American Water Heater ATO-305-N, GTS-305-PI, GTS-305-NE, GTS-705-NI, ATI-705-P User Manual

...

Tankless Water Heater

System Design Manual

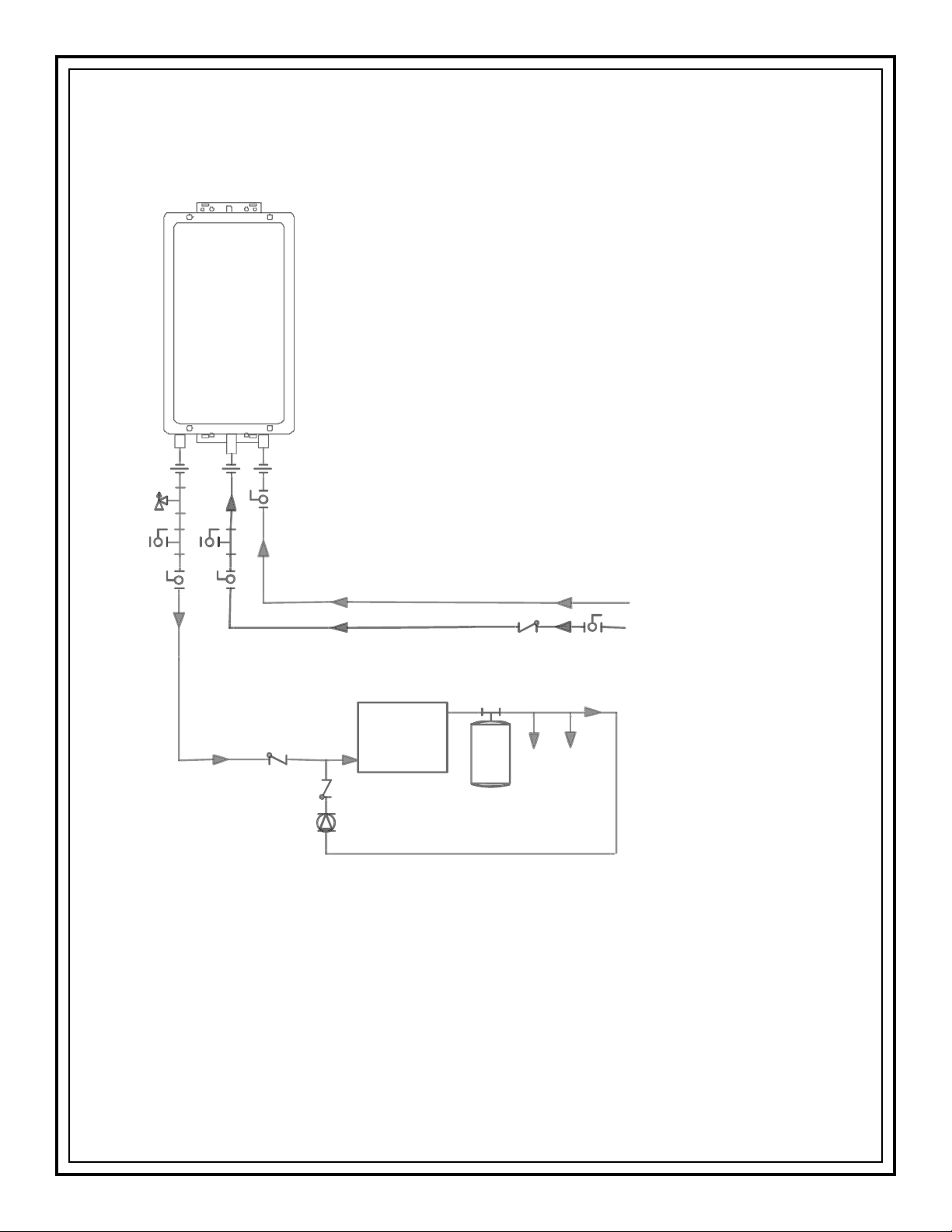

Plumbing schematics for single

and multiple tankless water

heaters in use with domestic

systems, recirculation, and

storage tanks.

PRINTED 0708 186965-000

Table of Contents

Certifications..................................................................................3

Water Quality and Scale ................................................................4

Pump Sizing for Circulation..........................................................5

Tank Water Heaters in a Circulation Loop

Additional Guidelines

Pump Sizing for Storage Tank Applications

Pressure Loss Curves

Domestic Hot Water - Standard Installation

1 Water Heater

2 Water Heaters (WH3 Water Heaters (WH4 Water Heaters (WH5 Water Heaters (WH6 Water Heaters (WH-

Domestic Hot Water with Optional Freeze Protection

on Outdoor Models

1 Water Heater

2 Water Heaters (WH-23 Water Heaters (WH-36 Water Heaters (WH-6-

Domestic Hot Water with Circulation Systems

1 Water Heater - Preferred (WH1 Water Heater - Optional (WH-1-R)

2 Water Heaters - Preferred (WH-2-RGE)

2 Water Heaters - Optional (WH3 Water Heaters - Preferred (WH-3-RGE)

6 Water Heaters - Preferred (WH-6-RGE)

Domestic Hot Water with Backup Storage Tanks

1 Water Heater

1 Water Heater with Circulation (WH2 Water Heaters (WH-22 Water Heater with Circulation (WH3 Water Heaters (WH-33 Water Heater with Circulation (WH6 Water Heaters (WH-66 Water Heater with Circulation (WH-

