American Water Heater 319407-002 User Manual

O

Residential Gas

Water Heater

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas

supplier, call the fire department.

Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

with the Flame Guard

™

Safety System

Installation

Instructions and

Use & Care Guide

(Flammable Vapor Ignition Resistant)

NATURAL & L.P. GAS MODELS

To obtain technical, warranty, or service assistance during or after

the installation of this water heater, or call toll free

1-800-999-9515

When calling for assistance, please have the following

information ready:

1. Model number

2. 7 digit product number

3. Serial number

4. Date of installation

5. Place of purchase

Table of Contents ...................................................... 2

INSTALLER:

• AFFIX THESE INSTRUCTIONS TO OR ADJACENT

TO THE WATER HEATER.

OWNER:

• RETAIN THESE INSTRUCTIONS AND WARRANTY

FOR FUTURE REFERENCE. RETAIN THE ORIGINAL

RECEIPT AS PROOF OF PURCHASE.

LOW LEAD

NTENT

C

319407-002

April 2013

1

WATER HEATER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or

“WARNING.” These words mean:

indicates an imminently hazardous situation which. If

not avoided, will result in death or injury.

indicates apotentially hazardous situation which, if not

avoided, could result in death or injury.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what can happen if the instructions are not followed.

Important Instructions

• Do not use this appliance if any part has been under water. Immediately call a qualified person. Water heaters subjected to flood conditions or any time the gas controls, main burner or pilot have been submerged in water require

replacement of the entire water heater.

• Hydrogen gas can be produced in a hot water system that has not been used for a long period of time (generally

two weeks or more). Hydrogen gas is extremely flammable and can ignite when exposed to a spark or flame. To

prevent the possibility of injury under these conditions, we recommend the hot water faucet be opened for several

minutes at the kitchen sink before using any electrical appliance which is connected to the hot water system. If

hydrogen is present, there will probably be an unusual sound such as air escaping through the faucet as water

begins to flow. Do not smoke or have any open flame near the faucet at the time it is open.

The California Safe Drinking Water and Toxic Enforcement Act requires the Governor of California to publish a list of

substances known to the State of California to cause cancer, birth defects, or other reproductive harm, and requires

businesses to warn of potential exposure to such substances.

• WARNING: This product contains a chemical known to the State of California to cause cancer, birth defects, or

other reproductive harm.

• This appliance can cause low-level exposure to some of the substances listed in the act.

This product is certified to comply with a maximum weighted average of 0.25% lead content as required in some areas.

Table Of Contents

Water Heater Safety ..............................................................................1-2

Installing Your Gas Water Heater ........................................................3-15

Unpacking the Water Heater ........................................................... 3

Location Requirements ................................................................4-5

Gas Supply ..................................................................................6-7

Combustion Air Supply and Ventilation ...................................... 7-11

Water System Piping ...............................................................12-13

Temperature & Pressure Relief Valve ........................................... 14

Special Applications ...................................................................... 15

Installation Checklist ..................................................................... 16

Operating Your Water Heater ............................................................17-22

Lighting Instructions ...................................................................... 17

Electrical Connections .................................................................. 20

Operating the Temperature Control System ................................. 21

Operational Conditions ................................................................. 22

Maintenance of Your Water Heater ...................................................23-28

Troubleshooting Charts ..................................................................... 28-32

Repair Parts Illustration ..................................................................... 33-34

2

PAGE

INSTALLING YOUR GAS WATER HEATER

Important Information About

This Water Heater

This gas water heater was manufactured to voluntary

safety standards to reduce the likelihood of a flammable

vapor ignition incident. New technology used in meeting

these standards makes this product more sensitive to

installation errors or improper installation environments.

Please review the Installation Checklist found at the end of

the installation instructions section and make any required

installation upgrades or changes.

installed in accordance with Massachusetts Plumbing and

Fuel Gas Code 248 CMR Section 2.00 and 5.00.

A data plate identifying your water heater can be found next

to the gas control valve/thermostat. When referring to your

water heater, always have the information listed on the data

plate readily available.

Retain your original receipt as proof of purchase.

Unpacking the Water Heater

WARNING

Consumer Information

This water heater is design-certified by CSA International

as a Category I, non-direct vented water heater which takes

its combustion air either from the installation area or from

air ducted to the unit from the outside.

This water heater must be installed according to all local

and state codes or, in the absence of local and state codes,

the “National Fuel Gas Code”, ANSI Z223.1(NFPA 54)current edition. This is available from the following:

CSA America, Inc.

8501 East Pleasant Valley Road

Cleveland, OH 44131

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02269

Check your phone listings for the local authorities having

jurisdiction over your installation.

Consumer Responsibilities

This manual has been prepared to acquaint you with the

installation, operation, and maintenance of your gas water

heater and provide important safety information in these

areas.

Read all of the instructions thoroughly before attempting

the installation or operation of this water heater.

Do not discard this manual. You or future users of this

water heater will need it for future reference.

Service to the Flame Guard

performed by a qualified person.

Examples of a qualified person include: licensed plumbers,

authorized gas company personnel, and authorized

service personnel.

IMPORTANT: The manufacturer and seller of this water

heater will not be liable for any damages, injuries, or

deaths caused by failure to comply with the installation and

operating instructions outlined in this manual.

If you lack the necessary skills required to properly install

this water heater, or you have difficulty following the

instructions, you should not proceed but have a qualified

person perform the installation of this water heater.

Massachusetts code requires this water heater to be

™

Safety System should only be

Excessive Weight Hazard

Use two or more people to move and install

water heater.

Failure to do so can result in back or

other injury.

IMPORTANT: Do not remove any permanent instructions,

labels, or the data label from either the outside of the water

heater or on the inside of water heater panels.

• Remove exterior packaging and place installation components aside.

• Inspect all parts for damage prior to installation and

start-up.

• Completely read all instructions before attempting to

assemble and install this product.

• After installation, dispose of/recycle all packaging

materials.

