Page 1

1986l Resolver Data Sheet

Absolute Rotary Sensing

1986 Series

The Gemco Series 1986 Resolver

has been the preferred source

for rugged and accurate rotary

positioning in a variety of industrial

applications.

The brushless resolver works on the

same principle as a rotary transformer

to couple power in the rotor. The

internal brushless resolver has three

separate windings: a reference

winding, a SIN winding and a COS

winding.

The reference winding is excited by

an AC voltage. The SIN and COS

winding are set 90° apart and provide

two different output voltages whose

ratio represent absolute position of

the shaft.

The advantage of resolver

transducers over other rotary position

products is that resolvers hold up

better in harsh environments and they

are always absolute, so if power is

lost and restored, the exact position

data will be communicated.

In long cable runs a resolver signal

can typically go much further than

other technologies. Resolvers have

long been the standard rotary position

method in packaging, primary metals

manufacturing, stamping, automotive,

tire and rubber, paper mills and

mining.

Gemco has always been a pioneer

in the design and manufacturing of

“built to order” resolver packages.

We can mechanically and electrically

match any competitor’s package while

improving on the overall design to

enhance the performance, accuracy or

durability.

Through our wide range of materials

for construction and precision gear

reducers we can extend your sensor’s

life many times over.

We offer packages with multiple

sensors and gear reducers in a variety

of materials. We have engineered

special resolver packages with

stainless steel housings, oil filled

packages, high RPM, high resolution,

resolver/encoder combinations and

tach generators.

Resolver Specifications

Shaft Loading Axial

Shaft Loading Radial 100 lbs. Max.

Enclosure NEMA 4

Temperature

Shock 50G’s for 11 mSec

Vibration 5 to 2000Hz @ 20G’s

RPM 5,000 Max.

Stator 1 Voltage

Stator 2 Voltage

90 180 270 360

50 lbs. Max.

-40° to 125°C

Ratiometric conversion of the

two secondary coil voltages

provides absolute position data,

and factors out EMI.

