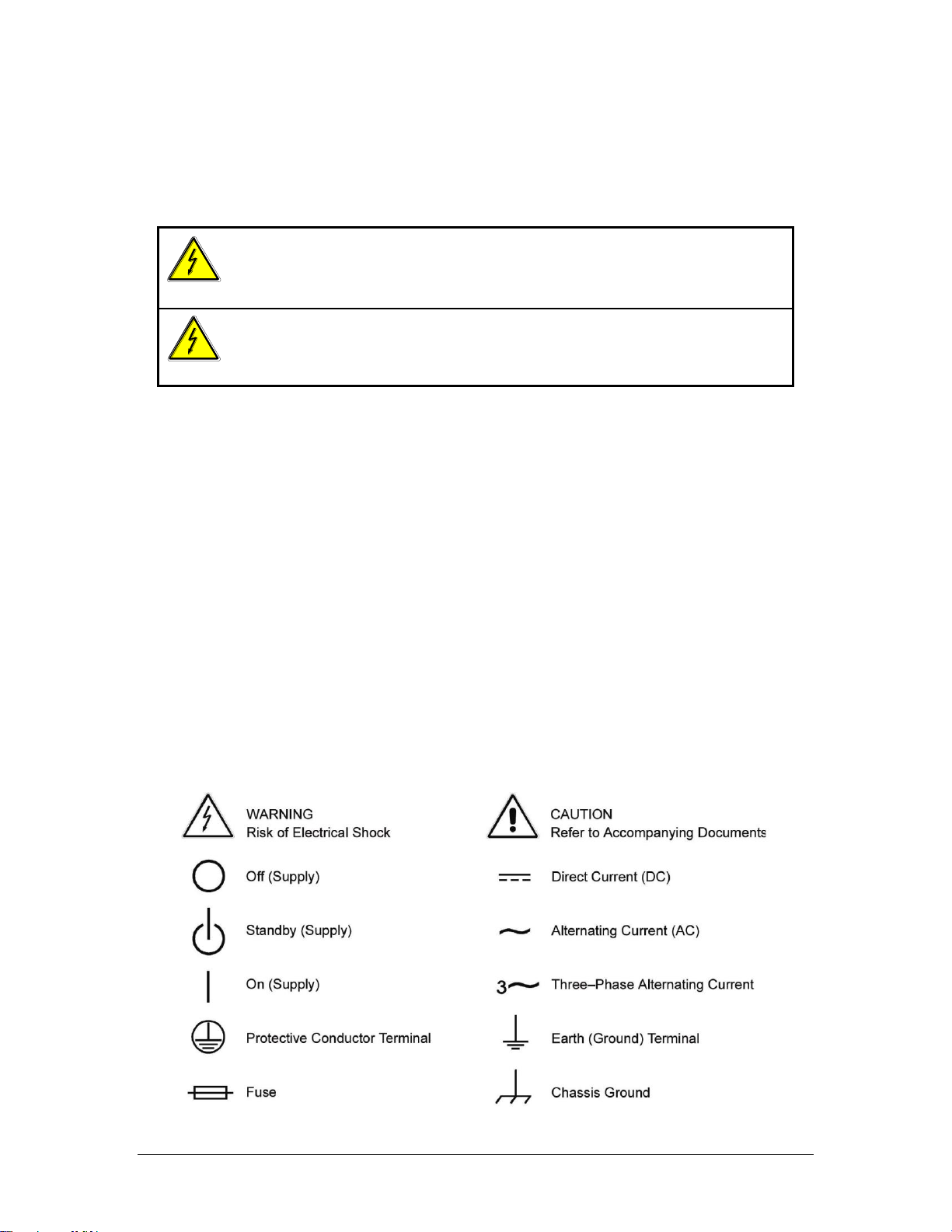

WARNING

Hazardous voltages may be present when covers are removed. Qualified

personnel must use extreme caution when servicing this equipment.

Circuit boards, test points, and output voltages also may be floating above

(below) chassis ground.

WARNING

The equipment used contains ESD sensitive ports. When installing

equipment, follow ESD Safety Procedures. Electrostatic discharges might

cause damage to the equipment.

Important Safety Instructions

Before applying power to the system, verify that your product is configured properly for your

particular application.

Only qualified personnel who deal with attendant hazards in power supplies, are allowed to perform

installation and servicing.

Ensure that the AC power line ground is connected properly to the Power Rack input connector or

chassis. Similarly, other power ground lines including those to application and maintenance

equipment must be grounded properly for both personnel and equipment safety.

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting any

cable.

In normal operation, the operator does not have access to hazardous voltages within the chassis.

However, depending on the user’s application configuration, HIGH VOLTAGES HAZARDOUS TO

HUMAN SAFETY may be normally generated on the output terminals. The customer/user must

ensure that the output power lines are labeled properly as to the safety hazards and that any

inadvertent contact with hazardous voltages is eliminated.

Guard against risks of electrical shock during open cover checks by not touching any portion of the

electrical circuits. Even when power is off, capacitors may retain an electrical charge. Use safety

glasses during open cover checks to avoid personal injury by any sudden component failure.

Neither AMETEK Programmable Power Inc., San Diego, California, USA, nor any of the subsidiary

sales organizations can accept any responsibility for personnel, material or inconsequential injury,

loss or damage that results from improper use of the equipment and accessories.

SAFETY SYMBOLS

iii

Page 8

Product Family: Lx\Lx Series II

Warranty Period: One Year

WARRANTY TERMS

AMETEK Programmable Power, Inc. (“AMETEK”), provides this written warranty covering the

Product stated above, and if the Buyer discovers and notifies AMETEK in writing of any defect in

material or workmanship within the applicable warranty period stated above, then AMETEK may,

at its option: repair or replace the Product; or issue a credit note for the defective Product; or

provide the Buyer with replacement parts for the Product.

The Buyer will, at its expense, return the defective Product or parts thereof to AMETEK in

accordance with the return procedure specified below. AMETEK will, at its expense, deliver the

repaired or replaced Product or parts to the Buyer. Any warranty of AMETEK will not apply if the

Buyer is in default under the Purchase Order Agreement or where the Product or any part

thereof:

is damaged by misuse, accident, negligence or failure to maintain the same as

specified or required by AMETEK;

is damaged by modifications, alterations or attachments thereto which are not

authorized by AMETEK;

is installed or operated contrary to the instructions of AMETEK;

is opened, modified or disassembled in any way without AMETEK’s consent; or

is used in combination with items, articles or materials not authorized by AMETEK.

The Buyer may not assert any claim that the Products are not in conformity with any warranty

until the Buyer has made all payments to AMETEK provided for in the Purchase Order Agreement.

PRODUCT RETURN PROCEDURE

1. Request a Return Material Authorization (RMA) number from the repair facility (must be

done in the country in which it was purchased):

In the USA, contact the AMETEK Repair Department prior to the return of the

product to AMETEK for repair:

Telephone: 800-733-5427, ext. 2295 or ext. 2463 (toll free North America)

858-450-0085, ext. 2295 or ext. 2463 (direct)

Outside the United States, contact the nearest Authorized Service Center

(ASC). A full listing can be found either through your local distributor or our

website, www.programmablepower.com, by clicking Support and going to the

Service Centers tab.

2. When requesting an RMA, have the following information ready:

Model number

Serial number

Description of the problem

NOTE: Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

NOTE: A returned product found upon inspection by AMETEK, to be in specification is subject to

an evaluation fee and applicable freight charges.

iv

Page 9

Programming Manual Lx \ Ls Series II

Table of Contents

1. Introduction .......................................................................................................................................... 8

1.1 Documentation Summary ............................................................................................................... 8

1.2 Lx Series and Ls Series Differences............................................................................................... 9

1.3 Manual organization and format ................................................................................................... 10

1.4 Introduction to Programming ........................................................................................................ 10

2. Introduction to SCPI .......................................................................................................................... 12

2.1 Conventions Used in This Manual ................................................................................................ 12

2.2 The SCPI Commands and Messages .......................................................................................... 12

2.3 Using Queries ............................................................................................................................... 15

2.4 Coupled Commands ..................................................................................................................... 15

2.5 Structure of a SCPI Message ....................................................................................................... 15

2.6 SCPI Data Formats ....................................................................................................................... 18

3. System Considerations ..................................................................................................................... 20

3.1 IEEE-488 / GPIB Interface ............................................................................................................ 20

3.2 USB Interface ............................................................................................................................... 21

3.3 LAN Option ................................................................................................................................... 28

3.4 RS232C Serial Interface ............................................................................................................... 33

3.5 Instrument Drivers and Application Software ................................................................................ 34

4. SCPI Command Reference ................................................................................................................ 35

4.1 Introduction ................................................................................................................................... 35

4.2 Subsystem Commands................................................................................................................. 36

4.3 Calibration Subsystem .................................................................................................................. 37

4.4 Diagnostic Subsystem .................................................................................................................. 39

4.5 Display Subsystem ....................................................................................................................... 40

4.6 Instrument Subsystem .................................................................................................................. 42

4.7 Limit Subsystem ........................................................................................................................... 43

4.8 Array Measurement Subsystem ................................................................................................... 45

4.9 Current Measurement Subsystem ................................................................................................ 51

4.10 Frequency Measurement Subsystem ........................................................................................... 56

4.11 Power Measurement Subsystem .................................................................................................. 57

4.12 Voltage Measurement Subsystem ................................................................................................ 59

4.13 Output Subsystem ........................................................................................................................ 62

4.14 Power On Subsystem ................................................................................................................... 67

4.15 Sense Subsystem - Sweep ........................................................................................................... 69

4.16 Source Subsystem - Current ........................................................................................................ 71

4.17 Source Subsystem - Frequency.................................................................................................... 73

4.18 Source Subsystem - Function ....................................................................................................... 76

4.19 Source Subsystem - List ............................................................................................................... 79

4.20 Source Subsystem - Phase .......................................................................................................... 86

4.21 Source Subsystem - Pulse ........................................................................................................... 88

4.22 Source Subsystem - Voltage ........................................................................................................ 91

4.23 Status Subsystem Commands ..................................................................................................... 98

4.24 System Commands .................................................................................................................... 105

4.25 Trace Subsystem Commands .................................................................................................... 111

4.26 Trigger Subsystem ...................................................................................................................... 113

5. Common Commands ....................................................................................................................... 118

5.1 *CLS ............................................................................................................................................ 119

5.2 *ESR? ......................................................................................................................................... 119

5.3 *IDN? .......................................................................................................................................... 120

5.4 *OPC ........................................................................................................................................... 120

5.5 *OPT? ......................................................................................................................................... 120

5.6 *PSC ........................................................................................................................................... 120

5

Page 10

Programming Manual Lx \ Ls Series II

5.7 *RCL ........................................................................................................................................... 121

5.8 *RST ........................................................................................................................................... 122

5.9 *SAV ........................................................................................................................................... 123

5.10 *SRE ........................................................................................................................................... 123

5.11 *STB?.......................................................................................................................................... 123

5.12 *TRG ........................................................................................................................................... 124

5.13 *TST? .......................................................................................................................................... 124

5.14 *WAI ............................................................................................................................................ 125

6. Programming Examples .................................................................................................................. 126

6.1 Introduction ................................................................................................................................. 126

6.2 Programming the Output ............................................................................................................ 126

6.3 Coupled Commands ................................................................................................................... 130

6.4 Programming Output Transients ................................................................................................ 131

6.5 Step and Pulse Transients .......................................................................................................... 132

6.6 List Transients ............................................................................................................................ 134

6.7 Triggering Output Changes ........................................................................................................ 135

6.8 Making Measurements ............................................................................................................... 139

6.9 Controlling the Instantaneous Voltage and Current Data Buffers ............................................... 144

6.10 Downloading Arbitrary Waveforms ............................................................................................. 148

