Page 1

Model 7280

Wide Bandwidth

DSP Lock-in Amplifier

Instruction Manual

190398-A-MNL-C

Copyright © 2005 AMETEK ADVANCED MEASUREMENT TECHNOLOGY, INC

Page 2

Firmware Version

The instructions in this manual apply to operation of a Model 7280 DSP Lock-in Amplifier that is fitted with

revision 5.0 or later operating firmware. Users of instruments that are fitted with earlier firmware revisions

can update them to the current revision free of charge by downloading an Update Pack from our website

at www.signalrecovery.com The pack includes full instructions for use.

Trademarks

AMETEK® and the b® and a logos are registered trademarks of AMETEK, Inc

Microsoft is a registered trademark, and Windows a trademark, of Microsoft Corporation. National

Instruments is a registered trademark of National Instruments Corporation

FCC Notice

This equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used in

accordance with this manual, may cause interference to radio communications. As temporarily permitted

by regulation, operation of this equipment in a residential area is likely to cause interference, in which case

the user at his own facility will be required to take whatever measures may be required to correct the

interference.

Company Names

SIGNAL RECOVERY is part of Advanced Measurement Technology, Inc, a division of AMETEK, Inc. It

includes the businesses formerly trading as EG&G Princeton Applied Research, EG&G Instruments

(Signal Recovery), EG&G Signal Recovery and PerkinElmer Instruments (Signal Recovery).

Declaration of Conformity

This product conforms to EC Directives 89/336/EEC Electromagnetic Compatibility Directive, amended by

92/31/EEC and 93/68/EEC, and Low Voltage Directive 73/23/EEC amended by 93/68/EEC.

This product has been designed in conformance with the following IEC/EN standards:

EMC: BS EN55011 (1991) Group 1, Class A (CSPIR 11:1990)

BS EN50082-1 (1992):

IEC 801-2:1991

IEC 801-3:1994

IEC 801-4:1988

Safety: BS EN61010-1: 1993 (IEC 1010-1:1990+A1:1992)

Page 3

Table of Contents

Table of Contents

Chapter One, Introduction

1.1 How to Use This Manual.................................................................................................................................. 1-1

1.2 What is a Lock-in Amplifier?........................................................................................................................... 1-2

1.3 Key Specifications and Benefits....................................................................................................................... 1-3

Chapter Two, Installation & Initial Checks

2.1 Installation ........................................................................................................................................................ 2-1

2.1.01 Introduction ............................................................................................................................................. 2-1

2.1.02 Rack Mounting ........................................................................................................................................ 2-1

2.1.03 Inspection ................................................................................................................................................ 2-1

2.1.04 Line Cord Plug ........................................................................................................................................ 2-1

2.1.05 Line Voltage Selection and Line Fuses ................................................................................................... 2-1

2.2 Initial Checks.................................................................................................................................................... 2-3

2.2.01 Introduction ............................................................................................................................................. 2-3

2.2.02 Procedure................................................................................................................................................. 2-3

2.3 Line Frequency Filter Adjustment.................................................................................................................... 2-6

2.3.01 Introduction ............................................................................................................................................. 2-6

2.3.02 Procedure................................................................................................................................................. 2-6

Chapter Three, Technical Description

3.1 Introduction ...................................................................................................................................................... 3-1

3.2 Operating Modes .............................................................................................................................................. 3-1

3.2.01 Introduction ............................................................................................................................................. 3-1

3.2.02 Single Reference / Dual Reference.......................................................................................................... 3-1

3.2.03 Single Harmonic / Dual Harmonic .......................................................................................................... 3-1

3.2.04 Internal / External Reference Mode......................................................................................................... 3-2

3.2.05 Virtual Reference Mode .......................................................................................................................... 3-2

3.3 Principles of Operation..................................................................................................................................... 3-2

3.3.01 Block Diagram......................................................................................................................................... 3-2

3.3.02 Signal Channel Inputs.............................................................................................................................. 3-3

3.3.03 Line Frequency Rejection Filter .............................................................................................................. 3-4

3.3.04 AC Gain and Dynamic Reserve............................................................................................................... 3-4

3.3.05 Anti-Aliasing Filter.................................................................................................................................. 3-6

3.3.06 Main Analog-to-Digital Converter .......................................................................................................... 3-7

3.3.07 Reference Channel................................................................................................................................... 3-7

3.3.08 Phase-Shifter............................................................................................................................................ 3-8

3.3.09 Internal Oscillator - General .................................................................................................................... 3-9

3.3.10 Internal Oscillator - Update Rate............................................................................................................. 3-9

3.3.11 Internal Oscillator - Frequency & Amplitude Sweeps............................................................................. 3-9

3.3.12 Demodulators......................................................................................................................................... 3-10

3.3.13 Output Processor - Output Filters.......................................................................................................... 3-11

3.3.14 Output Processor - Output Offset and Expand ...................................................................................... 3-12

3.3.15 Output Processor - Vector Magnitude and Phase .................................................................................. 3-12

3.3.16 Output Processor - Noise Measurements............................................................................................... 3-13

i

Page 4

TABLE OF CONTENTS

3.3.17 Auxiliary Analog Inputs and Outputs (ADCs and DACs) .................................................................... 3-14

3.3.18 Main Microprocessor - Spectral Display............................................................................................... 3-15

3.3.19 Main Microprocessor - User Settings.................................................................................................... 3-15

3.3.20 Main Microprocessor - General............................................................................................................. 3-15

3.3.21 Main Microprocessor - Auto Functions ................................................................................................ 3-15

3.4 General ........................................................................................................................................................... 3-17

3.4.01 Accuracy................................................................................................................................................ 3-17

3.4.02 Power-up Defaults................................................................................................................................. 3-18

Chapter Four, Front and Rear Panels

4.1 Front Panel ....................................................................................................................................................... 4-1

4.1.01 A and B/I Signal Input Connectors ......................................................................................................... 4-1

4.1.02 OSC OUT Connector .............................................................................................................................. 4-1

4.1.03 REF IN Connector................................................................................................................................... 4-1

4.1.04 Electroluminescent Screen ...................................................................................................................... 4-2

4.1.05 HELP Key ............................................................................................................................................... 4-5

4.1.06 MENU Key.............................................................................................................................................. 4-5

4.1.07 SELECT CONTROL Key....................................................................................................................... 4-5

4.2 Rear Panel......................................................................................................................................................... 4-6

4.2.01 Line Power Switch .................................................................................................................................. 4-6

4.2.02 Line Power Input Assembly .................................................................................................................... 4-6

4.2.03 RS232 Connector .................................................................................................................................... 4-6

4.2.04 AUX RS232 Connector........................................................................................................................... 4-6

4.2.05 GPIB Connector ...................................................................................................................................... 4-7

4.2.06 DIGITAL I/O Connector......................................................................................................................... 4-7

4.2.07 PRE-AMP POWER Connector ............................................................................................................... 4-7

4.2.08 REF MON Connector.............................................................................................................................. 4-7

4.2.09 REF TTL Connector................................................................................................................................ 4-7

4.2.10 DAC 1 and DAC 2 Connectors ............................................................................................................... 4-7

4.2.11 CH 1 and CH 2 Connectors..................................................................................................................... 4-7

