American Standard 50A50-405, 50A50-406, 50A50-471, 50A50-472, 50A50-473 Operation Manual

...

40” Residential Gas

40” Residential Gas

Furnace Operation

Furnace Operation

© American Standard Inc. 1999

© American Standard Inc. 1999

• Model Evolution/Nomenclature

• Model Evolution/Nomenclature

• Heating Sequence of Operation

• Heating Sequence of Operation

• Schematics

• Schematics

• Ignition Systems

• Ignition Systems

• Service/Troubleshooting

• Service/Troubleshooting

1

Preface

Air Conditioning and heating service technicians

must have a working knowledge of basic electrical and

refrigeration service procedures. In order to service

gas furnaces, a thorough understanding of the units

sequence of operation is essential. This publication is

based on White-Rogers controls and provides the

narrative and schematic drawingsnecessary to

provide this understanding for thesefurnaces. Also

included is a description of operating principles of

different ignition systems.

Contents

Model Evolution .......................................................................................................................................................... 3

Model Nomenclature .................................................................................................................................................. 4

Component Identification – ✽UD/✽DD-R Models ...................................................................................................... 5

Component Identification – ✽UY/✽DY-R Models ....................................................................................................... 6

Integrated Furnace Controls (I.F.C.) ............................................................................................................................ 7

Self Diagnostic Features 50A50 and 50A51 ............................................................................................................... 9

Integrated Furnace Control Timing ............................................................................................................................ 10

Abnormal Furnace Operation – 50A50 and 50A51 .................................................................................................... 11

Single Stage 50A50 Sequence of Operation.............................................................................................................. 14

Wiring Schematic – Single Stage 50A50 Integrated Furnace Control ...................................................................... 15

Two Stage 50A51-405 Sequence of Operation .......................................................................................................... 16

Wiring Schematic – Two Stage Heat 50A51-405 Integrated Furnace Control ......................................................... 17

Two Stage Variable Speed Sequence Of Operation .................................................................................................. 18

Wiring Schematic – Two Stage Variable Speed 50A51-505/50A51-506 Integrated Furnace Control ..................... 19

Integrated Control Quick Reference ........................................................................................................................... 20

Furnace ECM

TM

ECM

Schematic – Motor Control Board .............................................................................................................................. 24

Flame Rectification Principle – Measurement ........................................................................................................... 25

Flame Current Tester/Simulator ................................................................................................................................. 26

Combustion Air Pressure Switch Check – Measurement ......................................................................................... 27

Furnace Pressure Switch Settings .............................................................................................................................. 28

Gas Valves .................................................................................................................................................................... 29

✽ Models maybe an A or T or F continued

TM

2 Motor Operation ............................................................................................................................. 21

2 Variable Speed Furnace Motor Quick Check ............................................................................................... 22

Note: This publication is general in nature and is intended for

INSTRUCTIONAL PURPOSES ONLY. It is not to be used for

equipment selection, application, installation, or specific service

procedures.

1

Contents

Manifold Pressure Settings ......................................................................................................................................... 31

Direct Vent Manifold Pressure Check ......................................................................................................................... 32

Determining Natural Gas Furnace Input .................................................................................................................... 33

Single Stage Twinning Kit ........................................................................................................................................... 34

Field Wiring Diagrams – Single Stage and Two Stage Thermostats ....................................................................... 35

Two Stage Twinning Kit .............................................................................................................................................. 36

Fields Wiring Diagram – Twinning ✽UD-R Furnaces ................................................................................................. 37

Single Wire Twinning – For Models with Twin Terminals ......................................................................................... 38

Radiant Sense Ignition Controls ................................................................................................................................. 39

Identifying Radiant Sense Controls ............................................................................................................................ 40

Radiant Energy Sensor................................................................................................................................................ 41

50A52-100 Sequence of Operation ............................................................................................................................. 42

Wiring Schematic – Version 1 Radiant Sense Control .............................................................................................. 43

50A52-100 Sequence of Operation ............................................................................................................................. 44

Wiring Schematic – Version 2 Radiant Sense Control .............................................................................................. 45

– continued

50A52-100 Sequence of Operation ............................................................................................................................. 46

Wiring Schematic – Version 3 Radiant Sense Control .............................................................................................. 47

50A52-100/101/102 Sequence of Operation ............................................................................................................... 48

Wiring Schematic – Version 4 Radiant Sense Control .............................................................................................. 49

