Page 1

ALS-500M Instruction Manual

TABLE OF CONTENTS

ALS-500M Features........................................................................................................ 1

General Information ........................................................................................................ 2

Load Fault Circuit ...............................................................................................2

Bias Control Circuits........................................................................................... 2

Drive Power......................................................................................................... 2

Supply Voltage.................................................................................................... 3

SWR Considerations ........................................................................................... 3

Periodic Maintenance.......................................................................................... 3

Technical Assistance ........................................................................................... 3

Export Modifications........................................................................................... 4

Installation....................................................................................................................... 4

Location............................................................................................................... 4

Power Requirements ........................................................................................... 4

Fuse Holder Installation ...................................................................................... 5

Auxiliary Battery Installation.............................................................................. 5

Grounding........................................................................................................................ 6

Unibody Vehicles................................................................................................ 6

Frame-Type Vehicles .......................................................................................... 6

Interconnections Diagram ............................................................................................... 7

Interconnections .............................................................................................................. 8

Operation......................................................................................................................... 9

ALS-500M Parts List ...................................................................................................... 10

Combiner Board Parts List.................................................................................. 10

Power Amplifier Board Parts List....................................................................... 11

Output Filter Board .............................................................................................13

Bias Board Parts List........................................................................................... 15

Chassis Components Parts List ........................................................................... 17

Page 2

ALS-500M Instruction Manual

ALS-500M FEATURES

1. Rugged devices.

The ALS-500M uses four rugged linear RF power devices.

2. Fast warm-up time.

The ALS-500M has no vacuum tubes to warm-up.

3. No tune operation.

Tuning adjustments are not necessary. A simple one knob selector switch permits operation on

frequencies between 1.5 and 21.6 MHz.

4. Load Fault Protection

The PA load impedance is monitored and the amplifier is bypassed if the bandswitch setting or

the external load is incorrect.

5. Current meter.

The ALS-500M has a DC current meter to monitor collector current.

6. Off/On switch.

This switch allows the amplifier to be by-passed for "bare-foot" operation without disconnecting

the high current leads.

7. Remote Off/On control.

A separate connection on the power connector allows low current control of the amplifier Off/On

function for remote mounting.

8. Remote A and B.

Ports A and B are for connecting the ALS-500RC. The ALS-500RC is a remote control head

that allows the amplifier to be located away from the operating station and still have access of the

front panel controls.

9. Compact size.

The ALS-500M weighs only 7.5 pounds and measures 3 3/4"H x 9"W x 15 1/2"D .

1

Page 3

ALS-500M Instruction Manual

GENERAL INFORMATION

Load Fault Circuit

The ALS-500M features a load fault trip circuit that bypasses the amplifier if the amplifier frequency

switch is set to a lower frequency range than the exciter or if the load reflected power exceeds 70-100

watts. This circuit virtually eliminates the danger of component failures due to operating errors.

The Combiner circuit board near the PA contains the components that sense the reflected power at the

input of the low-pass filters used in the output circuit. Selecting a filter that has a cut off frequency

below the operating frequency or operating into loads with reflected power levels that exceed 70-100

watts will trip the overload and bypass the amplifier. SCR (Q5) on the Bias board keeps the amplifier

"locked out" until the POWER (ON/OFF) switch is cycled off and on.

Bias Control Circuits

The Bias board contains the temperature and bias control circuitry. The output transistor temperature is

monitored with diodes D1 and D2 on the PA module. The voltage drop across the diodes decreases as

the PA transistor temperature rises. The reduction in diode voltage with increasing temperature causes

IC 1c/d to reduce the PA base bias current supplied by Q2/3. Diodes D1/2 on the bias board limit the

available bias voltage if a failure in the bias circuit occurs.

IC 1a compares the voltage from the Power Amplifier temperature diodes to the reference voltage from

the temperature sensitivity control R28. If the temperature becomes too high (voltage too low) IC 1a

switches high and Q4 turns the cooling fan on. If the temperature continues to increase IC 1b will

eventually pull low and the voltage for the transmit relay and the bias voltage will be removed. The

THERMAL OVERLOAD LED is illuminated when the output of IC 1b is low. This circuit

automatically resets when the temperature drops to a safe operating range.

