American Water Heater 505, 305 User Manual

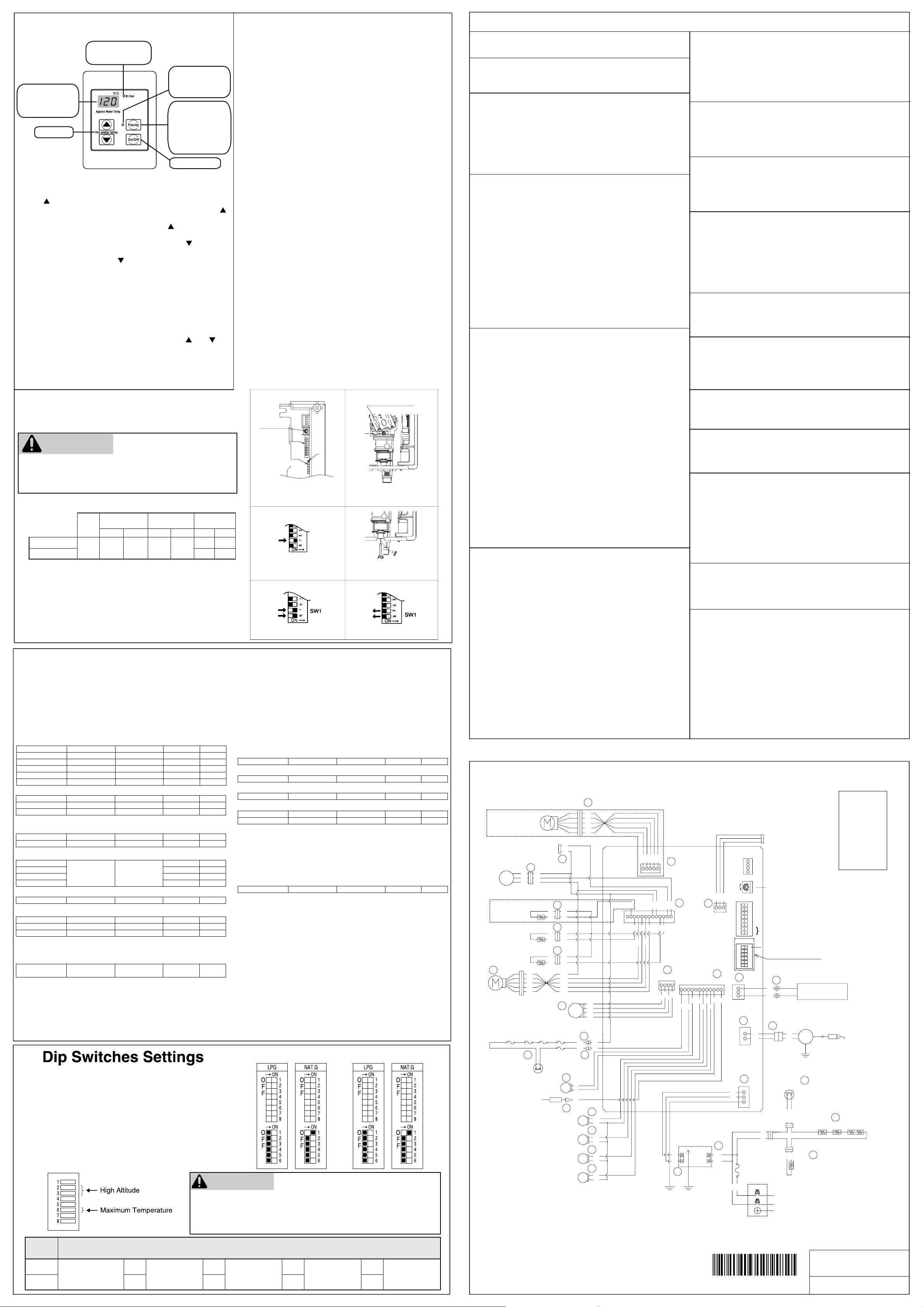

Controller

In Use Indicator

Indicates that hot water

is being supplied.

