American Standard 7075.050, 7075.054, 7075.005, 7075.004, 7075.006 Installation Instructions Manual

...

F.W. WEBB COMPANY- O & M

PLUMBING, HEATING, COOLING, AND INDUSTRIAL SUPPLIES

SERVING NEW ENGLAND & NEW YORK SINCE 1866

WARREN MECHANICAL

O&M FIXTURES

HARTLEY BLOCK

06/08/2018

Erica Bryant @ FW

07/29/2016

150 Postal Service Way • South Portland, Maine

Phone: (207) 772-8364 Fax: (207) 773-4571

Webb Co.

INSTALLATION

INSTRUCTIONS

P-2, P-2B - 7075.050

COLONY® PRO

SINGLE CONTROL

CENTERSET

7075.054 / 7075.055 / 7075.056

7075.050 / 7075.004 / 7075.005

7075.006 / 7075.002 / 7075.000

LAVATORY FAUCET

Thank you for selecting American Standard...

the benchmark of fine quality for over 100 years.

To ensure that your installation proceeds smoothly-please read

these instructions carefully before you begin.

RECOMMENDED TOOLS

Screwdriver Adjustable Wrench Tubing CutterChannel Locks

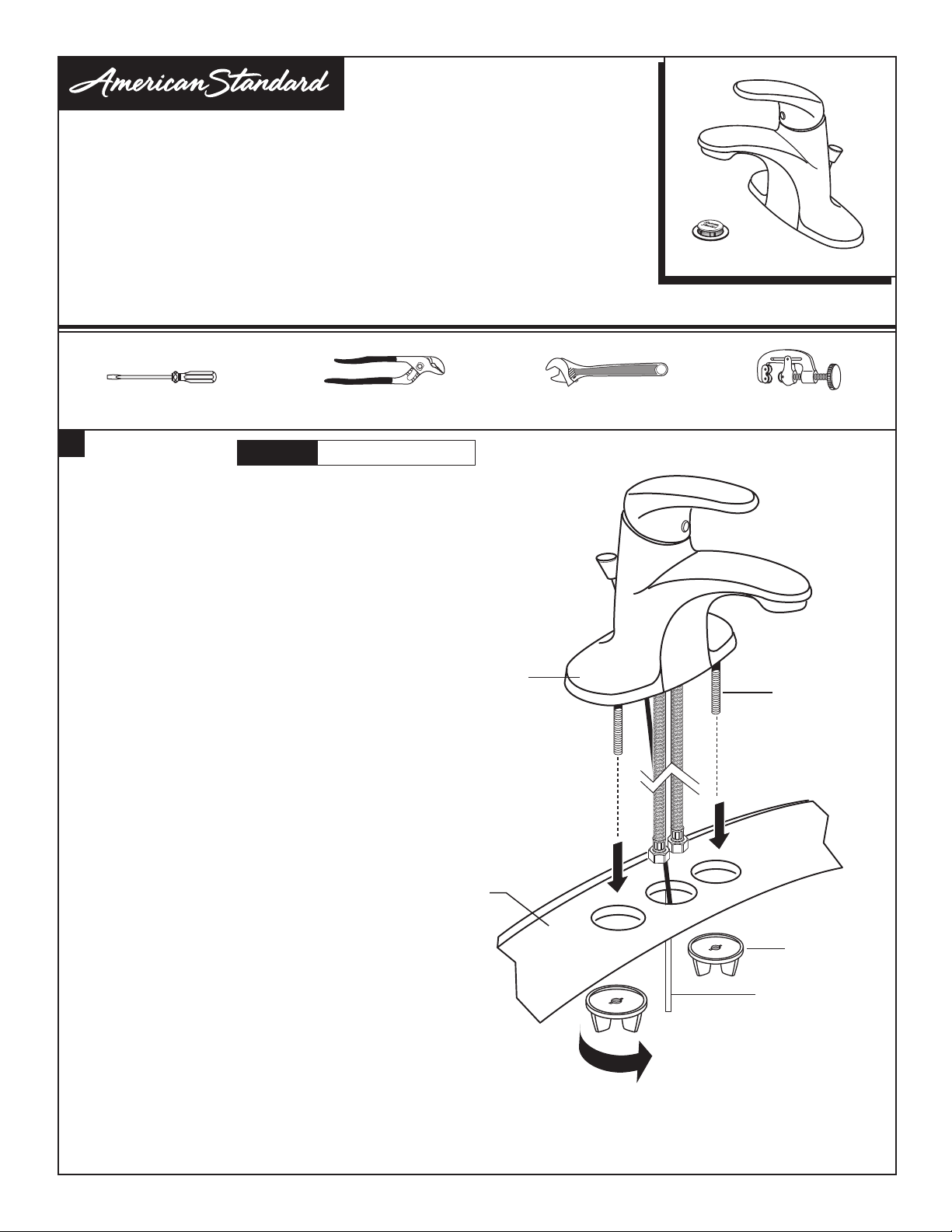

1

INSTALL FAUCET

• Insert FAUCET (1) and POP-UP CABLE (2) through mounting

holes of Sink or Mounting Surface.

• Assemble LOCKNUTS (3) onto SHANKS (4) from under

side of Sink. Hand tight

CAUTION

Turn off hot and cold water

supplies before begining.

Certied to comply with ANSI A112.18.1M

SINK OR

MOUNTING

SURFACE

(HAND TIGHTEN)

1

4

3

2

Product names listed herein are trademarks of AS America, Inc.

© AS America, Inc. 2016

- 1 -

M965766 (8/16)

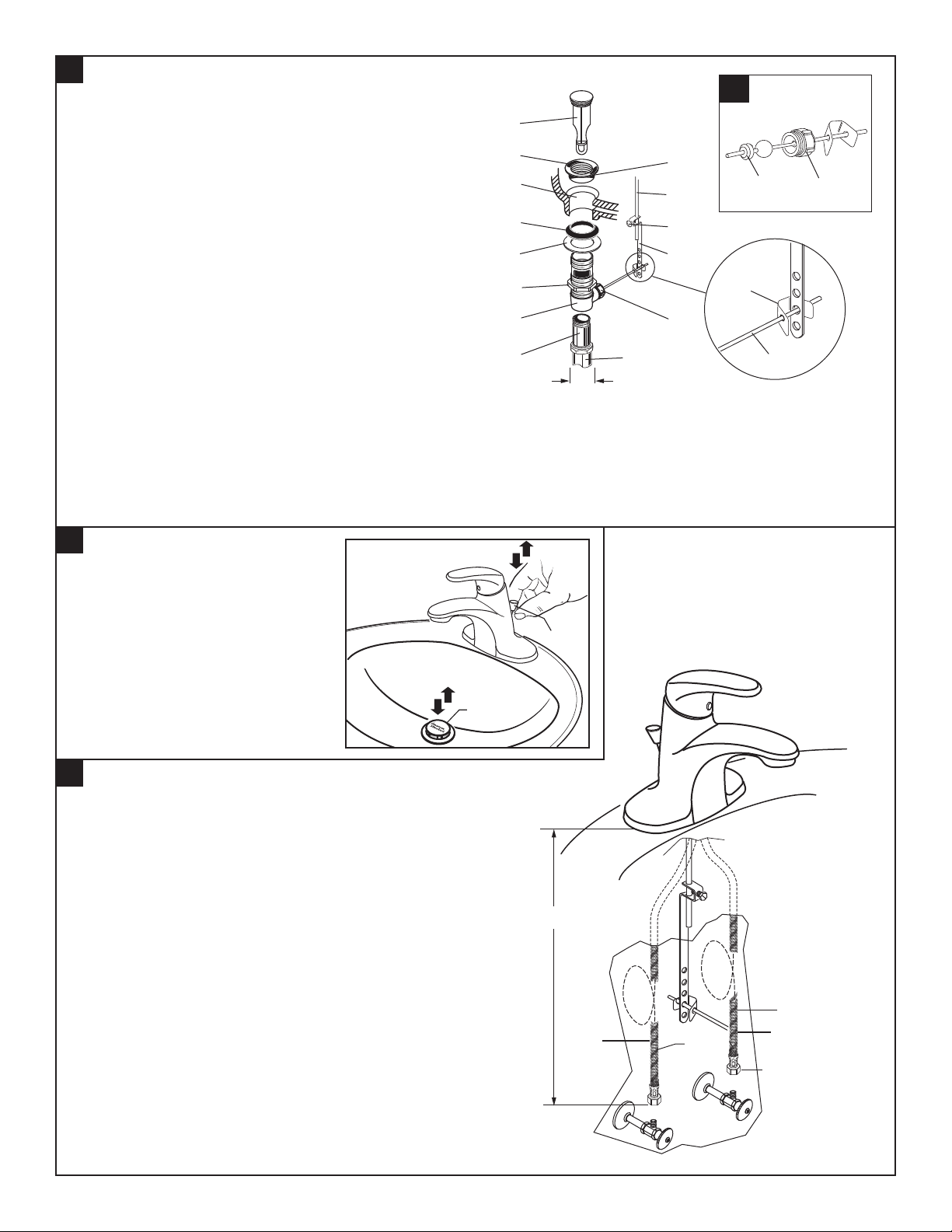

2

INSTALL POP-UP DRAIN

P-2, P-2B - 7075.050

2a

• Push TAIL PIECE (11) down into TRAP (C) (threaded end up).

