Page 1

Installation

Instructions

SERIN

™

2064.451

WALL MOUNT FAUCET

IN-WALL LAVATORY FITTING

Thank you for selecting American-Standard...

the benchmark of fine quality for over 100 years.

To ensure that your installation proceeds smoothly-please read these instructions carefully before you begin.

To ensure that your installation proceeds smoothly-please read these instructions carefully before you begin.

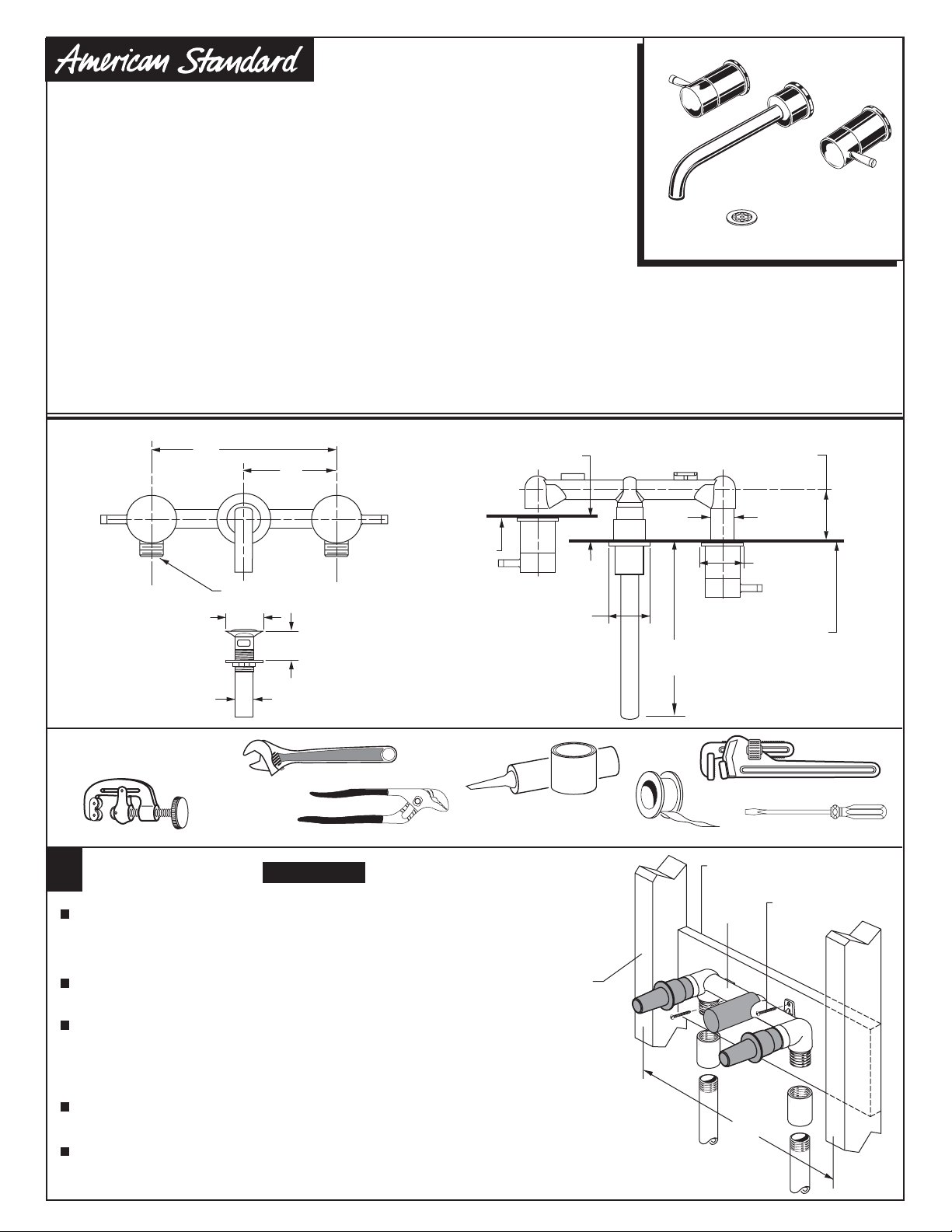

ROUGHING-IN DIMENSIONS

8"

(203mm)

CROSS

HANDLE

HOT

1/2" NPT INLETS

2-1/8" D.

(54mm)

4"

(102mm)

COLD

2" MAX. (51mm) MAX.

FINISHED

WALL

2" MIN.

(51mm)

2" D.

(52mm)

Certified to comply with ASME A112.18.1M

U.S. Patent No. 5,819,789

M968852 Rev.1.3

3" MAX.

(76mm) MAX.

1"

(25mm)

2" D.

(52mm)

FINISHED

9-1/4"

WALL

(235mm)

1-1/4" O.D.

(32mm) O.D.

