American Standard 6058.102, 6058.105, CERATRONIC Proximity Faucet User Manual

Installation InstructionsInstallation Instructions

(In Toronto Area only: 1-905-3061093)

CERATRONIC™

Proximity Faucet with Touch-Free

Temperature Control

To l ea rn m or e ab ou t A me ri ca n St an da rd Fa u ce ts v is it o ur w eb si te at : www.us.amstd.com or U.S.

customer's e-mail us at: faucetsupport@amstd.com

For Parts, Service, Warranty or other Assistance,

please call

1-800-442-1902 (In Canada: 1-800-387-0369)

NOTE TO INSTALLER: Please give this manual to the customer after installation.

(In Toronto Area only: 1-905-3061093)

Certified to comply with ASME A112.18.1M

© 2006 American Standard

M 9 6 8 8 5 7 R E V. 1.2

Product No.'s & Options

Specifications

How to Install

Electrical Hook-up

Operation

Maintenance

FAQ,s

Replacement Parts

1

2

2-3

4

5-6

6-8

8

9

PRODUCT NUMBERS

6058.105

6058.102

M 9 6 8 8 5 7 R E V. 1.2

Thank you for selecting American-Standard...the benchmark of fine quality for over 100 years . To

ensure that your installation proceeds smoothly--please read these instructions carefully before

you begin.

How to order the Selectronic Product

1. Choose Power Supply

2. Choose Desired Spout

UNPACKING

All American Standard Faucets Are Water Tested At Our Factory.

Some Residual Water May Remain In The Faucet During Shipping.