Maintenance Procedure

Scale Flush

(WH-1)....................................................................9

(WH-1-D)..............................................................15

(WH-1-B)..............................................................25

Procedure (M-1-F

....................................................................6

2)................................................................10

3)................................................................11

4)................................................................12

5)................................................................13

6)................................................................14

..................................................................8

D)............................................................16

D)............................................................17

D)............................................................18

1-RGE).......................................19

..............................................20

2-R)............................................22

1-B-R)................................. 26

B) ............................................................27

2-B-R)................................. 28

B) ............................................................29

3-B-R)................................. 30

B) ............................................................31

6-B-R)................................. 32

) .....................................................33

...................................6

...............................7

.....................................21

.....................................23

.....................................24

2

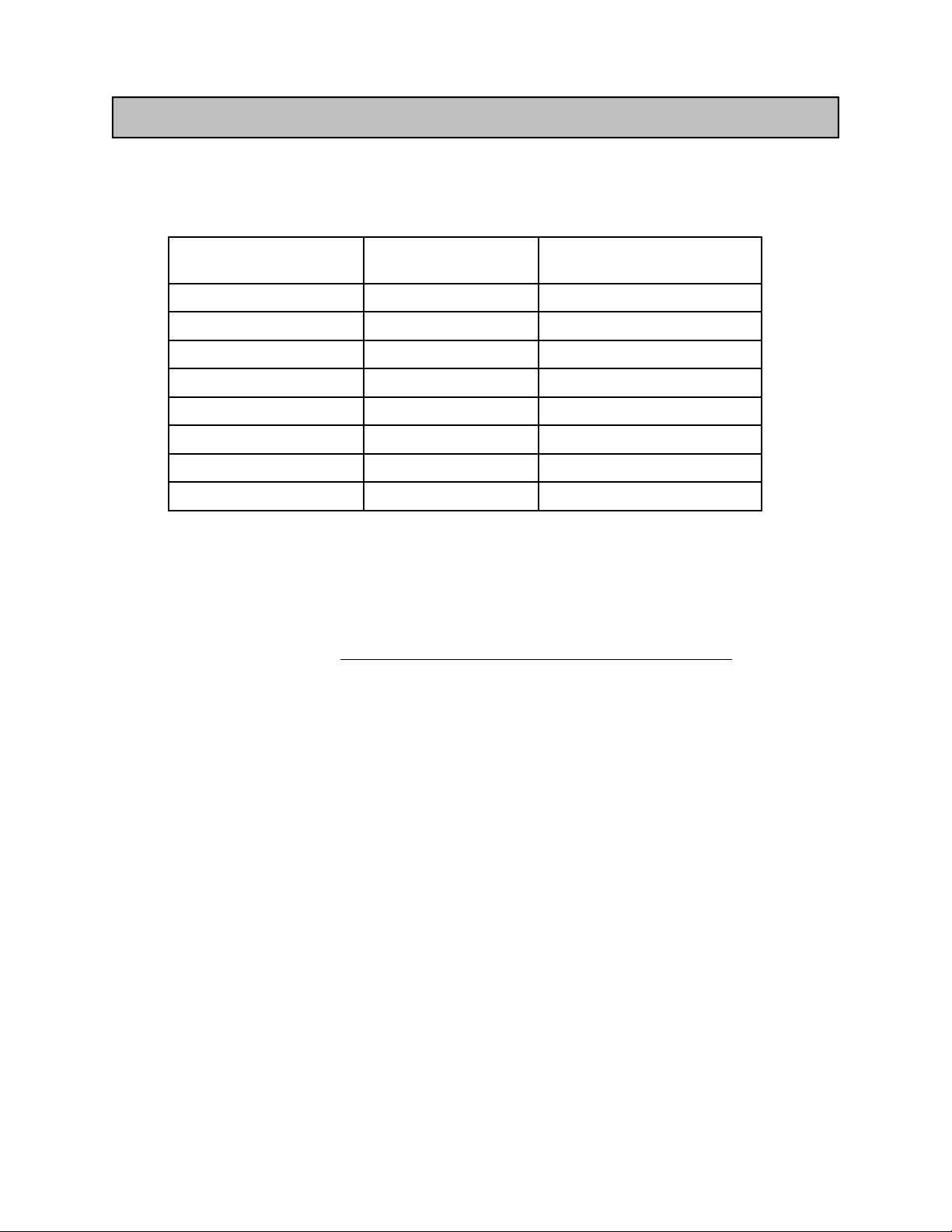

Approvals

ATI-305-N GTS-305-NI GT-305-NI

ATI-305-P GTS-305-PI GT-305-PI

ATO-305-N GTS-305-NE GT-305-NE

ATO-305-P GTS-305-PE GT-305-PE

ATI-505-N GTS-505-NI GT-505-NI

ATI-505-P GTS-505-PI GT-505-PI

ATO-505-N GTS-505-NE GT-505-NE

ATO-505-P GTS-505-PE GT-505-PE

ATI-705-N GTS-705-NI GT-705-NI

ATI-705-P GTS-705-PI GT-705-PI

ATO-705-N GTS-705-NE GT-705-NE

ATO-705-P GTS-705-PE GT-705-PE

ATI-705A-N GTS-705-NIA AGT-705-NI

ATI-705A-P GTS-705-PIA AGT-705-PI

ATO-705A-N GTS-705-NEA AGT-705-NE

ATO-705A-P GTS-705-PEA AGT-705-PE

The models listed in this manual have received the following certifications except where noted:

Certified to applicable U.S.

standards for appliances using

gas or other petroleum fuel.

EFFICIENCY

HEATING

CERTIFIED

Energy efficiency certified by

Gas Appliance Manufacturers

Association (GAMA),

www.gamanet.org

Certified to applicable Canadian

standards for appliances using

Met the California Energy

Commission (CEC) standards

gas or other petroleum fuel.

U

P

C

Certified by the Uniform

Plumbing Code (UPC)

Certified by National Sanitation

Foundation (NSF), www.nsf.org

(indoor models must use the

Approved by the Commonwealth

of Massachusetts

Received New York City’s

Material and Equipment

Acceptance (MEA)

NSF approved top guard)

3

Water Quality and Scale

A complete water analysis and an understanding of system requirements are needed to protect the

tankless water heaters and water heating systems from scale. Water analysis shows whether

water is hard or soft. Hard water, unless treated, will cause scaling or liming of the heat exchanger.

