American Water Heater ABCG385T500-8N, ABCG38T500-8P User Manual

COMMERCIAL GAS WATER HEATERS

P.O. Box 1597

Johnson City, TN 37605

Service Handbook

MODELS (A)BCG385T500-8N

& (A)BCG38T500-8P

INSTALLATION CONSIDERATIONS - PRE SERVICE

INSTALLATION CONSIDERATIONS - PRE SERVICE

CHECKS - OPERATION & SERVICE -TROUBLESHOOTING

OPERATION & SERVICE - TROUBLESHOOTING

SERIES 120/121

CHECKS - WATER HEATER CONSTRUCTION -

SERVICING SHOULD ONLY BE PERFORMED BY A QUALIFIED SERVICE AGENT.

PRINTED IN THE U.S.A 0510 318664-000

1

COMMERCIAL GAS WATER HEATER

SERVICE MANUAL

TABLE OF CONTENTS

INTRODUCTION ............................................................3

Qualifications ...........................................................3

Service Warning........................................................3

Service Reminder .....................................................3

REQUIREMENTS ...........................................................4

Instruction Manual ....................................................4

Tools Required ..........................................................4

Tools Optional ...........................................................4

INSTALLATION CONSIDERATIONS .............................5

Water Piping .............................................................5

Closed Water Systems ........................................5

Thermal Expansion .............................................5

Gas Pressure Requirements ....................................5

Air Requirements ......................................................6

Air Supply ............................................................6

Insufficient Make-up Air, Negative Air Pressure,

and Downdrafts ...................................................7

Make-up Air: Direct Communication with Out-

doors ...................................................................8

Contaminated Air ................................................9

Clearances (Water Heater) .......................................9

Clearances (Exterior) ..............................................10

Venting ....................................................................11

OPERATION AND SERVICE .......................................12

Sequence of Operation ...........................................12

Electrical Sequence ................................................13

Wiring Diagram .......................................................14

Operating Sequence - Flow Chart ..........................15

Gas Control Valve ..................................................16

Measuring Gas Pressures ................................16

Manifold Pressure Adjustment ..........................17

Main Valve Solenoid Connections ....................17

Gas Control Valve/Burner Area View ......................18

Blower Prover Switch - Settings .............................19

Thermostat and Ignition control Board View ...........20

White Rodgers Integrated Control - Thermostat .....21

White Rodgers Ignition Control Board ....................21

Pre-Service Checklist .............................................22

TROUBLESHOOTING .................................................23

Ignition Control Board: Error Codes ........................23

1 Flash ..............................................................23

2 Flashes ..........................................................23

3 Flashes ..........................................................24

4 Flashes ..........................................................24

6 Flashes ..........................................................24

7 Flashes ..........................................................24

8 Flashes ..........................................................25

Continuous Flash ..............................................25

Continuous On ..................................................25

Integrated Heater Control: Display Lights ..............26

Test 1: 120 VAC to Heater Check ...........................27

Test 2: Polarity Check .............................................28

Test 3: Continuity Check of High Limit (ECO) .........29

Test 4: Upper Temperature Probe

Continuity Check .....................................................30

Test 5: Calling for Heat - No Blower Operation .......31

Test 6: Blower On, No Ignition ................................32

Test 7: Blower On, Blower Prover Switch Closed,

No Igniter Operation ...............................................33

Test 8: Igniter Heats, No Main Burner .....................34

Test 9: Igniter Heats, No Main Burner .....................35

Test 10: Main Burner Ignition for Less than

Five Seconds ..........................................................36

Test 11: Water Heater Shutting Off Below Setting ..37

Servicing should only be performed by a Qualifi ed Service Agent

2

INTRODUCTION

This Service Manual is designed to be an aid in servicing and troubleshooting American

models (A)BCG385T500-8N/8P Series 120/121 commercial water heaters. The instructions

and illustrations contained in this service manual will provide you with troubleshooting

procedures to verify proper operation and to diagnose and repair common service

problems.

This Service Manual does not replace or supersede the instruction manual that came with

the water heater. Always refer to the instruction manual that came with the water heater for

complete installation instructions. If the instruction manual is not available, copies can be

obtained from the manufacturer’s web site or by calling the toll free phone number shown

on the back cover of this service manual.