Troubleshooting Procedures ....................................................................................................................................... 50

• 50A50 Flow Chart 1 ................................................................................................................................................. 51

• 50A50 Flow Chart 2 .................................................................................................................................................. 52

• 50A50 Flow Chart 3 ................................................................................................................................................. 53

• 50A50 Flow Chart 4 ................................................................................................................................................. 54

• 50A50 Flow Chart 5 ................................................................................................................................................. 55

• 50A51 Flow Chart 1 .................................................................................................................................................. 56

• 50A51 Flow Chart 2 .................................................................................................................................................. 57

• 50A51 Flow Chart 3 .................................................................................................................................................. 58

• 50A51 Flow Chart 4 .................................................................................................................................................. 59

• 50A51 Flow Chart 5 .................................................................................................................................................. 60

• 50A52 Flow Chart 1 .................................................................................................................................................. 61

• 50A52 Flow Chart 2 .................................................................................................................................................. 62

• 50A52 Flow Chart 3 .................................................................................................................................................. 63

• 50A52 Flow Chart 4 .................................................................................................................................................. 64

Legends – System Wiring ........................................................................................................................................... 65

✽ Models maybe an A or T or F

2

40" Residential Gas Furnace Evolution

Third Quarter 1991 – ✽UD-R and ✽UD-C 40" induced draft upflow models introduced to replace the TUD-B

linear burner upflow models.

Second Quarter 1992 – ✽DD-R and ✽DD-C 40" induced draft downflow/horizontal models introduced to

replace the TDD-B linear burner downflow models and the THP, THS and THD series

horizontal models.

Second Quarter 1993 – ✽UE 40" single stage radiant sense ignition model introduced.

Third Quarter 1993 – ✽UC-C and ✽DC-C 40" condensing models introduced to replace the TUC-B and TDC-B

linear burner condensing models. (✽UC-C models convert to horizontal left, ✽DD-C

models convert to horizontal right.)

Fourth Quarter 1993 – ✽DE 40" single stage radiant sense ignition models introduced.

Second Quarter 1994 – ✽UX-C and ✽DX-C 40" direct vent condensing models introduced to replace the

✽UX-B and ✽DX-B linear burner direct vent models.

Third Quarter 1994 – TUJ-A 40" radiant sense ignition model introduced. Model converts to horizontal left

or horizontal right and is shipped without bottom panel and filter. Model discontinued

third quarter 1995.

Fourth Quarter 1994 – ✽UY-R-V 40" two-stage, direct vent variable speed condensing models introduced to

replace the TUC/TDC-B-V variable-speed models.

Second Quarter 1995 – ✽DD-C-C Downflow/Horizontal and ✽UD-C-H Upflow/Horizontal models introduced.

Previous upflow models were for upflow applications only. The ✽UD-C-H and TUE-A-H

models are also approved for horizontal installation. The ✽DD-C-C and ✽UD-C-H

models are equiped with the “enhanced” integrated furnace control with 120 VAC

humidifier output, adaptive hot surface ignitor timing and improved fault tolerances.

First Quarter 1996 – TUE/TDE-A-K up graded to 80% AFUE. These models have remote flame rectification

ignition control systems.

Fourth Quarter 1997 – Introduced the Silicon Nitride Ignitor and appropriate controls.

For all models equipped with the Silicon Nitride

Hot Surface Ignitor, see Pub. No. 34-3405.

