Page 1

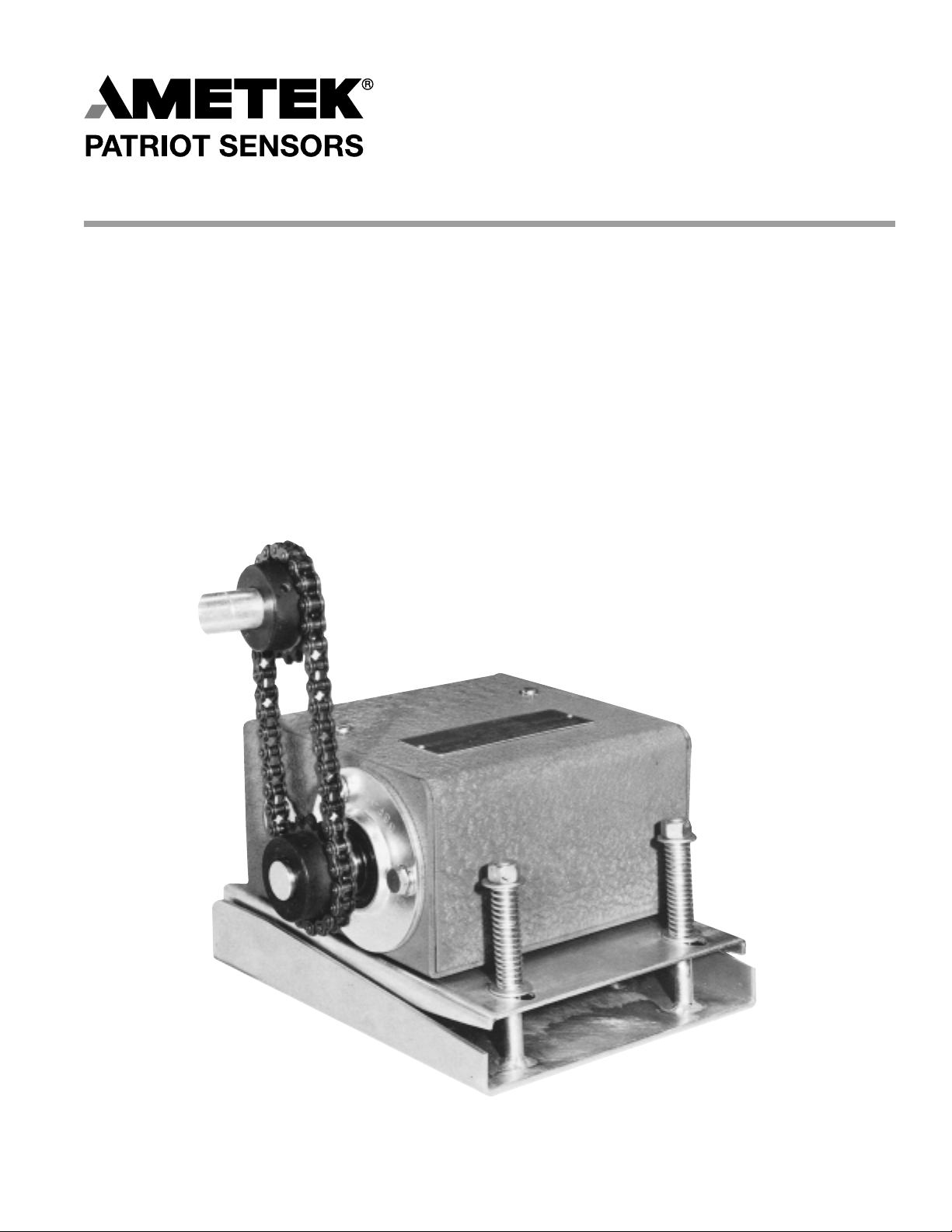

Series 1970

Gemco

™

Drive-Chek

TM

Control Catalog

. . . OFFERS ENGINEERED PROTECTION FROM . . .

• BROKEN DRIVE CHAINS

• VIBRATION

• LOOSE DRIVE CHAINS

• SHOCK DAMAGE

DRIVE-CHEK

WITH GEMCO ROTATING

CAM LIMIT SWITCH

Page 2

2

DESCRIPTION

The DRIVE-CHEK is a multi-purpose sub base that is

mounted under a chain or belt driven mechanism. The unit

serves three purposes; namely, a broken chain or belt

detector, a chain or belt tightener, and a shock and vibration

isolator.

