American Water Heater 6510238 User Manual

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

· Do not try to light any appliance.

· Do not touch any electrical switch;

do not use any phone in your

building.

· Immediately call your gas supplier

from a neighbors phone. Follow the

gas suppliers instructions.

· If you cannot reach your gas supplier,

call the fire department.

Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

Direct Vent

Gas Water Heater

Installation

Instructions and

Use & Care Guide

To obtain technical, warranty, or service assistance during or

after the installation of this water heater, visit our website at:

http://www.americanwaterheater.com

or call toll free:

1-800-999-9515

When calling for assistance, please have the following

information ready:

1. Model number

2. 7 Digit product number

3. Serial number

4. Date of installation

5. Place of Purchase

Table of Contents ................................................... 2

INSTALLER: AFFIX THESE INSTRUCTIONS TO OR

ADJACENT TO THE WATER HEATER.

OWNER: RETAIN THESE INSTRUCTIONS AND

WARRANTY FOR FUTURE REFERENCE. RETAIN

THE ORIGINAL RECEIPT AS PROOF OF

PURCHASE.

6510238

January 2005

Supercedes 6510220

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word DANGER or

WARNING. These words mean:

You can be killed or seriously injured if you don't

immediately follow instructions.

You can be killed or seriously injured if you don't

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what can

happen if the instructions are not followed.

Important Instructions

· Do not use this appliance if any part has been under water. Immediately call a qualified service

technician. Water heaters subjected to flood conditions or anytime the gas controls, main burner or pilot have

been submerged in water require replacement of the entire water heater.

· Hydrogen gas can be produced in a hot water system that has not been used for a long period of time (generally

two weeks or more). Hydrogen gas is extremely flammable and can ignite when exposed to a spark or flame.

To prevent the possibility of injury under these conditions, we recommend the hot water faucet be opened for

several minutes at the kitchen sink before using any electrical appliance which is connected to the hot water

system. If hydrogen is present, there will probably be an unusual sound such as air escaping through the faucet

as water begins to flow. Do not smoke or have any open flame near the faucet at the time it is open.

The California Safe Drinking Water and T oxic Enforcement Act requires the Governor of California to publish a list of

substances known to the State of California to cause cancer, birth defects, or other reproductive harm, and requires

businesses to warn of potential exposure to such substances.

Warning: This product contains a chemical known to the State of California to cause cancer, birth defects, or other

reproductive harm.

This appliance can cause low-level exposure to some of the substances listed, including formaldehyde, carbon monxide,

and soot.

Table of Contents

Water Heater Safety...........................................................

Installing Your Gas Water Heater............................

Unpacking the Water Heater..................................

Location Requirements...........................................

Vent Cap Termination............................................

Gas Supply..............................................................

Combustion Air Supply and Ventilation..................

Vent Pipe System....................................................

Water System Piping..............................................

Special Applications..........................................

Installation Checklist...............................................

Operating Your Water Heater............................................

Lighting Instructions............................................................

Operational Conditions...........................................

Maintenance of Your Water Heater........................

Troubleshooting Chart........................................................

Repair Parts Illustration...............................................