4.2.12 ADC 1, ADC 2, ADC 3 and ADC 4 Connectors .................................................................................... 4-8

4.2.13 TRIG Connector ...................................................................................................................................... 4-8

4.2.14 SIG MON Connector............................................................................................................................... 4-8

Chapter Five, Front Panel Operation

5.1 Introduction ...................................................................................................................................................... 5-1

5.2 Menu Structure................................................................................................................................................. 5-2

5.3 Menu Descriptions - Single Reference Mode .................................................................................................. 5-3

5.3.01 Main Display ........................................................................................................................................... 5-3

5.3.02 Control Selection Menu........................................................................................................................... 5-5

5.3.03 Main Menu 1 ........................................................................................................................................... 5-7

5.3.04 Signal Channel Menu .............................................................................................................................. 5-8

5.3.05 Reference Channel Menu ...................................................................................................................... 5-11

5.3.06 Output Filters Menu .............................................................................................................................. 5-12

5.3.07 Output Offset & Expand Menu ............................................................................................................. 5-13

5.3.08 Output Equations Menu......................................................................................................................... 5-15

5.3.09 Oscillator Menu..................................................................................................................................... 5-16

5.3.10 Frequency Sweep Menu ........................................................................................................................ 5-17

ii

Page 5

TABLE OF CONTENTS

5.3.11 Amplitude Sweep Menu ........................................................................................................................ 5-20

5.3.12 Auto Functions Menu ............................................................................................................................ 5-23

5.3.13 Configuration Menu .............................................................................................................................. 5-25

5.3.14 Communications Menu.......................................................................................................................... 5-28

5.3.15 RS232 Settings Menu ............................................................................................................................ 5-28

5.3.16 GPIB Settings Menu.............................................................................................................................. 5-30

5.3.17 Communications Monitor...................................................................................................................... 5-32

5.3.18 Analog Outputs Menu - Single & Virtual Reference Modes................................................................. 5-33

5.3.19 Options Menu ........................................................................................................................................ 5-38

5.3.20 Spectral Display..................................................................................................................................... 5-39

5.3.21 Main Menu 2 ......................................................................................................................................... 5-41

5.3.22 Curve Buffer Menu................................................................................................................................ 5-42

5.3.23 Curve Select Menu ................................................................................................................................ 5-45

5.3.24 Single Graph Menu................................................................................................................................ 5-46

5.3.25 Double Graph Menu .............................................................................................................................. 5-48

5.3.26 User Settings Menu ............................................................................................................................... 5-49

5.3.27 Auxiliary I/O Menu ............................................................................................................................... 5-50

5.3.28 Digital Port Menu .................................................................................................................................. 5-53

5.4 Menu Descriptions - Virtual Reference Mode................................................................................................ 5-54

5.4.01 Virtual Reference Menus....................................................................................................................... 5-54

5.4.02 Main Display - Virtual Reference Mode ............................................................................................... 5-56

5.4.03 Configuration Menu - Virtual Reference Mode .................................................................................... 5-57

5.5 Menu Descriptions - Dual Reference Mode ................................................................................................... 5-57

5.5.01 Dual Reference Setup Menu.................................................................................................................. 5-57

5.5.02 Dual Reference Main Display ............................................................................................................... 5-58

5.5.03 Reference Channel Menu ...................................................................................................................... 5-62

5.5.04 Dual reference Output Filters Menu...................................................................................................... 5-64

5.5.05 Output Offset Ref 1 Menu ..................................................................................................................... 5-65

5.5.06 Output Offset Ref 2 Menu ..................................................................................................................... 5-66

5.5.07 Auto Functions Menu ............................................................................................................................ 5-67

5.5.08 Configuration Menu - Dual Reference Mode........................................................................................ 5-68

5.5.09 Analog Outputs Menu - Dual Reference and Dual Harmonic Modes................................................... 5-68

5.6 Menu Descriptions - Dual Harmonic Mode ................................................................................................... 5-75

5.6.01 Dual Harmonic Setup Menu .................................................................................................................. 5-75

5.6.02 Dual Harmonic Main Display................................................................................................................ 5-76

5.6.03 Reference Channel Menu ...................................................................................................................... 5-80

5.6.04 Dual Harmonic Output Filters Menu..................................................................................................... 5-82

5.6.05 Output Offset Harm 1 Menu.................................................................................................................. 5-83

5.6.06 Output Offset Harm 2 Menu.................................................................................................................. 5-84

5.6.07 Auto Functions Menu ............................................................................................................................ 5-85

5.6.08 Configuration Menu - Dual Harmonic Mode ........................................................................................ 5-86

5.7 Typical Lock-in Amplifier Experiment.......................................................................................................... 5-87

iii

Page 6

TABLE OF CONTENTS

Chapter Six, Computer Operation

6.1 Introduction ...................................................................................................................................................... 6-1

6.2 Capabilities....................................................................................................................................................... 6-1

6.2.01 General .................................................................................................................................................... 6-1

6.2.02 Curve Storage.......................................................................................................................................... 6-1

6.2.03 Curve Display.......................................................................................................................................... 6-1

6.3 RS232 and GPIB Operation ............................................................................................................................. 6-2

6.3.01 Introduction ............................................................................................................................................. 6-2

6.3.02 RS232 Interface - General Features ........................................................................................................ 6-2

6.3.03 Choice of Baud Rate................................................................................................................................ 6-3

6.3.04 Choice of Number of Data Bits ............................................................................................................... 6-3

6.3.05 Choice of Parity Check Option ............................................................................................................... 6-3

6.3.06 Auxiliary RS232 Interface....................................................................................................................... 6-4

6.3.07 GPIB Interface - General Features .......................................................................................................... 6-4

6.3.08 Handshaking and Echoes......................................................................................................................... 6-5

6.3.09 Terminators ............................................................................................................................................. 6-6

6.3.10 Command Format.................................................................................................................................... 6-6

6.3.11 Delimiters ................................................................................................................................................ 6-7

6.3.12 Compound Commands ............................................................................................................................ 6-7

6.3.13 Status Byte, Prompts and Overload Byte ................................................................................................ 6-7

6.3.14 Service Requests...................................................................................................................................... 6-9

6.3.15 Communication Monitor Menu............................................................................................................... 6-9

6.4 Command Descriptions .................................................................................................................................... 6-9

6.4.01 Signal Channel ...................................................................................................................................... 6-10

6.4.02 Reference Channel ................................................................................................................................ 6-12

6.4.03 Signal Channel Output Filters ............................................................................................................... 6-14

6.4.04 Signal Channel Output Amplifiers ........................................................................................................ 6-16

6.4.05 Instrument Outputs ................................................................................................................................ 6-18

6.4.06 Internal Oscillator.................................................................................................................................. 6-21

6.4.07 Auxiliary Outputs.................................................................................................................................. 6-23

6.4.08 Auxiliary Inputs..................................................................................................................................... 6-24

6.4.09 Output Data Curve Buffer ..................................................................................................................... 6-26

6.4.10 Computer Interfaces (RS232 and GPIB)............................................................................................... 6-31

6.4.11 Instrument Identification ....................................................................................................................... 6-33

6.4.12 Front Panel ............................................................................................................................................ 6-33