If the band switch is in the wrong position, the antenna SWR is high, or the amplifier is being driven

into non-linear operation a "load fault" will occur. When a load fault occurs gate voltage is applied to

SCR Q5. This causes Q5 to latch in a conducting state. Q5 will remain in this condition and the

amplifier's relay line will be disabled until the OFF/ON switch is cycled off and on. The LOAD

FAULT LED on the front panel is illuminated whenever SCR Q5 is in conduction and the amplifier is

bypassed from a load fault.

Drive Power

The ALS-500M normally requires much less than 100 watts of drive to produce full output power.

This drive power varies considerably with the gain of the transistors used in the amplifier and the

power supply voltage. As a general rule, exceeding 100 watts of drive for long periods of time may

cause component failures. Exceeding 70 watts of peak drive power may cause distortion and increase

the bandwidth of the transmitted signal.

2

Page 4

ALS-500M Instruction Manual

Supply Voltage

Low voltage solid state amplifiers are very sensitive to power supply voltage changes. For maximum

performance, the voltage should be maintained as high as possible consistent with component life. The

devices used in this amplifier have demonstrated excellent life with supply voltages up to 16 volts, and

will produce the rated output power at 14 volts dc. The output power will decrease by approximately

85 watts per volt as the supply voltage is lowered from 14 to 12 volts.

SWR Considerations

SWR (Standing Wave Ratio) causes higher voltages and/or currents to appear at the output connector

of the amplifier. This problem occurs with all amplifiers regardless of whether tubes or

semiconductors are used in the output stage.

The devices used in the ALS-500M have very good overload tolerance. The low pass output network

in the ALS-500M not extremely sensitive to load impedance changes. This makes the ALS-500M less

sensitive to frequency and SWR changes than many other similar amplifiers. The multiple section

output network and push-pull output configuration used in the ALS-500M also offers excellent

harmonic suppression.

The only danger presented by a high SWR is that the current and power dissipation in the output

devices may exceed safe limits. This can result in heat damage and failure of the amplifying devices.

If the SWR exceeds 2:1 the power level should be reduced until the reflected power is 60 watts or less.

At approximately 70 watts of reflected power the internal safety circuitry will disable the amplifier.

Periodic Maintenance

The lack of high voltage in this unit eliminates the chance of dirt and dust causing high voltage arcing

in this unit. The only deleterious effect of dust and dirt is a reduction in cooling efficiency. The

primary maintenance requirement is to monitor the amount of dirt and dust in the amplifier, and

remove the dust and dirt before cooling problems begin. Low pressure compressed air can be used to

blow the dust out of this amplifier whenever a noticeable accumulation of dust builds up.

A soft bristled brush and a small amount of alcohol can be used to clean stubborn dust from the fan or

the other components. Be careful not to get any cleaning compounds on relay contacts or in switches.

If it becomes necessary to perform maintenance on any switch or relay contact Ameritron. Ameritron

has free technical support for customers that wish to service their own equipment.

Technical Assistance

Ameritron has free technical information bulletins that provide assistance with the most common

operational problems. Technical assistance is also available by calling (662) 323-8211 or FAX (662)

323-6551 during our normal business hours (8:00 to 4:30 Central Time on weekdays) for questions

that are not properly addressed by the technical bulletins. Ameritron's policy is to provide complete

technical support to our customers. Before calling, please have the following information available:

1. The model and serial number the unit.

2. The date of purchase and the dealer.

3. A brief description of the station equipment and antenna system.

4. A complete description of the problem along with all meter readings.

3

Page 5

ALS-500M Instruction Manual

Written assistance is also available. Due to time delays in processing mail, please allow a minimum of

three weeks for a written reply. Send questions to: Ameritron, 116 Willow Road, Starkville, MS

39759

Export Modifications

A simple modification will allow operation on frequencies above 22 MHz. A parts kit to make this

modification is available by sending a written request for an MOD-10M export modification kit along

with a copy of your valid amateur license to the Ameritron. There is a charge for this kit. Export

models are shipped with this modification installed and have an "X" following the serial number.

