Page 1

™

Installation

STAINLESS STEEL SINKS

Instructions

UNDERCOUNTER MOUNTING FOR CULINAIRE™

COLLECTION STAINLESS STEEL

KITCHEN SINKS

MODELS 7501.000, 7502.000, 7504.000, 7507.000

Thank you for selecting American-Standard...the

benchmark of fine quality for over 100 years.

To ensure that your installation proceeds smoothly-please read these instructions carefully before you begin.

BEFORE YOU BEGIN...

Unpack new sink and inspect carefully for damage. Notify your American Standard distributor of any damage. Replace the

sink in its original packing carton to protect it until you are ready to begin installation.

Certified to comply with ANSI A112.19.3.M

CAN/C.S.A. B-45

Observe local plumbing and building codes.

790766-100

Recommended Tools & Materials:

Putty Knife

Pipe Wrench

Channel Lock Pliers

Phillips Screwdriver

Regular Screwdriver

Adjustable Wrench

Drill

CAUTION

SINK CUTOUTS:

Locate and mark center lines of sink on countertop. Provide proper clearance under the countertop for the faucet

supply lines and the structural parts of the cabinet. Do not use permanent markers to indicate the center lines.

Cut the inner portion from the supplied template and discard.

Attach the outer portion of the template to the countertop using masking tape. Be sure that the center lines on

the template are aligned with those on the counter.

A. After cutout is complete, mark underside of countertop at approximate locations shown in 1 for appropriate

model. Locate holes 1" back from cutout edge. Drill 1/4" diameter holes ('E' drill) 1/4" deep for brass inserts.

Tap in brass inserts, slotted end first.

Minimum countertop thickness is 12mm (1/2") for marble and solid surface material.

Basin Wrench

Saber Saw

Plumbers' Putty or Caulking

Tubing Cutter

Tape Measure

Hacksaw

Mineral Spirits

Silicone Sealant

B. Some products are supplied with a plastic film. This film protects the product during the shipping and has to be

removed before mounting. Apply sealant to mounting surface.

C. Mount hardware shown in Step 3 by first threading wingnut well up on screw near the head with washer and

slotted clip. Tighten screw securely to lock brass insert.

When sink is correctly positioned over cutout, tighten wing nuts evenly to secure sink.

(Refer to Step 3 on page 3.)

1

©AMERICAN STANDARD INC. 2002

Page 2

IMPORTANT: DIMENSIONS OF FIXTURES ARE NOMINAL AND MAY VARY WITHIN THE RANGE

OF TOLERANCES ESTABLISHED BY A.N.S.I. AND C.S.A. STANDARDS

.