6.4.13 Auto Default.......................................................................................................................................... 6-33

6.4.14 Dual Mode Commands.......................................................................................................................... 6-34

6.5 Programming Examples ................................................................................................................................. 6-36

6.5.01 Introduction ........................................................................................................................................... 6-36

6.5.02 Basic Signal Recovery........................................................................................................................... 6-36

6.5.03 Frequency Response Measurement ....................................................................................................... 6-36

6.5.04 X and Y Output Curve Storage Measurement....................................................................................... 6-37

6.5.05 Transient Recorder ................................................................................................................................ 6-38

6.5.06 Frequency Response Measurement using Curve Storage and Frequency Sweep ................................. 6-38

iv

Page 7

TABLE OF CONTENTS

Appendix A, Specifications

Appendix B, Pinouts

B1 RS232 Connector Pinout .................................................................................................................................B-1

B2 Preamplifier Power Connector Pinout ..............................................................................................................B-1

B3 Digital Output Port Connector..........................................................................................................................B-2

Appendix C, Demonstration Programs

C1 Simple Terminal Emulator................................................................................................................................C-1

C2 RS232 Control Program with Handshakes .......................................................................................................C-1

C3 GPIB User Interface Program ...........................................................................................................................C-3

Appendix D, Cable Diagrams

D1 RS232 Cable Diagrams......................................................................................................................................D1

Appendix E, Default Settings

Auto Default Function............................................................................................................................................. E1

Appendix F, Alphabetical Listing of Commands

Index

Warranty

...................................................................................................................................... End of Manual

v

Page 8

TABLE OF CONTENTS

vi

Page 9

Introduction

1.1 How to Use This Manual

This manual gives detailed instructions for setting up and operating the

SIGNAL RECOVERY Model 7280 Digital Signal Processing (DSP) dual phase,

wide bandwidth, lock-in amplifier. It is split into the following chapters:-

Chapter 1 - Introduction

Provides an introduction to the manual, briefly describes what a lock-in amplifier is

and the types of measurements it may be used for, and lists the major specifications

of the model 7280.

Chapter 2 - Installation and Initial Checks

Describes how to install the instrument and gives a simple test procedure which may

be used to check that the unit has arrived in full working order.

Chapter 3 - Technical Description

Provides an outline description of the design of the instrument and discusses the

effect of the various controls. A good understanding of the design will enable the

user to get the best possible performance from the unit.

Chapter 1

Chapter 4 - Front and Rear Panels

Describes the instrument’s connectors, controls and indicators as referred to in the

subsequent chapters.

Chapter 5 - Front Panel Operation

Describes the capabilities of the instrument when used as a manually operated unit,

and shows how to operate it using the front panel controls.

Chapter 6 - Computer Operation

This chapter provides detailed information on operating the instrument from a

computer over either the GPIB (IEEE-488) or RS232 interfaces. It includes

information on how to establish communications, the functions available, the

command syntax and a detailed command listing.

Appendix A

Gives the detailed specifications of the unit.

Appendix B

Details the pinouts of the multi-way connectors on the rear panel.

Appendix C

Lists three simple terminal programs which may be used as the basis for more

complex user-written programs.

1-1

Page 10

Chapter 1, INTRODUCTION

Appendix D

Shows the connection diagrams for suitable RS232 null-modem cables to couple the

unit to an IBM-PC or 100% compatible computer.

Appendix E

Provides a listing of the instrument settings produced by using the Auto-Default

functions.

Appendix F

Gives an alphabetical listing of the computer commands for easy reference.

New users are recommended to unpack the instrument and carry out the procedure in

chapter 2 to check that it is working satisfactorily. They should then make themselves

familiar with the information in chapters 3, 4 and 5, even if they intend that the unit

will eventually be used under computer control. Only when they are fully conversant

with operation from the front panel should they then turn to chapter 6 for information

on how to use the instrument remotely. Once the structure of the computer commands

is familiar, appendix F will prove convenient as it provides a complete alphabetical

listing of these commands in a single easy-to-use section.

1.2 What is a Lock-in Amplifier?

In its most basic form the lock-in amplifier is an instrument with dual capability. It

can recover signals in the presence of an overwhelming noise background or

alternatively it can provide high resolution measurements of relatively clean signals

over several orders of magnitude and frequency.

Modern instruments, such as the model 7280, offer far more than these two basic

characteristics and it is this increased capability which has led to their acceptance in

many fields of scientific research, such as optics, electrochemistry, materials science,

fundamental physics and electrical engineering, as units which can provide the

optimum solution to a large range of measurement problems.

The model 7280 lock-in amplifier can function as a:-

AC Signal Recovery Instrument Transient Recorder

Vector Voltmeter Precision Oscillator

Phase Meter Frequency Meter

Spectrum Analyzer Noise Measurement Unit

These characteristics, all available in a single compact unit, make it an invaluable

addition to any laboratory.

1-2

Page 11

1.3 Key Specifications and Benefits

The SIGNAL RECOVERY Model 7280 represents a significant advance in the

application of DSP technology in the design of a lock-in amplifier. Until now,

limitations in the available semiconductor devices have restricted the operating

frequency range of such instruments to at most a few hundred kilohertz. The model

7280, with its use of the latest technology, extends this limit to 2 MHz. What is more,

it does this without compromising any other important specifications.

Key specifications include:

Frequency range: 0.5 Hz to 2.0 MHz

Voltage sensitivity: 10 nV to 1 V full-scale

Current input mode sensitivities: 1 pA to 100 µA full-scale

Line frequency rejection filter

Chapter 1, INTRODUCTION

10 fA to 1 µA full-scale

10 fA to 10 nA full-scale

Dual phase demodulator with X-Y and R-θ outputs

Very low phase noise of < 0.0001

Output time constant: 1 µs to 100 ks

5-digit output readings

Dual reference mode - allows simultaneous measurement of two signals at

different reference frequencies up to 20 kHz, or 800 kHz with option 7280/99 or

2.0 MHz with option 7280/98

Single and dual harmonic mode - allows simultaneous measurement of up to two

different harmonics of a signal at up to 20 kHz, or 800 kHz with option 7280/99

or 2.0 MHz with option 7280/98

Virtual reference mode - allows reference free measurement of signals up to

2.0 MHz

Spectral Display mode shows frequency spectrum of the signal prior to the

demodulators to help in selecting a reference frequency

Direct Digital Synthesizer (DDS) oscillator with variable amplitude and

frequency

°

rms

Oscillator frequency and amplitude sweep generator

8-bit programmable digital I/O port for external system control

Four auxiliary ADC inputs and two auxiliary DAC outputs

1-3

Page 12

Chapter 1, INTRODUCTION

Full range of auto-modes

Non-volatile memory for 8 complete instrument settings

Standard IEEE-488 and RS232 interfaces with RS232 daisy-chain capability for

Large high-resolution electroluminescent display panel with menus for control

Easy entry of numerical control settings using keypad

32,768 point internal curve storage buffer

up to 16 instruments

and display of instrument outputs in both digital and graphical formats

1-4

Page 13

Installation &

Initial Checks

2.1 Installation

2.1.01 Introduction

Installation of the model 7280 in the laboratory or on the production line is very

simple. It can be operated on almost any laboratory bench or be rack mounted, using

the optional accessory kit, at the user's convenience. With an ambient operating

temperature range of 0 °C to 35 °C, it is highly tolerant to environmental variables,

needing only to be protected from exposure to corrosive agents and liquids.