✽ Models maybe an A or T or F

3

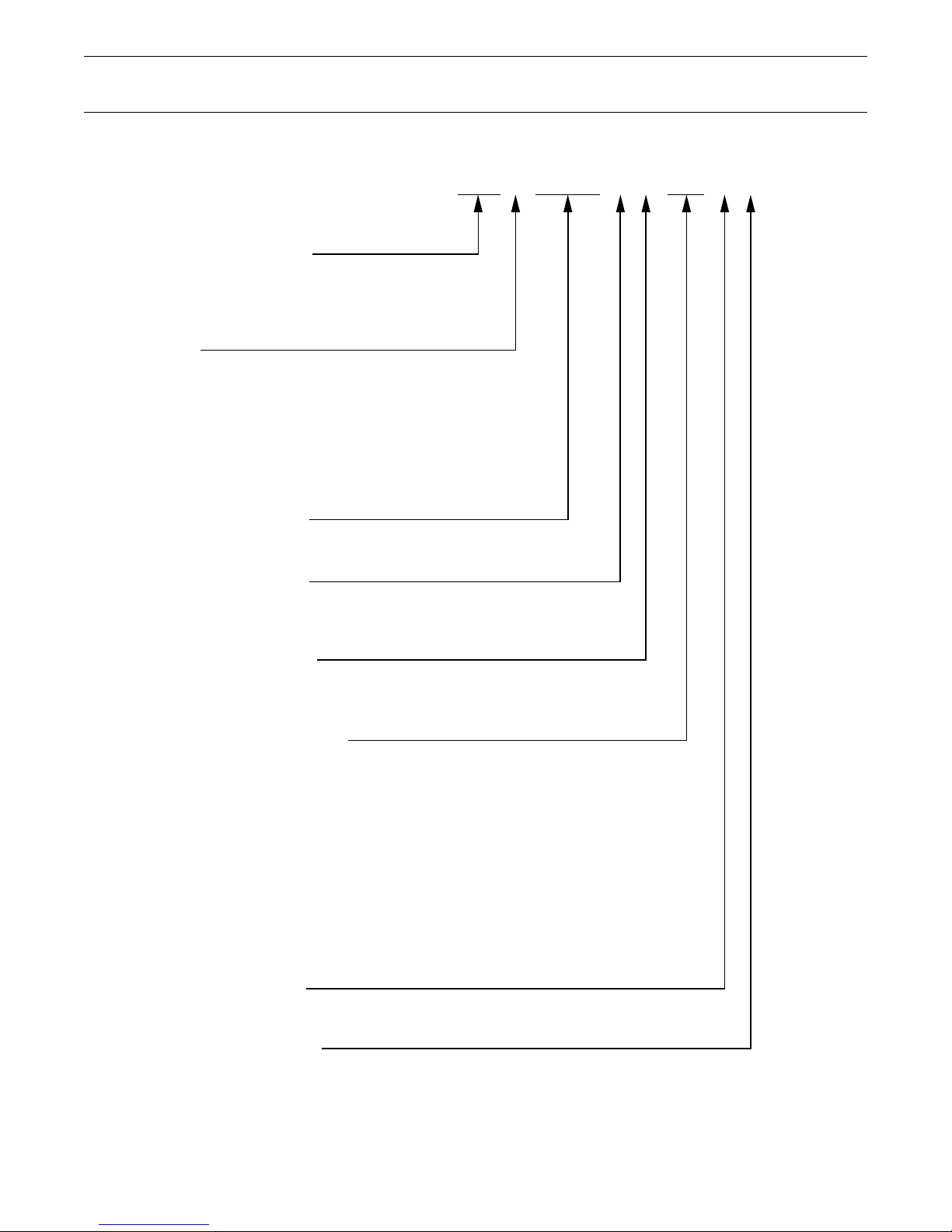

Model Nomenclature

Furnace Configuration

U = Upflow

U = Upflow/Horizontal

D = Downflow/Horizontal

Type

C = Condensing – 90% AFUE

D = Induced Draft – 80% AFUE

E = 78%/80% AFUE

X = Direct Vent Condensing

Y = Direct Vent Condensing Variable-Speed

A =

J =

Heating Input MBTUH

Example: 040 = 40,000 MBTUH

Major Design Change

C = Single Stage

R = Two Stage

78%/80% AFUE Cumberland

}

✽ UC040C924A

1

Power Supply and Fuel

115 Volt

Natural Gas

Airflow Capacity for Cooling

18 = 1 1/2 Tons 42 = 3 1/2 Tons

24 = 2 Tons 48 = 4 Tons

30 = 2 1/2 Tons 60 = 5 Tons

36 = 3 Tons

Example: 24 MBTUH = 2 Tons

400 CFM per Ton

2 Tons x 400 CFM/Ton = 800 CFM

V3 = 2 1/2 – 3 1/2 Tons, Variable Speed Motor

V4 = 3 – 4 Tons, Variable Speed Motor

V5 = 3 – 5 Tons, Variable Speed Motor

Minor Design Change

H = Horizontal (Upflow/Horizontal Models Only)

Product Service Change

Part I.D.