Priority Indicator

Indicates that this

controller is setting the

Temperature Display

Indicates temperature

setting or flashes error

code.

Thermostat

Diagnostic Use of the Controller

1. To display error codes, press the ON/OFF button followed by

the thermostat button to cycle through the error codes.

2. To display the water flow through the water heater, press the

thermostat button (hold for 2 seconds) and then press the

ON/OFF button while continuing to hold the thermostat

button.

3. To display the outlet water temperature, press the thermostat

button (hold for 2 seconds) and then press the ON/OFF button

while continuing to hold the thermostat button.

water temperature.

Priority Button

When no water is

being supplied,

pressing this button

allows this controller to

set the water

temperature.

ON/OFF Button

Ensure gas pressure check under Commissioning has been

completed first! The regulator is electronically controlled and

factory pre-set. Under normal circumstances it does not require

adjustment during installation. Make adjustments only if the unit is

not operating correctly and all other possible causes for incorrect

operation have been eliminated.

1. Turn OFF the gas supply.

2. Turn OFF the 120 V power supply.

3. Remove the front panel from the appliance.

4. Check the gas type using the data plate on the side of the unit.

5. Attach the pressure gauge to the burner test point, located on

6. Turn ON the gas supply.

7. Turn ON the 120 V power supply.

8. If a controller is installed, turn the unit ON with the controller.

9. Set the unit to “Forced Low” combustion by setting No. 7 dip

10. Check the burner test point pressure.

11. Remove the rubber access plug and adjust the regulator screw

12. Set the unit to “Forced High” combustion by setting both No. 7

To Change the Temperature Scale (ºF / ºC)

Gas Pressure Setting

With the water heater turned off, press and hold the ON/OFF

button until the display changes to the other temperature scale

(about 5 seconds).

To Turn Off the Controller Sound (Mute)

To turn the sound off (mute), press and hold both the and

thermostat buttons until a “beep” is heard (about 5 seconds).

13. Check the burner test point pressure.

14. Adjust the high pressure potentiometer (POT) on the PC board

15. Return the unit to normal operation by setting dip switches 7

16. Turn OFF the gas supply and 120 V power supply.

17. Remove the pressure gauge and install sealing screw.

18. Turn ON the gas supply and 120 V power supply.

19. Operate the unit and check for gas leaks at the test point.

20. Install the front panel.

Gas Pressure Setting

NOTE: For additional installation and commissioning information refer

to the Operation and Installation Manual.

WARNING

This appliance must be installed, serviced and removed by a trained

and qualified person. During pressure testing of the consumer piping,

ensure gas valve is turned off before unit is shut off. Failure to do so

may result in serious injury to yourself or damage to the unit.

APPLIANCE OPERATING PRESSURES

Gas Inlet

Min./Max

NAT.G

5"W.C.

/10.5"W.C.

305

505

Water

Inlet Max.

Commissioning

With all gas appliances in operation at maximum gas rate, the

flowing inlet pressure at the incoming test point on the water

heater should read 5” W.C. - 10.5” W.C. on natural gas and

8” W.C. - 13.5 W.C. on propane gas. If the pressure is lower,

the gas supply is inadequate and the unit will not operate to

specification. Check the gas meter regulator and pipework for

correct operation/sizing and correct as required.

Troubleshooting

Important Safety Notes

There are a number of (live) tests that are required when fault

finding this product. Extreme care should be used at all times to

avoid contact with energized components inside the water heater.

Only trained and qualified service technicians should attempt to

repair this product. Before checking for resistance readings,

disconnect the power source to the unit and isolate the item from

the circuit (unplug it).