The instrument uses forced-air ventilation and as such should be located so that the

ventilation holes on the sides and rear panels are not obstructed. This condition is

best satisfied by leaving a space of at least 2" (5 cm) between the side and rear panels

and any adjacent surface.

2.1.02 Rack Mounting

Chapter 2

An optional accessory kit, part number K02004, is available from

SIGNAL RECOVERY to allow the model 7280 to be mounted in a standard 19-inch

rack.

2.1.03 Inspection

Upon receipt the model 7280 Lock-in Amplifier should be inspected for shipping

damage. If any is noted, SIGNAL RECOVERY should be notified immediately and

a claim filed with the carrier. The shipping container should be saved for inspection

by the carrier.

2.1.04 Line Cord Plug

A standard IEC 320 socket is mounted on the rear panel of the instrument and a

suitable line cord is supplied.

2.1.05 Line Voltage Selection and Line Fuses

Before plugging in the line cord, ensure that the model 7280 is set to the voltage of

the AC power supply to be used.

A detailed discussion of how to check and, if necessary, change the line voltage

setting follows.

CAUTION: The model 7280 may be damaged if the line voltage is set for 110 V AC

operation and it is turned on with 220 V AC applied to the power input connector.

The model 7280 can operate from any one of four different line voltage ranges, 90110 V, 110-130 V, 200-240 V, and 220-260 V, at 50-60 Hz. The change from one

range to another is made by repositioning a plug-in barrel selector internal to the Line

2-1

Page 14

Chapter 2, INSTALLATION & INITIAL CHECKS

Input Assembly on the rear panel of the unit. Instruments are normally shipped from

the factory with the line voltage selector set to 110-130 V AC, unless they are

destined for an area known to use a line voltage in the 220-260 V range, in which

case, they are shipped configured for operation from the higher range.

The line voltage setting can be seen through a small rectangular window in the line

input assembly on the rear panel of the instrument (figure 2-1). If the number

showing is incorrect for the prevailing line voltage (refer to table 2-1), then the barrel

selector will need to be repositioned as follows.

Observing the instrument from the rear, note the plastic door immediately adjacent to

the line cord connector (figure 2-1) on the left-hand side of the instrument. When the

line cord is removed from the rear-panel connector, the plastic door can be opened

outwards by placing a small, flat-bladed screwdriver in the slot on the right-hand side

and levering gently. This gives access to the fuse and to the voltage barrel selector,

which is located at the right-hand edge of the fuse compartment. Remove the barrel

selector with the aid of a small screwdriver or similar tool. With the barrel selector

removed, four numbers become visible on it: 100, 120, 220, and 240, only one of

which is visible when the door is closed. Table 2-1 indicates the actual line voltage

range represented by each number. Position the barrel selector such that the required

number (see table 2-1) will be visible when the barrel selector is inserted and the door

closed.

Figure 2-1, Line Input Assembly

VISIBLE # VOLTAGE RANGE

100 90 - 110 V

120 110 - 130 V

220 200 - 240 V

240 220 - 260 V

Table 2-1, Range vs. Barrel Position

Next check the fuse rating. For operation from a nominal line voltage of 100 V or

120 V, use a 20 mm slow-blow fuse rated at 2.0 A, 250 V. For operation from a

nominal line voltage of 220 V or 240 V, use a 20 mm slow-blow fuse rated at 1.0 A,

250 V.

To change the fuse, first remove the fuse holder by pulling the plastic tab marked

with an arrow. Remove the fuse and replace with a slow-blow fuse of the correct

voltage and current rating. Install the fuse holder by sliding it into place, making sure

the arrow on the plastic tab is pointing downwards. When the proper fuse has been

installed, close the plastic door firmly. The correct selected voltage setting should

now be showing through the rectangular window. Ensure that only fuses with the

2-2

Page 15

required current and voltage ratings and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is

prohibited and potentially dangerous.

2.2 Initial Checks

2.2.01 Introduction

The following procedure checks the performance of the model 7280. In general, this

procedure should be carried out after inspecting the instrument for obvious shipping

damage.

NOTE: Any damage must be reported to the carrier and to SIGNAL RECOVERY

immediately. In addition the shipping container must be retained for inspection by

the carrier.

Note that this procedure is intended to demonstrate that the instrument has arrived in

good working order, not that it meets specifications. Each instrument receives a

careful and thorough checkout before leaving the factory, and normally, if no

shipping damage has occurred, will perform within the limits of the quoted

specifications. If any problems are encountered in carrying out these checks, contact

SIGNAL RECOVERY or the nearest authorized representative for assistance.

Chapter 2, INSTALLATION & INITIAL CHECKS

2.2.02 Procedure

1) Ensure that the model 7280 is set to the line voltage of the power source to be

used, as described in section 2.1.05.

2) With the rear-panel mounted power switch (located to the right of the line power

input connector) set to 0 (off), plug in the line cord to an appropriate line source.

3) Turn the model 7280 power switch to the I (on) position.