✽ First letter may be A or T or F

4

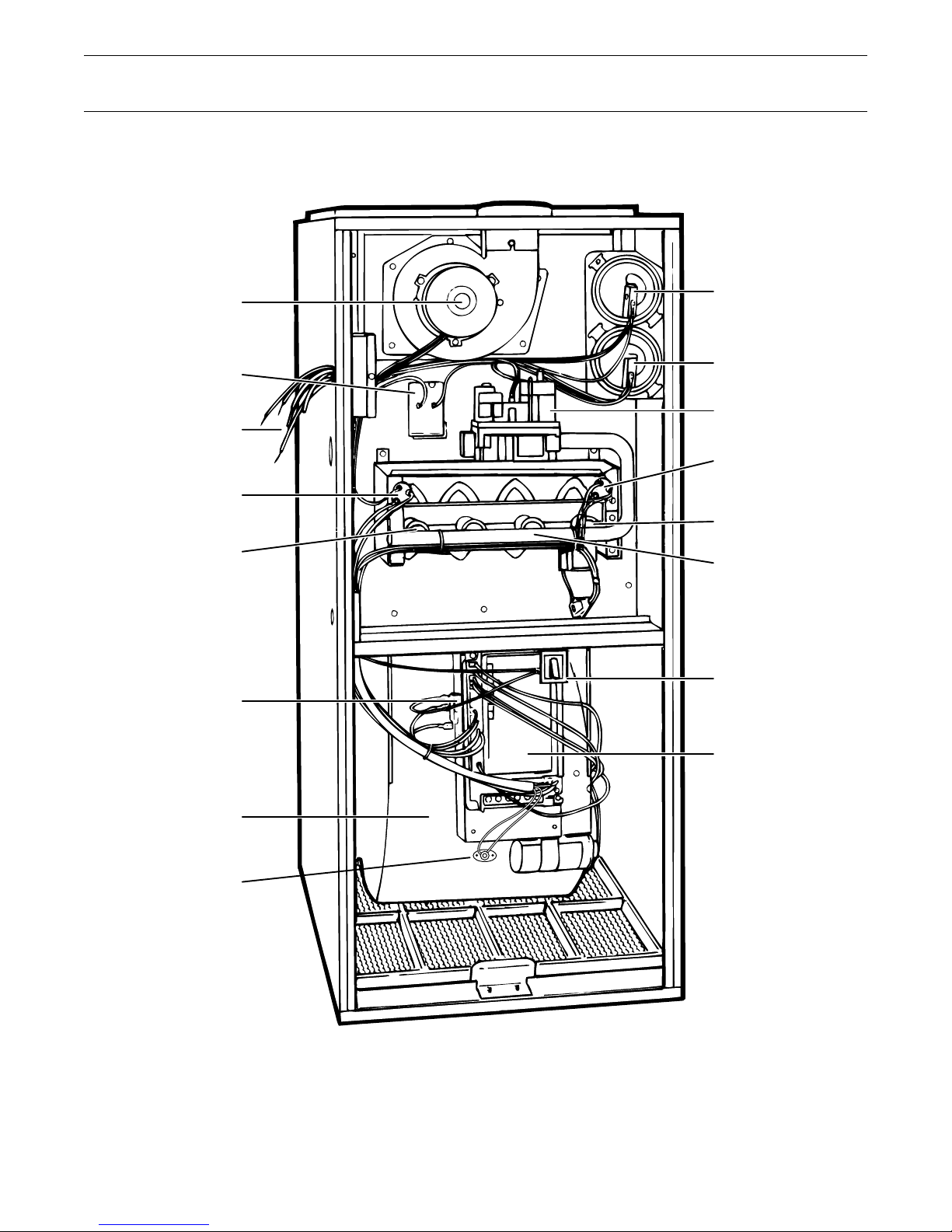

Component Identification – ✽UD/✽DD-R Models

INDUCED DRAFT

BLOWER (2 SPEED)

HIGH TEMPERATURE

LIMIT (TCO)

HIGH VOLTAGE

AND ACCESSORY

HOOK-UP

FLAME ROLL-OUT

MAY BE A FUSE LINK

OR A BIMETAL SWITCH

FLAME SENSOR

TRANSFORMER

1ST STAGE

PRESSURE SWITCH

2ND STAGE

PRESSURE SWITCH

GAS VALVE

(2 STAGE)

