American Water Heater ADCG, 71681, DCG, DCG3 User Manual

Commercial Gas

Index

Water Heater

Installation

Instructions and

Use & Care Guide

for models with prefix DCG and ADCG

To obtain technical, warranty or service assistance during

or after the installation of this water heater, call toll free:

1-800-456-9805

When calling for assistance, please have the following

information ready:

1. Model number

2. 7 digit product number

3. Serial number

4. Date of installation

5. Place of purchase

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . 2

71681 REV.A 03-09

what can happen if the instructions are not followed.

Table of Contents

Water Heater Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Unpacking the Water Heater . . . . . . . . . . . . . . . . . . . . . . 3

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . ..4

Site Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Clearances and Accessibility . . . . . . . . . . . . . . . . . . . . . . 5

Combustion Air Supply and Ventilation . . . . . . . . . . . . . . . . . . . . . 6-9

Water System Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

Gas Supply and Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operating Your Water Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Maintenance of Your Water Heater . . . . . . . . . . . . . . . . . . . . . . . 22-23

Trouble Shooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

Repair Parts Illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2

INSTALLATION INSTRUCTIONS

Index

Consumer Information

This water heater is design-certified by CSA

International as a Category I, non-direct vented water

heater which takes its combustion air either from the

installation area or from air ducted to the unit from the

outside.

This water heater must be installed according to all

local and state codes, or in the absence of local and

state codes, with the “National Fuel Gas Code”, ANSI

Z223.1(NFPA 54)- latest edition. Canadian installations

must be performed in accordance with CAN/

CSA-B149.1. This is available from the following:

American Gas Association

1515 Wilson Boulevard

Arlington, VA 22209

National Fire Protection Agency

1 Batterymarch Park

Quincy, MA 02269

Canadian Standards Association

5060 Spectrum Way

Mississauga, ON

L4W 5N6

Check the phone listings for the local authorities having

jurisdiction over this installation.

Installer and Owner Responsibilities

This manual has been prepared to acquaint you with

the installation, operation and maintenance of this gas

water heater and provide important safety information in

these areas.

Massachusetts code requires this water heater to be

installed in accordance with Massachusetts Plumbing

and Fuel Gas Code 248 CMR Sections 2.00 and 5.00.

A data plate identifying this water heater can be found

on the front of the water heater. When referring to this

water heater always have the information listed on the

data plate readily available.

Retain your original receipt as proof of purchase.

Unpacking the Water Heater

Excessive Weight Hazard

Use two or more people to move and

install water heater unless proper

handling equipment is utilized.

Failure to do so can result in back or

other injury.

Removing Packaging Materials

Important: Do not remove any permanent instructions,

labels, or the data label from outside of the water heater

or on the inside of panels.

• Remove exterior packaging and place

installation components aside.

• Inspect all parts for damage prior to installation

and start-up.

• Completely read all instructions before

attempting to assemble and install this product.

• After installation, dispose of packaging material

in the proper manner.

Read all of the instructions thoroughly before attempting

the installation or operation of this water heater. Keep

this manual for future reference.

Do not discard this manual. You or future users of this

water heater will need it for future reference.

The manufacturer and seller of this water heater will not

be liable for any damages, injuries or deaths caused by

failure to comply with the installation and operating

instructions outlined in this manual.

The manufacturer of this water heater recommends

that it be professionally installed by qualified

service technicians. Examples of qualified service

technicians include: those trained in the plumbing

and heating industry, local gas utility personnel or

an authorized service person.