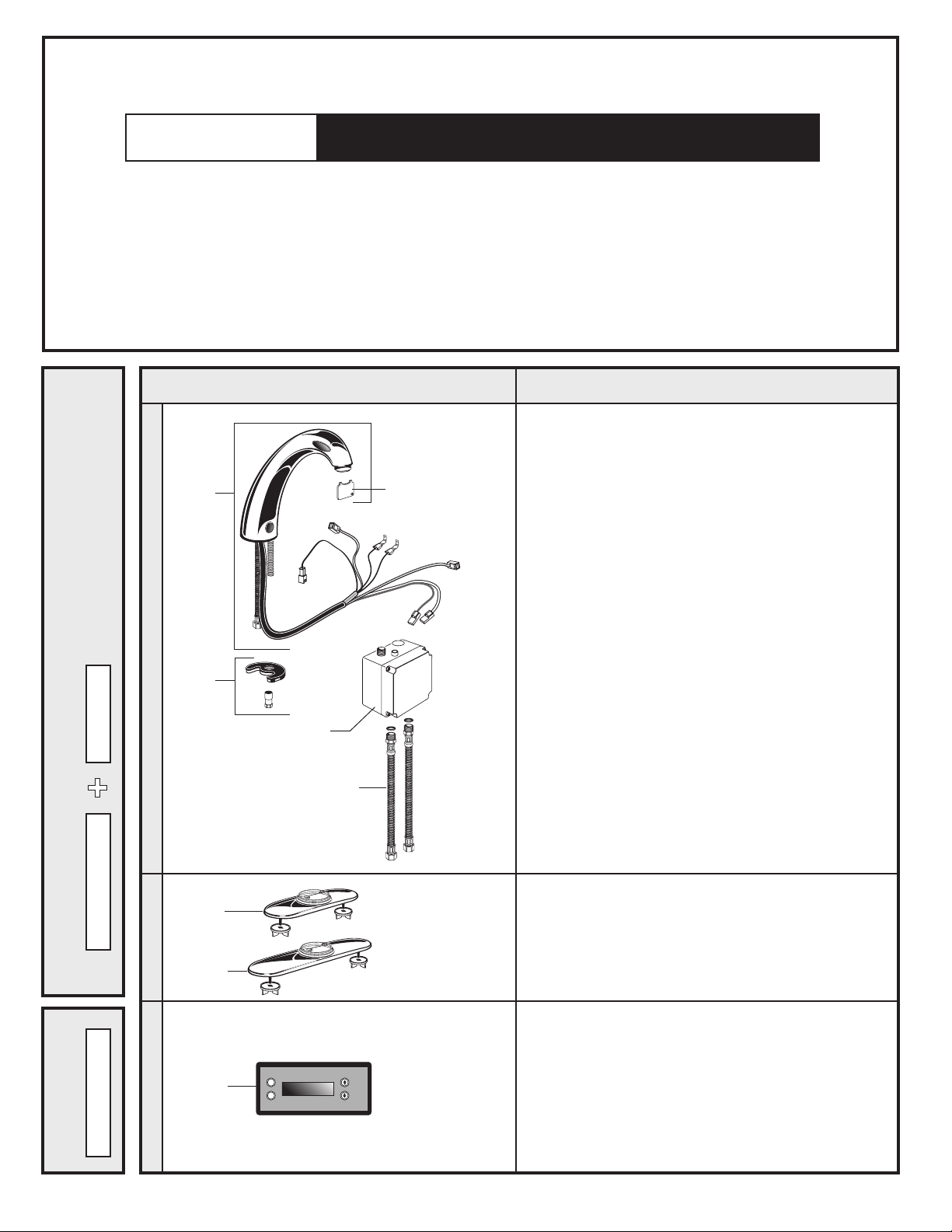

1. Remove the fitting and loose items from the carton. The illustration below shows the fitting

and all loose items after they have been removed from the carton. Some items may be

packaged partially assembled to other items.

1.Ceratronic Spout Assembly

2. Mounting Kit

3. Electrical Enclosure

4. Supply Hoses

Ceratronic

Lavatory Faucets

1

8

5. 4" Deck plate ( optional must be ordered separately)

6. 8" Deck plate ( optional must be ordered separately)

7. Optional Remote Control

8. Key for vandal resistant aerator

DescriptionPart Number

6058.105

Ceratronic Proximity Faucets

• Colored LED's signal temperature

change mode

• Cast spout

• Vandal resistant

• 0.5/gpm, 1.9L/min Spray

• Fully enclosed, water-resistant

• AC Plug-in Power supply included

• 3/8" SS compression flex hoses,

15" length

• Order deck plate and remote

control separately (optional)

• Single Hole Sink

• Hot and Cold Inlets

Base Product Deck Plate (optional)

• 1 and 3 Hole Sinks

• Hot and Cold Inletst

Remote Control

2

Deck Plate Base Product

5

6

Remote Control

7

6058.102

Same as above

• 2.2 gpm/8.3L/min. aerator

3

4

605P400

605P800

605XRCN

Val

Can

4" Deck plate, cast brass

• 1/4" fixation bolts at 4" centers;

Spin nuts

8" Deck plate

• Cast brass

• 1/4" fixation bolts at 8" centers;