PAGE

1-2

3-16

3

4-5

5-6

7-8

9

9-11

12-14

15

16

17-18

17-18

20

21-24

25-26

27-28

2

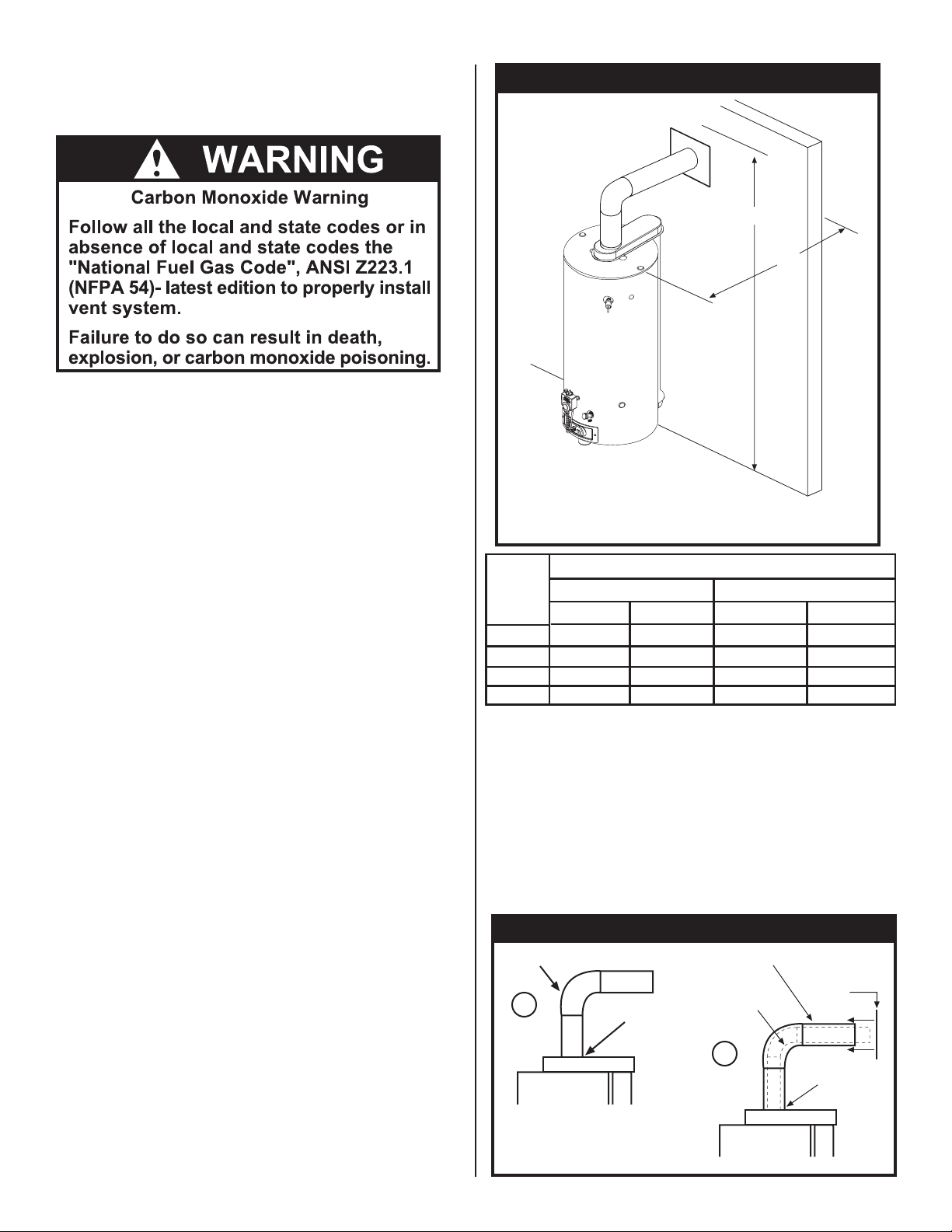

INSTALLING YOUR GAS WATER HEATER

Consumer Information

This water heater is design-certified by CSA International

as a Category I, direct vented water heater which takes

its combustion air from the outside of the structure and

exhausts all products of combustion to the outside of the

structure.

This water heater must be installed according to all local

and state codes or, in the absence of local and state

codes, the National Fuel Gas Code, ANSI Z223.1(NFPA

54)- latest edition. This is available from the following:

CSA America, Inc.

8501 East Pleasant Valley Road

Cleveland, OH 44131

National Fire Protection Agency

1 Batterymarch Park

Quincy, MA 02169-7471

Check your phone listings for the local authorities having

jurisdiction over your installation.

Consumer Responsibilities

This manual has been prepared to acquaint you with the

installation, operation, and maintenance of your gas

water heater and provide important safety information in

these areas.

Read all of the instructions thoroughly before attempting

the installation or operation of this water heater.

Do not discard this manual. You or future users of this

water heater will need it for future reference.

The manufacturer and seller of this water heater will not

be liable for any damages, injuries, or deaths caused by

failure to comply with the installation and operating

instructions outlined in this manual.

If you lack the necessary skills required to properly install

this water heater, or you have difficulty following the

instructions, you should not proceed but have a qualified

service technician perform the installation of this water

heater. Examples of qualified service technicians include:

those trained in the plumbing and heating industry, local

gas utility personnel, or an authorized service person.

Massachusetts code requires this water heater to be

installed in accordance with Massachusetts Plumbing

and Fuel Gas Code 248 CMR Section 2.00 and 5.00.

A data plate identifying your water heater can be found

next to the gas control valve/thermostat. When referring

to your water heater, always have the information listed

on the data plate readily available.

Retain your original receipt as proof of purchase.

Unpacking the Water Heater

Use two or more people to move and install

water heater unless proper handling

equipment is utilized.

Failure to do so can result in back or other

injury.

Removing Packaging Materials

Important: Do not remove any permanent instructions,

labels, or the data label from outside of the water heater

or on the inside of panels.

· Remove exterior packaging and place installation

components aside.

· Inspect all parts for damage prior to installation

and start-up.

· Completely read all instructions before attempting

to assemble and install this product.

· After installation, dispose of packaging material

in the proper manner.

