Page 1

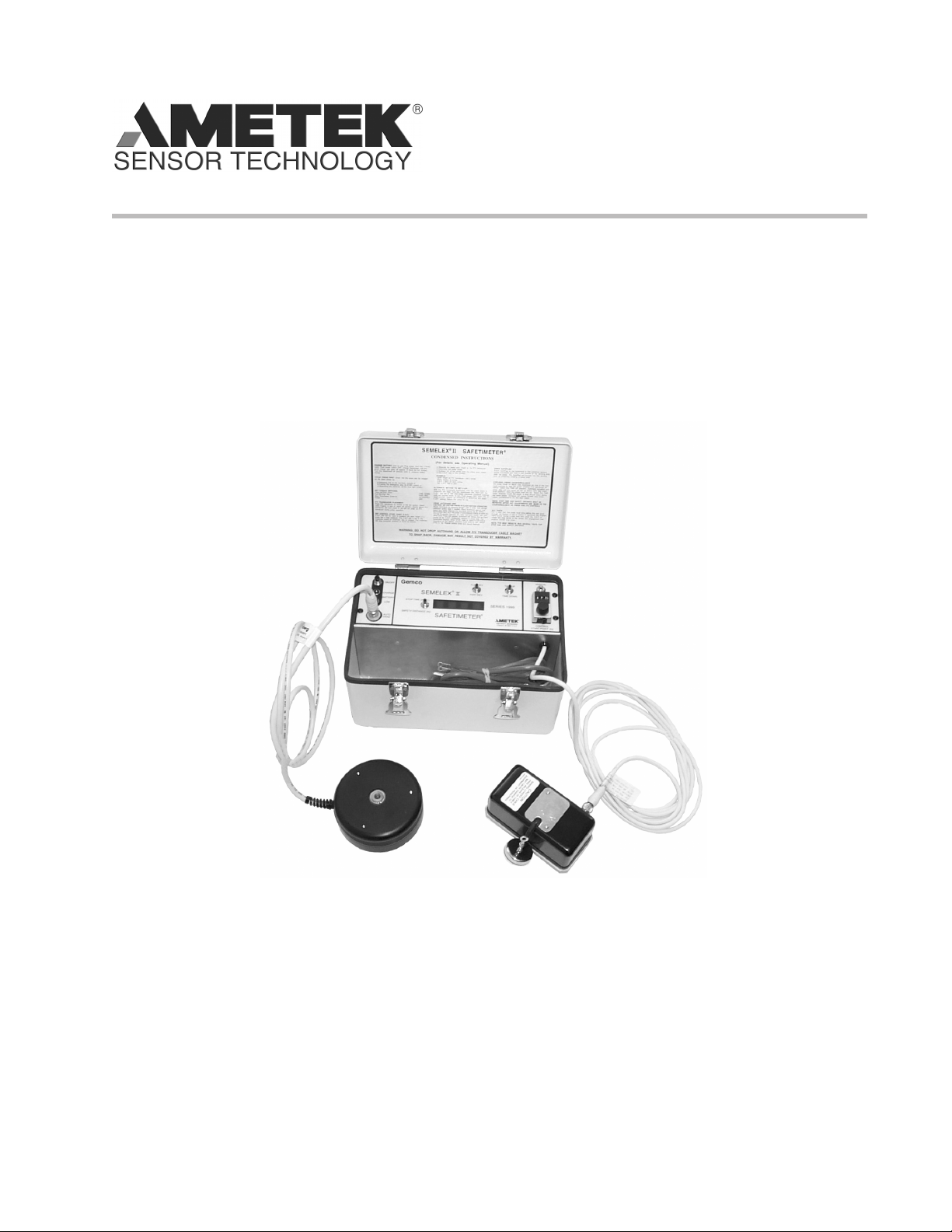

Semelex IITM Safetimeter

Operating Manual

Series 1999

TM

Gemco

Self-Contained, Portable Electronic Stop-Time Meter

Page 2

.

Page 3

1080 North Crooks Road

Clawson, MI 48017-1097

Phone: (248) 435-0700

FAX: (248) 435-8120

Internet: www.ametek.com www.ameteksensortech.com

Preface

This manual will instruct user in operating the Gemco 1999 Semelex II Safetimeter.

Copyright 1999 by AMETEK Sensor Technology

All Rights Reserved - Made in the U.S.A.

Version 0.1

AMETEK has checked the accuracy of this manual at the time it was printed. Any

comments you may have for the improvement of this manual are welcomed.