Spin nuts

Optional Remote Control

• Change functions or adjust

setup parameters

• Battery Powered

• Can be used to operate all

Selectronic™ fittings and fixtures

1

M 9 6 8 8 5 7 R E V. 1.2

9

7

10

8

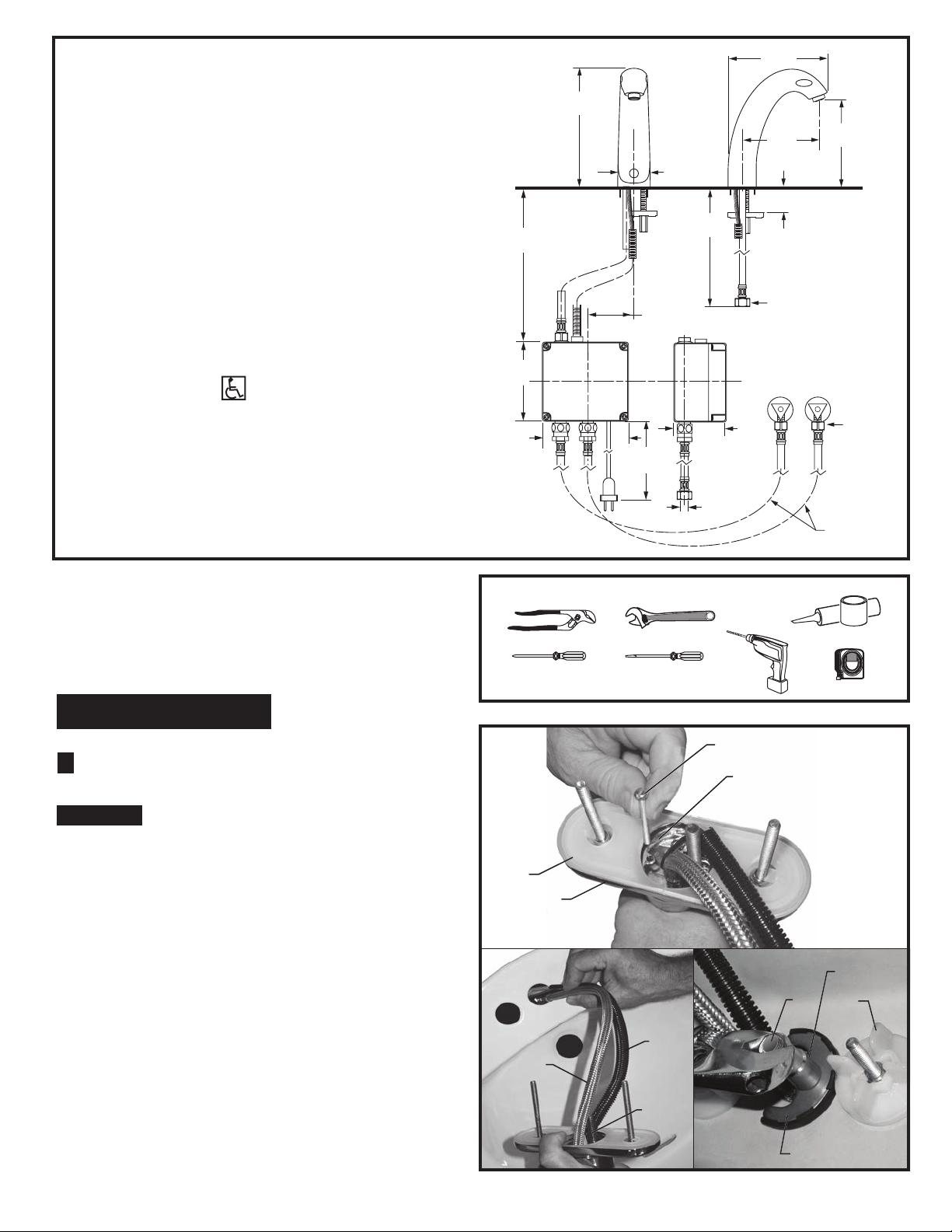

TOOLS REQUIRED

1 Channel Locks

2 Adjustable Wrench

3 Plumbers' Putty or

Caulking

4 Phillips Screwdriver

12 3

456 7

INSTALL SPOUT ASSEMBLY;

Fig. 1

INSTALLATION

CAUTION

Turn off hot and cold water

supplies before beginning

2

10'

1

Roughing-in Dimensions

1. (Optional) Assemble DECK PLATE (1) and PUTTY

PLATE (2) to FAUCET BODY (3) with SCREW (4). Fig.

1.

2. Insert WIRES (5), FLEX HOSE (6) and SPOUT

SHANK (7) through center hole of mounting surface.

Fig. 1a.

3. Assemble "C" WASHER (8) and LOCKNUT (9)

onto threads of SPOUT SHANK (7) from underside of

mounting surface. Fig. 1b.

4. Align FAUCET (3) and tighten LOCKNUT (9). If using

DECK PLATE (1) hand tighten DECK PLATE SPIN

NUTS (10) to secure FAUCET (3) to mounting surface.

Fig. 1b.

Fig. 1a

Fig. 1b

5

7

6

Fig. 1

GENERAL DESCRIPTION:

Electronic faucet with proximity operation. Colored

LED's signal temperature change mode. Vandal

resistant solid brass construction single post mounting.