3

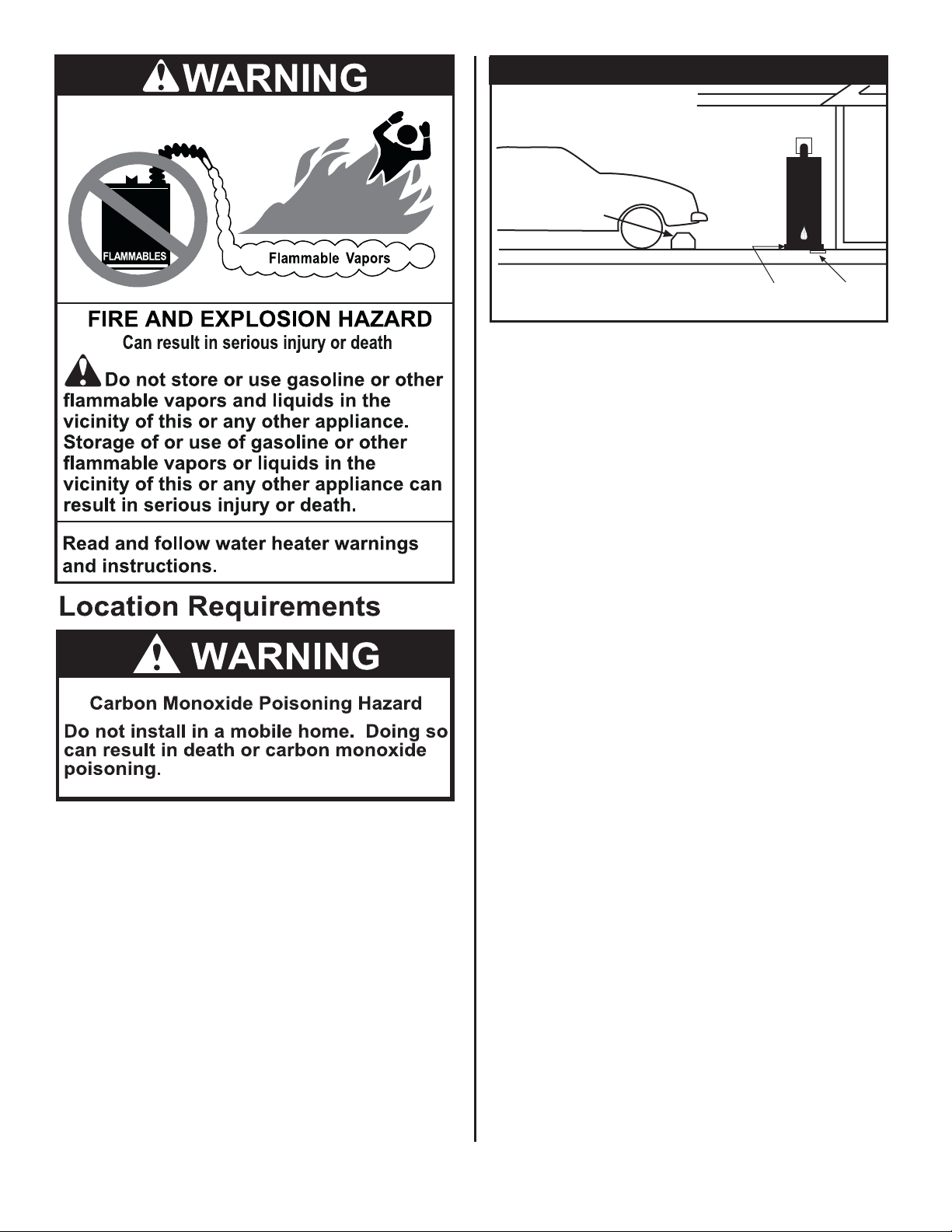

Figure 1: Residential Garage Installation

Vehicle

Stop

This water heater design has been tested by CSA

International and complies with ANSI Z21.10.1, Section

2.35 Flammable Vapors Resistance. Therefore this water

heater does not need to be installed 18 inches above the

floor unless specifically required by state or local codes.

The water heater must be located or protected to avoid

physical damage by vehicles or flooding.

Do not use or store flammable products such as gasoline,

solvents, or adhesives in the same room or area near the

water heater. If such flammables must be used, all gas

burning appliances in the vicinity must be shut off and their

pilot lights extinguished. Open the doors and windows for

ventilation while flammable substances are in use.

If flammable liquids or vapors have spilled or leaked in the

area of the water heater, leave the area immediately and

call the fire department from a neighbor's home. Do not

attempt to clean the spill until all ignition sources have

been extinguished.

Drain

Pan

Drain

NOTE:

In the State of California, the water heater must be braced,

anchored, or strapped to avoid moving during an earthquake.

Contact local utilities for code requirements in your area or

call 1-800-999-9515 and request instructions.

Site Location

· Select a location near the center of the water

piping system. The water heater must be installed

indoors and in a vertical position on a level surface.

DO NOT install in bathrooms, bedrooms, or any

occupied room normally kept closed. Note: The water

heater may be installed in a closet with a door off a

bedroom or bathroom providing the units are installed

and vented per the manufacturers instructions.

· Consider the vent piping and vent cap termination

location. This is a direct vent water heater and

may be vented through-the-wall. See Vent Cap

Termination on pages 5-6 of this manual for the

proper vent cap locations.

· Locate the water heater near the existing gas

piping. If installing a new gas line, locate the water

heater to minimize the pipe length and elbows.

Note: The water heater must be installed according to all

local and state codes or, in absence of the local and state

codes, the "National Fuel Gas Code, ANSI Z223.1 (NFPA

54)-latest edition.

4

Important: The water heater should be located in an

area where leakage of the tank or connections will not

result in damage to the area adjacent to the water heater

or to lower floors of the structure. Due to the normal

corrosive action of the water, the tank will eventually

leak after an extended period of time. Also any

external plumbing leak, including those from

improper installation, may cause early failure of the

tank due to corrosion if not repaired. If the

homeowner is uncomfortable with making the repair

a qualified service technician should be contacted.

A suitable metal drain pan should be installed under

the water heater as shown below, to help protect the

property from damage which may occur from condensate

formation or leaks in the piping connections or tank.

The pan must limit the water level to a maximum depth

of 1-3/4 and be two inches wider than the heater and

piped to an adequate drain. The pan must not restrict

combustion air flow. Locate the water heater near a

suitable indoor drain. Outside drains are subject to

freezing temperatures which can obstruct the drain line.

The piping should be at least 3/4 ID and pitched for

proper drainage. Under no circumstances will the

manufacturer or seller of this water heater be held liable

for any water damage which is caused by your failure

to follow these instructions.