QUALIFICATIONS

Servicing the products referenced in this manual requires the ability (in the field involved)

equivalent to that of a Qualified Service Agent as defined by the American National Standards

Institute (ANSI) below. Installation skills such as plumbing, air supply, venting, gas supply,

electrical supply are required in addition to diagnostic and electrical testing skills.

INTRODUCTION

ANSI Z223.1 2006 Sec. 3.3.83: “Qualified Agency” - “Any individual, firm, corporation or

company that either in person or through a representative is engaged in and is responsible

for (a) the installation, testing or replacement of gas piping or (b) the connection,

installation, testing, repair or servicing of appliances and equipment; that is experienced in

such work; that is familiar with all precautions required; and that has complied with all the

requirements of the authority having jurisdiction.”

SERVICE WARNING

If you are not qualified (as defined by ANSI above) and licensed or certified as required by

the authority having jurisdiction to perform a given task, do not attempt to perform any of

the procedures described in this manual. If you do not understand the instructions given in

this manual, do not attempt to perform any procedures outlined in this manual.

SERVICE REMINDER

When performing any troubleshooting step outlined in this service manual, always consider

the wiring and connectors between components. Perform a close visual inspection of all

wiring and connectors to and from a given component before replacement. Ensure wires

were stripped before being crimped in a wire connector, ensure wires are crimped tightly in

their connectors, ensure connection pins in sockets and plugs are not damaged or worn,

ensure plugs and sockets are mating properly and providing good contact.

Failure to perform this critical step or failing to perform this step thoroughly often results in

needless down time, unnecessary parts replacement, and customer dissatisfaction.

Servicing should only be performed by a Qualifi ed Service Agent

3

REQUIREMENTS

INSTRUCTION MANUAL

Have a copy of the instruction manual that came with the water heater on hand for the

model being serviced. Instruction manuals can be obtained at the American Water Heaters

web site (www.americanwaterheater.com) or by calling technical support at 800-456-9805.

Installation information given in this service manual is not a complete installation instruction.

Installation information covered in this service manual has a limited focus as it applies

to servicing the water heater. This Service Manual does not replace or supersede the

instruction manual that came with the water heater. Always refer to the instruction manual

that came with the water heater for complete installation instructions.

TOOLS REQUIRED

Phillips head screwdriver•

standard screwdrivers•

3/8 and 7/16 inch open end wrench•

REQUIREMENTS

set of marked drill bits•

electrical multimeter tester capable of measuring continuity, AC voltage, and DC voltage•

gas pressure gauge or manometer•

water pressure gauge•

thermometer (range 0 - 220 degrees F)•

1/2 inch socket with extension for removal of the clean out cover•

1-1/16 inch socket with extension for anode removal•

TOOLS OPTIONAL

Two digital manometers range -20.00 to +20.00” W.C., resolution 0.01” W.C. •

Recommend UEI model EM200, TPI model 620 or equivalent.

Servicing should only be performed by a Qualifi ed Service Agent

4

INSTALLATION CONSIDERATIONS

INSTALLATION CONSIDERATIONS

Installation information given in this service manual IS NOT a complete installation

instruction. Installation information covered in this service manual has a limited focus as

it applies to servicing. This service manual does not replace or supersede the Instruction

Manual that came with the water heater. Always refer to the instruction manual that came

with the water heater for complete installation instructions.

If the instruction manual that came with the water heater is not on hand, copies can be

obtained from the manufacturer’s web site or by calling the toll free phone number shown

on the back cover of this service manual.

WATER PIPING

Closed Water Systems

Water supply systems may, because of code requirements or such conditions as high line

pressure, among others, have installed devices such as pressure reducing valves, check

valves, and back flow preventers. Devices such as these cause the water system to be a

closed system.

Thermal Expansion

As water is heated, it expands (thermal expansion). In a closed system, the volume

of water will grow when it is heated. As the volume of water grows, there will be a

corresponding increase in water pressure due to thermal expansion. Thermal expansion

can cause premature tank failure (leakage). This type of failure is not covered under the

limited warranty. Thermal expansion can also cause intermittent temperature-pressure relief

valve operation: water discharged from the valve due to excessive pressure build up. This

condition is not covered under the limited warranty. The temperature-pressure relief valve is

not intended for the constant relief of thermal expansion.