(SV1, SV2, SV3 and POV) Gas valve and Modulating solenoids: (Set meter above 2K)

Wire color Voltage Resistance Connector # Pin #'s

(Main) Pink - Black

(SV1) Black - Yellow 11 ~ 13 VDC 36.8 ~ 44.8 ohms H6 5 - 6

(SV2) Black - Blue 11 ~ 13 VDC 36.8 ~ 44.8 ohms H7 4 - 6

(SV3) Black - Brown 11 ~ 13 VDC 36.8 ~ 44.8 ohms H8 3 - 6

(POV) Pink - Pink 2 ~ 15 VDC 67 ~ 81 ohms H3 9 - 10

(M) Water Flow Control Device Servo or Geared Motor:

Red - Blue 11 ~ 13 VDC 22 ~ 28 ohms F7 9 - 10

Grey - Brown 4 ~ 6 VDC N / A F7 5 - 7

Grey - Yellow N / A N / A F7 5 - 8

NOTE: The grey wire listed above turns to black at F connector on the PCB.

(QS) Water Flow Sensor:

Black - Red 11 ~ 13 VDC 5.5 ~ 6.2 K ohms F2 1 - 3

Yellow - Black 4 ~ 7 VDC 1 ~ 1.4 Mega ohms F2 2 - 3

By-pass Flow Control (By-pass servo model ONLY):

Orange - White 2 ~ 6 VDC

Yellow - White

(IG) Ignition System:

Grey - Grey 90 ~ 110 VAC N / A C1 1 - 2

(FM) Combustion Fan Motor:

Red - Black 6 ~ 45 VDC N / A E1 1 - 2

White - Black 5 ~ 10 VDC 9.2 ~ 9.4 K ohms E1 2 - 4

Yellow - Black 11 ~ 13 VDC 3.5 ~ 3.9 K ohms E1 2 - 3

Set your meter to the hertz scale. Reading across the white and black wires at terminals 2 and 4

you should read between 60 and 420 hertz.

Thermal Fuse / Overheat Switch:

Red - Red 11 ~ 13 VDC Below 1 ohms

Flame Rod:

Place one lead of your meter to the flame rod and the other to ground.

With the unit running you should read between 5-150 VAC. Set your

meter to the µ amp scale and series your meter in line with the flame

rod. You should read 1 µ amp or greater for proper flame circuit. In

the event of low flame circuit remove the flame rod and check for

carbon or damage.

The original PC boards on the water heaters do not have the

bank of 6 dip switches. Only spare PC boards have this bank.

Models 305 and 505 have a default maximum temperature

of 120°F (49°C) and an option to increase the maximum

temperature to 140°F (60°C). Temperature settings from

125-140°F (52-60°C) are available by setting dip switch 6 to

ON in the SW1 bank of 8 dip switches.

Adjust switches 2 and 3 in the bank of 8 depending on

your altitude according to the table below.

11 ~ 13 VDC 36.8 ~ 44.8 ohms H5 6 - 7

(Unit in operating mode)

Table 1

Forced Low

LPG NAT.G LPG NAT.G LPG

8"W.C.

/13.5"W.C.

15 ~ 35 ohms

G1 2 - 5

G1 3 - 5

F6

H1

2.9"W.C. 4.2"W.C.

.C.W"88.0.C.W"65.0ISP 051

3.3"W.C. 5.1"W.C.

Forced High

Heat Exchanger and Outgoing Water Temperature

Thermistors:

Check all thermistors by inserting meter leads into each end of the

thermistor plug. Set your meter to the 20 K scale and read

resistance. Applying heat to the thermistor bulb should decrease

the resistance. Applying ice to the thermistor bulb should increase

the resistance. See below for examples of typical temperatures and

resistance readings.

Outgoing Water Thermistor:

Heat Exchanger Temperature Thermistor:

Intake Air Thermistor (Indoor model ONLY)

Surge Protector:

With the power off you can check the continuity through the surge

protector. Place a meter lead on the top pin #1 of the surge

protector and pin #3 on the bottom of the surge protector. Check

across the top pin #3 and bottom pin #1. If you read continuity

5 - 11GetihW - nworB

across these two points then the surge protector is good. If you do

not get continuity then replace the surge protector.

5 - 41GdnuorG - etihW-deR

Remote Controls:

Frost Protection:

This unit has frost protection heaters mounted at different points to

protect the water heater from freezing. The heaters located on the

hot water outlet line should have a resistance reading of 180-207

ohms through each of these heaters. The heater located on the

heat exchanger piping should have a resistance reading of 156-180

ohms and the one located in the water flow sensor valve should

F6 - H12

have a resistance reading 24-28 ohms.