6.11 Command Processing Times ..................................................................................................... 149

7. Programming the Status and Event Registers ............................................................................. 150

7.1 Power-On Conditions .................................................................................................................. 150

7.2 Operation Status Group .............................................................................................................. 150

7.3 Questionable Status Group ........................................................................................................ 153

7.4 Questionable Instrument Isummary Status Group ..................................................................... 154

7.5 Standard Event Status Group ..................................................................................................... 155

7.6 Status Byte Register ................................................................................................................... 156

7.7 Examples .................................................................................................................................... 157

7.8 Remote Inhibit and Discrete Fault Indicator ................................................................................ 160

7.9 SCPI Command Completion....................................................................................................... 161

8. Option Commands ........................................................................................................................... 162

8.1 Introduction ................................................................................................................................. 162

8.2 APE Command Language (Abbreviated Plain English) .............................................................. 163

8.3 ABLE Command Language (Atlas Based Language Extension)................................................ 183

8.4 RTCA/DO-160D (-160) ............................................................................................................... 188

8.5 RTCA/DO160 Rev E Test Option ............................................................................................... 195

8.6 MIL-STD 704 Rev D - F (-704) ................................................................................................... 196

8.7 MIL-STD 704 Rev A - F (-704F) ................................................................................................. 202

8.8 Airbus ABD0100.1.8 Test Option (-ABD) .................................................................................... 218

8.9 Airbus A350, ABD0100.1.8.1 Test Option (-A350) ..................................................................... 218

8.10 Airbus AMD24 Test Option (-AMD) ............................................................................................ 218

8.11 Boeing 787B3-0147 Test Option (-B787) ................................................................................... 218

Appendix A: SCPI Command tree .......................................................................................................... 219

Appendix B: SCPI Conformance Information ....................................................................................... 223

Appendix C: Error Messages ................................................................................................................. 226

Appendix D: iL Series / HP6834B Compatability ................................................................................. 231

Index .................................................................................................................................................. 234

6

Page 11

Programming Manual Lx \ Ls Series II

Table of Figures

Figure 2-1: Partial Command Tree .............................................................................................................. 13

Figure 2-2: Command Message Structure .................................................................................................. 16

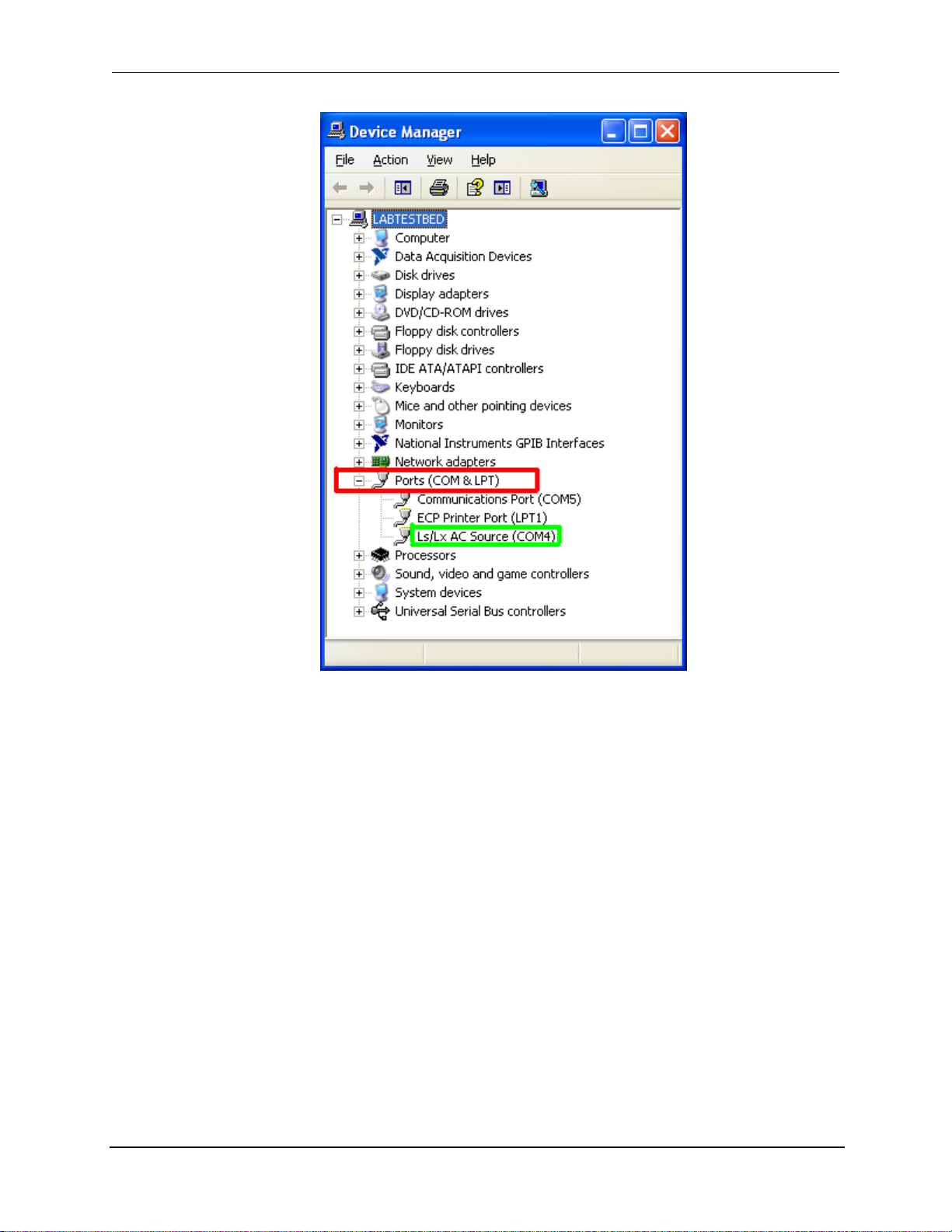

Figure 3-1: Windows XP Device Manager - USB Port ................................................................................ 26

Figure 3-2: LxGui Interface Settings for use of USB port. ........................................................................... 27

Figure 3-3: Pinging AC Source LAN IP address. ........................................................................................ 32

Figure 3-4: Position of LAN/RS232C selection jumper W2 on 7004-716-2 Range/Relay board. ............... 33

Figure 6-1: Model of transient system. ...................................................................................................... 132

Figure 6-2: Model of output trigger system................................................................................................ 136

Figure 6-3: Model of Measurement triggers. ............................................................................................. 142

Figure 6-4: Pre- and Post Event Triggering............................................................................................... 147

Figure 7-1: Status Register Model. ............................................................................................................ 151

Figure 7-2: SMA Connector Trigger Model. .............................................................................................. 159

Figure 8-1: APE Command Tree ............................................................................................................... 169

Table of Tables

Table 2-1: Command parameters Suffixes and Multipliers ......................................................................... 18

Table 3-1: LAN Setting screens. ................................................................................................................. 31

Table 4-1: PULSe:HOLD = WIDTh parameters ......................................................................................... 89

Table 4-2: PULSe:HOLD = DCYCle parameters ........................................................................................ 89

Table 4-3: Bit Configuration of Status Operation Registers ........................................................................ 99

Table 4-4: Bit Configuration of Questionable Registers ............................................................................ 100

Table 4-5: Bit Configuration of Questionable Instrument Summary Registers ......................................... 102

Table 5-1: Bit Configuration of Standard Event Status Enable Register ................................................... 119

Table 5-2 : factory-defined *RST states .................................................................................................... 122

Table 5-3: Bit Configuration of Status Byte Register ................................................................................. 124

Table 6-1: Command Processing Times. .................................................................................................. 149

Table 7-1: Operation Status registers ....................................................................................................... 150

Table 7-2: Bit Configurations of Status Registers ..................................................................................... 152

Table 7-3: Questionable Status registers .................................................................................................. 153

Table 7-4: Questionable Instrument Isummary Status registers ............................................................... 154

Table 8-1: APE to SCPI mode change commands ................................................................................... 163

Table 8-2: APE versus SCPI equivalent power initialization commands ................................................... 165

Table 8-3: APE language syntax program headers .................................................................................. 171

Table 8-4: APE Language TLK Arguments ............................................................................................... 173

Table 8-5: Example TALK responses for 3 phase systems ...................................................................... 179

Table 8-6: APE Status Byte Error Codes .................................................................................................. 181

Table 8-7: ABLE to SCPI mode change commands ................................................................................. 183

Table 8-8: ABLE languange synstax (-ABL option) ................................................................................... 186

Table 8-9: ABLE languange - Serial Poll Status Bytes. ............................................................................. 187

Table 8-10: MS704 Steady state frequency by group ............................................................................... 205

Table 8-11: SCPI error codes and messages. .......................................................................................... 231

7

Page 12

Programming Manual Lx \ Ls Series II

1. Introduction

This instruction manual (P/N 7004-981) contains programming informationfor the Lx Series II and

Ls Series II AC power sources. The Series II versions of the Lx and Ls Series are backward

compatible with the Series I models. The Programming Manual for Series I models is CI P/N

7004-961 and is available for download at www.programmablepower.com.

Series II models are different from the original Lx/Ls Series in the following areas:

Standard USB interface has been added.

Available 100Mbit Ethernet LAN interface has been added. (Option –LAN).

The front panel graphic design has been enhanced for a more pleasing look.

The Output D and E terminal block is no longer installed on the standard Lx and Ls units

unless the auxiliary output option –AX is installed. This makes the standard output

terminal block more easily accessible.

No other functional differences exist between the Series I and Series II AC power sources. The

RS232C interface is still available in addition to the USB interface.

The expression "AC source" as used in the manual also applies to the same series. You will find

the following information in the rest of this manual:

Chapter 2 Introduction to SCPI

Chapter 3 System Considerations

Chapter 4 SCPI Command Reference

Chapter 5 Common Commands

Chapter 6 Programming Examples

Chapter 7 Programming the Status and Event Registers

Chapter 8 Options

Appendix A SCPI command tree

Appendix B SCPI conformance information

Appendix C Error messages

1.1 Documentation Summary

The following document is related to this Programming Manual and may have additional helpful

information for using the AC source.

User's Manual. P/N 7004-980 Includes specifications and supplemental characteristics, how

to use the front panel, how to connect to the instrument, and calibration procedures.

1.1.1 External References

SCPI References

The following documents will assist you with programming in SCPI:

Beginner's Manual to SCPI. Highly recommended for anyone who has not had previous

experience programming with SCPI.

Controller programming manuals: consult the documentation supplied with the IEEE-488

controller or IEEE-488 PC plug in card for information concerning general IEEE-488.2

conventions and concepts.

8

Page 13

Programming Manual Lx \ Ls Series II

The following are two formal documents concerning the IEEE-488 interface:

ANSI/IEEE Std. 488.1-1987 IEEE Standard Digital Interface for Programmable

Instrumentation. Defines the technical details of the IEEE-488 interface. While much of the

information is beyond the need of most programmers, it can serve to clarify terms used in this

manual and in related documents.

ANSI/IEEE Std. 488.2-1987 IEEE Standard Codes, Formats, Protocols, and Common

Commands. Recommended as a reference only if you intend to do fairly sophisticated

programming. Helpful for finding precise definitions of certain types of SCPI message

formats, data types, or common commands.

The above two documents are available from the IEEE (Institute of Electrical and Electronics

Engineers), 345 East 47th Street, New York, NY 10017, USA or via the web at www.ieee.org .

1.2 Lx Series and Ls Series Differences

The Lx Series and Ls Series of AC power sources are both based on the same AC power source

hardware platform and share many common components. The differences are primarily in

configuration and options. This manual covers both model series. Some commands listed may

not apply to Ls Series AC sources without the –ADV option and / or –MODE option.

1.2.1 Firmware differences

The Lx Series is fully featured and supports all commands listed in the programming manual.