4) The instrument's front panel display will now briefly display the following:-

2-3

Page 16

Chapter 2, INSTALLATION & INITIAL CHECKS

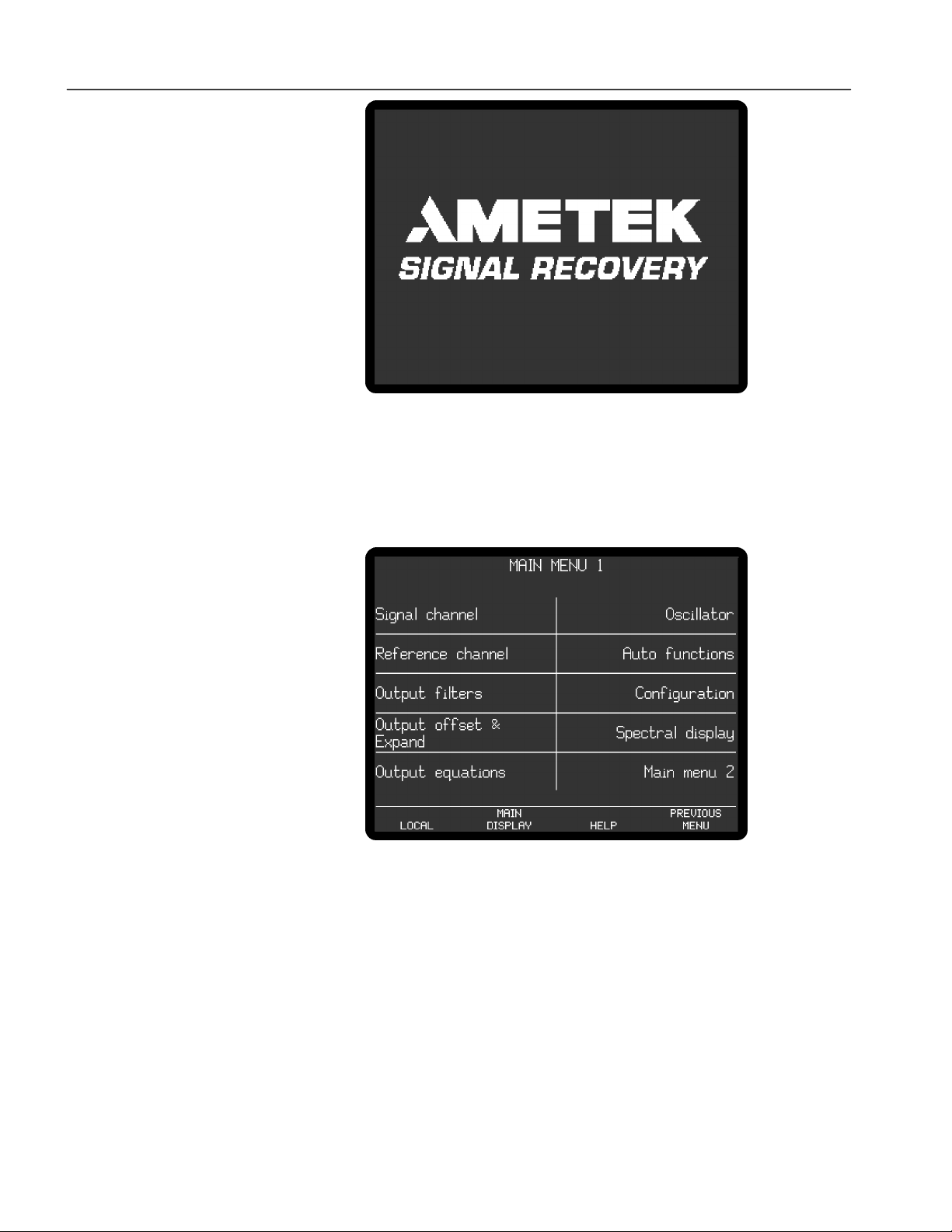

5) Wait until the opening display has changed to the Main Display and then press the

key under the bottom right hand corner of the display identified by the legend

MENU on the display. This enters the first of the two main menus, Main Menu 1,

shown below in figure 2-3.

Figure 2-2, Opening Display

2-4

Figure 2-3, Main Menu 1

6) Press one of the keys adjacent to the Auto functions menu item to enter the Auto

Functions menu, shown below in figure 2-4.

Page 17

Chapter 2, INSTALLATION & INITIAL CHECKS

Figure 2-4, Auto Functions Menu

7) Press one of the keys adjacent to the Auto Default menu item. This will set all of

the instrument's controls and the display to a defined state. The display will

revert to the Main Display, as shown below in figure 2-5, with the right-hand

side showing the vector magnitude, R, and the phase angle, θ, of the measured

signal in digital form, with two bar-graphs showing the X channel output and Y

channel output expressed in millivolts. The left-hand side shows five instrument

controls, these being the AC Gain in decibels, full-scale sensitivity, output time

constant, reference phase and internal oscillator frequency. The resulting

dynamic reserve (DR), in decibels, is also shown.

Figure 2-5, Main Display

8) Connect a BNC cable between the OSC OUT and A input connectors on the

front panel.

2-5

Page 18

Chapter 2, INSTALLATION & INITIAL CHECKS

9) The right-hand side of the display should now indicate R, the vector magnitude,

close to 100% of full-scale (i.e. the sinusoidal oscillator output, which was set to

1 kHz and a signal level of 0.5 V rms by the Auto-Default function, is being

measured with a full-scale sensitivity of 500 mV rms) and θ, the phase angle, of

near zero degrees, if a short cable is used.

This completes the initial checks. Even though the procedure leaves many functions

untested, if the indicated results were obtained then the user can be reasonably sure

that the unit incurred no hidden damage in shipment and is in good working order.

2.3 Line Frequency Filter Adjustment

2.3.01 Introduction

The model 7280 incorporates a line-frequency rejection filter which is normally

supplied set to 60 Hz. If the power line frequency of the country in which the

instrument is to be used is also 60 Hz then the setting does not need to be changed. If,

however, the unit is to be used in an area with a 50 Hz power line frequency the

setting should be changed using the following procedure.

2.3.02 Procedure

1) Turn the model 7280’s power switch to the I (on) position.

2) The instrument's front panel display will now briefly display the following:-

Figure 2-6, Opening Display

2-6

3) Wait until the opening display has changed to the Main Display and then press

the key under the bottom right hand corner of the display identified by the legend

MENU on the display once. This enters the first of the two main menus, Main

Menu 1, shown below in figure 2-7.

Page 19

Chapter 2, INSTALLATION & INITIAL CHECKS

Figure 2-7, Main Menu 1

4) Press one of the keys adjacent to the Configuration menu item to enter the

Configuration menu, shown below in figure 2-8.

Figure 2-8, Configuration Menu

5) The present line frequency setting is shown in reversed text under the

LINE FREQUENCY label and is either 50 or 60 Hz. In figure 2-8, the filter is set

to 60 Hz. If this setting does not match the prevailing line frequency, then press a

key adjacent to this item once to change it.

6) Press the key marked MAIN DISPLAY once to return to the Main Display.

This completes the procedure for adjusting the line frequency filter.

2-7

Page 20

Chapter 2, INSTALLATION & INITIAL CHECKS

2-8

Page 21

Technical Description

3.1 Introduction

The model 7280 lock-in amplifier is a sophisticated instrument with many

capabilities beyond those found in other lock-in amplifiers. This chapter discusses the

various operating modes provided and then describes the design of the instrument by

considering it as a series of functional blocks. In addition to describing how each

block operates, the sections also include information on the effect of the various

controls.

3.2 Operating Modes

3.2.01 Introduction

The model 7280 incorporates a number of different operating modes which are

referred to in the following technical description, so in order to help the reader's

understanding they are defined here.

3.2.02 Single Reference / Dual Reference

Chapter 3

Conventionally, a lock-in amplifier makes measurements such as signal magnitude,

phase, etc. on the applied signal at a single reference frequency. In the model 7280

this is referred to as the single reference mode.

The dual reference mode incorporated in the model 7280 allows the instrument to

make simultaneous measurements at two different reference frequencies, an ability

that previously required two lock-in amplifiers. This flexibility incurs a few

restrictions, such as the requirement that one of the reference signals be external and

the other be derived from the internal oscillator, the limitation of the maximum

operating frequency to 20 kHz (unless the unit is equipped with the -/99 or -/98

extended frequency options) and the requirement that both signals be passed through

the same input signal channel. This last restriction implies either that both signals are

derived from the same detector (for example two chopped light beams falling onto a

single photodiode) or that they can be summed prior to measurement, either

externally or by using the differential input mode of the instrument. Nevertheless, the

mode will prove invaluable in many experiments.

3.2.03 Single Harmonic / Dual Harmonic

Normally, a lock-in amplifier measures the applied signal at the reference frequency.

However, in some applications such as Auger Spectroscopy and amplifier

characterization, it is useful to be able to make measurements at some multiple n, or

harmonic, of the reference frequency, f. The model 7280 allows this multiple to be set

to any value between 2 (i.e. the second harmonic) and 32, as well as unity, which is

the normal mode. The only restriction is that the product n × f cannot exceed 2 MHz.