3

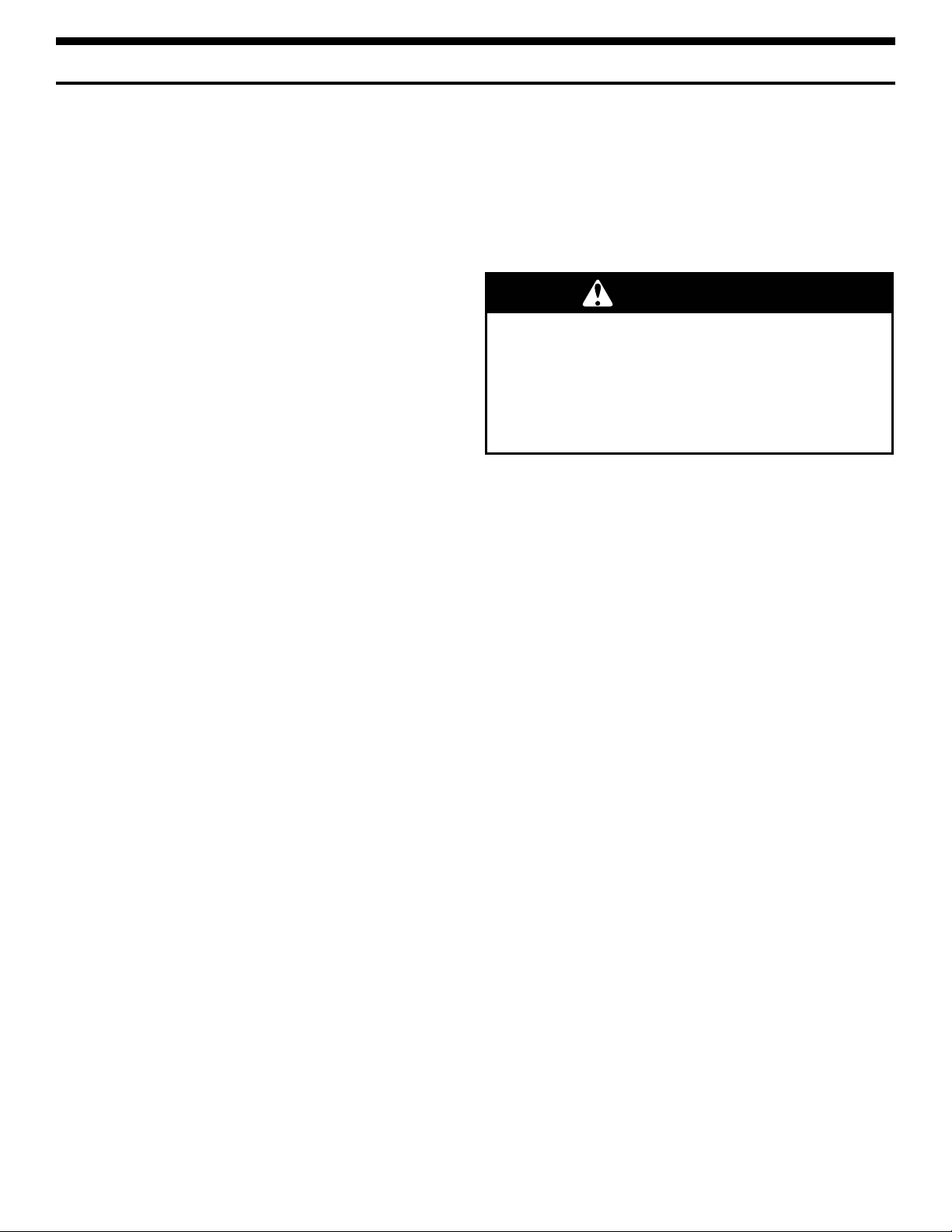

WARNING

FLAMMABLES

FIRE AND EXPLOSION HAZARD

Can result in serious injury or death

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

Storage of or use of gasoline or other

flammable vapors or liquids in the vicinity

of this or any other appliance can result in

serious injury or death.

Read and follow water heater warnings and

instructions.

Location Requirements

Flammable Vapors

WARNING

Carbon Monoxide Poisoning Hazard

Do not install in a mobile home.

Doing so can result in death or

carbon monoxide poisoning.

The FVIR System is designed to reduce the risk of

flammable vapor-related fires. Flammable liquids (such as

gasoline, solvents, propane, etc,) emit flammable vapors

which can be ignited by a gas water heater’s spark igniter

or main burner. The resulting flashback and fire can cause

death or serious burns to anyone in the area.

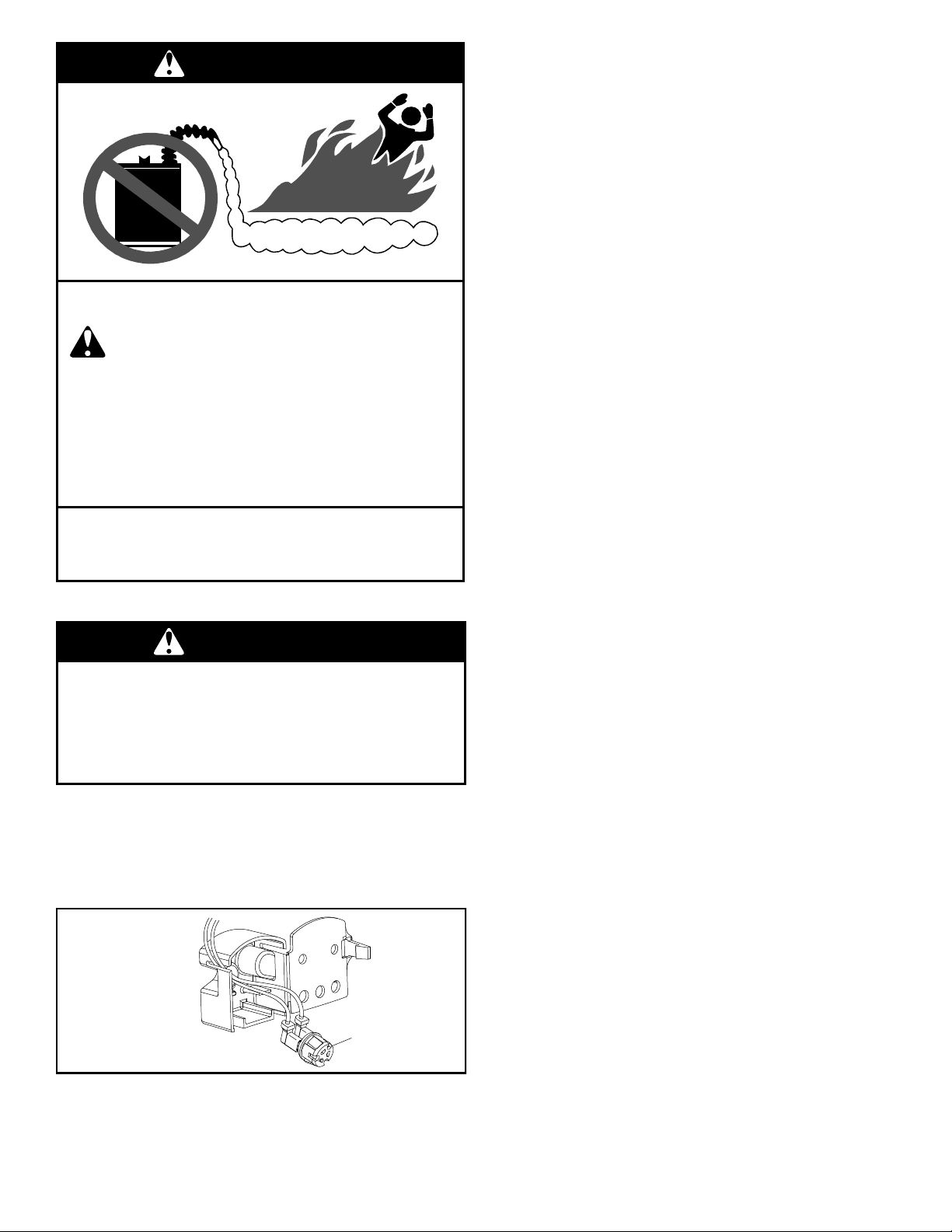

Figure 1:

FV Sensor

FV Sensor

This heater is equipped with an FV sensor for detecting the

presence of flammable vapors. When the sensor detects

those vapors, the unit will shut down and not operate.

Should this happen, please refer to the troubleshooting

guide. Even though this water heater is a flammable vapors

4

ignition resistant water heater and is designed to reduce

the chances of flammable vapors being ignited, gasoline

and other flammable substances should never be stored

or used in the same vicinity or area containing a gas water

heater or other open flame or spark producing appliance.

In the event the FVIR system does not prevent the ignition

of flammable vapors, the Flame Guard

is designed to reduce the risk of flammable vapor-related

fires.

The patented Flame Guard™ Safety System protects your

family by trapping the burning vapors within the water

heater combustion chamber through the special flame-trap.

The burning vapors literally “burn themselves out” without

escaping back into the room. In the event of a flammable

vapor incident, the Flame Guard

the water heater by shutting off the gas supply to the

water heater’s burner and pilot, preventing re-ignition of

any remaining flammable vapors in the area. This will not

prevent a possible fire/explosion if the igniter activates and

flammable vapors have accumulated in the combustion

chamber with the pilot light off. If you suspect a flammable

vapor incident has occurred, do not use this appliance.

Do not attempt to light this appliance if you suspect

flammable vapors have accumulated inside or outside the

appliance. Immediately call a qualified person to inspect

the appliance. Water heaters subjected to a flammable

vapors incident will show a discoloration on the flame-trap

and require replacement of the entire water heater. NOTE:

Not following these instructions and/or an inadequate air

supply can cause the Flame Guard

disable the water heater. Please make required installation

and venting/air supply changes prior to resetting the system

(see “Combustion Air Supply and Ventilation” section).

IMPORTANT: This water heater has a resettable thermal

switch installed as part of the Flame Guard

Do not attempt to disable or modify this feature in any way.

Do not use or store flammable products such as gasoline,

solvents, or adhesives in the same room or area near the

water heater. If such flammables must be used, all gas

burning appliances in the vicinity must be shut off and their

pilot lights extinguished. Open the doors and windows for

ventilation while flammable substances are in use.

