Page 1

Installation

Instructions

PORTSMOUTH

DECK MOUNT

BATH FILLER

™

7420.900

7420.901

Series

7420.920

7420.921

Series

Thank you for selecting American-Standard...

the benchmark of fine quality for over 100 years.

To ensure that your installation proceeds smoothly-please read these instructions carefully before you begin.

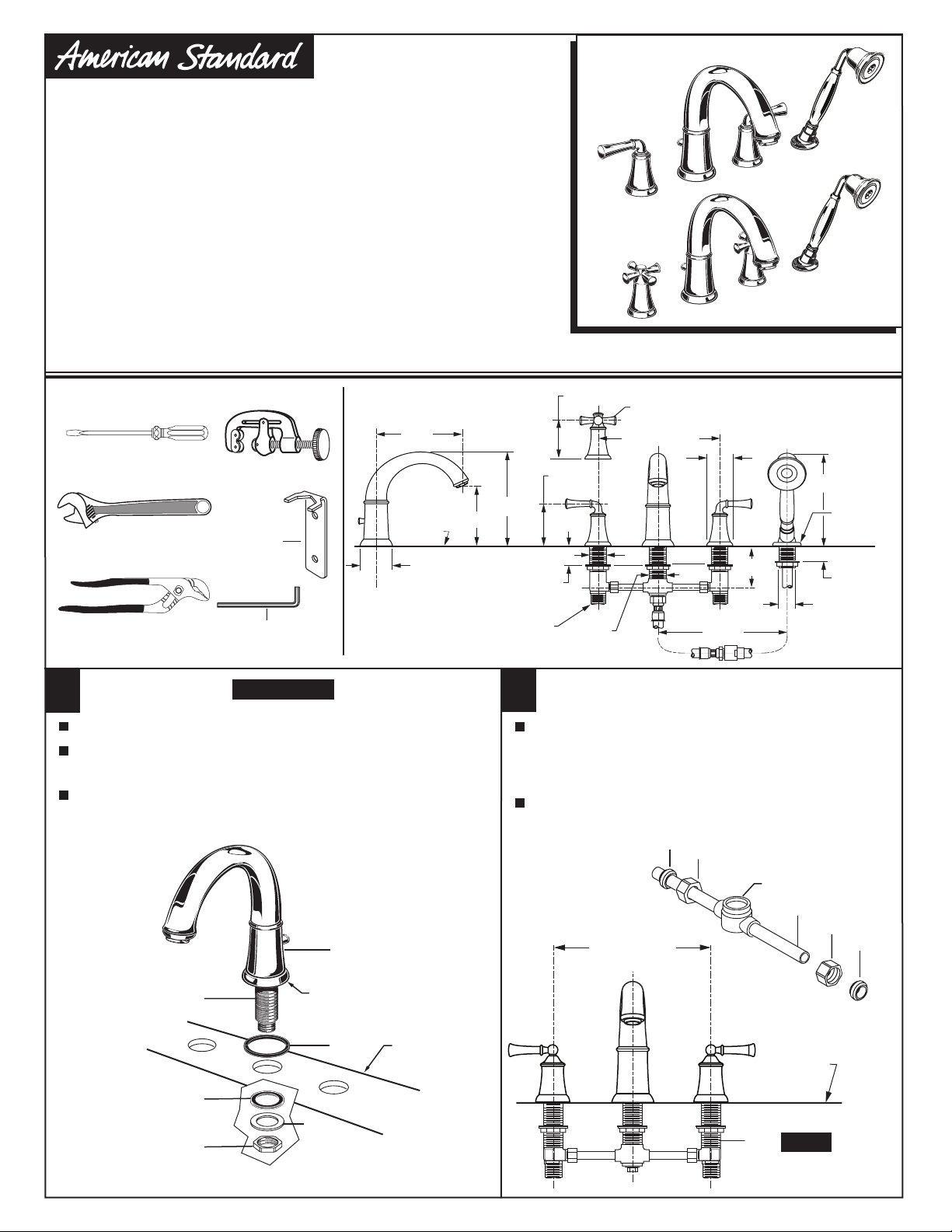

Recommended Tools

Flat Blade Screwdriver

Adjustable Wrench

Channel Locks

Tubing Cutter

*Wrench

*Hex key

*Supplied with Fitting

ROUGHING-IN DIMENSIONS

7-7/8"

(199mm)

7-7/8"

(200mm)

4-7/8"

2-5/8" D.