The Ls Series provides most basic functions in its standard configurations. More advanced

features can be added by specifying the –ADV (advanced) option. If the –ADV option is installed,

all commands listed in this programming manual are supported. If not, commands related to

arbitrary waveforms and harmonic analysis measurements are not supported and will generate a

“-113 Syntax Error” message.

1.2.2 Hardware differences

In addition to the firmware differences described, the following hardware differences exist

between the standard Lx Ac source and the Ls AC source.

Lx has a 150V / 300 V rms output range pair. Optional ranges of 135/270 (-HV option)

and 200/400 (-EHV option) are available at time of order.

Ls has a 135 V / 270 V rms output range pair. Optional ranges of 156/312 (-HV option)

and 200/400 (-EHV option) are available at time of order.

The Lx rear panel connector labeling is compliant with the California Instruments iL Series

which it replaces and the HP/Agilent model 6834B.

The Ls rear panel connector labeling is compliant with the California Instruments L Series.

The Lx Series II comes standard with both GPIB, USB and RS232C interfaces. An

optional Ethernet interface (-LAN option) is available.

The Ls Series II comes standard with USB and RS232C only. An optional GPIB interface

(-GPIB option) and Ethernet interface (-LAN option) is available.

Note: Both interfaces use the SCPI command syntax as described in the programming manual.

The Lx Series provides both three phase and single phase output modes which can be

selected from the front panel or over the bus.

9

Page 14

Programming Manual Lx \ Ls Series II

The Ls Series provides either three phase (-3 models) or single phase (-1 models).

Three phase Ls Series sources may optionally be equipped with the –MODE option which

provides the same phase mode switching as the Lx Series.

1.3 Manual organization and format

All user documentation for AMETEK Programmable Power power sources is provided on CDROM

in electronic format. (Adobe Portable Document Format) The required Adobe PDF viewer is

supplied on the same CDROM. This manual may be printed for personal use if a hardcopy is

desired. To request a hardcopy from AMETEK Programmable Power, contact customer service at

service@programmablepower.com. There will be an additional charge for printed manuals.

This manual contains sections on programming the Lx or Ls Series over the bus. The Lx Series is

equipped with GPIB, USB and RS232C interfaces. The Ls Series is equipped with a USB and

RS232C interface. An optional GPIB interface can be specified at the time of order. Refer to the

Lx / Ls Series User manual for information on using the remote control interface and command

syntax. The user manual (P/N 7004-980) is provided on the same CDROM as this user manual.

AMETEK Programmable Power may make updated versions of this manual available from time to

time in electronic format through it‟s website. To obtain an updated manual revision if available,

check the California Instruments Manual download page at www.programmablepower.com. You

need to register as a customer to obtain free access to manual and software downloads.

1.4 Introduction to Programming

This section provides some general information regarding programming instrumentation and

available interface types.

1.4.1 IEEE-488 Capabilities of the AC source

All AC source functions except for setting the IEEE-488 address are programmable over the

IEEE-488. The IEEE 488.2 capabilities of the AC source are listed in Chapter 2 of the User's

Manual. The Lx Series offers standard IEEE-488 interface. The Ls Series requires the –GPIB

option.

The AC source operates from an IEEE-488 address that is set from the front panel. To set the

IEEE-488 address, press the MENU key on the front panel repeatedly until the CONFIGURATION

entry is shown on the LCD display.

Move the indicator on the right hand side of the display to point to CONFIGURATION and press

the ENTER key.

This will display the IEEE ADRRESS currently set. To change the address, use the Voltage knob

to increment or decrement the value. Press the ENTER key to confirm your selection.

To set up the GPIB/IEEE-488 interface on a Windows XP PC, refer to section 3.1, “IEEE-488 /

GPIB Interface”.

10

Page 15

Programming Manual Lx \ Ls Series II

1.4.2 USB Capabilities of the AC source

All AC source functions are programmable over the USB interface. The USB capabilities of the

AC source are listed in Chapter 2 of the User's Manual. Some capabilities support on the GPIB

interface such as ATN, GET and SRQ interrupts do not apply to the USB interface. The USB

interface operates internally at a fixed baudrate of 460800 baud but USB 2.0 burst transfer rates

are supported.

To set up the USB interface on a Windows XP PC, refer to section 3.2, “ USB Interface”.

The USB interface may be used to install updated firmware for the Lx / Ls controller if needed.

Firmware updates and a Flash Loader utility program and instructions are available from the

AMETEK Programmable Power website for this purpose. (www.programmablepower.com )

Multiple USB connections to same PC:

The Windows driver used to interface to the power source‟s USB port emulates a serial com port.

This virtual com port driver is unable to reliable differentiate between multiple units however so the

use of more than one AC power source connected to the same PC via USB is not recommended.

Use of the GPIB interface is recommended for these situations.

1.4.3 LAN Capabilities of the AC source

All AC source functions are programmable over the LAN (Ethernet) interface if the –LAN option is

installed. The LAN capabilities of the AC source are listed in Chapter 2 of the User's Manual.

Some capabilities support on the GPIB interface such as ATN, GET and SRQ interrupts do not

apply to the LAN interface. The LAN interface operates internally at a fixed baudrate of 460800

baud but autodetection of 10Base-T, 100Base-T and 1000Base-T is supported.

To set up the LAN interface on a Windows XP PC, refer to section 3.3, “LAN Option”.

1.4.4 RS232C Capabilities of the AC source

All AC source functions are programmable over the RS232C interface. The RS232C capabilities

of the AC source are listed in Chapter 2 of the User's Manual. Some capabilities support on the

GPIB interface such as ATN, GET and SRQ interrupts do not apply to the RS232C interface.

Baudrates from 9600 to 115200 are supported.

To set up the RS232C interface, refer to section 3.4, “RS232C Serial Interface”.

The RS232C interface may be used to install updated firmware for the Lx / Ls controller if needed.

Firmware updates and a Flash Loader utility program and instructions are available from the

AMETEK Programmable Power website for this purpose. (www.programmablepower.com )

11

Page 16

Programming Manual Lx \ Ls Series II

2. Introduction to SCPI

SCPI (Standard Commands for Programmable Instruments) is a programming language for

controlling instrument functions over the IEEE-488. SCPI is layered on top of the hardware-portion

of IEEE 488.2. The same SCPI commands and parameters control the same functions in different

classes of instruments.

2.1 Conventions Used in This Manual

Angle brackets <> Items within angle brackets are parameter abbreviations. For

example, <NR1> indicates a specific form of numerical data.

Vertical bar | Vertical bars separate alternative parameters. For example,

NORM | TEXT indicates that either "TEXT" or "NORM" can be used as a

parameter.

Square Brackets [] Items within square brackets are optional. The representation

[SOURce:]LIST means that SOURce: may be omitted.

Braces {} Braces indicate parameters that may be repeated zero or more

times. It is used especially for showing arrays. The notation <A> <,B>

shows that parameter "A" must be entered, while parameter "B" may be

omitted or may be entered one or more times.

2.2 The SCPI Commands and Messages

2.2.1 Types of SCPI Commands

SCPI has two types of commands, common and subsystem.

Common commands generally are not related to specific operation but to

controlling overall AC source functions, such as reset, status, and synchronization. All common

commands consist of a three-letter mnemonic preceded by an

asterisk: *RST, *IDN?, *SRE 8

Subsystem commands perform specific AC source functions. They are organized

into an inverted tree structure with the "root" at the top. Some are

single commands while others are grouped within specific

subsystems.

Refer to appendix A for the AC source SCPI tree structure.

2.2.2 Types of SCPI Messages

There are two types of SCPI messages, program and response.

A program message consists of one or more properly formatted SCPI commands sent from

the controller to the AC source. The message, which may be sent at any time, requests the

AC source to perform some action.

A response message consists of data in a specific SCPI format sent from the AC source to

the controller. The AC source sends the message only when commanded by a program

message called a "query."

12

Page 17

Programming Manual Lx \ Ls Series II

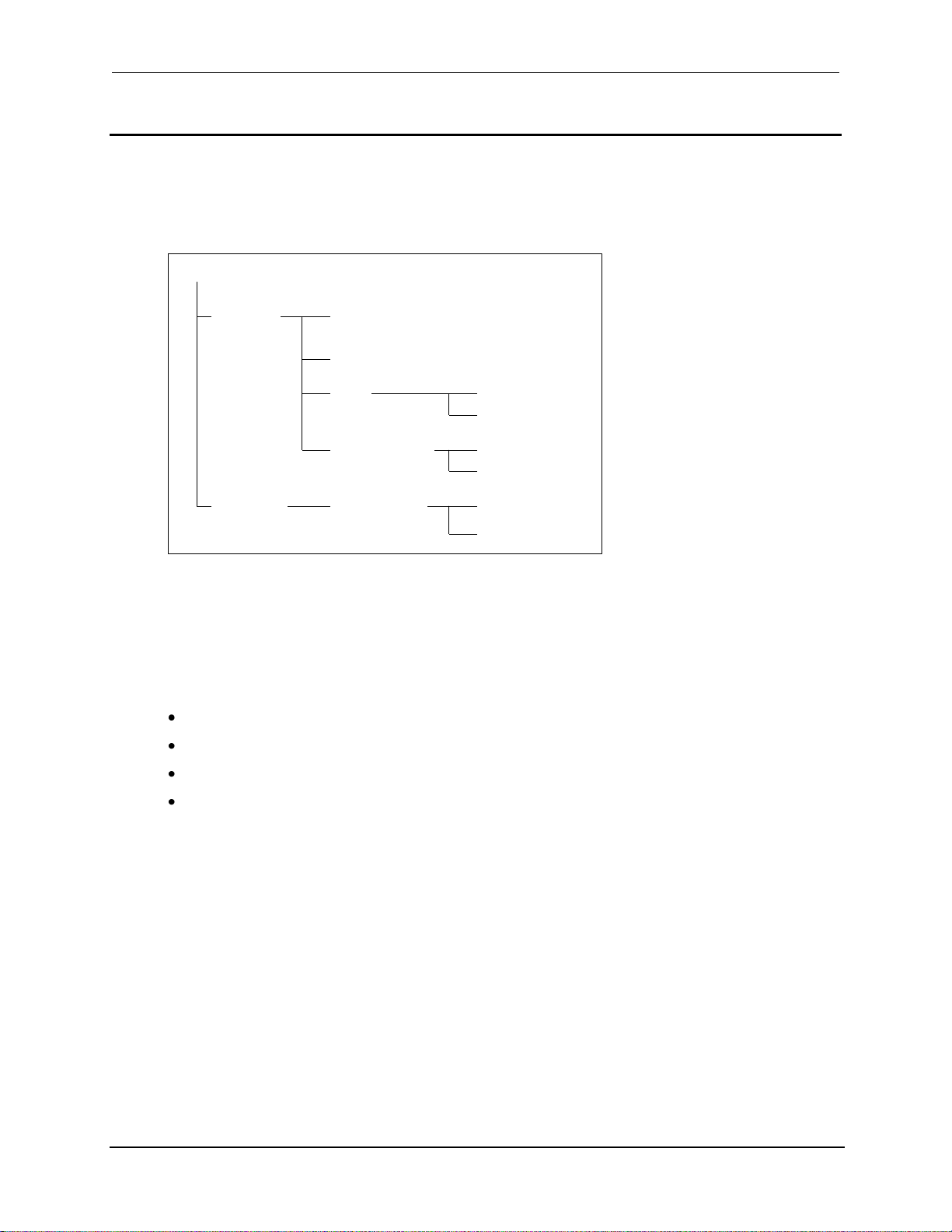

Root

:OUTPut

:COUPling

:DFI

:PROTection

:OPERation

:SOURce

:CLEar

:DELay

:STATus

[:STATe]

[:STATe]

[:EVEN]?

:CONDition?