A properly sized thermal expansion tank should be installed on all closed systems to control

the harmful effects of thermal expansion. Contact a local Qualified Service Agency (page 3)

to have a thermal expansion tank installed.

GAS PRESSURE REQUIREMENTS

Table 1 shows supply and manifold gas pressure requirements for (A)BCG385T500-8N and

(A)BCG38T500-8P 120 - 121 model water heaters. Supply gas pressure is the pressure of

fuel gas being supplied to the water heater. Manifold gas pressure is the pressure of the

gas being supplied to the water heater’s burners.

Supply gas pressure should be measured twice. One measurement while the water

heater is not firing (static) and again while the water heater is firing (dynamic). If the

supply gas pressure drops more than 1.5” W.C. between the static and dynamic pressure

measurements, this may indicate the gas line and/or gas regulator to the water heater is

undersized. See the gas line requirements in the Instruction Manual that came with the

water heater.

Servicing should only be performed by a Qualifi ed Service Agent

5

INSTALLATION CONSIDERATIONS

Table 1

NATURAL GAS PROPANE (LP) GAS

‡

Maximum Supply Gas Pressure

†

Minimum Supply Gas Pressure

* Manifold Gas Pressure

‡ Maximum supply pressure; readings are taken while gas is not fl owing (static pressure) AND while gas is fl owing (dynamic pressure).

Supply pressure must never exceed this maximum value.

† Minimum supply gas pressure; readings are taken while gas is not fl owing (static pressure) AND while gas is fl owing (dynamic

pressure). Supply pressure must never fall below the minimum values. Supply gas pressures should be measured with all gas fi red

appliances conencted to a common main fi ring at full capacity. If supply pressure drops more than 1.5” W.C. as gas begins to fl ow,

the supply gas system (gas line/regulator) may be restricted or undersized. See the instruction manual for more information.

* Manifold gas pressure; reading can only be taken while gas is fl owing. Reading taken should be ± 0.3” W.C. of the listed value.

These water heaters are certifi ed for use without modifi cation for altitudes up to 10,000 feet. For elevations above 10,000 feet

(3,048 meters), see High Altitude Installations section of instruction manual.

10” W.C. (2.49 kPa) 12” W.C. (2.99 kPa)

5.2” W.C. (1.29 kPa) 11” W.C. (2.74 kPa)

3.5” W.C. (0.87 kPa) 10” W.C. (2.49 kPa)

AIR REQUIREMENTS

Carefully review the requirements for combustion and ventilation air in the instruction

manual that came with the water heater. Failure to meet these requirements when the

water heater is installed or overlooking their importance when servicing the water heater

often results in operational problems (some are listed below), needless down time,

unnecessary parts replacement, and customer dissatisfaction.

Ensure additional air for combustion and ventilation is provided when additional gas fired

appliances are installed to increase hot water supply in an existing location.