Amp Fuses:

This unit has one inline (3) amp glass fuses. Remove the fuse and

check continuity through it. If you have continuity through the fuse

then it is good. Otherwise the fuse is blown and must be replaced.

WARNING

DO NOT adjust the other dip switches unless specifically instructed

to do so. Incorrect Dip Switch Settings can cause the water heater

to operate in an unsafe condition and may damage the water heater

and void the warranty.

If using a spare PC board, check that the gas type switches are

in the correct position (dip switch 1 of SW2: ON for natural gas,

NG, and OFF for propane, LPG). See dip switch settings

section below. (ON is towards the right and OFF is towards the

left.)

the gas control (Fig. 2).

Select the maximum delivery temperature and open all

available hot water taps at full.

switch of the SW1 set to ON (Fig. 3).

on the modulating valve (Fig. 4) as required in Table 1.

Replace the rubber access plug.

and No. 8 dip switches of the SW1 set to ON (Fig. 5). Ensure

maximum water flow.

as required to the pressure shown in Table 1.

and 8 of the SW1 set back to OFF (Fig. 6). Close all water

taps.

BURNER TEST POINT

High Pressure

Potentiometer

SW1

SW2

Spare Parts

Only

1

Fig. 1 Fig. 2

Regulator adjustment

screw access plug

Fig. 3 Fig. 4

Fig. 5 Fig. 6

Example:

White - White N / A See example above F5 3 - 4

Pink - White N / A See example above F4 3 - 11

Orange - White N / A See example above F3 3 - 12

Black - White 108 ~ 132 VAC N / A D2 1 - 3

Blue - Brown 108 ~ 132 VAC N / A D1 1 - 3

Te rminals B1 10 ~ 13 VDC 1.5 ~ 3.0 K ohms B 1 - 3

59°F = 11.4 ~ 14K

86°F = 6.4 ~ 7.8K

113°F = 3.6 ~ 4.5K

505

140°F = 2.2 ~ 2.7K

221°F = 0.6 ~ 0.8K

305

Error Codes

No burner operation during freeze protection mode

02

• Service Call

Power interruption during Bath fill (Water will not flow when

03

power returns)

• Turn off all hot water taps. Press ON/OFF twice.

Air Supply or Exhaust Blockage

10

• Ensure approved venting materials are being used.

• Check that nothing is blocking the flue inlet or exhaust.

• Check all vent components for proper connections.

• Ensure vent length is within limits.

• Ensure condensation collar was installed correctly.

• Verify dip switches are set properly.

• Check fan for blockage.

No Ignition

11

• Check that the gas is turned on at the water heater, gas meter,

or cylinder.

• Ensure gas type and pressure is correct.

• Ensure gas line, meter, and/or regulator is sized properly.

• Bleed all air from gas lines.

• Verify dip switches are set properly.

• Ensure appliance is properly grounded.

• Disconnect EZConnect or MSA controls to isolate the problem.

• Ensure igniter is operational.

• Check igniter wiring harness for damage.

• Check gas solenoid valves for open or short circuits.

• Remove burner cover and ensure all burners are properly

seated.

• Remove burner plate and inspect burner surface for

condensation or debris.

Flame Failure

12

• Check that the gas is turned on at the water heater and gas

meter. Check for obstructions in the flue outlet.

• Ensure gas line, meter, and/or regulator is sized properly.

• Ensure gas type and pressure is correct.

• Bleed all air from gas lines.

• Ensure proper venting material was installed.

• Ensure condensation collar was installed properly.

• Ensure vent length is within limits.

• Verify dip switches are set properly.

• Ensure appliance is properly grounded.

• Disconnect keypad.

• Disconnect EZConnect or MSA controls to isolate the problem.

• Check power supply for loose connections.

• Check power supply for proper voltage and voltage drops.

• Ensure flame rod wire is connected.

• Check flame rod for carbon build-up.

