Page 1

7250X Digital Stik Sensor Data Sheet

Proven Magnetostrictive Sensing Performance

in a Revolutionary New Package

7250 Series

The 7250X Digital Stik takes f eld proven

magnetostrictive sensing technology

and packages it in a revolutionary new

way for greater reliability and easier

installation and mounting. It is ideal for

liquid level monitoring, interface level and

leak detection in a variety of liquid media

in both above ground and underground

storage tanks.

The 7250X Digital Stik combines low

power consumption with a patented high

resolution design. It requires only 5 volts

DC making it ideal for mobile, battery

operated and wireless applications.

The system has been designed to meet

EPA Leak Detection and API Inventory

Monitoring requirements and has

been approved for use in hazardous

environments.

The sensor’s electronics are SMT

components and integrated into a 5/8”

diameter sensing tube. This breakthrough

design eliminates the bulky electronics

enclosure at the top of the sensor and

offers greater options for insertion and

mounting.

The probe is constructed of 316 Stainless

Steel and comes with a variety of

connectors, including a mini connector

for quick connect applications, a single

3/4” NPT that can be used with a

compression f tting, a double 3/4” NPT for

mounting with a f ange or bushing, and a

1/2” right angle for use in low overhead

applications.

The 7250 communicates through a

single signal. The data is transmitted via

asynchronous serial communications

and is offered with serial protocol options

including an ASCII format. There are

other options available to OEMs for use

in developing a communications interface

with the probe. The patented design

allows for very high resolution on a low

power budget. The resolution of the 7250X

is 0.0001” with a linearity of 0.01% (See

specif cations).

Factory Mutual (FM) certif ed that the

7250X Digital Stik is Intrinsically Safe for

use in ethylene and propane (petroleum)

applications (See specif cations). The

7250X has been approved to the following

standards:

CSA C22.2 Nos. 25,142,157 and 213

FM 3600, 3610, 3611 and 3810

Cenelec EN 50014, 50020 and 50284

The 7250X has an inherently lower cost

design which results in savings. It provides

the same performance and reliability

as sensors that consume more power.

Combining low power requirements with

high resolution provides the ultimate

performance and reliability.

Specifi cations

Power Supply

Voltage

Current (at +5 VDC)

Operating Temperature

Sensing Area

Electronics Area

Pressure Rating

Resolution

Repeatability

Linearity

Hysteresis

Null Zone

Dead Band

Intrinsically Safe Barrier

Enclosure Material

Rating

+5 VDC ± 10% typical (+3.7 VDC min.)

10mA max. (8mA typical) plus

1.5mA max. (1mA typical) per temperature

sensor

-40°C to 100°C (Non Hazardous Location)

-40°C to 70°C (Hazardous Location)

-40°C to 70°C

Steel Probe: 1000 psi max.

Float: Dependent. Call Factory.

0.0001” (Protocol Dependent)

Equal to Resolution

Probes up to 288”: ± 0.01% of span

or ± 0.015”, whichever is greater.

Probes up to 288”: ± 0.002% of span

or ± 0.005”, whichever is greater.

R Style: 9”

D, S and M Style: 8”

2”

See Installation Drawing E0241200.

Consult Factory.

316 Stainless Steel IP68

Specifi cations are subject to change without notice. Patented.

Probe Length

Stainless Steel R Style

Stainless Steel D, S, M Style

(Probes available in 1” increments)

Hazardous Areas Approvals

FM

-40° O Tamb O 70° C

Class I, II, III, Div. 1

Groups C, D, E, F, G, T4

Class I, Div. 2

Groups A, B, C, D, T4

Class I, Zone 0, AEx ia IIB T4

ATEX

Ex ia IIB T4

NEMKO 05 ATEX 1219X

0344

II 1G

Sanitary Approvals

(3A

74-03)

21” to 288”

20” to 288”