FLAME ROLL-OUT

MAY BE A FUSE LINK

OR A BIMETAL SWITCH

HOT SURFACE

IGNITOR

INSHOT BURNER

DOOR SWITCH

DIRECT DRIVE

BLOWER

REVERSE FLOW

SWITCH TCO-B

✽ Models maybe an A or T

INTEGRATED

FURNACE CONTROL

5

Component Identification – ✽UY/✽DY-R Models

HIGH TEMPERATURE

LIMIT SWITCH

BURNER

SIGHT GLASS

ELECTRICAL

JUNCTION BOX

2ND STAGE

PRESSURE SWITCH

1ST STAGE

PRESSURE SWITCH

LINE CHOKE

(NOT ON ALL MODELS)

TRANSFORMER

FLAME ROLL-OUT

SWITCH

(MANUAL RESET)

2 STAGE

GAS VALVE

INDUCED DRAFT

BLOWER

(2 SPEED)

TCO (LIMIT)

DOOR SWITCH

TM

MOTOR

ECM

CONDENSATE

TRAP

✽ Models maybe an A or T

IGNITION

CONTROL

TM

INTERFACE

ECM

BOARD

(MOTOR ONLY)

6

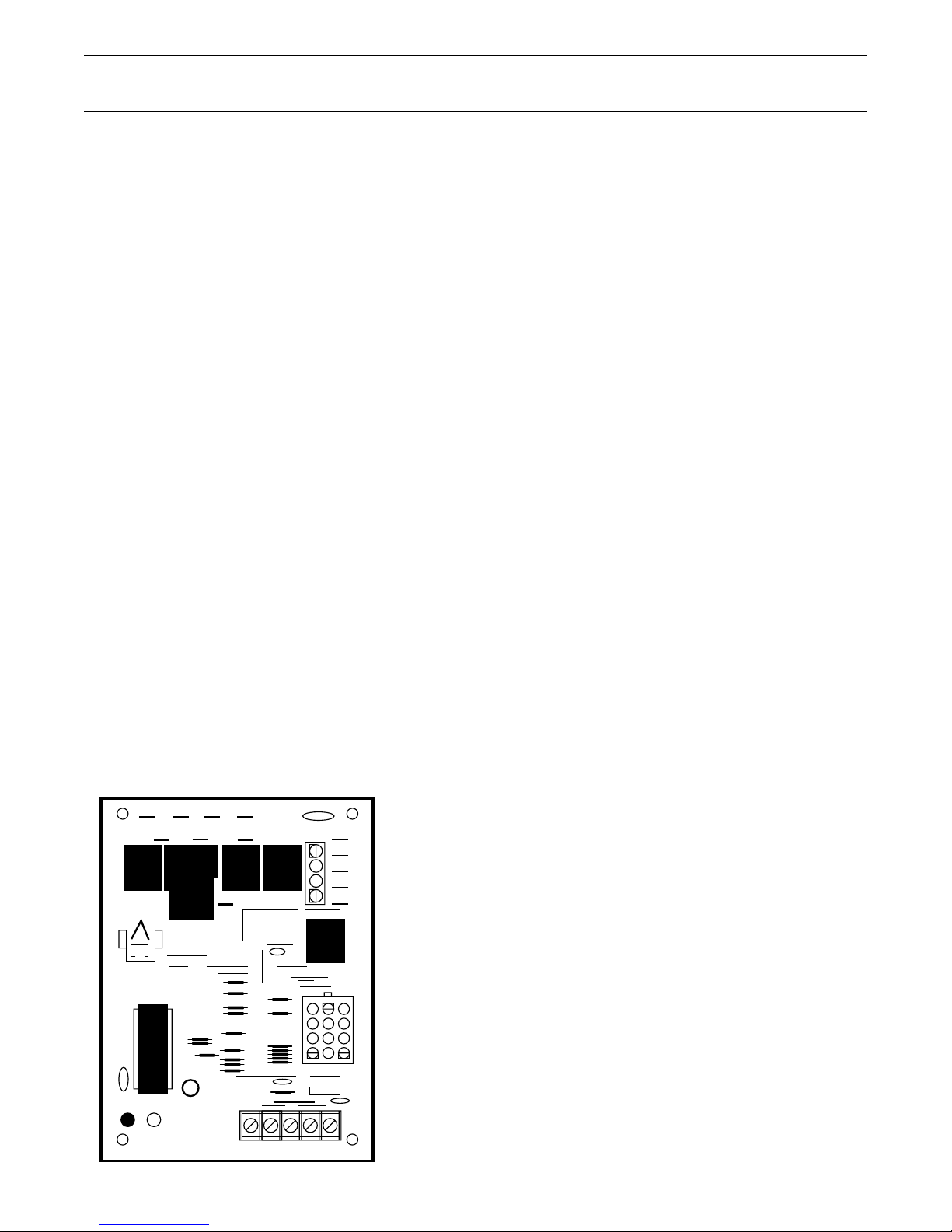

White-Rodgers Integrated Furnace Controls –

50A50 & 50A51 Series

The White-Rodgers Integrated Furnace Control (I.F.C.)