• Thread LOCKNUT (5), WASHER (4) and GASKET (3)

(Bevel side up) onto DRAIN BODY (10).

• Apply a bead of PUTTY (D) to underside of FLANGE (2).

• Feed DRAIN BODY (10) up through SINK (A) and thread

the FLANGE (2) fully onto DRAIN BODY (10).

• Tighten LOCKNUT (5) rmly, keeping the pivot rod hole pointed

towards the back of the sink.

• Assemble PIVOT ROD (9) as shown in Figure-2a.

Notice the position of the CONCAVE WASHER (G).

• Insert PIVOT ROD (9) into DRAIN BODY (10) and tighten

PIVOT NUT (F).

• Pull TAIL PIECE (11) up and thread tightly into

DRAIN BODY (10).

• Position EXTENSION ROD (7) onto POP-UP ROD (E) and tighten

THUMBSCREW (6).

• Remove one end of CLIP (8) from PIVOT ROD (9) by squeezing ENDS TOGETHER WHILE SLIDING.

• Insert PIVOT ROD (9) into second or third hole in EXTENSION ROD (7) and reassemble CLIP (8).

• DROP STOPPER (1) into DRAIN BODY (10).

• Adjust stopper height by repositioning EXTENSION ROD (7) and tightening THUMBSCREW (6).

3

CHECK OPERATION OF POP-UP

A

4

10

11

1

2

3

5

C

1-1/4"

D

E

G

F

6

7

8

F

9

• Operate LIFT KNOB (1) to verify that

STOPPER (2) opens and closes.

4

MAKE WATER SUPPLY AND WASTE CONNECTIONS

• Connect FLEXIBLE SUPPLIES (1, 2) directly to wall supplies.

Connection on tting supplies are 3/8" compression.

Connect left SUPPLY (1) to Hot (Marked with a Red Band)

and right supply to COLD (2) wall supply.

• Faucet supplies are 20" long from faucet base.

Note: If additional supply length is required, installer must

purchase additional parts separately.

Important: If SUPPLY HOSES (1, 2) are to long, loop as

illustrated to avoid kinking.

• Connect 1-1/4” O.D. tailpiece on POP-UP DRAIN to

waste outlet.

2

1

APPROX. 20"

2

1

RED

BAND

BLUE

BAND

3/8" COMPRESSION

- 2 -

HOT

COLD

M965766 (8/16)