If flammable liquids or vapors have spilled or leaked in the

area of the water heater, leave the area immediately and

call the fire department from a neighbor’s home. Do not

attempt to clean the spill until all ignition sources have been

extinguished.

Keep combustibles such as boxes, magazines, clothes,

etc. away from the water heater area.

™

Safety System

™

Safety System disables

™

Safety System to

™

Safety System.

Site Location

• Select a location near the center of the water piping

system. The water heater must be installed indoors and

in a vertical position on a level surface. Do not install in

bathrooms, bedrooms, or any occupied room normally

kept closed.

• Locate the water heater as close to the chimney or gas

vent as practical. Consider the vent system piping and

combustion air supply requirements when selecting the

water heater location. The venting system must be able

to run from the water heater to termination with minimal

length and elbows.

• Locate the water heater near the existing gas piping.

If installing a new gas line, locate the water heater to

minimize the pipe length and elbows.

NOTE: This water heater must be installed according to all

local and state codes or, in the absence of local and state

codes, the “National Fuel Gas Code”, ANSI Z223.1(NFPA

54)-current edition.

IMPORTANT: The water heater should be located

in an area where leakage of the tank or connections

will not result in damage to the area adjacent to the

water heater or to lower floors of the structure. Due

to the normal corrosive action of the water, the tank

will eventually leak after an extended period of time.

Also any external plumbing leak, including those from

improper installation, may cause early failure of the tank

due to corrosion if not repaired. If the homeowner is

uncomfortable with making the repair a qualified person

should be contacted. A suitable metal drain pan should

be installed under the water heater as shown below,

to help protect the property from damage which may

occur from condensate formation or leaks in the piping

connections or tank. The pan must limit the water level

to a maximum depth of 1-3/4” and be two inches wider

than the heater and piped to an adequate drain.

NOTE: The pan must not restrict combustion air flow.

Locate the water heater near an adequate indoor drain.

The discharge pipe must terminate a maximum of six

inches above a floor drain or external to the building. In

cold climates, it is recommended that the discharge pipe

be terminated at an adequate drain inside the building.

Outside drains are subject to freezing temperatures

which can obstruct the drain line. The piping should be

at least 3/4” ID and pitched for proper drainage. Under

no circumstances will the manufacturer or seller of this

water heater be held liable for any water damage which

is caused by your failure to follow these instructions.

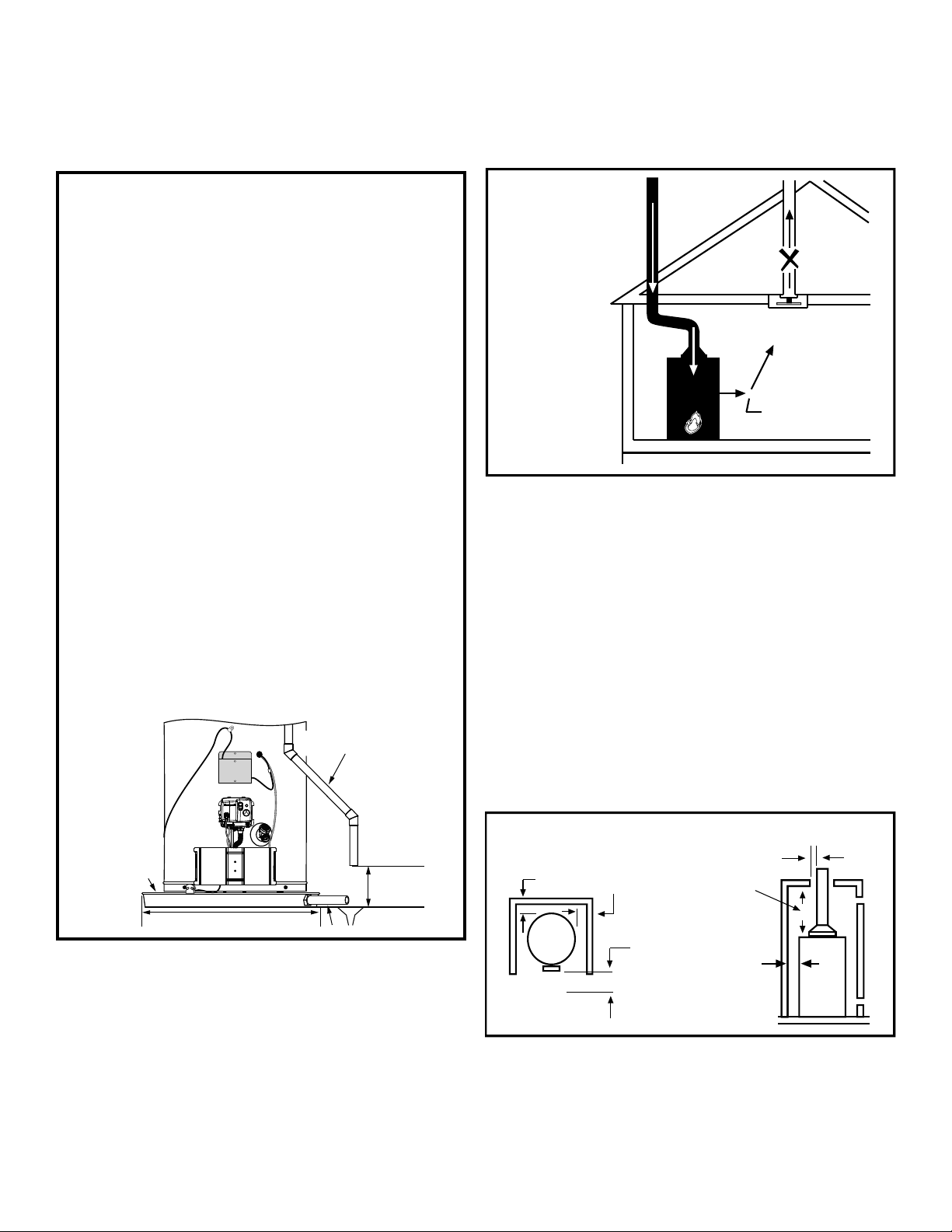

Figure 2

Drain Pan

Installation

DISCHARGE PIPE

(DO NOT CAP OR PLUG)

conditions these devices may create. Flow reversal of

flue gases may cause an increase of carbon monoxide

inside of the dwelling.

• If the water heater is located in an area that is

subjected to lint, dirt, and oil, it may be necessary

to periodically clean the flame-trap (see “External

Inspection & Cleaning of the Flame-trap” section).

Figure 3

Air-moving

Devices

Exhaust

Fan

Reverse flow

of gases

Clearances and Accessibility

NOTE: Minimum clearances from combustible surfaces are

stated on the data plate adjacent to the gas control valve/

thermostat of the water heater.

The water heater is certified for installation on a

combustible floor.

• IMPORTANT: If installing over carpeting, the carpeting

must be protected by a metal or wood panel beneath

the water heater. The protective panel must extend

beyond the full width and depth of the water heater by

at least three inches (76.2mm) in any direction; or if in

an alcove or closet installation, the entire floor must be

covered by the panel.

• Figure 4 may be used as a reference guide to locate

the specific clearance locations. A minimum of 24

inches of front clearance should be provided for

inspection and service.

METAL

DRAIN

PAN

AT LEAST 2” GREATER THAN THE

DIAMETER OF THE WATER HEATER.

6” MAXIMUM

AIR GAP

• The water heater should be located in an area not

subject to freezing temperatures. Water heaters located

in unconditioned spaces (i.e., attics, basements,

etc.) may require insulation of the water piping and

drain piping to protect against freezing. The drain and

controls must be easily accessible for operation and

service. Maintain proper clearances as specified on the

data plate.

• Do not locate the water heater near an air-moving

device. The operation of air-moving devices such as

exhaust fans, ventilation systems, clothes dryers,

fireplaces, etc., can affect the proper operation of

the water heater. Special attention must be given to

Figure 4

Minimum Clearance

Locations

Back

View

Top

Sides

Front

24” minimum

for service

Top

to

ceiling

Sides

Vent

State of California

NOTE: For California installation, this water heater must

be braced, anchored, or strapped to avoid falling or moving

during an earthquake. Correct installation procedure

instructions may be obtained from California’s Office of the

State Architect, 1102 Q street, Suite 5100, Sacramento,

CA 95811. Instructions can also be downloaded to your

computer at www.dsa.dgs.ca.gov/Pubs.