Consult Factory for

longer lengths

AUTOMATION & PROCESS TECHNOLOGIES

®

Page 2

7250X Digital Stik Stainless Steel Sensor

7250X.D5R

05/12.Z193

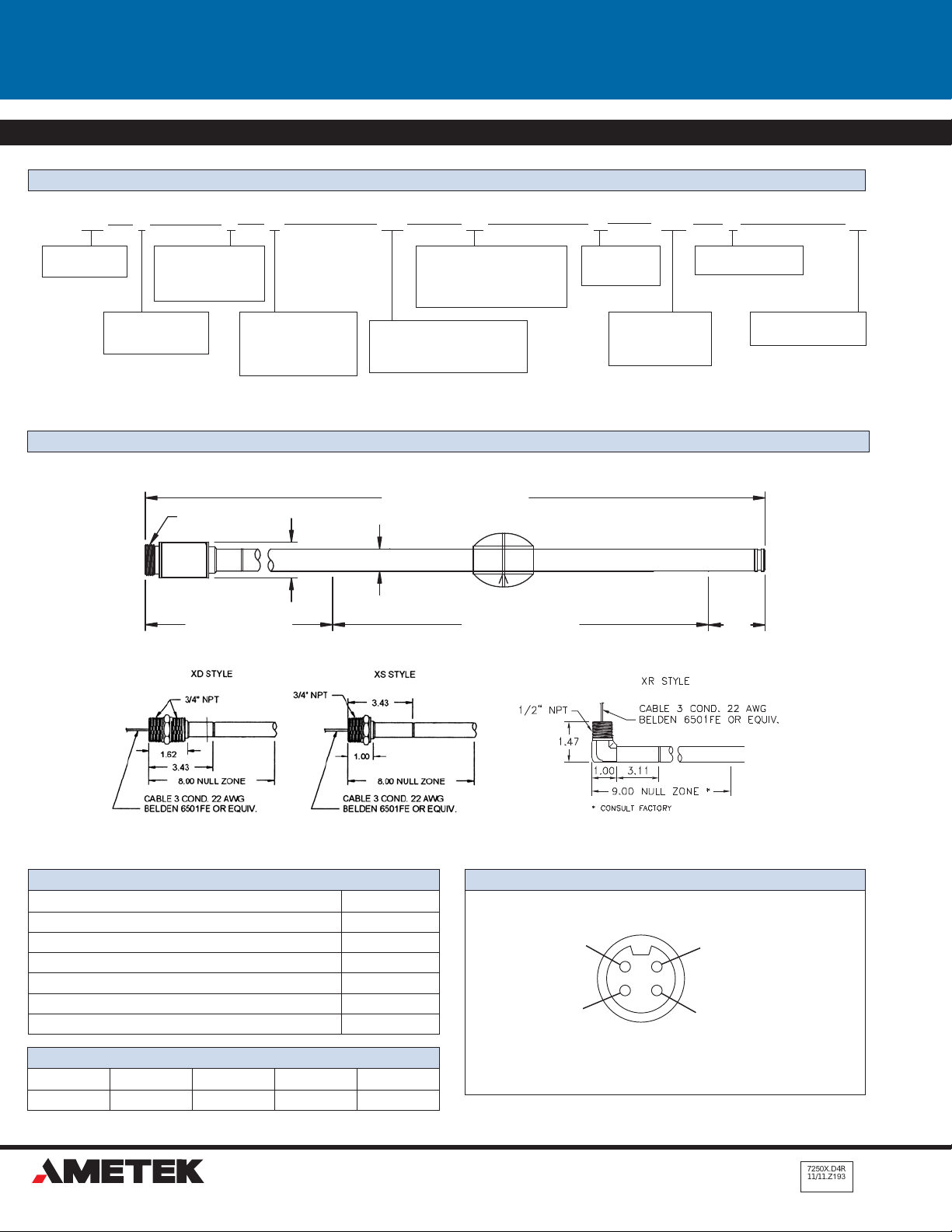

Part Numbering

725 0 X M LLL F1 XXX X XX

7250

Digital Stik

Output Protocol

2 = 25 level readings

5 = 10 level readings

Style/Material

X = 316 Stainless Steel

Consult factory for other

options.

Connector Style

M = 4 Pin Mini

R = 1/2” NPT Right Angle

D = 3/4” NPT Dual

S = 3/4” NPT Single

Span

In 1” increments

i.e. 072 = 72” (Min 8” Max 278”. Max

span is equal to overall length -10)

RX

Number of Temp Points

R1 = 1 Sensor,18”*

R5 = 5 Sensors

T1 = 1 Sensor, 4”*

*From the bottom of the probe.

# of Floats

F1 = 1 Float

F2 = 2 Floats

Overall Length

In 1” increments

i.e. 072 = 72”

(Min 18” Max 288”)

Mounting Style

X = None

Special Mounting

XX = None

Dimension Drawing

M Connector

M STYLE

OVERALL LENGTH (O.A.L.)

7/8-16 UNS-2A

1.00

8.00" NULL ZONE

.625

TEMPERATURE SPAN

2.00"

DEAD

BAND

Accessories

Item Part Number

Float Kit, 316 SS, 2.05” Diameter w/ E Clip and Spacer 0.54s.g. SD0515000

Float Kit, Nitrophyl, 2.02” Diameter w/ E Clip and Spacer 0.40s.g. SD0536500

Cable Assembly, 4 pin, 6 feet long (M style only) 01533141

Adjustable Tube Coupling 5/8” x 3/4” NPT 04283800

Junction Box, side mount, N4X with zero & span push buttons SD0536101

Bushing, 3/4” x 2” NPT 316SS 04587241

Intrinsically Safe Entity Parameters

V

max

I

max

7.93 V 280mA 1.0 W 30.1μF0μH

AUTOMATION & PROCESS TECHNOLOGIES

P

I

®

1080 N. Crooks Road, Clawson, MI 48017-1097

Phone: 248.435.0700 Toll Free: 800.635.0289 Fax: 248.435.8120 www.ametekapt.com

Copyright 2011 by AMETEK Automation & Process Technologies. All Rights Reserved.

C

I

Wiring Diagram

Common

(Black wire)

1

Data Signal

(White wire)

243

Connector View

Contact Factory for additional drawings.

L

I

Drain

(Cable Shield, chassis

gorund on ss housing

probes)

Power

(Red wire)

7250X.D5

.Z193

Loading...

Loading...