Page 1

INSTALLATION MANUAL

R

ESOLVER

& LDT I

NTERFACING

2120

PLC Interface Module

Series 2120

Series 956

ABSOLUTE PROCESS CONTROL

KNOW WHERE YOU ARE... REGARDLESS

Page 2

1080 North Crooks Road

Clawson, MI 48017-1097

Phone: (248) 435-0700

FAX: (248) 435-8120

Internet: www.ametekapt.com

www.ametek.com

Preface

This manual is divided into four parts. Part 1 provides an introduction for the Theory and

Operation of the Series 2120 PLC Interface Module. Part 2 contains a Hardware Overview.

Part 3 explains the Mounting and Wiring of the 2120 PLC Interface Module. Part 4 provides

the Programming Instructions. Also included are four Appendixes; Error Messages, Function

Summary Chart, Catalog Numbering System, and Specifi cations. A glossary and index are also

provided at the back of this manual.

Disconnect power before servicing. The Gemco Series 2120 contains no servicable

components other than the power supply fuse. Consult factory for repair or replacement.

Copyright 1997, 1998, 1999, 2001 by AMETEK

All Rights Reserved - Made in the U.S.A.

Version 0.3

AMETEK has checked the accuracy of this manual at the time it was printed. Any comments you may

have for the improvement of this manual are welcomed.

AMETEK reserves the right to revise and redistribute the entire contents or selected pages of this manual.

All rights to the contents of this manual are reserved by AMETEK.

i Installation and Programming Manual

Page 3

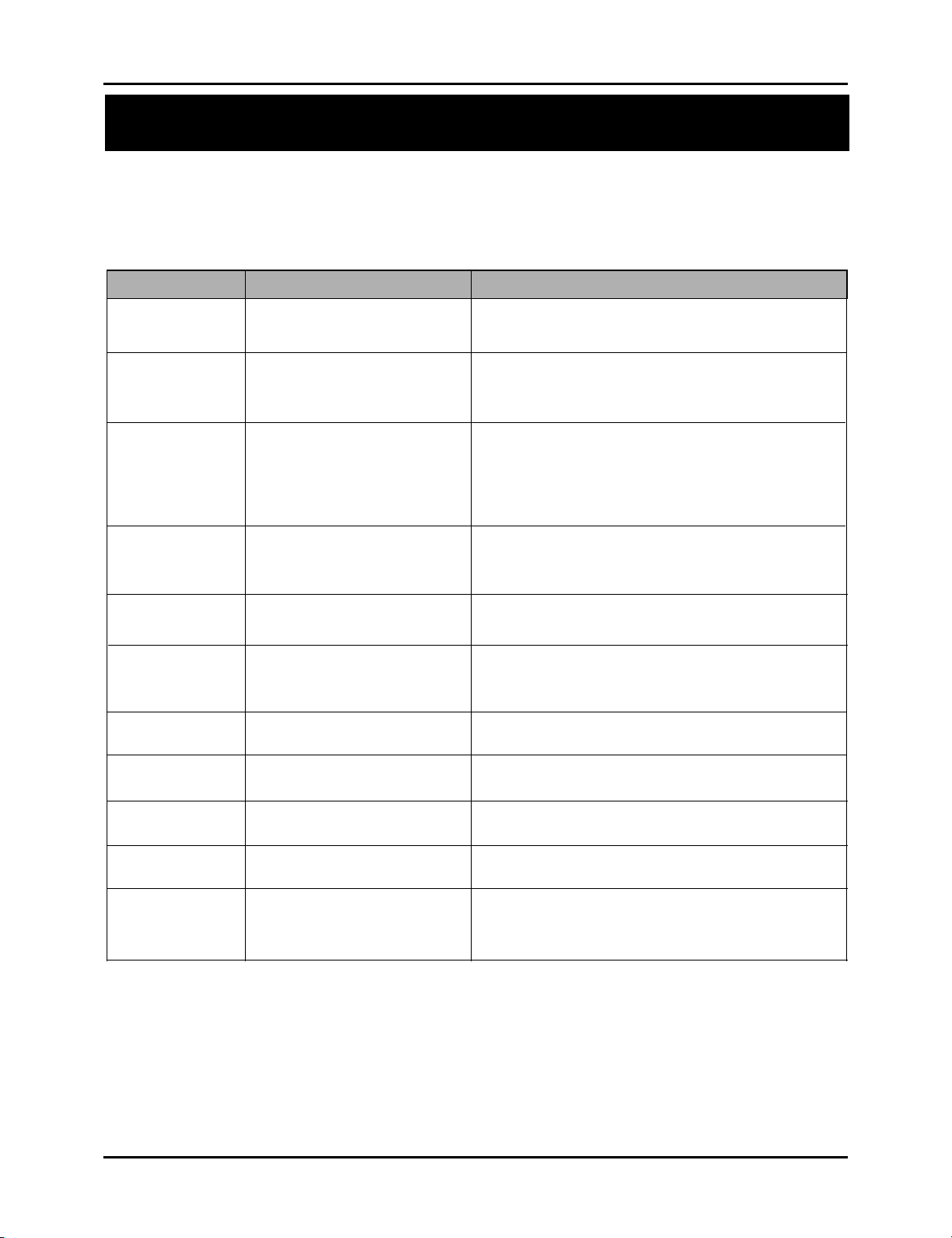

Contents

Chapter 1: Theory of Operation 1

Chapter 2: Hardware Overview 2

2.1 Standard Modules ..................................................................................................................... 3

Controller (FMMP01) ......................................................................................................... 3

Power Supply (FMPS01) .................................................................................................... 3

2.2 Input/Output Module ............................................................................................................... 3

Resolver (FMIR01) ............................................................................................................. 3

Variable Pulse (FMIP01)..................................................................................................... 4

LDT Input (FMIP020) ........................................................................................................ 4

Digital Output (FMOD01) .................................................................................................. 4

Analog Output (FMOA01).................................................................................................. 4

Relay Output (FMOR01) .................................................................................................... 5

2.3 Status LEDs Defi ned ................................................................................................................ 5

Chapter 3: Mounting and Wiring 7

Things to Consider ..............................................................................................................7

3.1 Mounting ................................................................................................................................. 7

Interface Module ................................................................................................................. 7

Cabling ................................................................................................................................ 8

3.2 Wiring ..................................................................................................................................... 10

Controller Module (FMMP01).......................................................................................... 10

Relay Output Module (FMOR01)..................................................................................... 10

Power Supply Module (FMPS01)..................................................................................... 11

Resolver Module (FMIR01).............................................................................................. 12

Variable Pulse LDT Module (FMIP01)............................................................................. 12

LDT Input (FMIP02) ........................................................................................................ 13

Digital Output (FMOD01) ................................................................................................ 13

Analog Output (FMOA01)................................................................................................ 14

Chapter 4: Programming 21

Before You Start ................................................................................................................21

Programming Keys Defi ned .............................................................................................. 22

4.1 Resolver Input Confi guration Functions................................................................................. 23

Scale Factor (300) ............................................................................................................. 23

Turns Counting (301)........................................................................................................ 23

Turns Counting Wrap Around (308) ................................................................................. 24

Position Offset (302)......................................................................................................... 24

Programming Scale Factor (300) ...................................................................................... 24

Display Power-Up (305) ................................................................................................... 26

Resolver Reset-to-Preset (307) ......................................................................................... 26

Installation and Programming Manual ii

Page 4

4.2 : LDT Confi guration Functions..........................................................................................27

Wire Speed (300) .............................................................................................................. 28

Count Direction (301) ....................................................................................................... 28

Position Offset (302)......................................................................................................... 29

Fault Pulse Time (306) ...................................................................................................... 30

LDT Output Type (307) .................................................................................................... 30

LDT L1 Input Reset-to-Preset (311)................................................................................. 31

4.3 : Monitor Setup Functions .................................................................................................31

Unit of Measurement (14)................................................................................................. 31

Decimal Location (13) ...................................................................................................... 32

Position Hold (15)............................................................................................................. 32

Auxiliary LED (16)........................................................................................................... 33

Move Detection Time-Out(12)..........................................................................................

34

4.4: Relay Setup Functions ......................................................................................................34

Upper End Limit (400)...................................................................................................... 35

Lower End Limit (401) ..................................................................................................... 35

Relay State (402)...............................................................................................................36

Relay Override (403)......................................................................................................... 36

4.5: Digital Outputs..................................................................................................................37

Output Type (200) ............................................................................................................. 37

Latch/Synchronize Handshake (201) ................................................................................ 37

Logic Level (202).............................................................................................................. 38

Error Condition Output State (203) .................................................................................. 38

4.6: Analog Outputs................................................................................................................39

Analog Output Channel 1 ................................................................................................. 39

Analog Output Channel 2 ................................................................................................. 42

4.7: Program and Supervisory Mode Functions .....................................................................43

Program Mode Access (10)............................................................................................... 43

Program Mode Time-out (11) ........................................................................................... 44

Appendix A: Error Messages 45

Error Conditions (306) ...................................................................................................... 50

Appendix B: Function Summary Chart 51

Appendix C: Catalog Numbering System 53

Appendix D: Specifi cations 54

Glossary ............................................................................................................................ 56

Index.................................................................................................................................. 58

iii Installation and Programming Manual

Page 5

Chapter 1: Theory of Operation

Chapter 1: Theory of Operation

The Gemco Series 2120 PLC Interface Module converts the input signal from a resolver based

rotary transducer or Magnetostrictive Linear Displacement Transducer (LDT) to digital analog or

overtravel relay outputs. Resolver based inputs provide up to 14 bit resolution per turn with a

fi eld programmable scale factor. LDT based inputs allow fi eld selection of position data in inches

to .001 inches or millimeters to .01 millimeter. The module’s 6 digit display can show position

or velocity data. The optional 20 bit digital output board allows fi eld confi guration of parallel

digital outputs in a binary, BCD or grey code format. The optional analog output board allows

fi eld selection of a voltage or current output of position or velocity and is scalable over any

portion of the displayed data. The optional relay output board provides two mechanical relay

outputs intended for use as overtravel limits.

Advanced features include:

Reset-to-Preset input for continuous recalibration or compensation for process

drift.

Turns counting software for multiple turn applications using a single turn resolver.

Move detection software for detection of a jammed motor driven mechanism or

drive component failure.

Position hold input to freeze displayed data during high vibration periods at the

sensor.

Field programmed data is protected by a hard contact closure on the back of the module and a

user selectable security code.