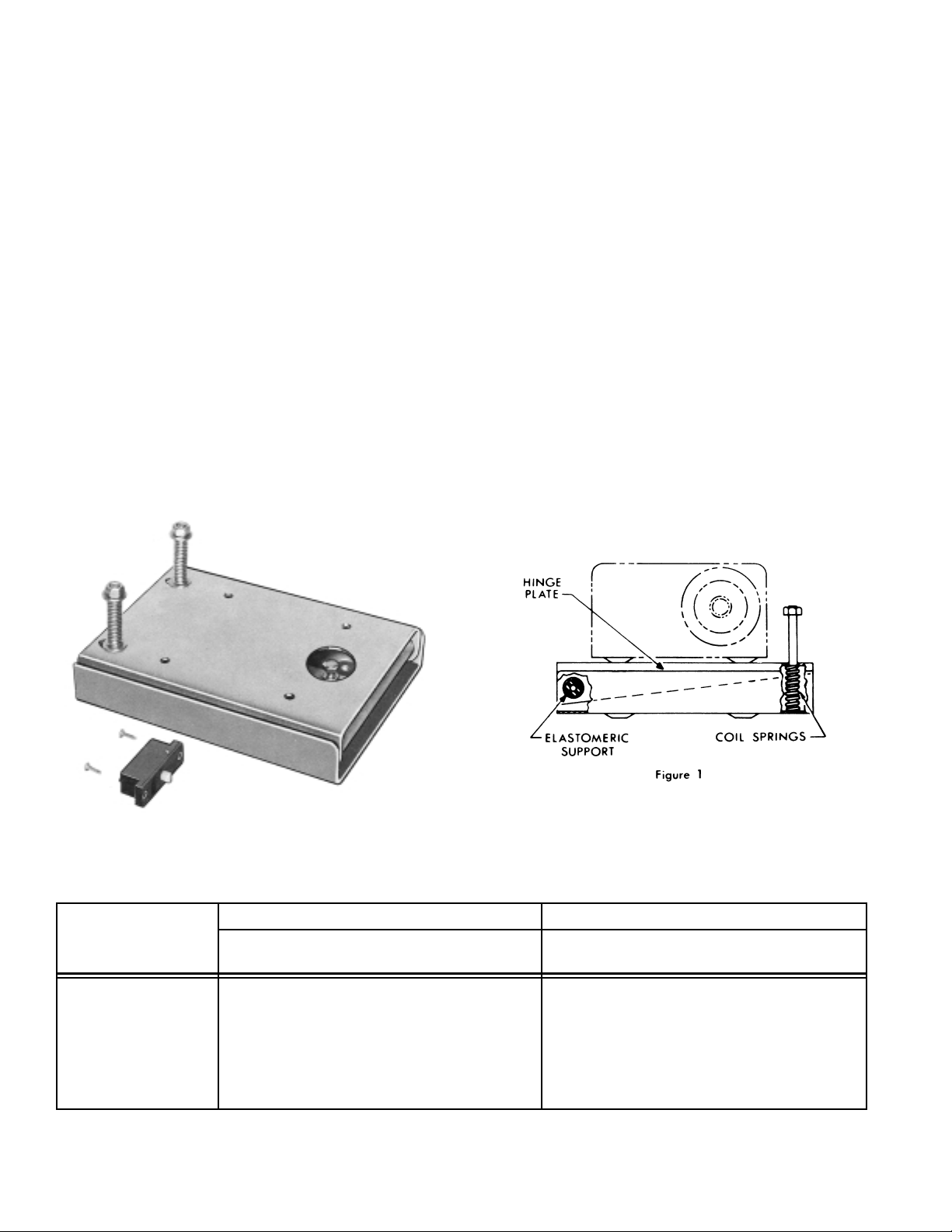

A Gemco Indicator Switch is provided with each DRIVE-

CHEK Unit to indicate when a drive belt or chain failure has

occurred. Shock and vibration from the machine to the

hinge plate of the DRIVE-CHEK Unit are dampened by coil

springs on one end of the hinge plate and an elastomeric

support on the other end.