Air Supply

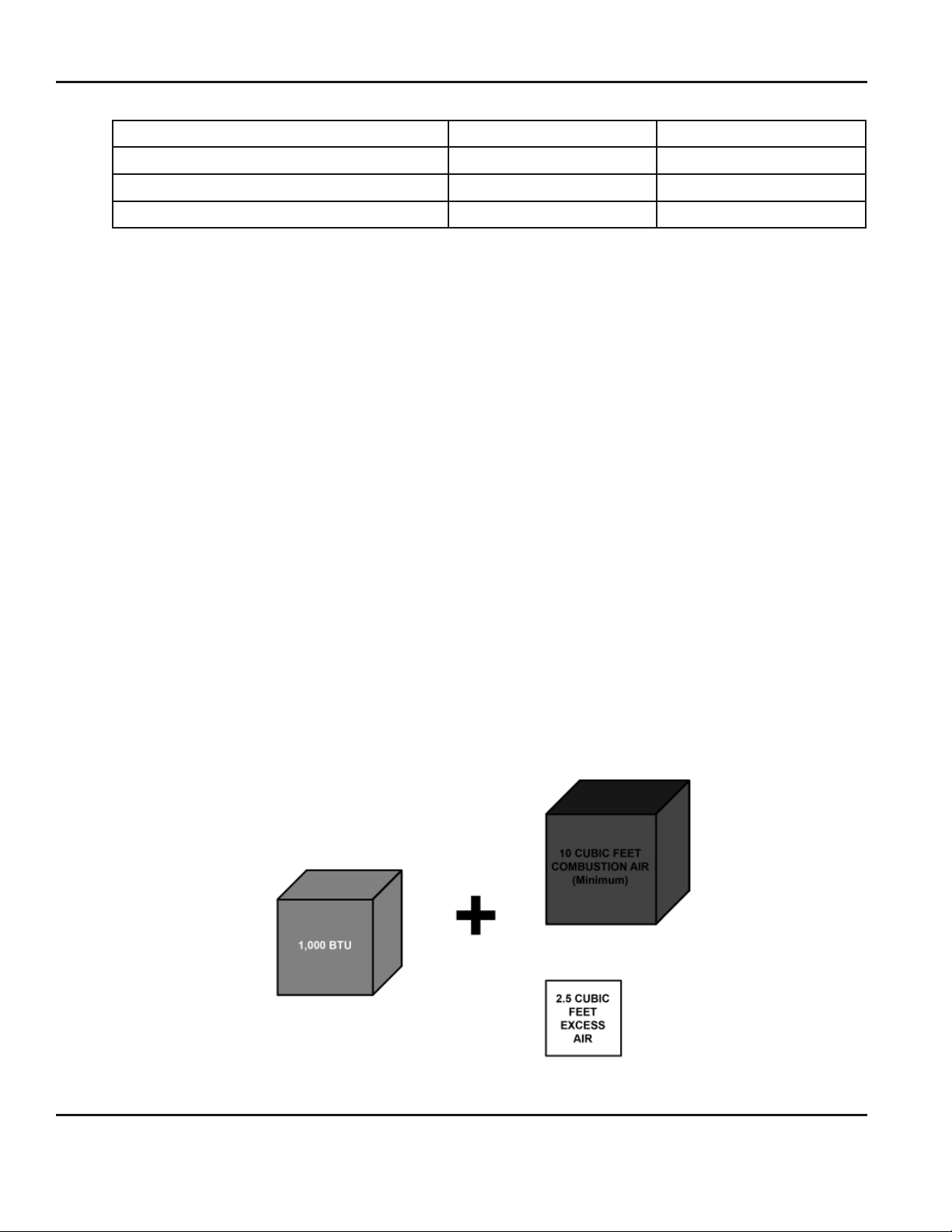

Stoichiometric or theoretical complete combustion requires 10 cubic feet of air per 1,000

BTUH of gas supplied. The National Fuel Gas Code also recommends an additional 2.5

cubic feet of “excess” air. For information on minimum make-up air opening sizes for

various building installations, refer to the National Fuel Gas Code NFPA 54, ANSI Z223.1.

Figure 1

Servicing should only be performed by a Qualifi ed Service Agent

6

INSTALLATION CONSIDERATIONS

Insufficient Make-up Air, Negative Air Pressure, and Downdrafts

A lack of combustion and ventilation air can create a negative ambient air pressure in the

installed space. The vent system on one or more gas fired appliances can experience down

drafts due to the outdoor air pressure being greater than the ambient air pressure in the

installed space. Where multiple gas fired appliances are installed, one or more gas fired

appliances can “pull air” through the vent system(s) of other appliances installed nearby.

Downdraft Caused by Kitchen Vent Hood

Figure 2

One common example is in a restaurant installation where exhaust vent equipment was not

considered in sizing make-up air requirements. This condition may result in air being back

drafted by the restaurant exhaust equipment through the water heater, causing the draft

proving switch to open and/or erratic heater shutdown. See Figure 2.

Down drafts can cause poor mixing of fuel gas and combustion air in the burners.•

Down drafts can cause flue gases to spill into the installed space.•

Down drafts can cause common service problems such as ignition failure. Down drafts •

can sweep pilot gas away from the spark igniter during ignition and prevent ignition of

the pilot.

Down drafts may cause extremely dangerous conditions such as flame rollout where the •

flames from the main burner “roll out” of the combustion chamber.

Servicing should only be performed by a Qualifi ed Service Agent

7

INSTALLATION CONSIDERATIONS

Make-up Air: Direct Communication with Outdoors

A fresh supply of make-up air for combustion can be supplied to the water heater through

make-up air ducts, which directly communicate with the outdoors. (Not Direct Vent.)