is an automatic ignition control module that uses

microcomputer based circuitry to continuously monitor,

analyze and control the proper operation of the gas

burner, induced draft motor and indoor blower. The

microcomputer provides continuous surveil-lance of

the thermostat, flame sensor and safety devices to

initiate automatic gas burner ignition and shutoff

sequences during normal, or fault condition operation.

There are currently several versions of the White-Rodgers

50A50/50A51 Integrated Furnace Controls:

1. 50A50 Series -405 Single-Stage controls are used in

✽UD/✽DD-C-A, B and FCA/FUA-A-A.

2. 50A50 Series -406 Single-Stage controls are used in

✽UC/✽DC-A & B and ✽UX/✽DX-C-A.

3. 50A50-471 and 473 Single-Stage used in ✽UD-C-H

and ✽DD-C-C.

4. 50A50-472 and 474 Single-Stage used in ✽UC/

✽DC-C-C.

5. 50A50-571 Single-Stage used in ✽UE/✽DE-A-K,

FUA- and FCA-E and is part of the up-grade

control system for Radiant Sense Controls,

Part No. KIT 3793.

6. 50A51 Series -405 or -495 Two-Stage used in

✽UD/✽DD-R.

7. 50A51-506 Two-Stage Variable-Speed used in

✽UD/✽DD-R9V. 50A51-505 superseded by 50A51-506

after October 1995.

8. 50A51-506 Two-Stage Variable-Speed used in

✽UY/✽DY-R9V.

9. 50A51-507 Two-Stage Variable-Speed used on all

Variable-Speed models after September 1996.

✽ First letter may be A or T or F

Note: Control models 50A50-406/472 and 474 and

50A51-405/-495/-505/-506/-507 provide on-board

relay switching of 120V AC system power for the

optional humidifier and electronic air cleaner accessories.

Control models 50A50-471/473 provides on-board

relay switch-ing of system power for the optional

humidifier accessory only.

During heating cycles, the Control provides on-board relay

switching of 120V AC system power for the

induced draft motor, hot surface ignitor and 24V AC power

for the gas valve. During heating and cooling cycles, the

Control provides on-board relay switching of system power

for the indoor blower motor.

Fan On

When the thermostat fan switch is in the ON position,

24V AC is applied from the thermostat “G” terminal

to the I.F.C. Control “G” terminal.

The “G” call to the I.F.C. control will cause it to energize

an internal relay coil. This relay’s switch will close,

energizing the indoor blower.

On single stage controls, the blower will run on

Heating Speed. On Two-Stage I.F.C. controls, the

blower will run on the low Heating Speed. On

Variable-Speed models, the “G” call to the blower

motor will signal it to run at 50% of the programmed

cooling CFM speed.

Cooling Air Flow

When the thermostat system switch is in the COOL

position and the thermostat calls for cooling, 24V AC

is applied from the thermostat “Y” terminal to the

I.F.C. Control “Y” terminal.

The “Y” call to the I.F.C. Control will cause it to

energize an internal relay coil. This relay switch will close

energizing the indoor blower on the cooling speed tap.

The I.F.C. control’s fan speed relays are inter-locked to

prevent power from being applied to two blower motor

speed taps at the same time. On Variable-Speed models,

the “Y” call to the blower motor will signal it to run at

80% of the programmed cooling CFM Speed. Note:

Y and BK must be jumper or humidistat connected to

BK to get 100%.

If the “Y” connection is not made to the Control,

the indoor blower will run on heating speed during a

cooling cycle.

Cooling Blower Delay to Off

The Control provides an optional indoor blower off

delay of 80 seconds in cooling cycles. The off delay is

field selectable by adjusting Dip-Switch 1 to OFF

except 50A50-571 Control. A jumper wire must be cut.

Dip-Switch 1 must be in the ON position always on

variable speed furnace models using 50A51-505/-506/-507

Controls. See Furnace ECM

TM

2 Motor Operation.

7

2

A

White-Rodgers Integrated Furnace Controls –

50A50 & 50A51 Series

Heating Blower On and Off Delay

These controls provide a fixed 45 second indoor “blower

on” delay after the flame is sensed during heating

cycles. After this time delay, the indoor blower

motor will be energized to run on heating speed. The

Control also provides an indoor “blower off” delay.