• Disconnect and re-connect all wiring harnesses on unit and PC

board.

• Check all components for electrical short.

• Check gas solenoid valves for open or short circuits.

• Remove burner plate and inspect burner surface for

condensation or debris.

Thermal Fuse

14

• Check gas type of unit and ensure it matches gas type being

used.

• Check for restrictions in air flow around unit and vent terminal.

• Check for low water flow in a circulating system causing short-

cycling.

• Ensure dip switches are set to the proper position.

• Check for foreign materials in combustion chamber and/or

exhaust piping.

• Check heat exchanger for cracks and/or separations.

• Check heat exchanger surface for hot spots which indicate

blockage due to scale build up. Refer to instructions in manual

for flushing heat exchanger.

• Measure resistance of safety circuit.

• Ensure high fire and low fire manifold pressure is correct.

• Check for improper conversion of product.

Wiring Diagram

G

3

4

FM

P

P

Y

F

R

R

H

SV0

SV1

SV2

SV3

BR

6

1

O

Y

R

W

5

O

13

BL BR

P

R

Y

W

Y

BK

R

R

R

1

H

5

P

BK

H

6

Y

BK

H

7

BL

BK

H

8

BR

BK

(CN12)

GND

BY-PASS SERVO MODEL ONLY

BY-PASS FLOW

CONTROL DEVICE

FREEZE PROTECTION

OPTION

WATER FLOW

SENSOR

QS

INDOOR MODEL ONLY

AIR TEMPERATURE

THERMISTOR

HEAT EXCHANGER

THERMISTOR

OUTGOING WATER

THERMISTOR

F

7

WATER FLOW

CONTROL DEVICE

F

2

RR

Y

Y

BK

BK

R

BL

BR

Y

GY

THERMAL FUSES

H

2

MODULATING

SOLENOID VALVE

FLAME ROD

MAIN SOLENOID VALVE

SOLENOID VALVE 1

SOLENOID VALVE 2

SOLENOID VALVE 3

G

R

F

1

F

3

W

W

W

O

F

4

W

W

W

P

F

5

W

W

W

W

GY

R

BL

Y

BR

E

1

COMBUSTION FAN

OVERHEAT

SWITCH

H

POV

H

BRROYW

G

1

(CN7)

F

YBKR

G

1

(CN5)

WW

E

41

YBKR

W

SURGE

PROTECTOR

BL

BR

D

1

G/Y

Over Temperature Warning

16

• Check for restrictions in air flow around unit and vent terminal.

• Check for low water flow in a circulating system causing short-

cycling.

• Check for foreign materials in combustion chamber and/or

exhaust piping.

• Check for clogged heat exchanger.

Outgoing Water Temperature Sensor Fault

32

• Check sensor wiring for damage.

• Measure resistance of sensor.

• Clean sensor of scale build up.

• Replace sensor.

Heat Exchanger Outgoing Temperature Sensor Fault

33

• Check sensor wiring for damage.

• Measure resistance of sensor.

• Clean sensor of scale build up.

• Replace sensor.

Combustion Air Temperature Sensor Fault

34

• Check for restrictions in air flow around unit and vent terminal.

• Check sensor wiring for damage.

• Measure resistance of sensor.

• Clean sensor of scale build up.

• Ensure fan blade is tight on motor shaft and is in good

condition.

• Replace sensor.

Modulating Solenoid Valve Signal Abnormal

52

• Check modulating gas solenoid valve wiring harness for loose

or damage terminals.

• Measure resistance of valve coil.

Combustion Fan Failure

61

• Ensure fan will turn freely.

• Check wiring harness to motor for damaged and/or loose

connections.

• Measure resistance of motor winding.

Water Flow Servo Faulty (does not stop flow properly)

65

If blank screen is present on remote control then the flow control

has shorted out. Unplug flow control. If remote lights up and unit

starts operating then replace flow control assembly.

SV0, SV1, SV2, and SV3 Solenoid Valve Circuit Fault

71

• Check wiring harness to all solenoids for damage and/or loose

connections.

• Measure resistance of each solenoid valve coil.