3

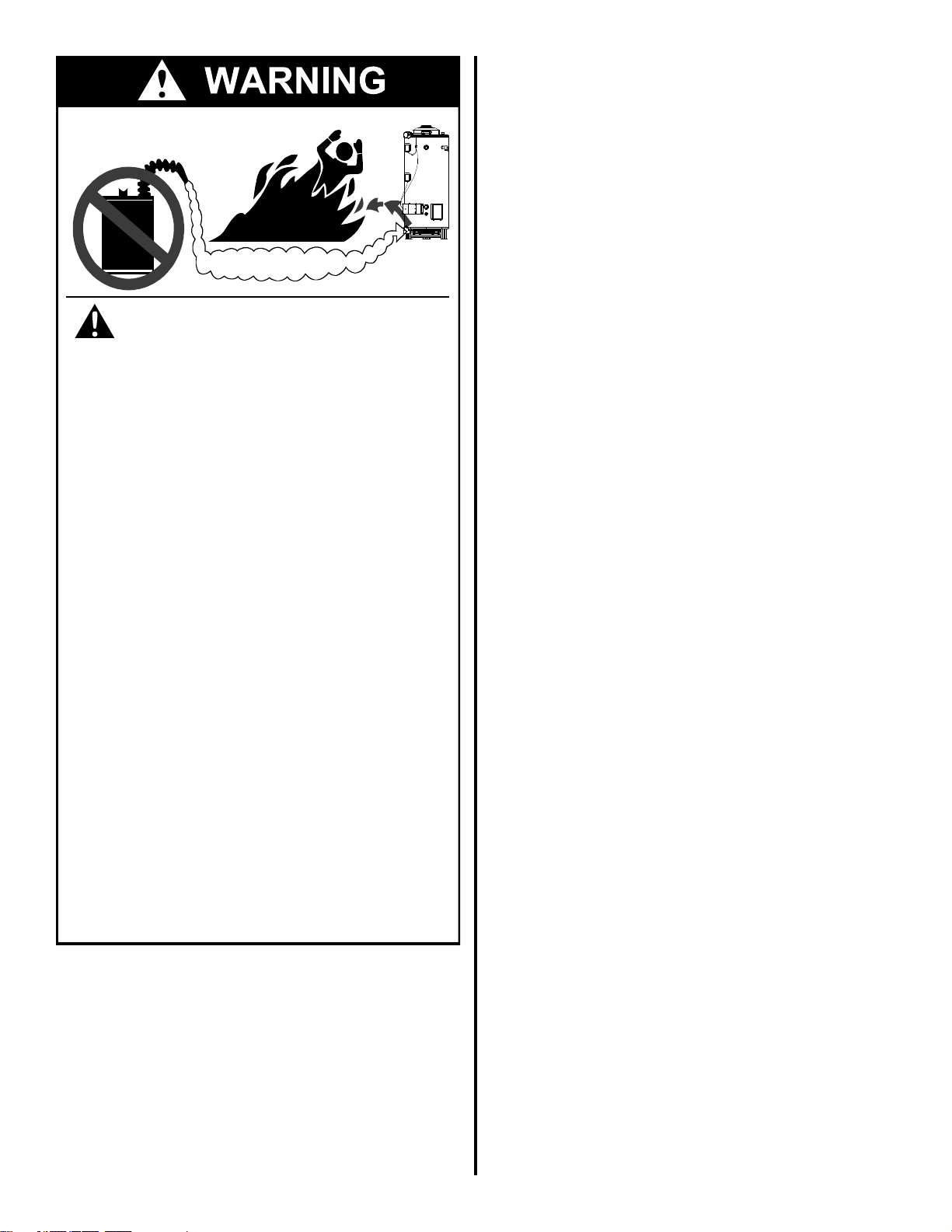

Vapors from flammable liquids will

explode and catch fire causing death or

severe burns.

Do not use or store flammable products

such as gasoline, solvents or adhesives

in the same room or area near the water

heater.

Keep flammable products:

1. far away from heater

2. in approved containers,

3. tightly closed and

4. out of children’s reach.

This water heater has a main burner and

an automatic ignition system. The ignition

system:

1. can come on at any time and

2. will ignite flammable vapors.

Vapors:

1. cannot be seen,

2. are heavier than air,

3. go a long way on the floor and

4. can be carried from other

rooms to the water heater by air

currents.

Do not install this water heater where

flammable products will be stored.

FLAMMABLE VAPORS

FLAMMABLES

Index

Installation Requirements

The water heater must be installed according to all local

and state codes, or in the absence of local and state

codes, the "National Fuel Gas Code”, ANSI Z223.1

(NFPA 54)-latest edition. Canadian installations must be

performed in accordance with CAN/CSA-B149.1.

