American Standard 6045SM013, 6045SM051, 6045SM101 Installation Manual

FLUSH VALVE

Exposed Urinal Flushometer

with Side-Mount Operator

for 3/4" Top Spud Urinals

OPERATING PRESSURE:

• 20 psi (owing) - 80 psi (static)

MODEL NUMBERS

6045SM013

6045SM051

6045SM101

FLOW REQUIREMENT:

• 10gpm (37.9 L/min).

** Water pressure over 80 psi is not

recommended with most plumbing xtures

Installation Instructions

Certied to comply with:

• ASSE 1037

• ANSI/ASME A112.19.2

• ADA Compliant

NOTE TO INSTALLER: Please give this manual to the customer after installation.

To learn more about American Standard Products visit our website at: www.americanstandard-us.com

or e-mail us at: CRTTEAM@americanstandard.com

For Parts, Service, Warranty or other Assistance,

please call (844) CRT-TEAM / (844) 278-8326 (In Canada: 1-800-387-0369)

(In Toronto Area only: 1-905-306-1093)

© 2017 AS America Inc.

1

M965832 (6/17)

Thank you for selecting American Standard...the benchmark of ne quality for over 100 years. To ensure

that your installation proceeds smoothly--please read these instructions carefully before you begin.

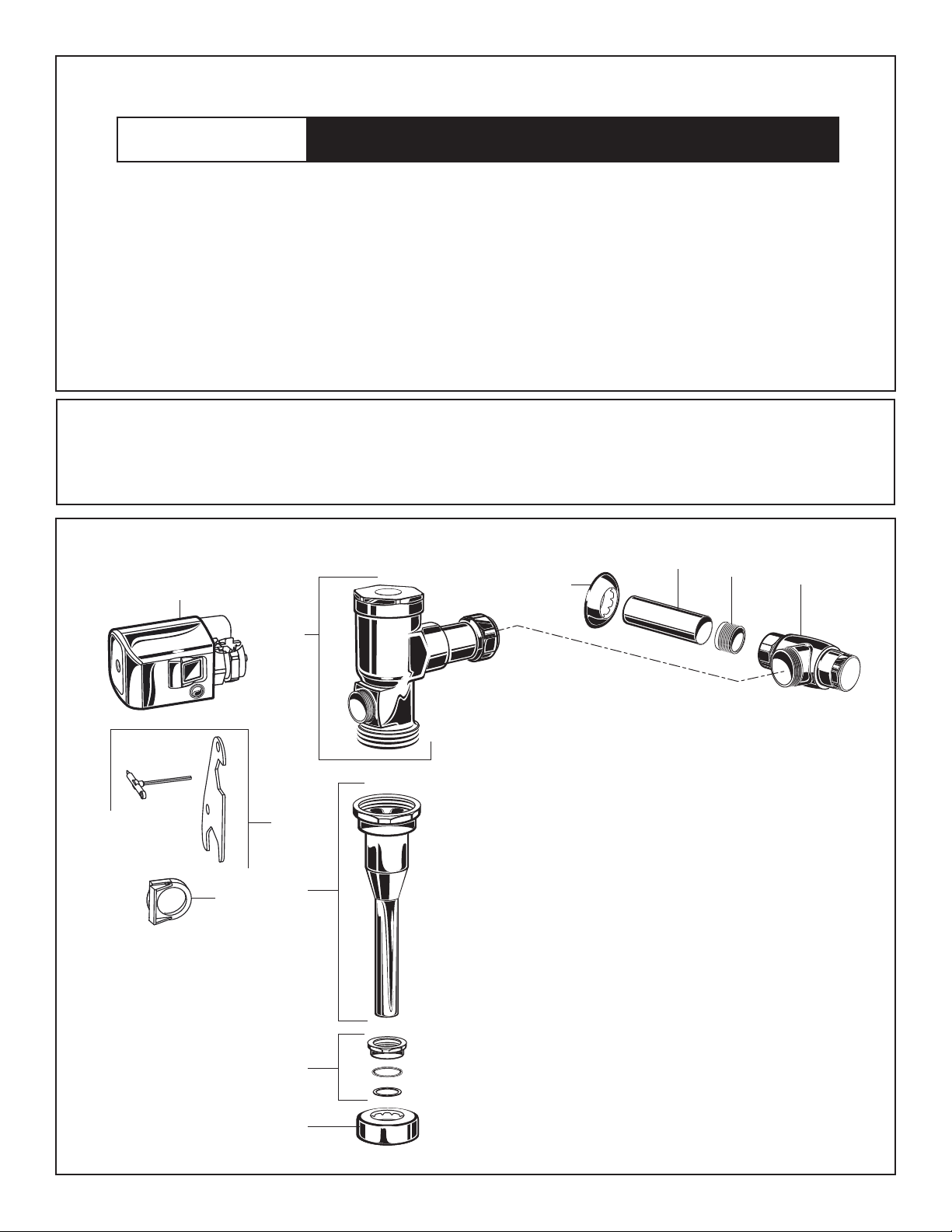

UNPACKING

1. Remove the Flush Valve items from the carton. The illustration below shows all items

after they have been removed from the carton. Some items may be packaged partially

assembled to other items.

1. Flush Valve Assembly

2. Vertical Tube and Vacuum Breaker

3. Spud Coupling Nut and Washers

4. Spud Flange

5. Sweat Adapter

All American Standard Products Are Water Tested At Our Factory.

Some Residual Water May Remain In The Valve During Shipping

6. Cover Tube

7. Wall Escutcheon

8. Supply Stop

9. Side-Mount Operator

10. Wrench Kit

11. Angle Locking Ring

CARE INSTRUCTIONS:

DO: CLEAN WITH CLEAR WATER. DRY WITH A SOFT COTTON FLANNEL CLOTH.

DO NOT: DO NOT CLEAN THE PRODUCT WITH SOAPS, ACID, POLISH, ABRASIVES, HARSH CLEANERS, OR A

CLOTH WITH A COARSE SURFACE.

6

9

7

5

8

11

1

10

2

3

4

2

M965832 (6/17)