2.2.3 The SCPI Command Tree

As previously explained, the basic SCPI communication method involves sending one or more

properly formatted commands from the SCPI command tree to the instrument as program

messages. Figure 2-1 shows a portion of a subsystem command tree, from which you access the

commands located along the various paths (you can see the complete tree in appendix A).

Figure 2-1: Partial Command Tree

The Root Level

Note the location of the ROOT node at the top of the tree. Commands at the root level are at the

top level of the command tree. The SCPI interface is at this location when:

the AC source is powered on

a device clear (DCL) is sent to the AC source

the SCPI interface encounters a message terminator (LF)

the SCPI interface encounters a root specifier (:)

Active Header Path

In order to properly traverse the command tree, you must understand the concept of the active

header path. When the AC source is turned on (or under any of the other conditions listed above),

the active path is at the root. That means the SCPI interface is ready to accept any command at

the root level, such as OUTPut or STATe.

If you enter OUTPut, the active header path moves one colon to the right. The interface is now

ready to accept :STATe, :COUPling,:DFI, or :PROTection as the next header. You must include

the colon, because it is required between headers.

If you now enter :PROTection, the active path again moves one colon to the right. The interface is

now ready to accept either :CLEar or :DELay as the next header.

If you now enter :CLEar, you have reached the end of the command string. The active header

path remains at :CLEar. If you wished, you could have entered :CLEar;DELay 20 and it would be

accepted as a compound message consisting of:

1. OUTPut:PROTection:CLEAr and

13

Page 18

Programming Manual Lx \ Ls Series II

2. OUTPut:PROTection:DELay 20.

The entire message would be:

OUTPut:PROTection:CLEar;DELay 20

The message terminator after DELay 20 returns the path to the root.

The Effect of Optional Headers

If a command includes optional headers, the interface assumes they are there. For example, if

you enter OUTPut OFF, the interface recognizes it as OUTPut:STATe OFF. This returns the

active path to the root (:OUTPut). But if you enter OUTPut:STATe OFF, then the active path

remains at :STATe. This allows you to send

OUTPut:STATe OFF;PROTection:CLEar

in one message. If you tried to send

OUTPut OFF;PROTection:CLEar

the header path would return to :OUTPut instead of :PROTection.

The optional header [SOURce] precedes the current, frequency, function, phase, pulse, list, and

voltage subsystems. This effectively makes :CURRent,:FREQuency, :FUNCtion, :PHASe,

:PULse, :LIST, and :VOLTage root-level commands.

Moving Among Subsystems

In order to combine commands from different subsystems, you need to be able to restore the

active path to the root. You do this with the root specifier (:). For example, you could clear the

output protection and check the status of the Operation Condition register as follows:

OUTPut:PROTection:CLEAr

STATus:OPERation:CONDition?

Because the root specifier resets the command parser to the root, you can use the root specifier

and do the same thing in one message:

OUTPut:PROTection:CLEAr;:STATus:OPERation:CONDition?

The following message shows how to combine commands from different subsystems as well as

within the same subsystem:

VOLTage:LEVel 70;PROTection 80;:CURRent:LEVel 3;PROTection:STATe ON

Note the use of the optional header LEVel to maintain the correct path within the voltage and

current subsystems and the use of the root specifier to move between subsystems.

Note: The "Enhanced Tree Walking Implementation" given in appendix A of the IEEE 488.2

standard is not implemented in the AC source.

Including Common Commands

You can combine common commands with system commands in the same message. Treat the

common command as a message unit by separating it with a semicolon (the message unit

separator). Common commands do not affect the active header path; you may insert them

anywhere in the message.

VOLTage:TRIGger 7.5;INITialize;*TRG

OUTPut OFF;*RCL 2;OUTPut ON

14

Page 19

Programming Manual Lx \ Ls Series II

2.3 Using Queries

Observe the following precautions with queries:

Set up the proper number of variables for the returned data.

Read back all the results of a query before sending another command to the AC source.

Otherwise a Query Interrupted error will occur and the unreturned data will be lost.

2.4 Coupled Commands

When commands are coupled it means that the value sent by one command is affected by the

settings of the other commands. The following commands are coupled in the AC source:

the voltage and function shape commands

the step, pulse, and list commands that control output voltages and function shapes

the pulse commands that program the width, duty cycle, period, and the hold parameter

the voltage range and current limit commands

As explained later in chapter 4, the order in which data is sent by these coupled commands can

be important when more than one parameter is changed.

2.5 Structure of a SCPI Message

SCPI messages consist of one or more message units ending in a message terminator. The

terminator is not part of the syntax, but implicit in the way your programming language indicates

the end of a line (such as a newline or end-of-line character).

2.5.1 The Message Unit

The simplest SCPI command is a single message unit consisting of a command header (or

keyword) followed by a message terminator.

ABORt<newline>

VOLTage?<newline>

The message unit may include a parameter after the header. The parameter usually is

numeric, but it can be a string:

VOLTage 20<newline>

VOLTage MAX<newline>

2.5.2 Combining Message Units

The following command message is briefly described here, with details in subsequent paragraphs.

15

Page 20

Programming Manual Lx \ Ls Series II

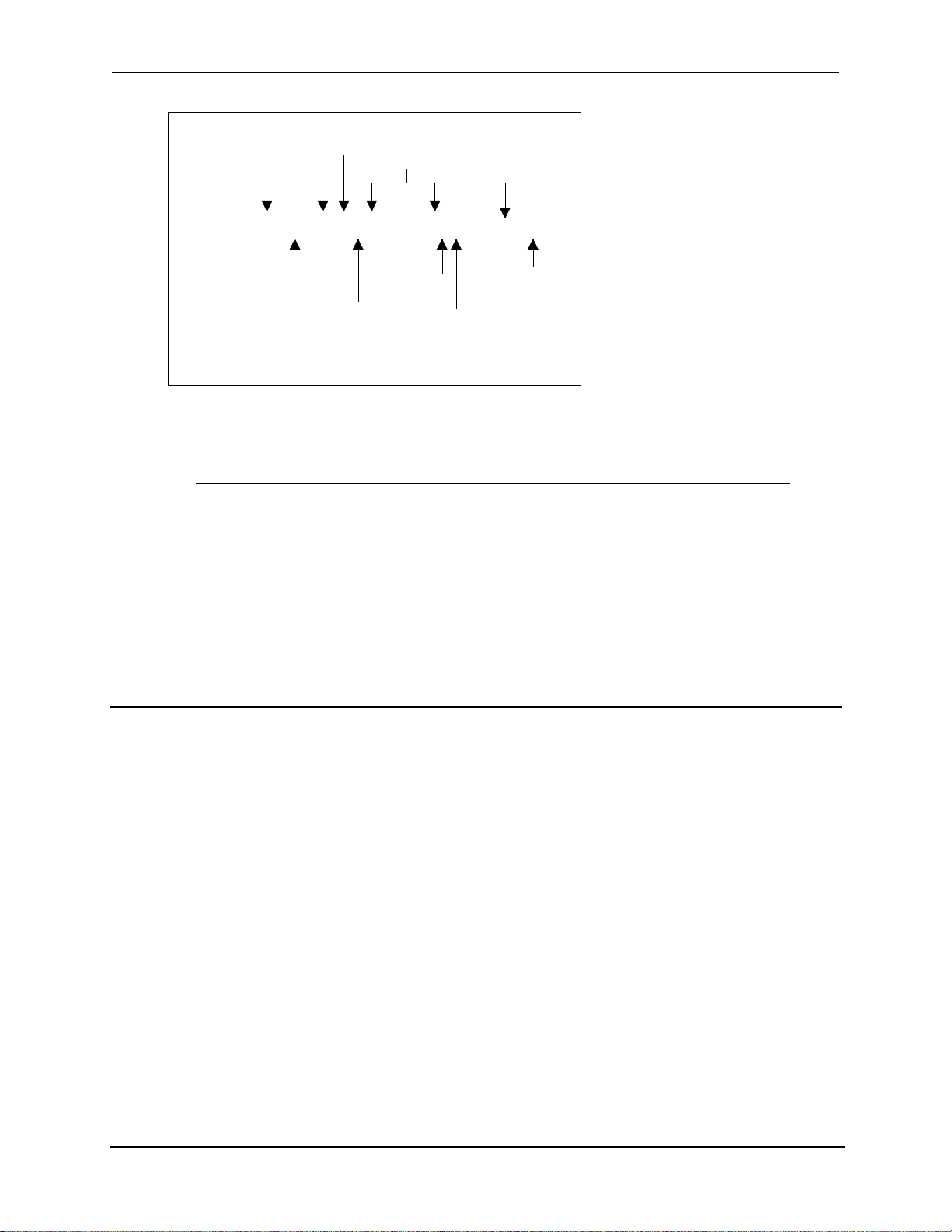

VOLT : LEV 80 ; PROT 88 ; : CURR? <NL>

Headers

Data

Message Unit

Query Indicator

Header

Separator

Message

Unit

Separator

Root Specifier

Message

Terminator

Figure 2-2: Command Message Structure

The basic parts of the above message are:

Message Component Example

Headers VOLT LEV PROT CURR

Header Separator The colon in VOLT:LEV

Data 80 88

Data Separator The space in VOLT 80 and PROT 88

Message Units VOLT:LEV 80 PROT 88 CURR?

Message Unit Separator The semicolons in VOLT:LEV 80; and PROT 88;

Root Specifier The colon in PROT 88;:CURR?

Query Indicator The question mark in CURR?

Message Terminator The <NL> (newline) indicator. Terminators are not part of the SCPI syntax

2.5.3 Headers

Headers are instructions recognized by the AC source. Headers (which are sometimes known as

"keywords") may be either in the long form or the short form.

Long Form The header is completely spelled out, such as VOLTAGE, STATUS, and

DELAY.

Short Form The header has only the first three or four letters, such as VOLT, STAT,

and DEL.

The SCPI interface is not sensitive to case. It will recognize any case mixture, such as TRIGGER,

Trigger, TRIGger. Short form headers result in faster program execution.

Header Convention

In the command descriptions in chapter 3 of this manual, headers are emphasized with boldface

type. The proper short form is shown in upper-case letters, such as DELay.

Header Separator

If a command has more than one header, you must separate them with a colon (VOLT:PROT

OUTPut:RELay:POLarity).

Optional Headers

The use of some headers is optional. Optional headers are shown in brackets, such as

16

OUTPut[:STATe] ON. As previously explained under "The Effect of Optional Headers", if you

Page 21

Programming Manual Lx \ Ls Series II

combine two or more message units into a compound message, you may need to enter the

optional header.

2.5.4 Query Indicator

Following a header with a question mark turns it into a query (VOLTage?,

VOLTage:PROTection?). If a query contains a parameter, place the query indicator at the end of

the last header (VOLTage:PROTection? MAX).

2.5.5 Message Unit Separator

When two or more message units are combined into a compound message, separate the units

with a semicolon (STATus:OPERation?;QUEStionable?).

2.5.6 Root Specifier

When it precedes the first header of a message unit, the colon becomes the root specifier. It tells

the command parser that this is the root or the top node of the command tree. Note the difference

between root specifiers and header separators in the following examples:

OUTPut:PROTection:DELay .1 All colons are header separators

:OUTPut:PROTection:DELay .1 Only the first colon is a root specifier

OUTPut:PROTection:DELay .1;:VOLTage 12.5 Only the third colon is a root specifier

Note: You do not have to precede root-level commands with a colon; there is an implied colon in

front of every root-level command.

2.5.7 Message Terminator

A terminator informs SCPI that it has reached the end of a message. Three permitted messages

terminators are:

newline (<NL>), which is ASCII decimal 10 or hex 0A.

end or identify (<END>)

both of the above (<NL><END>).