Note: In the State of California, the water heater must

be braced, anchored, or strapped to avoid moving during an earthquake. Contact local utilities for code

requirements in your area or call 1-800-456-9805 and

request instructions.

4

Site Location

• Select a location near the center of the water

piping system. The water heater must be

installed indoors and in a vertical position on a

level surface. DO NOT install in bathrooms,

bedrooms, or any occupied room normally kept

closed.

• Locate the water heater as close to the gas

vent as practical. Consider the vent system

piping and combustion air supply requirements

when selecting the water heater location. The

venting system must be able to run from the

water heater to termination with minimal length

and elbows.

• Locate the water heater near the existing gas

piping. If installing a new gas line, locate the

water heater to minimize the pipe length and

elbows.

• The water heater should be located in an area

not subject to freezing temperatures. Water

heaters located in unconditioned spaces (i.e.,

attics, basements, etc.) may require insulation

of the water piping and drain piping to protect

against freezing. The drain and controls must

be easily accessible for operation and service.

Maintain proper clearances as specified on the

data plate.

• The operation of air-moving devices such as

exhaust fans, ventilation systems, clothes

dryers, fire-places, etc., can affect the proper

operation of the water heater. Note: Special

attention must be given to the location of these

devices and the conditions they may create.

Flow reversal of flue gases may cause an

increase of carbon monoxide inside of the

dwelling.

Important: Air for combustion and ventilation must not

come from a corrosive atmosphere. Any failure due to

corrosive elements in the atmosphere is excluded from

warranty coverage.

The following types of installation (but not limited to the

following) will require outdoor air for combustion due to

chemical exposure, and may reduce but not eliminate

the presence of corrosive chemicals in the air:

• Beauty shops

• Photo processing labs

• Buildings with indoor pools

• Water heaters installed in laundry, hobby or

craft rooms

• Water heaters installed near chemical storage

areas

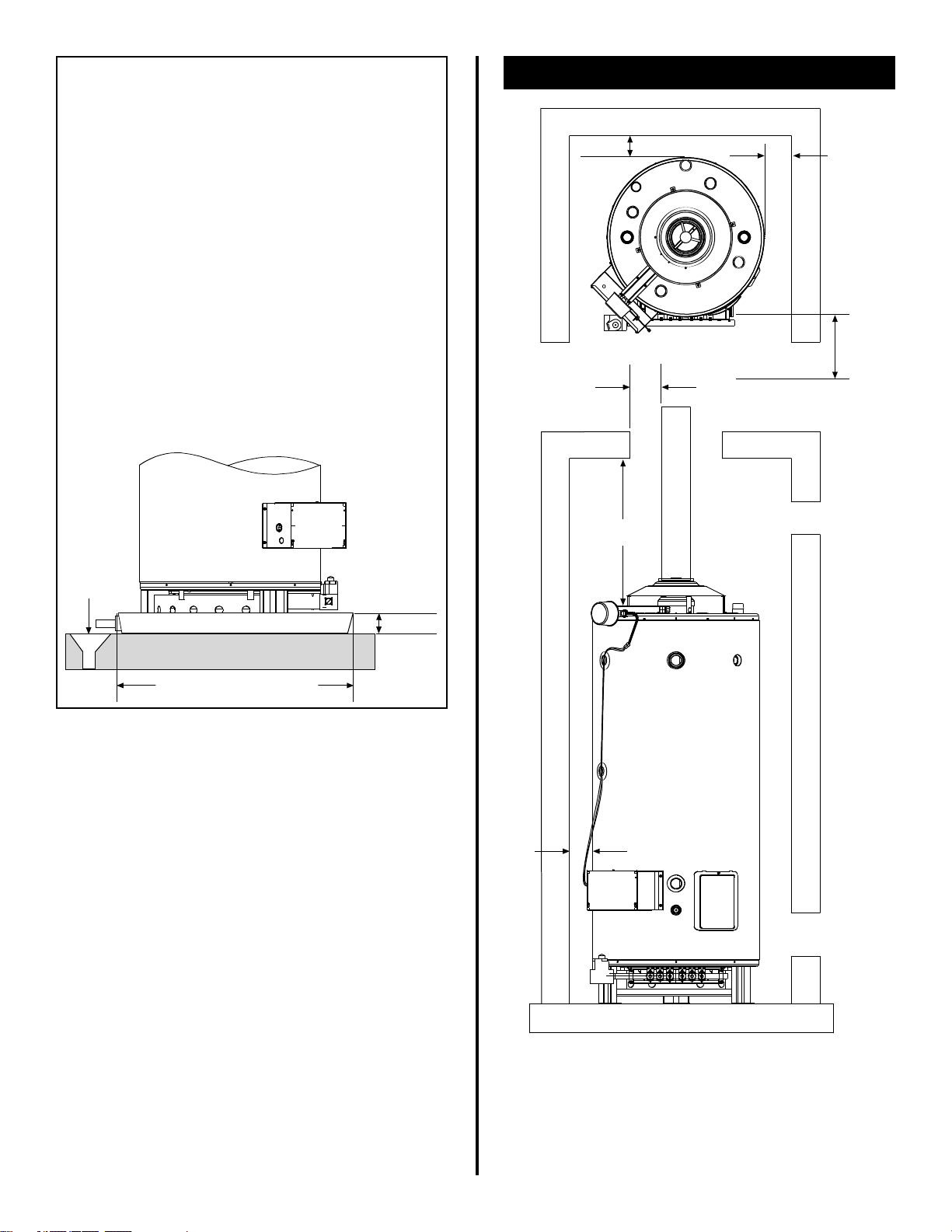

Important:

1 3/4” Max

Pipe to

adequate

drain

At least 2” greater than the

diameter of the water heater

Vent

Top to

ceiling

Sides

Front 24” min.

for service

Sides

Back

Top View

Front View

Index

The water heater should be located in an area where

leakage of the tank or connections will not result in damage to the area adjacent to the water heater or to lower

floors of the structure. Due to the normal corrosive

action of the water, the tank will eventually leak after

an extended period of time. A suitable metal drain pan

should be installed under the water heater as shown

below, to help protect the property from damage which

may occur from leaks in the piping connections or tank.

The pan must limit the water level to a maximum depth of

1 3/4 inches (45mm) and be 2 inches (51mm) wider than

the water heater and piped to an adequate drain. The

pan must not restrict combustion airflow. Locate the

water heater near a suitable indoor drain. Outside drains

are subject to freezing temperatures which can obstruct

the drain line. The piping should be at least 3/4” (19mm)

ID and pitched for proper drainage. Under no circumstances will the manufacturer or seller of this water heater

be held liable for any water damage which is caused by

your failure to follow these instructions.

Figure1: Minimum Clearance Locations

Clearances and Accessibility

Notice: Minimum clearances from combustible

materials are stated on the data plate located on the

front of the water heater.

• If the water heater is installed in a restaurant

or food service location where the floor is

cleaned frequently, NSF International requires

the water heater to maintain 6 inches (150mm)

of clearance above the floor. To comply with the

NSF International requirement, install leg

extension kit. For availability contact

1-800-456-9805

• The water heater is certified for installation on a

combustible floor.

Important: If installing over carpeting, the carpeting

must be protected by a metal or wood panel beneath

the water heater. The protective panel must extend

beyond the full width and depth of the water heater by

at least 3 inches (76mm) in any direction, or if in an

alcove the entire floor must be covered by the panel.

The panel must be strong enough to carry the weight of

the water heater when full of water.

Figure 1 may be used as a reference guide to locate

the specific clearance locations. A minimum of 24

inches (610mm) of front clearance and 4 inches

(102mm) on each side should be provided for inspection

and service.

5

COMBUSTION/VENT PIPE SYSTEM

Carbon Monoxide Hazard

Follow all instructions to locate and install

the vent pipe system.

Instructions can be found in this manual,

in state or local codes (or the authority

having jurisdiction), or in the absence of

such, the National Fuel Gas Code, ANSI

Z223.1, NFPA 54, Latest Edition. Canadian

installations must be performed in

accordance with CAN/CSA-B149.1

Failure to properly locate and install the

vent pipe system can result in death,

explosion, or carbon monoxide poisoning.

