Page 1

Installation

Instructions

7871.702

7871.712

Spread Lavatory Faucet with the

Speed Connect™ Drain

Congratulations on purchasing your American Standard

faucet with Speed Connect drain, a feature found only on

American Standard faucets.

Speed Connect Drain*

• Fewer parts, installs in less time

• Never needs adjustment

• Guaranteed to seal properly the first time, every time.

*Your new American Standard faucet is designed to work only with the Speed Connect drain.

To ensure that your installation proceeds smoothly-please read these instructions carefully before you begin.

Recommended tools

7871.722

7871.732

7881.702

7881.712

7881.722

7881.732

Certified to comply with ANSI A112.18.1

US60404 Rev.1.2

Adjustable Wrench Screwdriver Channel Locks

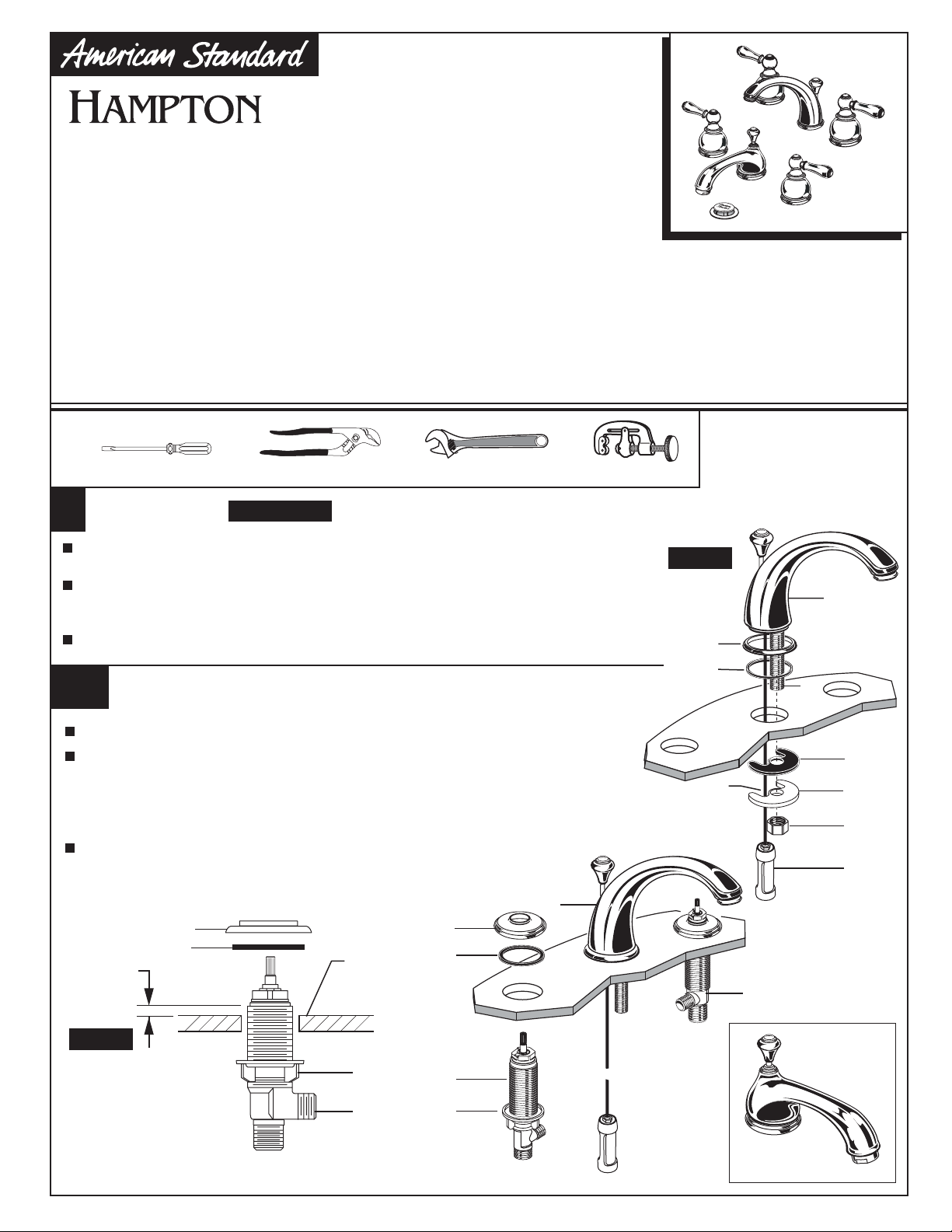

INSTALL SPOUT

1

Insert SPOUT (1) and CABLE CONNECTOR (12) through center hole, making sure

the SPOUT ESCUTCHEON (2) and SEAL WASHER (3) are properly seated.