Installation and Programming Manual

1

Page 6

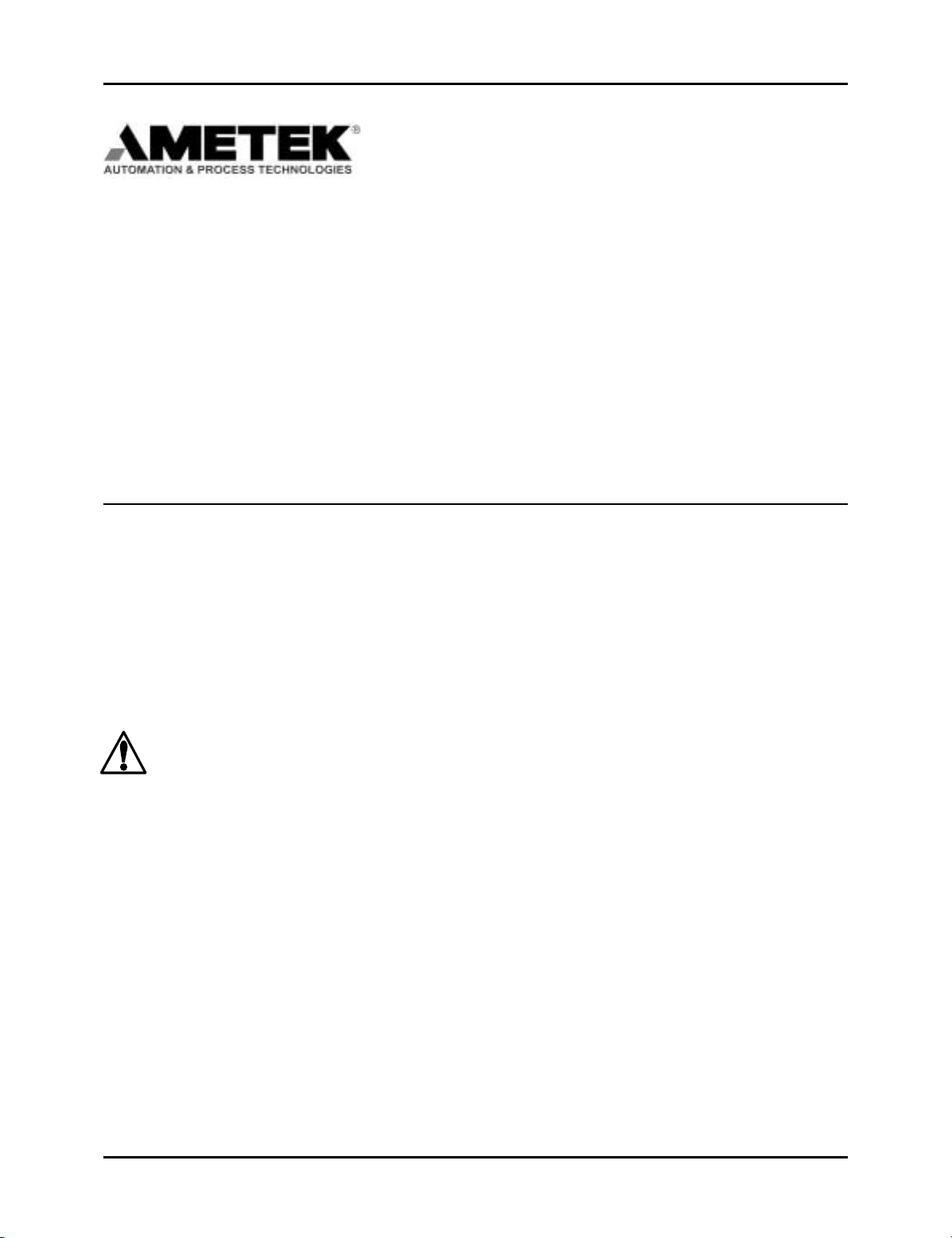

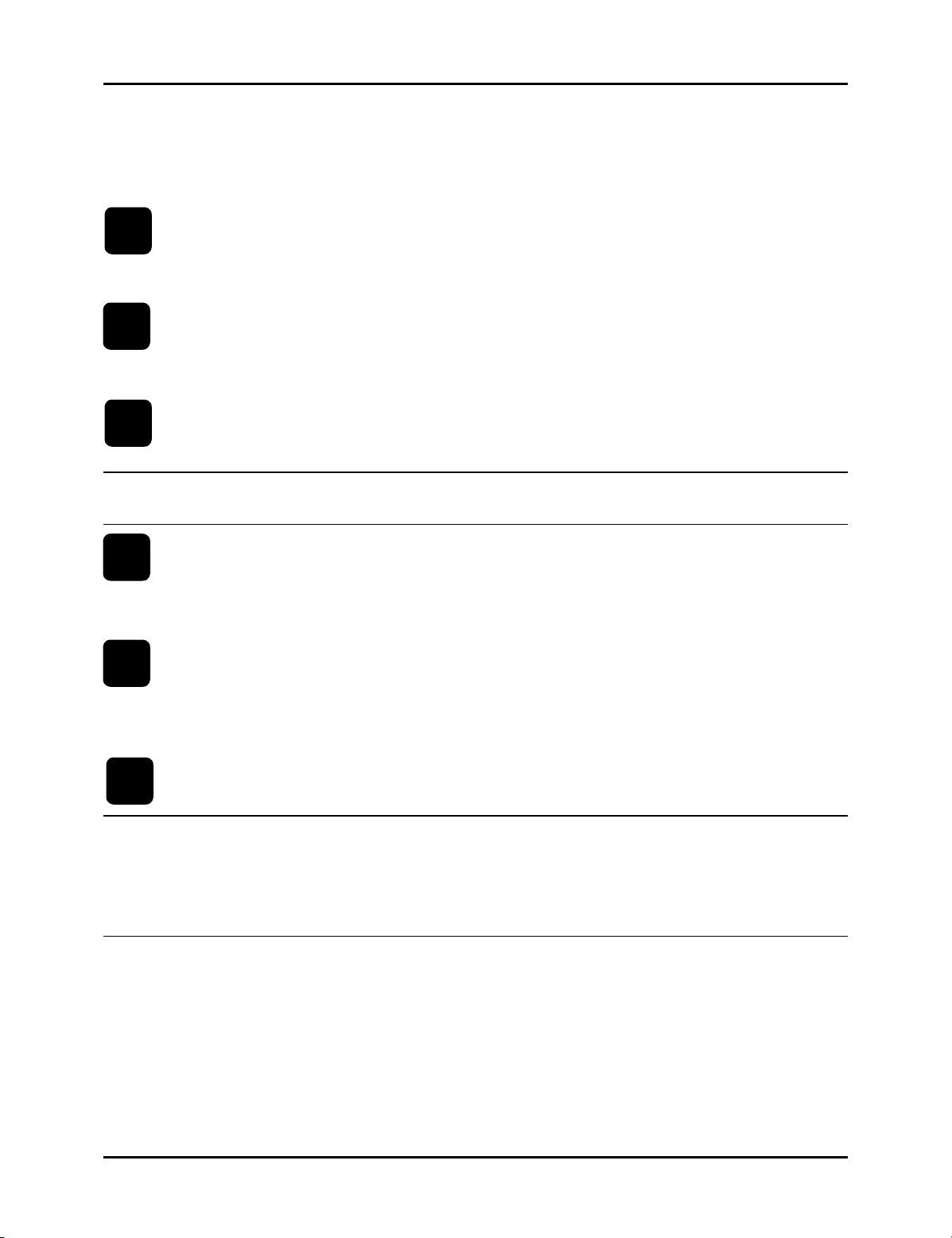

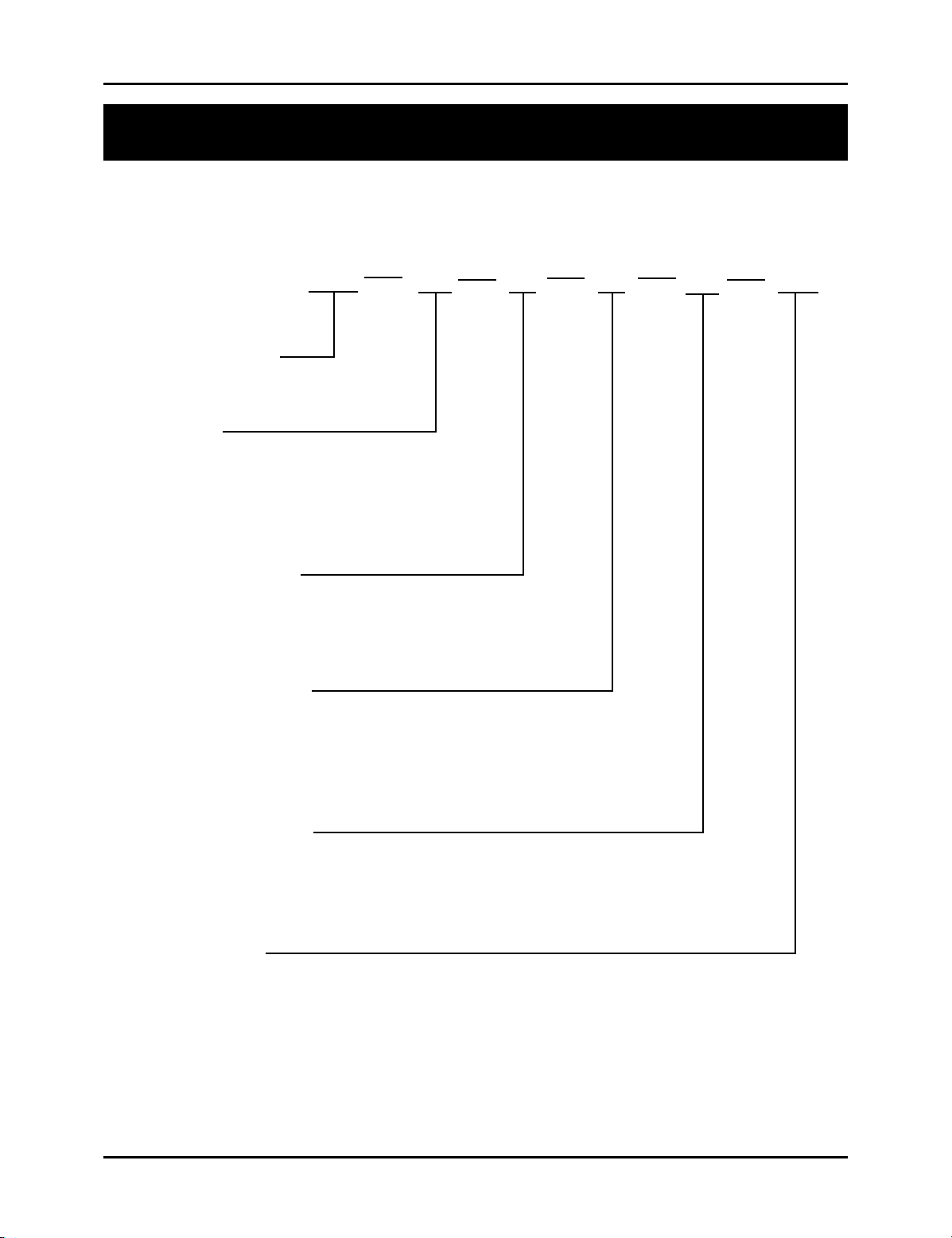

Chapter 2: Hardware Overview

Chapter 2: Hardware Overview

This chapter contains descriptions of the Interface Module’s components. For installation

instructions, see Chapter 3: Mounting and Wiring.

The Interface Module contains a heavy-duty case which can hold up to fi ve modules. Several

optional modules can be used with the Interface Module. See also Appendix C: Catalog

Numbering System for more information on optional modules.

Power Supply

Controller (CPU)

Digital Output (optional)

Analog Output (optional)

Resolver Input (optional)

Linear Displacement Transducer L1 (optional)

Linear Displacement Transducer V1 (optional)

Relay Output (optional)

The Interface Module’s faceplate contains a 6-digit, seven-segment LED display and four

programming keys. The LED display is used to indicate the position, as well as to display

parameters when programming. The programming keys are used to program the Interface

Module. Ten small status LEDs are also provided. These LEDs are used to indicate the state

of the monitor during machine operation.

PROGRAM

FLT OK

MVT FLT

POS

RPM

UPR LIM

LWR LIM

AUX1

AUX2

AUX3

()

F

POWER

POWER SUPPLY

100-240VAC 50/60HZ

L1

L2

3 5 6412

GND

FLT CHK

}

AUX INP

7

}

FMPS01

POWER

FRONT

4

RELAY

R

E

L

A

Y

FMOR01

4

BACK

3

RSLVR

FMIR01

3

R

E

S

O

L

V

E

R

SERIES

2120

2 1

C.P.U.

D

G

T

L

O

U

T

P

U

T

FMMP01

2

1

Figure 2-1 Interface Module with Resolver/Digital Modules

2

Installation and Programming Manual

Page 7

Chapter 2: Hardware Overview

2.1: Standard Modules

This section provides descriptions of basic Interface Modules (also see Section 2.2: Input/Output

Modules).

Controller (FMMP01)

This module contains the Central Processing Unit (CPU) which is used to process data it receives from

the resolver or Linear Displacement Transducer (LDT). It then shows the position on the Interface

display. The controller is also responsible for continuously monitoring all programmed setpoints and

timing functions. To store programmed functions, including fi xed settings, the controller contains

battery-backed memory. This battery requires no maintenance and is non-replaceable. To allow for

remote communications with the Interface Module, RS-232 and RS-485 serial ports are available through

a D9 connector. The controller is located in slot 1 of the enclosure. (For wiring instructions, see Section

3.2: Wiring)

Power Supply (FMPS01)

This module supplies power to the Interface Module. It also contains a fault check relay and an auxiliary

input. The fault check relay is designed to take power away from the operating machine when a fault

occurs during machine operation, or when power is taken away from the Interface Module. In order for

this to perform it’s intended function, the fault check relay must be properly wired to the machine’s safety

interlock. For a listing of errors which will cause the fault check relay to deenergize, see Chart A-4 in

Appendix A: Error Messages. The auxiliary input is designed for the Move Detection Time-out and

Position Hold functions and accepts an 85-265 VAC input signal. The power supply is located in slot 5 of

the enclosure. (For wiring instructions, see Section 3.2: Wiring.)

2.2: Input/Output Modules

The PLC Interface Module can be used with a resolver or Linear Displacement Transducer (LDT). Either

input module will be located in slot 3 of the enclosure. You can identify the module type by the name

found on the back of the module.

Resolver (FMIR01) Input Option R1

This module is used with a Gemco resolver. The resolver assembly consists of a highly accurate and

repeatable brushless resolver, housed in an industrial-grade enclosure. The shaft position is calculated

from two analog signals that vary as a function of the angular rotation of the input shaft.

The brushless resolver works on the same principle as a rotary transformer to couple power into the rotor.

The construction of the brushless resolver consists of a two-phase stator and a single-phase rotor. Each

stator is positioned 90° apart from each other. The two stators continually provide two different output

voltages. Using these two outputs, the module performs a ratiometric conversion and provides an absolute

position. This results in a highly accurate and repeatable transducer having excellent reliability with an

infi nite resolution which can be converted by a resolver-to-digital converter into digital position data. This

module also provides the reset-to-preset input terminals. An input at these terminals will reset the position

display and outputs to a preprogrammed value. This input can be used to continuously compensate for

position drift caused by slippage in the drive mechanism turning the resolver.

Installation and Programming Manual

3

Page 8

Chapter 2: Hardware Overview

Variable Pulse (FMIP01) Input Option V1

This module is used with an LDT that provides its output in the form of a pulse width modulated RS-422

signal. This module only works with Gemco Series 951VP2110 LDT’s.

LDT Input (FMIP02) Input Option L1

This module will accept an output from a controlled pulse, start stop pulse or variable pulse

magnetostructive LDT. This card accepts a wide range of LDT inputs and provides faster updates than

the variable pulse version described above.

It allows the PLC Interface Module to receive the signals from the LDT. The pulse width signal is

converted to position data which the monitor displays. The module also provides +24 VDC to supply

power to the LDT. The module was designed to work with the Gemco Series 951 or 952CP or RS LDT.

However, other LDTs can be used with the module. If you are using a different type of LDT, contact the

factory for wiring and programming instructions.

This module also contains reset-to-preset input terminals. A signal at this input will reset the position

display and outputs to a preprogrammed value. This feature is useful for quick recalibration of the

system to a gauge block or known machine position.

Digital Output (FMOD01) Output Option D1, D2 or D3

This module is used to transmit parallel digital output data to a PLC or personal computer. The digital

output is fi eld confi gurable for position or velocity data in a binary, BCD or grey code format. This data

is updated every 50 microseconds. The electrical characteristics of this output data can be current sinking,

current sourcing or TTL which must be specifi ed in the module’s part number.

This module also provides two input pins for use as a fi eld confi gured latch or synchronized handshake

input. The latch input freezes the digital output data while the PLC reads it. The data is updated when the

input is released. When confi gured for synchronized handshake, the PLC must provide a clocked square

wave input into these input pins. Digital data is updated on each transition of the square wave and the PLC

is synchronized to read the updated position data after a 100 microsecond settling time.

This input accepts a 5 to 24 VDC source from the PLC to perform the latch or synchronized handshake

function described above. For details on wiring to the digital output board, see pages 17 & 18.

Analog Output (FMOA01) Output Option A1

This module is used to transmit position or velocity data to a PLC in an analog format. The module

provides two separate analog output channels that can be independently confi gured for position or

velocity data.

These analog outputs can be fi eld scaled over any range and confi gured for 0 - 10 VDC, 10 - 0 VDC,

-10 VDC to +10 VDC, 4 - 20 mA, 20 - 4 mA, 0 - 20 ma or 20 - 0 mA.

For applications that require remote indication it is recommended to use an aftermarket analog input

display or a digital input display. When using one of these displays the optional analog or digital output

board must be specifi ed in the part number.

4

Installation and Programming Manual

Page 9

Chapter 2: Hardware Overview

Relay Output (FMOR01)

This optional module contains two overtravel limit relays. These relays can be programmed to either

energize or deenergize upon reaching the programmed overtravel position. These relays will also actuate

upon detection of the system and operating errors listed in chart A-5 in Appendix A.