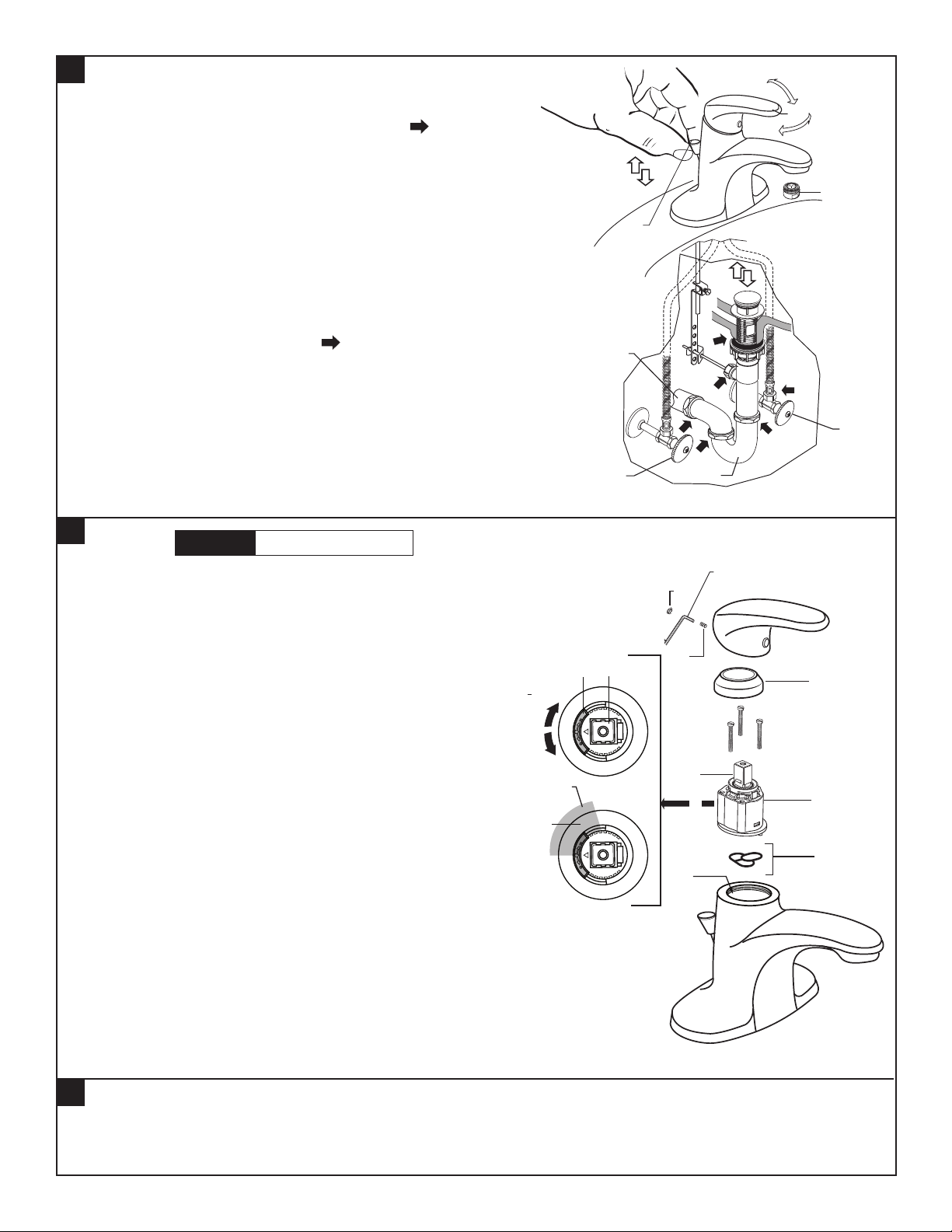

5

TEST INSTALLED FITTING

• With HANDLE (1) in OFF position, turn on WATER

SUPPLIES (2) and check all connections for leaks.

Remove AERATOR (3).

•

Operate HANDLE (1) to ush water lines thoroughly.

•

Replace AERATOR (3).

•

CHECK DRAIN CONNECTIONS

• Operate POP-UP KNOB (4) and ll lavatory with water.

Check that DRAIN STOPPER (5) makes a good seal

and retains water in Sink.

Release POP-UP KNOB (4) down and check all drain

•

connections and “P” trap for leaks. Tighten

if necessary.

WASTE

OUTLET

P-2, P-2B - 7075.050

ON

OFF

COLD

1

HOT

3

4

2

6

SERVICE

CAUTION

Turn off hot and cold water

supplies before beginning.

• To remove or replace cartridge:

– Turn valve to OFF position.

– Pull out PLUG BUTTON (1) and remove HANDLE SCREW (2).

– Pull off HANDLE (3) and CAP (4).

– Pull out CARTRIDGE (5).

– Inspect CARTRIDGE (5) and O-RINGS (6) for debris and

clean if necessary.

– Clean MANIFOLD (7) and rinse clean.

– Reinstall CARTRIDGE (5) and O-RINGS (6) onto

MANIFOLD (7).

– Reinstall CAP (4) and HANDLE ASSEMBLY (3).

If spout drips, operate handle several times from OFF to ON

•

and HOT to COLD position. Do not force - handle turns only 90˚.

ADJUST HOT LIMIT SAFETY STOP

By restricting HANDLE rotation and limiting the amount of

hot water allowed to mix with the cold, the HOT LIMIT SAFETY

STOP (8) reduces risk of accidental scalding. To lower the

maximum hot water temperature of your faucet, all you need to

do is adjust the setting on the HOT LIMIT SAFETY STOP (8).

Note: The HOT LIMIT SAFETY STOP (98 is set at the neutral

setting from the factory. Fig. A.