5

Gas Supply

WARNING

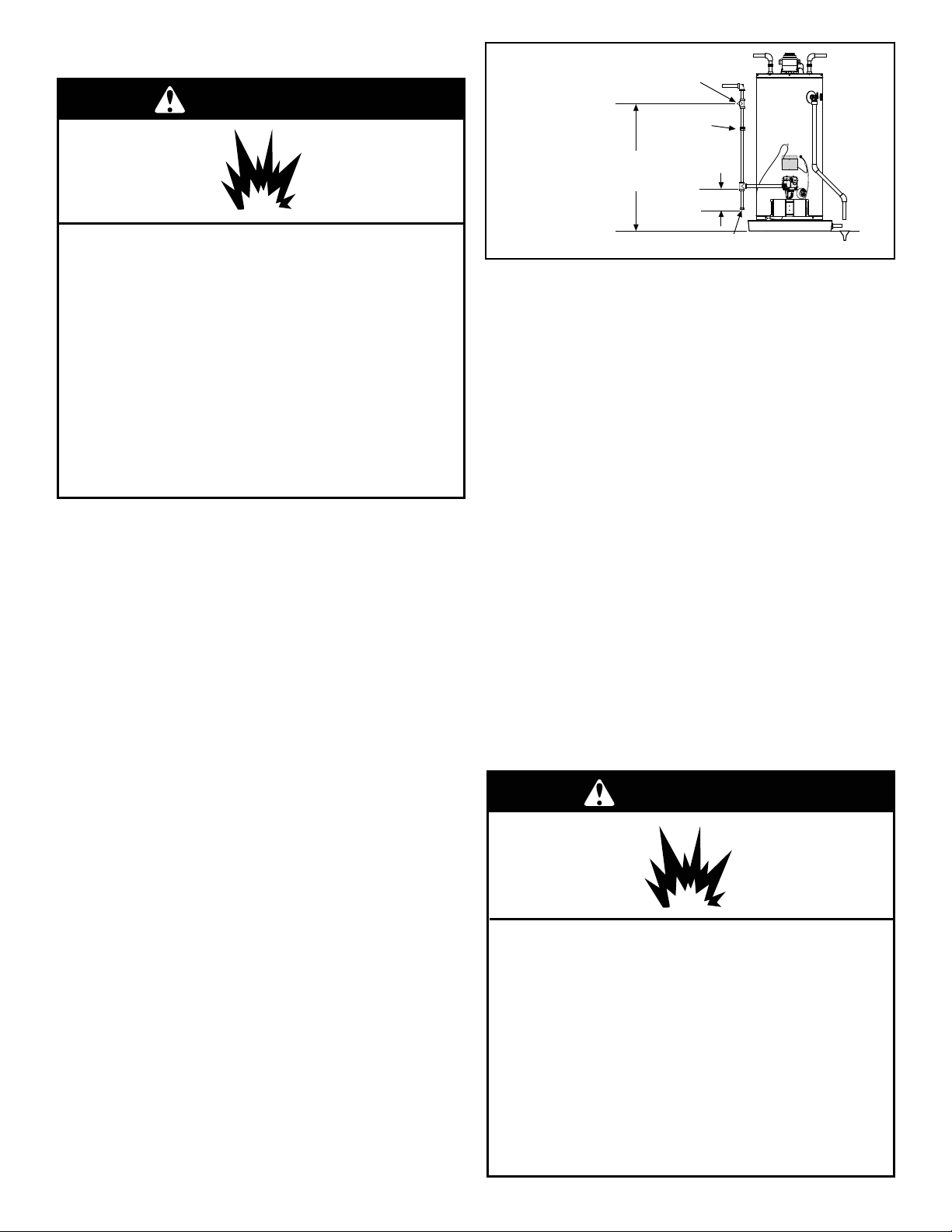

Figure 5

Gas Piping

Manual Gas

Shut-off Valve

Check with local

utility for

minimum height

Ground

Joint

Union

3” Minimum

Explosion Hazard

Use a new CSA approved gas supply line.

Install a shut-off valve.

Do not connect a natural gas water heater to

an L.P. gas supply.

Do not connect an L.P. gas water heater to

a natural gas supply.

Failure to follow these instructions can

result in death, explosion, or

carbon monoxide poisoning.

Gas Requirements

IMPORTANT: Read the data plate to be sure the water

heater is made for the type of gas you will be using in

your home. This information will be found on the data

plate located near the gas control valve/thermostat. If the

information does not agree with the type of gas available,

do not install or light. Call your dealer.

NOTE: An odorant is added by the gas supplier to the gas

used by this water heater. This odorant may fade over an

extended period of time. Do not depend upon this odorant

as an indication of leaking gas.

Gas Piping

The gas piping must be installed according to all local and state

codes or, in the absence of local and state codes, the “National

Fuel Gas Code”, ANSI Z223.1(NFPA 54)-current edition.

Tables 1 and 2 on page 7 provides a sizing reference for

commonly used gas pipe materials. Consult the “National

Fuel Gas Code” for the recommended gas pipe size of other

materials.

Refer to Figure 5

NOTE: When installing gas piping, apply approved pipe joint

compound.

1. Install a readily accessible manual shut-off valve in the

gas supply line as recommended by the local utility.

Know the location of this valve and how to turn off the

gas to this unit.

2. Install a sediment trap (if not already incorporated

as part of the water heater) as shown. The sediment

trap must be no less than three inches long for the

accumulation of dirt, foreign material, and water droplets.

3. Install a ground joint union between the gas control

valve/thermostat and the manual shut-off valve. This

is to allow easy removal of the gas control valve/

thermostat.

4. Turn the gas supply on and check for leaks. Test all

connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak.

Correct any leak found.

6

Sediment Trap

Gas Pressure

IMPORTANT: The gas supply pressure must not exceed the

maximum supply pressure as stated on the water heater’s data

plate. The minimum supply pressure is for the purpose of input

adjustment.

Gas Pressure Testing

IMPORTANT: This water heater and its gas connection must

be leak tested before placing the appliance in operation.

• If the code requires the gas lines to be tested at a pressure

exceeding 14” W.C., the water heater and its manual shutoff valve must be disconnected from the gas supply piping

system and the line capped.

• If the gas lines are to be tested at a pressure less than

14” W.C., the water heater must be isolated from the gas

supply piping system by closing its manual shut-off valve.

U.L. recognized fuel gas and carbon monoxide (CO) detectors

are recommended in all applications and should be installed

using the manufacturer’s instructions and local codes, rules, or

regulations.

NOTE: Air may be present in the gas lines and could prevent

the pilot from lighting on initial start-up. The gas lines should

be purged of air by a qualified person after installation of the

gas piping system. While purging the gas piping system of air,

make sure that the fuel is not spilled in the area of the water

heater installation, or any source of ignition. If the fuel is spilled

while purging the piping system of air follow the “WHAT TO DO

IF YOU SMELL GAS” instructions on the cover of this manual.

LP Gas Only

WARNING

Explosion Hazard

Have a qualified person make sure L.P. gas

pressure does not exceed 13” water column.

Examples of a qualified person include:

licensed plumbers, authorized gas company

personnel, and authorized service

personnel.

Failure to do so can result in death,

explosion, or fire.

BTU/HR.

Combustion Air Supply and

Ventilation

WARNING

Carbon Monoxide Hazard

Water heater must be vented to outdoors.

Vent must be installed by a qualified person

using the installation instructions.

Examples of a qualified person include:

gas technicians,

authorized gas company personnel,

and authorized service persons.

Failure to follow these instructions can result

in death or carbon monoxide poisoning.

IMPORTANT: Air for combustion and ventilation must

not come from a corrosive atmosphere. Any failure due

to corrosive elements in the atmosphere is excluded from

warranty coverage.