In the examples of this manual, there is an assumed message terminator at the end of each

message. If the terminator needs to be shown, it is indicated as <NL> regardless of the actual

terminator character.

17

Page 22

Programming Manual Lx \ Ls Series II

Class

Suffix

Unit

Multiplier

Amplitude V Volt

MV (millivolt)

Current A Ampere

MA (milliamp)

Frequency

Hz

Hertz

KHZ (kilohertz)

Time s second

MS (millisecond)

Common Multipliers

1E3

K

kilo 1E-3

M

milli 1E-6

U

micro

2.6 SCPI Data Formats

All data programmed to or returned from the AC source is ASCII. The data may be numerical or

character string.

2.6.1 Numerical Data Formats

Symbol Data Form

Talking Formats

<NR1> Digits with an implied decimal point assumed at the right of the least-

significant digit. Examples: 273

<NR2> Digits with an explicit decimal point. Example: .0273

<NR3> Digits with an explicit decimal point and an exponent. Example: 2.73E+2

<Bool> Boolean Data. Example: 0 | 1or ON | OFF

Listening Formats

<Nrf> Extended format that includes <NR1>, <NR2> and <NR3>. Examples:

<Nrf+> Expanded decimal format that includes <Nrf> and MIN MAX. Examples:

<Bool> Boolean Data. Example: 0 | 1

2.6.2 Character Data

273 273. 2.73E2

273 273. 2.73E2 MAX. MIN and MAX are the minimum and maximum

limit values that are implicit in the range specification for the parameter.

Table 2-1: Command parameters Suffixes and Multipliers

Character strings returned by query statements may take either of the following forms, depending

on the length of the returned string:

<CRD> Character Response Data. Permits the return of character strings.

<AARD> Arbitrary ASCII Response Data. Permits the return of undelimited 7-bit ASCII.

This data type has an implied message terminator.

18

Page 23

Programming Manual Lx \ Ls Series II

<SRD> String Response Data. Returns string parameters enclosed in double quotes.

19

Page 24

Programming Manual Lx \ Ls Series II

3. System Considerations

This chapter addresses some system issues concerning setting up interfaces such as GPIB, USB

or Ethernet.

3.1 IEEE-488 / GPIB Interface

All Lx Series power sources are equipped with an industry standard IEEE-488.2 interface (GPIB).

On Ls models, the IEEE-488.2 interface is available as an option (Option –GPIB).

A GPIB controller such as a Windows PC with suitable GPIB controller card is required to use the

GPIB interface.

3.1.1 Assigning the IEEE-488 Address

The AC source address cannot be set remotely. It must be set from the front panel. Once the

address is set, you can assign it inside programs. The GPIB address can be set/changed from the

CONFIGURATION menu screen. Press the MENU key and scroll to the CONFIGURATION

menu using the Up/Down arrow keys or press the MENU key repeatedly until the

CONFIGURATION screen appears. Press the ENTER key to enter the CONFIGURATION

screen.

Scroll to the ADDRESS field using the Up/Down arrow keys on the front panel. The value of the

ADDRESS can be set from 0 through 31. Avoid using address 0 as it is generally reserved for the

GPIB bus controller. Once set, the GPIB address of the power source is retained in non-volatile

memory.

For systems using the National Instruments VISA or IVI drivers, the address is specified in the

resource descriptor (GPIB::1). Consult you programmer‟s reference documentation on how to

address a GPIB instrument using your specific GPIB controller‟s function library.

3.1.2 LxGui and IEEE-488

The provided Windows LxGui program supports the GPIB interface on both Lx Series and Ls

Series models but only in combination with a National Instruments GPIB controller. The default

controller ID is zero but controller ID‟s from 0 thorugh 3 can be selected in the LxGui Interface

screen if multiple GPIB controllers are present in the same PC. Note that the LxGui program only

supports one Lx/Ls power source at a time.

20

Page 25

Programming Manual Lx \ Ls Series II

3.2 USB Interface

Unlike RS232C, there are no generic drivers available as a rule for us in programming

environments such as LabView, LabWindows/CVI or Visual Basic. However, support for USB is

included under VISA and may be used to interface to the power source using the USB interface.

For other environments, a virtual serial port utility is provided on CD ROM CIC496 which ships

with the Lx/Ls Series power source. This utility will provide a virtual COM port on a PC under

Windows XP. This allows legacy programs to use the USB port as though it is a regular serial

port on the PC. The baud rate for this mode of operation is fixed at 460,800. If you plan to use

this feature, the USB-Serial Adaptor installation must be run to install the virtual com port driver.

This option is only supported under Windows XP / Windows Vista.

3.2.1 USB Driver Installation

When connecting the AC source through the USB interface to Windows XP/Windows Vista PC,

the presence of a new USB device will be detected. Windows will display a dialog after a short

delay prompting the user to install the USB device drivers.

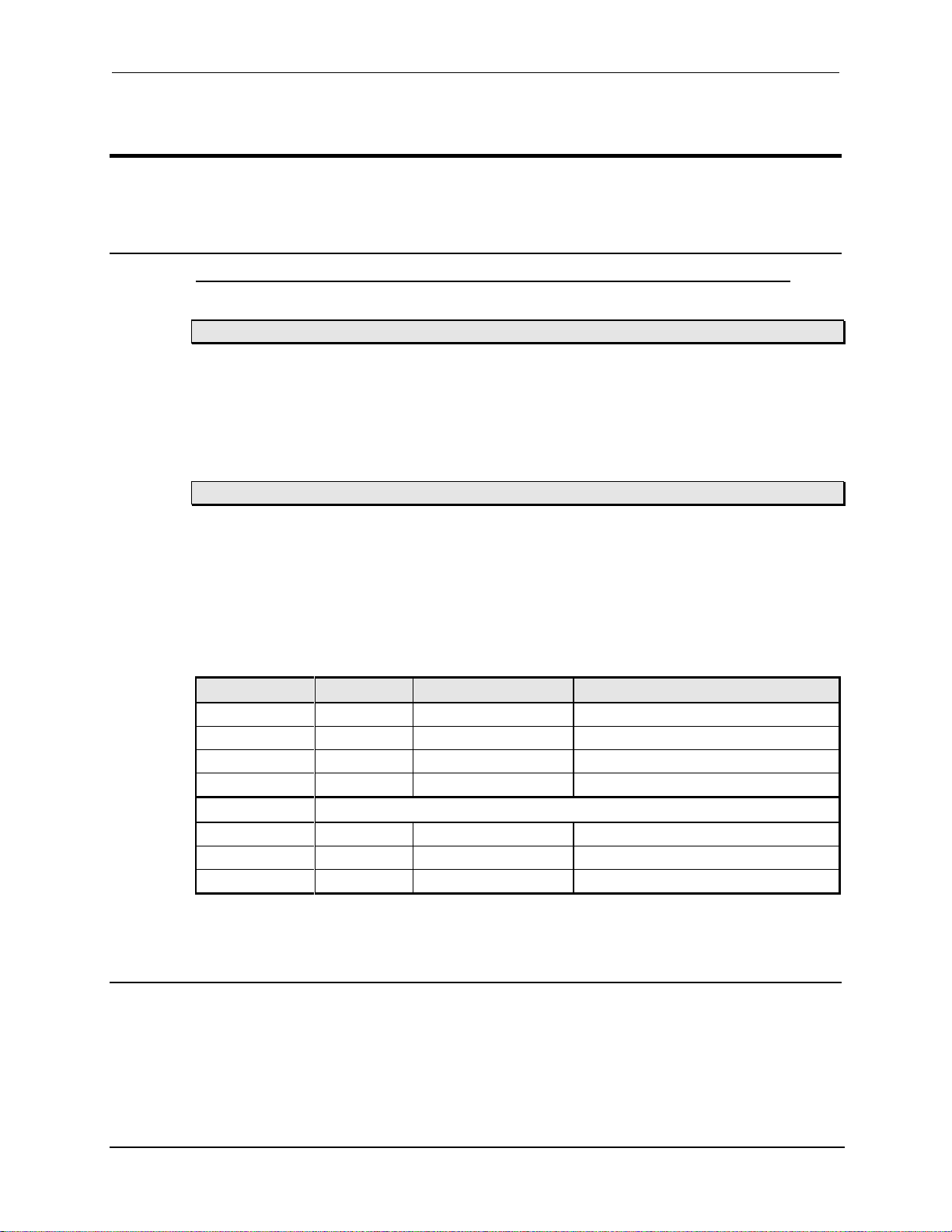

On the CIC496 CD browser, select “USB-to-COM(WinXP/Vista32), select “GUI Software” tab and

click “Execute Selection” to complete the USB driver installation by selecting “Next”, “Next”,

“Install”, then “Finish”.

Close CD browser and restart computer.

This driver will allow access to the AC source USB interface using a virtual COM port. Many

programming environments support RS232 access but not USB. The USB-to-COM virtual port

driver is distributed on the CIC496 CD ROM.

21

Page 26

Programming Manual Lx \ Ls Series II

USB Device Driver installation

Plug in USB cable to power soure, turn on power soure.

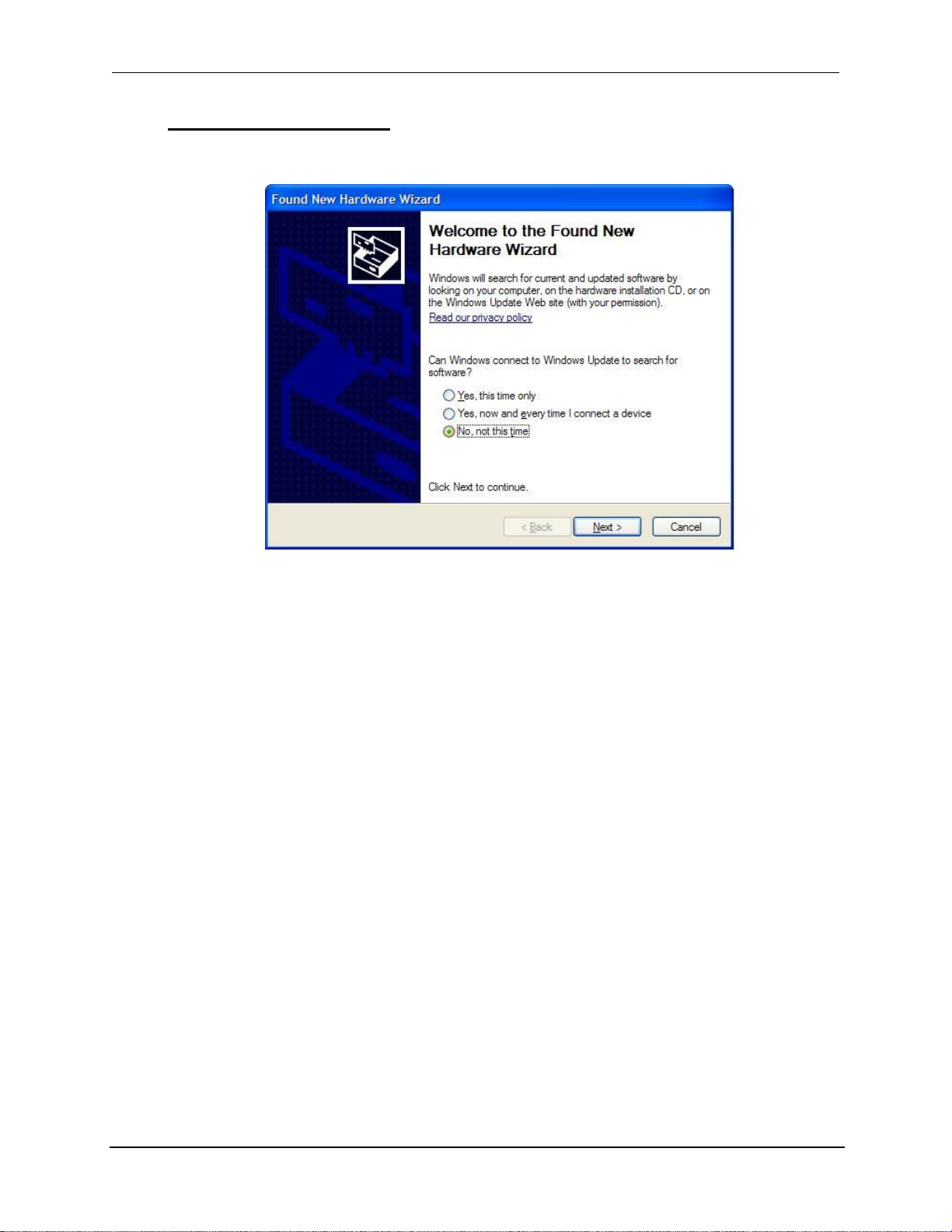

When the “Found New Hardware Wizard” dialog appears, select the “No, not this time.”option.