AMETEK reserves the right to revise and redistribute the entire contents or selected

pages of this manual. All rights to the contents of this manual are reserved by AMETEK.

iInstallation & Programming Manual

Page 4

Contents

Chapter 1: Overview 1

1.1 Safetimeter Switches and Connectors.................................................1

1.2 Theory of Operation............................................................................2

Chapter 2: Unpack & Set-Up 3

2.1 Set-Up and Test .................................................................................3

Chapter 3: Operating Instructions 5

3.1 Placement of Position/Velocity (P/V) Transducer ................................5

3.2 Set the Control Start Point (CSP) ........................................................5

3.3 Set the TIME UP/TIME DOWN Switch ................................................7

3.4 Using Auto-Hand ...............................................................................8

3.5 Using Auto-Flag with Auto-Hand ........................................................9

3.6 Using Optional Manual Start Switches .............................................10

3.7 Using Optional Remote Tachometer..................................................10

3.8 Calculate Stop Angle ........................................................................11

3.9 Using the Safetimeter to Aid in Setting Cam Limit Switch Brake-

Monitors...........................................................................................13

3.10 Test Presses Running in a Continuous Mode ....................................14

3.11 Set Press Counterbalance.................................................................15

3.12 Test Full Revolution Clutch Presses..................................................16

Chapter 4: Certifi cation and Warranty 17

4.1 Optional 5 Year Warranty.................................................................17

Chapter 5: Specifi cations 18

Installation & Programming Manualii

Page 5

Chapter 1: Overview

Chapter 1: Overview

The Series 1999 Semelex II Safetimeter is a self-contained, portable electronic stop

time meter capable of measuring elapsed time, stop time (Ts) from 1-9999 milliseconds.

It also calculates the minimum safety distance (Ds) based on the OSHA formula, as

understood by the factory, and will display up to 999.9 inches to the nearest 0.1

inches.

The Semelex II Safetimeter Test Set consists of four components:

Safetimeter This is the “brains” of the unit, with processing electronics

that display the test results.

Position/Velocity (P/V) This motion and position sensor attaches to the press with

Transducer its base and cable magnets.

Auto-Hand (A/H) This hand-held device is used to automatically release a run

control or press an E-Stop control on the press.

Auto-Flag (A/F) This assembly is attached to the Auto-Hand to test presses

equipped with electronic guards, i.e. photoelectric barrier

guards (light curtains) or capacitance type guards (conduit

rail sensors).

Option:

Manual Start Switches These two switches plug into the MANUAL START jack on the

Safetimeter panel and are used to manually start the

Safetimeter timing.

Option:

Remote Tachometer The tachometer replaces the P/V Transducer and Auto-Hand

with Base when testing high speed or continuous stroke presses that

can’t stop within one stroke. With the wheel attachment, it

can be used to test conveyors or indexing tables.

1.1: Safetimeter Switches and Connectors

ON/OFF This is the unit’s power switch. In the ON or OFF position

the power cord may be plugged into 115 VAC outlet for

recharging the battery. In the ON position, the unit may be

operated from the internal battery or 115 VAC line.

NOTE: With the Safetimeter ON and plugged in, the battery charges at a lower rate.

Operating Manual

1

Page 6

Chapter 1: Overview

TIME UP/TIME DOWN This switch determines the direction of the test. In the

TIME DOWN position you are performing a standard test

according to OSHA requirements. The switch should be in

the TIME UP position when checking press top stop.

STOP TIME (mSEC)/ This switch is used to select the display mode, either time or

SAFETY DISTANCE (IN) distance. Time is measured in milliseconds and distance is

measured in inches.

FULL REV/PART REV This switch is used to determine the press clutch operation

mode, either full or part revolution. The majority of tests

are run in the part revolution mode.

CONTROL START Known as CSP, this dial is used to set the point in the

POINT (IN) stroke at which the command to start timing and fi res

the Auto-Hand is given. When the CSP dial is turned

clockwise, the dial will increment and de-increment when

turned counterclockwise. The CSP dial reads in tenths of

an inch. Example: 123 equals 12.3”.

MANUAL START This jack is used with the optional manual start switches.

AUTO-HAND This connector is used to connect the Auto-Hand to the

Safetimeter.

1.2: Theory of Operation

The P/V transducer measures the open height of a press. When this measurement

coincides with the preset CSP position, and the ram is traveling in the direction

selected on the TIME UP/TIME DOWN switch, the Auto-Hand will release one of the

two run controls or press an E-STOP control to initiate the press stop. When the

ram stops, the P/V transducer sends a stop signal to the Safetimeter and the meter

displays either stop time or safety distance, whichever display mode was selected

prior to the test.

NOTE: No OSHA standard exists for defi ning when a press has stopped (at what

ram velocity). The Safetimeter ends its measurement when the ram velocity

is approximately .17 inches per second (10 inches per minute). When

measuring stop time, you must take into account all elements and devices

used to bring the ram to rest. These include the “fl ight time” of the run and

E-STOP buttons (time for switch to activate), control relays, solenoids valves

and clutch and brake mechanical elements. Where an electronic guard (light

curtain) is used, response time of the device and the depth penetration factor

must be added to that measured by the Safetimeter before calculating safety

distance. Response time is generally stated by manufacturers of electronic

guards. However, to verify systems, the Auto-Flag can be used.