Index

Important: Check to make sure the vent pipe is not

blocked in any way.

• Venting should be as direct as possible with a

minimum number of pipe fittings.

• Exhaust gas vents must be installed with U.L.

listed type B vent pipe according to the vent

manufacturer’s instructions and the terms of its

listing.

• Single wall vent connectors must have 6”

(152mm) of clearance from unprotected com-

bustible surfaces.

• If sidewall venting is necessary, a power vent

kit is required. For availability contact 1-800456-9805.

• Vents that run through unconditioned spaces

where below freezing temperatures are expected should be properly insulated to prevent

freezing.

• Existing vent systems must be inspected for

obstructions, corrosion and proper installation.

Combustion

Combustion air must be free of acid-forming chemicals.

These chemicals are found in aerosol sprays, detergents, bleaches, cleaning solvents, air freshener, paint

and varnish removers, refrigerant, and many other commercial products. When burned, vapors from these

products form highly corrosive acid compounds. These

products should not be stored or used near the water

heater or air inlet.

Venting

Vent pipe installation must be installed according to all

state and local codes, or in the absence of local and

state codes, the National Fuel Gas Code, NFPA 54,

ANSI Z223.1-latest edition. Canadian installations must

be performed in accordance with CAN/CSA-B149.1

It is the responsibility of the installing contractor to

provide a vent adequate in capacity and in good usable

condition. Btu/hr capacity limitations are governed by

the style and height of the vent/chimney. For installations in the United States, capacity tables are available

in the National Fuel Gas Code (ANSI Z223.1- latest edition). Canadian installation information can be found in

CAN/CSA-B149.1

U.L. recognized fuel gas and carbon monoxide (CO)

detectors are recommended in all applications and

should be installed using the manufacturer’s

instructions and local codes, rules, or regulations.

• Vents must be connected to the water heater’s

drafthood by a certified vent connector or by

directly originating at the drafthood opening.

• Vertical gas vents must terminate with a listed

cap or other roof assembly and be installed

according to their manufacturer’s instructions.

• Horizontal vent connections must have an

upward slope of at least 1/4” (6mm) per

foot (305mm).

• Gas vents must be supported to prevent

damage, joint separation, and maintain

clearances to combustible materials.

• Vent connection joints should be fastened by

sheet metal screws or by other approved

methods.

• Vent and vent connectors should have

adequate support to keep weight off the

draft hood.

All pipe, fittings, and procedures must conform to

American National Standard Institute and American

Society for Testing and Materials (ANSI/ASTM) standards in the United States.

Important: If you lack the necessary skills required to

properly install this venting system, you should not

proceed, but get help from a qualified service

technician.

6

Air Requirements

Index

An adequate air supply shall be provided

for combustion and ventilation of this

water heater.

An insufficient supply can result in poor

combustion and possible sooting of the

burner, combustion chamber or flue

passageway. This may present a potential

fire hazard or could create a serious

health hazard by producing carbon

monoxide.

General

Where an exhaust fan or any other air consuming

appliance (Eg. Clothes dryer, furnace, etc.) is installed

in the same space as the water heater, sufficient air

openings must be available to provide fresh air when all

appliances are operating simultaneously.

The area in which the heater is located is classified as

either “an unconfined space” or “a confined space.”

An unconfined sp

volume not less than 50 cubic feet per 1000 BTU/hour

(4.8 cubic meters per kilowatt) of combined input rating

of all appliances using the space. Adjacent open rooms

may be included as part of the unconfined space.

There shall be no closeable doors between these

rooms. An example of this is an open basement.

A confined sp

Air shall be supplied through permanent openings as

described in Figure 2. At no time shall an air opening

have a dimension of less than 3” (75 mm) and at no

time shall any top opening be lower than the top of the

water heater.

ace is defined as a space having a

ace is one smaller than described above.

For buildings that are not well sealed (do not have tight

fitting doors and windows) natural air infiltration may

provide sufficient air required for combustion and ventilation. For buildings using tight construction (newer and

renovated structures), the air supply shall be introduced

from the outdoors, regardless of whether the space is

confined or unconfined.