Flame Sensing Device Fault

72

• Ensure flame rod is touching flame when unit fires.

• Check all wiring to flame rod for damage.

• Remove flame rod and check for carbon build-up; clean with

sand paper.

• Check inside burner chamber for any foreign material blocking

flame at flame rod.

• Measure micro amp output of sensor circuit with flame present.

• Replace flame rod.

Scale Build-up in Heat Exchanger (when checking

LC

maintenance code history “00” is substituted for “LC”)

• Flush heat exchanger. Refer to instructions in manual.

• Replace heat exchanger.

No Code (Nothing happens when water flow is activated.)

• Clean inlet water supply filter.

• On new installations ensure hot and cold water lines are not

reversed.

• Check for bleed over. Isolate unit from building by turning off

hot water line to building. Isolate the circulating system if

present. Open your pressure relief valve; if unit fires, there is

bleed over in your plumbing.

• Ensure you have at least the minimum flow rate required to fire

unit.

• Ensure turbine spins freely.

• Measure the resistance of the water flow control sensor.

• Remote control does not light up but you have 12 VDC at the

terminals for controls.

COLOR CODING

W :White

BK:Black

BR:Brown

R :Red

BL:Blue

Y :Yellow

P :Pink

O :Orange

G :Green

GY:Gray

D

5

A

3

(CN9)

H

(CN2)

12 1

P

YP

G/Y

GND

BLBKP

D

BK

3

1

W

R

1

3

for 2-Unit Connection

(Optional)

MAX

MIN

BKRW

Dip SW1

O

1

F

F

Dip SW2

O

F

F

B

YBR

(CN1)

C

D

(CN3)

BL

BR

2

FUSE

(3A)

BKW

MODULATING VALVE

CURRENT ADJUSTING

1

2

3

4

5

6

7

Gas pressure

8

1

Gas type

2

3

Spare Parts Only

4

5

6

B

BK

BK

C

W

W

1

1

GY

GY

IGNITER

(W) (W)

AC120VAC120V

HOT

HOT

NEUTRAL

NEUTRAL

GROUND

1

3

(CN4)

GY

GY

1

3

REMOTE CONTROLLER

SPARK

ELECTRODE

IG

GND

D

3

FROST SENSING

SWITCH

BLBL

ANTI-FROST HEATER

D

BLBL

4

ANTI-FROST HEATER

SW

No.

2

3

High Altitude

Off

Off

Level 0

0-2000ft

(0-610m)

Off

On

NOTES

Level 1

2001-5200ft

(610-1585m)

On

Off

(1585-2347m)

Level 2

5201-7700ft

On

7701-10200ft

On

(2347-3109m)

Level 3

070 00012 39526 5

505

Outdoor

305

U287-1185 (02)