Figure 2: Minimun Clearance Locations

Back 0

Top

View

Sides 0

Front

4 Inches

From

Combustibles

Sides

0

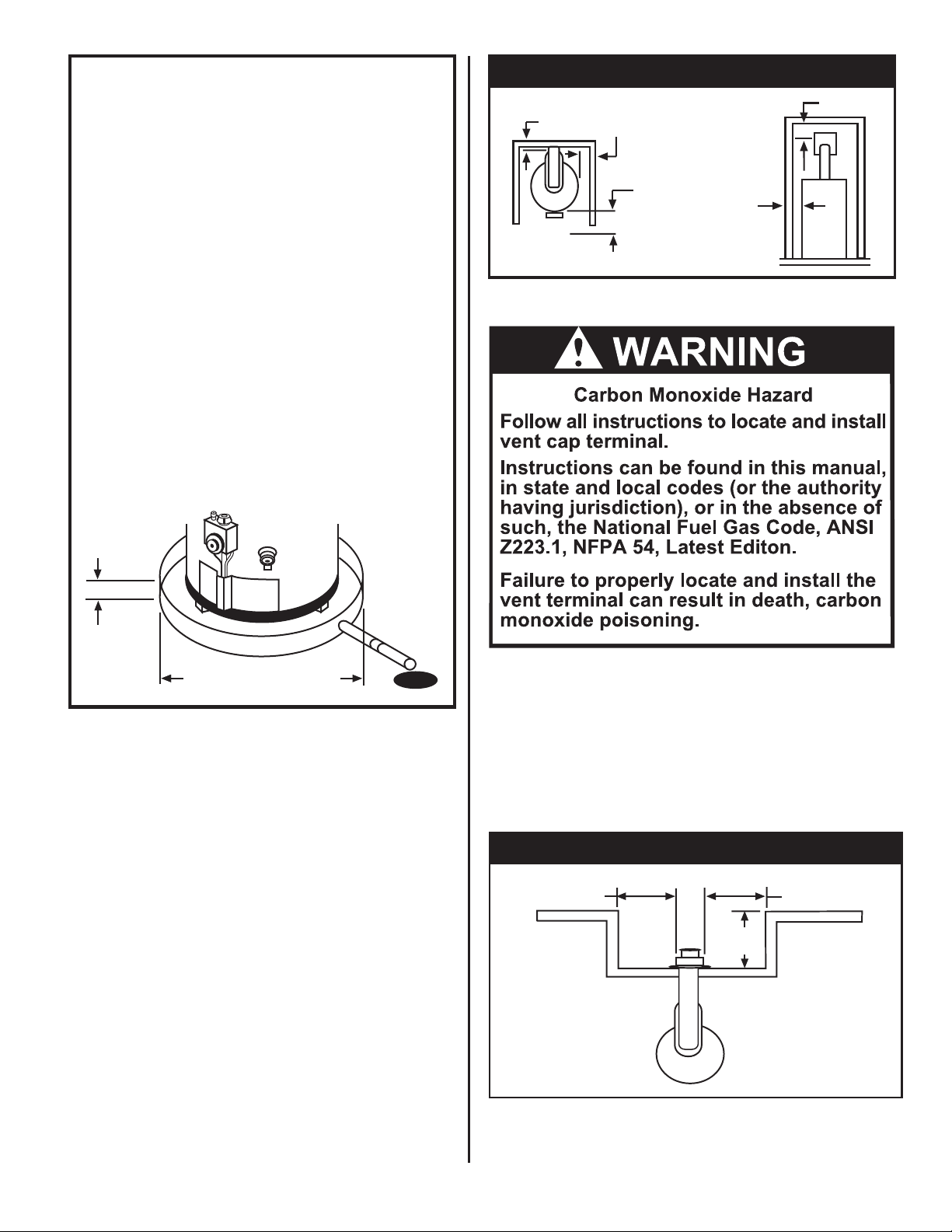

Vent Cap Termination

Vent 0

1 3/4 Max

Pipe to

Adequate

Drain

At least 2 inches greater

than the diameter of the

water heater.

· The water heater should be located in an area not

subject to freezing temperatures. Water heaters

located in unconditioned spaces (i.e., attics,

basements, etc.) may require insulation of the

water piping and drain piping to protect against

freezing. The drain and controls must be easily

accessible for operation and service. Maintain

proper clearances as specified on the data plate.

Clearances and Accessibility

Notice: Minimum clearances from combustible materials

are stated on the data plate adjacent to the thermostat

of the water heater.

· The water heater is certified for installation on a

combustible floor.

Important: If installing over carpeting, the carpeting must

be protected by a metal or wood panel beneath the water

heater. The protective panel must extend beyond the full

width and depth of the water heater by at least 3 inches

(76.2mm) in any direction or if in a alcove or closet

installation, the entire floor must be covered by the panel.

The panel must be strong enough to carry the weight of

the heater when full of water.

Figure 2 may be used as a reference guide to locate the

specific clearance locations. A minimum of 24 inches of

front clearance should be provided for inspection and

service.

The termination of the vent cap must be in accordance with

the local code or the authority having jurisdiction, or in the

absence of such, the National Fuel Gas Code, ANSI Z223.1,

NFPA 54, Latest Edition.

Do not terminate the vent cap in areas containing acid forming

chemicals. Inlet air must not contain any corrosive elements.