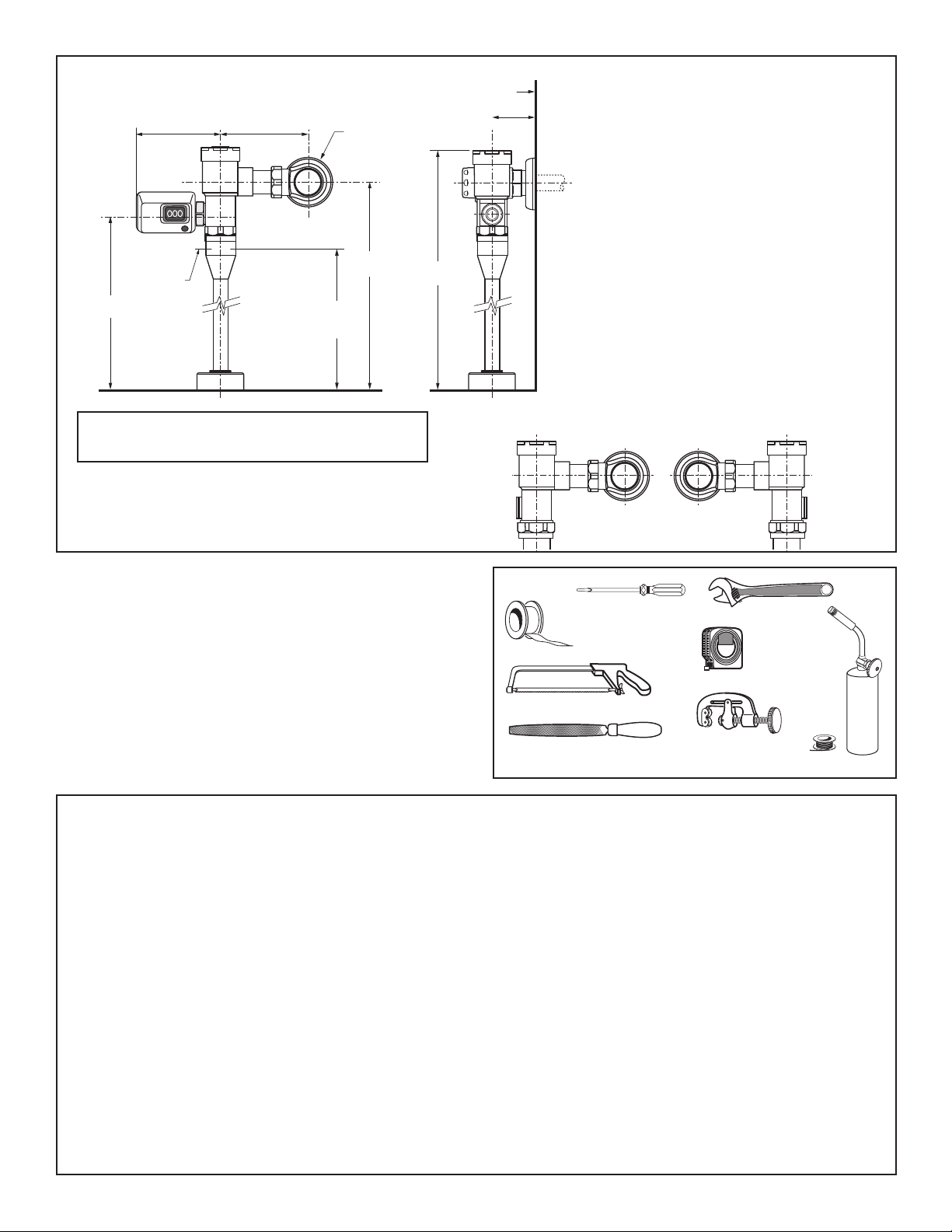

Roughing-in Dimensions

Fig.1

108 mm-133 mm

(4-1/4" to 5-1/4")

-C-L-

3/4" VACUUKM

BREAKER SHOWN

253 mm

(9-15/16")

147 mm

(5-13/16")

*CRITICAL

LEVEL

152 mm

(6)

(Min.)

SUPPLY

DN 19 mm

(3/4" I.P.S.

For 3/4"

Top Spud)

295 mm

(11-1/2")

FINISHED WALL

38 mm-127 mm

(1-1/2-5")

135 mm

(13-1/2")

-C-L-

GENERAL DESCRIPTION

MANUAL FLUSH VALVE, 0.5 GPF

Exposed Flushometer

for 3/4" Top Spud Fixtures

• 20 psi (owing) - 80 psi (static)

FLOW REQUIREMENT:

• 10gpm (37.9 L/min).

** Water pressure over 80 psi is not

recommended with most plumbing xtures

*Note: The Critical Line (-C-L-) on Vacuum Breaker

must typically be 6

Consult Codes for details.

" (152mm) minumim above fixture.

See (Section 8) for converting

Flush Valve to Left Hand Installation.

RECOMMENDED TOOLS; Fig. 2

1. Teon Tape

2. Flat Blade Screwdriver (For adjusting Supply Stop)

3. Adjustable Wrench

4. Tape Measure

5. Hacksaw

6. Tubing Cutter

7. File

8. For Sweat Connection; Solder and Torch

PRIOR TO INSTALLATION

Note: Prior to installing the Flush Valve the following

items must be installed.

1. Urinal

2. Drain line

3. Water supply line

IMPORTANT:

• All plumbing must be installed in accordance with

applicable codes and regulations.

• The use of water hammer arrestors is strongly

recommended for commercial applications. All

piping behind the walls should be properly secured

and fastened.

• Water supply lines must be sized to provide an

adequate volume of water for each xture.

Right or Left Hand Installation

Fig.2

1

2

10'

4

3

5

7

• Flush all water lines prior to operation

(See Step 5). Dirt and debris can cause ush

valve to run continuously.

• With the exception of Supply Stop Inlet,

DO NOT use pipe sealant or plumbing grease

on any valve component or coupling!

• Protect the chrome or special nish on the

Flushometer. DO NOT USE toothed tools on

nished surfaces to install or service these

valves. Also see “Care and Cleaning” section

of this manual.

• This product contains mechanical and/or

electrical components that are subject to

normal wear. These components should be

checked on a regular basis and replaced as

needed to maintain the valve’s performance.

6

8

3

M965832 (6/17)

Loading...

Loading...