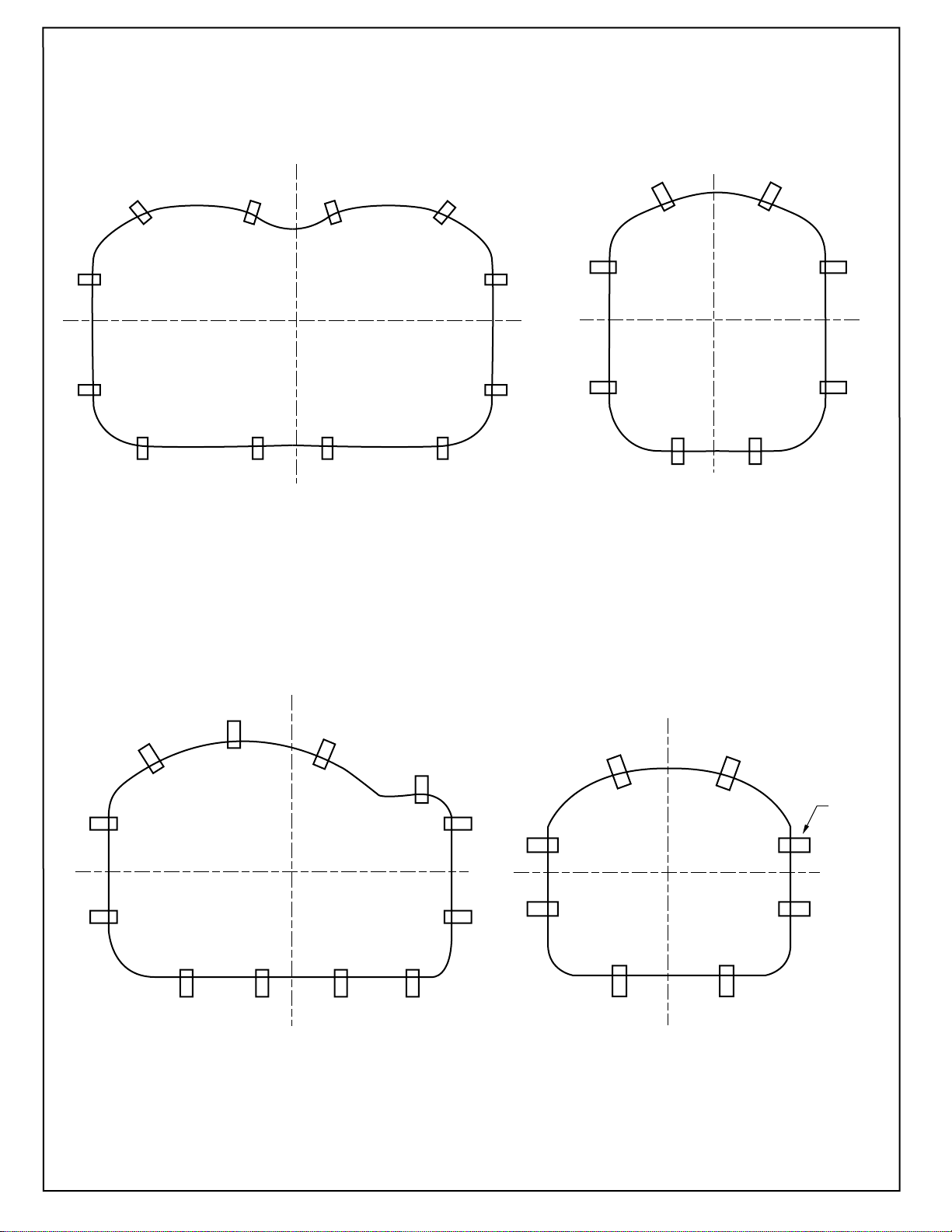

SUPPORT CLIP LOCATIONS:

MODEL 7507.000MODEL 7502.000

SUPPORT

CLIPS

MODEL 7501.000MODEL 7504.000

2

790766-100

Page 3

1

4

Drill a clearance hole

inside the cutout line.

2

Cut opening on cut line

of the template.

Note - Contact your

countertop distributor for

the best method of cutting materials such

as marble, hard synthetics, etc.

Countertop

Template

Countertop

Template

Cutout

template

Cutout

Countertop

Mount the faucet and

drain assembly following

the manufacturer's

instructions.

5

Connect supply lines to

faucet finger tight, and

carefully bend to engage

with the supply stops.

Tighten connections to

faucet for secure seal.

3

INSERT

CLAMP

WASHER

WINGNUT

INNER EDGE

OF CUTOUT

SCREW

6

Connect drain assembly

hand tight to check alignment. It may be necessary

to cut off part of the tailpiece

(area "A") or part of the

horizontal leg of the trap

1"

(area "B").

Secure joint for watertight

assembly.

Trap

Single Bowl

Double Bowl

A

Trap

B

END

790766-100

3

Page 4

Maintenance for stainless steel sinks:

To keep the original quality of your Stainless Steel Sink, we recommend regular cleaning. Use a mild liquid

dish detergent and water to clean the product after use. Rinse carefully and dry.

Please have the following in mind:

• Do not let water or other liquids dry on the product. Liquids that are left to dry leave a grey build-up

stain on the steel.