2

Operating Manual

Page 7

Chapter 2: Unpack & Set-Up

Chapter 2: Unpack & Set-up

The Series 1999 Semelex II Safetimeter has been carefully inspected and tested before

shipment. Unpack the unit and perform a visual inspection to assure that no damage

has occurred during shipping. If damage is found, notify the transportation company

immediately. Only the consignee may institute a claim with the carrier for damage

during shipment.

2.1: Set-Up and Test

1. The Safetimeter battery is shipped with a partial charge. Plug in the unit

and charge the battery until the green LED goes off (maximum charge time

is eight (8) hours).

2. Connect the P/V transducer with the appropriate connector.

3. Make the following Safetimeter switch settings:

Display SAFETY DISTANCE (IN)

Revolution PART REV

Timing Direction TIME DOWN

Control Start Point (CSP) 200 (20.0 inches)

4. Push the ON/OFF switch ON.

5. Place the P/V transducer on a metal desk or steel plate. The magnetic base

will hold the unit in place.

6. Carefully slide the cable magnet from its keeper. Do not let the cable run

free, it can be damaged by impact from sudden release. Pull the cable magnet

out approximately 24 inches.

7. Bring the magnet back towards the P/V transducer. The P/V transducer

will reel in the cable automatically. When the cable magnet is about 20

inches from the base of the P/V transducer, the Safetimeter will start

counting. The unit will continue counting as long as the cable velocity is .17

inch per second (10 inches/minute) or greater.

8. Stop the cable from rewinding or pull the magnet out. The display will stop

incrementing and show the results.

9. Again, pull the cable out approximately 24 inches. The display’s current value

will remain because the Safetimeter is set in the TIME DOWN direction.

10. Let the cable rewind. The display will reset to “0” and start counting. The

zero reset occurs automatically at the beginning of the count and cannot

be seen.

NOTE: The Safetimeter will count when the cable is rewinding and stop when the

cable stops or the direction is reversed.

Operating Manual

3

Page 8

Chapter 2: Unpack & Set-up

11. Change the TIME UP/TIME DOWN switch to the TIME UP position and start

with the cable rewound. The Safetimeter will begin to count when the 20 inch

CSP setting is reached and continue until the cable stops or the direction is

reversed.

12. Set the CSP dial to several values and check that the Safetimeter begins to

count at the preset positions when the cable is moving in the direction selected

by the TIME UP/TIME DOWN switch.

13. If the optional Manual Start Switches are available, continue with steps 14-15.

If not, move to Chapter 3: Operating Instructions.

14. Plug one of the Manual Start Switches in the MANUAL Start jack. If the

Safetimeter is ON, the counter will begin to run. Switch the Safetimeter OFF

and then ON to reset the counter.

15. If the Manual Start Switch is normally closed (red plug), the Safetimeter will

begin to count when the switch is pushed. If the Manual Start Switch is

normally open (black plug), the Safetimeter will begin to count when the switch

is released.

4

Operating Manual

Page 9

Chapter 3: Operating Instructions

Chapter 3: Operating Instructions

3.1: Placement of Position/Velocity (P/V) Transducer

1. Position the magnetic base of the P/V transducer on a clean area of the

press’s bed or bolster plate.

2. Extend the cable magnet to the ram in a straight line, perpendicular to the

transducer and attach the magnet to the ram. A test will not start at 90

degrees if the cable is angled.

3. Connect the P/V transducer to the Safetimeter using the cable provided.

CAUTION: Never place the transducer where the press or dies can close in on

it. Also, be sure when the press closes, the transducer still has some

cable extended to keep it from slamming the magnet into the body of

the transducer.

3.2: Set the Control Start Point (CSP)

There are three ways to set the CSP depending on the following conditions. Proceed to

the section that best fi ts your condition.

A. Setting the CSP dial when the press stroke is known.

B. Setting the CSP dial when the press stroke is not known.

C. Setting the CSP dial at the 90 degree crankshaft position.

A . Setting the CSP dial when the press stroke is known.

1. Raise the press to the top of its stroke.

2. a. Set the TIME UP/TIME DOWN switch to TIME DOWN position.

b. Set the FULL REV/PART REV switch to PART REV.

c. Select either STOP TIME (mSEC) or SAFETY DISTANCE (IN) display.

3. Switch on the Safetimeter.

4. Turn the CSP dial clockwise until the Safetimeter begins to count.

5. Switch the Safetimeter OFF and then ON to stop the counter.

Operating Manual

5

Page 10

Chapter 3: Operating Instructions

6. Turn the CSP dial counterclockwise somewhere below the reading where the Safetimeter began

to count.

7. Slowly turn the CSP dial clockwise and stop when the Safetimeter begins to count. The

number displayed in the CSP dial is the distance between the base of the P/V transducer and

the ram.

8. Subtract 1/2 of the press stroke from the number displayed in the CSP dial to calculate the

Control Start Point.