Any water heater failure due to corrosive elements in the

atmosphere is excluded from warranty coverage.

See Figures 3 and 4 for correct Vent Cap Termination

Locations.

Figure 3: Alcove Installation Minimums

18 Min.

24

Max.

18 Min.

5

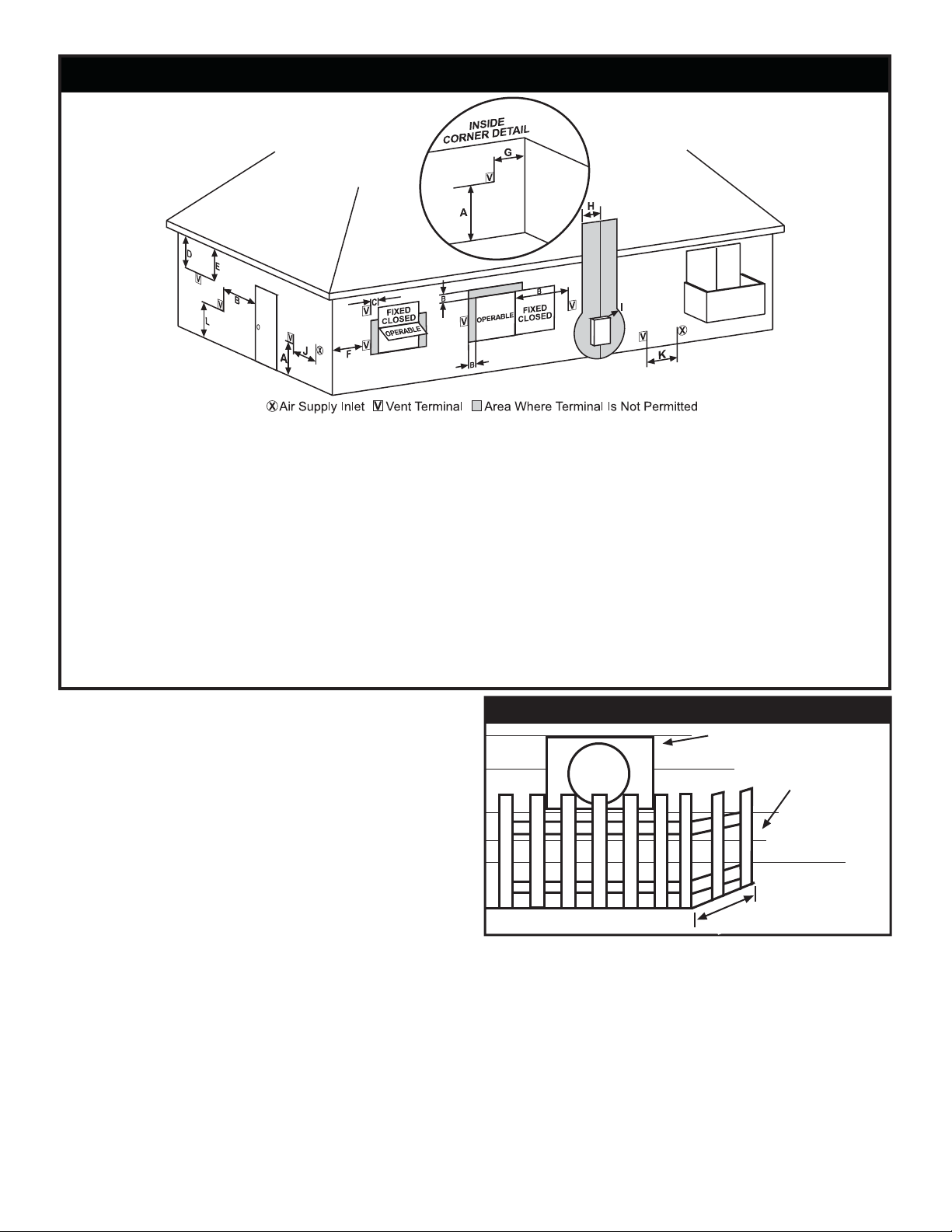

U.S. Installation

Figure 4: Vent Cap Termination Locations

A. 12 in (30 cm) min. clearance above grade, veranda,

porch, deck, balcony, or maximum anticipated snow

level.

B. 9 in (23 cm) min. clearance on top and side of window

or door that may be opened. Do not install below a

window or door that may be opened.

C. Clearance to permanently closed window.**

D. 12 in (30 cm) min vertical clearance to ventilated soffit.

E. 12 in (30 cm) min. clearance to unventilated soffit.

F. Clearance to outside corner **

**Clearance in accordance with local installation codes and the requirements of the gas supplier

The Vent terminal is HOT when the water heater is in

operation. Do not touch the vent terminal or place any object

where contact with the vent terminal may occur. A protective

louvered wall or fence is recommended when the hot vent

cap is low enough to be touched accidentally (see Figure 5).

A Vent guard kit (Kit # 6907245) may be ordered by contacting

the manufacturer of this water heater at 1-800-999-9515.

The exhaust outlet must not terminate under a patio, deck,

or any covered area.

Do not terminate the exhaust outlet near walkways or into

alleys or other publicly accessible areas.

Do not locate the vent terminal too close to shrubs or

bushes.

Caulk all cracks, seams, and joints within 6 feet horizontally

above and below the vent.