Page 2

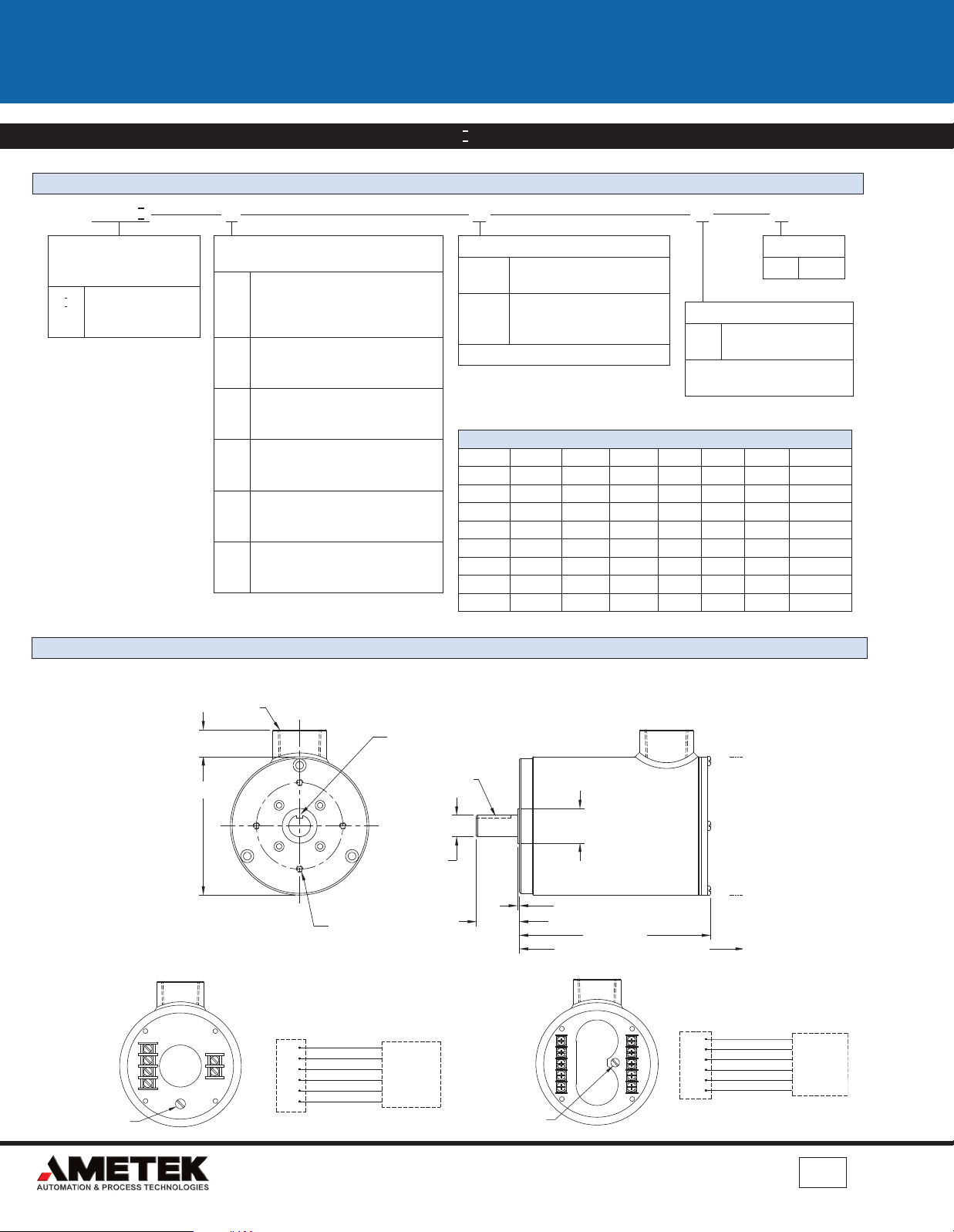

4.00 [101.6]

.78 [19.81]

1.25 [31.75]

.06 [1.59]

.6247

.6

243

[

15.87

15.86

]

1.003 [25.48]

1" NPT

CONDUIT

[ ] = DIMENSIONS IN MILLIMETERS

SPECIFICATIONS

SEE KEY WAY

10-32 UNF 2B

.3

8 DEEP (4 PLACES)

ON 2.500 DIA. B.C.

5.50 [139.70]

APPROXIMATE ZERO

REFERENCE POSITION

WITH KEYWAY

6.50 [165.10] HIGH RATIO UNITS

DIA.

DIA.

DIA.

1.25 [31.75]

.06 [1.59]

.6247

.6

243

[

15.87

15.86

]

1.003 [25.48]

S2 (YELLOW)

TERMINAL BLOCK

TRANSFORMER

S4 (BLUE)

RESOLVER

"SIN" WINDING

1

RED / WHITE

YELLOW / WHITE

6

BLUE

YELLOW

RED

BLACK

4

5

2

3

RESOLVER TO TERMINAL

WIRING DIAGRAM

(RED / WHITE)

ROTARY

R1

(Y

ELLOW / WHITE)R2

[ ] = DIMENSIONS IN MILLIMETERS

2

RESOLVER SCHEMATIC

"COS." WINDING

(RED)

S1

(BLACK)

S3

SPECIFICATIONS

SEE KEY WAY

10-32 UNF 2B

.3

8 DEEP (4 PLACES)

ON 2.5

00 DIA. B.C.

5.50 [139.70]

1 2 5

3 4

6 7

108 9

APPROXIMATE ZERO

REFERENCE POSITION

WITH KEYWAY

GROUND SCREW

(SH

IELD)

CAUTION

USE OF FLEXIBLE SHAFT

COUPLING IS RECOMMENDED.

DO NOT HAMMER OR PRESS

COUPLINGS, PULLEYS, ETC. ON

SHAFT. USE SLIP FIT ITEMS .