The springs also maintain a constant tension in the drive

belt or chain. DRIVE-CHEK is of rugged welded construction and is painted to prevent corrosion. The drive chain or

belt can be attached to the mechanism being driven from

either above or below the DRIVE-CHEK base.

The mounting and set up procedures for the DRIVE-CHEK

Indicator Switch and the location of the coil springs are outlined on pages 4 and 5.

DRIVE-CHEK INDICATOR SWITCH

Function and Installation

A Gemco single pole double throw switch with mounting

plate is supplied with each DRIVE-CHEK Unit and can be

easily mounted inside the Gemco Rotating Cam Limit

Switch enclosure. A Gemco double pole double throw

switch can also be supplied at additional cost.

Three holes are drilled in the base of the Rotating Cam Limit

Switch (see pages 6 and 7 for size and location) to mount

the DRIVE-CHEK Indicator Switch. After the unit is mount-

ed on the machine with the Rotating Cam Limit Switch and

drive chain in place, the two coil springs between the stationary and movable part of the unit will be compressed to

nearly their solid height.

The indicator switch is then adjusted to be engaged. If the

chain breaks or runs off its sprockets, the coil springs will

raise the hinge plate and the indicator switch will be disengaged (when the drive is below the hinge plate). The switch

would be wired into the control circuit of the machine drive

to stop the machine.

When ordering the DRIVE-CHEK Unit with the Gemco

Rotating Cam Limit Switch, there will not be any additional

charge for drilling the holes in the Rotating Cam Limit Switch

enclosure for the Gemco Indicator Switch.

1980 NEMA 1 1980 NEMA 4 and 12

No. of

Circuits Catalog Number Catalog Number

2 – 4 1970-104 1970-1204

5 – 6 1970-106 1970-1206

7 – 8 1970-108 1970-1208

9 – 12 1970-112 1970-1212

13 – 16 1970-116 1970-1216

17 – 20 1970-120 1970-1220

21 – 24 1970-124 1970-1224

Addition Replacement indicator switch

S.P.D.T. Cat. No. 1950-1404

D.P.D.T. Cat. No. 1950-1405

DRIVE-CHEK for Gemco Catalog Section

1980 Rotating Cam Limit Switches*

Page 3

3

1. Align Drive Sprockets and mount DRIVE-CHEK

base using 5/16" bolts.

2. Engage proper length drive chain to allow hinge

plate to be parallel to the base when drive chain

is tight.

3. Attach flexible conduit to allow free movement of

the hinge plate.

4. Set switch adjustment bolt to engage indicator

switch if the drive chain breaks.

5. Tighten adjustment bolt locknut.

6. Assemble springs with washers on each end of

the coil springs and self-locking nuts. The springs

should be compressed to nearly solid height.

7. Check the movement of the hinge plate to insure

that the conduit and chain guard does not restrict

the hinge plate from tripping the DRIVE-CHEK

Indicator Switch.

MOUNTING and SET-UP for GEMCO DRIVE-CHEK

with DRIVE CHAIN UNIT

1 2

3 4

5 6

6A

6A - Drive chain below is the same procedure to

install

Page 4

1970.C1

4/99 • Z26

1M

DRIVE-CHEK DIMENSIONS FOR SERIES 1980

NEMA 1 NEMA 4 and 12

NO. OF

ABCD

CIRCUITS

2-4 7.31 4.42 5.00 9.75

5-6 9.75 6.86 5.00 9.75

7-8 12.19 9.30 5.00 9.75

9-12 17.07 14.18 5.00 9.75

13-16 23.48 20.60 5.50 10.25

17-20 28.36 25.48 5.50 10.25

21-24 33.24 30.36 5.50 10.25

NO. OF

ABCD

CIRCUITS

2-4 7.31 4.42 5.00 11.40

5-6 9.75 6.86 5.00 11.40

7-8 12.19 9.30 5.00 11.40

9-12 17.07 14.18 5.00 11.40

13-16 23.48 21.62 7.00 13.40

17-20 28.36 26.50 7.00 13.40

21-24 33.24 31.38 7.00 13.40

Dimensions shown apply

when platform and base

are parallel.

1080 NORTH CROOKS ROAD • CLAWSON, MI 48017 USA

800-635-0289 • 248-435-0700 • Fax 248-435-8120

www.patriotsensors.com • www.ametek.com

Loading...

Loading...