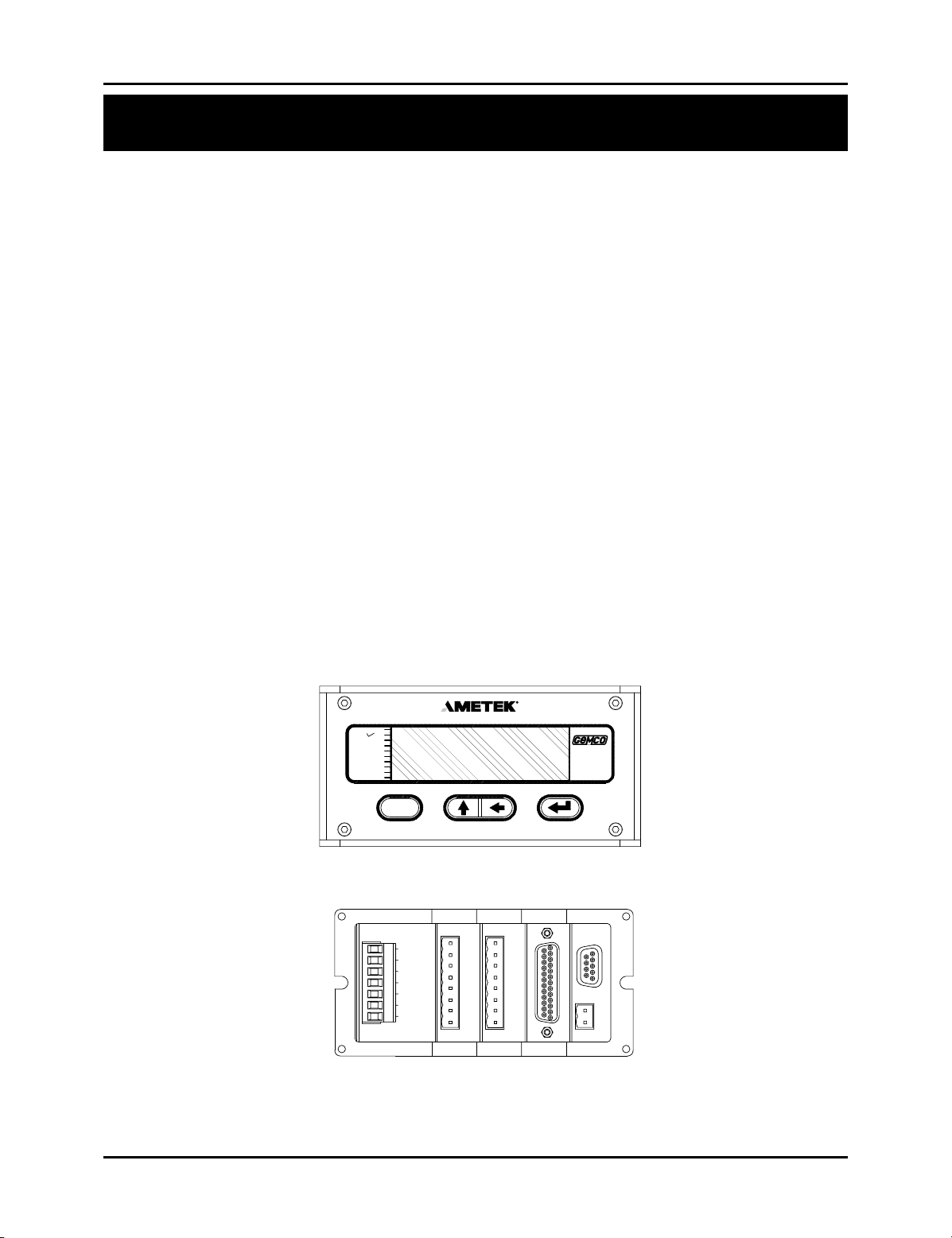

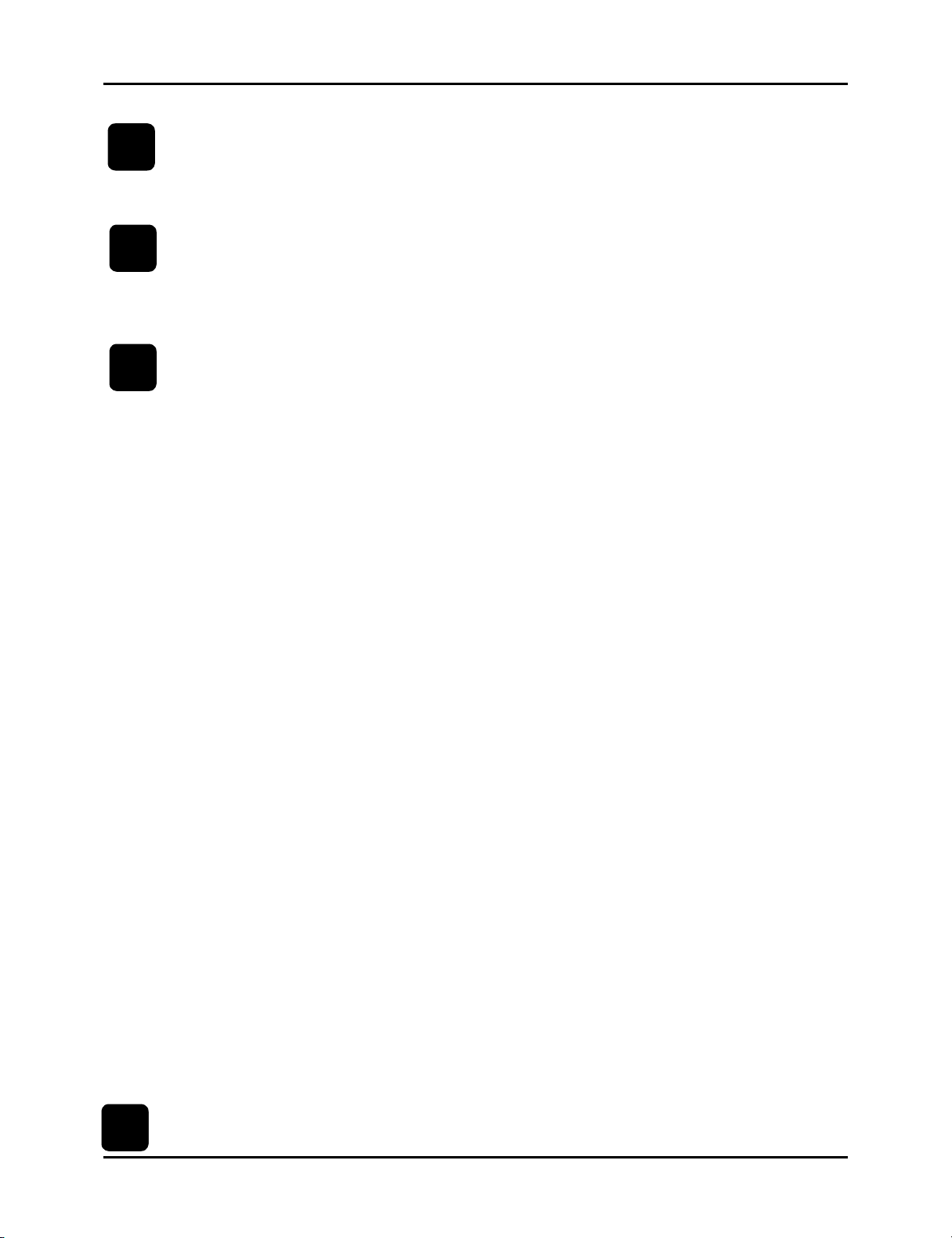

2.3: Status LEDs Defi ned

The Interface Module has 10 status LEDs and four programming keys. The LEDs provide information on

the monitor’s state during machine operation, and the programming keys are used to program functions

and perform basic operations.

Status LEDs

PROGRAM

FLT OK

MVT FLT

POSITION

RPM

UPR LIM

LWR LIM

AUX 1

AUX 2

AUX 3

SERIES

2120

()

F

Enter Key

Shift Key

Scroll Key

Function Key

Figure 2-2 Status LEDs and Programming Keys

PROGRAM

turns off when it is not. Functions cannot be programmed when this LED is off.

The program LED turns on when the Interface Module is in program mode and

FAULT OK The fault check OK LED turns on when the power supply’s fault check relay is

energized, indicating the system is OK. This LED will turn off when a fault is

detected, indicating that the fault check relay is deenergized.

MVT FLT The movement fault LED turns on when a movement fault is detected. (For more

information, see Move Detection Time-out in Section 4.3: Setup Functions.)

Installation and Programming Manual

5

Page 10

Chapter 2: Hardware Overview

POSITION This position LED turns on when the Interface Module is showing position in the

large LED display.

RPM The RPM LED turns on when the Interface Module is showing RPM in the large

LED display.

UPR LIM The upper limit LED refl ects the state of the relay when the value programmed in

the Upper End Limit function is reached. The relay can be programmed to energize

or deenergize upon reaching the programmed overtravel position. (For more

information, see Upper End Limit in Section 4.3: Setup Function).

LWR LIM The lower limit LED refl ects the state of the relay when the value programmed in

the Lower End Limit function is reached. The relay can be programmed to

energize or deenergize upon reaching the programmed overtravel position. (For

more information, see Lower End Limit in Section 4.3: Setup Functions.)

AUX 1 For future expansion.

AUX 2 For future expansion.

AUX 3 The auxiliary LED is programmable and can be used with the Position Hold

function. When enabled, this LED indicates when the position is being held. (For

more information, see Position Hold and Auxiliary LED in Section 4.3: Setup

Functions.)

The function key is used to begin a process for programming a function. When

this key is pressed, the Interface Module prepares itself for the entry of a specifi c

(F)

function number.

The scroll key is used to scroll through the Interface Module’s list of function

numbers, as well as other lists. This key is also used to increment selected digits

shown on the Interface Module’s LED display.

The shift key is used to move to (select) a specifi c digit shown on the Interface

Module’s LED display from right to left.

The enter key is selected after a function number has been entered. This begins

the programming process for the selected function. The enter key is also used to

program a value in a function.

NOTE: For more information on how to use the programming keys, see Chapter 4: Programming

6

Installation and Programming Manual

Page 11

Chapter 3: Mounting and Wiring

Chapter 3: Mounting and Wiring

This chapter provides instructions for mounting and wiring the PLC Interface Module. These instructions

have been divided into two sections: Section 3.1: Mounting and Section 3.2: Wiring.

Things to Consider

It is recommended that you consider the following before installing the PLC Interface Module:

To minimize the effects of electromagnetic interference (EMI), the monitor should be

mounted as far away as possible from motor starters, drives and control relays.

The monitor should be mounted in an area free of water spray, corrosive gases, fl ying

chips, or any other foreign matter that could cause damage to the unit.

If the module is mounted directly on the machine, it should be installed in an area

where shock and vibration will be minimized.

The module should be located in an area that is within the temperature and humidity

specifi cations. (See Appendix D: Specifi cations.)

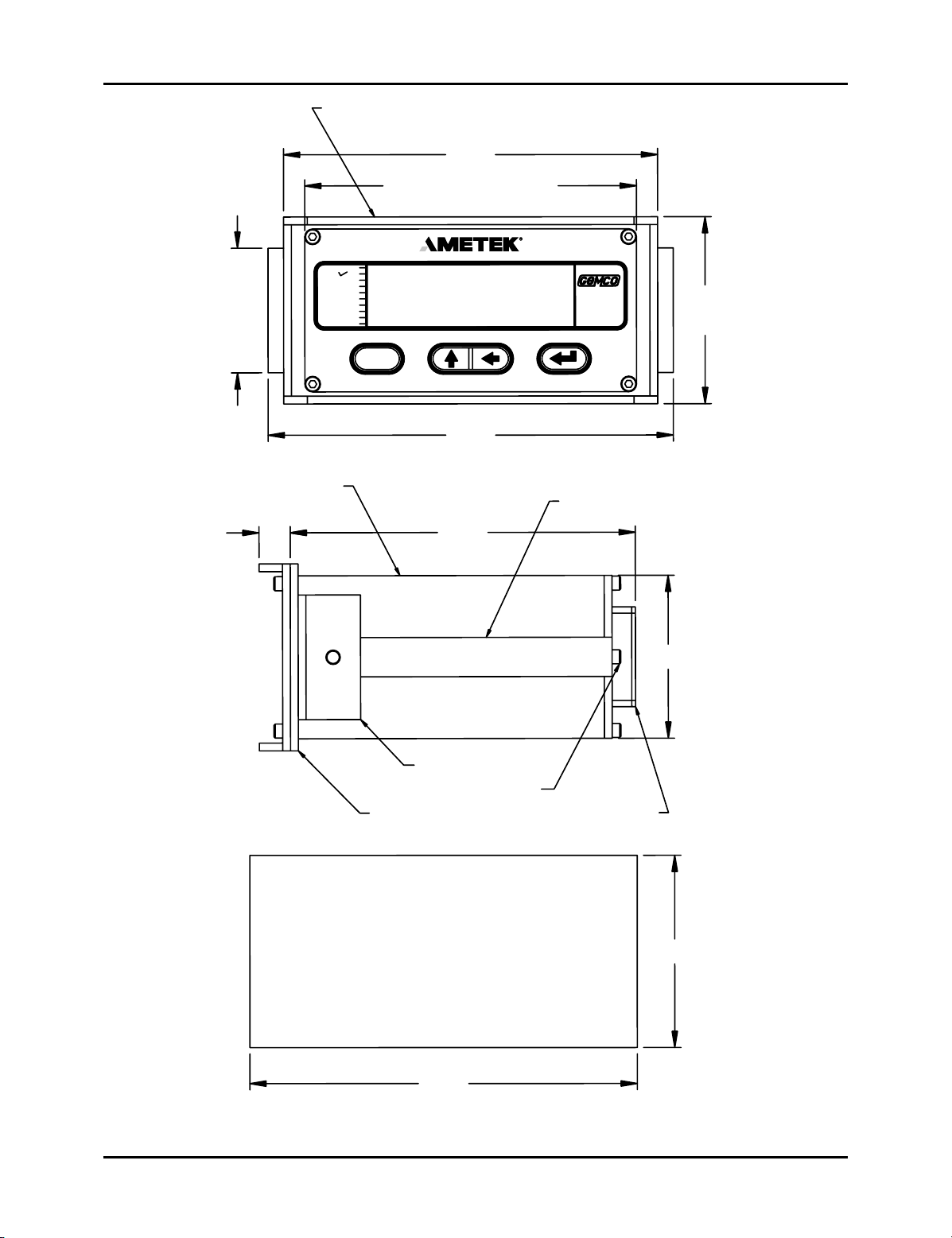

3.1: Mounting

Interface Module

To assist you in mounting the PLC Interface Module, refer to Figure 3-1. Perform the following steps:

1. According to the dimensions as shown in Figure 3-1, cut out a section of the panel

you wish to mount the module in.

2. Remove the mounting rails on the left and right side of the unit by removing the

#6-32 UNC screws located on the rear of the unit.

3. Place the module in the cutout section of the panel.

4. From behind the panel, insert the two mounting rails into the module’s side grooves.

The feet of the rails must be inserted fi rst. See Figure 3-1 for the location of the

mounting rails.

The mounting rails secure the monitor by their feet being pressed against the back

of the panel.

Installation and Programming Manual

7

Page 12

Chapter 3: Mounting and Wiring

5. Insert each #6-32 UNC screw into each of the module’s screw holes.

6. Using a 7/64" Allen wrench, secure the screws into position. This will secure the

mounting rails. 8 to 10 inch pounds of torque is required.

Cabling

The signals from a resolver or LDT are inherently very immune to electrical noise. However, to ensure

trouble free operation in an industrial environment, it is recommended that these cables be routed in a

separate conduit isolated from all power handling leads. A continuous uninterrupted length of cable from

the transducer to the Interface Module is preferred. If fi eld splices to the cable are required, they must

be done in an isolated grounded junction box with no other power handling leads present. Shielded cable

must be used that has similar shielding as the standard Gemco cable and the shield must not be tied to

ground anywhere along the cable run except as shown in the wiring diagram in this manual.

The cabling should also be routed away from noise generating devices like variable frequency drives,

servo amplifi ers, solenoid valves or large contactors.

8

Installation and Programming Manual

Page 13

2

.

0

0

T

Y

P

Chapter 3: Mounting and Wiring

U

M

L

A

R

P

O

R

G

K

O

T

F

L

M

F

T

V

T

I

S

O

P

R

U

R

L

P

R

L

W

L

U

A

X

U

A

X

U

A

X

E

S

A

C

M

U

N

I

M

U

L

A

D

T

S

N

I

D

8

/

3

L

N

Z

E

I

U

E

M

B

0

0

.

6

H

T

ID

W

E

S

A

C

2

3

.

5

M

A

T

L

N

O

I

M

P

M

I

M

I

1

2

3

()

F

0

5

.

6

M

S

R

E

I

E

S

0

2

1

2

O

F

/

W

L

I

A

R

G

N

I

T

N

U

O

3

.0

0

T

O

3

5

.

0

5

.

A

G

"

/8

1

R

E

P

A

5

1

6

.

2

T

O

O

F

L

I

A

R

G

N

I

T

N

U

O

M

S

W

E

R

C

S

G

N

I

T

N

U

O

M

E

L

B

A

G

G

U

L

P

E

T

E

K

S

E

M

N

C

M

O

N

E

D

E

D

U

O

C

L

T

U

T

D

M

R

E

T

S

P

I

R

T

S

L

A

IN

7

6

.

2

8

3

.