Example: If the number displayed in the CSP dial is 240 (24.0”) and the press stroke is 6”, subtract 3”

(1/2 stroke) from 24.0” equals 21.0”. This is the mid-stroke position. While it may not represent the

exact 90 degree point of the crankshaft, it is close. This electronically measured point in the stroke will

start the Safetimeter, and fi res the Auto-Hand.

9. Set the CSP dial to the result of Step 8. From the example, the CSP dial would be set to 210

(21.0”)

B. Setting the CSP dial when the press stroke is not known.

1. Find the open height of the press by performing steps 1-7 in subsection (A). Record the

distance determined in step 7.

2. Lower the press ram to the bottom of the stroke. Find the closed height of the press by

performing steps 2-7 in subsection (A). Record the distance determined in step 7.

3. Using the two distances determined from steps 1 and 2, calculate the mid-stroke position using

the following method: Add the two measurements together and divide by two (2).

Example: Midstroke = (Open Height + Closed Height) ÷ 2

4. Set the CSP dial to the above result.

C. Setting the CSP dial at the 90 degree crankshaft position.

To test at the 90 degree crankshaft position, or when the P/V Transducer cable is angled, the CSP will

act as a reference setting.

1. Inch the press to 90 degrees by observing the crankshaft or stroke indicator.

2. Perform steps 2-7 in subsection (A).

6

Operating Manual

Page 11

Chapter 3: Operating Instructions

3. The distance determined in step 7 (number displayed on the CSP dial) is the 90

degree point of the crankshaft, which includes allowance for the cable angle.

NOTE: When testing the top stop, the distance determined in step 3 will correspond

to the 270 degree position of the crankshaft when the TIME UP/TIME DOWN

switch is in the TIME UP position.

3.3: Set the TIME UP/TIME DOWN Switch

The TIME UP/TIME DOWN switch is used to select the direction the press (closing

or opening) is moving when the automatic stop command is given. This switch must

be properly set even when a manual test, with the optional manual start switches,

is performed.

NOTE: The Gemco Semelex II Safetimeter has the capability to check both down and

up stop times to aid in setting the press counterbalance.

For best results, the down stop time test should be initiated at 90 degrees, and the

up stop time should be initiated at 270 degrees. During these tests, it is important to

stop the ram before the dies engage on the down stoke and before top dead center on

the up stroke. On some presses, however, the ram may take more than 90 degrees to

come to a complete stop. If so, adjust the CSP as follows:

1. On the down stop time test, increase the Control Stop Point (CSP) setting to

initiate a stop between 0 and 90 degrees. Continue increasing the CSP and

testing the press until the ram can be stopped before the dies engage.

2. Similarly, on the up stop time test, decrease the CSP setting to initiate a stop

between 180 and 270 degrees. Continue decreasing the CSP and testing the

press until the ram can be stopped before top dead center.

It is important to test both the down and up stop times using the same press control.

Typically, an inch button or two-hand control in the inch mode is used since the up

stop time test is not possible in the single-stroke mode with two hand controls.

Adjusting the counterbalance air pressure to obtain near equal down and up stop

times will set the counterbalance at is optimum point.

NOTE: Always follow the press manufacturer’s recommendations for setting the

counterbalance. Several down stroke Safety Distance and/or Stop Time tests

must be performed after setting the counterbalance to ensure proper press

operation and guarding.

Operating Manual

7

Page 12

Chapter 3: Operating Instructions

3.4: Using Auto-Hand

The Auto-Hand is designed to release or push press controls. It can release a twohand control or inch button, or push an E-Stop button. Auto-Hand is not required if

you are using one of the optional Manual Start Switches.

Using Auto-Hand with Two Hand or Inch Control (Release to Stop)

The Auto-Hand releases or pushes buttons with a spring-loaded plunger. When the

plunger is pushed, it will latch into position. The Safetimeter provides a voltage pulse

to energize a solenoid that releases the spring loaded plunger. If the two-hand control

has a ring guard, the Auto-Hand should rest on the guard and the three support

legs are not needed.

1. Connect Auto-Hand to the Safetimeter. Depress the plunger and place the

extended end over one of the two-hand buttons. Rest Auto-Hand on the

button’s ring guard. If no ring guard exists, screw in the three legs to serve as a

rest. Use your other hand to press the other button.

2. Cycle the press. The Auto-Hand will actuate when the desired CSP is reached,

releasing the button and initiate a press stop.

NOTE: The Auto-Hand can only release 10 lbs. of force and may not release if pushed

against the button with excessive force. In this case, use one leg as a spacer,

to prevent applying excessive force. Place over switch and repeat step 2.

NOTE: Be sure the press has stopped before the bottom of the stroke. Readings are

invalid if the press goes through the bottom of the stroke before stopping. If

this happens, increase the CSP setting slightly until the press stops before

the bottom.

3. Remove Auto-Hand and restart the press to return the ram to top stop.

4. Read the Safetimeter display. This value is the Stop Time or Safety Distance,

depending on the display mode selected prior to the test.