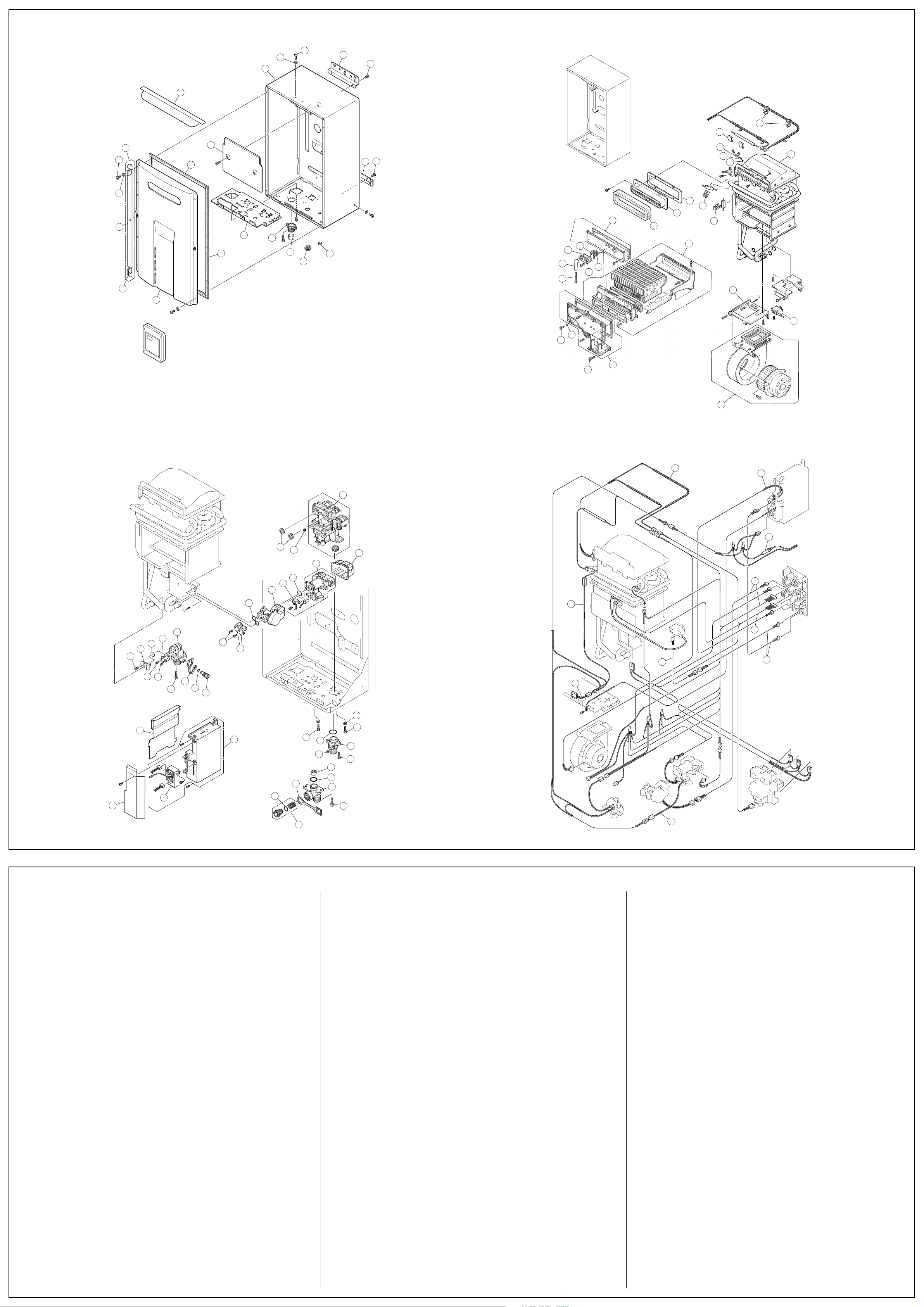

EXPLODED VIEW - CABINET

EXPLODED VIEW - INTERNALS

801

802

011

012

017

006

015

007

005

008

004

001

013

807

014

806

003

016

002

002

808

808

708

707

118

116

119

117

114

138

135

137

103

717

718

716

710

709

711

143

810

132

REMOTE CONTROLLER

EXPLODED VIEW - INTERNALS

818

101

401

100

413

113

812

803

110

125

EXPLODED VIEW - ELECTRICAL

725

706

729

721

703

805

409

702

730

814

810

804

701

822

408

410

816

411

805

700

404

815

403

814

727

813

405

821

817

101

402

813

400

820

102

820

807

819

713

712

726

724

723

722

Number

001

002

003

004

005

006

007

008

011

012

013

014

015

016

017

100

101

102

103

103

110

110

113

114

116

117

118

119

125

132

135

137

138

Description

Main Body (W)

Wall Mounting Bracket (W)

Rubber Bushing

Connection Reinforcement Panel

Heat Protection Plate

Front Panel

Front Panel Packing

Front Panel Packing Side

Screw Cover

Screw Cover Lid

Cable Access Assy

Rubber Bushing

Rain Hood

Packing

Screw Cover Assy

Gas Control Assembly

Test Port Set Screw

Gas Connection (3/4" NPT)

Burner Unit Assy (LPG)

Burner Unit Assy (NG)

Manifold Assembly (LPG)