5

Figure 3-1 Dimensional Drawing

Drawing E0232200

Installation and Programming Manual

9

Page 14

Chapter 3: Mounting and Wiring

3.2: Wiring

This section contains pinout diagrams for each module. System wiring diagrams follow.

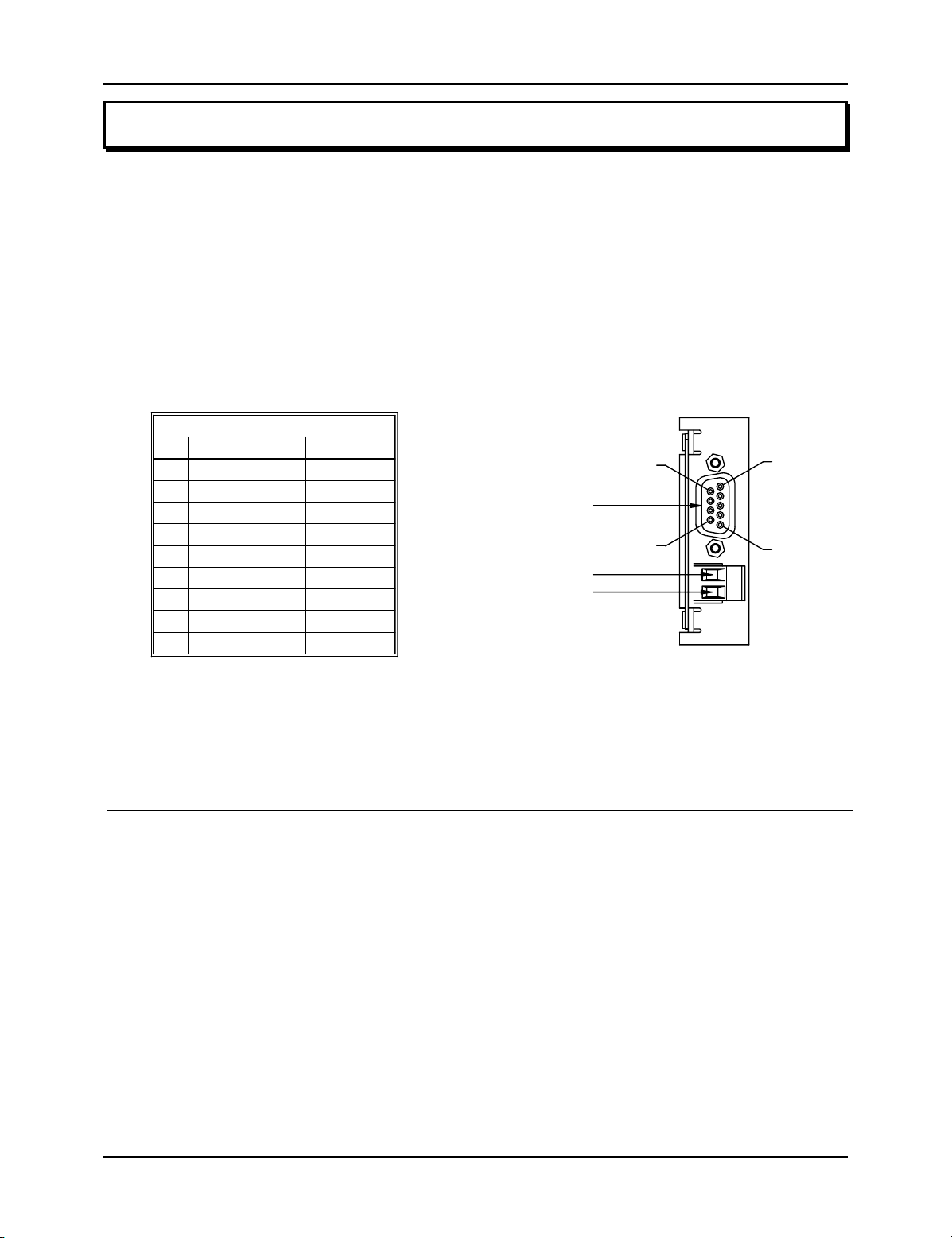

Controller Module (FMMP01)

The controller has two connectors: a D9 connector (J1) for RS-232 and RS-485 serial

communications, and a program lockout connector (J2) intended for a keyswitch. (See Figure

3-2). Making connections to both connectors is optional. However, the program lockout

connector must be jumpered to allow the unit to enter program mode. J2’s input rating is +5

VDC maximum dry contact or open collector (drain) only. Actuation voltage must be less than

+1.0 VDC at 0.2 mA. The terminal wire size is No. 22-12 AWG.

COMMUNICATIONS CONNECTOR

PIN SIGNAL NAME DIRECTION

GND CHASSIS

1

RXD RS-232

2

3

TXD RS-232

4

NO CONNECTION

5

GND SIGNAL

6

TX2+ RS-485

7

RTS RS-232

8

CTS RS-232

9

TX2- RS-485

OUTPUT

INPUT

I / O

INPUT

OUTPUT

I / O

INPUT +

{

INPUT -

(J1)

COMMUNICATIONS

CONNECTOR D9 FEMALE

(J2)

PIN 9

PIN 6

C.P.U.

PIN 5

PIN 1

21

FMMP01

Figure 3-2 Controller Pinout Diagram

Drawing E8002099

NOTE: The controller’s program lockout connector (J2) must be jumpered to allow the unit

to enter program mode.

Relay Output Module (FMOR01)

The relay output module contains two overtravel limit relays. Each relay contains a N.O. contact

pair and a separate N.C. contact pair. (See Figure 3-3). The relay contacts are rated at 8 amps

250 VAC, 30 VDC, 1/4 HP 125, 250 VAC. The terminal wire size is 22-12 AWG.

10

Installation and Programming Manual

Page 15

Chapter 3: Mounting and Wiring

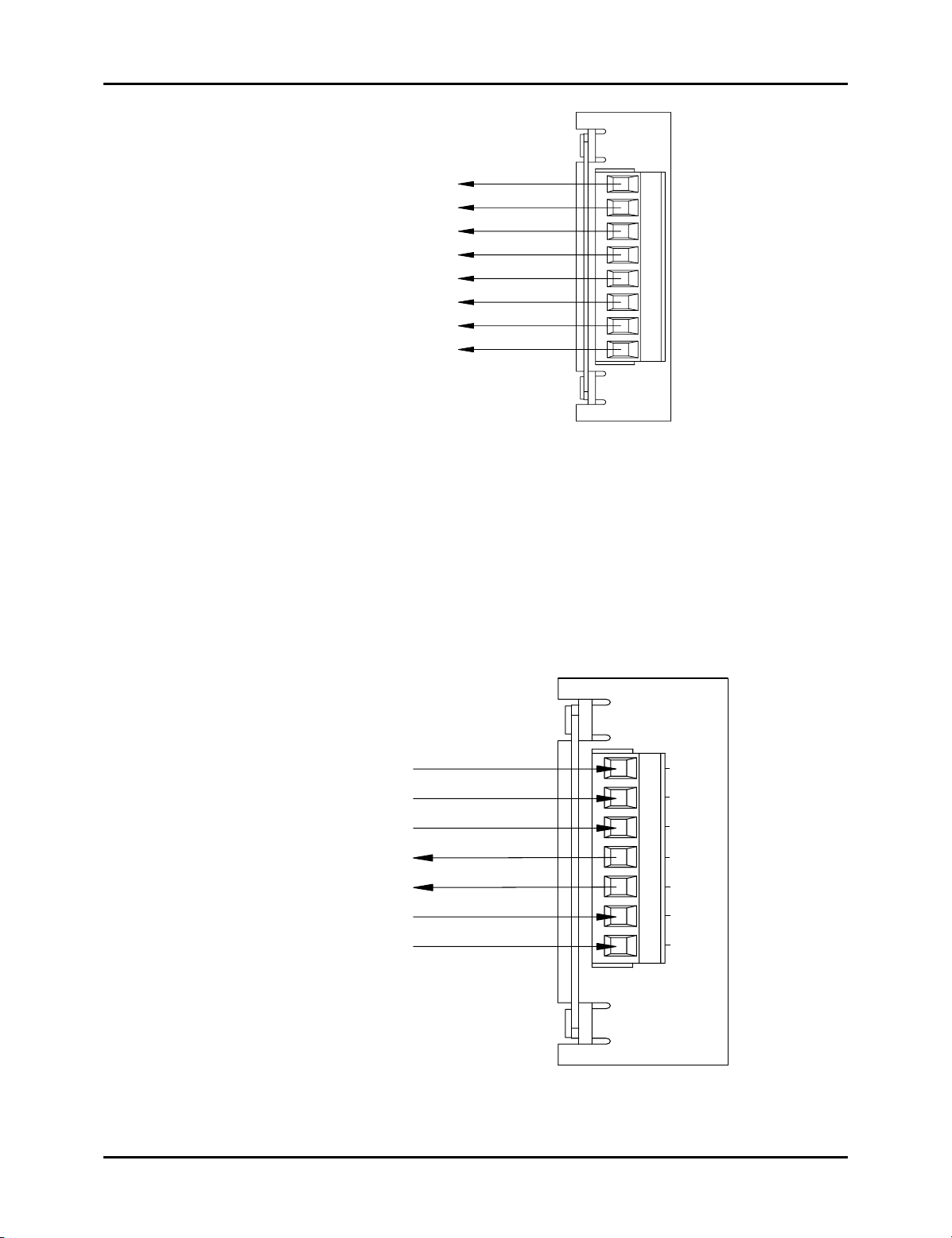

RELAY

NO

{

{

NO

NC

NC

NO

NO

NC

NC

RELAY 1

UPPER LIMIT

RELAY 2

LOWER LIMIT

Figure 3-3 Relay Output Pinout Diagram

Power Supply Module (FMPS01)

The power supply module has a main power input, an auxiliary input, and a fault check output.

(See Figure 3-4). Power input: 85-265 VAC at 450 mA maximum. Fault check output: 8 amps

250 VAC, 30 VDC, 1/4 HP 125, 250 VAC. It is recommended that the fault check contacts be

connected to the required safety interlock. Auxiliary input: 85-265 VAC at 12 mA maximum.

The terminal wire size for all connectors is No. 22-12 AWG. See page 3, 15 and 16 for use of

this special purpose input, concerning position hold and move detection.

21

3

4

5

687

FMOR01

POWER

INPUT

FAULT

CHECK

AUXILIARY

INPUT

{

Figure 3-4 Power Supply Pinout Diagram

L1

L2

GND

NO

{

NO

L1

{

L2

POWER SUPPLY

100-240VAC 50/60Hz

L1

21

L2

3

GND

4

{

FLT CHK

5

6 7

{

AUX INP

FMPS01

Installation and Programming Manual

11

Page 16

Chapter 3: Mounting and Wiring

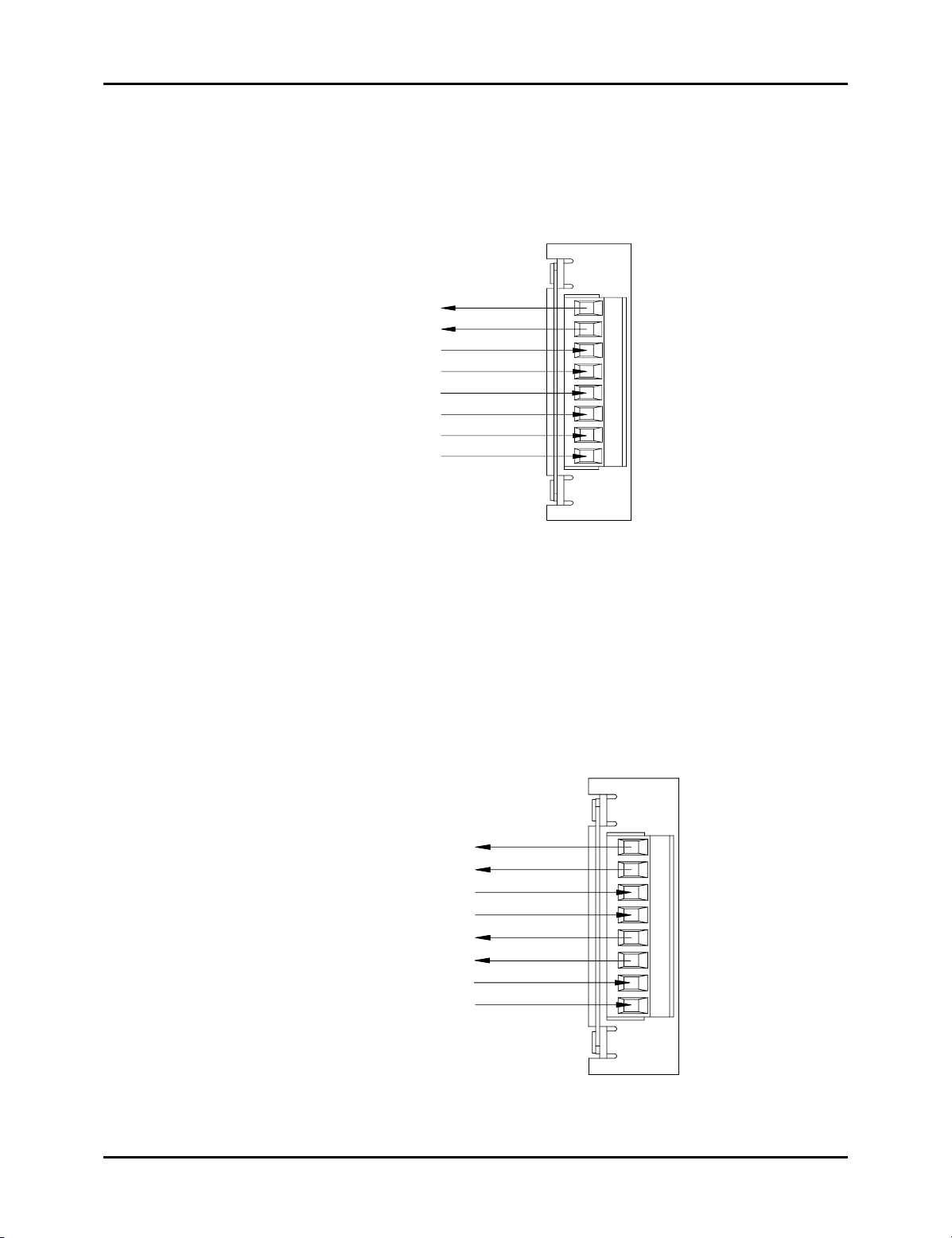

Resolver Module (FMIR01)

The resolver module has an eight-position connector. (See Figure 3-5). The terminal wire size

for all positions is No. 22-12 AWG. The reset-to-preset input is an edge sensitive input that

resets position data to a preprogrammed value. An open collector sinking device or dry contact

applied to these terminals activates the input. For programming of reset-to-preset value, see

Chapter 4: Programming.

RSLVR

1

2

3

4

5

867

FMIR01

Reset-to-Preset

Input

{

Input +

Input -

RH

RL

S3

S1

S2

S4

(See wiring

diagram for

ratings)

Figure 3-5 Resolver Pinout Diagram

Variable Pulse LDT Module (FMIP01) Input Option V1

The variable pulse LDT module has an eight-position connector. It is only necessary to connect

your LDT to positions 1 through 4. (See Figure 3-6). Positions 1 and 2 provide +24 VDC to

power the LDT. Positions 3 and 4 are used for the LDT’s pulse-width output signals. These

signals comprise an RS-422 differential input. Positions 5-8 are provided for future expansion.