Assemble RUBBER WASHER (4), BRASS WASHER (5) and LOCKNUT (6) onto SPOUT

SHANK (7) from under side of sink . Make sure SPOUT (1) is centered in the mounting

hole and the slot in the BRASS WASHER (5) faces toward the rear of the sink.

Tighten LOCKNUT (6) firmly. Fig. A.

1A

INSTALL VALVE BODY

Place RUBBER RING (9) into SCUTCHEON (10).

Install LOCKNUT (11) onto VALVE BODY (8).

From under side of mounting surface, install VALVE BODY (8) through valve

mounting holes. Threads of VALVE BODY (8) should extent at least 5/16

of a inch above mounting surface top. Fig. B. Thread ESCUTCHEON (10)

onto VALVE BODY (8) until snug against internal stop. If necessary, adjust

LOCKNUT (11).

Hand tighten LOCKNUT (11) to secure VALVE BODY (8).

Repeat above steps for opposite VALVE BODY (8A).

CAUTION

10

9

5/16'' MIN.

Turn off hot and cold water

supplies before beginning.

10

MOUNTING

SURFACE

9

Tubing Cutter

Fig. A.

1

2

3

7

4

SLOT

5

6

12

1

8A

Fig. B.

11

8

8

11

7871 SERIES

1

Page 2

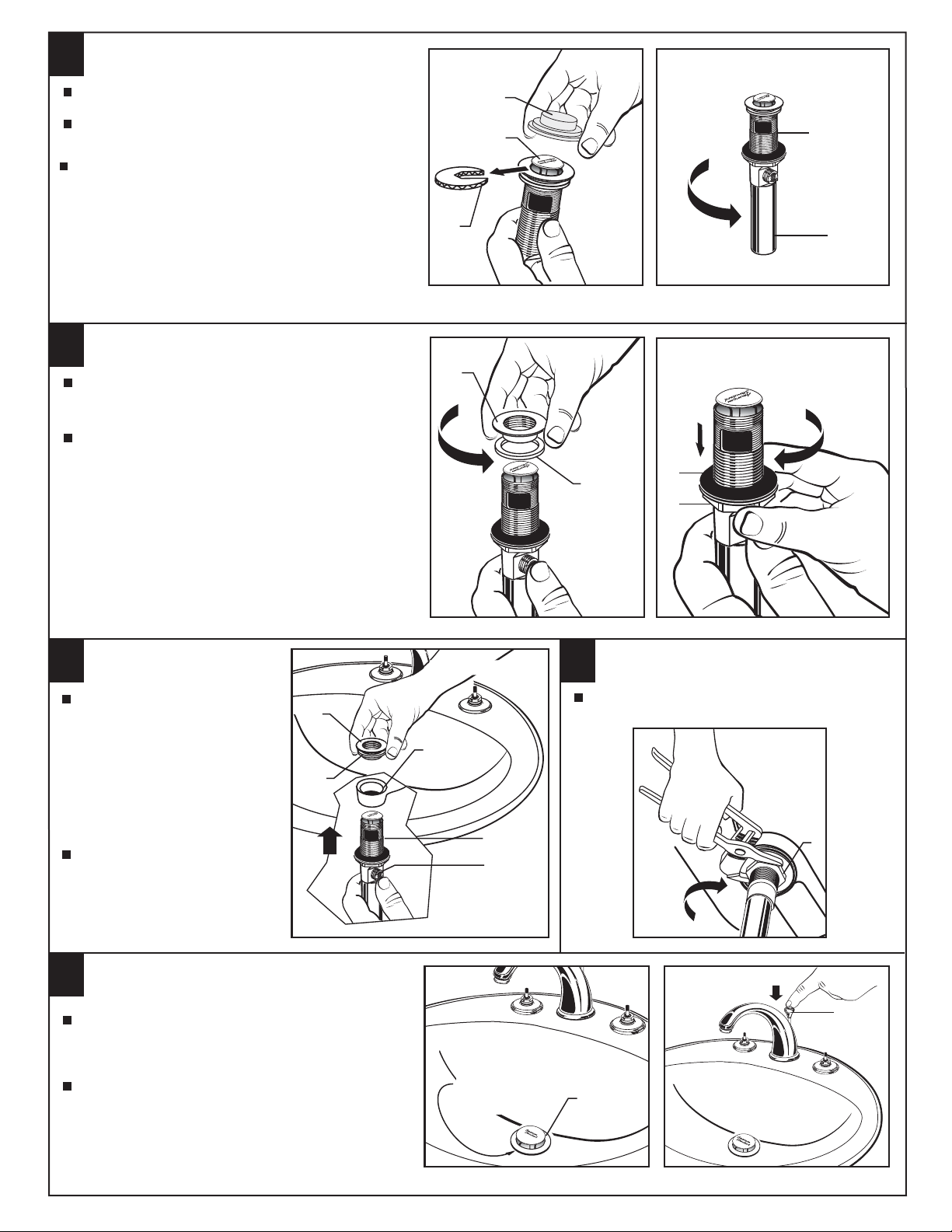

POP-UP DRAIN

2

Fig. A. Fig. B.

Remove CLEAR PLASTIC COVER (1).

Remove CARDBOARD SPACER (2) from under

DRAIN POP-UP (3).

Tighten TAILPIECE (4) on DRAIN BODY before

installing DRAIN BODY.

REMOVE FLANGE

3

Thread FLANGE (1) counter-clockwise and remove

FLANGE (1) and FOAM GASKET (2) from drain

body.

Fig. A.

Thread LOCKNUT (3) clock-wise to bottom of

drain body. Push GASKET (4) down against

LOCKNUT (3).

Fig. B.

Fig. B.

1

3

2

Fig. A. Fig. B.

1

2

4

3

DRAIN

BODY

4

INSTALL DRAIN FROM

4

BELOW FIXTURE

From under side of SINK

install DRAIN BODY (1) up

through drain outlet.