(125mm)

1-3/16" MAX.

(30mm) MAX.

3/4-14 MALE

N.P.T. INLETS

MOUNTING

SURFACE

(66mm) D.

3-3/16"

(81mm)

1-1/8 D.

2-7/8"

(73mm)

(H)

1-1/16 D.

(27mm) D.

CROSS HANDLE

6-1/2" to 12"

(165mm to 305mm)

LEVER

HANDLE

Certified to comply with ANSI A112.18.1M

M 9 6 5 0 2 7 R E V. 1.6

2-1/4" D.

(56mm) D.

8-1/4"

(210mm)

2-1/16" D.

(52mm) D.

3'

(C)

12 MAX.

(305mm)

(76mm)

1-1/2 MAX.

(38mm) MAX.

1-3/16 D.

(30mm) D.

SPOUT ASSEMBLY

1

CAUTION

Turn off hot and cold water

supplies before beginning.

Install RUBBER RING (1) into recess of spout base.

Insert SPOUT SHANK (2) through center hole of MOUNTING LEDGE.

Make sure that the RUBBER RING (1) is properly seated in RECESS

of SPOUT BASE.

Assemble RUBBER WASHER (3) and BRASS WASHER (4) onto

SHANK (2). From underside of ledge secure SPOUT (6) into position

with LOCKNUT (5).

6

2

RECESS

1

MOUNTING

SURFACE

3

4

5

PREPARE TUBE AND TEE ASSEMBLY

2

Prepare TUBE and TEE ASSEMBLY (1) to fit center to center

VALVE (2) location (between 6-1/2" and 12"). If necessary,

cut and/or bend TUBING carefully. Make sure tube bend is

close to the TEE (1) so that it will not effect the compression

joint at the VALVE CONNECTION.

Remove COUPLING NUT (3) and FERRULE (4) from each

VALVE (2) and slide onto TUBING (5).

4

3

1

5

6-1/2" to 12"

(165mm to 305mm)

MOUNTING

SURFACE

2

NOTE

VALVE inlet is

3/4-inch NPT male.