Using Auto-Hand with and E-STOP Button (Push to Stop)

1. Screw the plunger extension into the plunger end that retracts when the

plunger is depressed. This end is used to push an E-STOP button. Attach the

three legs to this side, if required.

2. With the Auto-Hand plunger depressed, place the unit over the E-STOP button

to be

pushed. Check that the plunger extension is adjusted out far enough to push the

button when the Auto- Hand releases.

8

Operating Manual

Page 13

Chapter 3: Operating Instructions

3. Position the Auto-Hand over the E-STOP button. The plunger extension should

not touch the E-STOP button.

4. Cycle the press while holding Auto-Hand over the button. Auto-Hand will

operate when the desired CSP is reached and push the E-STOP button, stopping

the press.

3.5: Using Auto-Flag with Auto-Hand

Auto-Flag is used in conjunction with Auto-Hand to test the entire press control loop

which includes electronic guards, i.e. photoelectric barrier guards (light curtains) or

capacitance type guards (conduit rail sensor).

This test initiates a press stop by obstructing the sensing area with Auto-Flag,

causing the guard to activate a stop signal in the press.

Attaching Auto-Flag to Auto-Hand

1. Screw the Auto-Flag into the retracted end of the plunger when the Auto-Hand

plunger is depressed. Adjust the Auto-Flag so that it is just outside of the

light curtain.

2. Rest the Auto-Hand with Auto-Flag against the light curtain enclosure just

outside the sensing area.

3. Now, set up the Safetimeter and the P/V Transducer as described earlier to

run a test.

4. Cycle the press. When the ram crosses the 90 degree point (position in the

stroke desired to initiate a press stop), the Auto-Hand will release the fl ag into

the sensing area initiating a press stop.

NOTE: During this test, verify that when the press stops, the dies have not fully

engaged and the press has not gone through the bottom of its

stroke. If either situation occurs, increase the CSP setting slightly

and repeat the test. The displayed stop time is the total of the

electronic guard delay plus press control and braking effectiveness.

If desired, the OSHA formula for safety distance can be read directly from

the Safetimeter display. Set the STOP TIME/SAFETY DISTANCE switch

to SAFETY DISTANCE prior to the test. Presses using electronic

guards have other mandated control requirements (brake monitors,

for example) which should be in place and operating correctly.

When determining SAFETY DISTANCE for light curtains, the depth

penetration factor must be added to the Safetimeter reading.

Operating Manual

9

Page 14

Chapter 3: Operating Instructions

3.6: Using Optional Manual Start Switches

The Safetimeter can be used in a manual mode with one of two optional Manual

Start Switches. These switches are plugged into the MANUAL START jack on the

Safetimeter panel. No wiring to the press control is required.

1. Normally Open Switch (PSD0110400). Designated with a black plug. Used over

an inch button or two-hand control, this switch starts the Safetimeter when

released.

2. Normally Closed Switch (PSD0110309). Designated with a red plug. Used over

an E-STOP button, this switch starts the Safetimeter timing when pressed.

Perform the following Steps:

1. Set the TIME UP/TIME DOWN, FULL REV/PART REV, and STOP TIME/SAFETY

DISTANCE switches as required.

2. Mark the ram or slide and frame with chalk, paint, etc. at the 90 degree point.

3. When the marks are aligned during the stroke of the press, release or push the

Manual Start Switch being used. This takes practice to get into sync with the

press. Ten to 20 strokes may be needed. Be sure the readings are fairly

repetitive. Using the Manual Start Switches is less accurate than Auto-Hand.

3.7: Using Optional Remote Tachometer

For testing continuous stroke or high speed presses perform the following steps:

1. Connect the Remote Tachometer to the P/V Transducer cable in the Safetimeter

case.

2. Position the Remote Tachometer on the press (machine) with the magnetic

base. Center the rubber nose cone on the rotating shaft, such as a press’s

crankshaft or cam switch shaft. Good axial alignment is needed.

NOTE: If the shaft rotation, viewed by the tachometer, is clockwise, toggle the TIME

UP/TIME DOWN switch to TIME UP. If the shaft rotation is counterclockwise,

toggle the switch to TIME DOWN. Toggle the STOP TIME/SAFETY DISTANCE

switch to STOP TIME.

3. If the press is to be tested from the E-STOP button, use the normally closed

(red) Manual Start Switch. (See section 3.6: Using Optional Manual Start

Switches). When testing the press RUN or INCH button(s), use the normally

open (black) Manual Start Switch.

4. Choose the correct switch and plug it into the Manual Start jack on the

10

Operating Manual

Page 15

Chapter 3: Operating Instructions

5. Tape the switch temporarily over the control button. Cycle the press. When

pressing the Manual Start Switch and E-STOP button simultaneously, the press

begins to stop and the Safetimeter starts counting. After the press stops, the

Safetimeter displays STOP TIME in milliseconds. Similarly, the Normally Open

Manual Start Switch released simultaneously with the RUN or INCH button

starts the Safetimeter counting upon release.