The drivers are not available on line. Click on Next button to continue.

22

Page 27

Programming Manual Lx \ Ls Series II

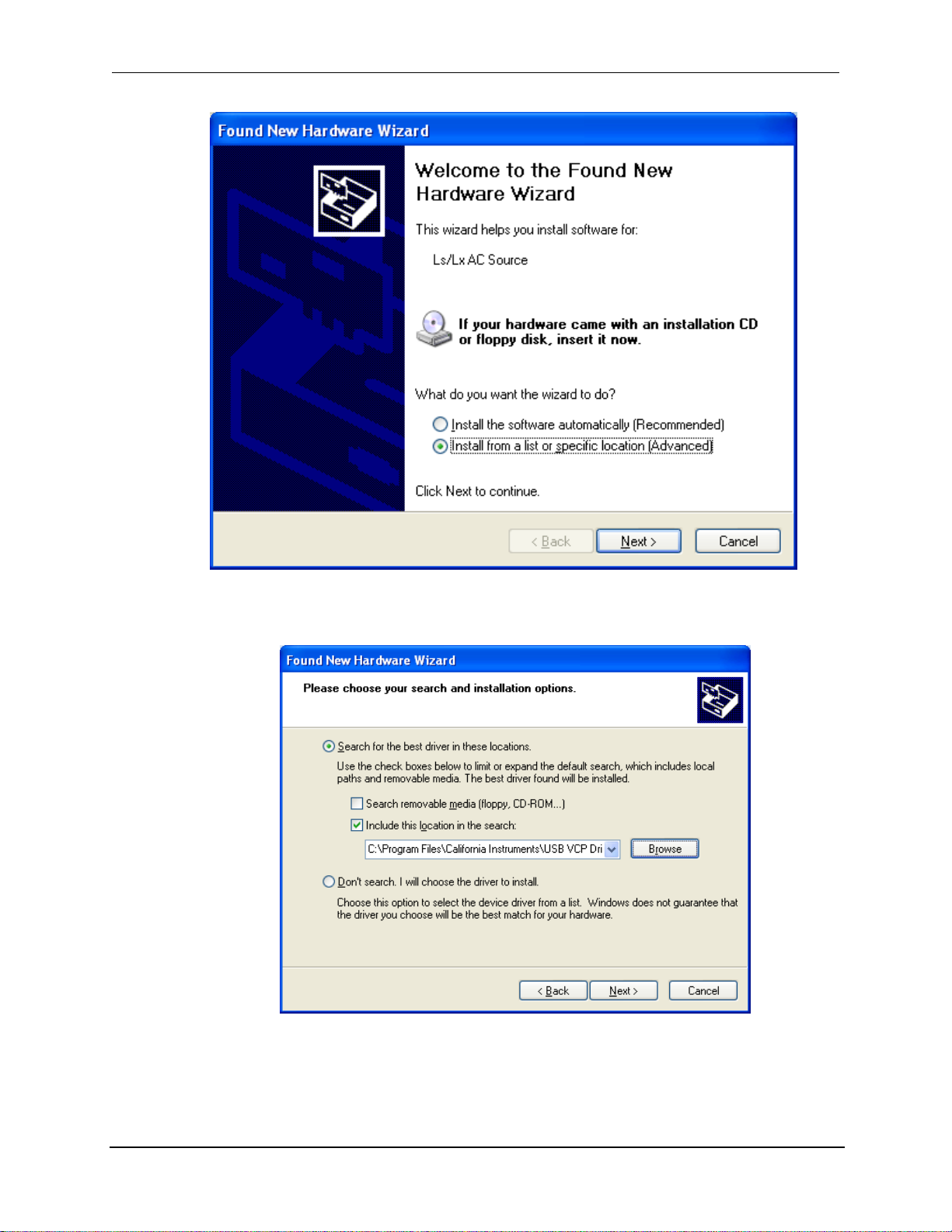

Select the second choice from the list to install the driver by browsing to a specific location.

Click on Next button to continue.

For Windows Vista OS, browse to the following location: C:\Program Files\California

Instruments\USB VCP Drivers\Vista(32-bits).

23

Page 28

Programming Manual Lx \ Ls Series II

For Windows XP OS, browse to the following location: C:\Program Files\California

Instruments\USB VCP Drivers\XP(32-bits).

Select “Browse”, “My Computer”, “C:\”, “Prgram Files”, “California Instrumnets”. “USB VCP

Driver”, WinXP(32bit). then select “OK”. See picture below for detail.

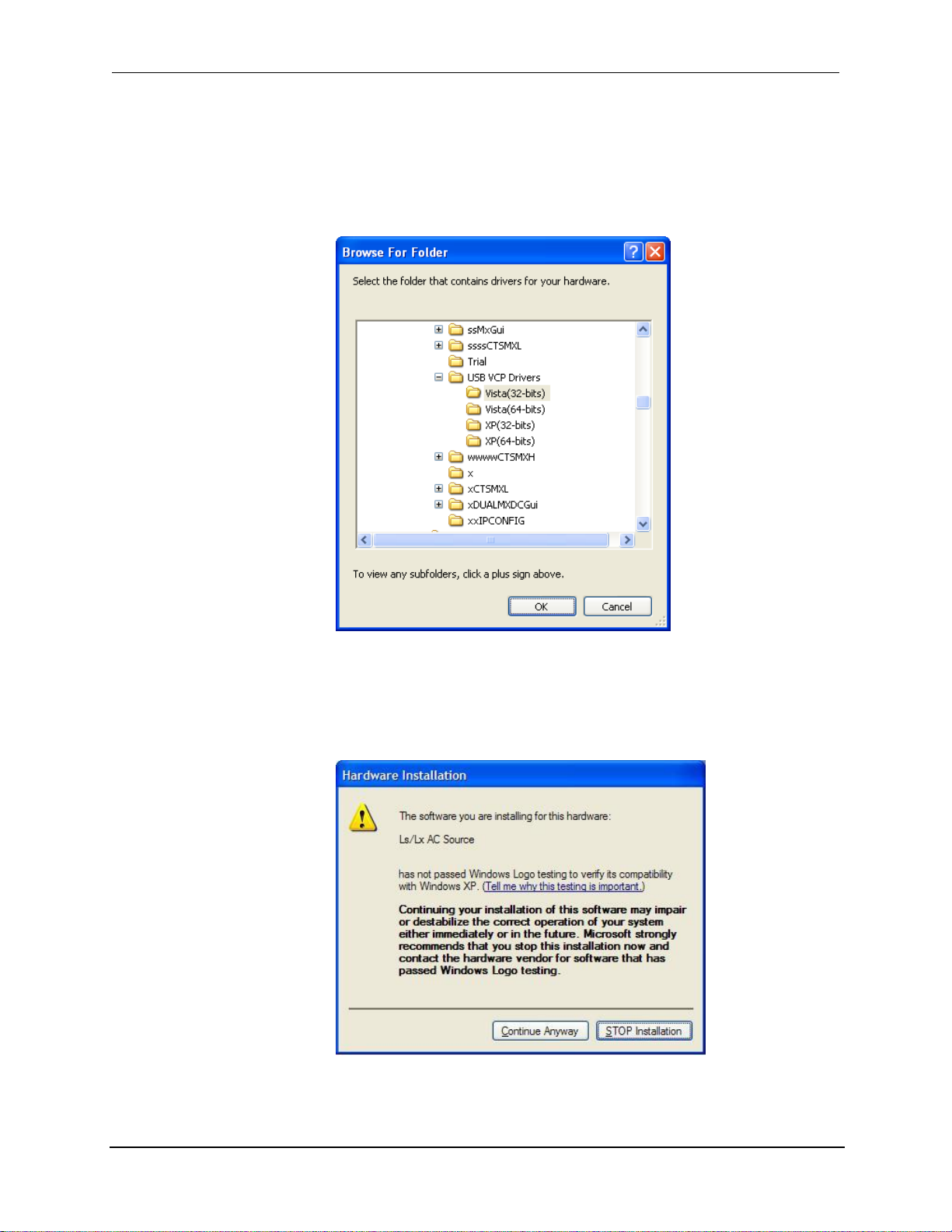

The USB device drivers have not been Windows XP / Windows Vista Logo certified. Due to the

limited distribution of these drivers, this is unlikely to be done. This Logo certification has no

bearing on the functionality or legitimacy of this device driver so you can ignore this message.

Click the “Continue Anyway” button to continue. Note that some PCs may have this verification

disabled in which case this screen will not pop up.

The installation will now proceed. This process may take several minutes to complete.

24

Page 29

Programming Manual Lx \ Ls Series II

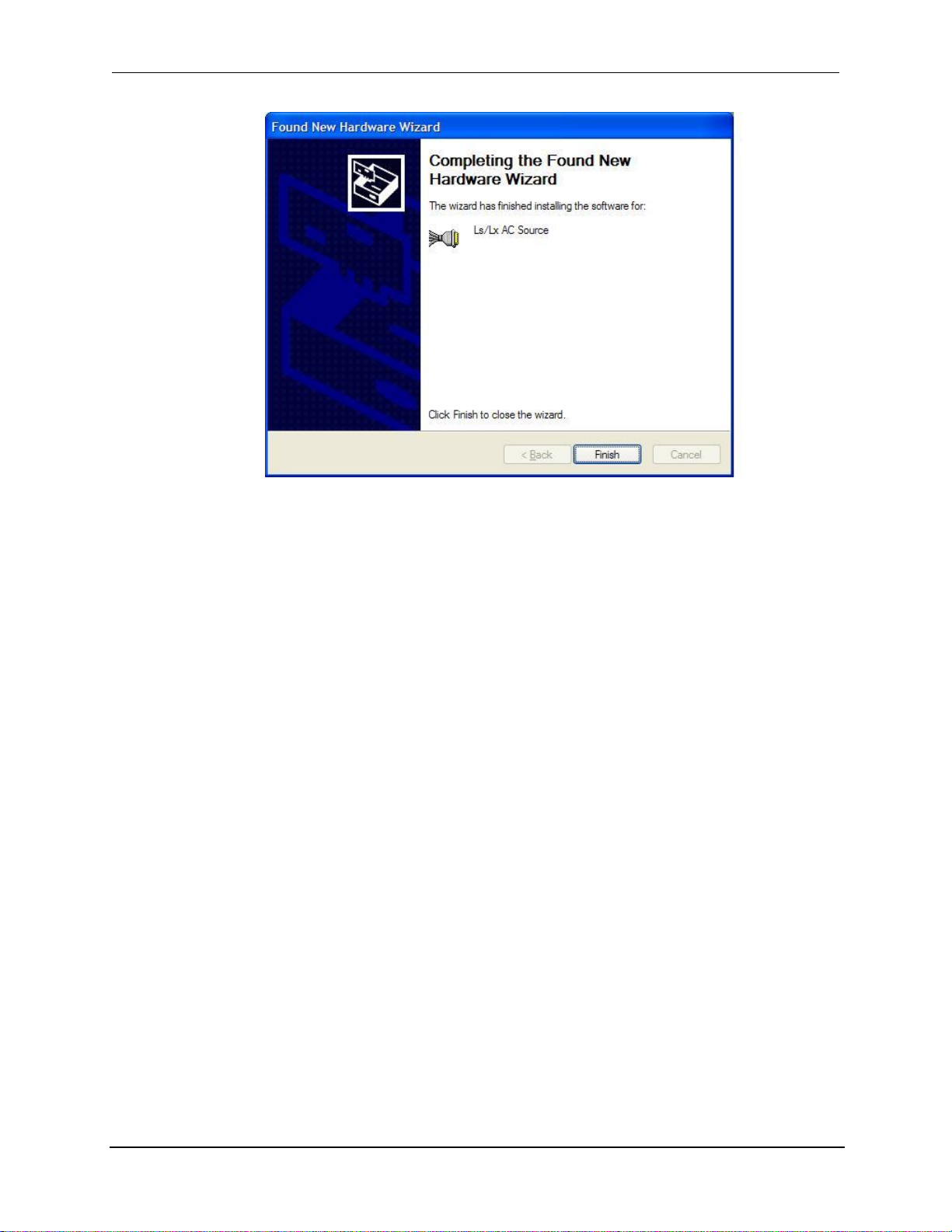

Once completed, the dialog box shown above will appear signaling the device drivers have been

installed. The USB interface is now available to the PC‟s operating system. To complete the install

process, click on the “Finish” button.