Do not terminate the vent within 12 inches of any other

direct vented appliance vent

G. 12 in (30 cm) min. clearance to inside corner formed

by two exterior walls.

H. 4 ft (122 cm) min. clearance to each side of center line

extending above meter/regulator assembly.

I. 4 ft (122 cm) min. clearance to service regulator vent

outlet.

J. 12 in (30 cm) min. clearance to nonmechanical air

supply inlet to building or the combustion air inlet to

any other appliance.

K. 3 ft (91 cm) above if within 10 ft (3 m) horizontally of

mechanical air supply inlet.

Figure 5: Protective Louvered Wall or Fence

HOT

Hot Vent Cap

Protective Louvered

Wall or Fence

3 feet Min.

6

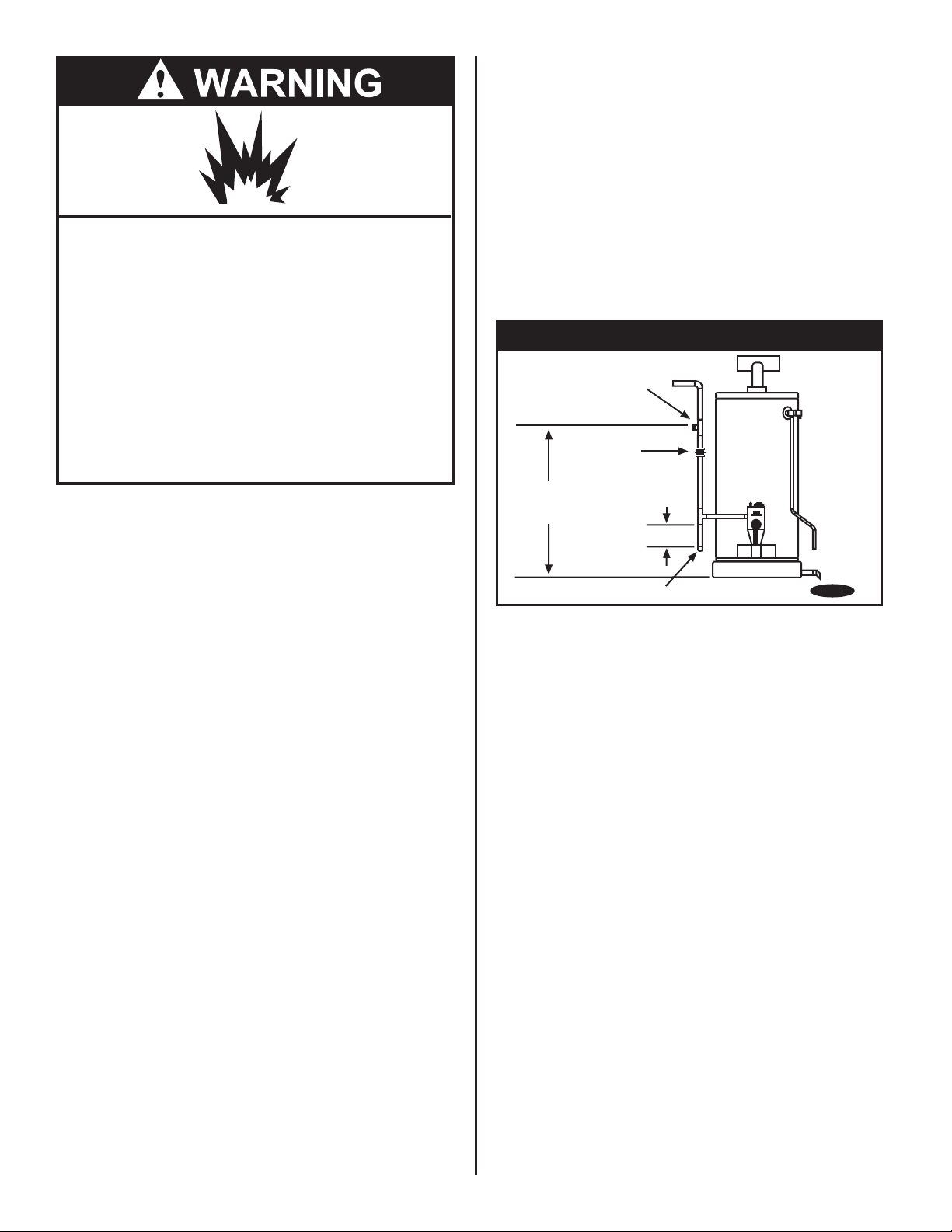

Explosion Hazard

Use a new AGA or CSA approved gas

supply line.

Install a shut-off valve.

Do not connect a natural gas water heater

to a L.P. Gas Supply.

Do not connect a L.P. gas water heater to

a natural gas supply.

Failure to follow these instructions can

result in death, explosion, or carbon

monoxide poisoning.

Gas Requirements

Read the data plate to be sure the water heater is made

for the type of gas you will be using in your home. This

information will be found on the data plate located near the

gas control valve. If the information does not agree with the

type of gas available, do not install or light. Call your dealer.

Note:

used by this water heater. This odorant may fade over an

extended period of time. Do not depend upon this odorant

as an indication of leaking gas.

An odorant is added by the gas supplier to the gas

Gas Piping

The gas piping must be installed according to all local and

state codes or, in absence of local and state codes, the

National Fuel Gas Code, ANSI Z223.1 (NFPA 54)-latest

edition.