The terminal wire size for all positions is No. 22-12 AWG. This module should only be used

with Gemco LDT model 951VP-2110 transducers. An open collector sinking device or dry

contact applied to the Reset to Preset terminals activates the input.

PROBE

+24VDC @135mA

PROBE VP -

Aux 24VDC @15mA

Reset-to-Preset

Input

GROUND

PROBE VP+

GROUND

Input +

{

Input -

1

2

3

4

5

867

12

FMIP01

Figure 3-6 Variable Pulse LDT Pinout

Diagram Input Option V1

Installation and Programming Manual

Page 17

Chapter 3: Mounting and Wiring

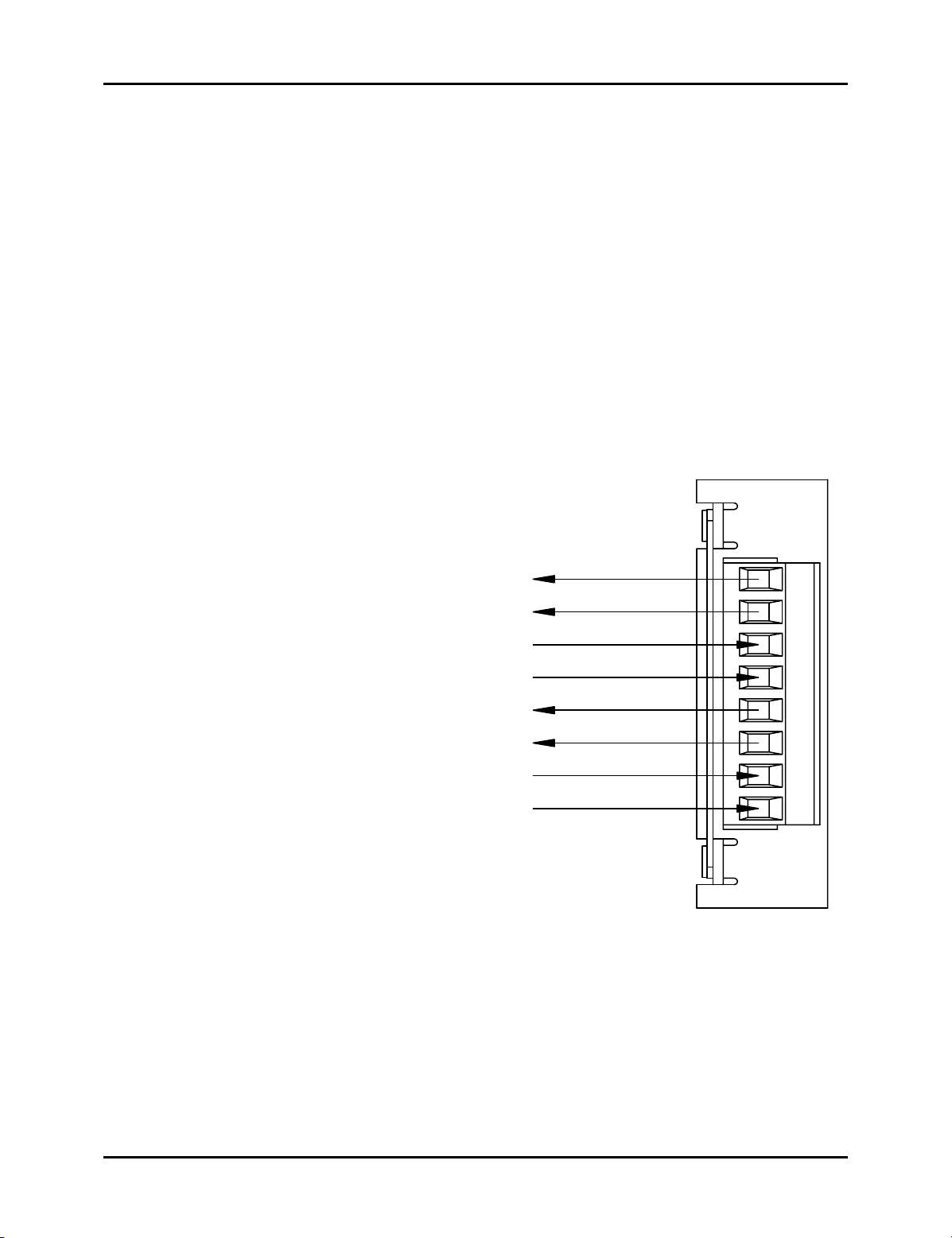

LDT Input (FMIP02) Input Option L1

This module will accept an output from a controlled pulse, start stop pulse or variable pulse

magnetostrictive LDT. (See Figure 3-7). This card accepts a wide range of LDT inputs and

provides faster updates than the variable pulse module as described on page 12.

The pulse width signal is converted to position data which the monitor displays. The module

also provides +24 VDC to supply power to the LDT. The monitor was designed to work with

the Gemco 951 or 952CP & RS LDTs. However, other LDTs can be used with the PLC

Interface Module. If you are using a different type of LDT, contact the factory for wiring and

programming instructions. The terminal wire size for all positions is No. 22-12 AWG.

The reset-to-preset input is an edge sensitive input that resets position data to a preprogrammed

value. A 5-24VDC source applied to these terminals activates the input. For programming of

reset value, see Chapter 4: Programming.

Reset-to-Preset

Input

+24VDC @ 135mA

GROUND

+RS422 IN

-RS422 IN

+RS422 OUT

-RS422 OUT

+ INPUT 5-24VDC

- INPUT

Figure 3-7 LDT Pinout Diagram Input Option L1

{

Common

PROBE

21

3

4

5

876

FMIP02

Digital Output (FMOD01) Output Option D1, D2 or D3

This module will output Binary, BCD, or Grey Code digital outputs in either current sinking,

current sourcing, or TTL level outputs. See Fig. 3-13A & B and Fig. 3-14 for wiring details. It

also contains a 5-24VDC source input for freezing the digital data while the PLC reads it. See

page 37, Latch/Synchronize Handshake.

Installation and Programming Manual

13

Page 18

Chapter 3: Mounting and Wiring

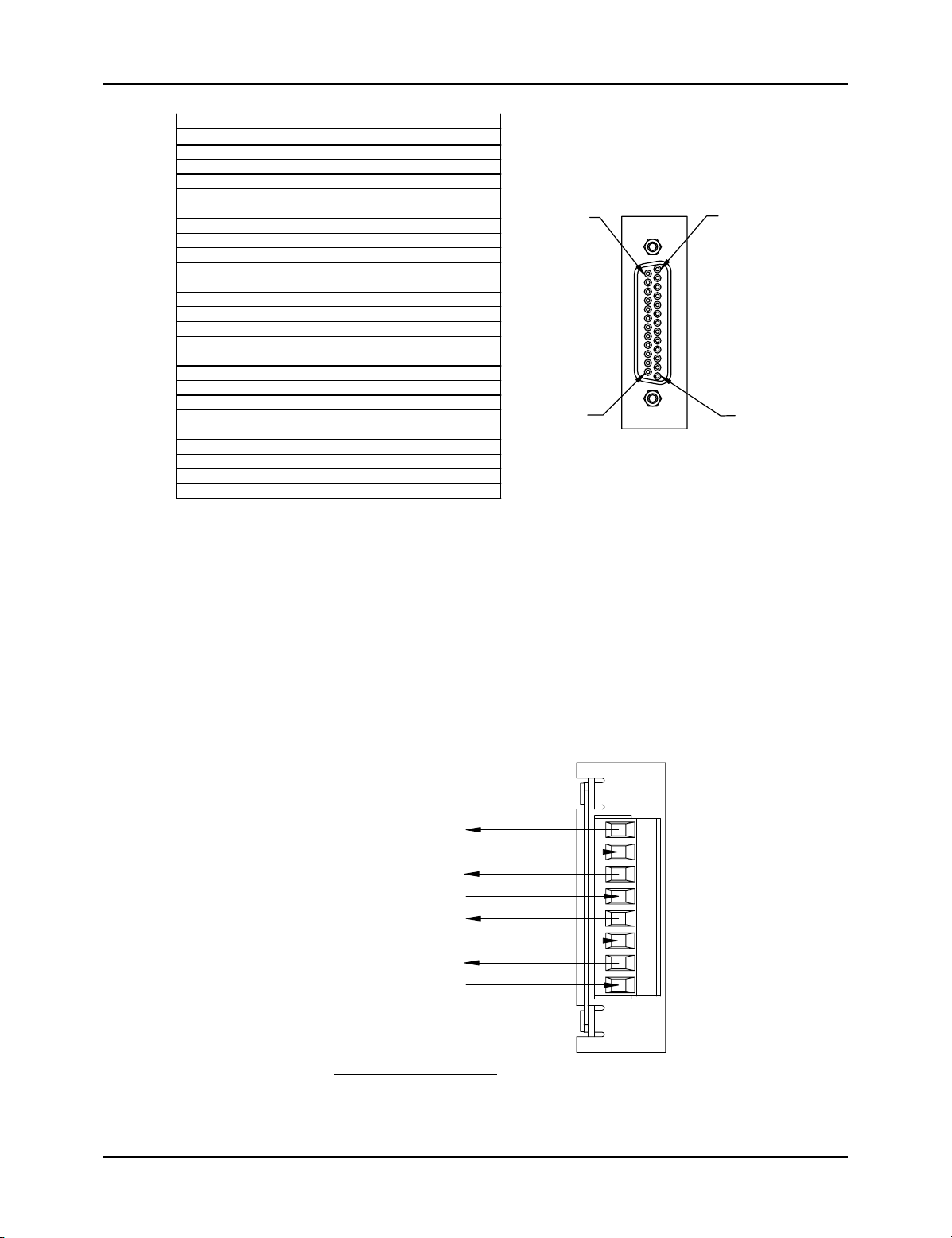

PIN

DIRECTION

1

2

3

4

5

6

7

8

9

10

11

12 IN

13 IN

14

15

16

17

18

19

20

21

22

23

24

25

DATA OUT BIT 0

OUT

DATA OUT BIT 2

OUT

DATA OUT BIT 4

OUT

OUT

DATA OUT BIT 6

OUT

DATA OUT BIT 8

DATA OUT BIT 10

OUT

OUT

DATA OUT BIT 12

DATA OUT BIT 14/INCREMENTAL OUT Z*

OUT

DATA OUT BIT 16/INCREMENTAL OUT A*

OUT

OUT

DATA OUT BIT 18/INCREMENTAL OUT B

OUT

BUSY*

BUS ENABLE*

GND

OUT

DATA OUT BIT 1

DATA OUT BIT 3

OUT

DATA OUT BIT 5

OUT

OUT

DATA OUT BIT 7

DATA OUT BIT 9

OUT

DATA OUT BIT 11

OUT

DATA OUT BIT 13

OUT

DATA OUT BIT 15/INCREMENTAL OUT B*

OUT

DATA OUT BIT 17/INCREMENTAL OUT Z

OUT

OUT

DATA OUT BIT 19/INCREMENTAL OUT A

SYNC

IN

VSRC+

IN

DESCRIPTION

Figure 3-8 Pinout Diagram Digital Output

Drawing E8002099

PIN25

PIN13

D

G

T

L

O

U

T

P

U

T

PIN1PIN14

Analog Output (FMOA01) Output Option A1

The Analog Output board provides two channels of analog output that can be independently

confi gured and scaled. Each channel can be confi gured for an output based upon position or

velocity. Velocity will be RPM if the sensor is a resolver or inches/mm per second if the input

sensor is an LDT. The two channels of analog output allow you to confi gure one analog output

to be based on position while the other channel provides a simultaneous indication of velocity.

ANALOG

CH1 VDC OUTPUT

CH1 VDC GROUND

CH1 CURRENT OUT

CH1 CURRENT RETURN

CH2 VDC OUTPUT

CH2 VDC GROUND

CH2 CURRENT OUT

CH2 CURRENT RETURN

423 867

51

FMOA01

14

Terminal Wire Size: No. 22-12 AWG

Figure 3-9 Pinout Diagram Analog Output

Drawing E8005099

Installation and Programming Manual

Page 19

Chapter 3: Mounting and Wiring

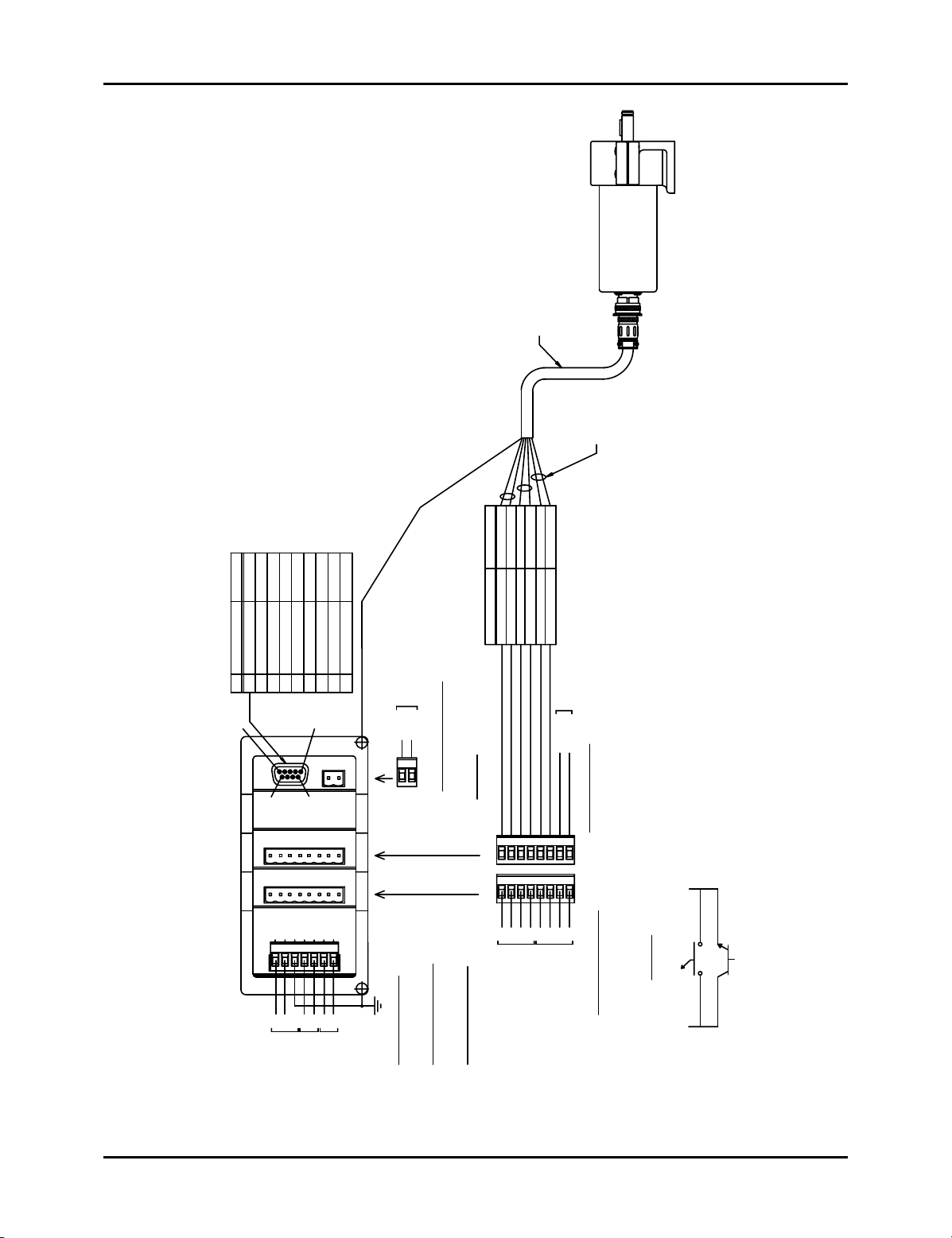

RESOLVER

ASSEMBLY

SD0284200

DIRECTIONPIN SIGNAL NAME

INPUT

OUTPUT

TXD RS-232

RXD RS-232

GND CHASSIS

24365

1

PIN 5

1

C.P.U.