Combustion Air “Supply” Ducts

Air supply ducts shall be of galvanized steel or equivalent corrosion resistant material. A single air duct may

not be substituted when required for upper and lower

air openings. Horizontal upper combustion air ducts

shall not slope downward toward the air inlet.

Louvers and Grills

Openings for air supply ducts must provide free unobstructed air movement. Louver and grill openings must

be sized to ensure that the FREE OPEN AREA is never

less than the area of the air duct.

LOCATION:

The location for top and bottom openings are as follows;

For U.S. installations:The top opening shall commence within 12” (300 m) of the top of space and the

bottom opening shall commence within 12” (300mm) of

the bottom of the enclosure.

For Canadian installations:The top opening shall be

located as close to the ceiling as practical but never

lower than the relief opening of the lowest draft control

device. The bottom opening shall be located neither

more than 18 inches (450 mm), nor less than 6 inches

(150 mm), above floor level.

7

Combustion

Air Duct

Permanent

Ventilation

Air

12” Grade

12”

Outdoor

Air Ducts

Venting

Combustion

Inlet

Air Ducts

Outlet Air

(a)

(b)

(d)

(c)

Air Opening Requirements

A

1

B

2

BTU/hr(kW)

in2(mm2)

in(mm) in(mm)

75,000(23) 11(7,000) 4(100) 5(125)

100,000(30) 14(9,000) 4(100) 5(125)

125,000(37) 18(12,000) 5(125) 6(150)

150,000(45) 22(14,000) 5(125) 6(150)

175,000(53) 25(16,000) 6(150) 7(175)

200,000(60) 29(19,000) 6(150) 7(175)

225,000(68) 32(21,000) 6(150) 7(175)

250,000(75) 36(23,000) 7(175) 8(200)

275,000(83) 40(26,000) 7(175) 8(200)

300,000(90) 43(28,000) 7(175) 8(200)

325,000(98) 47(30,000) 8(200) 9(225)

350,000(105) 50(32,000) 8(200) 9(225)

375,000(113) 54(35,000) 8(200) 9(225)

400,000(120) 58(37,000) 9(225) 10(250)