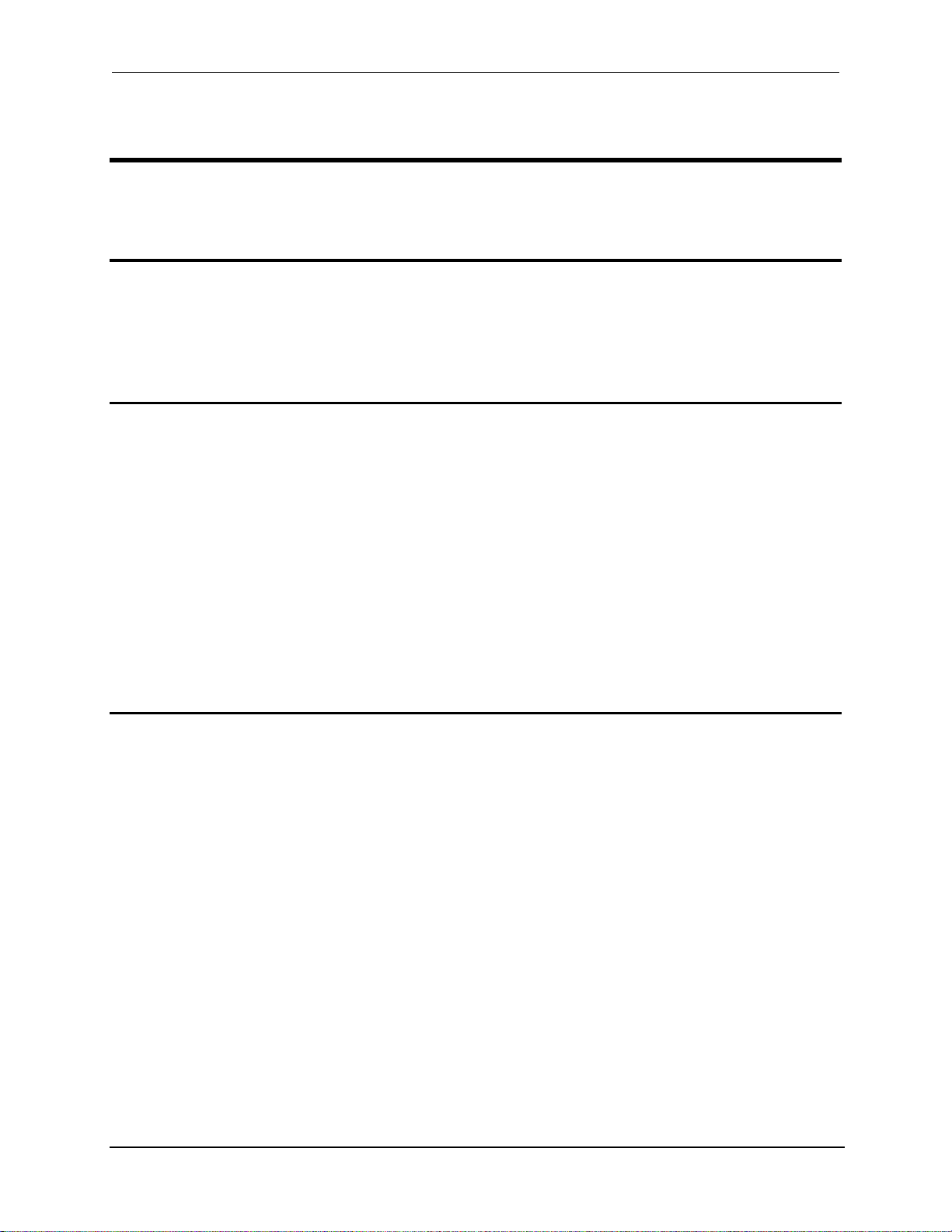

To verify the USB port is available, you can access the Windows System Properties screen, select

the Hardware tab and open the Windows Device Manager screen. The Lx/Ls Source should be

listed under “Port (COM & LPT)” as shown in the image below.

25

Page 30

Programming Manual Lx \ Ls Series II

Figure 3-1: Windows XP Device Manager - USB Port

26

Page 31

Programming Manual Lx \ Ls Series II

3.2.2 USB Interface Use

Note that the power source will be detected automatically when turn on or plugged in once the

drivers have been installed. It is recommended however to close any open USB connections to

the AC source before turning it off.

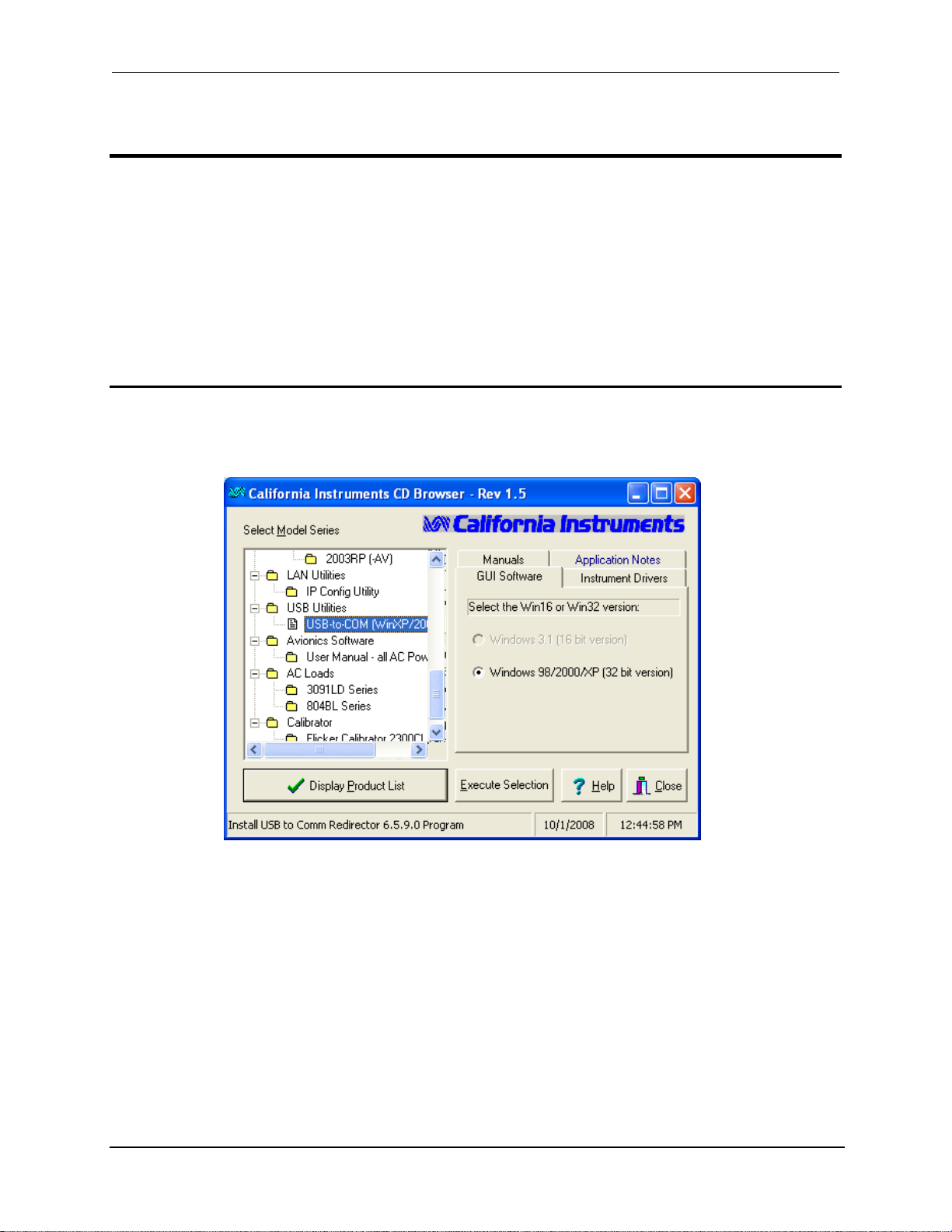

To use the USB interface, you may use the Gui Windows software supplied with the power source

or develop your own application code. In either case, set the baud rate on the power source to

460,800 in the Configuration menu. From Lx/Ls Front panel, press MENU key, scroll to

CONFIGURATION and press ENTER key. Select BAUDRATE field and scroll to 460800.

For use with the LxGui program, select the “RS232C Serial” interface type and set the Baud rate

to match the baud rate on the Lx/Ls Source.

Figure 3-2: LxGui Interface Settings for use of USB port.

Note: Use of the USB port to control more than one power source from a single PC is not

recommended, as communication may not be reliable. Use GPIB interface for

multiple power source control.

27

Page 32

Programming Manual Lx \ Ls Series II

3.3 LAN Option

An Ethernet LAN interface option is available for the Lx/Ls Series II power sources. This option

must be specified at the time of order. A LAN option indicator will appear on the model number

tag at the rear-panel of the power source to indicate the presence of this option. Also, a RJ45

socket will be present on the rear panel.

Using LAN lets you communicate with the instrument remotely, it is fast, simple and the LAN from

your PC does not require any additional proprietary software or cards.

Note: If a USB cable is plugged into the USB interface connector of the power source, the LAN

interface will be disabled. Remove any USB connection to use the LAN / Ethernet port.

3.3.1 MAC Address

Each power source with the –LAN option installed has a unique network address (MAC address).

The MAC address (Media Access Conrol) is a unique hexadecimal address and is listed on a

label on the rear panel of the power source. To operate the power source on a network, this MAC

address needs to be assigned to a TCP/IP address which will be used to address the device on

the network.

3.3.2 TCP/IP and Gateway Address

The first decision you need to make is how to connect the instrument. You can connect the

instrument directly to a network LAN port with a LAN cable, or you can connect it directly to the

PC. When connecting the instrument directly to the PC LAN port you will need a special cable

called a cross connect cable. (For more on private network connections, see section 3.3.3) Once

connected you must establish an IP address for the instrument. An IP address consists of four

groups of numbers separated by a decimal. Dynamic Host Configuration Protocol (DHCP) is

typically the easiest way to configure the instrument for LAN communication. DHCP automatically

assigns a dynamic IP address to a device on a network. To set the power source to DHCP mode,

see section 3.3.4.