2

PIN 9

3

RSLVR

4

RELAY

+I/O

INPUT

OUTPUT

NO CONNECTION

GND SIGNAL

CTS RS-232

RTS RS-232

TX2+ RS-485

789

PIN 1

PIN 6

V

SER

L

R

E

O

REALY

-I/O

TX2- RS-485

SECURITY

PROGRAM

SHEILD TO CASE ASSEMBLY

INPUT+

INPUT-

1 2

1

FMMP01

2

3

FMIR01

4

FMOR01

(P/N SD0481500)

CABLE ASSEMBLY

SHIELD

PIN C

PIN B

PIN A

RESOLVER CONN.

WIRE COLORS

RED

PROGRAM SECURITY INPUT

ON AT < 1VDC @ 0.2mA

SINKING DEVICE, +5VDC MAX

SEE DIAGRAM 1 FOR SUGGESTED CONNECTIONS

12

RESOLVER

12

RELAY

PIN F

PIN E

PIN D

BLACK OF GREEN

BLACK OF WHITE

BLACK OF RED

WHITE

GREEN

S3RHRLS2S1

S4

534 6

5

34 6

AUX 3 INPUT

INPUT-

7

8

7

8

TWISTED PAIR

SOURCING DEVICE, +24V MAX

SINKING DEVICE, +5VDC MAX

ON AT > 21.6VDC @ 5mA

ON AT < 1VDC @ 5mA

AUX 3 INPUT RATING :

REVERSE GREEN-BLACK PAIR.

TO CHANGE RESOLVER DIRECTION

INPUT-

L1

1 2345

POWER

POWER SUPPLY

100-240VAC 50/60HZ

L1

GND

L2

L2

INPUT

POWER

FLT CHK

}

NO

NO

FAULT

CHECK

AUX INP

}

67

L2

L1

INPUT

AUXILIARY

FMPS01

POWER

85-265VAC @ 450mA

50-60 Hz

85-256VAC @ 12mA

AUXILIARY INPUT RATING :

POWER INPUT RATING :

RELAY CONTACT RATING :

FAULT CHECK

NCNONONONC

NO

LIMIT

UPPER

1/4 HP 125, 250VAC

8A 250VAC 30VDC

LIMIT NC INPUT+

LOWER

NC

UPPER & LOWER LIMIT

RELAY CONTACT RATINGS :

1/4 HP 125, 250VAC

8A 250VAC 30VDC

Figure 3-10 Resolver - Based System Wiring Diagram

Drawing E0235800

Installation and Programming Manual

(CLOSED)

PROGRAM

DIAGRAM 1

SWITCH CLOSED ENABLES PROGRAM MODE

OR

INPUT+

15

Page 20

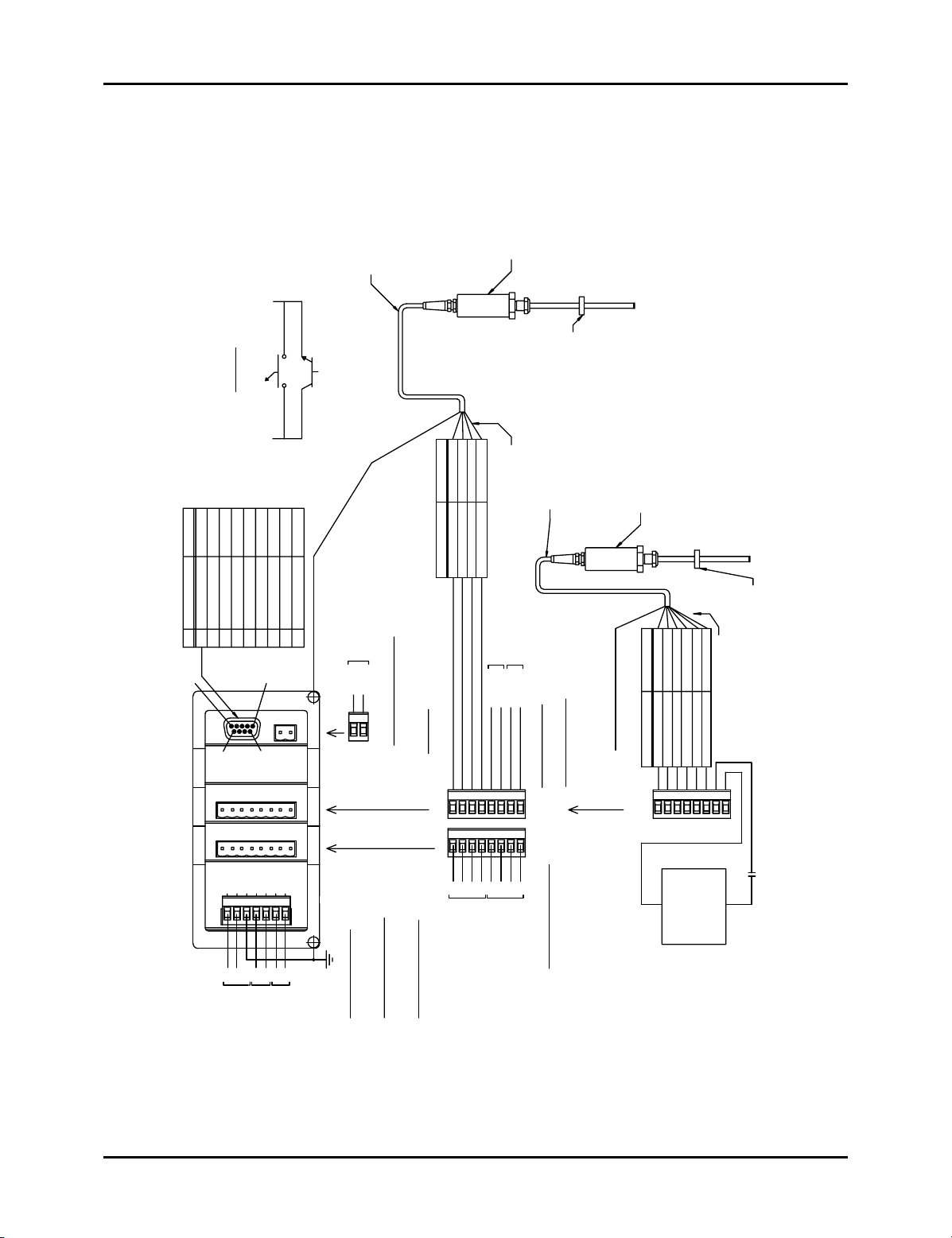

Chapter 3: Mounting and Wiring

PROGRAM

(CLOSED)

DIAGRAM 1

SWITCH CLOSED ENABLES PROGRAM MODE

OR

INPUT+ INPUT-

CABLE ASSEMBLY

(P/N SD0439700)

PIN C

PIN B

PIN F

PIN E

SERIES 951VP-2110

LINEAR TRANSDUCER

(P/N SD0439700)

CABLE ASSEMBLY

TO PROBE WILL RESULT.

RS PROBE TO FM1P01 INPUT CARD. DAMAGE

1. REQUIRED FOR RESET TO PRESET ONLY.

2. WARNING: DO NOT CONNECT A 951 CP OR

NOTES: UNLESS OTHERWISE SPECIFIED

MAGNET ASSEMBLY

LINEAR TRANSDUCER

SERIES 951 OR 952 CP, RS OR VPE

WARNING: SEE NOTE 2.

GND CHASSIS1

PIN SIGNAL NAME DIRECTION

PIN 5

C.P.U.

PROBERELAY

4 3 2 1

POWER

POWER SUPPLY

RXD RS-2322 OUTPUT

PIN 9

1

100-240VAC 50/60HZ

TXD RS-2323 INPUT

L1

L1

POWER

NO CONNECTION4

GND SIGNAL5

PROBEY

R

L2

GND

L2

INPUT

TX2+ RS-485

RTS RS-2327 INPUT

6 +I/O

PIN 1

PIN 6

ALE

FLT CHK

}

4523

67

NO

NO

FAULT

CHECK

CTS RS-2328 OUTPUT

TX2- RS-4859 -I/O

FMIP01

FMOR01 FMMP01

AUX INP

}

FMPS01

L1

L2

INPUT

AUXILIARY

POWER 4 3 2 1

PROGRAM

SECURITY

SHEILD TO CASE ASSEMBLY

INPUT+

INPUT-

21

PROGRAM SECURITY INPUT

SINKING DEVICE, +5VDC MAX

:

AUXILIARY INPUT RATING

85-256VAC @ 12mA

POWER INPUT RATING :

85-265VAC @ 450mA

50-60 Hz

FAULT CHECK

INSULATE AND TIE BACK

ALL UNUSED WIRES

RED

BLACK

BLUE

BROWN

WIRE COLORS PROBE CONN.

AUX POWER

AUX 3 INPUT

INPUT-

INPUT+

+24VDC

GROUND

ON AT < 1VDC @ 0.2mA

SEE DIAGRAM 1 FOR SUGGESTED CONNECTIONS

546

312

FMIP01

PROBE

312

RELAY

NONONCNCNONONC

LIMIT

UPPER

RELAY CONTACT RATING :

8A 250VAC 30VDC

1/4 HP 125, 250VAC

78

87564

LOWER

LIMIT

NC

AUX POWER RATING :

+24VDC @ 15mA

AUX 3 INPUT RATING :

RELAY CONTACT RATINGS :

UPPER & LOWER LIMIT

8A 250VAC 30VDC

SHEILD TO CASE ASSEMBLY

ON AT < 1VDC @ 2mA

SINKING DEVICE, +5VDC MAX

1/4 HP 125, 250VAC

PROBE CONN.

PIN B

PIN C

WIRE COLORS

BLACK

RED

21

PROBE

FMIP02

-

PIN E

PIN F

BROWN

BLUE

GRAY PIN K

3 68745

SUPPLY

OPTIONAL

CUSTOMER

DC POWER

SEE NOTE 1

MAGNET ASSEMBLY

PIN A

ALL UNUSED WIRES

INSULATE AND TIE BACK

WHITE

+

5-24VDC

6mA MAX.

16

Figure 3-11 LDT - Based System Wiring Diagram

Installation and Programming Manual

Page 21

CABLE ASSEMBLY

(P/N SD0403803) FOR 951

VP TRANSDUCER UNIT

PROGRAM

(CLOSED)

INPUT+ INPUT-

OR

JUNCTION BOX

(P/N SD0402100)

DIAGRAM 1

SWITCH CLOSED ENABLES PROGRAM MODE

SD04038031

CABLE TERMINATION KIT

(P/N SD0482700)

QTY PART NUMBER

SD04021001

SD04826001

CABLE ASSEMBLY

(P/N SD0482600)

PIN C

PIN B

PIN F

PIN E

SERIES 951VP-2110

LINEAR TRANSDUCER

Chapter 3: Mounting and Wiring

RS PROBE TO FM1P01 INPUT CARD. DAMAGE

TO PROBE WILL RESULT.

2. WARNING: DO NOT CONNECT A 951 CP OR

1. REQUIRED FOR RESET TO PRESET ONLY.

NOTES: UNLESS OTHERWISE SPECIFIED

MAGNET ASSEMBLY

WARNING: SEE NOTE 2.

LINEAR TRANSDUCER

SERIES 951 OR 952 CP, RS OR VPE

GND CHASSIS1

PIN SIGNAL NAME DIRECTION

PIN 5

C.P.U.

PROBERELAY

4 3 2 1

POWER

POWER SUPPLY

RXD RS-2322 OUTPUT

TXD RS-2323 INPUT

PIN 9

L1

1

100-240VAC 50/60HZ

L1

POWER

NO CONNECTION4

GND SIGNAL5

PROBEY

R

L2

GND

4523

L2

INPUT

TX2+ RS-4856 +I/O

RTS RS-2327 INPUT

CTS RS-2328OUTPUT

TX2- RS-4859-I/O

PIN 1

PIN 6

ALE

AUX INP

FLT CHK

}

}

67

L1

L2

NO

NO

INPUT

FAULT

CHECK

AUXILIARY

FMIP0X

FMOR01 FMMP01

FMPS01

POWER 4 3 2 1

RED

BLACK OF RED

WHITE

BLACK OF WHITE

WIRE COLORS PROBE CONN.

PART NUMBER

SD0403803

SD0402800

SD0402100

1

PROGRAM

SECURITY

SHEILD TO CASE ASSEMBLY

INPUT+

INPUT-

AUX POWER

AUX 3 INPUT

INPUT-

INPUT+

+24VDC

GROUND

CABLE TERMINATION KIT

(P/N SD0443800)

QTY

1

MAGNET ASSEMBLY

1

21

PROGRAM SECURITY INPUT

SINKING DEVICE, +5VDC MAX

ON AT < 1VDC @ 0.2mA

SEE DIAGRAM 1 FOR SUGGESTED CONNECTIONS

AUX POWER RATING :

78

546

312

PROBE

FM1P01

LIMIT

87564

NC

LOWER

LIMIT

UPPER & LOWER LIMIT

312

RELAY

NONONCNCNONONC

UPPER

RELAY CONTACT RATING :

8A 250VAC 30VDC

85-256VAC @ 12mA

FAULT CHECK

1/4 HP 125, 250VAC

AUXILIARY INPUT RATING :

POWER INPUT RATING :

85-265VAC @ 450mA

50-60 Hz

ON AT < 1VDC @ 2mA

+24VDC @ 15mA

AUX 3 INPUT RATING :

SINKING DEVICE, +5VDC MAX

RELAY CONTACT RATINGS :

8A 250VAC 30VDC

1/4 HP 125, 250VAC

SHEILD TO CASE ASSEMBLY

PROBE CONN.

PIN B

PIN C

WIRE COLORS

BLACK OF RED

RED

21

PROBE

FMIP02

-

SEE NOTE 1

PIN E

PIN F

BLACK OF WHITE

WHITE

GREEN PIN K

3 68745

SUPPLY

OPTIONAL

CUSTOMER

DC POWER

PIN A

ALL UNUSED WIRES

INSULATE AND TIE BACK

BLACK OF GREEN

+

5-24VDC

6mA MAX.

Figure 3-12 LDT - Based System w/Cable Termination Kit, Wiring Diagram

Drawing E0228600

Installation and Programming Manual

17

Page 22

Chapter 3: Mounting and Wiring

POWER

POWER SUPPLY

100-240VAC 50/60HZ

L1

21

L2

3

GND

4

FLT CHK

}

5

AUX INP

}

76

FMPS01

POWER

4

RELAY

R

E

L

A

Y

FMOR01

4

PIN25

RSLVR

FMIR01

PIN14

3

3

2

R

E

S

O

L

V

E

R

2

D25 FEMALE

PIN13

1

C.P.U.