INSTALLATION

Location

Do not locate this amplifier in excessively warm locations, near heater vents, or in unventilated areas

with ambient temperatures exceeding 120 degrees Fahrenheit. Be sure that air can circulate freely

around and through the amplifier cabinet. Do not obstruct the air inlet at the right front side of the

amplifier or the outlet air holes on the lower left side of the amplifier.

When not using the ALS-500M remote control head the best location for this amplifier is one that

allows the meter to be easily read and the controls accessed during operation. The length of each 13.8

volt high current cable is very important. Every consideration should be given to keeping the high

current battery lead lengths as short as practical. This includes the ground leads to the battery and the

ground lead to the vehicle's chassis.

The lengths of the remaining low current power and control cables are not critical. The relay control

lead can be made from any good quality two wire cable. Low level audio type cables sold for stereo

and VCR use are ideal for the relay connection. The RF cables should be kept as short as practical.

Power Requirements

This amplifier requires 11-18 volts positive at low current (less than 4 amperes) for the control and

bias circuits. This is a non-critical voltage. The voltage applied to the low current control line will not

affect the performance of the amplifier if it is within the specified range. The control line is the small

red wire that connects between pin 10 of the power connector and the 5 ampere fuse.

The heavy RED conductors and the black battery return and chassis ground conductors must carry the

full peak current of the amplifier. This current can reach 80 amperes on voice peaks or 40 amperes of

average current. This large current is split between the two large RED wires leaving pins 3 and 4 of the

power connector. The ground connections from pins 11 and 12 must also carry this current. It is

extremely important to minimize the voltage drop across these conductors. For maximum performance,

all of the high current leads (including the ground leads) must be kept as short as possible.