Tables 1 and 2 on page 8 are provided as a sizing reference

for commonly used gas pipe materials. Consult the National

Fuel Gas Code for the recommended gas pipe size of other

materials.

Refer To Figure 6

1. Install a readily accessible manual shutoff valve

in the gas supply line as recommended by the

local utility. Know the location of this valve and

how to turn off the gas to this unit.

2. Install a drip leg (if not already incorporated as

part of the water heater) as shown. The drip leg

must be no less than 3 inches long for the

accumulation of dirt, foreign material and water

droplets.

3. Install a ground joint union between the gas

valve/thermostat and the manual shutoff valve.

This is to allow easy removal of the gas valve/

thermostat.

Figure 6: Gas Piping

Manual gas

shutoff valve

Ground joint

union

Check with

local utility

for min. height

3 In. Min.

Drip leg

Gas Pressure

Important: The gas supply pressure must not exceed the

maximum supply pressure as stated on the water heaters

data plate. The minimum supply pressure is for the purpose

of input adjustment.

7

Gas Pressure Testing

Important: This water heater and its gas connection

must be leak tested before placing the appliance in

operation.

· If the code requires the gas lines to be tested at

a pressure exceeding 14 W.C., the water heater

and its manual shutoff valve must be disconnected

from the gas supply piping system and the line

capped.

· If the gas lines are to be tested at a pressure less

than 14 W.C., the water heater must be isolated

from the gas supply piping system by closing its

manual shutoff valve.

U.L. recognized fuel gas and carbon monoxide (CO)

detectors are recommended in all applications and

should be installed using the manufacturers instructions

and local codes, rules, or regulations.

Note: Air may be present in the gas lines and could

prevent the pilot from lighting on initial start-up. The gas

lines should be purged of air by a qualified service

technician after installation of the gas piping system.

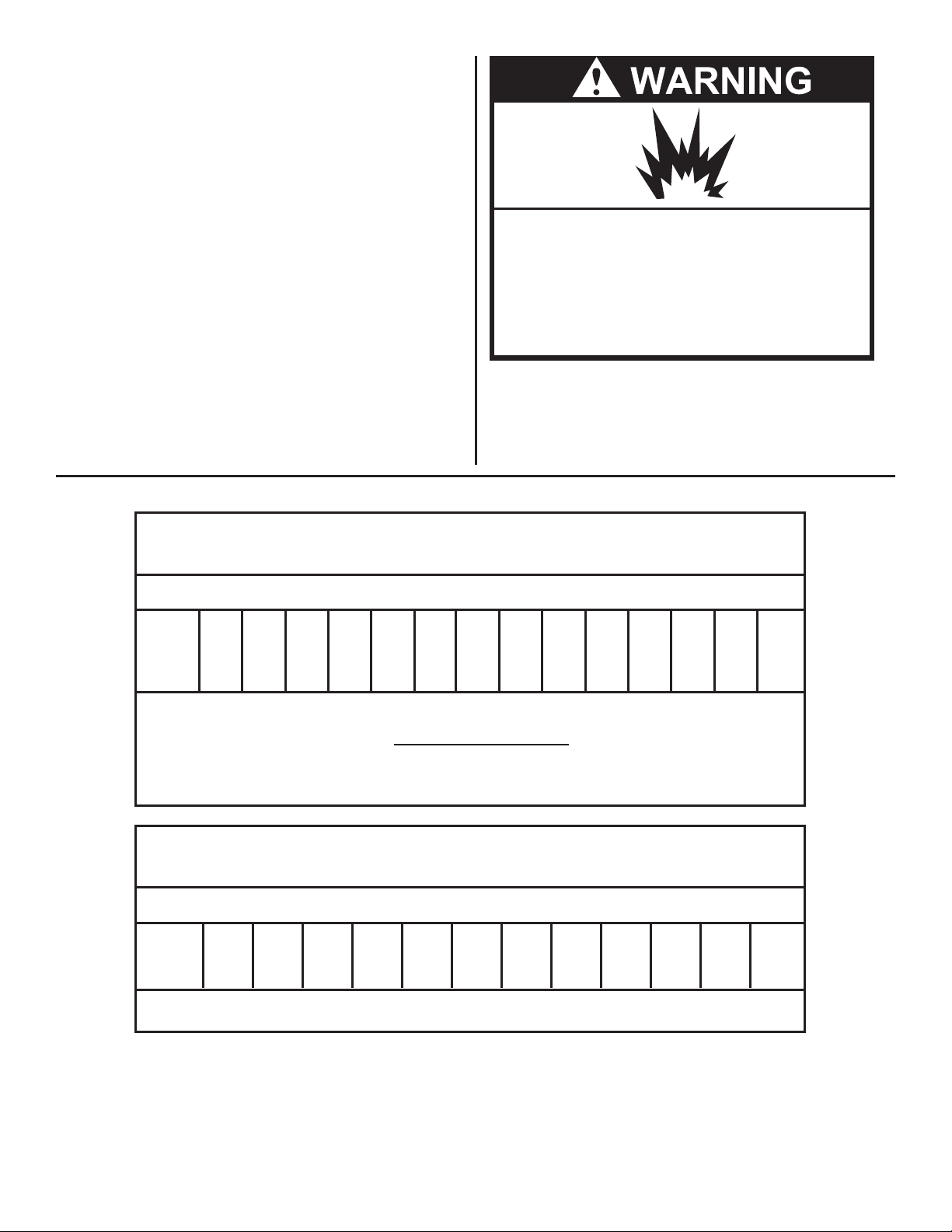

TABLE 1

NATURAL GAS PIPE CAPACITY TABLE (CU. FT./HR)

Capacity of gas pipe of different diameters and lengths in cu. ft. per hr. with pressure drop of 0.3 in. and specific gravity

of 0.60 (natural gas).