Note: No plumber’s putty

or caulk is required.

The CABLE ATTACHMENT

POINT (2) must face towards

the rear of the SINK.

Install FOAM GASKET (3) and

FLANGE (4) onto drain body

from above SINK and tighten

FLANGE (4) firmly.

FLANGE GASKET AND POP-UP KNOB

6

Check DRAIN FLANGE in SINK to ensure that

WHITE FOAM GASKET (3) is fully compressed

and not visible. Fig. A.

POP-UP KNOB (1) must be fully down. Fig. B.

REAR OF SINK

4

DRAIN

OUTLET

TIGHTEN LOCKNUT

5

Tighten LOCKNUT (1) firmly with Adjustable

Wrench or Channel Locks.

3

1

1

2

Fig. A. Fig. B.

DOWN

1

WHITE FOAM

GASKET

NOT VISIBLE

DRAIN

FLANGE

US60404 Rev.1.2

2

Page 3

ATTACH CABLE CONNECTOR

7

Thread CABLE CONNECTOR (1) clockwise

onto DRAIN BODY CONNECTION (2) and

hand tighten. Fig. A.

Your new POP-UP DRAIN installation is

now complete. Fig. B.

Note: Tailpeice on pop-up drain is 1-1/4” O.D.

Fig. B.

Fig. A.

Fig. B.

1

CHECK OPERATION OF POP-UP

8

Operate LIFT KNOB (1) to verify that STOPPER (2) opens and

closes.

Note: If STOPPER (2) does not open and close properly then refer

to the “troubleshooting section” of these instructions.

MAKE WATER SUPPLY AND WASTE CONNECTIONS

9

NOTE: FLEXIBLE SUPPLIES OR BULL-NOSE RISERS NOT INCLUDED

AND MUST BE PURCHASED SEPARATELY.

Thread TEE BODY (4) to SPOUT SHANK (5).

2

1-1/4” O.D.

1

2

Thread HOSE CONNECTOR (6, 6A) to VALVE CONNECTIONS (7, 7A).

Connect water supply to VALVE BODIES (1,1A) with 1/2" IPS FLEXIBLE

SUPPLIES (2) or 3/8" O.D. BULL-NOSE RISERS (3). Use

adjustable wrench to tighten connections. Do not over tighten.

Be careful not to kink copper supply when bending. Use tubing

cutter to cut to proper length.