The rate of scaling increases with temperature and usage because calcium carbonate and other

scaling compounds lose solubility (fallout of solution) at higher temperatures. For example, for every

20°F over 140°F, the rate of scale increases by a factor of 2 (See figure below). Reference target

water quality levels found in the operation / installation manual and consider water treatment if these

levels are exceeded. *

LIME DEPO SITED, lb/yr

210

180

150

120

90

60

30

BASED ON 10 grains/gal HARDNESS

*

180°F

170°F

160°F

150°F

140°F

0

300

0

900

1500

2100

2700

3300

120°F

3900

WATER USA G E , g al/day

*Source 2003 ASHRAE Handbook HVAC Applications

4

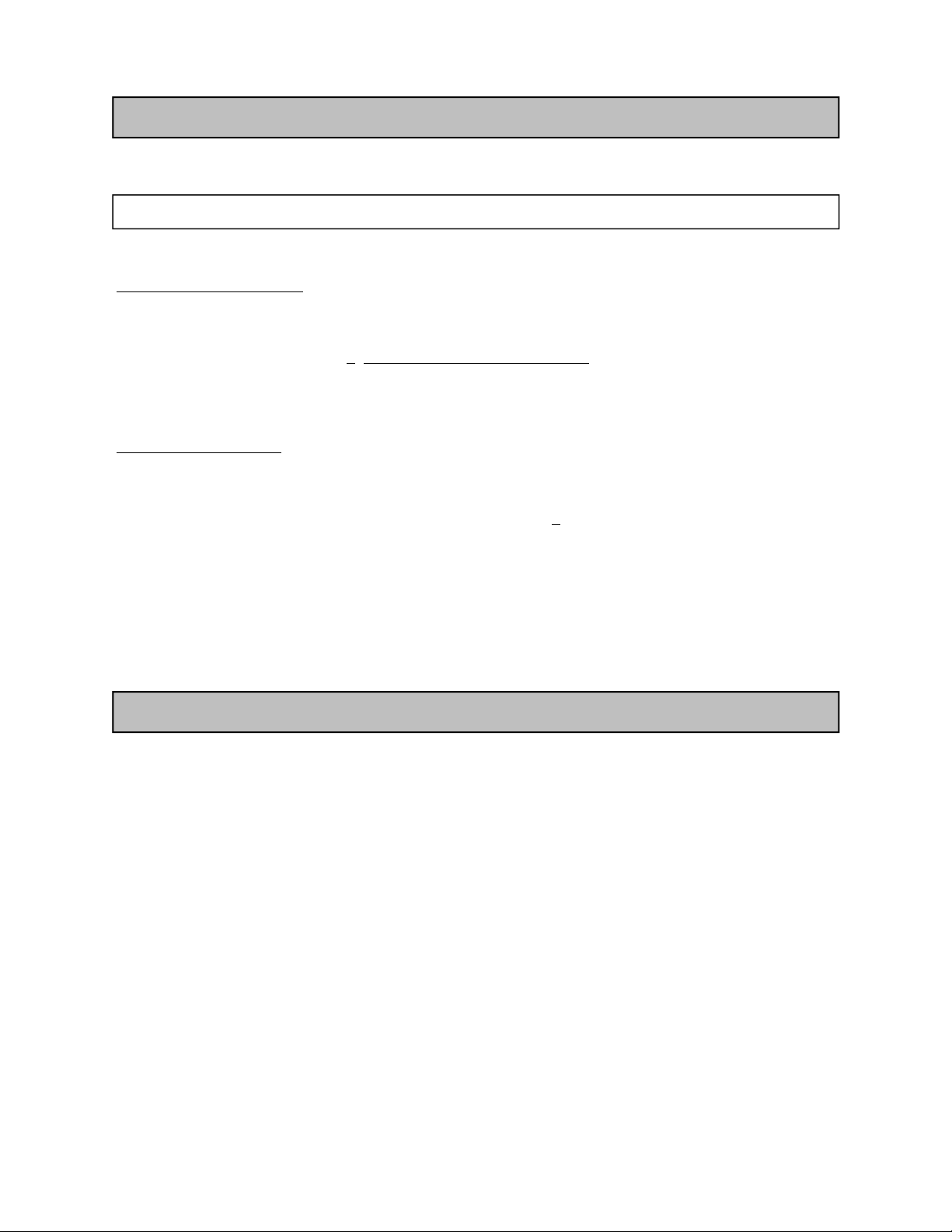

Pump Sizing for Circulation

1. Use the chart below or one appropriate for your conditions to determine the heat loss in the length of

the hot water supply and return piping. For example, 100 ft of 1-1/2 in bare copper tubing results in a

heat loss of 5300 Btu/h.

Approximate Heat Loss from Piping at 140 ºF Inlet, 70 ºF Ambient *

Nominal Size, in. Bare Copper Tubing,

Btu/h-ft

2/1-2

* Source: 2003 ASHRAE Handbook HVAC Applications

2. Determine the acceptable temperature drop at the last fixture in the loop. For example, if the supply

temperature from the water heater is 120 ºF (49 ºC) and an acceptable temperature at the last fixture

is 100 ºF (38 ºC) then the acceptable temperature drop is 20 ºF (7 ºC).

3. Calculate the required pump flow rate using the following formula:

FLOW RATE (gpm) = HEAT LOSS (BTU / h)

500 X ACCEPTABLE TEMPERATURE DROP (ºF )

1/2 in. Glass Fiber Insulated

Copper Tubing, Btu/h-ft

7.71 03 4/3

3.02 83 1

4.32 54 4/1-1

4.52 35 2/1-1

6.92 66 2

8.33 08

5.93 49 3

4.84 021 4

4. Based on the above calculations select a pump for the type of circulation system you will be utilizing:

A). Preferred Method (reference drawing WH-1-RGE) - Reference pump manufacturers flow vs.

pressure specifications to select a pump that can provide the flow rate calculated above

while overcoming the pressure loss through:

• Tank water heater (reference manufacturer’s information)

• All building supply and return plumbing in the circulation loop (reference

local plumbling codes, standards, or practices)

B). Optional Method (WH-1-R) - Reference pump manufacturers flow vs. pressure specifications

to select a pump that can provide 3 gpm of flow or the flow rate calculated above, whichever

is greater, while overcoming the pressure loss through:

• Tankless water heater (reference flow

being used)

• Optional storage tank (reference manufacturer’s information)

• All building supply and return plumbing in the circulation loop (reference

local plumbling codes, standards, or practices)

NOTE: Only use pumps of brass or stainless steel construction. Do not use pumps of iron

construction as they will oxidize and clog the inlet filter on the appliance.

vs. pressure curve of the model

5

Tank Water Heaters in a Circulation Loop

The following applies when using a tank water heater (gas or electric) to provide heat for a circulation

loop. Drawing WH-1-RGE is an example.