Nominal Iron Pipe Length of Pipe, Feet

Size, in.

1/2

3/4

1-1/4

1-1/2

After the length of pipe has been determined, select the pipe size which will provide the minimum cubit feet per hour required for the

gas input rating of the water heater. By formula:

The gas input of the water heater is marked on the water heater data plate. The heating value of the gas (BTU/FT3) may be determined

by consulting the local natural gas utility.

10 20 30 40 50 60 70 80 90 100 125 150 175 200

132

278

1

520

1050

1600

92

73

190

152

350

285

730

1100

Cu. Ft. Per Hr. Required =

590

890

63

130

245

500

760

56

115

215

440

670

Gas Input of Water Heater (BTU/HR)

Heating Value of Gas (BTU/FT³)

50

105

195

400

610

Explosion Hazard

Have a qualified person make sure L.P.

gas pressure does not exceed 13 water

column.

Failure to do so can result in death,

explosion, or fire.

46

43

40

38

34

31

28

96

180

370

560

90

170

350

530

84

160

320

490

79

150

305

460

72

130

275

410

64

120

250

380

110

225

350

59

26

55

100

210

320

TABLE 2

LP GAS CAPACITY TABLE

Maximum capacity of pipe in thousands of BTU per hour of undiluted liquefied petroleum gases (at 11 inches water column pressure).

Based on a Pressure Drop of 0.5 Inch Water Column.

Nominal Iron Pipe Length of Pipe, Feet

Size, in.

1/2

3/4

1-1/4

Example: Input BTU requirement of the water heater, 100,000 BTUH

Total pipe length, 80 feet = 3/4" IPS required.

8

10 20 30 40 50 60 70 80 90 100 125 150

275

576

1

1071

2205

Additional tables are available in the latest edition of the "National Fuel Gas Code", ANSI Z223.1

189

393

732

1496

152

315

590

1212

129

267

504

1039

114

237

448

913

103

217

409

834

96

196

378

771

89

185

346

724

83

173

322

677

78

162

307

630

69

146

275

567

63

132

252

511

Figure 7: A & B Dimensions

Combustion Air Supply and

Ventilation

Important: Air for combustion and ventilation must not

come from a corrosive atmosphere. Any failure due to

corrosive elements in the atmosphere is excluded from

warranty coverage.

Vent Pipe System

This is a direct vent water heater which draws its combustion

air from outside of the structure and exhausts all products

of combustion to the outside of the structure.

Through-the-wall installations require locating the water

heater next to an outside wall. All necessary components

are supplied for the standard through-the-wall installation.

Optional vertical and horizontal extension kits are available

for installations that exceed the standard horizontal and

vertical distances (see table at right). Only one vertical and

one horizontal kit can be used on the same installation.

Through the Wall Venting

1. Make sure a proper location has been selected for the

water heater installation. Consider the following:

· Water piping

· Gas Piping

· Access for service

· Proper clearance for combustibles

· Drainage for the temperature and pressure relief

valve and drain pan.

· Vent cap termination

2. Determine the A dimension for your specific water heater

by referencing figure 7. Cut a 6 inch opening through the

wall in the location as shown. Determine the location of

electrical wiring, pipes, or wall studs before cutting.

NOTE: Installations requiring an A dimension (vertical

height) greater than what is shown as standard in the table

will require the use of a vertical extension kit (See Vertical

Install Kit on Page 10).

Figure 7: A & B Dimensions

A

B

NOTE:

1. Dim. A measured from center of cutout to bottom of heater.

2. Dim. B measured from center of heater to outside of wall.

CAPACITY

KIT

STANDARD

HORIZONTAL

VERTICAL

BOTH

40 GALLON

A

62.75

62.75

62.75 - 89.75

62.75 - 89.75

B

15.75 - 24.50

27.00 - 38.00

15.75 - 24.50

27.00 - 38.00

3. If you are not using the vertical extension kit, place the

3 elbow on the flue pipe reducer on the air box and point

it in the desired direction (See Figure 8). Press it firmly

downward until seated. Drill 4 holes 90

drill bit and fasten the four #8 sheet metal screws provided.

Apply silicone sealant to the joint. Install the 5 elbow

over the 3 elbow and seat it into the collar on the air box.

Drill 4 holes 90° apart with a 1/8 drill bit and fasten the

four #8 sheet metal screws provided. Apply silicone

sealant to the joint. Place the inner wall cover plate over

the 5 elbow. This plate will be positioned later.

50 GALLON

A

71.00

71.00

71.00 - 98.00

71.00 - 98.00

° apart with a 1/8

B

15.75 - 24.50

27.00 - 38.00

15.75 - 24.50

27.00 - 38.00

Figure 8: Vertical Installation

3 Elbow

1

Screws &

Sealant

2

5 Pipe

3 Elbow

Inside Cover

Plate

Screws

& Sealant

9

Loading...

Loading...