3

4

Page 2

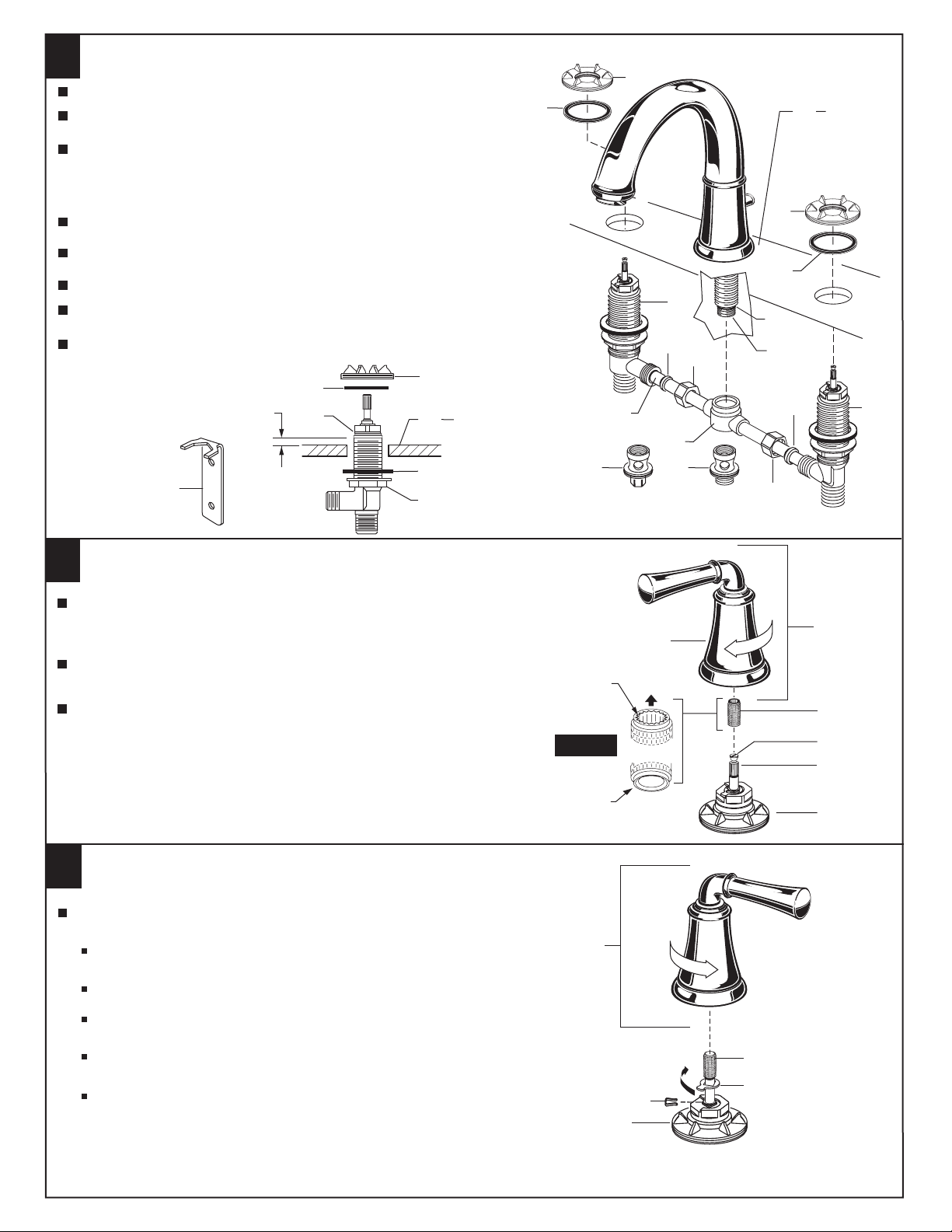

VALVE ASSEMBLY

3

Install LOCKNUTS (1) and RUBBER WASHERS (2) onto valve shanks.

Push TUBING (3) ends into VALVE (4) side outlets. Insert VALVES (4)

into mounting holes from underside of ledge.

Press TEE (5) onto SPOUT SHANK (6) making certain that the O-RING (7) is

properly seated on SHANK (6). Push COUPLING (8) into TEE (5) and attach to

SPOUT SHANK (6) and tighten using a 10mm (3/8'') hex wrench. Tighten

COUPLING (8) using a 10mm (3/8") Hex wrench. (FOR 7020.900/920) Use

COUPLING (8a) for fitting less spray.

Thread of VALVE BODY (4) should extend at least 5/16 inch above MOUNTING

SURFACE (11). If necessary, adjust LOCKNUT (1).

Place RUBBER RING (10) into ESCUTCHEON ADAPTERS (9) and thread onto

valves until snug against internal stop.

Tighten LOCKNUT (1) with WRENCH supplied to secure VALVE (4) position.

Slide FERRULE (12) and COUPLING NUT (13) to outlet of VALVE (4) and tighten

COUPLING NUT (13) firmly.

Connect HOT water supply to inlet of left VALVE and COLD water supply to inlet of

right VALVE using appropriate connector.

9

11

MOUNTING

SURFACE

5/16'' MIN.

10

4

2

Wrench

1

10

HOT

8a

9

MOUNTING

11

SURFACE

9

10

4

7

12

13

3

6

12

4

5

8

13

COLD

INSTALL HANDLES

4

Push ADAPTER (1) on VALVE STEM (2), so that the hole of the

ADAPTER (1) with the spline is facing up. Fig. A. Tighten

STEM SCREW (3) to secure ADAPTER (1).

Find correct position of LEVER HANDLE ASSEMBLY (4) by adjusting

male teeth on ADAPTER (1) to female teeth in HANDLE (4).

Thread LEVER HANDLE ASSEMBLY (4) onto DECK ADAPTER (5)

until snug against mounting surface.

SERVICE

5

To change direction of handle rotation,

proceed as follows:

Turn valve to OFF position. Unthread HANDLE BASE (1) from DECK

ADAPTER (2).

Pull HANDLE ASSEMBLY off VALVE STEM (3).

Remove SPRING CLIP (4). Lift STOP WASHER (5), turn 90˚ and replace.

Replace SPRING CLIP (4).