Connect HOT water supply to inlet of left SHANK and COLD

water supply to right SHANK using sealant, appropriate

connectors, and COUPLING NUTS.

Connect 1-1/4” O.D. tailpiece on POP-UP DRAIN to

waste outlet.

1/2" PIPE THREAD

HOT

3

1A

5

6A

7A

COUPLING

NUT

1

7

6

2

FLEXIBLE

SUPPLIES

3/8 COMPRESSION

CONNECTION

4

3/8 O.D.

BULL-NOSE

RISERS

COLD

3

COMPRESSION

NUT

FERRULE

US60404 Rev.1.2

Page 4

10

INSTALL HANDLES (Lever) INSTALL HANDLES (Cross)

Turn VALVE into OFF position.

Push ADAPTER (1) into HANDLE

BASE (2) in a way that the male

square on the ADAPTER (1) fits

in the female square of the

HANDLE BASE (2).

Push HANDLE BASE (2) and

ADAPTER (1) onto VALVE STEM (5).

Check alignment, if not satisfactory

aligned;

Push out ADAPTER (1) carefully.

Turn ADAPTER (1) either 45˚ or 90˚

so that male square on ADAPTER (1)

catches different female square in

HANDLE BASE (2).

Secure HANDLE BASE (2) with HANDLE SCREW (3).

Push INDEX CAP (4) in hole of LEVER BALL (6).

WASHER

(PORCELIAN

CROSS

4

3

7

4

3

6

2

1

5

Turn VALVE into OFF position.

Push ADAPTER (1) into HANDLE

BASE (2) in a way that the male

square on the ADAPTER (1) fits

in the female square of the

HANDLE BASE (2).

Push HANDLE BASE (2) and

ADAPTER (1) onto VALVE STEM (5).

Check alignment, if not satisfactory

aligned;

Push out ADAPTER (1) carefully.

Turn ADAPTER (1) either 45˚ or 90˚

so that male square on ADAPTER

(1) catches different female square

in HANDLE BASE (2).

Secure HANDLE BASE (2) and METAL

CROSS (6) or PORCELAIN CROSS (7) with HANDLE SCREW (3).

Push INDEX CAP (4) in hole of METAL CROSS (6) or

PORCELAIN CROSS (7).

4

6

3

2

1

5

HANDLE ONLY)

11

12

TEST INSTALLED FITTING

With HANDLES (1) in OFF position, turn on WATER

SUPPLIES (2) and check all connections for leaks.

Remove AERATOR (3).

Operate both HANDLES (1) to flush water

lines thoroughly.

Replace AERATOR (3).

CHECK DRAIN CONNECTIONS

Operate POP-UP KNOB (5) and fill Sink with water. Check

that DRAIN STOPPER (4) makes a good seal and retains

water in Sink. If STOPPER (4) does not seal properly, please

refer to “Troubleshooting Guide” in these instructions.

Release POP-UP KNOB (5) down and check all drain

connections and "P" trap for leaks. Tighten

if necessary.

5

1

3

1

4

WASTE

OUTLET

2

COLD

13

DO: SIMPLY RINSE THE PRODUCT

CLEAN WITH CLEAR WATER.DRY

WITH A SOFT COTTON FLANNEL

CLOTH.

DO NOT: DO NOT CLEAN THE

PRODUCT WITH SOAPS, ACID,

POLISH, ABRASIVES, HARSH

CLEANERS, OR A CLOTH WITH

A COARSE SURFACE.

CARE INSTRUCTIONS:

HOT

14

SERVICE

To change direction of handle rotation, proceed as follows:

Turn valve to OFF position.

Remove IINDEX (1) and HANDLE SCREW (2).

Pull HANDLE (3) off.

Remove ADAPTER (4).

Remove SPRING CLIP (5).

Lift STOP WASHER (6), turn 90˚ and replace.

Replace SPRING CLIP (5).

Replace ADAPTER (4), HANDLE (2),

SCREW (2), and INDEX (1).

If spout drips, operate handles several

times from OFF to ON position. Do not

force - handles turn only 90˚.

4

“P” TRAP

2

1

2

3

90˚

7

5

US60404 Rev.1.2

4

Page 5

Speed Connect™ Drain

Troubleshooting Guide

If sink does not hold water even though Stopper is in the “down” position:

• Follow CABLE ADJUSTMENT PROCEDURE.