6.50 [165.10] HIGH RATIO UNITS

S4

S2

S3

R2

S1

R1

DIA.

DIA.

1.25 [31.75]

.06 [1.59]

Ø

.6

247

.6

243

[

15.87

15.86

]

Ø1.003 [25.48]

S2 (YELLOW)

TRANSFORMER

S4 (BLUE)

"SIN" WINDING

RESOLVER TO TERMINAL

WIRING DIAGRAM

(RED / WHITE)

ROTARY

R1

(Y

ELLOW / WHITE)R2

[ ] = DIMENSIONS IN MILLIMETERS

adial: 100 lb.

xial: 50 lb.

2

RESOLVER SCHEMATIC

"COS." WINDING

(RED)

S1

(BLACK)

S3

SPECIFICATIONS

SEE KEY WAY

10-32 UNF 2B

.3

8 DEEP (4 PLACES)

ON 2.5

00 DIA. B.C.

5.50 [139.70]

APPROXIMATE ZERO

REFERENCE POSITION

WITH KEYWAY

GROUND SCREW

(SH

IELD)

CAUTION

USE OF FLEXIBLE SHAFT

COUPLING IS RECOMMENDED.

DO NOT HAMMER OR PRESS

COUPLINGS, PULLEYS, ETC. ON

SHAFT. USE SLIP FIT ITEMS .

S1

S2

S3

S4

R1

R2

RESOLVER

YELLOW

TERMINAL BLOCK

BLACK

BLUE

S4

S2

S3

RED / WHITE

RED

YELLOW / WHITE

R2

S1

R1

1986l Resolver

Part Numbering

1986l 1 X S X

Mounting

Configuration and

Shaft Size

4.00” round face

I

mount 5/8” input

shaft

Resolver Electrical Output

Characteristics

1 Standard output compatible with

all Gemco electronic modules &

Autotech.

Resolver No. 04535001

2 Special output compatible with

AMCI resolver input devices.

Resolver No. 04535076

3 Special output compatible with

GE axis positioning modules.

Resolver No. 04535044

4 Special output compatible with

Modicon motion cards.

Resolver No. 04535076

5 Special output compatible with

Reliance resolver input card.

Resolver No. 04535023

6 Special output compatible with

Namco resolver input card.

Resolver No. 04535053

Dimension Drawing

Single/Multi-Turn

Single turn resolver.

X

No gear reducer.

GR__

Single turn resolver with

internal gear reducer

1.5:1 to 520:1.

Lengths may vary with gear reducer.

S Side conduit entrance

w/ terminal blocks

Options

X None

Connection

Consult factory for other

connector options.

Single Resolver Gear Reducers

1.5:1 7.5:1 15:1 24:1* 48:1 75:1 160:1 360:1

2:1 7.625:1 16:1 25:1 50:1 80:1 180:1 400:1

3:1 8:1 17:1 30:1 54:1 90:1 200:1 500:1

4:1 9:1 18:1 31.25:1 58:1 91:1 210:1 520:1

4.75:1 9.2:1 19:1 35:1 60:1 100:1 225:1

5:1 9.5:1 19.5:1 36:1* 64:1 115:1 250:1

6:1 10:1 20:1 38:1 65:1 120:1 270:1

6.15:1 12:1 21.66:1 40:1 70:1 128:1 310:1

7:1 14:1 23:1 42:1 73:1 150:1 350:1

1080 N. Crooks Road, Clawson, MI 48017-1097

Phone: 248.435.0700 Toll Free: 800.635.0289 Fax: 248.435.8120 www.AMETEKAPT.com

Copyright 2004 by AMETEK AUTOMATION & PROCESS TECHNOLOGIES. All Rights Reserved. Made in the USA. Version 1.0.

SINGLE TURN

*

**

GEARED SINGLE TURN

* Single Turn Models.

Also 24:1 and 36:1 Ratios.

** Multi Turn Models.

1986I.DOR

2/05.Z178

1M

Loading...

Loading...