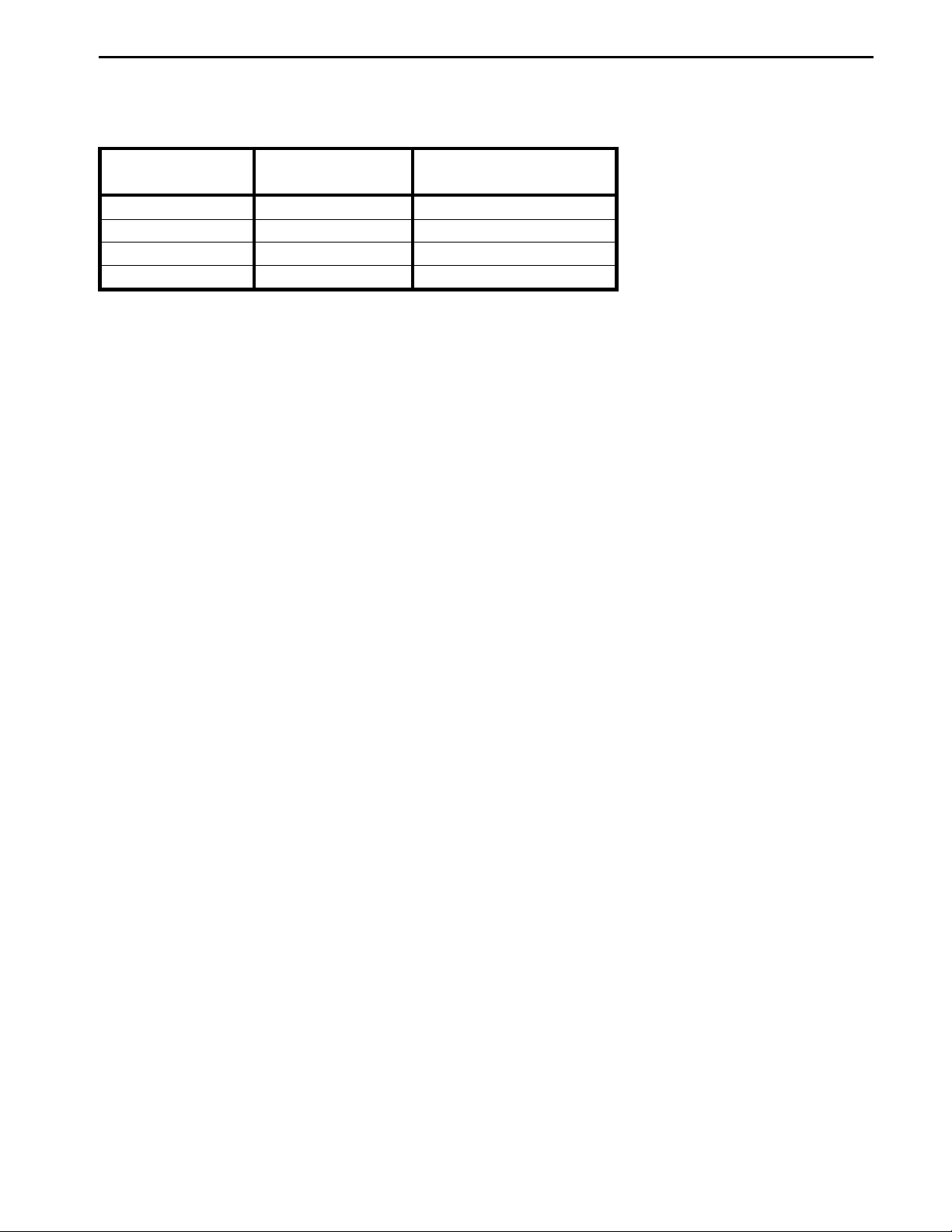

The following chart gives the approximate peak voltage drop in volts per foot of a single supply wire

with 40 amperes of current. Remember the ground wires also carry high current. This chart assumes

that the chassis ground of the vehicle has negligible resistance, and that the negative lead to the battery

is the same wire gauge as the positive supply leads. The chart on page 5 indicates the maximum length

of each individual wire for full performance:

4

Page 6

ALS-500M Instruction Manual

AWG

(single conductor)

10 gauge 0.04 V/ft 5 ft.

8 gauge 0.025 V/ft 8 ft.

6 gauge 0.015 V/ft 12 ft.

4 gauge 0.01 V/ft 20 ft.

For best performance the voltage drop at maximum power in the high current power and ground leads

should be limited to a 0.2 volt maximum. Refer to the Interconnections section for information on the

wiring and fuse requirements of this amplifier.

Fuse Holder Installation

Included in the wire harness bag are 3 fuses and fuse holders. Install these fuse holders at the battery

or electrical system voltage source after the power harness wires have been routed to their final

destinations.

The cartridge type low current fuse holder is for the red low current power lead. Use 3AG type

(automotive glass) 5 ampere fast blow fuses for this lead. This holder is usually shipped with the lead

connected to both sides of the holder. Cut the lead in the middle and remove 1/2 inch of insulation.

Connect the short side of the holder (without a spring) to the lead from the amplifier. If a remote

on/off switch other than the ALS-500RC is used it should be installed between this fuse and the

amplifer. Connect the long side of the holder to an ignition key switched source or to a positive

battery lead. A switched source can usually be obtained from a fuse in the fuse box (radio or

accessory) or a convenient wire under the dash. Use wire nuts or solder and tape all connections.

The plug-in fuse holders and 30 ampere fuses are for the red high current power leads. Do not insert

any fuses until wiring is complete. These holders have Teflon coated 12 gauge leads. They can be

used for any size of power lead because their length is short. Solder one lead of each holder to one of

the lugs supplied. Install the lugs over the starter solenoid post that connects to the battery or over the

bolt that secures the positive battery terminal. Use a separate nut to secure the lugs to avoid disturbing

battery connections if possible.