Find correct position of HANDLE ASSEMBLY by adjusting male teeth on

VALVE STEM (3) to female teeth in HANDLE.

Thread HANDLE ASSEMBLY onto DECK ADAPTER (2) until snug against

mounting surface.

SPLINE

END UP

Fig. A.

BOTTOM

HANDLE

ASSEMBLY

2

4

REMOVE

HANDLE

4

90˚

THREAD ON

TO DECK

ADAPTER

1

3

2

5

3

5

M 9 6 5 0 2 7 R E V. 1.6

Page 3

HANDSHOWER INSTALLATION (For 2064.901 only)

6

Drop SPRAY ESCUTCHEON (1) through the fourth hole of the tub ledge (12" max from SPOUT

center) with SPRAY ESCUTCHEON (1) directed towards tub center. Be sure RUBBER RING (2)

is properly seated in SPRAY ESCUTCHEON (1). Install RUBBER WASHER (3), BRASS WASHER (4)

and LOCKNUT (5) from underside of ledge.

Secure SPRAY ESCUTCHEON (1) by tightening LOCKNUT (5).

Install SEAL (9) and connect HOSE (10) to outlet nipple at the bottom of TEE (7). Tighten firmly.

Slip SHOWER HOSE (8) with COUPLING NUT through SPRAY

HOLDER (6) and SPRAY ESCUTCHEON (1). Note: SPRAY

HOLDER (6) must be seperate from ESCUTCHEON (1) to

pass HOSE (8) through ESCUTCHEON.(1)

Insert SEAL (9) into SHOWER HOSE (8). Connect HOSE (8)

to HOSE (10).

Install SEAL (9) and connect HAND SHOWER (11) to

SPRAY HOSE (8).

NOTE

7

When not in use, HANDSHOWER should be seated

in the HOLDER.

MAKE WATER SUPPLY CONNECTIONS

Connect HOT water supply to LEFT INLET

UNION (1) and COLD water supply to

RIGHT INLET UNION (2). Pipe connections

are 3/4" NPT. Use sealant or Teflon tape

on pipe connections.

Do not solder directly to valve body.

7

9

TRANSFER KNOB

10

11

9

6

1

2

9

3

4

5

8

HAND

SHOWER

7A

8

TEST INSTALLED FAUCET

With HANDLES in OFF position, turn on

WATER SUPPLIES and check all connections

for leaks.

Operate both HANDLES to flush water lines

thoroughly.

Lift HAND SHOWER from HOLDER, direct spray

into tub. Lift TRANSFER KNOB to check HAND

SHOWER and HOSES for leaks.

Turn handles "off" and replace HAND SHOWER.

Before the bathroom is completely finished, you may

want to remove spout, handshower, and handles to

avoid damage during construction.

To remove handles, reverse steps in section 4.

To remove SPOUT (1), proceed as follows:

Unthread LIFT ROD KNOB (2) and remove.

Remove PLUG BUTTON (3) and remove SET SCREW (4) using

4mm hex wrench supplied.

Lift SPOUT (1) off SHANK (5) carefully and remove RUBBER

RING (6).

Unthread SHANK SLEEVE (7) and remove from SHANK (5).

Reverse sequence to re-install SPOUT (1). Be sure RUBBER

RING (6) is properly seated in its recess at the base of the

SPOUT (1). Make certain SET SCREW (4) is properly aligned

and tight so that SPOUT (1) is locked in place.

3/4" NPT

1

HOT

COLD

2

3/4" NPT

3/4" X 3/4" NPT UNION

(NOT SUPPLIED)

IMPORTANT: It is strongly recommended that access be

provided for all enclosed mechanical parts to this system.

2

VIEW "A"

1

6

3

4

Hex wench

(supplied)

VIEW "A"

7

5

CARE INSTRUCTIONS:

9

DO: SIMPLY RINSE THE PRODUCT CLEAN WITH CLEAR WATER. DRY WITH A SOFT COTTON FLANNEL CLOTH.

DO NOT: DO NOT CLEAN THE PRODUCT WITH SOAPS, ACID, POLISH, ABRASIVES, HARSH CLEANERS, OR A

CLOTH WITH A COARSE SURFACE.

M 9 6 5 0 2 7 R E V. 1.6

Loading...

Loading...