Dual harmonic mode allows the simultaneous measurement of two different

harmonics of the input signal. As with dual reference mode, there are a few

restrictions, such as a maximum value of n × f of 20 kHz (800 kHz with the option /99 or 2 MHz with the option -/98).

3-1

Page 22

Chapter 3, TECHNICAL DESCRIPTION

3.2.04 Internal / External Reference Mode

In the internal reference mode, the instrument's reference frequency is derived from

its internal oscillator and the oscillator signal is used to drive the experiment.

In the external reference mode, the experiment includes some device, for example an

optical chopper, which generates a reference frequency that is applied to one of the

lock-in amplifier's external reference inputs. The instrument's reference channel

"locks" to this signal and uses it to measure the applied input signal.

3.2.05 Virtual Reference Mode

If the instrument is operated in internal reference mode, measuring a signal which is

phase-locked to the internal oscillator, with the reference phase correctly adjusted,

then it will generate a stable non-zero X channel output and a zero Y channel output.

If, however, the signal is derived from a separate oscillator, then the X channel and

Y channel outputs will show variations at a frequency equal to the difference between

the signal and internal oscillator frequencies. If the latter is now set to be equal to the

former then in principle the variation in the outputs will cease, but in practice this

will not happen because of slow changes in the relative phase of the two oscillators.

In the virtual reference mode, believed to be unique to SIGNAL RECOVERY lockin amplifiers, the Y channel output is used to make continuous adjustments to the

internal oscillator frequency and phase to achieve phase-lock with the applied signal,

such that the X channel output is maximized and the Y channel output zeroed.

If the instrument is correctly adjusted, particularly ensuring that the full-scale

sensitivity control is maintained at a suitable setting in relation to changes in the

signal level, then the virtual reference mode is capable of making signal recovery

measurements which are not possible with most other lock-in amplifiers.

3.3 Principles of Operation

3.3.01 Block Diagram

The model 7280 uses digital signal processing (DSP) techniques implemented in

field-programmable gate arrays (FPGA), a microprocessor and very low-noise analog

circuitry to achieve its specifications. A block diagram of the instrument is shown in

figure 3-1. The sections that follow describe how each functional block operates and

the effect it has on the instrument's performance.

3-2

Page 23

Chapter 3, TECHNICAL DESCRIPTION

Figure 3-1, Model 7280 - Block Diagram

3.3.02 Signal Channel Inputs

The signal input amplifier can be set for either single-ended or differential voltage

mode operation, or single-ended current mode operation. In voltage mode a choice of

AC or DC coupling is available using an FET input device. In current mode a choice

of three conversion gains is available to give optimum matching to the applied signal.

In both modes the input connector shells may be either floated via a 1 kΩ resistor or

grounded to the instrument's chassis ground. These various features are discussed in

the following paragraphs.

Input Connector Selection, A / -B / A - B

When set to the A mode, the lock-in amplifier measures the voltage between the

center and the shell of the A input BNC connector, whereas when set to the A-B

mode it measures the difference in voltage between the center pins of the A and B/I

input BNC connectors.

The latter, differential, mode is often used to eliminate ground loops, although it is

worth noting that at very low signal levels it may be possible to make a substantial

reduction in unwanted offsets by using this mode with a short-circuit terminator on

the B/I connector, rather than by simply using the A input mode.

The specification defined as the Common Mode Rejection Ratio, C.M.R.R., describes

how well the instrument rejects common mode signals applied to the A and B/I

inputs when operating in differential input mode. It is usually given in decibels.

Hence a specification of > 100 dB implies that a common mode signal (i.e. a signal

simultaneously applied to both A and B/I inputs) of 1 V will give rise to less than

10 µV of signal out of the input amplifier.

The input can also be set to the -B mode, in which case the lock-in amplifier

measures the voltage between the center and the shell of the B/I input connector. This

extra mode effectively allows the input to be multiplexed between two different

3-3

Page 24

Chapter 3, TECHNICAL DESCRIPTION

single-ended signals, subject to the limitation that the user must allow for the signal

inversion (equivalent to a 180° phase-shift) which it introduces when reading the

outputs.

Input Connector Shell, Ground / Float

The input connector shells may be connected either directly to the instrument's

chassis ground or floated via a 1 kΩ resistor. When in the float mode, the presence of

this resistor substantially reduces the problems which often occur in low-level lock-in

amplifier measurements due to ground loops.

Input Coupling Mode, Fast/Slow

When the input coupling mode is set to Slow, the signal channel gain is essentially

flat down to 0.5 Hz, but recovery from input overload conditions may take a long

time. Conversely, when the coupling mode is set to Fast, recovery from overload is

much faster, but there will be a noticeable roll-off in magnitude response and

significant phase shifts at frequencies below typically 20 Hz.

Input Signal Selection, V / I

Although the voltage mode input is most commonly used, a current-to-voltage

converter may be switched into use to provide current mode input capability, in

which case the signal is connected to the B/I connector. High impedance sources

(> 100 kΩ) are inherently current sources and need to be measured with a low

impedance current mode input. Even when dealing with a voltage source in series

with a high impedance, the use of the current mode input may provide advantages in

terms of improved bandwidth and immunity from the effects of cable capacitance.

The converter may be set to low-noise, normal or wide bandwidth conversion

settings, but it should be noted that if the best possible performance is required a

separate current preamplifier, such as the SIGNAL RECOVERY models 181 or

5182, should be considered.

3.3.03 Line Frequency Rejection Filter

Following the signal input amplifier there is an option to pass the signal through a

line frequency rejection filter, which is designed to give greater than 40 dB of

attenuation at the power line frequencies of 50 Hz or 60 Hz and their second

harmonics at 100 Hz and 120 Hz.

The filter uses two cascaded rejection stages with "notch" characteristics, allowing it

to be set to reject signals at frequencies equal to either of, or both of, the fundamental

and second harmonic of the line frequency.

Instruments are normally supplied with the line frequency filter set to 60 Hz with the

filter turned off. If the prevailing line frequency is 50 Hz then the filter frequency

should be set to this value using the control on the Configuration menu (see section

2.3).

3.3.04 AC Gain and Dynamic Reserve

3-4

The signal channel contains a number of analog filters and amplifiers whose overall

gain is defined by the AC Gain parameter, which is specified in terms of decibels

(dB). For each value of AC Gain there is a corresponding value of the INPUT LIMIT

Page 25

Chapter 3, TECHNICAL DESCRIPTION

parameter, which is the maximum instantaneous (peak) voltage or current that can be

applied to the input without causing input overload, as shown in table 3-1 below.

AC Gain (dB) INPUT LIMIT (mV)

0 1600

6 800

14 320

20 160

26 80

34 32

40 16

46 8

54 3.2

60 1.6

66 0.8

Table 3-1, Input Limit vs. AC Gain

It is a basic property of the digital signal processing (DSP) lock-in amplifier that the

best demodulator performance is obtained by presenting as large a signal as possible

to the main analog-to-digital converter (ADC). Therefore, in principle, the AC Gain

value should be made as large as possible without causing the signal channel

amplifier or converter to overload. This constraint is not too critical however and the

use of a value one or two steps below the optimum value makes little difference. Note

that as the AC Gain value is changed, the demodulator gain (described later in section

3.3.12) is also adjusted in order to maintain the selected full-scale sensitivity.