If Stopper does not raise up fully or sink drains too slowly:

• Follow CABLE ADJUSTMENT PROCEDURE.

If you need to remove the Stopper:

• Follow STOPPER REMOVAL PROCEDURE.

If you would like the ability to remove your Stopper simply by lifting it out of the drain:

• Follow STOPPER INSTALLATION PROCEDURE for “Unlocked” mode.

CABLE ADJUSTMENT PROCEDURE

Disconnect the Cable from the Drain by threading the Cable Connector (1) counter-clockwise. Fig. A.

Look at the area on the Drain Body where the Cable was attached and locate the component labeled as

“Cam” in the illustration. Fig. B.

Use a small screwdriver to rotate the Cam in the clockwise direction as far as it will go. At this point the

Stopper should be in the UP position. Fig. B, C.

Push DOWN on the Lift-Knob to make sure it is fully down. Fig. C.

Re-attach the Cable to the Drain Body Connection (2) by threading the Cable Connector (1) clockwise onto the

Drain Body Connection (2) and hand-tighten. Fig. A.

1

RE-ATTACH

DISCONNECT

Fig. B.Fig. A.

CAM

CAM CAP

Fig. C.

2

STOPPER REMOVAL PROCEDURE

Disconnect the Cable from the Drain by threading the Cable Connector (1) counter-clockwise. Fig. A.

Look at the area on the Drain Body where the Cable was attached and locate the component labeled

as “Cam” and “Cam Cap” in the illustration. Fig. B.

Use fingers or small screwdriver under either side of the Cam Cap to pry it out from the Drain. Fig. D.

Remove the Cam by pulling it straight out while wiggling gently to loosen the Rubber Seal. Fig. E.

The Stopper can now be removed by lifting it out of the Drain. Fig. F.

Fig. D.

Fig. E.

STOPPER

REMOVE

CAM

DOWN

1

Fig. F.

REMOVE

CAM CAP

US60404 Rev. 1.2

5

Page 6

STOPPER INSTALLATION PROCEDURE

The Stopper can be installed two ways, “Locked” Mode (Stopper cannot be

removed) or “Unlock” Mode (Stopper is removable).

Locked Mode:

Look at the Plastic Loop at the bottom of the Stopper and notice

that the Loop is on one side of the Stopper. Fig. G.

To install the stopper in “Locked” mode, insert the Stopper into

the Drain so that the Plastic Loop is facing toward the rear of the

Sink and the American Standard logo is facing front. Rotate

Stopper slightly if necessary so that the Stopper slides all the

way down.Fig. G.

Re-install the Cam into the Drain, rotating the Cam if necessary

to make sure it is fully inserted. Fig. J.

Re-install the Cam Cap, making sure the guide teeth are facing

outward. If the Cam Cap does not “snap” into place, then rotate

the Cam to make sure it is fully inserted. Fig. K.

LOGO

LOOP TOWARD

REAR OF SINK

DRAIN

Fig. G.

Re-attach Cable. See “CABLE ADJUSTMENT PROCEDURE” in

Troubling Shooting Guide to complete installation. Stopper will be

in “Locked” mode and not be removable.

Unlocked Mode:

Look at the Plastic Loop at the bottom of the Stopper and notice

that the Loop is on one side of the Stopper. Fig. H.

To install the stopper in “Unlocked” mode, insert the Stopper into

the Drain so that the Plastic Loop is facing toward the front of the

Sink and the American Standard logo is facing rear. Rotate Stopper

slightly if necessary so that the Stopper slides all the way down.

Fig. H.

Re-install the Cam into the Drain, rotating the Cam if necessary

to make sure it is fully inserted. Fig. J.

Re-install the Cam Cap, making sure the guide teeth are facing

outward. If the Cam Cap does not “snap” into place, then rotate

the Cam to make sure it is fully inserted. Fig. K.

Re-attach Cable. See “CABLE ADJUSTMENT PROCEDURE” in

“Troublingshooting Guide” to complete installation. Stopper will be

in “Unlocked” mode and removable

.

Locked Mode

(Vandal Proof)

Fig. H.

LOGO

180˚

LOOP TOWARD

FRONT OF SINK

DRAIN

Unlocked Mode

Fig. J. Fig. K.

INSTALL CAM

CAM

INSTALL

CAM CAP

US60404 Rev. 1.2

6

Loading...

Loading...