The following types of installation (not limited to the

following) will require outdoor air for combustion due to

chemical exposure and may reduce but not eliminate the

presence of corrosive chemicals in the air:

• beauty shops

• photo processing labs

• buildings with indoor pools

• water heaters installed in laundry, hobby, or craft rooms

• water heaters installed near chemical storage areas

Combustion air must be free of acid-forming chemicals

such as sulfur, fluorine, and chlorine. These elements are

found in aerosol sprays, detergents, bleaches, cleaning

solvents, air fresheners, paint, and varnish removers,

refrigerants, and many other commercial and household

products. When burned, vapors from these products form

highly corrosive acid compounds. These products should

not be stored or used near the water heater or air inlet.

Combustion and ventilation air requirements are

determined by the location of the water heater. The water

heater may be located in either an open (unconfined) area

or in a confined area or small enclosure such as a closet or

small room. Confined spaces are areas with less than 50

cubic feet for each 1,000 BTU/HR of the total input for all

gas-using appliances.

7

Unconfined Space

A water heater in an unconfined space uses indoor air for

combustion and requires at least 50 cubic feet for each

1,000 BTU/HR of the total input for all gas appliances. The

table below shows a few examples of the minimum square

footage (area) required for various BTU/HR inputs.

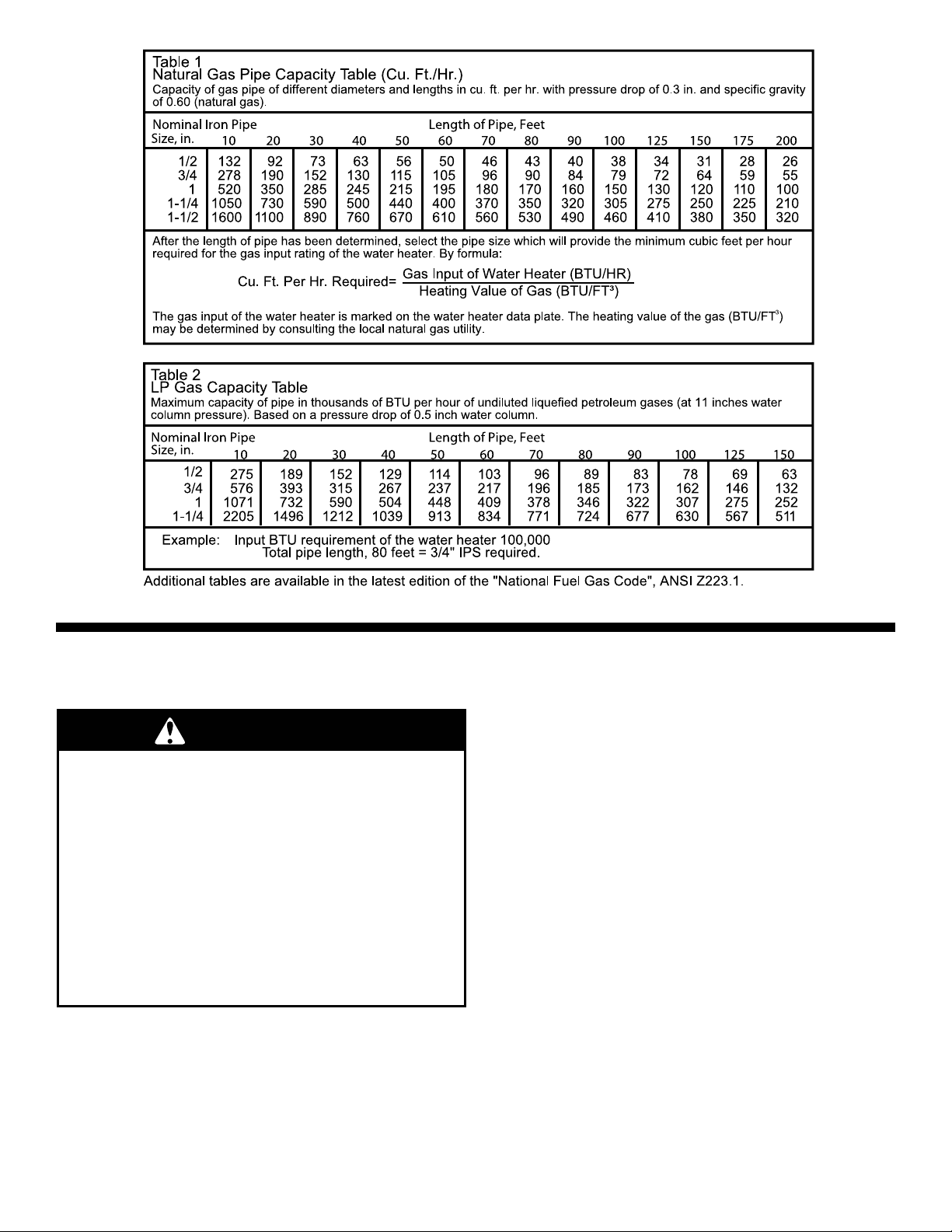

Table 3

BTU/HR

Input

Minimum Square

Feet with

8' Ceiling

Typical Room

with 8' Ceiling

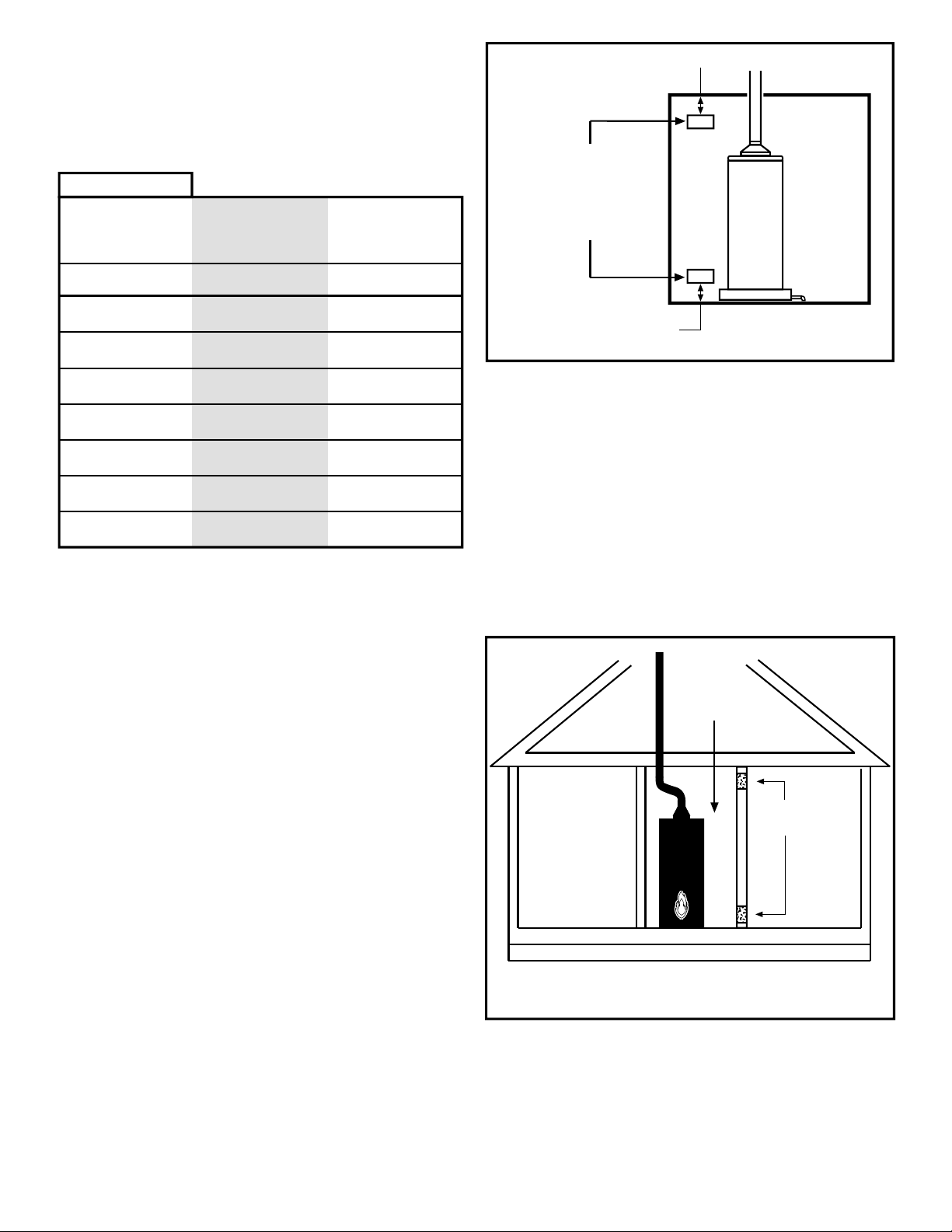

Figure 6

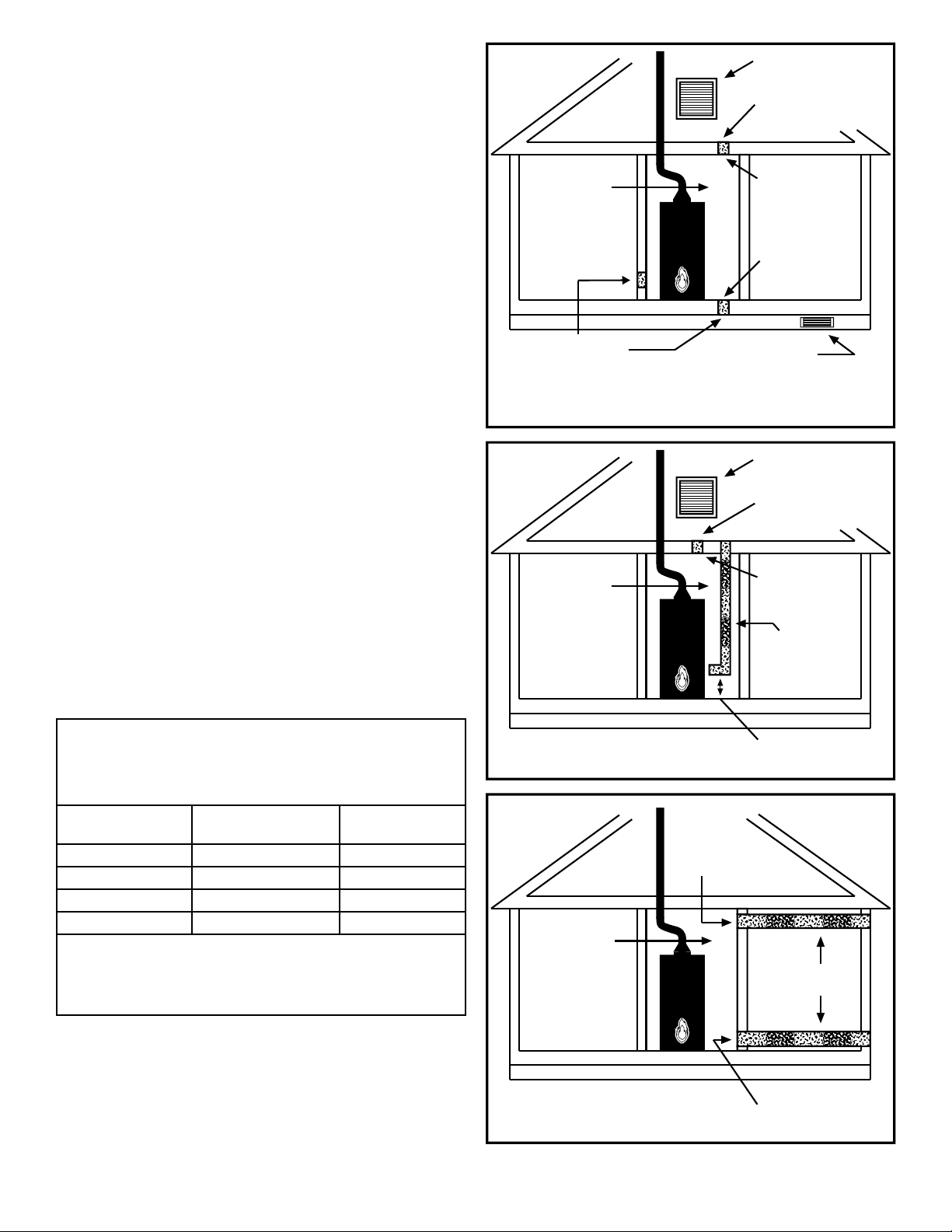

Opening LocationsConfined Spaces

Permanent

openings to

the outside or

additional

rooms within

the building

12” maximum

Closet

or

other

confined

space

30,000

45,000

60,000

75,000

90,000

105,000

120,000

135,000

188

281

375

469

563

657

750

844

9 x 21

14 x 20

15 x 25

15 x 31

20 x 28

20 x 33

25 x 30

28 x 30

IMPORTANT:

• The area must be open and be able to provide the

proper air requirements to the water heater. Areas that

are being used for storage or contain large objects may

not be suitable for water heater installation.

• Water heaters installed in open spaces in buildings with

unusually tight construction may still require outdoor

air to function properly. In this situation, outside air

openings should be sized the same as for a confined

space.

• Modern home construction usually requires supplying

outside air into the water heater area.

Confined Space

For the correct and proper operation of this water heater,

ample air must be supplied for the combustion, ventilation,

and dilution of flue gases. Small enclosures and confined

areas must have two permanent openings so that sufficient

fresh air can be drawn from outside of the enclosure. One

opening shall be within 12 inches of the top and one within

12 inches of the bottom of the enclosure as shown in

Figure 6.

The size of each opening (free area) is determined by the

total BTU/HR input of all gas utilization equipment (i.e.,

water heaters, furnaces, clothes dryers, etc.) and the

method by which the air is provided. The BTU/HR input can