The heat output of the tank must be equal to or greater than the calculated circulation loop heat loss.

(Reference page 6, Step 1 on calculating heat loss).

Electric Tank Water Heater

Since the input and output are the same for an electric tank water heater, this can be expressed as:

Electric Tank Input (Kw) >

3413

(1 Kilowatt = 3,413 BTU)

Gas Tank Water Heater

When using a gas style water heater, the efficiency of the tank must be taken into account.

Available Btu output = (Btu input of tank) x (efficiency) >

Example:

30,000 Btu input gas tank

0.62 Efficiency

30,000 x .62 = 18,600 available Btu output

Circulation loop heat loss (Btu/h)

Circulation loop heat loss (Btu/h)

Additional Guidelines

Tankless water heaters not recovering a storage tank: In applications involving a commercial

dishwasher, a hot water circulation loop feeding the dishwasher is required.

Tankless water heater recovering a storage tank: In applications involving a commercial dishwasher, a

hot water circulation loop feeding the dishwasher may be required depending on the distance between

the dishwasher and the storage tank. Refer to local codes when determining the need for circulation

loops to dishwashers.

6

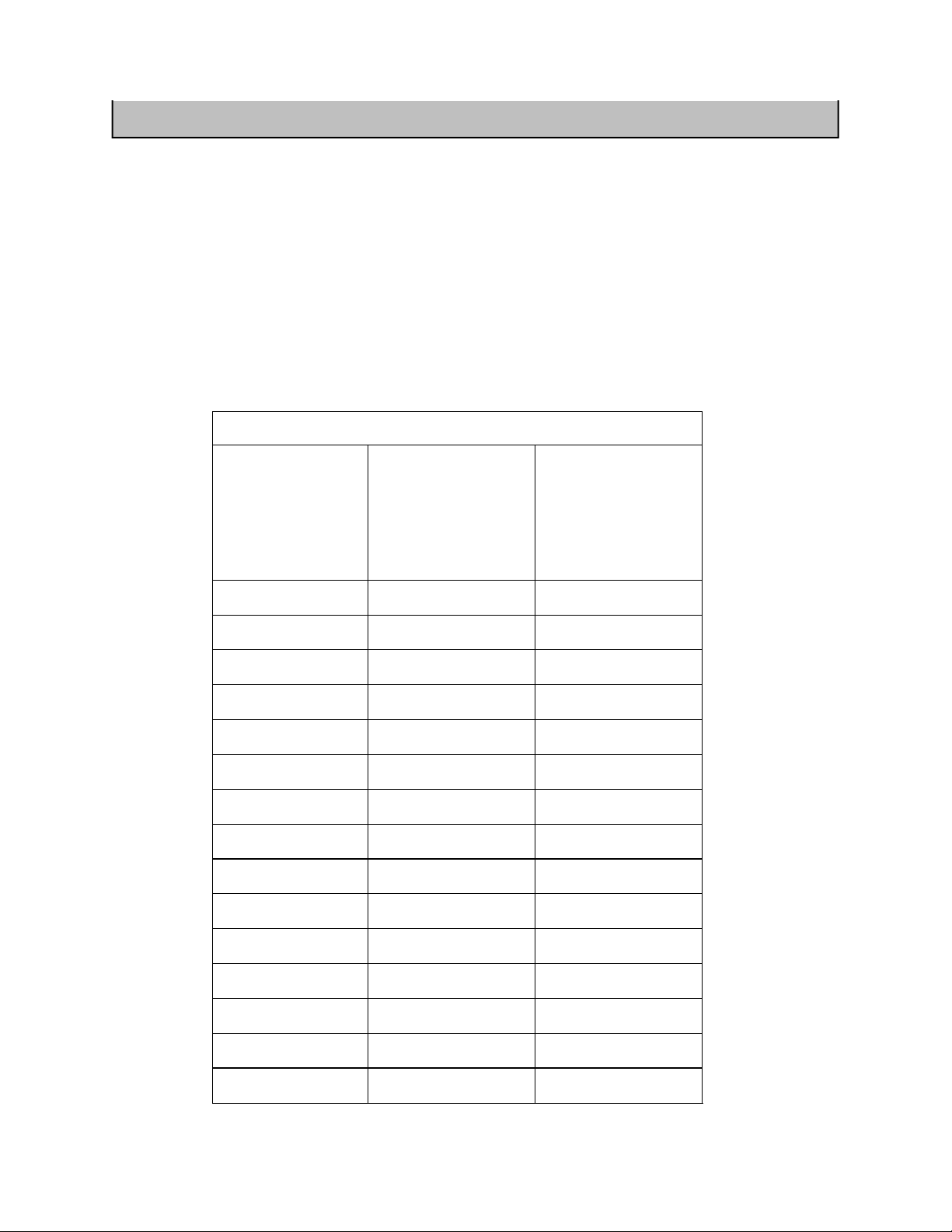

Pump Sizing for Storage Tank Application

The following applies when using tankless water heaters to recover a storage tank.

Drawing WH-1-B is an example.

Tankless water heaters have a pressure loss which must be considered in the system design.

Reference the pressure loss curve for the heater model being used to determine the pump size for the

desired recovery rate.