Two openings are required: one within 12 inches of the top of the enclosure and one

within 12 inches of the bottom of the enclosure. Each opening must have a free area of

not less than 1 square inch per 4,000 BTUH of the total input of all appliances within

the enclosure. The lower opening primarily provides combustion air. The upper opening

provides vent dilution air and acts as a relief opening for flue gases should the vent become

obstructed or a downdraft condition occur.

Figure 3

Additionally, when the water heater is installed in a confined space and communicating with

the outdoor air, one permanent opening, beginning within 12 inches (30 cm) of the top of

the enclosure, must be permitted where the equipment has clearances of at least 1 inch

(2.5 cm) from the sides and back, and 6 inches (16 cm) from the front of the appliance. The

opening must directly communicate with the outdoors and must communicate through a

vertical or horizontal duct to the outdoors or spaces (crawl or attic) that freely communicate

with the outdoors, and must have a minimum free area of a) 1 square inch per 3,000 BTUH

2

per kW) of the total input of all equipment located in the enclosure and b) not less

(7cm

than the sum of the areas of all vent connectors in the confined space.

Servicing should only be performed by a Qualifi ed Service Agent

8

INSTALLATION CONSIDERATIONS

Contaminated Air

Carefully review the warnings concerning contaminated combustion and ventilation air in the

instruction manual that came with the water heater. Combustion air that is contaminated can

greatly diminish the life span of the water heater and water heater components such as burners,

igniters, flue baffles and vent system components. Propellants of aerosol sprays, beauty shop

supplies, water softener chemicals and chemicals used in dry cleaning processes that are

present in the combustion, ventilation or ambient air can cause such damage.

Vapors from volatile compounds such as solvents, cleaners, chlorine based chemicals and

refrigerants in addition to being highly flammable in many cases, can also react to form

highly corrosive substances such as hydrochloric acid inside the water heater’s combustion

chamber. The results can be hazardous and cause product failure.

Contaminated Air Causes Aggressive Corrosion of Water Heater Components

(Burners, Igniters, Flue Baffles, Vent System, Sheet Metal Parts)

Figure 4

CLEARANCES (WATER HEATER)

A 24-inch clearance for all serviceable parts is recommended. See also Figure 5 and

Table 2. You may also refer to the instruction manual or to the label on the water heater

for clearances applicable to your specific model.

Minimum Clearances to Combustible Surfaces

Figure 5

Servicing should only be performed by a Qualifi ed Service Agent

9

INSTALLATION CONSIDERATIONS

Table 2

MINIMUM CLEARANCES TO COMBUSTIBLE SURFACES

“A” - Right Side “B” - Left Side “C” - Back

5” (12.7 cm) 5” (12.7 cm) 5” (12.7 cm)

A, B, and C clearances to non-combustible surfaces is “0” inches. A 20” clearance to cover remains unchanged.