To adjust HOT LIMIT SAFETY STOP:

•

– Remove HANDLE ASSEMBLY (3), CAP (4)

– Set the CARTRIDGE STEM (9) to the OFF position.

– Lift up the HOT LIMIT SAFETY STOP 8).

– Place the HOT LIMIT SAFETY STOP (8) in the desired GRAY

SHADED AREA (10) to limit the hot water. Fig. B.

– Reinstall CAP (4) and HANDLE ASSEMBLY (3).

COLDER

+HOTTER

SETTING

MARKS

10

2

“P” TRAP

2.5mm HEX KEY

1

2

9

8

4

A

9

B

8

5

6

7

7

CARE INSTRUCTIONS:

DO: SIMPLY RINSE THE PRODUCT CLEAN WITH CLEAR WATER. DRY WITH A SOFT COTTON FLANNEL CLOTH.

DO NOT: DO NOT CLEAN THE PRODUCT WITH SOAPS, ACID, POLISH, ABRASIVES, HARSH CLEANERS, OR A

CLOTH WITH A COARSE SURFACE.

- 3 -

M965766 (8/16)

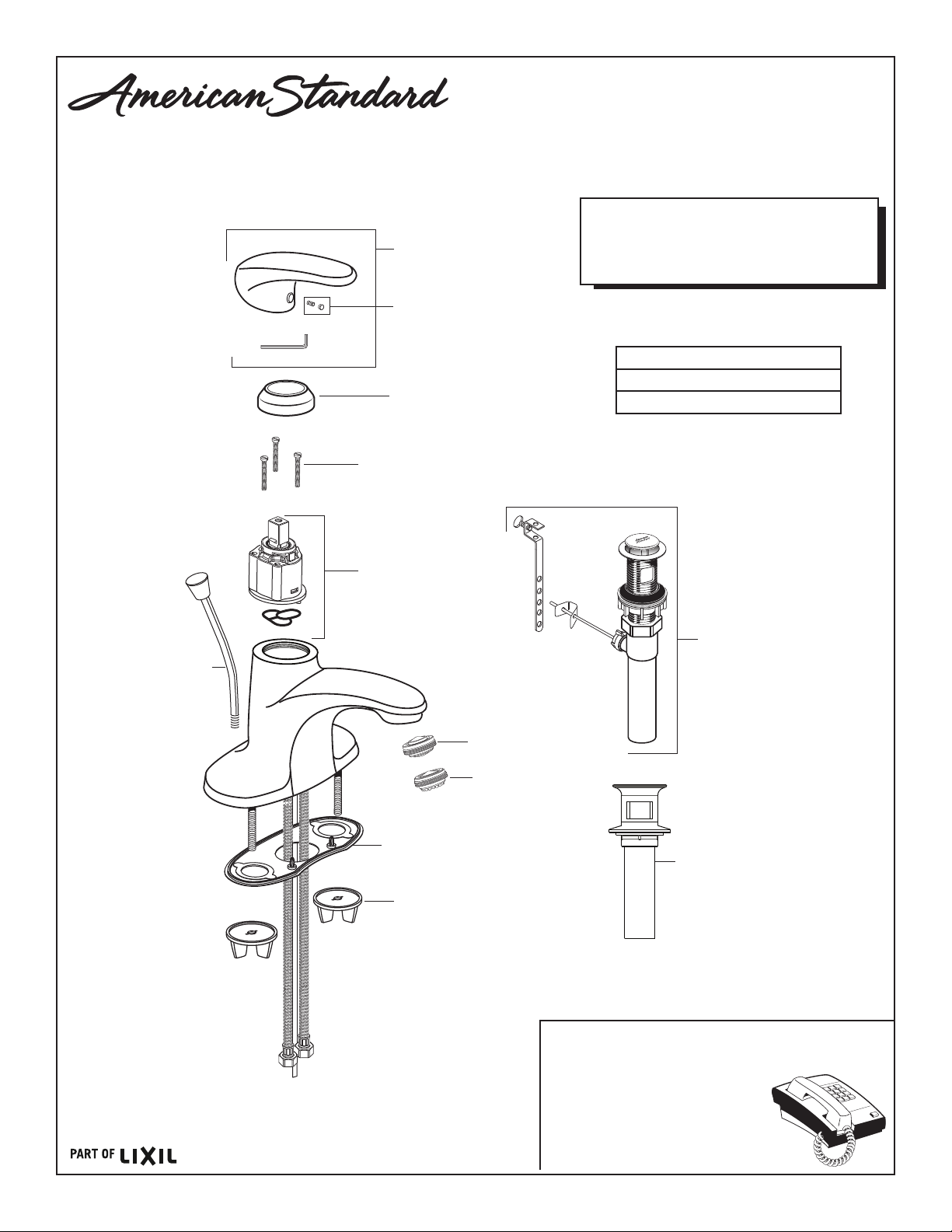

M970184-YYY0A

HANDLE KIT

M970194-YYY0A

SET SCREW & BUTTON

& INDEX BUTTON RED/BLUE

M907315-YYY0A

CARTRIDGE CAP

M918511-0070A

CARTRIDGE SCREWS

P-2, P-2B - 7075.050

COLONY® PRO

SINGLE CONTROL

CENTERSET

LAVATORY FAUCET

MODEL NUMBERS

7075.054 / 7075.055 / 7075.056

7075.050 / 7075.004 / 7075.005

7075.006 / 7075.002 / 7075.000

Replace the “YYY” with

appropriate finish code

POLISHED CHROME 002

LEGACY BRONZE 278

SATIN NICKEL 295

M970185-YYY0A

LIFT ROD

M951483-0070A

CARTRIDGE

M910942-0070A

PUTTY PLATE

044912-0070A

MOUNTING NUT

M953465-YYY0A

PLASTIC DRAIN ASSEMBLY

M953450-YYY0A

METAL DRAIN ASSEMBLY

M964479-0070A

AERATOR (1.2 GPM)

M922917-0070A

AERATOR (0.5 GPM)

M953455-YYY0A

GRID DRAIN

- 4 -

HOT LINE FOR HELP

For toll-free information and answers to your questions, call:

1 (800) 442-1902

Mon. - Fri. 8:00 a.m. to 8:00 p.m. EST

Saturday 10:00 a.m. to 4:00 p.m. EST

IN CANADA 1-800-387-0369

(TORONTO 1-905-306-1093)

Weekdays 8:00 a.m. to 7:00 p.m. EST

IN MEXICO 01-800-839-1200

M965766 (8/16)

P-3 - SYMMONS 9602-XP

Origins

S-9600-P, S-9600TS-P, S-9601-P, S-9602-P

Operation & Maintenance Manual

Model Numbers

S-9600-P

Origins Shower Valve

S-9600TS-P

Origins Tub/Shower Valve