For recommended pump sizes use the table below. Additional pressure losses in plumbing between the

Heater(s) and the storage tank must also be taken into consideration.

The specified pump size is to provide maximum recovery of the storage tank. A smaller pump size may

be used, but could result in longer recovery time of the tank. Please contact the Tech Services department

with any questions on pump sizing.

NOTE: Only use pumps of brass or stainl ess steel construction. Do not use pumps of iron

construction as they will oxidize and clog

Pump Flow Requirements

Number of

Tankless

705/505

Water Heaters

the inlet filter on the appliance.

305

1 6 gpm @ 30' head 5 gpm @ 25' head

2 12 gpm @ 30' head 10 gpm @ 25' head

3 18 gpm @ 30' head 15 gpm @ 25' head

4 24 gpm @ 30' head 20 gpm @ 25' head

5 30 gpm @ 30' head 25 gpm @ 25' head

6 36 gpm @ 30' head 30 gpm @ 25' head

7 42 gpm @ 30' head 35 gpm @ 25' head

8 48 gpm @ 30' head 40 gpm @ 25' head

9 54 gpm @ 30' head 45 gpm @ 25' head

10 60 gpm @ 30' head 50 gpm @ 25' head

11 66 gpm @ 30' head 55 gpm @ 25' head

12 72 gpm @ 30' head 60 gpm @ 25' head

13 78 gpm @ 30' head 65 gpm @ 25' head

14 84 gpm @ 30' head 70 gpm @ 25' head

15 90 gpm @ 30' head 75 gpm @ 25' head

7

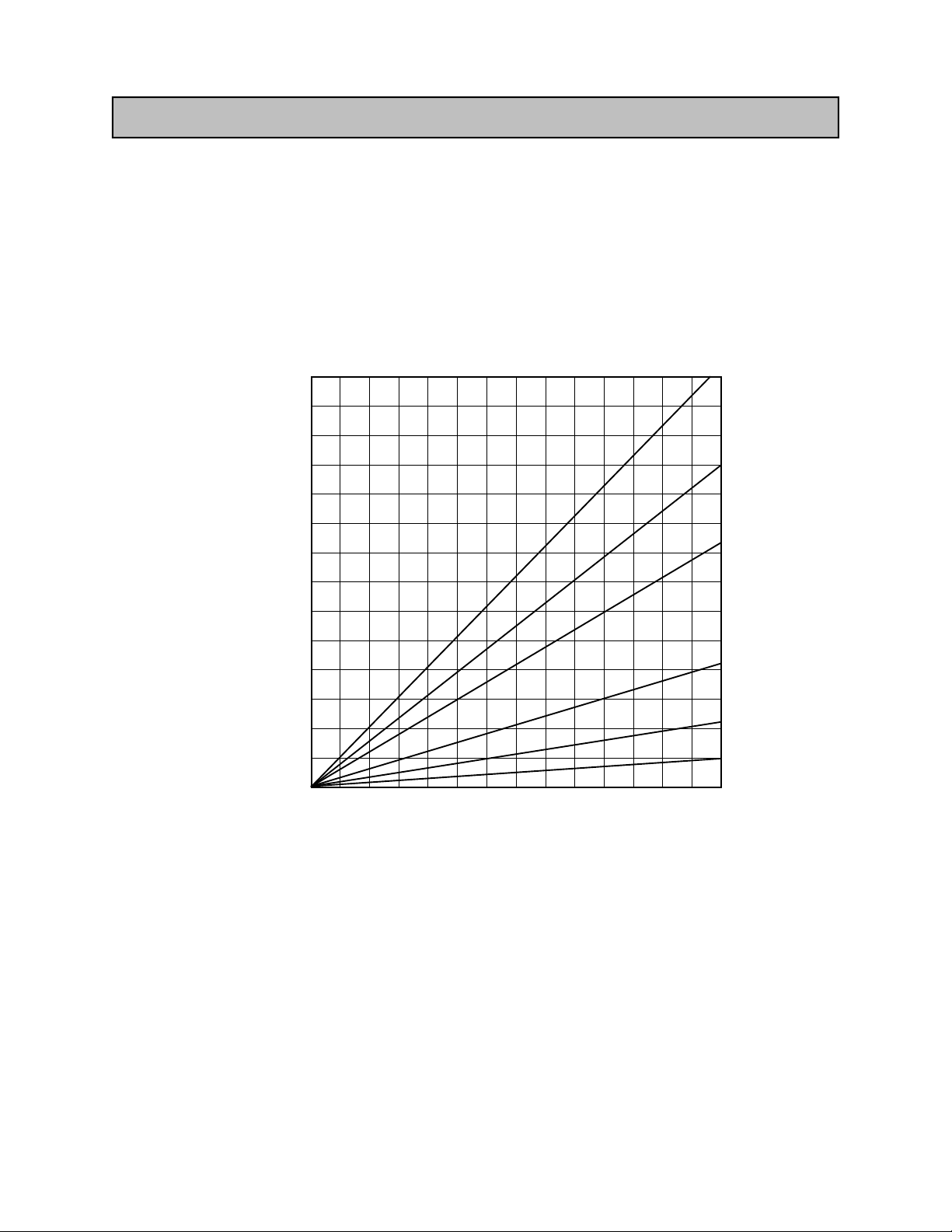

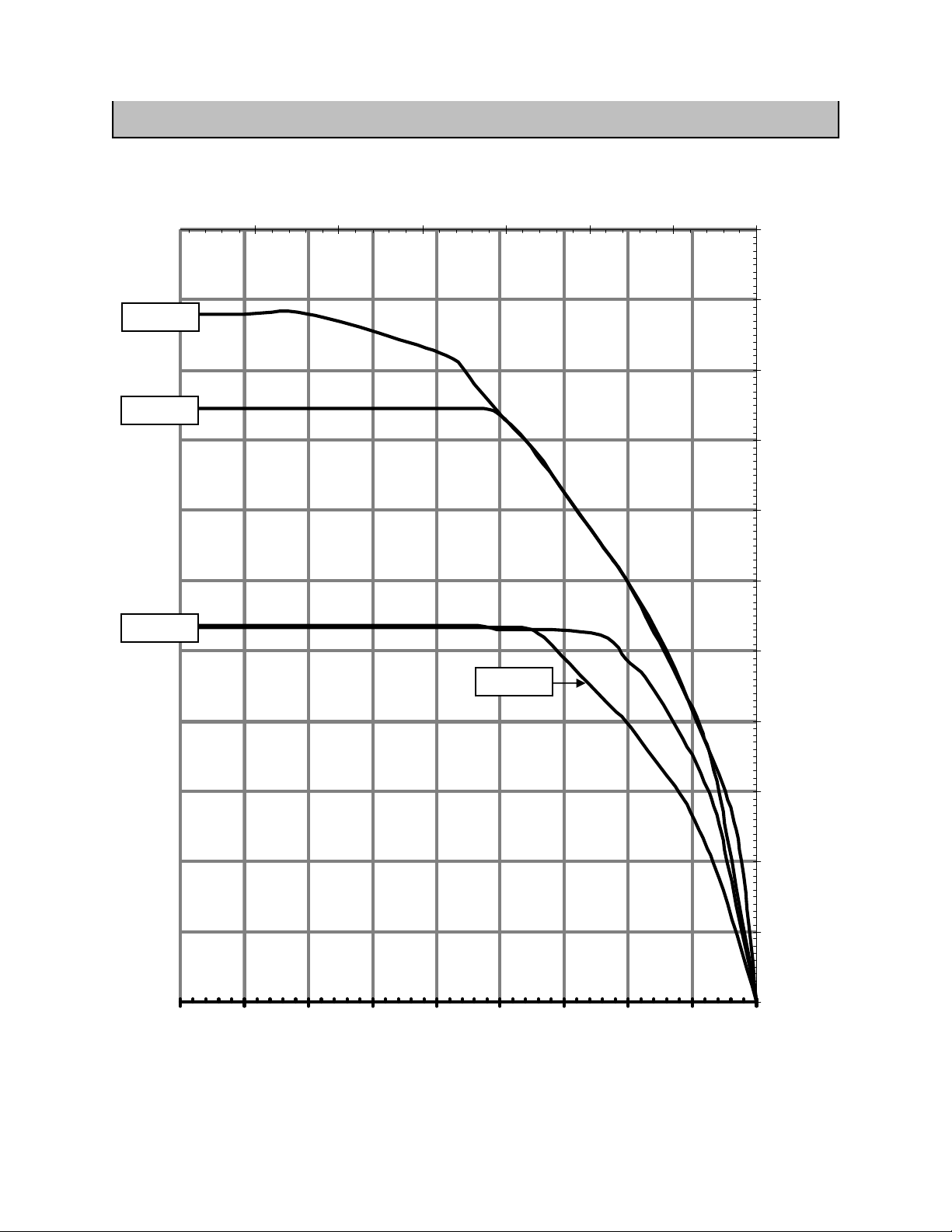

Pressure Loss Curves

Pressure Loss (ft head)

705

505

305i

60.0

50.0

40.0

30.0

20.0

10.0

0.0

305e

45.0

40.0

35.0

30.0

25.0

20.0

15.0

10.0

5.0

0.0

Water Flow (gpm)

01234567891011

Pressure Loss (psi)

8

Pressure Regulator

Circulating Pump

Solenoid Valve

Boiler Drain Valv e

S

Key

QTY

Tankless

Equi pment List

1

Tankless

Water Heaters

Tankless

3/4" Ball Valve

3/4" U nion

e

in

ly

L

p

ly

p

p

u

p

S

u

s

S

a

r

G

e

t

a

W

d

l

o

C

"