Connect the other lead of each 30 ampere fuse holders to the heavy gauge power leads by stripping,

twisting, and then soldering the leads together. Bare wires should be wrapped with several layers of

electrical tape. Be sure to dress all amplifier leads so that they are not exposed to sharp edges, high

temperatures, or moving parts. After wiring is completed install the fuses.

Voltage Drop

at 40 amps

Maximum Length For

Full Performance

Auxiliary Battery Installation

If possible, avoid the use of an auxiliary storage battery. Ameritron does not assume any liability and

does not recommend the use of an auxiliary battery. The individual installation is left entirely up to

the installer. The following suggestions will increase the safety of the installation.

The positive lead that connects the auxiliary battery to the main battery should be fused at both ends

with automotive type fuse links rated at 75 to 100 amperes. The positive power cable that connects the

5

Page 7

ALS-500M Instruction Manual

batteries should be number 6 AWG automotive type cable. The negative return can usually be made

through the chassis of the vehicle.

The battery should be securely mounted in a well ventilated area. The hydrogen gas that forms when

the battery is charging can be explosive if trapped in a confined area. Remember that hydrogen gas

rises, and it can be trapped in the top of any compartment. Vents must exit vertically above the area to

be ventilated. Ventilation holes below the battery do not remove the hydrogen gas.

The battery mounting must be secure and outside the passenger compartment of the vehicle. A poorly

secured battery can be a lethal projectile in a collision. A suitable battery box can be obtained from

marine accessory stores. WARNING: The installation of a second battery increases the hazard of

fire or explosion in an accident!!

GROUNDING

Unibody Vehicles

The amplifier ground connection should attach to a large fixed body panel of the vehicle. Never

depend on a connection made to the dash board, doors, trunk or hood of a vehicle for grounding. Use

the heaviest and shortest connections possible. The best conductors for all ground connections are

densely woven copper braiding or heavy stranded cable that is rated to safely carry 100 amperes.

Multiple ground connection points are usually superior to a single ground connection point.

The negative terminal of the battery is almost always directly grounded to the engine block of the

vehicle. This prevents the high starter motor currents from flowing through the engine and drive line

bearings. To be sure that the high amplifier current does not flow through the driveline of the vehicle,

and to minimize the voltage drop in the negative supply lead, the body (chassis) of the vehicle must be

securely grounded to the engine.

The engine block of the vehicle is almost always poorly grounded to the body of the vehicle. This is

usually accomplished by a small gauge wire that connects the negative post of the battery to the

chassis of the vehicle. Remember that the manufacturer of the vehicle calculated the size of the

grounding conductors to only handle the normal accessory electrical load of the vehicle.

Improvements to this ground are mandatory. Improving this ground will also reduce ignition noise and

help prevent interference or damage to the sensitive control devices in modern vehicles. This ground

can be improved by connecting a heavy ground wire from the chassis or frame to an engine accessory

mounting bolt (such as an alternator mounting bracket bolt) or to the same engine bolt that the

manufacturer uses for the negative battery cable.

WARNING: Never ground the negative battery post of the battery directly to the vehicle frame.

Never install a ground under any bolt unless you are sure the bolt connects to the

engine block. Be sure the bolt does not have a critical mechanical function.

The head gasket of an engine may fail and severely damage the engine if a soft lug or washer is placed

under a head bolt. Bolts can NOT be properly torqued against the soft materials used in electrical lugs.

Frame-Type Vehicles

Vehicles with frames often have rubber body mounts that insulate the body from the frame. The

vehicle designers do this to minimize noise, vibration and harshness. The bodies of vehicles that use

6

Page 8

ALS-500M Instruction Manual

insulating body mounts must have flexible strapping connected between the body and the frame at all

four corners of the body. This includes pick-up truck beds.

7

Page 9

ALS-500M Instruction Manual

8

Page 10

ALS-500M Instruction Manual

INTERCONNECTIONS

1. The negative battery lead must be disconnected from the battery post.

2. The positive battery terminal must be disconnected from the positive battery post.

3. Add a heavy ground strap from the engine block or the battery's negative lead to the chassis of the

vehicle.