NOTE: Run several tests, initiate stops at the same position in the stroke. Results

should be fairly repetitive. Use only the largest values in determining safety

distance to be used. Prudent judgement suggests adding 10% to 20% to the

readings being measured.

NOTE: The Auto-Hand and P/V Transducer are not used with the Remote Tachometer.

3.8: Using Optional Remote Tachometer

1. To calculate the Stop Angle requires a press stop started exactly at 90 degrees

or 270 degrees, use the Auto-Hand. Set the Control Start Point (CSP) to 90

degree crankshaft position. To set the CSP, see Section 3.2: Set the Control

Start Point (CSP).

2. Raise the press to top stop, then cycle the press. The press will begin to stop

when the ram reaches 90 degrees. Leave the ram where it stopped.

3. Rotate the CSP dial counterclockwise somewhere below the point where the ram

is stopped. This will be approximate, accuracy is not required.

4. Rotate the CSP dial clockwise until the Safetimeter starts to count.

5. Switch the Safetimeter OFF then ON to reset the counter.

6. Repeat steps 3-5 until the CSP dial displays the new position of the stopped ram.

7. Subtract the stopped ram position in step 6 from the 90 degree position in step

1. The result is the distance the ram moved after a stop occurred. This distance

is called, “ram or slide after-travel”, “stopping distance” or “over-run”.

8. Use the curve in the following fi gure to determine the stopping angle. This curve

is based on a connecting rod to stroke length ratio of two (2).

Example: 16” connection rod, 8” stroke = 2.0. Lower ratios than 2 will have smaller

stopping angles. Higher ratios will have greater stopping angles. The curve is useful

for ratios of 1.5 to 4.0 and across the 15 degree to 40 degree stopping angle range.

Higher ratios and larger than 40 degree stops should not use this curve.

Operating Manual

11

Page 16

Chapter 3: Operating Instructions

9. Determine the ratio of press stroke to stopping distance (divide stroke by

stopping distance). Locate this ratio on the horizontal axis of the graph, move

up to the curve and read across to the vertical axis, fi nding the stopping angle

in degrees.

Review Points:

1. Be sure to start at exactly 90 degrees or 270 degrees by observing crankshaft

or indicator.

2. Be sure press does not go through bottom or top of stroke.

3. Small differences in stopping distance make for large differences in stopping

angle, especially when the stopping angle exceeds 45 degrees. Read the CSP

dial carefully.

When determining stop angle be sure of the following:

1. The P/V transducer cable must be parallel to the slide motion. The cable

magnet must be directly above the P/V transducer.

2. In down stroke tests, the ram must stop before it reaches the bottom of the

stroke.

3. The mid-stroke position can be used as the 90 degree crankshaft position.

Since this is one of the reference points used to make linear measurements of

the ram travel to determine stop angle, care must be taken to initiate the stop

at exactly the 90 degree position.

4. If the press is equipped with a functioning angular position indicator, this can

be used to indicate crank or cam angular position. If no indicator is available,

the angular position may be determined from the crank or camshaft position.

Mark the 90 degree position.

12

Operating Manual

Page 17

Chapter 3: Operating Instructions

5. Using the stop angle from the previous graph, add the desired brake wear

allowance, typically 10-15%. This is the included angle setting between the top

stop cam limit and the brake monitor cam limit switch. This setting should be

locked or adjusted only by authorized personnel.

6. If the brake wear allowance on the brake monitor was 10%, add 20% to the

safety distance measurement used to set the two-handed controls, or electronic

guards such as optical presence sensors. Increasing the stop time will cause

the brake monitor to activate and the operator will have an additional 10%

safe distance margin.

3.9: Using the Safetimeter to Aid in Setting

Cam Limit Switch Brake Monitors

Cam limit switch brake monitors check the angular travel of a press during a top stop,

thus determining the brake effi ciency by determining the total included stop angle

between the normal top stop cam switch and the brake cam switch. The function of

the top stop cam is to bring the press to a stop at, or very near, the top of the press

stroke. Very often, the exact parked position of the press is affected by the type

of part being made. Most often, users favor a parked position typically 5 degrees

after top dead center.

The top stop cam switch is set to disengage the clutch, and apply the brake at

some point on the up stroke in order to allow the press to coast to the desired top

stop position. As die weight, brake wear and other response factors increase, this

setting may have to be adjusted to operate earlier in the stroke to compensate for

this additional wear. This adjustment results in parking the press at the desired top

stop location but ignores the fact that this setting may also affect an overtravel cam

switch used as a brake monitor.

Adjusting the top stop cam, without adjusting the brake monitor cam, causes longer

stop times to occur before the brake monitor activates.