4

/

3

Pressure Relief Valve

Check Valve

Water Heater

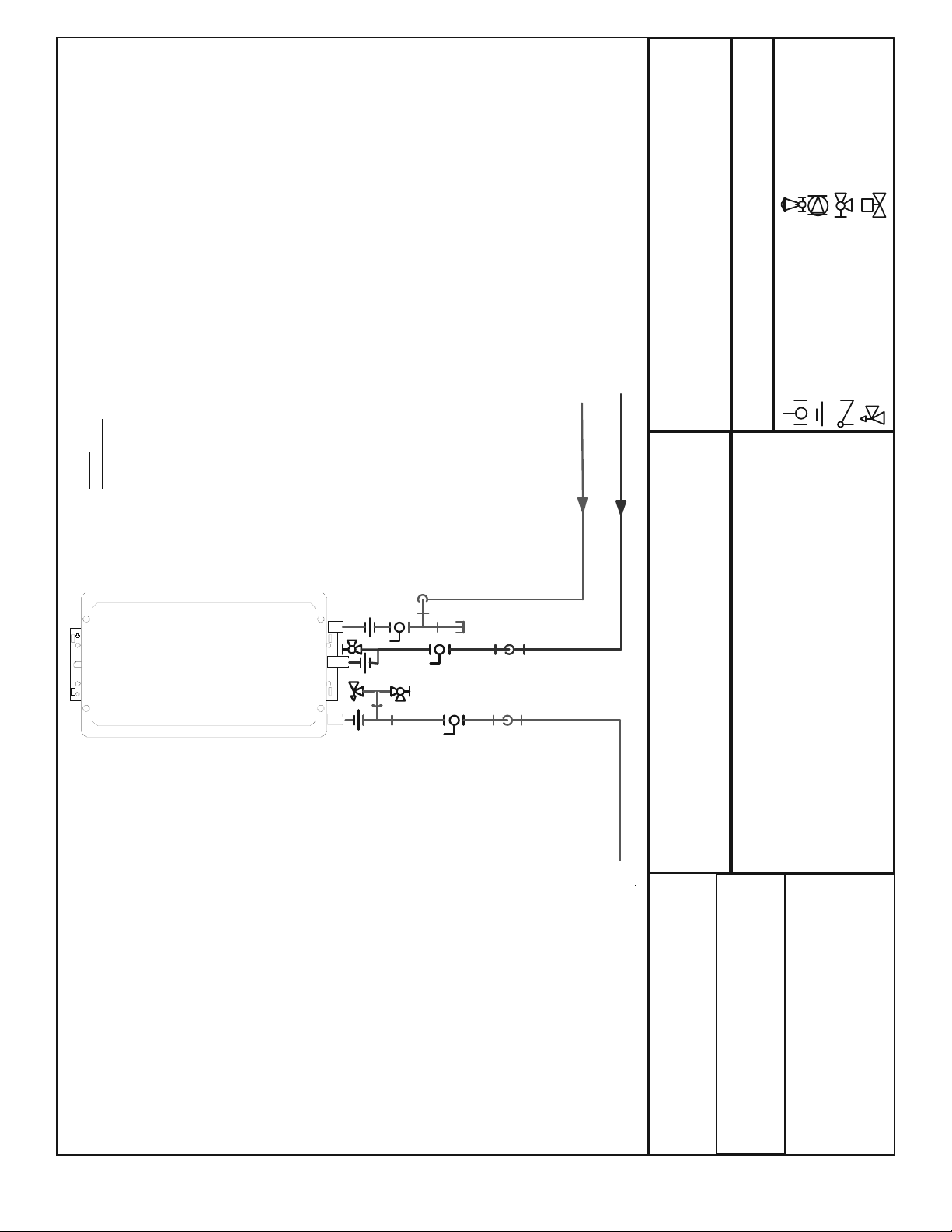

1 Tankless Water Heater

Preferred Piping Installation

Domestic Hot Water - Standard Installation

3/4" Hot Water Su pply Line

WH-1

Drawing Number:

as a replacement for professional engineering project drawings. This

drawing is not intended to describe a complete system. It is up to the

This is not an engineering drawing; it is intended only as a guide and not

contractor or engineer to determine the necessary components and

configuration of the particular system to be installed. The drawing does

not imply compliance with local building code requirements. It is the

responsibility of the engineer or contractor to ensure that the installation is

in accordance with all local building codes. Confer with local building

officials before installation.

June 11, 2007

Drawing Date:

9

Pressure Regulator

Circulating Pump

Solenoid Valve

Boiler Drain Valv e

S

Key

Tankless

Equipment List QTY

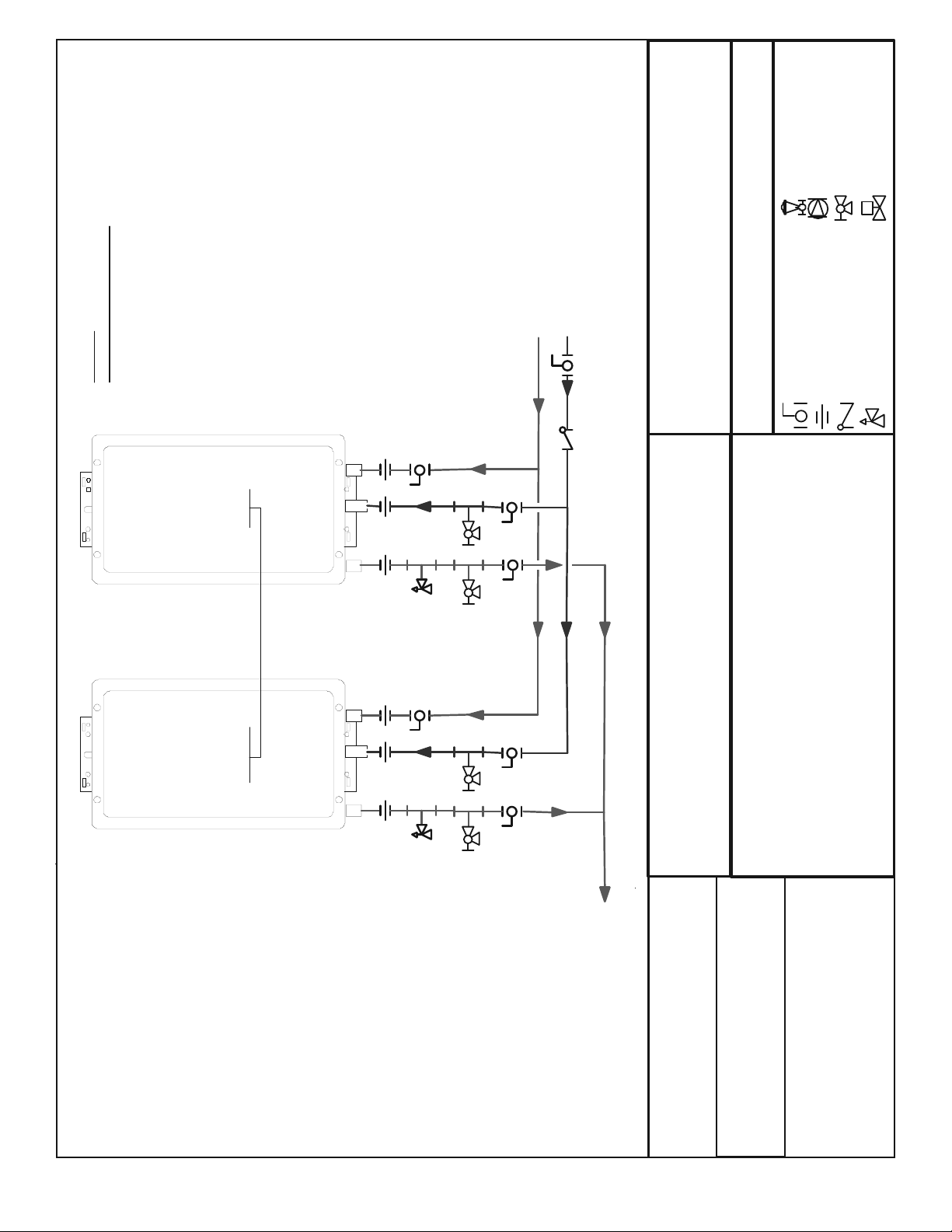

Tankless 2

Water Heaters

Tankless

Water Heater

Tankless

Water Heater

Electronic Connection *

electronic connection details.