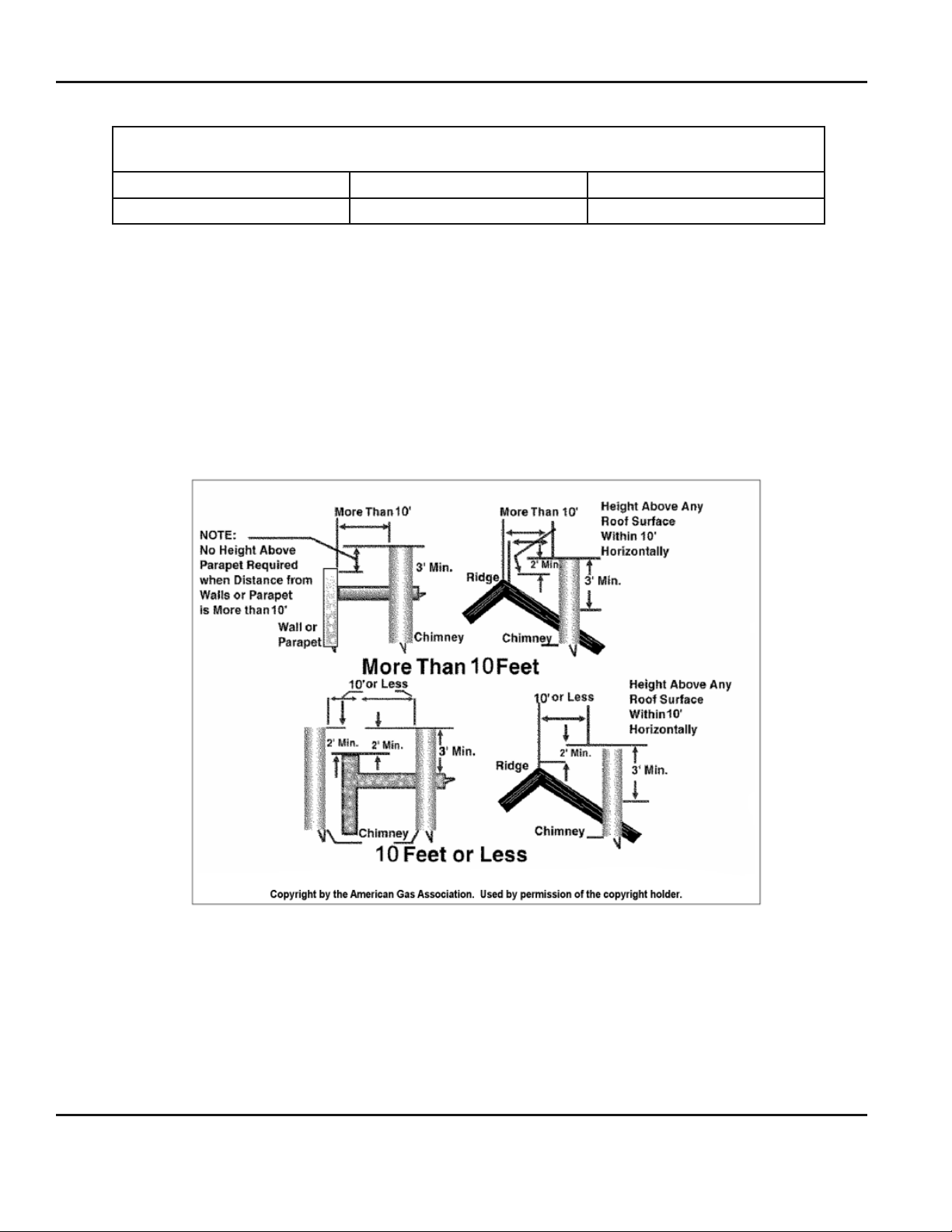

CLEARANCES (EXTERIOR)

The illustration below shows the required clearances for venting units using natural draft venting.

The vent must extend at least 3 feet above the highest point where it passes through a

roof of a building and at least 2 feet higher than any portion of a building within a horizontal

distance of 10 feet (for vents of 12 inches in diameter or less).

Reference: NFPA 54 ANSI Z 223.1.