If the current safety distance is not increased, a dangerous situation can exist

whereby the operator’s controls or safeguard devices may be too close to the point of

operation. The top stop brake monitor is trying to judge the stop effi ciency on the

down stroke based on the test made on the upstroke. To do this, stopping time and

stop angle on both down and up stroke should be known. Ideally, they should be the

same, and in a press where counterbalances are used, they must be the same.

Operating Manual

13

Page 18

Chapter 3: Operating Instructions

Checking the down and up stroke time should be done prior to making the down

stop time test. This is done by using the Safetimeter with Auto-Hand. The two-hand

control circuit will not generally do this. Typically, the simplest control that can do

this is the inch circuit. Auto-Hand can be used over this control for initiating a stop

anywhere in the stroke. The timing direction selector switch on the

Safetimeter is set for either down or up, whichever direction is being tested. Several

stops should be made in both directions, and an average in each direction should be

made. Readings taken in each direction should be close to the others made in that

direction. Erratic readings are reason to suspect a defective brake or control circuit

which should be repaired before proceeding.

The Gemco Semelex II Safetimeter measures slide position, direction and velocity to

determine brake effi ciency stop time. The initiation of a stop can be made at almost

any reasonable point near mid-stroke (assuming the press is balanced), and will

accurately measure the stop time.

3.10: Test Presses Running in a Continuous Mode

Because the Safetimeter sends a release command to the Auto-Hand each time the

P/V transducer crosses the Control Start Point (CSP), a special method must be used

to test a press running in a continuous mode. Typically, this test is performed on the

press’s Emergency Stop (E-STOP) button or a presence sensor.

1. Position the P/V transducer as described in Section 3.1: Placement of

Position/Velocity (P/V) Transducer.

2. Set the CSP to initiate a stop at the 90 degree crankshaft position.

3. Ready Auto-Hand to press the E-STOP button or interrupt the presence sensor

with Auto-Flag.

4. Make the following Safetimeter switch settings:

Display (as desired)

Timing Direction TIME DOWN

Revolution PART REV

5. Press the Safetimeter power switch OFF.

6. Start the press in continuous mode.

7. Observe that the press is up to speed.

14

Operating Manual

Page 19

Chapter 3: Operating Instructions

8. When the ram is on the up stroke, press the power switch ON. When the

ram goes through the top of the stroke and crosses the 90 degree point, Auto Hand will release and press the E-STOP button or interrupt the presence

sensing fi eld with Auto-Flag.

9. After the press stops, verify that the ram has not gone through the bottom

of the stroke or that the dies have engaged. If either of these conditions

have occurred, the reading is inaccurate. Increase the CSP setting slightly and

test until neither of these conditions occur.

NOTE: In some cases, stopping a continuous run press requires more than one

stroke of the ram. The standard Semelex II Safetimeter is incapable of

testing such an occurrence. To perform this type of test, the optional Remote

Tachometer is needed. Contact the factory for details.

3.11: Set Press Counterbalance

The Gemco Semelex II Safetimeter has the capability of checking both down and up

stop times to aid in setting the press’s counterbalance. For best results, the down

stop time test should be initiated at 90 degrees and the up stop time test at 270

degrees. It is important to stop the ram before engagement of the dies on the down

stroke, and before top dead center on the up stroke. However, on some presses,

the ram may take longer than 90 degrees to come to a complete stop. Test this

condition as follows:

1. On the downward stop time test, increase the Control Start Point (CSP) setting

to initiate a stop between 0 and 90 degrees. Continue increasing the CSP and

testing the press until a down stop of the ram can be made before the dies

have fully engaged.

2. On the upward stop time test, decrease the CSP setting to initiate a stop

between 180 degrees and 270 degrees. Continue decreasing the CSP and

testing the press until an upward stop of the ram can be made before the

top stop.

NOTE: It is important to test both the down and up stop times using the

same press control. Typically, an inch button or two-hand control

in the inch mode will be used since an up stop time test is

not possible in the single stroke mode using a two-hand control.

Adjust the counterbalance to obtain equal down and up stop times. This sets

the counterbalance at the optimum point.

Always follow the press manufacturer’s recommendations when setting the

counterbalance. Several safety distance and/or stop time tests must be

performed after the setting of the counterbalance to ensure safe press

operation and guarding.

Operating Manual

15

Page 20

Chapter 3: Operating Instructions

3.12: Test Full Revolution Clutch Presses

Calculating the safety distance of a full revolution clutch press per OSHA 29 CFR

1910.217(c)(3)(viii)(c) is as follows:

Dm=63 inches/second x Tm; where:

Dm=Minimum safety distance (inches);

63 inches/second = hand speed constant:

and

Tm = the maximum time the press takes for die closure after it has been tripped

(seconds). For full revolution clutch presses with only one engaging point, Tm is

equal to the time necessary for one and one-half revolutions of the crankshaft.

For full revolution clutch presses with more than one engaging point, Tm shall

be calculated as follows:

Tm = [1/2 + (1 / Number of engaging points per revolution)] x time necessary to

complete

The Safetimeter can aid in calculating safety distance of a full revolution clutch

press by measuring the time necessary to complete one revolution of the crankshaft.