Required Tools

Adjustable Wrench

Tubing Cutter

INSTALL VALVE BODY

1

CAUTION

Channel Locks

Turn off hot and cold water

supplies before beginning.

Determine where the finished wall location will be. This measurement

is very important! Note: The rough-in measurement from the finished

wall is; 2" minimum and 3" maximum. This is a 1" tolerance. See

rough-in illustration above.

Secure FAUCET BODY (1) to cross brace of wall structure

at required height using two wood screws.

Connect HOT water supply to left VALVE inlet and COLD water

supply to right VALVE inlet. Use pipe sealant or Teflon tape for

all threaded connections. For sweat connections, do not make

sweat connections directly to valve body. Damage to seals and

and valve cartridge may occur.

Turn valves to off position. Turn hot and cold supplies on and

check fitting connections for leaks .

Complete wall construction.

Plumbers' Putty or

Caulking

WALL STUDS

Teflon Tape

M

A

X

W

A

L

L

M

I

N

1

-

5

/

8

"

D

E

E

P

HOT

Pipe Wrench

Flat Blade Screwdriver

CROSS BRACE

1

WOOD SCREWS

M

A

X

W

A

L

L

M

I

N

1

-

5

/

8

"

D

E

P

E

16"

COLD

Page 2

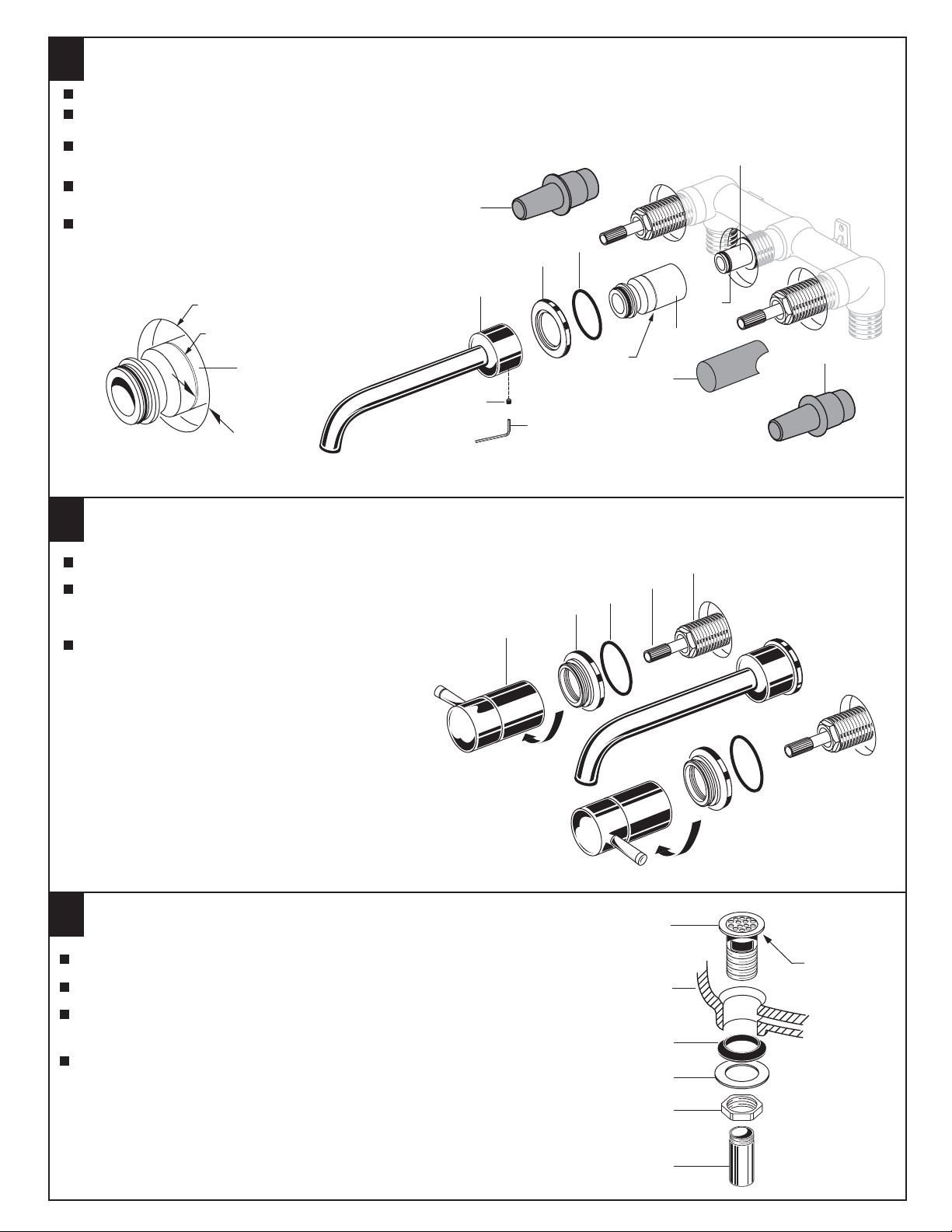

INSTALL WALL SPOUT

2

Remove PLASTER GUARDS (1) from valve bodies.