Acceptable Equivale nt duct

diam eter

Combined input of a ll

appli ances in

confined space

Require d

free area of

duct

Index

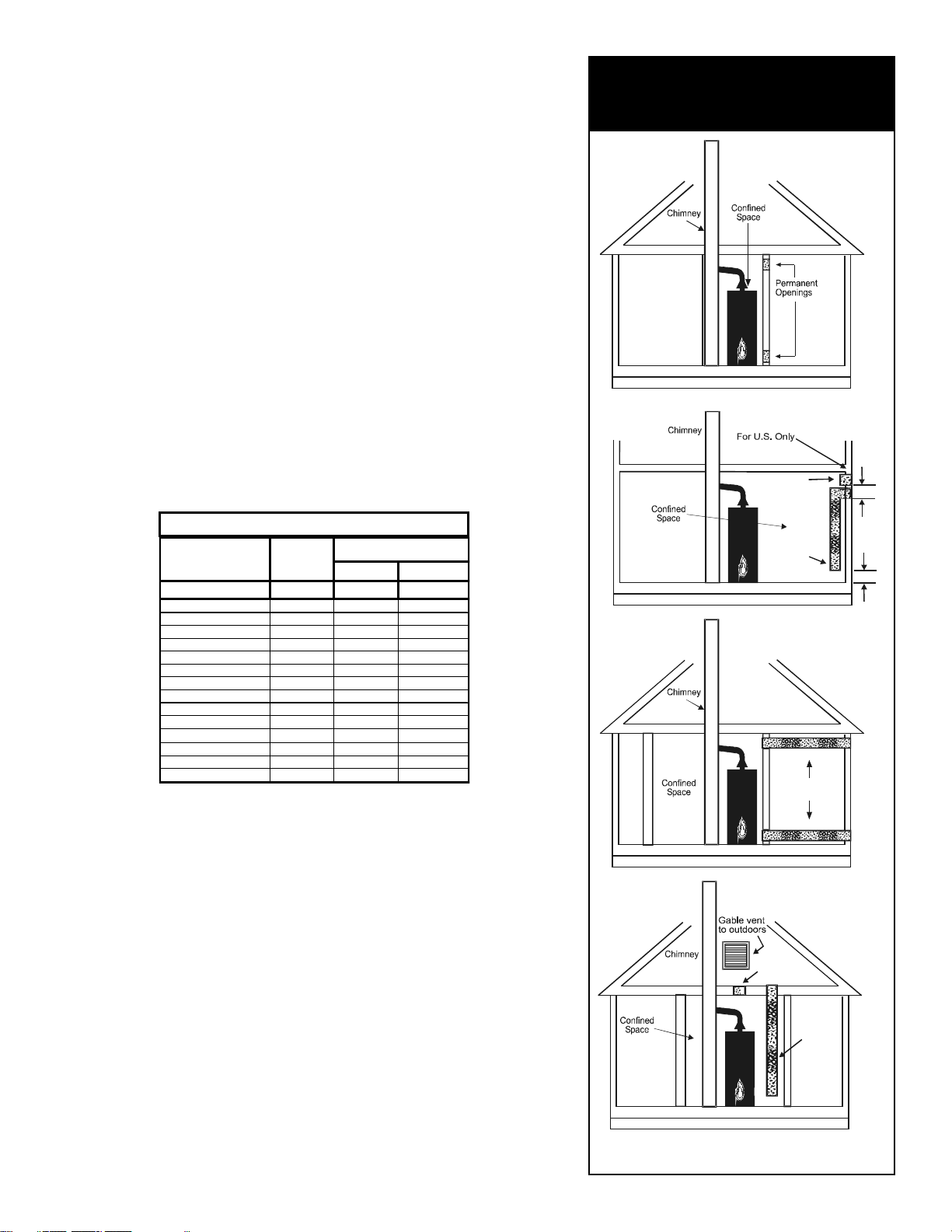

(a) EQUIPMENT LOCATED IN CONFINED SPACES; ALL AIR FROM

INSIDE THE BUILDING.

Two permanent openings (top and bottom) shall be provided connecting

the confined space (e.g., closet/small room) with the unconfined space.

Each opening shall have a free area of one square inch per 1,000

BTU/hour (22 cm²/kW) input of all appliances in the confined space, but

not less than 100 square inches (645 cm²).

b) BASEMENT INSTALLATION, EQUIPMENT LOCATED IN CONFINED SPACES; ALL AIR FROM OUTDOORS.

Outside air inlets shall be a minimum of 12” (300mm) above the grade

(snow) line. When supplying air directly from the outdoors:

For American installations: Two openings (top and bottom) shall be

provided with each opening having a minimum free area of one square

inch per 4,000 BTU/hour input (5.5 cm²/kW) of total input rating of all

appliances in the confined space.

For Canadian installations: Canadian codes specify single air supply

source. Canadian customers and authorities having jurisdiction may use

the sizing listed in Table 1. When using a single air supply, the duct shall

terminate within 1 foot (300 mm) above and within 2 feet (600 mm) horizontally from the burner level of the appliance having the largest input.

Figure: 2 Equipment Location

and Combustion/Ventilation Air

Requirements

Table 1

Notes:

1.Maximum lenght of ducts in column A is 20 equivalent feet(6.1 meters).

2.Maximum lenght of ducts in column B is 50 equivalent feet(15.2 meters).

(c) EQUIPMENT LOCATED IN CONFINED SPACES; ALL AIR FROM

OUTDOORS.

For American installations: When supplying air directly from the out-

doors using horizontal ducting, each opening shall have a free minimum

area of one square inch per 2,000 BTU/hour (11 cm²/kW) of total input

rating of all appliances in the confined space.

For Canadian installations: Refer to Table 1 of part (b).

(d) EQUIPMENT LOCATED IN CONFINED SPACES; ALL AIR FROM

OUTDOORS THROUGH VENTILATED ATTIC

For American installations: When supplying air directly through vertical

ducting, each opening shall have a free minimum area of one square

inch per 4,000 BTU/hour (5.5 cm²/kW) of total input rating of all appliances in the confined space.

8

.

*U.S. installations require a dual duct system.

Loading...

Loading...