• Stainless steel can stand hard treatment, but sharp objects can easily scratch the surface. These

scratches are more visible when the product is new. After a period of use these marks will be

smoothed out without the product losing it luster.

• Never use scouring powder or steel wool to clean the surface. Apart from the risk of scratches, there

is also a risk that rust stains will attack the steel.

• Avoid Chlorine-based solutions from coming into contact with the stainless steel.

• Silver polish leaves spots that cannot be removed.

• Acidic foods (e.g. juices, salt, mustard, mayonnaise, etc.) must be cleaned up immediately.

Discoloration

More stubborn spots are often caused by impurities in the water or household substances. These can be

removed with special polish agents for stainless steel. Dull spots can become lustrous again if rubbed with

chalk on a soft cloth.

AMERICAN-STANDARD LIMITED LIFETIME WARRANTY FOR STAINLESS STEEL SINKS

American-Standard warrants to the original purchaser consumer of an American-Standard stainless steel sink that it will, at

its option, repair or replace such product if it is found by American-Standard, in its sole judgment, to be defective under

normal residential use, provided that it has been installed and maintained in accordance with American-Standard's

instructions. This limited warranty applies only to the initial installation and is not transferable from the original consumer

purchaser. In the event of a limited warranty claim, proof of purchase will be required – save sales receipt.

This limited lifetime warranty DOES NOT COVER the following:

1. Defects or damages arising from shipping, installation, alterations, accidents, abuse, misuse, environmental factors, lack

of proper maintenance and use of other than genuine American Standard replacement parts, in all cases whether caused by

a plumbing contractor, service company, the owner or any other person.

2. Deterioration through normal wear and tear and the expense of normal maintenance.

3. Commercial application.

4. Options and accessories. American-Standard’s limited warranty on these items is one year for parts only. This one year

limited warranty covers accessories manufactured by American-Standard against defects of material or workmanship.

Limited warranty coverage begins on the date the accessory was originally purchased by the owner.

5. Postage or shipping costs for returning products for repairs or replacement under this limited warranty and labor or other

costs incurred in connection with product removal or installation under this limited warranty.

6. ANY LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING LABOR, ALL OF WHICH ARE HEREBY

EXPRESSLY DISCLAIMED, OR THE EXTENSION BEYOND THE DURATION OF THIS LIMITED WARRANTY OF ANY IMPLIED

LIMITED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY OR FITNESS FOR AN INTENDED PURPOSE. IN NO EVENT

WILL AMERICAN STANDARD BE LIABLE FOR THE COST OF REPAIR OR REPLACEMENT OF ANY INSTALLATION MATERIALS

INCLUDING BUT NOT LIMITED TO TILES, MARBLE ETC. (Some jurisdictions do not allow limitations on how long an implied

limited warranty lasts, or the exclusion or limitation of incidental or consequential damages, so these limitations and

exclusions may not apply to you.)

7. Responsibility for compliance with local code requirements. (Since local code requirements vary greatly distributors,

retailers, dealers, installation contractors and users of plumbing products should determine whether there are any code

restrictions on the installation or use of a specific product.)

This limited warranty gives you specific legal rights. You may have other legal rights that vary from state to state or from

province to province.

In the United States:

American Standard Inc.,

P.O. Box 6820

Piscataway, New Jersey, 08855

Attention: Director of Consumer Affairs

For residents of the United States,

warranty information may also be

obtained by calling the following

toll free number: (800) 223-0068

In Canada:

American-Standard,

2480 Stanfield Road

Mississauga, Ontario

Canada L4Y 1S2

Toronto Area: (905) 306-1093

Toll Free: (800) 387-0369

4

In Mexico:

Ideal Standard, S.A. de C.V.

Planta Santa Clara

Via Morelos #330

Santa Clara Coatitla

Ecatepec de Morelos 55540,

Estado de Mexico, Mexico

790766-100

Loading...

Loading...