Perform the following steps:

one revolution of the crankshaft (seconds).

1. Set the FULL REV/PART REV switch to FULL REV.

2. Set the TIME UP/TIME DOWN switch to TIME UP.

3. Set the STOP TIME/SAFETY DISTANCE switch to STOP TIME.

4. Position the P/V transducer as described in Section 3.1: Placement of

Position/Velocity (P/V) Transducer.

5. Push the Safetimeter power switch to ON.

6. Cycle the press. The Safetimeter will begin counting when the ram begins to

travel down and will stop counting when the ram stops on the up stroke. The

Safetimeter will display the time for one stroke of the press.

NOTE: Do not set the STOP TIME/SAFETY DISTANCE switch to SAFETY DISTANCE.

The Safetimeter can not read safety distance for full revolution clutch presses.

16

Operating Manual

Page 21

Chapter 4: Certifi cation and Warranty

Chapter 4: Certifi cation and Warranty

The factory certifi es that the Gemco Series 1999 Semelex II Safetimeter has been

inspected and tested at the factory prior to shipment and meets requirements defi ned

by the contract under which it is furnished.

All products of the factory are warranted against defective material and workmanship

for a period of one year from the date of delivery. The factory will repair or replace, at

their option, all defective equipment returned (transportation charges prepaid) during

the warranty period without charge, provided there is no evidence that the equipment

has been mishandled or abused. This warranty does not apply to expendable parts or

materials whose normal life is less than the warranty period, nor is the factory liable

for consequential damages arising out of use or handling of its products.

4.1: Optional 5 Year Warranty

Warranty Plan Includes:

Warranty

Seller warrants its products against defects in workmanship and materials of the

items purchased under this order provided, however, that notice of such defect

is received in writing by Seller within fi ve years from the date of delivery of the

item under this order. Seller’s liability under this clause is restricted to replacing,

repairing, or issuing credit (at Seller’s option) for any return unit and only under

the following conditions: (1) Seller must be properly notifi ed in writing as soon as

possible after the defects have been noted by the customer, but no later than fi ve

years from date of delivery. (2) The defective merchandise is to be returned to place

of manufacture, shipping charges prepaid by the customer. (3) Our inspection of

the returned units shall disclose to our satisfaction that the units were defective in

workmanship or material at the time of delivery. ALL OTHER WARRANTIES, FOR ANY

OF SELLER’S PRODUCTS, EXPRESS OR IMPLIED, STATUTORY OR OTHERWISE,

INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PURPOSE ARE EXCLUDED.

Four Annual Re-Calibrations

Annual factory re-calibrations of the units are required to ensure accuracy of test

results. Under the conditions stated in the above warranty, the Seller will provide

four (4) annual re-calibrations of the unit, at no charge, during the life of the

warranty. (Value: $1,000.00) Shipping of the unit to and from the manufacturer for

re-calibration is the responsibility of the customer.

Operating Manual

17

Page 22

Chapter 5: Specifi cations

Chapter 5: Specifi cations

ELECTRONICS

Display 4 digit, 14 segment, 1/4” red LED Stop Time: 0-9999 milliseconds

Safety Distance: 0-999.9 inches

Accuracy +/-1%

Power Source Internal Battery or 115 VAC

Battery Type 6 Volt, sealed lead acid

Operating Time (Full Charge) 10 hours (continuous)

Recharge Time 8 hours

MECHANICAL

Safetimeter Material: aluminum. Finish: baked enamel

Dimensions: 11”L x 7” W x 7”H. Weight: 9.0 lbs.

Auto-Hand Material: aluminum. Finish: anodized.

Dimensions: 4.5” dia. x 2” H. Weight: 3.0 lbs.

P/V Transducer Material: aluminum. Finish: anodized

Dimensions (cable magnet extended):

5.25”L x 2.75”W x 4.75”H. Weight: 1.6lbs. Cable Stroke: 49”

STANDARD EQUIPMENT

(1) Electronic Safetimeter SD0500900

(1) Position/Velocity Transducer SD0500400

(1) Auto-Hand SD0502200

(1) Auto-Flag SD0502100

(1) Cable Extension Set (1’, 2’, 4’) SD0500300

(1) Auto-Hand Plunger Extension 04579042

(3) Auto-Hand Leg Kit SD0503900

OPTIONAL EQUIPMENT

Remote Tachometer SD0505000

Manual Start PSD0110200

Switches (N.O., N.C.) (SET)

Manual Start Switch (N.O.) PSD0110400

Manual Start Switch (N.C.) PSD0110309

18

Operating Manual

Page 23

.

Page 24

AMETEK Sensor Technology 1080 N. Crooks Road Clawson, MI 48017

800-635-0289 248-435-0700 Fax 248-435-8120

www.ametek.com www.ameteksensortech.com

836

1999.M1R

1/08.Z76

1C

Loading...

Loading...