be found on the water heater data plate. Additional air can

be provided by two methods:

1. All air from inside the building.

2. All air from outdoors.

12” maximum

All Air from Inside the Building

When additional air is to be provided to the confined area

from additional room(s) within the building, the total volume

of the room(s) must be of sufficient size to properly provide

the necessary amount of fresh air to the water heater

and other gas utilization equipment in the area. If you are

unsure that the structure meets this requirement, contact

your local gas utility company or other qualified agency for

a safety inspection.

Each of the two openings shall have a minimum free area

of 1 square inch per 1,000 BTU/HR of the total input rating

of all gas utilization equipment in the confined area, but not

less than 100 square inches (Figure 7).

Confined

Space

Permanent

Openings

1 square

inch/1000

BTU/HR

(minimum

100 sq. In.)

Figure 7

All Air from Inside Building

Confined Space Installation

8

All Air from Outdoors

Outdoor fresh air can be provided to a confined area either

directly or by the use of vertical and horizontal ducts. The

fresh air can be taken from the outdoors or from crawl or

attic spaces that freely communicate with the outdoors.

Attic or crawl spaces cannot be closed and must be

properly ventilated to the outside.

Ductwork must be of the same cross-sectional area as

the free area of the opening to which they connect. The

minimum dimension of rectangular air ducts cannot be less

than three inches.

The size of each of the two openings is determined by the

method in which the air is to be provided. Refer to Table

4 to calculate the minimum free area for each opening.

Figures 8, 9, and 10 are typical examples of each method.

Louvers and Grilles

In calculating free area for ventilation and combustion

air supply openings, consideration must be given to the

blocking effect of protection louvers, grilles, and screens.

These devices can reduce airflow, which in turn may

require larger openings to achieve the required minimum

free area. Screens must not be smaller than 1/4” mesh. If

the free area through a particular design of louver or grille

is known, it should be used in calculating the specified free

area of the opening. If the design and free area are not

known, it can be assumed that most wood louvers will allow

20 - 25% of free area while metal louvers and grilles will

allow 60 - 75% of free area.

Louvers and grilles must be locked open or interconnected

with the equipment so that they are opened automatically

during equipment operation.

Keep louvers and grilles clean and free of debris or other

obstructions.

Gable vent

to outdoors

Install above

insulation

Confined

Space

Alternate

Air Inlet

1 sq. inch per

4000 BTU/HR

Figure 8

All Air from Outdoors; Inlet Air from Ventilated

Crawl Space/Outlet Air to Ventilated Attic

Confined

Space

Outlet

air to attic

1 Sq. inch per

4000 BTU/HR

Inlet air

from the

crawl

space

Open

Foundation

Vent

Gable vent

to outdoors

Install above

insulation

Outlet air

to attic

1 Sq. inch per

4000 BTU/HR

Inlet air duct

1 sq. inch per

4000 BTU/HR

Table 4

Minimum Free Area of Permanent Openings for Ventilation and

Combustion Air Supply - All Air from Outdoors Only.