4. The long heavy black ground lead on the amplifier power plug should be connected to battery's

negative ground cable terminal. Please note this cable is slightly longer than optimum for the 10

gauge wire supplied.

5. Connect the short black ground lead from the amplifier power plug directly to the vehicle's

chassis.

6. Both of the heavy red positive high current leads must be fused at the battery with two 30

ampere fuses. Each lead will carry 40 amperes peak (20 amperes average) during normal operation

of the amplifier. Two 30 ampere spade type fuses, PN 755-1730, fit into fuse holders supplied with

this amplifier. See page 5 for fuse holder installation instructions. Please note this cable is slightly

longer than optimum for the 10 gauge wire supplied.

Note: If using as a fix station with two supplies in parallel, remove the jumper from pins 3 and 4

of the power plug inside of amplifier.

7. The red low current power lead must connect to the positive battery supply through a 5 ampere

fuse, PN 755-1405. This lead will reset a LOAD FAULT condition if power is momentarily

interrupted and restored. This lead can also provide a remote operate - standby function. This can

be accomplished by connecting a remote switch in series with this lead. Connecting this lead to a

permanent voltage source without a series off-on switch will result in a battery drain of a few

milliamperes if the amplifier's POWER switch is accidentally left "ON". This lead should be

connected to a manually switched electrical system lead for controlling the off-on function, an

ignition key switched power source, or through a combination of the two.

8. Connect the RF output (antenna) of the exciter to the RF IN (SO-239) of the ALS-500M with a

good quality 50 ohm cable capable of handling 100 watts.

9. Connect the vehicle's antenna system to the RF OUT (SO-239) connector with 50 ohm coax that

will safely carry 600 watts. This is where the RF output meter or antenna connects.

10. Use a shielded audio type cable with standard male phono (RCA) connectors to connect the RLY

jack of the ALS-500M to the transceiver or transmitter normally open amplifier relay terminal.

This connection has 12 volts open circuit and supplies less than 100 mA of current when pulled to

ground. There is a back pulse canceling diode in the amplifier for exciter protection. The ALS500RC’s Relay jack has the same function. When using the ALS-500RC use the amplifier’s Relay

jack or the remote’s Relay jack, whichever makes installation easier.

9

Page 11

ALS-500M Instruction Manual

11. Plug the female multi-pin power connector onto the multi-pin male connector on the rear of the

ALS-500M chassis.

12. Reconnect the positive and negative battery leads to the battery.

OPERATION

Follow these instructions in numerical order. Consult the manual for the exciter, if necessary. Be sure

all electrical connections is properly wired and the vehicle is running with a fully charged battery. See

the Installation instructions for wiring details.

1. Set the ALS-500M front panel ON-OFF to OFF.

2. Set the amplifier's frequency range switch to the same frequency as the exciter. When using the

ALS-500RC, set the amplifier’s frequency switch to the Remote position and the remote’s

frequency range switch to the same frequency as the exciter.

3. With the amplifier still OFF transmit into the antenna with the exciter. Measure the SWR with the

transceiver's internal SWR indicator or with an external SWR indicator. Do not operate this

amplifier with an SWR greater than 2:1 or with more than 60 watts of reflected power. See the

"SWR Considerations" section on page 3.

4. Place the amplifier in the ON position with ALS-500RC remote on and amplifier off. The DC

AMPERES meter should increase slightly and the relay should "click" when the exciter is keyed.

5. Place the exciter in the transmit mode on CW, FM or RTTY. Gradually increase the output power

and observe the DC AMPERES meter. The current should be around 60 to 80 amperes at full

output. An external watt meter should indicate 400 watts or more of carrier power.

Full output levels of 400 watts CW should be obtained with drive levels of under 60 watts. Peak

envelope output levels on SSB may reach as high as 600 watts depending on voice and exciter

characteristics. The lowest IMD and splatter will be obtained if the amplifier is operated at an output

level slightly below the maximum level obtainable.