* Refer to Tankless Accessories

and Model Applicability for

Sub 1

Primary

Gas Supply

Cold Water Supply Line

2 Tankless Water Heaters

Preferred Piping Installation

Domestic Hot Water - Standard Installation

3/4" Ball Valve

3/4" U nion

Pressure Relief Valve

Check Valve

10

Hot Water Supply Line

Drawing Number:

as a replacement for professional engineering project drawings. This

drawing is not intended to describe a complete system. It is up to the

This is not an engineering drawing; it is intended only as a guide and not

WH-2

contractor or engineer to determine the necessary components and

configuration of the particular system to be installed. The drawing does

not imply compliance with local building code requirements. It is the

responsibility of the engineer or contractor to ensure that the installation is

in accordance with all local building codes. Confer with local building

officials before installation.

February 27, 2008

Drawing Date:

Gas Supply

Pressure Regulator

Circulating Pump

Solenoid Valve

Boiler Drain Valv e

S

Key

Tankless

Equipment List QTY

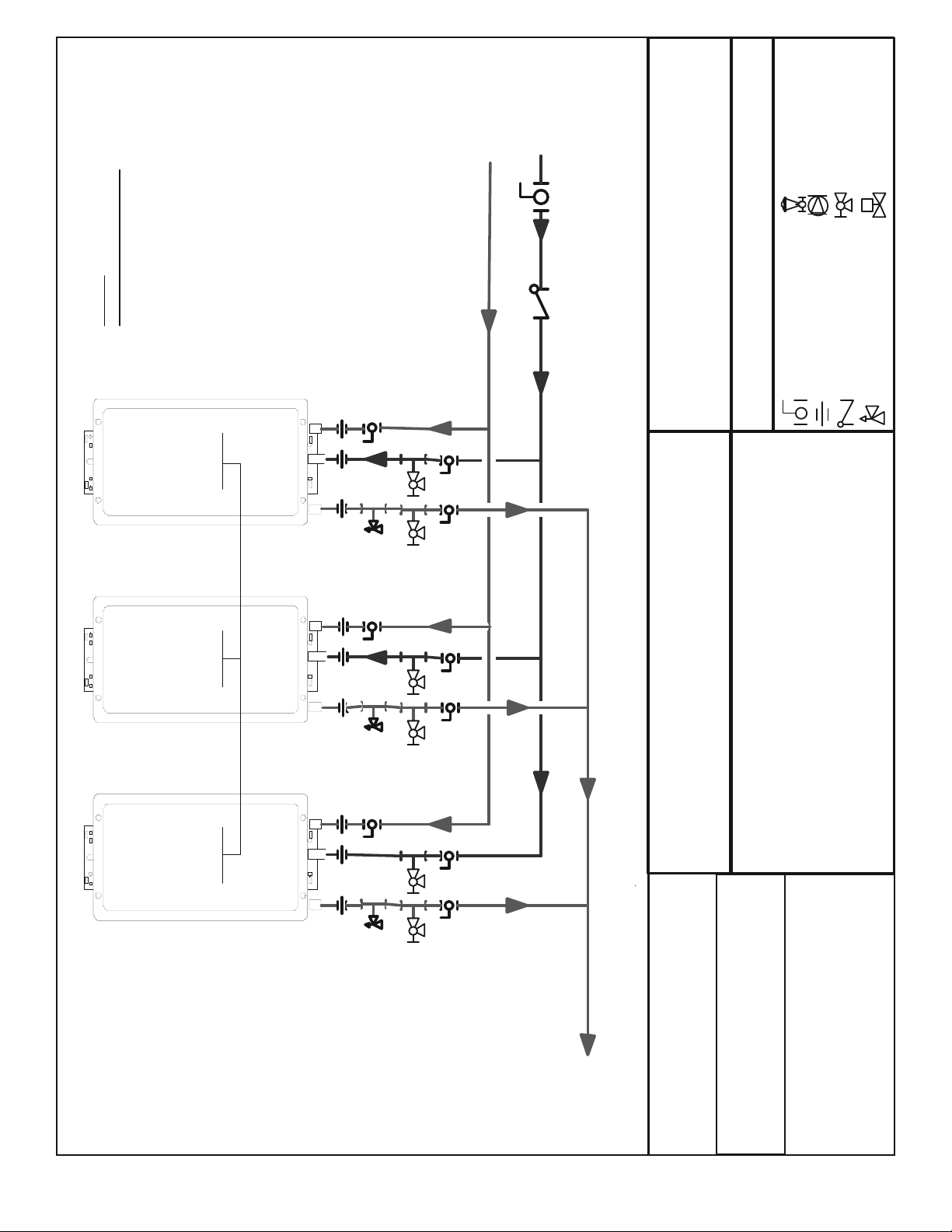

Tankless 3

Water Heaters

Tankless

Water Heater

Tankless

Water Heater

Electronic Connection *

electronic connection details.

* Refer to Tankless Accessories

and Model Applicability for

Sub 1 Sub 2Primary

Cold Water Supply Line

3 Tankless Water Heaters

Preferred Piping Installation

3/4" Ball Valve

3/4" U nion

Check Valve

Pressure Relief Valve

Tankless

Water Heater

11

Domestic Hot Water - Standard Installation

Hot Water Supply Line

Drawing Number:

as a replacement for professional engineering project drawings. This

drawing is not intended to describe a complete system. It is up to the

This is not an engineering drawing; it is intended only as a guide and not

WH-3

contractor or engineer to determine the necessary components and

configuration of the particular system to be installed. The drawing does

not imply compliance with local building code requirements. It is the

responsibility of the engineer or contractor to ensure that the installation is

in accordance with all local building codes. Confer with local building

officials before installation.

February 27, 2008

Drawing Date:

Loading...

Loading...