Based on the total BTU/HR input rating for all utilizing equipment within the confined space.

Opening Source

* Direct to outdoors 1 sq. in, per 4000 BTU/HR Figure 8

Vertical ducts 1 sq. in, per 4000 BTU/HR Figure 9

Horizontal ducts 1 sq. in, per 2000 BTU/HR Figure 10

Single Opening 1 sq. in, per 3000 BTU/HR Figure 11

Example: A water heater with an input rate of 50,000 BTU/HR

using horizontal ducts would require each opening to have a

minimum free area of 25 square inches.

Minimum free area = 50,000 BTU/HR x 1 sq. in. / 2000 BTU/HR =

25 Sq. Inches.

These openings connect directly with the outdoors

*

Minimum Free Area

Per Opening (sq. in.)

Reference

Drawing

through a ventilated attic, a ventilated crawl space, or

through an outside wall.

Consult the local codes of your area for specific ventilation

and combustion air requirements.

Figure 9

All Air from Outdoors

Through Ventilated Attic

Confined

Space

Figure 10

All Air from Outdoors

Using Horizontal Ducts

12” maximum

1 sq. inch

per

2000 BTU/HR

Outlet

Outdoor

Air Ducts

Inlet

1 sq. Inch

per

2000 BTU/HR

9

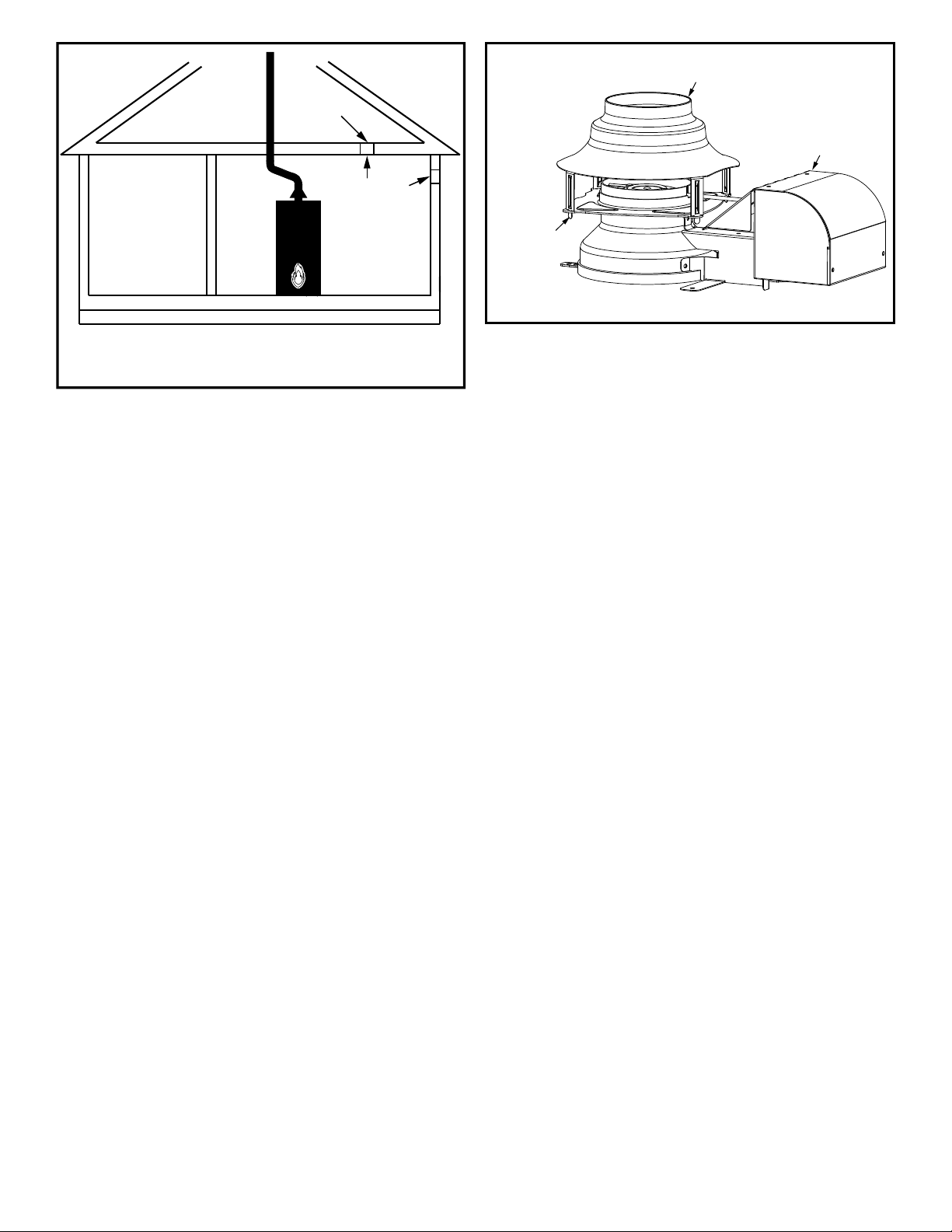

Alternative

Opening

Location

Figure 12

Draft hood Inst allation

Draft hood

Flue Damper

Confined

Space

Figure 11

All Air from Outdoors

Using a Single Permanent Opening

1 sq. Inch

Per 3000 BTU/HR

Vent Pipe System

This water heater uses a non-direct, single-pipe vent

system to remove exhaust gases created by the burning of

fossil fuels. Air for combustion is taken from the immediate

water heater location or is ducted in from the outside (see

“Combustion Air Supply and Ventilation” section).

This water heater must be properly vented for the removal

of exhaust gases to the outside atmosphere. Correct

installation of the vent pipe system is mandatory for the

proper and efficient operation of this water heater and is an

important factor in the life of the unit.

The vent pipe must be installed according to all local and

state codes or, in the absence of local and state codes, the

“National Fuel Gas Code”, ANSI Z223.1(NFPA 54)-current

edition. The vent pipe installation must not be obstructed so

as to prevent the removal of exhaust gases to the outside

atmosphere.

IMPORTANT: The use of vent dampers is not

recommended by the manufacturer of this water heater.

Although some vent dampers are certified by CSA

International, this certification applies to the vent damper

device only and does not mean they are certified for use on

this water heater.

U.L. recognized fuel gas and carbon monoxide (CO)

detectors are recommended in all applications and should

be installed using the manufacturer’s instructions and local

codes, rules, or regulations.

IMPORTANT: If you lack the necessary skills required

to properly install this venting system, you should not

proceed, but get help from a qualified person.

Draft Hood Installation

Align the legs of the draft hood with the slots provided.

Insert the draft hood leg tips into slots on the flue dampers

flange as shown in Figure 12. Secure the draft hood by

twisting or bending the leg tips. See Figure 12. Do not alter

the draft hood in any way. If you are replacing an existing

water heater, be sure to use the new draft hood supplied

with the water heater.

10

Draft hood

Leg Tips*

* Twist or bend the leg tips to secure the draft hood to the flue damper

Vent Pipe Size

It is important that you follow the guidelines in these

instructions for sizing a vent pipe system. If a transition to

a larger vent size is required, the vent transition connection

must be made at the draft hood outlet.

Vent Connectors

1. Type B, Double wall, U.L. Listed Vent Pipe.

2. Single wall Vent Pipe.

Maintain the manufacturer’s specified minimum clearance

from combustible materials when using type B double wall

vent pipe.

Vent connectors made of type B, double wall vent pipe

material may pass through walls or partitions constructed

of combustible material if the minimum listed clearance is

maintained.

Maintain a six inch minimum clearance from all combustible

materials when using single wall vent pipe.

IMPORTANT: Single wall vent pipe cannot be used for

water heaters located in attics and may not pass through

attic spaces, crawl spaces or any confined or inaccessible

location. A single wall metal vent connector cannot pass

through any interior wall.