As the temperature rises the fan should start to run. If the temperature rises too far the THERMAL

OVERLOAD LED will light and the amplifier will not operate. This feature automatically resets

when the temperature reaches safe limits.

If the reflected power level is too high, the FREQUENCY selector is set to a cutoff frequency below

the transmission frequency, one PA section looses power, or the amplifier is overdriven, the LOAD

FAULT LED will light and the amplifier will not operate. The OFF-ON switch must cycled off to

reset the LOAD FAULT after the problem is corrected.

10

Page 12

ALS-500M Instruction Manual

ALS-500M PARTS LIST

Combiner Board Parts List

Designator Description Part Number

C101,102 Capacitor, Trimmer, 500V, 3-12 pF 204-0150

C107,108 Capacitor, Ceramic Disc, 50v, .01 uF 200-0416

C109 Capacitor, Monolithic, 50v, .33 uF 205-2233

C103,106 Not used

C104,105 Capacitor, DM15, 500 pF 208-5691

D101,102 Diode, 1N34A 300-0346

R101,102 Resistor, 3 watt, 100 ohm 103-2100

R110 Resistor, Trimpot, 2.5k 104-2520

R103,104 Resistor, 1/2 watt, 100 ohm 101-2100

R105,106 Resistor, 1/2 watt, 4.7k ohm 101-3470

R107,108 Resistor, Film, 1/4 watt, 2.2k 100-3220

R109 Resistor, 1/4 watt, 2.7k ohm 100-3270

T101,102 Pickup Transformer 10-14136

T103 Combiner Transformer 11-0500-4

W101,102 Terminal PC Board Posts 720-2670

11

Page 13

ALS-500M Instruction Manual

Power Amplifier Board Parts List

Designator Description Part Number

C225,226 Capacitor, DM19, 500v, 360 pF 208-5688-1

C227,228 Capacitor, SM19, 500v, 750 pF 208-5668

C237,238 Capacitor, DM19, 500v, 820 pF 208-5381

C201,208,211,212-216,

229,230,235,236

C202,207,209,210,233,234 Capacitor, Ceramic Disc, .1 uF 200-0754

C203,205 Capacitor, Electrolytic, 25v, 100 uF 203-0564

C204,206 Capacitor, polyester, .15 uF 201-2215

C217-220 Capacitor, Ceramic Disc, 25v, .01 uF 203-0416

C221,224 Capacitor, SM15, 500v, 100 pF 208-5174

C222,223 Capacitor, SM15, 500v, 150 pF 208-5396

C231,232 Capacitor, Electrolytic, 25v, 10 uF 203-0654

D201,202 Diode, 1N4007 300-0266

HD202 8 pin header 612-0108

L201-204 Ferrite Beads 412-1599

PCB Power Amplifier PC Board 862-0500-2

Q201-204 Transistor, Power, 28C2879 305-2879

R201,204,211,214 Resistor, Metal Oxide, 3 watt, 6.8 ohm 103-0680

R202,203,205-209,210,

212,213,215,216-220

R221-232 Resistor, Metal Oxide, 3 watt, 100 ohm 103-3100

R233-236 Resistor, Metal Oxide, 3 watt, 33 ohm 103-1330

R237,238 Resistor, 1/4 watt, 10 ohm 100-1100

R239,240 Resistor, 1/2 watt, 18 ohm 101-1180

T201 Not used

T202,203 Output Transformer 11-0500-1

T204,205 Input Transformer 11-0500-2

T206,207 Feedback Transformer 11-0500-3

W201-202 Terminal PC Board Posts 720-2670

Capacitor, 50v, .33 uF 205-2233

Resistor, 1/2 watt, 10 ohm 101-1100

12

Page 14

ALS-500M Instruction Manual

13