Figure 6

Servicing should only be performed by a Qualifi ed Service Agent

10

INSTALLATION CONSIDERATIONS

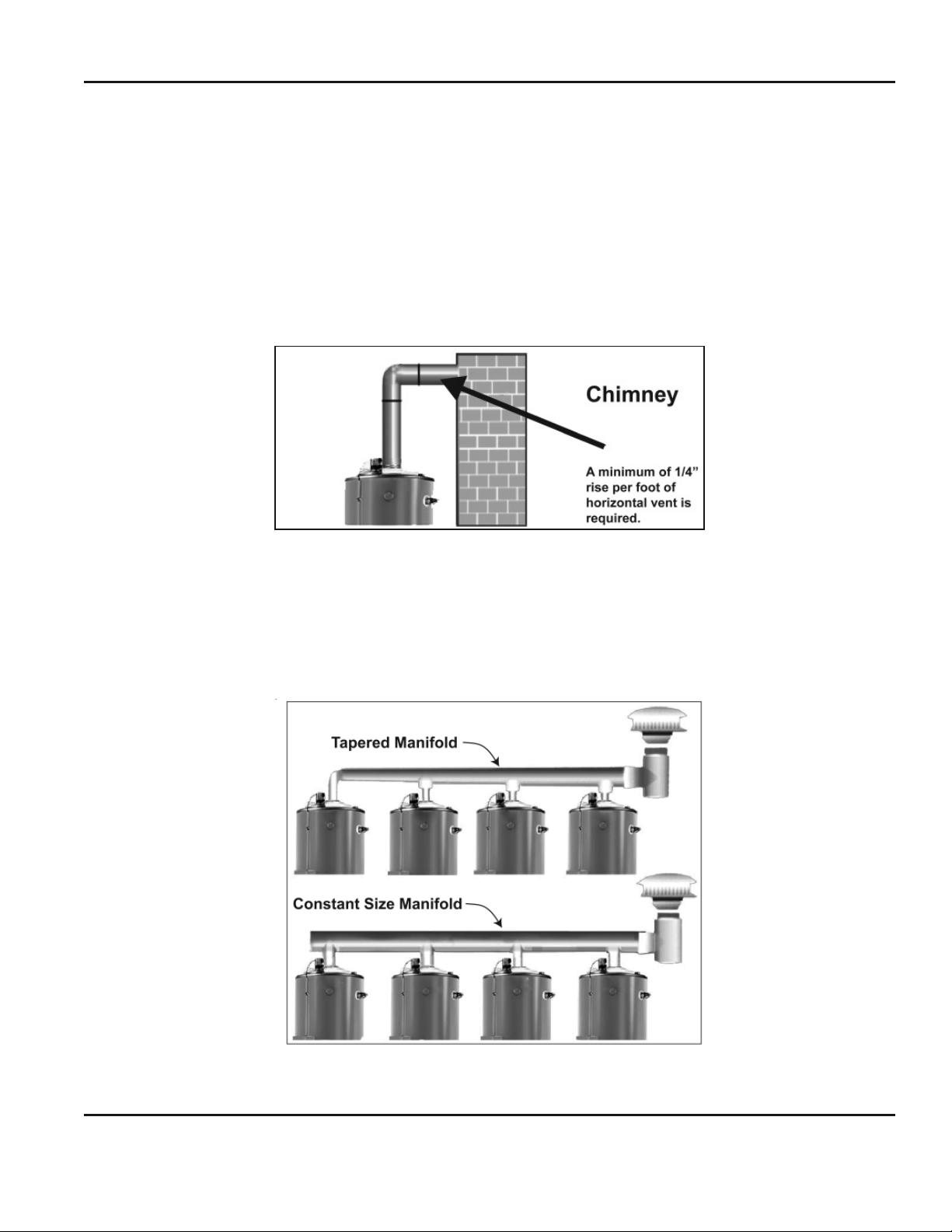

VENTING

The (A)BCG385T500-8N/8P water heater is classified by ANSI as a Category I (noncondensing, negative pressure venting) appliance. It is approved for type B vent. The

blower (draft inducer) does not pressurize the exhaust.

NOTE: This section of the service manual is not a complete venting installation instruction.

Refer to the instruction manual that came with the water heater; ensure the venting has

been installed per all instruction manual requirements. Installation must also conform with

the current edition of the National Fuel Gas Code (NFPA 54/ANSI Z223.1). Costs to correct

installation errors are not covered under the limited warranty.

Figure 7

For larger applications, (A)BCG385T500-8N/8P water heaters can be common vented

together, either in a tapered manifold or a constant size manifold. See Figure 8. In such

cases, follow the National Fuel Gas Code requirements for the sizing and installation of fanassisted products. The (A)BCG385T500-8N/8P model may be common vented only with

other Category I appliances.

Figure 8

Servicing should only be performed by a Qualifi ed Service Agent

11

OPERATION AND SERVICE

OPERATION AND SERVICE

SEQUENCE OF OPERATION

1. Call for heat is activated when temperature sensed from Thermistor Probes falls below

the Thermostat setting.

2. Blower (Draft Inducer) is energized.

3. Ignition Control Board verifies that the Blower Prover Switch is closed and that the

Blower (Draft Inducer) is operating.

4. Igniter is energized.

5. Gas Valve is energized and burners ignite

6. Ignition Control Board verifies flame at burners.

7. Water is heated to Thermostat set point.

8. Gas Valve is de-energized.

9. Blower runs for purge period and is de-energized.

10. Ignition Control Board goes into standby mode and Blower Prover Switch Opens.

Blower (Draft Inducer)

Thermistors

(probes)

Main Gas

Valve

Main

Burner

Hot Surface Igniter

(Not Shown)

Figure 9

Servicing should only be performed by a Qualifi ed Service Agent

12

Loading...

Loading...