D

G

T

L

O

U

T

P

U

T

FMMP01

1

PIN1

DIRECTION

PIN

1

2

3

4

5

6

7

8

9

10

11 OUT

12

13

14

15

16

17

18

19

21

22

23

25

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

IN

COMMON

OUT

OUT

OUT

OUT

OUT

OUT

OUT20

OUT

OUT

OUT

IN

POWER

DESCRIPTION

DATA OUT BIT 0

DATA OUT BIT 2

DATA OUT BIT 4

DATA OUT BIT 6

DATA OUT BIT 8

DATA OUT BIT 10

DATA OUT BIT 12

DATA OUT BIT 14

DATA OUT BIT 16

DATA OUT BIT 18

BUSY

BUS ENABLE (Optional, Consult Factory)

GND

DATA OUT BIT 1

DATA OUT BIT 3

DATA OUT BIT 5

DATA OUT BIT 7

DATA OUT BIT 9

DATA OUT BIT 11

DATA OUT BIT 13

DATA OUT BIT 15

DATA OUT BIT 17

DATA OUT BIT 19

LATCH/SYNC HANDSHAKE24

VSRC+

SEE NOTE 1

}

SEE NOTE 2

SEE NOTE 1

}

18

Figure 3-13A Digital Output Wiring Diagram

Drawing E0232200

Installation and Programming Manual

Page 23

OUTPUT RATING:

SINKNG DEVICE,

5 TO 24 VDC

100mA MAX

OUTPUT RATING:

SOURCING DEVICE,

5 TO 24 VDC

100mA MAX

DIGITAL

OUTPUT

MODULE

DIGITAL

OUTPUTS

DIGITAL

OUTPUT

MODULE

VSRC+

DIGITAL

OUTPUTS

GND

GND

13

DATA 0-19, BUSY

13

25

DATA 0-19, BUSY

Chapter 3: Mounting and Wiring

5 TO 24 VDC

-+

CUSTOMER DC

POWER SUPPLY

COM

{

DC INPUT

SOURCING

5 TO 24 VDC

-+

CUSTOMER DC

POWER SUPPLY

POWER

{

ALLEN BRADLEY

1771.IV

MODICON B833

OR EQUIVALANT

ALLEN BRADLEY

1771.IB

MODICON B825

OR EQUIVALANT

OUTPUT RATING:

TTL DEVICE,

VOH = 3.7 MIN @ IOH = -24mA

VOL = .44 MAX @IOL = 24mA

INPUT RATING:

24VDC @ 9mA MAX

LOW < 1.4V @ 0.5mA

HIGH > 2.0V @ 1mA

TTL COMPATIBLE

DIGITAL

OUTPUT

MODULE

GND

DIGITAL

OUTPUTS

DIGITAL

OUTPUT

MODULE

GND

BUS

ENABLE

LATCH/SYNC

HANDSHAKE

13

DATA 0-19, BUSY

13

12

24

DC INPUT

SINKING

COM

{

DC INPUT

5 TO 24 VDC

-+

CUSTOMER DC

POWER SUPPLY

SOURCING

COM

DC OUTPUT

SOURCING

ALLEN BRADLEY

1771.IG

MODICON B837

OR EQUIVALANT

ALLEN BRADLEY

1771.OB

MODICON B820

OR EQUIVALANT

Figure 3-13B Digital Output Wiring Diagram

Drawing E0232200

Installation and Programming Manual

19

Page 24

Chapter 3: Mounting and Wiring

22 GAGE TWISTED PAIR

WITH SHIELD AND DRAIN

CUSTOMER SUPPLIED

CUSTOMER

EQUIPMENT

SUPPLIED

20

C.P.U.

2 1

4 3

L1

1

POWER

POWER SUPPLY

100-240VAC 50/60HZ

SHEILD TO

CASE ASSEMBLY

FMMP01

CURRENT OUTPUT:

CH2 VDC OUTPUT

CH1 VDC OUTPUT

CH1 VDC GROUND

CH2 VDC GROUND

CH1 CURRENT OUT

CH1 CURRENT RETURN

-10VDC TO +10VDC

CH2 CURRENT OUT

VOLTAGE OUTPUT:

CH2 CURRENT RETURN

INTO 750 OHM LOAD

INTO 1K OHM LOAD

SOURCING 0 - 20mA

{

3

21

ANALOG

AUX INP

FLT CHK

L2

GND

}

4523

}

67

FMPS01

REFER TO MANUAL

FOR CORRECT SLOT

LOCATION BEFORE

INSTALLING MODULE

POWER 4 3 2 1

Fig 3-14 Wiring Diagram Analog Output

Drawing E8005090

Installation and Programming Manual

87645

FMOA01

Page 25

Chapter 4: Programming

Chapter 4: Programming

This chapter provides detailed descriptions and instructions for programming all Interface

Module’s functions. A complete list of functions (with brief explanations) can be found in

Appendix B: Function Summary Chart. This chapter divides the functions into the following

seven sections.

4.1 Resolver Input Confi guration Functions

4.2 LDT Confi guration Functions

4.3 Monitor Setup Functions

4.4 Relay Setup Functions

4.5 Digital Outputs

4.6 Analog Outputs

4.7 Program and Supervisory Mode Functions

Resolver confi guration functions are used to confi gure the Interface Module for use with a

Resolver. (Refer to these functions only if you are using a resolver as an input device). LDT

confi guration functions are used to confi gure the Interface Module for use with a Linear

Displacement Transducer. (Refer to these functions only if you are using an LDT as an input

device.) Confi guration functions should be programmed before any other functions. Monitor

setup functions provide the means to customize the monitor’s setup for a specifi c installation.

System setup functions provide the means to customize the Interface Module for a specifi c

installation. Program and supervisory mode functions are used to put the Interface Module in

either program or supervisory mode, as well as program the length of programming time and to

change the program mode access code.

NOTE: Resolver or LDT confi guration functions should be programmed fi rst before any other

type of programming is done. Refer only to your specifi c confi guration section,

depending on which input device you are using.

Before You Start

Before confi guring or programming the Interface Module, the following must be done in the

following order:

Jumper the monitor’s program lockout connector (J2). To jumper this connector,

see Section 3.2 Wiring.

Put monitor in program mode. For instructions on putting the monitor in

program mode, see Program Mode Access in Section 4.7: Program and Supervisory Mode Functions.

The program mode LED will turn on when the monitor is in program mode.

Installation and Programming Manual

21

Page 26

Chapter 4: Programming

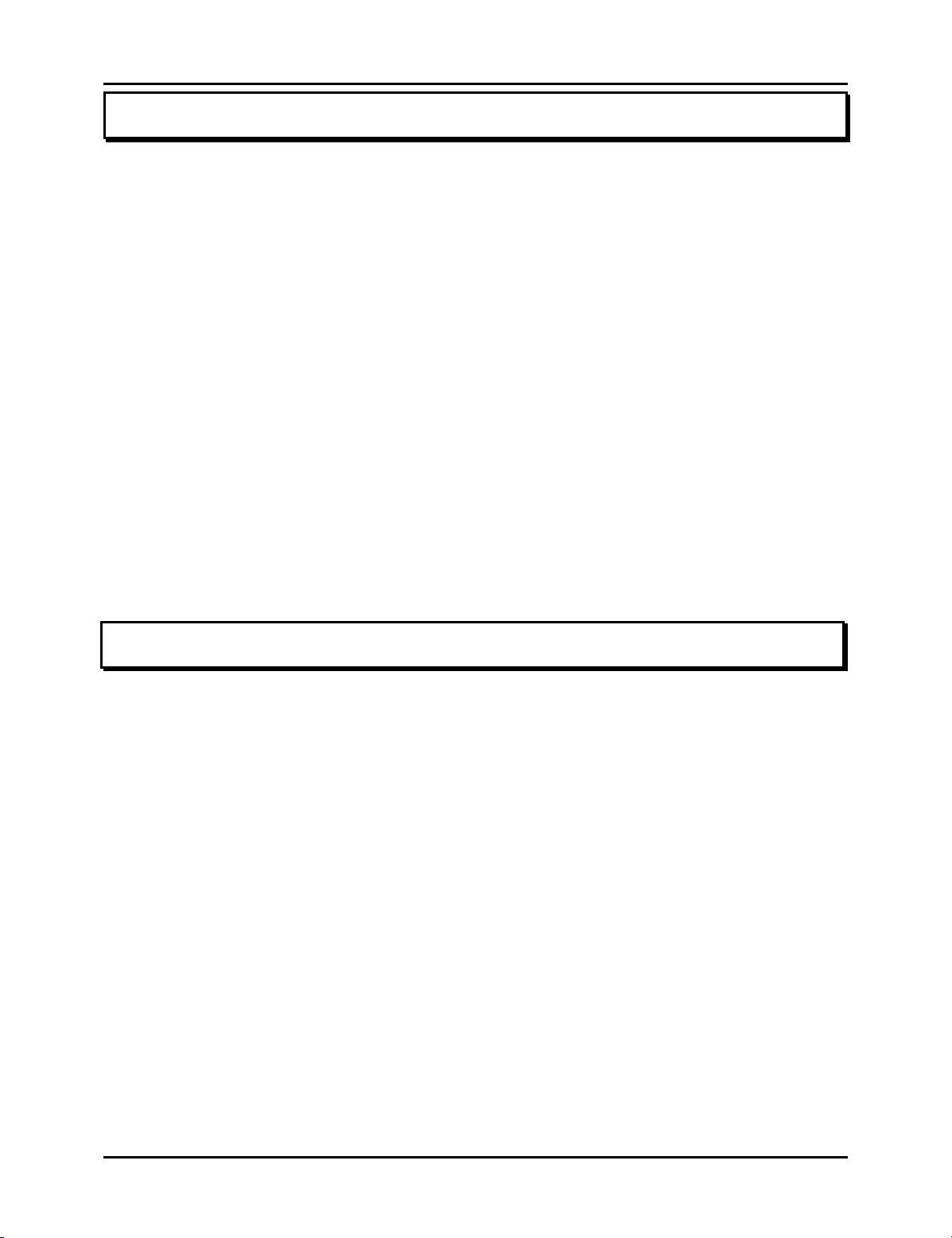

Figure 4-1 calls out the Interface Module’s programming keys. Following this fi gure are

descriptions of these keys and how they work, as well as, a short tutorial on how to use the

keys.

PROGRAM

FLT OK

MVT FLT

POSITION

RPM

UPR LIM

LWR LIM

AUX 1

AUX 2

AUX 3

Status LEDs

()

F

SERIES

2120

Enter Key

Shift Key

Scroll Key

Function Key

Figure 4-1 Programming Keys

Programming Keys Defi ned

The Interface Module has four keys located on the front panel. These keys are used to program

functions and perform basic operations.

The function key is used to begin a process for programming a function.

(F)

The scroll key is used to scroll through the Interface Module’s list of

When this key is pressed, the Interface Module prepares itself for the entry

of a specifi c function number.

function numbers, as well as, other lists. To scroll to a particular function

number, continue to select the scroll key (after selecting the function key)

until the Interface Module displays the desired function number. The

scroll key is also used to increment selected digits on the monitor’s LED

display. Incrementing digits can be done to either select a function number

or a value for a function. To move to a specifi c digit on the display, use

the shift key. A fl ashing digit indicates it is activated to be incremented.

This key can also be used to get you quickly out of an incorrect parameter rather than having to restart the function entry process. For example, if an

invalid parameter was entered in the Upper End Limit function, you could

select the scroll key. This would take the monitor back to displaying the

current value, where you could re-enter a new value.

22

Installation and Programming Manual

Page 27

Chapter 4: Programming

The shift key is used to move to a specifi c digit shown on the Interface

The enter key is used for several purposes. For example, it is selected after

Module’s LED display. This can be done to either select a function number

or a value for a function. To move to a specifi c digit on the display, select

the function key and then the shift key. The right-most digit will then fl ash.

This indicates that the digit is activated to be incremented. (To increment

the digit, select the scroll key.) Continue to select the shift key until the

desired digit is activated.

a function number is displayed. This begins the programming process for

the selected function. The enter key is also used to program a value in a

function. This is done by selecting the enter key after the desired value is

displayed on the monitor’s screen.

4.1: Resolver Input Confi guration Functions

To customize the Interface Module to your specifi c resolver and application, you must fi rst make

some confi gurations. These confi gurations are made through the use of resolver confi guration

functions, which are described in this section. Perform these confi guration procedures before

entering other function values. After the resolver input has been confi gured, you may proceed on

to function 305 ( Display Power Up) and 307 (Resolver Reset-to-Preset).

Scale Factor (300)

Turns Counting (301)

Position Offset (302)

Turns Counting Wrap Around (308)

Scale Factor (300)

The Scale Factor function is used to program the number of counts or the resolution that one

revolution of the resolver results in. For example, when the function is programmed with a value

of 100, the Interface Module will count from 0 to 99 as the resolver completes a full revolution.

The default value for this function is 4096.

Turns Counting (301)

The Turns Counting function defi nes the number of revolutions the resolver must rotate before

the scale factor is reached. For example, when this function is set at 2 and the scale factor is

set at 100, the resolver will have to make two full revolutions before 100 counts is reached.

The Turns Counting Function can be disabled by setting its value to 0. When disabled, the

scale factor will cover its entire range in one revolution and roll over to 0 after one complete

revolution. When the Turns Counting function is set to 1, the total count will increase by the

scale factor for each revolution. For example, if the scale factor was set at 100 and turns counting

at 1, after fi ve revolutions, the monitor would display 500 counts. The default value for this

function is 0.

Installation and Programming Manual

23

Page 28

Chapter 4: Programming

Turns Counting Wrap Around (308)

When using the Turns Counting software described above where the Turns Count Function (301)

is set for 2 or more, you have the option of selecting the Wrap Around feature. Under normal

operation, you select a scale factor using function 300 followed by the number of turns required

to reach the selected scale factor using function 301. Upon reaching the selected scale factor,

the count will continue to increase at the same rate if the resolver continues rotating in the same

direction. With a scale factor of 100 and a turns count of 2, the module will count from zero

to 100 over the fi rst two rotations and will continue to increase by a factor of 100 for every

additional two turns in the same direction. The Wrap Around function allows you to program a

scale factor followed by the number of turns required to reach the scale factor. Upon reaching

one digit less than the scale factor, the display and output count wraps around to zero and begins

counting up at the same rate over continued rotation in the same direction.

Position Offset (302)

The Position Offset function is used to synchronize the resolver’s position with the actual

machine position. The default value for this function is 0. This function is used to adjust the

Interface Module’s indicated position so that it truly refl ects the machine’s position.

Programming Scale Factor (300)

This subsection provides the necessary instructions to program the scale factor. Once these steps

have been performed they will not have to be repeated.

(F)

1. Select the function key.

The monitor displays “F-----”.

10

2. Enter function number 10. (This is the Program Mode Access function which

allows you to put the monitor in program mode. Only when the Interface

NOTE: If the Interface Module displays only one zero (i.e. “0”), then the program lockout

connector is not jumpered. For wiring instructions, see Section 3.2: Wiring.

Enter program mode

access code

Module is in program mode can other functions be programmed.) Select the

enter key.

The monitor displays “000000”.

3. Enter the program mode access code. The default code is 2100. Select the

enter key.

24

The monitor is now in program mode. The program mode LED is turned on.

Installation and Programming Manual

Page 29

Chapter 4: Programming

NOTE: The Interface Module is defaulted to stay in program mode for 120 seconds. The

monitor will drop out of program mode if a key is not pressed within this time. If this

occurs, you will have to repeat steps 1-3. Further, the access code (2100) is provided

initially. This code can be changed through the use of the New Access Code function.