Manifold Assembly (W-NG)

Pressure Point Sealing Screw

Combustion Chamber Sightglass Plate

Electrode

Flame Rod

Electrode Packing

Electrode Holder

Fan Assembly

Combustion Chamber Fan Bracket

Flue Outlet

Flue Outlet Gasket

Seal Packing

Par ts Number

701022-005

701022-007

701022-008

701022-009

701022-010

701022-012

701022-013

701022-014

701022-017

701022-018

701022-019

701022-021

701022-022

701022-023

701022-024

701022-025

701022-026

701022-027

701022-028

701022-029

701022-031

701022-033

701022-034

701022-035

701022-036

701022-037

701022-038

701022-039

701022-044

701022-047

701022-049

701022-052

701022-054

412

Quantity

505

1

2

1

1

1

1

1

2

2

4

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

305

1

2

1

1

1

1

1

2

2

4

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Number

143

143

400

401

401

402

403

404

404

405

408

409

410

411

412

413

700

700

701

701

702

703

706

707

708

709

710

711

712

713

715

716

717

PA RTS LIST

Description

Heat Exchanger Assembly

Heat Exchanger Assembly

Water Inlet (3/4" NPT)

Water Flow Servo & Sensor Assembly

Water Flow Servo & Sensor Assembly

Rectifier

By-pass Servo Assembly

Stop Bracket

Stop Bracket

Plug Band

Hot Water Outlet (3/4" NPT)

Stop Bracket

Plug Band (small)

Drain Valve

Water Filter Assy

Cover

PCB

PCB

Surge Protector

Surge Protector with terminal (optional)

PCB cover - side

PCB cover - front

Ignitor

High Tension Cord

Electrode Sleeve

Thermistor - Heat Exchanger

Thermistor Clip Large

Temperature Fuse Clip

Frost Sensing Switch

Anti Frost Heater (120V)

Valve Heater (120V) Assembly

Antifrost Heater Clip B

Antifrost Heater Clip A

Par ts Number

701022-061

701022-062

701022-070

701022-071

701022-072

701022-073

701022-074

701022-075

701022-076

701022-077

701022-078

701022-079

701022-080

701022-081

701022-082

701022-083

701022-281

701022-280

701022-086

701022-087

701022-089

701022-090

701022-091

701022-092

701022-093

701022-094

701022-095

701022-096

701022-097

701022-099

701022-100

701022-102

701022-103

Quantity

505

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

5

1

1

1

2

1

305

1

1

1

1

-

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

5

1

1

1

2

1

715

Number

718

721

722

723

724

724

725

726

727

729

730

801

802

803

804

805

806

807

808

810

812

813

814

815

816

817

818

819

820

821

822

888

889

Description

Antifrost Heater Clip C

Fuse Harness (W)

Power Harness

Solenoid Valve Harness

Sensor Harness

Sensor Harness

Thermal Fuse Harness Assy

Ignitor Harness

Flow Sensor

Remote Controller Harness

Thermistor

Screw

Resin Washer

O-ring

Thermistor Stop Screw

Screw

Screw

Resin Washer

Screw

O-ring

O-ring

O-ring

O-ring

O-ring

O-ring

O-ring

Packing

Screw

Screw

Screw

Screw

Manual

Tech Sheet

Quantity

Par ts Number

701022-105

701022-109

701022-110

701022-111

701022-114

701022-115

701022-116

701022-117

701022-118

701022-119

701022-120

701022-122

701022-123

701022-124

701022-125

701022-126

701022-127

701022-128

701022-129

701022-130

701022-132

701022-133

701022-134

701022-135

701022-136

701022-137

701022-138

701022-139

701022-140

701022-141

701022-142

315898-000

315896-000

505

1

1

1

1

1

1

1

1

1

1

4

4

3

1

3

2

2

4

2

1

2

2

2

1

1

2

2

4

2

3

1

1

305

1

1

1

1

1

1

1

1

1

1

4

4

3

1

2

2

2

4

2

1

1

2

1

1

1

2

2

4

2

3

1

1

Loading...

Loading...