Inspect that SPOUT NIPPLE O-RING (2) is seated in groove of SPOUT NIPPLE (3).

Thread SPOUT MOUNT (4) onto SPOUT NIPPLE (3). Align groove on SPOUT MOUNT (4)

with face of finished wall. See Figure A.

Install SEAL (5) into SPOUT ESCUTCHEON (6). Place SPOUT

ESCUTCHEON (6) with SEAL (5) onto SPOUT MOUNT (4).

1

Push SPOUT (7) onto SPOUT MOUNT (4). Align SPOUT (7)

and tighten SPOUT SET SCREW (8) with 3mm HEX WRENCH

(9) supplied.

Figure A

7

FINISHED WALL

GROOVE

6

4

8

9

INSTALL HANDLES

3

Turn VALVE STEMS (1) to off position.

Place O-RING (2) into HANDLE ESCUTCHEON (3).

Thread HANDLE ESCUTCHEON (4) onto VALVE (5) until

snug against finished wall.

Thread HANDLE BASE (4) onto HANDLE ESCUTCHEON (3)

until seated tightly against HANDLE ESCUTCHEON (3).

4

M

I

N

1

M

A

-

5

/

8

"

X

W

A

L

L

D

E

E

P

5

GROOVE

3

3

2

4

1

1

M

A

X

W

A

L

M

I

N

1

-

5

E

/

8

D

"

5

1

2

DRAIN INSTALLATION

4

Apply a bead of PUTTY to underside of FLANGE on DRAIN BODY (1).

Feed DRAIN BODY (1) down through lavatory.

Assembly GASKET (2) WASHER (3) and LOCKNUT (4) onto DRAIN BODY (1).

Tighten LOCKNUT (4) firmly.

Assembly TAILPIECE (5) to DRAIN BODY (1).

1

PUTTY

LAVATORY

2

3

4

5

M968852 Rev.1.3

Page 3

5

SERVICE

To change direction of handle rotation,

proceed as follows:

Turn valve to OFF position.

Thread counter-clock wise HANDLE BASE (1) to remove

HANDLE ASSEMBLY (2) from ESCUTCHEON BASE (3).

Use a flat blade screw driver to remove SPRING CLIP (4).

Lift STOP WASHER (5), turn 90˚ and replace.

Replace SPRING CLIP (4).

Reinstall HANDLE ASSEMBLY (2).

If spout drips, operate handles several times from OFF to ON

position. Do not force - handles turn only 90˚.

TEST INSTALLED FAUCET

6

1

2

TO REMOVE

HANDLE

3

4

90˚

5

Turn HANDLES to "off" position.

Remove AERATOR (1) using TOOL (2) supplied.

Turn hot and cold water supplies on. Operate

both HANDLES to flush water lines thoroughly.

Check spout connections for leaks.

Check all drain connections for leaks.

Turn handles to OFF position. Replace AERATOR (1).

1

2

CARE INSTRUCTIONS:

7

DO: SIMPLY RINSE THE PRODUCT CLEAN WITH CLEAR WATER. DRY WITH A SOFT COTTON FLANNEL CLOTH.

DO NOT: DO NOT CLEAN THE PRODUCT WITH SOAPS, ACID, POLISH, ABRASIVES, HARSH CLEANERS, OR A

CLOTH WITH A COARSE SURFACE.

M968852 Rev.1.3

Page 4

M962422-YYY0A

SPOUT ASSEMBLY

M962757-0070A

AERATOR

M962423-YYY0A

SPOUT ESCUTCHEON KIT

M962352-0070A

SPOUT MOUNTING KIT

SERIN

™

WALL MOUNT

LAVATORY FAUCET

MODEL NUMBER

2064.451

994053-0070A

CARTRIDGE

617852-0070A

ADAPTER

918555-0070A

HANDLE SCREW

Replace the "YYY" with

appropriate finish code

CHROME

SATIN NICKEL

002

295

621423-0070A

VALVE HOUSING

M962424-YYY0A

HANDLE ESCUTCHEON KIT

M950245-YYY0A

HANDLE ASSEMBLY

015025-YYY0A

DRAIN COMPLETE

070532-0040A

TAILPIECE

For toll-free information and answers to your questions, call:

IN CANADA 1-800-387-0369 (TORONTO 1-905-306-1093)

Product names listed herein are trademarks of American Standard Inc.

© AS America, Inc. 2008

HOT LINE FOR HELP

1 (800) 442-1902

Weekdays 8:00 a.m. to 6:00 p.m. EST

Weekdays 8:00 a.m. to 7:00 p.m. EST

IN MEXICO 01-800-839-12-00

M968852 Rev.1.3

Loading...

Loading...