28

Page 33

Programming Manual Lx \ Ls Series II

3.3.3 Private Networks without DHCP servers

If you are setting up a private network that connects the power source to a Windows PC using a

so called cross over RJ45 cable, the PC will assign itself an IP address in the absence of a DHCP

server. The available IP address range assigned by the Internet Assigned Network Authority

(IANA) for Automatic Private IP Addressing (APIPA) is 169.254.0.0 to 169.254.255.255.

When setting up a private network, you will have to log off and disconnect first from any network

connection and re-log in to Windows.

To check the PC‟s IP address, you can run the “ipconfig.exe” program from the command prompt.

The screen on a private network should look as follows:

Microsoft(R) Windows DOS

(C)Copyright Microsoft Corp 1990-2001.

C:\>ipconfig

Windows IP Configuration

Ethernet adapter Local Area Connection:

Connection-specific DNS Suffix . :

IP Address. . . . . . . . . . . . : 169.254.0.208

Subnet Mask . . . . . . . . . . . : 255.255.0.0

Default Gateway . . . . . . . . . :

Since there is no DCHP server present in a private network like this, the power source has to be

set to a static IP address. To determine what IP address to use, use the first 2 octets of the PC‟s

IP address and set a unique value for the third and fourth octet as long as there are no conflicts

with any other IP addresses (other instruments) on the same private network. In this example,

169.254.0.209 would work.

Note: For private network configurations, no Gateway address is required. (0.0.0.0)

3.3.4 Setting LAN Parameters

There are two ways to set the required LAN information on the power source.

1. Through Ethernet connection: Use the “GetAssignIPAddress.exe” Windows utility

program that is distributed on the CIC496 CD ROM with every power source. This uitility

uses the network connection to set parameters on the power source so the power source

and the PC will have to be connected to the same network through a hub or to each other

using a cross over network cable (local network).

2. Through Front Panel: Set the parameters from the front panel CONFIGURATION menu.

In this case, connection to a network is not required to set the LAN parameters.

This front panel setup mode requires firmware revision 1.33 of higher. Check AMETEK

Programmable Power web site for firmware downloads.

To use the CONFIGURATION menu, press the MENU and use the up/down error keys to display

the CONFIGURATION entry. Place the pointer on CONFIGURATION and press the ENTER key.

Then scroll down till you see LANetwork and press ENTER again.

29

Page 34

Programming Manual Lx \ Ls Series II

Menu

Values

Description

LANetwork

LAN

If the –LAN option is installed; pressing Enter while

the cursor is on the LANetwork entry provides

access to the LAN interface setting screens listed

below.1

IP Address

Displays the IP address setting. This value can be

changed by pressing the SET key and entering a

new value from the keypad or using the Voltage

and Frequency shuttles. Use the numeric data pad

or the voltage shuttle to enter each field. To move

between the four fields, use the decimal point key

on the keypad or the Frequency shuttle.

To set a fixed IP address, press SET and enter the

desired IP address. To set the unit to DHCP mode,

press SET and enter all zeros (0.0.0.0) as the IP

address and cycle power two times. The obtained

IP address will be displayed after the second power

on. For the DHCP setting to work however, the unit

MUST be connected to a network with a DHCP

server.

Any change to this value will NOT take effect until

after power on the unit has been cycled.

When changing mode from static IP to DHCP, it is

necessary to cycle power on the unit twice, once to

change mode and again to obtain and display a

new IP address from the network.

MAC Address

Displays the network Media Acces Control address.

This value is fixed and cannot be changed. The

same MAC is normally printed on the model serial

tag. The MAC address is shown as six hexadecimal

numbers separated by a colon, e.g.

00:20:4A:9A:02:FD. Note that the leading „0‟ is

never visible due to the maximum number of LCD

characters per line.

Note: If the MAC Address displayed is corrupted or

does not match the serial tag, there may have been a

problem retrieving the LAN port settings.This can

happen if a static IP was set that conflicts with

another device on the network. To recover, turn on

power to the unit while holding down the SET key.

This will allow the unit to boot without attempting to

collect the IP settings. You can then set the required

IP values. [See IP Address above].

GWAddress

Gateway address setting. A default gateway is a

node (a router) on a computer network that serves

as an access point to another network.

The following fields are available in the LANetwork menu:

1

This feature requires firmware revision 1.40 or higher. If you upgraded from a lower firmware revision, the LAN configuration has

to be enabled to display this menu. Contact customer service for information on enabled this screen.

30

Page 35

Programming Manual Lx \ Ls Series II

This value can be changed by pressing the SET

key and entering a new value from the keypad or

using the Voltage and Frequency shuttles. Use the

numeric data pad or the Voltage shuttle to enter

each field. To move between the four fields, use the

decimal point key on the keypad or the Frequency

shuttle.

Any change to this value will NOT take effect until

after power on the unit has been cycled.

HostBits

Number of host bits as opposed to network bits in

network mask. A CIDR class C network uses 24

network bits and 8 host bits. (Class A = 24, Class B

= 16).

This value can be changed by pressing the SET

key and entering a new value from the keypad. Any

change to this value will NOT take effect until after

power on the unit has been cycled.

Port No

TCP remote port number. This value must be set to

5025 (SCPI) to support the built in web page.

This value can be changed by pressing the SET

key and entering a new value from the keypad. Any

change to this value will NOT take effect until after

power on the unit has been cycled.

LAN Default

LAN default setting can be achieve by selecting the

Mac address screen and press the set key followed

by the Enter key. Press the Enter key again to

confirm. The IP address is set to DHCP or AUTO

IP.

Once you have an IP address, you can test the IP address from your Windows PC. An easy way

to do so is to use the ping utility under MS DOS. To do so, bring up a DOS window using the start

menu:

Start>Programs>Accessories>Command Prompt)

At the command prompt type

ping <IP address>.

This will send an IP ping request to the power source. For this to work, the power source must be

turned on and connected to the same network as the PC. Also, the power source interface

configuration must be set to use a baud rate of 460,800. If everything is working it will look like

this:

31

Table 3-1: LAN Setting screens.

Page 36

Programming Manual Lx \ Ls Series II

Microsoft(R) Windows DOS

(C)Copyright Microsoft Corp 1990-2001.

C:\>ping 100.10.1.63

Pinging 100.10.1.63 with 32 bytes of data:

Reply from 100.10.1.63: bytes=32 time<1ms TTL=64

Reply from 100.10.1.63: bytes=32 time<1ms TTL=64

Reply from 100.10.1.63: bytes=32 time<1ms TTL=64

Reply from 100.10.1.63: bytes=32 time<1ms TTL=64

Ping statistics for 100.10.1.63:

Packets: Sent = 4, Received = 4, Lost = 0 (0% loss),

Approximate round trip times in milli-seconds:

Minimum = 0ms, Maximum = 0ms, Average = 0ms

Figure 3-3: Pinging AC Source LAN IP address.

3.3.5 Socket Port Number

Now that a connection has been verified, you can develop your application code. If you are using

one of the Microsoft environments, the Winsock protocol which is part of the Windows operating

system can be used. Similar capabilities are supported on other operating systems.

To use Winsock, your will have to specificy the port number of the power source‟s LAN interface.

The port number determines the protocol for the communication. The Lx/Ls power source uses

ASCII characters and instrument SCPI commands for remote control. The IANA registered Port

number for the Instrument SCPI interface is 5025.

TCP Remote port = 5025

32

Page 37

Programming Manual Lx \ Ls Series II

3.4 RS232C Serial Interface

The RS232C interface has been retained on the Lx/Ls Series II power source models for

backward compatibility with the Series I products. It functions exactly like it did on the first

generation products.

Note: If a USB cable is plugged into the USB interface connector of the power source, the RS232

interface will be disabled. Remove any USB connection to use the serial port.

The RS232C interface is factory enabled for all Lx/Ls models, except those ordered with the

optional –LAN interface. Models with the –LAN option have the LAN interface enabled and the

RS232C port disabled.

Note: If the –LAN option is installed, jumper W2 on the range/relay board (Assy P/N 7004-716-1)

must be installed. This jumper must be removed to enable the RS232C serial interface.

Changing this setting requires the top cover to be removed. Contact customer service

(service@programmablepower.com) to obtain authorization to perform this setting

change.

Figure 3-4: Position of LAN/RS232C selection jumper W2 on 7004-716-2 Range/Relay board.

The RS232C cable required to connect the Lx/Ls Source to a PC serial port is a standard 9 pin

Male to 9 pin Female straight-thorugh serial cable. A suitable 6 feet long RS232C cable is

supplied with each power soruce. (CI P/N 250709). Replacement cables are available through

customer service (service@programmablepower.com)

33

Page 38

Programming Manual Lx \ Ls Series II

3.5 Instrument Drivers and Application Software

Instrument drivers for National Instruments LabWindows/CVI and LabView are generally available

for download from the AMETEK Programmable Power ' web site at

www.programmablepower.com. Also available are ready to use interactive graphical user

interface (GUI) programs for download.

34

Page 39

Programming Manual Lx \ Ls Series II

4. SCPI Command Reference

4.1 Introduction

This chapter provides a complete listing of all SCPI commands supported by the Lx\Ls Series of

AC sources. Commands are grouped by function according the root level commands. Some

general command related issues are:

Phases

If a command can apply to individual phases of an AC source, the entry “Phase Selectable” will

appear in the command description.

Related Commands

Where appropriate, related commands or queries are included. These are listed because they are

either directly related by function, or because reading about them will clarify or enhance your

understanding of the original command or query.

This chapter is organized as follows:

Subsystem commands, arranged by subsystem

IEEE 488.2 common commands

35

Page 40

Programming Manual Lx \ Ls Series II

4.2 Subsystem Commands

Subsystem commands are specific to AC source functions. They can be a single command or a

group of commands. The groups are comprised of commands that extend one or more levels

below the root. The description of common commands follows the description of the subsystem

commands.

The subsystem command groups are listed in alphabetical order and the commands within each

subsystem are grouped alphabetically under the subsystem. Commands followed by a question

mark (?) take only the query form. When commands take both the command and query form, this

is noted in the syntax descriptions.

You will find the subsystem command groups discussed on the following pages:

36

Page 41

Programming Manual Lx \ Ls Series II

4.3 Calibration Subsystem

The commands in this subsystem allow you to do the following:

Enter the calibration password

Calibrate the current and voltage output levels, and store new calibration constants in

nonvolatile memory.

Subsystem Syntax

CALibrate

:MEASure

:CURRent Begin current measurement calibration sequence

:SPHase Query format returns single phase current mea coefficient.

:VOLTage Begin current measurement calibration sequence

:PASSword Unlock calibration

:SAVE Save new cal constants in non-volatile memory

[:SOURce]

PHASe Phase offset calibration

:VOLTage:HRANge Query output voltage cal coefficient

CALibrate:MEASure:CURRent

Phase Selectable

This command can only be used in calibration mode. It initiates the calibration of the ac current

metering circuits and sets the reference value to calibrate to. The query format returns the actual

calibration coefficient. Use the INST:SEL or INST:NSEL to select the desired phase.

Command Syntax CALibrate:MEASure:CURRent <Nrf>

Parameters Reference instrument current reading

Query Syntax CALibrate:MEASure:CURRent?

Returned Parameters <NR3>

Examples CAL:MEAS:CURR 12.23

Related Commands CAL:SAVE CAL:MEAS:VOLT

CALibrate:MEASure:CURRent:SPHase

This command can only be used in calibration mode and in query form. It applies only to phase 1

(Lx) or A (Ls). It returns the single-phase mode current measurement calibration coefficient for Lx

models and Ls models that have the –MODE option. Its purpose is to be able to read the

calibration status without having to switch the AC source to single phase mode.

If the Lx or Ls is in single phase mode, this command is equivalent to the the CAL:MEAS:CURR?

query for phase 1/A except it can not be used to perform a calibration. It does not initiate a