The full-scale sensitivity is set by a combination of AC Gain and demodulator gain.

Since the demodulator gain is entirely digital, changes in full-scale sensitivity which

do not change the AC Gain do not cause any of the errors which might arise from a

change in the AC Gain.

The user is prevented from setting an illegal AC Gain value, i.e. one that would result

in overload on a full-scale input signal. Similarly, if the user selects a full-scale

sensitivity which causes the present AC Gain value to be illegal, the AC Gain will

change to the nearest legal value.

In practice, this system is very easy to operate. However, the user may prefer to make

use of the AUTOMATIC AC Gain feature which gives very good results in most

cases. When this is active the AC Gain is automatically controlled by the instrument,

which determines the optimum setting based on the full-scale sensitivity currently

being used.

At any given setting, the ratio

0.7DR ×=

LimitInput

ySensitivit Scale-Full

represents the factor by which the largest acceptable sinusoidal interference input

exceeds the full-scale sensitivity and is called the Dynamic Reserve of the lock-in

amplifier at that setting. (The factor 0.7 is a peak-to-rms conversion). The dynamic

3-5

Page 26

Chapter 3, TECHNICAL DESCRIPTION

reserve is often expressed in decibels, for which

Applying this formula to the model 7280 at the maximum value of INPUT LIMIT

(1.6 V) and the smallest available value of FULL-SCALE SENSITIVITY (10 nV),

gives a maximum available dynamic reserve of about 1 × 10

this magnitude are available from any DSP lock-in amplifier but are based only on

arithmetical identities and do not give any indication of how the instrument actually

performs. In fact, all current DSP lock-in amplifiers become too noisy and inaccurate

for most purposes at reserves of greater than about 100 dB.

For the benefit of users who prefer to have the AC Gain value expressed in decibels,

the model 7280 displays the current value of Dynamic Reserve (DR) in this form, on

the input full-scale sensitivity control, for values up to 100 dB. Above 100 dB the

legend changes to “DR>100”.

3.3.05 Anti-Aliasing Filter

Prior to the main analog-to-digital converter (ADC) the signal passes through an antialiasing filter to remove unwanted frequencies which would cause a spurious output

from the ADC as a result of the sampling process.

))ratio a log(DR(as20dB)DR(in ×=

8

or 160 dB. Figures of

Consider the situation when the lock-in amplifier is measuring a sinusoidal signal of

frequency f

Hz. In order to ensure correct operation of the instrument the output values

f

sampling

representing the f

Hz, which is sampled by the main ADC at a sampling frequency

signal

frequency must be uniquely generated by the signal to be

signal

measured, and not by any other process.

However, if the input to the ADC has, in addition, an unwanted sinusoidal signal

with frequency f

Hz, where f1 is greater than half the sampling frequency, then this

1

will appear in the output as a sampled-data sinusoid with frequency less than half the

sampling frequency, f

= |f1 - nf

alias

indistinguishable from the output generated when a genuine signal at frequency f

|, where n is an integer. This alias signal is

sampling

alias

is sampled. Hence if the frequency of the unwanted signal were such that the alias

signal frequency produced from it was close to, or equal to, that of the wanted signal

then it is clear that a spurious output would result.

For example, if the sampling frequency were 7.5 MHz then half the sampling

frequency would be 3.75 MHz. Assume for a moment that the instrument could

operate at reference frequencies up to 3.75 MHz and let it be measuring a signal of

40 kHz accompanied by an interfering signal of 3.7 MHz. The output of the ADC

would therefore include a sampled-data sinusoid of 40 kHz (the required signal) and,

applying the above formula, an alias signal of 0.05 MHz, or 50 kHz (i.e. |3.75 MHz -

3.7 MHz|). If the signal frequency were now increased towards 50 kHz then the

output of the lock-in amplifier would increasingly be affected by the presence of the

alias signal and the accuracy of the measurement would deteriorate.

3-6

To overcome this problem the signal is fed through the anti-aliasing filter which

restricts the signal bandwidth to an upper frequency of 2.0 MHz The filter is a

conventional elliptic-type, low-pass, stage, giving the lowest possible noise

Page 27

Chapter 3, TECHNICAL DESCRIPTION

bandwidth.

It should be noted that the dynamic range of a lock-in amplifier is normally so high

that practical anti-alias filters are not capable of completely removing the effect of a

full-scale alias. For instance, even if the filter gives 100 dB attenuation, an alias at the

input limit and at the reference frequency will give a one percent output error when

the dynamic reserve is set to 60 dB, or a ten percent error when the dynamic reserve

is set to 80 dB.

In a typical low-level signal recovery situation, many unwanted inputs need to be

dealt with and it is normal practice to make small adjustments to the reference

frequency until a clear point on the frequency spectrum is reached. In this context an

unwanted alias is treated as just another interfering signal and its frequency is

avoided when setting the reference frequency.

A buffered version of the analog signal just prior to the main ADC is available at the

signal monitor (SIG MON) connector on the rear panel; it may be viewed on an

oscilloscope to monitor the effect of the line frequency rejection and anti-aliasing

filters and signal-channel amplifiers.

3.3.06 Main Analog-to-Digital Converter

Following the anti-alias filter the signal passes to the main analog-to-digital converter

running at a sampling rate of 7.5 MHz. The output from the converter feeds the

demodulator circuitry, which uses DSP techniques to implement the digital

multipliers and the first stage of the output low-pass filtering for each of the X and Y

channels.

The ADC output also passes to the output processor to allow the power spectral

density of the input signal to be calculated using a discrete Fourier transform, which

in many ways is similar to a fast Fourier transform (FFT). The results of this

calculation are shown on the Spectral Display menu.

However, before discussing the demodulators and the output stages of the lock-in

amplifier, the reference channel which provides the other input to the demodulators,

will be described.

3.3.07 Reference Channel

The reference channel in the instrument is responsible for implementing the reference

trigger/phase-locked loop, digital phase-shifter and internal oscillator look-up table

functional blocks on the block diagram (see figure 3-1). The processor generates a

series of phase values, output at a rate of one every 133 ns, which are used to drive

the reference channel inputs of the demodulators.

In dual reference mode operation, an externally derived reference frequency is

connected to the external reference input and a second reference is derived from the

internal oscillator. The reference circuit generates new phase values for each

individual channel and sends these to the demodulators. Further discussion of dual

reference mode occurs in section 3.3.12.

In single harmonic mode, the reference circuit generates the phase values of a

3-7

Page 28

Chapter 3, TECHNICAL DESCRIPTION

waveform at the selected harmonic of the reference frequency. Dual harmonic mode

operates in a similar way to dual reference mode, but in this case the reference circuit

generates phase values for both of the selected harmonics of the reference frequency.

Dual harmonic mode may therefore be used with either internal or external

references.

External Reference Mode

In external reference mode the reference source may be applied to either a general

purpose input, designed to accept virtually any periodic waveform with a 50:50

mark-space ratio and of suitable amplitude, or to a TTL-logic level input. Following

the trigger buffering circuitry the reference signal is passed to a digital phase-locked

loop (PLL) implemented in the reference circuit. This measures the period of the

applied reference waveform and from this generates the phase values.