For security reasons, this function can only be implemented when the monitor is in

supervisory mode. For more information on, New Access Code, contact the factory.

(F)

300

Adjust the Turns Counting Factor (301)

(F)

301

Number

of Turns

4. Select the function key.

The monitor displays “F-----”.

5. Select function number 300 (Scale Factor function). Select the enter key.

The monitor displays currently programmed scale factor.

6. Enter the desired scale factor value, including digits up to a maximum of three

spaces to the right of the decimal point. Select the enter key.

7. Select the function key.

The monitor displays “F-----”.

8. Select function number 301 (Turns Counting function). Select the enter key.

The monitor displays currently programmed turns counting factor

9. Enter desired number of turns to reach scale factor. Select enter key.

Select Wrap Around Feature (308)

(F)

308

Enter 0 or 1

10. Select Function Key.

The monitor displays “F----”.

11. Select Function 308 (Wrap Around Feature). Select enter key.

The monitor displays 0 or 1.

0 = Wrap Around Disabled

1 = Wrap Around Enabled

12. Enter 0 or 1. Select enter key.

Installation and Programming Manual

25

Page 30

Chapter 4: Programming

Program Position Offset (302)

(F)

13. Select the function key.

The monitor displays “F----”.

302

14. Select function number 302 (Position Offset Function). Select the enter key.

Enter desired

reading

The monitor displays the current position.

15. Enter the actual or desired machine position reading. Select the enter key.

After confi guring the encoder module for use with a resolver, you can proceed

to Section 4.3: Monitor Setup functions.

Display Power Up (305)

This function is used to set what will be displayed on Power Up.

(F)

16. Select the function key.

The monitor displays “F----”.

305

17. Select function number 305 (Power Up Function). Select the enter key.

Enter 0 or 1

The monitor displays 0 or 1.

0 = Power Up Displaying Position

1 = Power Up Displaying RPM

18. Enter 0 or 1. Select enter key.

Resolver Reset-to-Preset (307)

The reset-to-preset input is an edge sensitive input that resets position data to a preprogrammed

value. An open collector sinking device or dry contact applied to these terminals activates

the input.

(F)

19. Select the function key.

The monitor displays “F----”.

307

20. Select function number 307 (Resolver Reset-to-Preset). Select the enter key.

The monitor displays current value.

26

Installation and Programming Manual

Page 31

Chapter 4: Programming

Enter Desired

Position

21. Enter desired Reset Value. Select the enter key.

NOTE: If 301 is set to 0, the Reset Value must be less than the Scale Factor.

4.2: LDT Confi guration Functions

There are two input cards available for use with LDTs.

1. Specifi ed as option V1 in the part number and is labeled (FMIP01) on the card.

2. Specifi ed as option L1 in the part number and is labeled (FMIP02) on the card.

The confi guration of the system is different depending on which module you have ordered.

Determine which module you have and proceed to the section below for programming

instructions.

Option V1 - This module can only be used with Gemco LDTs with a part number starting

with 951VP1992 or 951VP2110.

Wire speed and recirculations for these LDTs have been confi gured at the factory for maximum

resolution.

NOTE: Always refer to the LDT legend plate for programming wire speed (Function 300). The

wire speed will always be between 500.000 and 600.000 micro sec./inch.

Option L1 - This module is designed to be used with any LDT with digital output. These

include Series 951, 952 with VP, RS or CP outputs.

This module provides faster updates of position while using the LDT with standard wire speeds.

NOTE: Review the LDT legend plate for correct wire speed. Wire speed will always be

between 8.000 and 10.000 micro sec./inch.

4.2

NOTE: If option L1 is used, the fi rst step in confi guration must be Function 307 (LDT Type),

which tells the module which LDT is being used.

NOTE: Before an LDT confi guration function can be programmed, the Interface Module must

be in program mode. To put the monitor in program mode, see Program Mode Access

in Section 4.7: Program and Supervisory Mode Functions.

Installation and Programming Manual

27

Page 32

Chapter 4: Programming

Wire Speed (300)

Programming of the wire speed synchronizes the performance of the module with the performance

of the LDT. You will fi nd the wire speed on the legend plate of your LDT.

To program wire speed, perform the following steps:

(F)

1. Select the function key.

300

Enter new

value

The monitor displays “F-----”.

2. Select function number 300. Select the enter key.

The monitor displays the current wire speed.

3. Enter the new wire speed value. Select the enter key.

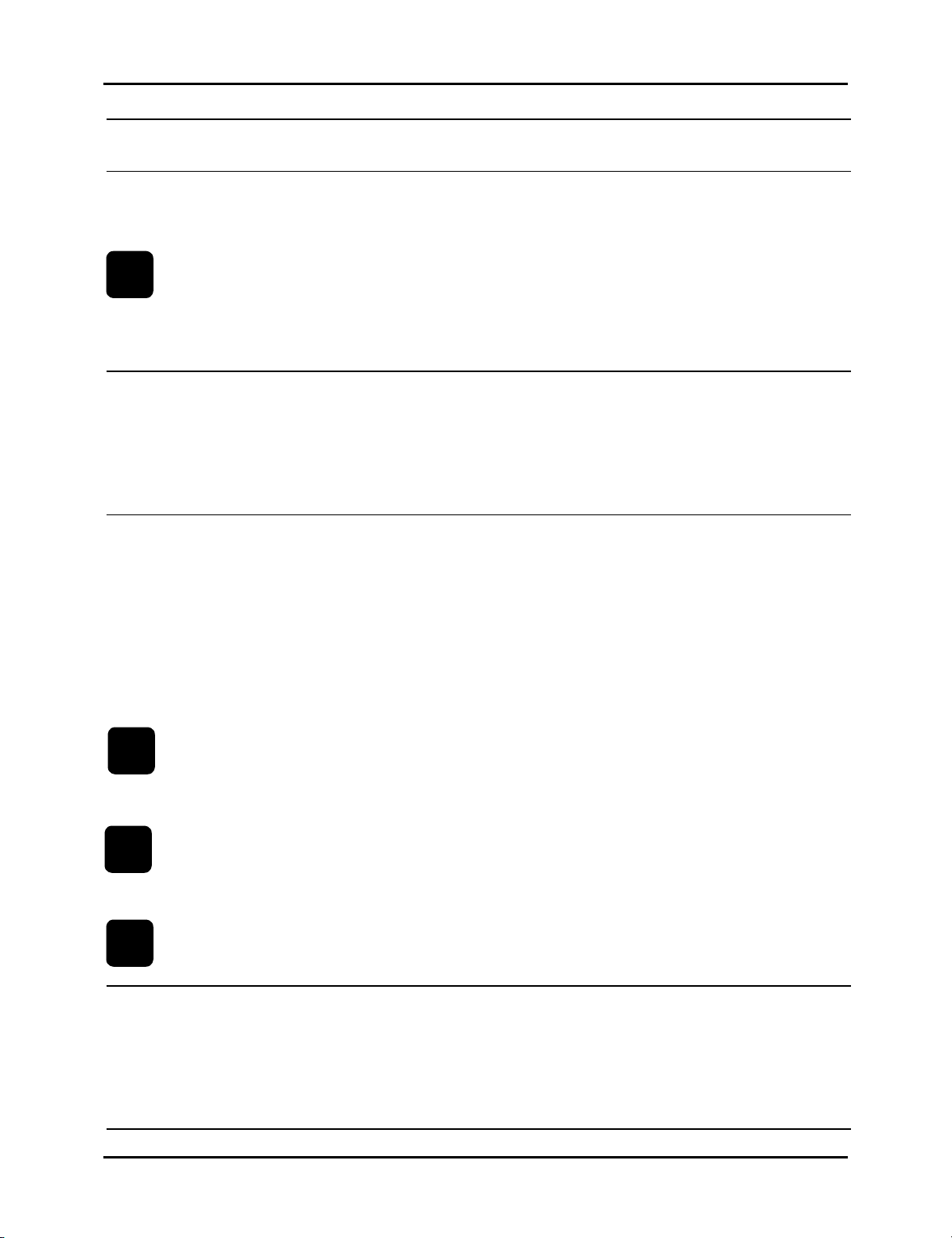

Count Direction (301)

The Count Direction function is used to change the direction the display counts as the LDT’s

magnet travels along the guide tube. A 0 value will cause the position value to increase as

the magnet moves away from the LDT head. A value of 1 will cause the position value to

increase as the magnet moves toward the LDT head. The default for this function is 1. For further

explanations, see Figure 4-2. To change the value of the Count Direction function, perform the

following steps:

(F)

301

1. Select the function key.

The monitor displays “F-----”.

Enter either

0 or 1

28

2. Select function number 301. Select the enter key.

The monitor displays the function’s current value.

3. Enter either a 0 or 1. Select the enter key.

Installation and Programming Manual

Page 33

Chapter 4: Programming

Count Direction Function = 0

0

When the Count Direction Function

is programmed with a value of 0, the

display value will increase when the

LDT’s magnet assembly is moving away

from the head of the LDT.

100

Count Direction Function = 1

100

When the Count Direction Function

is programmed with a value of 1, the

display value will increase when the

LDT’s magnet assembly is moving

toward the head of the LDT.

0

Figure 4-2 Count Direction Function Drawing

Position Offset (302)

NOTE: The display will read in inches or millimeters when used with an LDT. Make sure

the unit of measurement function is selected to your desired units before entering the

value for the Position Offset function. The unit of measurement is set in inches at the

factory. For instructions on selecting the unit of measurement, see Unit of Measurement

in Section 4.3: Monitor Setup Functions.

The Position Offset function is used to synchronize the monitors displayed value with actual

machine position. This value can range from -99.999 to 999.999 inches. With the machine

stationary at a known position, enter the desired position value using this function:

(F)

1. Select the function key.

The monitor displays “F-----”.

302

2. Select function number 302. Select the enter key.

Enter desired

reading

The monitor displays the current position.

3. Enter the new position value. Select the enter key.

Installation and Programming Manual

29

Page 34

Chapter 4: Programming

Fault Pulse Time (306)

Most magnetostrictive LDTs send out a fault pulse during a fault condition. The series 2120

Interface Module is preset for use with all Gemco LDT products. The Fault Pulse Time function

is used to program the pulse time of the fault signal sent by an LDT not manufactured by

Gemco. When the monitor receives a fault signal of this pulse time, it will indicate an error (see

Appendix A: Error Messages). The default for this function is 10 microseconds. This value

can range from 1 to 99 microseconds. A 0 is entered in this function to disable it. To change the

value of the fault pulse time or disable this function, perform the following steps:

NOTE: Do not change the value unless using an LDT other than Gemco.

(F)

1. Select the function key.

The monitor displays “F-----”.

306

2. Select function number 306 . Select the enter key.

The monitor displays the function’s current value.

LDT Output Type (307)

This function is used to confi gure the L1 input board for use with a specifi c LDT output. Review

legend plate of the LDT for output type, i.e. CP, RS or VP. Perform the following steps:

(F)

307

Enter New

Value

0 thru 3

3. Enter a 0 to disable this function or enter a new fault pulse time. Select

the enter key.

1. Select the function key.

The monitor displays “F-----”.

2. Select function number 307 . Select the enter key.

Enter either:

0 = CP

1 = RS

2 = VP (external interrogation) (See Note below)

3 = VP (internal interrogation)*

3. Select enter key.

*If used, consult the factory for additional settings.

NOTE: The Variable Pulse with external interrogation mode is not compatible with the 952 probe.

When using a 952 probe, select a different mode of operation.

30

Installation and Programming Manual

Page 35

Chapter 4: Programming

After confi guring the Interface Module for use with an LDT, you can proceed to Section 4.3:

Monitor Setup Functions.

LDT L1 Input Reset-to-Preset (311)

The reset-to-preset input is an edge sensitive input that resets position data to a preprogrammed

value. A 5-24VDC source applied to these terminals activates the input.

(F)

1. Select the function key.

The monitor displays “F----”.

311

2. Select function number 311 (LDT L1 Input Reset-to-Preset Function). Select

Enter desired

value

the enter key.

The monitor displays the current value.

3. Enter desired Reset-to-Preset value. Select the enter key.

4.3: Monitor Setup Functions

This section provides descriptions and instructions for the Interface Module setup functions.

These functions provide the means to customize the monitor’s setup for a specifi c installation.

Before any of these functions can be programmed, the monitor must be in program mode. To

put the monitor in program mode, see Program Mode Access in Section 4.7: Program and

Supervisory Mode Functions. The following is a list of the monitor setup functions:

Unit of Measurement (14)

Decimal Location (13)

Position Hold (15)

Auxiliary LED (16)

Unit of Measurement (14)

NOTE: This function applies to LDT inputs only.

The Unit of Measurement function is used to select the unit of measurement in which position

data is displayed. Measurements can be either in inches or millimeters. Enter 0 to select inches

or enter 1 to select millimeters. The default for this function is 0. To change the unit of

measurement, perform the following steps:

Installation and Programming Manual

31

Page 36

Chapter 4: Programming

(F)

1. Select the function key.

The monitor displays “F-----”

14

2. Enter function number 14. Select the enter key.

Enter either 0

or 1

The monitor displays the function’s current value.

3. Enter either 0 or 1. Select enter key.

NOTE: If you change the unit of measurement, the decimal location shown on the monitor’s

LED display will change to the default position for the unit of measurement selected.

If you select millimeters, position data will be displayed in hundredths; selecting inches

will display data in thousandths. For more information, see Decimal Location.

Decimal Location (13)

The Decimal Location function is used to program the resolution of the Interface Module and all

position data shown on the monitor’s LED display. Resolution can be either displayed in whole

units, tenths, hundredths, or thousandths. Resolution choices correspond to the following values:

0 = whole unit; 1 = tenths; 2 = hundredths; and 3 = thousandths. To change the resolution shown

on the monitor’s LED display, perform the following steps:

(F)

13

1. Select the function key.

The monitor displays “F-----”

2. Select function number 13. Select the enter key.

Enter either 0,

1, 2, or 3

The monitor displays the function’s current value.

3. Enter either a 0, 1, 2, or 3. Select the enter key.

Position Hold (15)

The Position Hold function stops the monitor from displaying irrelevant fl uctuations during

periods of high vibration at the sensor. When the monitor’s auxiliary input is activated, this

function will hold the last position read. Either 0, 1, or 2 can be programmed in this function.

Entering 1 will cause the monitor to hold the last position read when power is applied to the

auxiliary input. Entering 2 will cause the monitor to hold the last position read when power

is taken away from the auxiliary input. Entering 0 disables this function. The default for this

function is 0. Enabling this function disables the Move Detection Time-Out function. When

the Position Hold function is enabled, the value for the Move Detection Time-Out is then

32

Installation and Programming Manual

Page 37

Chapter 4: Programming

used for the Position Hold dwell time. The position hold dwell time is the amount of time

the monitor continues to hold the displayed position after the auxiliary input is released (or

activated, depending on the input’s programmed state). To enable or disable the Position Hold

function, perform the following steps:

(F)

15

Enter either 0,

1, or 2

1. Select the function key.

The monitor displays “F-----”

2. Enter function number 15. Select the enter key.

The monitor displays the function’s current value.

3. Enter either 0, 1, or 2. Select the enter key.

NOTE: The default time for the position hold dwell may be too long for your application. To

change this value for your application, perform the following steps.

(F)

12

4. The default value for the position hold dwell time function is 5.00 seconds. To

change this value, select the function key.

The monitor displays “F-----”