S-9601-P

Origins Shower System

S-9602-P

Origins Tub/Shower System

Modifications

-1.5 1.5 gpm (5.7 L/min) flow restrictor

-2.0 2.0 gpm (7.6 L/min) flow restrictor

-231 Super showerhead in place of Clear-Flo

-295 Institutional showerhead in place of

-SS Slip spout on any tub/shower unit

-X Integral service stops

-CHKS Integral check stops

-IPS 1/2” female IPS connections

-REV Reverse coring for back to back

-B Chrome brass escutcheon

-D Chrome brass dome cover

-VP Vandal proof escutcheon screws

-OP 13” oval plate

-L/HD Less showerhead

-TRM Trim only, valve not included

Clear-Flo

installations

™

Specification

S-9600-P/S-9601-P

Shower system powered by the Temptrol® Pressure

Balancing valve. Features adjustable stop screw to

limit handle turn, integrated volume control, 1 mode

showerhead with easy to clean rubber nozzles and

standard 2.5 gpm (9.5 L/min) ow restrictor. Components

made from metal and nonmetallic materials plated in

standard polished chrome nish.

S-9600TS-P/S-9602-P

Tub/shower system powered by the Temptrol® Pressure

Balancing valve. Features adjustable stop screw to limit

handle turn, integrated diverter, non-diverter tub spout, 1

mode showerhead with easy to clean rubber nozzles and

standard 2.5 gpm (9.5 L/min) ow restrictor. Components

made from metal and nonmetallic materials plated in

standard polished chrome nish.

Compliance

-ASME A112.18.1/CSA B125.1

-WaterSense 1.5 gpm (5.7 L/min)

2.0 gpm (7.6 L/min)

For California Residents

WARNING: This product contains chemicals known to

the State of California to cause cancer, birth defects, or

other reproductive harm.

Warranty

Limited Lifetime - to the original end purchaser in

consumer/residential installations.

5 Years - for industrial/commercial installations.

Refer to www.symmons.com/warranty for complete

warranty information.

Certied by

CSA Group

Note: Append appropriate -sufx to model number.

Loading...

Loading...