Operates on AC permanent power. Water pressure

range from 20 to 80 psi. In-line strainer for solenoid is

integral. Single inlet 3/8 compression, built-in checks,

and flexible stainless steel 15" reach inlet hose for

spout connection.

114mm

(4-1/2)

270mm MAX.

(10-5/8)

175mm MAX.

(6-7/8)

1524 mm

(60)

125m m

(4-7/8)

3/8" COMP.

81mm

(3-3/16)

508mm

(20)

132m m

(5-3/16)

55mm D.

(2-3/16)

143m m

(5-5/8)

183m m

(7-3/16)

381mm

(15)

3/8"

COMP.

3/8"

COMP.

25mm MAX.

(1)

190m m

(7-7/16)

CODES AND STANDARDS:

These products meet or exceed the following coded

standards:

ANSI A117.1

ASME A112.18.1

CSA B 125

NSF 61/Section 9

ADA Compliant

5 Flat Blade Screwdriver

6 Electric Drill & 1/4" Drill Bit

7 Tape Measure

4

1

2

3

M 9 6 8 8 5 7 R E V. 1.2

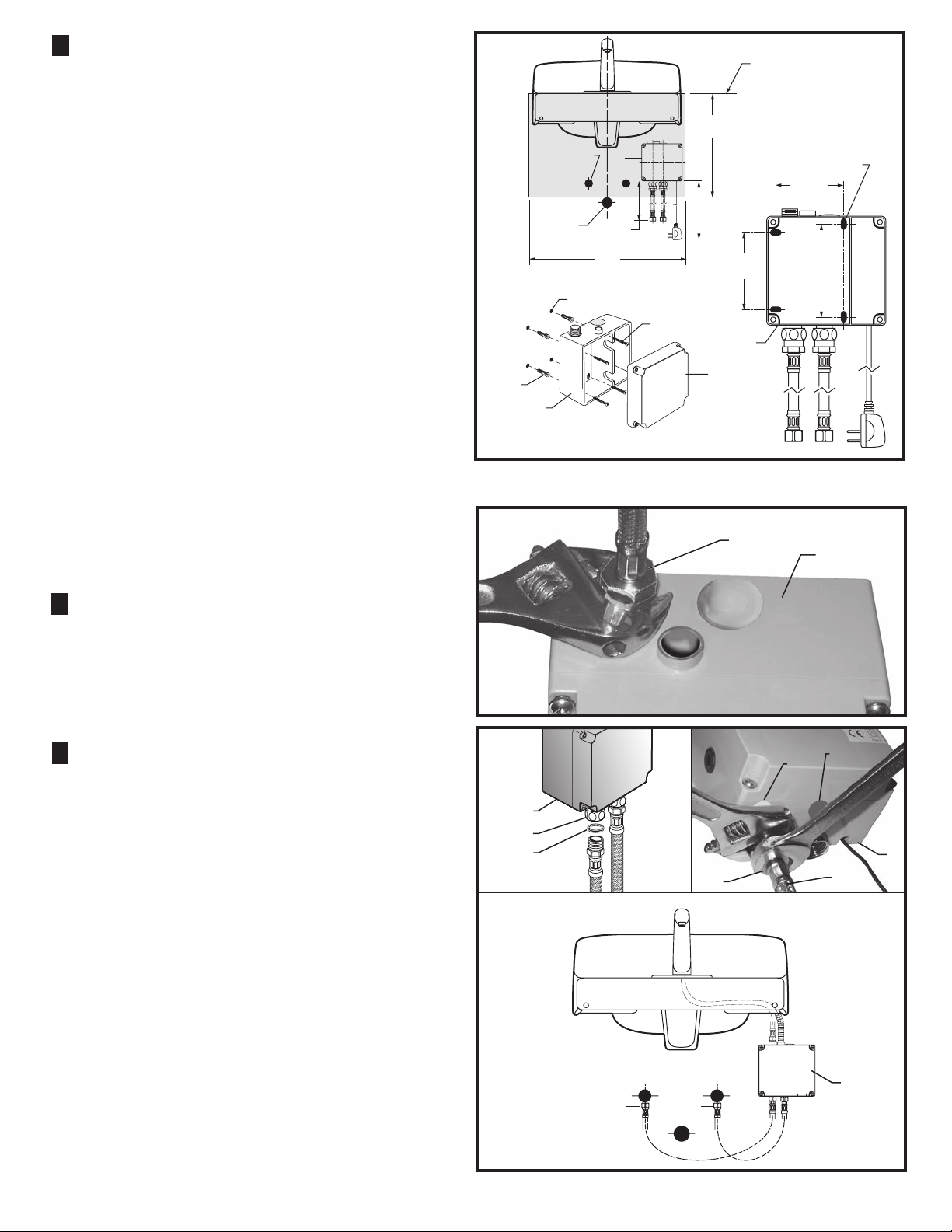

Fig. 2

1. Determine location of ENCLOSURE (1). It must be

located with-in the 14" (356mm) by 21" (533mm)

shaded area shown in Fig. 2 in order for electrical

connections from the spout assembly to be made.

NOTE: ENCLOSURE SUPPLY HOSE is 20". Distance

between wall supply and ENCLOSURE (1) must be

taken into consideration.

2. Remove 4 screws from COVER (2) and pull off

COVER (2). Hold the ENCLOSURE (1) in desired

location and mark the four mounting hole locations as

shown. Fig. 2.

3. The ENCLOSURE (1) works best if secured to a wall

stud or cross brace within the wall, using the SCREWS

(3) supplied. If the ENCLOSURE (1) is to be installed on

a tile or plaster wall the ANCHORS (4) and SCREWS

(3) should be used.

4. For installations on drywall or tiled walls; use

ANCHORS (4) and SCREWS (3) for securing

ENCLOSURE (1) to finished wall. Drill four 1/4" dia.