Internal Reference Mode

With internal reference operation the reference circuit is free-running at the selected

reference frequency and is not dependent on a phase-locked loop (PLL), as is the case

in most other lock-in amplifiers. Consequently, the phase noise is extremely low, and

because no time is required for a PLL to acquire lock, reference acquisition is

immediate.

Both the signal channel and the reference channel contain calibration parameters

which are dependent on the reference frequency. These include corrections to the

anti-alias filter and to the analog circuits in the reference channel. In external

reference operation the processor uses a reference frequency meter to monitor the

reference frequency and updates these parameters when a change of about 2 percent

has been detected.

A TTL logic signal at the present reference frequency is provided at the REF MON

connector on the rear panel.

3.3.08 Phase-Shifter

The reference circuit also implements a digital reference phase-shifter, allowing the

phase values being sent to the demodulator DSP to be adjusted to the required value.

If the reference input is a sinusoid applied to the REF IN socket, the reference phase

is defined as the phase of the X demodulation function with respect to the reference

input.

This means that when the reference phase is zero and the signal input to the

demodulator is a full-scale sinusoid in phase with the reference input sinusoid, the X

channel output of the demodulator is a full-scale positive value and the Y channel

output is zero.

3-8

The circuits connected to the REF IN socket detect a positive-going crossing of the

mean value of the applied reference voltage. Therefore when the reference input is

not sinusoidal, its effective phase is the phase of a sinusoid with a positive-going zero

crossing at the same point in time, and accordingly the reference phase is defined

with respect to this waveform. Similarly, the effective phase of a reference input to

the TTL REF IN socket is that of a sinusoid with a positive-going zero crossing at

the same point in time.

Page 29

Chapter 3, TECHNICAL DESCRIPTION

In basic lock-in amplifier applications the purpose of the experiment is to measure

the amplitude of a signal which is of fixed frequency and whose phase with respect to

the reference input does not vary. This is the scalar measurement, often implemented

with a chopped optical beam. Many other lock-in amplifier applications are of the

signed scalar type, in which the purpose of the experiment is to measure the

amplitude and sign of a signal which is of fixed frequency and whose phase with

respect to the reference input does not vary apart from reversals of phase

corresponding to changes in the sign of the signal. A well-known example of this

situation is the case of a resistive bridge, one arm of which contains the sample to be

measured. Other examples occur in derivative spectroscopy, where a small

modulation is applied to the angle of the grating (in optical spectroscopy) or to the

applied magnetic field (in magnetic resonance spectroscopy). Double beam

spectroscopy is a further common example.

In this signed scalar measurement the phase-shifter must be set, after removal of any

zero errors, to maximize the X channel or the Y channel output of the demodulator.

This is the only method that will give correct operation as the output signal passes

through zero, and is also the best method to be used in an unsigned scalar

measurement where any significant amount of noise is present.

3.3.09 Internal Oscillator - General

The model 7280, in common with many other lock-in amplifiers, incorporates an

internal oscillator which may be used to drive an experiment. However, unlike most

other instruments, the oscillator in the model 7280 is digitally synthesized with the

result that the output frequency is extremely accurate and stable. The oscillator

operates over the same frequency range as the lock-in amplifier, that is 500 mHz to

2.0 MHz, and is implemented using a dedicated direct digital synthesis circuit.

3.3.10 Internal Oscillator - Update Rate

The direct digital synthesis (DDS) technique generates a waveform at the DAC

output which is not a pure sinusoid, but rather a stepped approximation to one. This

is then filtered by the buffer stage, which follows the DAC, to reduce the harmonic

distortion to an acceptable level. The update rate is 22.5 MHz.

3.3.11 Internal Oscillator - Frequency & Amplitude Sweeps

The internal oscillator output may be swept in both frequency and amplitude. In both

cases the sweeps take the form of a series of steps between starting and finishing

values. Frequency sweeps may use equal increment step sizes, giving a linear change

of frequency with time as the sweep proceeds, or may use step sizes proportional to

the present frequency, which produces a logarithmic sweep. The amplitude sweep

function offers only linear sweeps.

A special form of the frequency sweep function is used to acquire lock when the

instrument is operating in the virtual reference mode. When this "seek" sweep is

activated, the oscillator starts at a user-specified frequency, which should be just

below that of the applied signal, and increments until the calculated magnitude output

is greater than 50%. At this point the sweep then stops and the virtual reference mode

achieves lock, by continuously adjusting the internal oscillator frequency to maintain

the Y channel output at zero.

3-9

Page 30

Chapter 3, TECHNICAL DESCRIPTION

It is important to note that this type of phase-locked loop, unlike a conventional edgetriggered type using a clean reference, does not automatically re-acquire lock after it

has been lost. Lock can be lost as a result of a signal channel transient or a phase

reversal of the signal, in which case it may be necessary to repeat the lock acquisition

procedure. However, if the measurement system is set up with sufficient precautions,

particularly ensuring that the full-scale sensitivity is maintained at a suitable setting

in relation to the signal level, then the virtual reference mode is capable of making

signal recovery measurements which are not possible with other lock-in amplifiers.

When virtual reference mode is in use, the signal at the OSC OUT connector is a

sinusoid which is phase-locked to the signal. Naturally, this cannot be used as a

source for the measurement.

3.3.12 Demodulators

The essential operation of the demodulators is to multiply the digitized output of the

signal channel by data sequences, called the X and Y demodulation functions, and to

operate on the results with digital low-pass filters (the output filters). The

demodulation functions, which are derived by use of a look-up table from the phase

values supplied by the reference channel DSP, are sinusoids with a frequency equal

to an integer multiple, n × f, of the reference frequency f. The Y demodulation

function is the X demodulation function delayed by a quarter of a period. The integer

n is called the reference harmonic number and in normal lock-in amplifier operation

is set to unity. Throughout this chapter, the reference harmonic number is assumed to

be unity unless otherwise stated.

The outputs from the X channel and Y channel multipliers feed the first stage of the

X channel and Y channel output filters, implemented as Finite Impulse Response

(FIR) stages with selectable 6 or 12 dB/octave roll-off. The filtered X channel signal

drives a 16-bit DAC that, for short time-constant settings, generates the signal at the

instrument's CH 1 analog output connector. Both signals are combined by a fast

magnitude algorithm and a switch then allows either the filtered Y channel signal or

the magnitude signal, again when using short time-constant settings, to be passed to a

second 16-bit DAC to give the signal at the instrument's CH 2 analog output. The

significance of the magnitude output is discussed later in section 3.3.15.

In addition the X and Y channel signals are fed to further low-pass filters before

subsequent processing by the instrument’s host microprocessor.

The demodulator output is digitally scaled to provide the demodulator gain control.

As discussed earlier in section 3.3.04 this gain is adjusted as the AC Gain is adjusted

to maintain a given full-scale sensitivity.

In dual reference and dual harmonic modes, the demodulators generate two sets of

outputs, one for each of the two references or harmonics, and includes two sets (four

channels) of initial output filtering. These outputs are passed to the host processor for

further processing and, when the time constant is less than 1 ms, the X

and X

1

2

outputs are also converted by fast DACs to analog signals that appear at the CH 1

and CH 2 analog output connectors.

3-10