When installing a vent connector, please note the following:

• Install the vent connector avoiding unnecessary bends,

which create resistance to the flow of vent gases.

• Install without dips or sags with an upward slope of at

least 1/4-inch per foot.

• Joints must be fastened by sheet metal screws or other

approved means. It must be supported to maintain

clearances and prevent separation of joints and

damage.

• The length of the vent connector cannot exceed 75% of

the vertical vent height.

• The vent connector must be accessible for cleaning,

inspection, and replacement.

• Vent connectors cannot pass through any ceiling, floor,

firewall, or fire partition.

• It is recommended (but not mandatory) that a minimum

12 inches of vertical vent pipe be installed on the draft

hood prior to any elbow in the vent system to improve

conditions for positive flow of venting gases.

IMPORTANT: Existing vent systems must be inspected for

obstructions, corrosion, and proper installation.

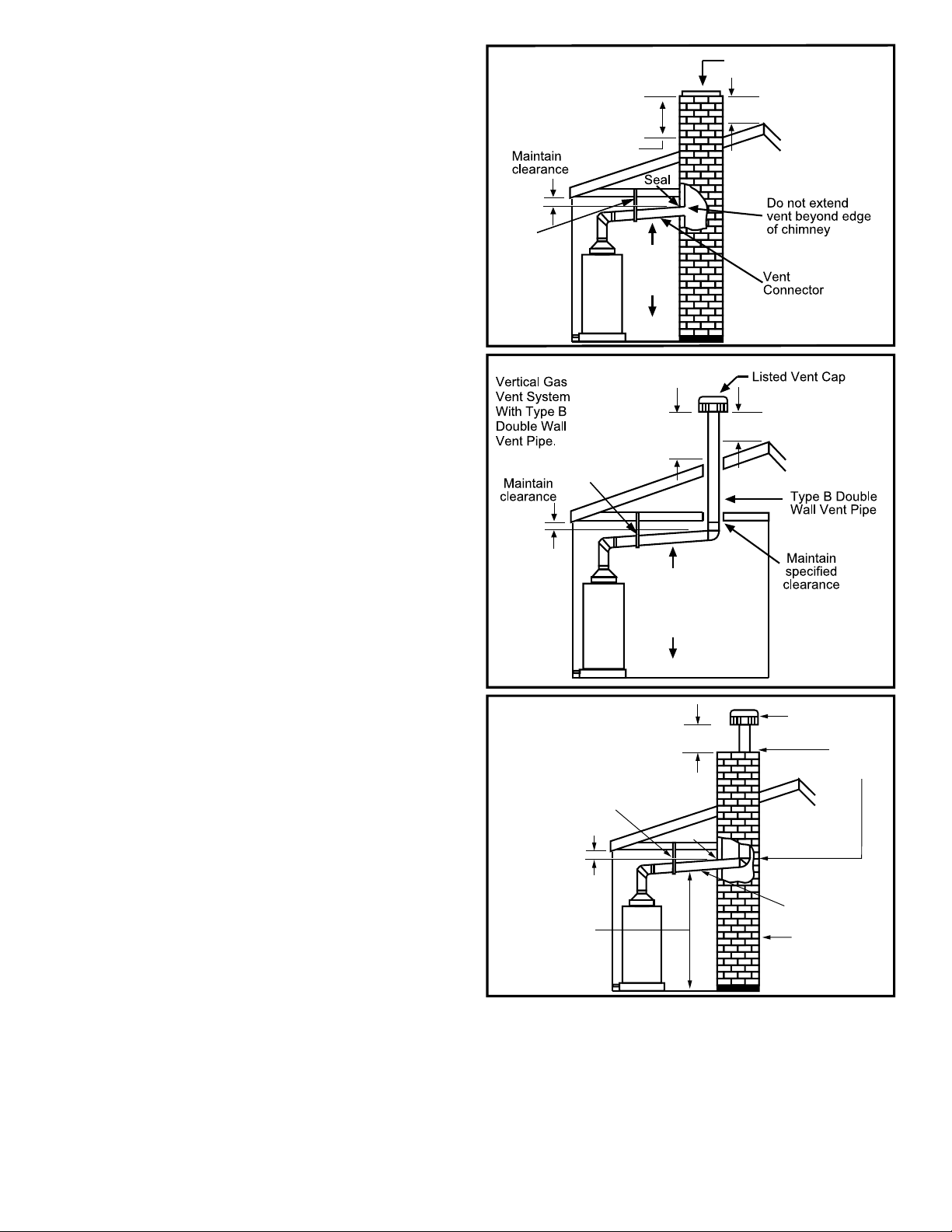

Chimney Connection

IMPORTANT: Before connecting a vent to a chimney,

make sure the chimney passageway is clear and free of

obstructions. The chimney must be cleaned if previously

used for venting solid fuel appliances or fireplaces. Also

consult local and state codes for proper chimney sizing and

application or, in the absence of local and state codes, the

“National Fuel Gas Code”, ANSI Z223.1(NFPA 54)-current

edition.

• The connector must be installed above the extreme

bottom of the chimney to prevent potentially blocking

the flue gases.

• The connector must be firmly attached and sealed to

prevent it from falling out.

• To aid in removing the connector, a thimble or slip joint

may be used.

• The connector must not extend beyond the inner edge

of the chimney as it may restrict the space between it

and the opposite wall of the chimney (Figure 13).

Do not terminate the vent connector in a chimney that has

not been certified for this purpose. Some local codes may

prohibit the termination of vent connectors in a masonry

chimney.

Figure 13

Chimney Termination

Vent System

3 ft. minimum

*

Support

Strap

Figure 14

Support Strap

*

Slope up

1/4 in.

per ft.

minimum

3 ft. minimum

Listed Lined

Chimney

2 ft. minimum above any

object within10 ft.

horizontally

2 ft. minimum above any

object within10 ft.

horizontally

Vertical Exhaust Gas Vent

Vertical exhaust gas vents must be installed with U.L. listed

type B vent pipe according to the vent manufacturer’s

instructions and the terms of its listing.

It must be connected to the water heater’s draft hood by a

listed vent connector or by directly originating at the draft

hood opening.

Vertical gas vents must terminate with a listed cap or

other roof assembly and be installed according to their

manufacturer’s instructions.

Gas vents must be supported to prevent damage, joint

separation, and maintain clearances to combustible

materials (Figures 14 and 15).

IMPORTANT: This gas vent must be terminated in a

vertical position to facilitate the removal of the burnt gases.

An unused chimney flue or masonry enclosure may be

used as a passageway for the installation of a gas vent

(Figure 15).

Common (combined) venting is allowable with vertical type

B vent systems and lined masonry chimneys as long as

proper draft for the water heater is established under all

conditions of operation.

IMPORTANT: Do not common vent this water heater with

any power vented appliance.

Figures 13-15 are examples of vent pipe system

installations and may or may not be typical for your specific

application. Consult the “National Fuel Gas Code”, NFPA

54, ANSI Z223.1-current edition and the guidelines set forth

by prevailing local codes.

**

Vent

connector

slope up

1/4 in. per ft.

minimum

Figure 15

Venting Through

a Chimney

with Type B

Double Wall

Vent Pipe.

*MAINTAIN

CLEARANCE

CONNECTOR

1/4 IN. PER FT.

Maintain vent pipe clearance requirements to local, state

*

and/or the “National Fuel Gas Code”, ANSI Z223.1(NFPA

MAINTAIN MANUFACTURER’S

SPECIFIED MINIMUM CLEARANCE

SUPPORT

STRAP

VENT

SLOPE UP

MINIMUM

SEAL

LISTED VENT CAP

**MAINTAIN

SPECIFIED

CLEARANCE

VENT CONNECTOR

UNUSED CHIMNEY

FLUE OR MASONRY

ENCLOSURE

54)-current edition.

NFPA 211, Standard for Chimneys, Fireplaces, Vents,

**

and Solid Fuel-Burning Appliances states that these

chimneys are intended to be installed in accordance with

the installation instructions provided with each chimney

support assembly. Minimum air space clearance to

combustible materials should be maintained as marked on

the chimney sections.

11

Loading...

Loading...