Page 15

ALS-500M Instruction Manual

Output Filter Board

Designator Description Part Number

C301,308 not used

C302,307 *Capacitor, SM-19, 1000v, 180 pF 252-0180

C303,309 *Capacitor, SM-19, 1000v, 270 pF 252-0270

C304,310 *Capacitor, SM-19, 1000v, 360 pF 252-0360

C305,311,319 *Capacitor, SM-19, 1000v, 680 pF 252-0680

C306,312,317 *Capacitor, SM-19, 1000v, 1500 pF 252-1150

C313,314 *Capacitor, SM-19, 1000v, 160 pF* 252-0160

C315,316 *Capacitor, SM-19, 1000v, 220 pF* 252-0220

C318 *Capacitor, SM-19, 1000v, 2700 pF* 252-1270

C320 Capacitor, Mica, 500 v, 27 pF 250-0027

C321-341 Capacitor, Ceramic Disc, 100 v, .01 uF 200-2100-1

D301 Diode, 1N4007 300-4007

J301,302 Jack, RJ45/641 610-6028

L301,306 Coil, Air Wound, 1/2" ID, 8.5 pass 10-13850

L302,307 Coil, Toroid, 8 pass 10-14168

L303,308 Coil, Toroid, 10 pass 10-14161

L304,309 Coil, Toroid, 14 pass 10-14214

L305,310 Coil, Toroid, 22 pass 10-14222

RLY301-312 Relay, 1PDT, 12Vdc 408-1216

RLY313 Relay, 3PDT 12 Vdc coil 408-6140

* Critical Components

14

Page 16

ALS-500M Instruction Manual

15

Page 17

ALS-500M Instruction Manual

Bias Board Parts List

Designator Description Part Number

C401,406-421, Capacitor, Ceramic Disc, 50v, .1 uF 200-0754

C402-405 Capacitor, Tantalum, 50v, .47 uF 203-0530

D401,402 Diode, 1N4007 300-0266

D403 Diode, Zener, 5.6 v, 1N4734 301-4734

FB401-405 Bead, Ferrite, #43 412-1599

For IC401 Socket, 14 pin 625-0014

IC401 LM324N 311-0324

IC402 Regulator, 78L08AC, 8 V 307-0012

HD401 Header, 8 pin 612-0108

HD402 Header, 10 pin 612-0110

PCB PC Board 862-0500-1

Q401-404 Transistor, MJF-3055 305-3055

Q405 Transistor, 2N6564 (2N5064) 321-6564

R401,416,417,424,425,429 Resistor, 1/4 watt, 470 ohm 100-2470

R402,430 Resistor, 1/4 watt, 22k 100-4220

R403 Resistor, 1/4 watt, 33k 100-4330

R404,407 Resistor, 1/4 watt, 2.2k 100-3220

R405,411,414,419,422 Resistor, 1/4 watt, 10 Ohm 100-1100

R406 Resistor, 1/4 watt, 10k 100-4100

R408 Resistor, 1/4 watt, 56k 100-4560

R409,410,428 Trim pot, 2.5k 104-2520

R412,420 Resistor, 1/4 watt, 10k 100-4100

R413,415,421,423,431,432 Resistor, 1/4 watt, 1k 100-3100

R418,426 Resistor, 3 watt, 1.5 ohm 103-3400

R427 Resistor, 1/4 watt, 100 ohm 100-2100

R433 Resistor, 1/4 watt, 3.3M 100-6330

16

Page 18

ALS-500M Instruction Manual

17

Page 19

ALS-500M Instruction Manual

ALS-500M Chassis Components

Designator Description Part Number

J1, 2 Jack, SO-239 610-2126

J3 Jack, RCA 600-1225

J4 Jack, Power 610-5012

B1 Fan, 12 volt, muffin, 3" 410-3512

C1,4 Capacitor, Ceramic Disc, 25v, .01 uF 200-0416

C2,3 Capacitor, Ceramic Disc, 25v, .1 uF 200-0754

Meter 100 Amp Induction Meter 400-2500

LED1 MV6753 Red LED 320-0522-1

LED2 MV6753 Yellow LED 320-0300

P1 Plug, Power for J4 610-6012

SW1 Switch, 12 vDC, lighted 507-1357

18

Loading...

Loading...