holes a minimum of 1-3/4" deep. Insert the four

ANCHORS (4) flush with face of the finished wall.

Align the ENCLOSURE (1) and Install the MOUNTING

SCREWS (3). Tighten to secure ENCLOSURE (1) to

mounting surface.

1524mm

(60)

14"

(356mm)

3-3/4"

(96mm)

2-3/4"

(71mm)

3"

(76mm)

21"

(mm)

2

4

3

1

1

1

20"

(500mm)

MOUNTING HOLES

SUPPLIES

WASTE

ENCLOSURE

MOUNTING

HOLES

LAVATORY R IM OR

MOUNTING SURFACE

3

MOUNT ENCLOSURE; Fig. 2

2

1. Connect SUPPLY NUT (1) from spout assembly to

nipple on top of ENCLOSURE (2). Tighten with

adjustable wrench to make a water tight connection.

Fig. 3.

CONNECT SPOUT HOSE TO

ENCLOSURE; Fig. 3

CONNECT HOSES TO WALL

SUPPLY; Fig. 4

3

4

3

33

Fig. 4 Fig. 4a

2

2

2

1

4

1

1. Insert FIBER WASHERS (4) into SUPPLY NUTS (1)

on ENCLOSURE (2). Fig. 4.

2. Connect SUPPLY NUT (1) on ENCLOSURE (2) to

FLEXIBLE SUPPLY HOSE (3). Tighten to make a

water tight connection. Use two wrenches if necessary.

Fig. 4a.

3. Connect FLEXIBLE SUPPLIES (3) corresponing to the

red dot on ENCLOSURE (2) to the hot water supply,

and the FLEXIBLE HOSE (3) corresponding to the blue

dot to cold water supply. Connection on FLEXIBLE

SUPPLIES (3) are 3/8" compression. Use adjustable

wrench to tighten connection. Do not over tighten.

FIG. 4b.

Note: FLEXIBLE SUPPLY (3) measures 20" from the

bottom of the ENCLOSURE (2) base. If additional

supply length is required, installer must purchase

parts separately.

Important: If FLEXIBLE SUPPLIES (3) are too long, loop

to avoid kinking.

COLD

RED

DOT

BLUE

DOT

COLD

HOT

HOT

Fig. 4b

Fig. 3

1

2

M 9 6 8 8 5 7 R E V. 1.2

Loading...

Loading...