The 50A50-571 I.F.C. delay to off is not adjustable,

all other 50A50 and 50A51 controls have field

adjustable delays to off. The off delay time is field

selectable by adjusting Dip-Switches 2 and 3 on

the Control.

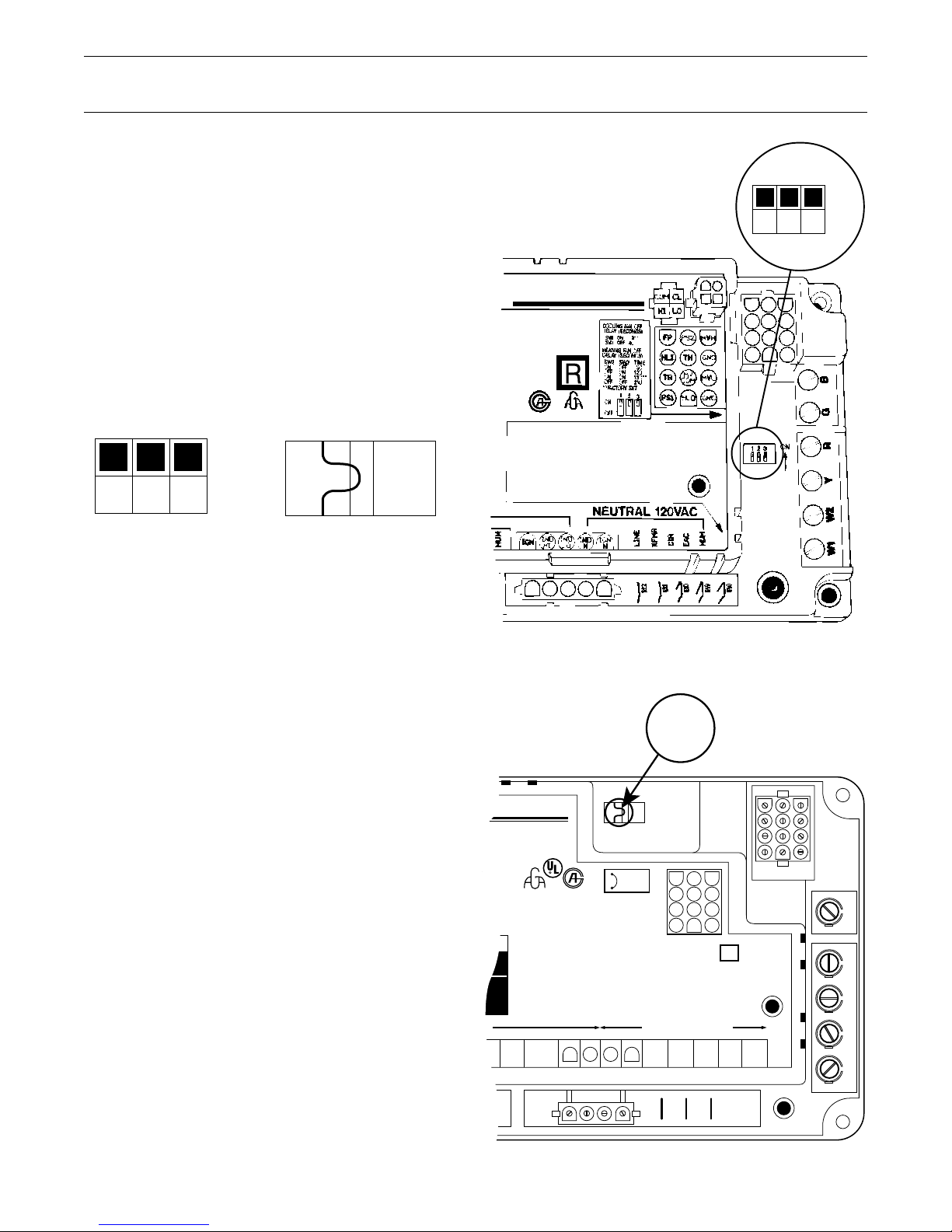

Dip-Switch Settings or Jumper Wire

123

ON

OFF

Cooling Fan Off Delay (seconds)

Switch 1/Jumper ON = 0 (Factory Setting)

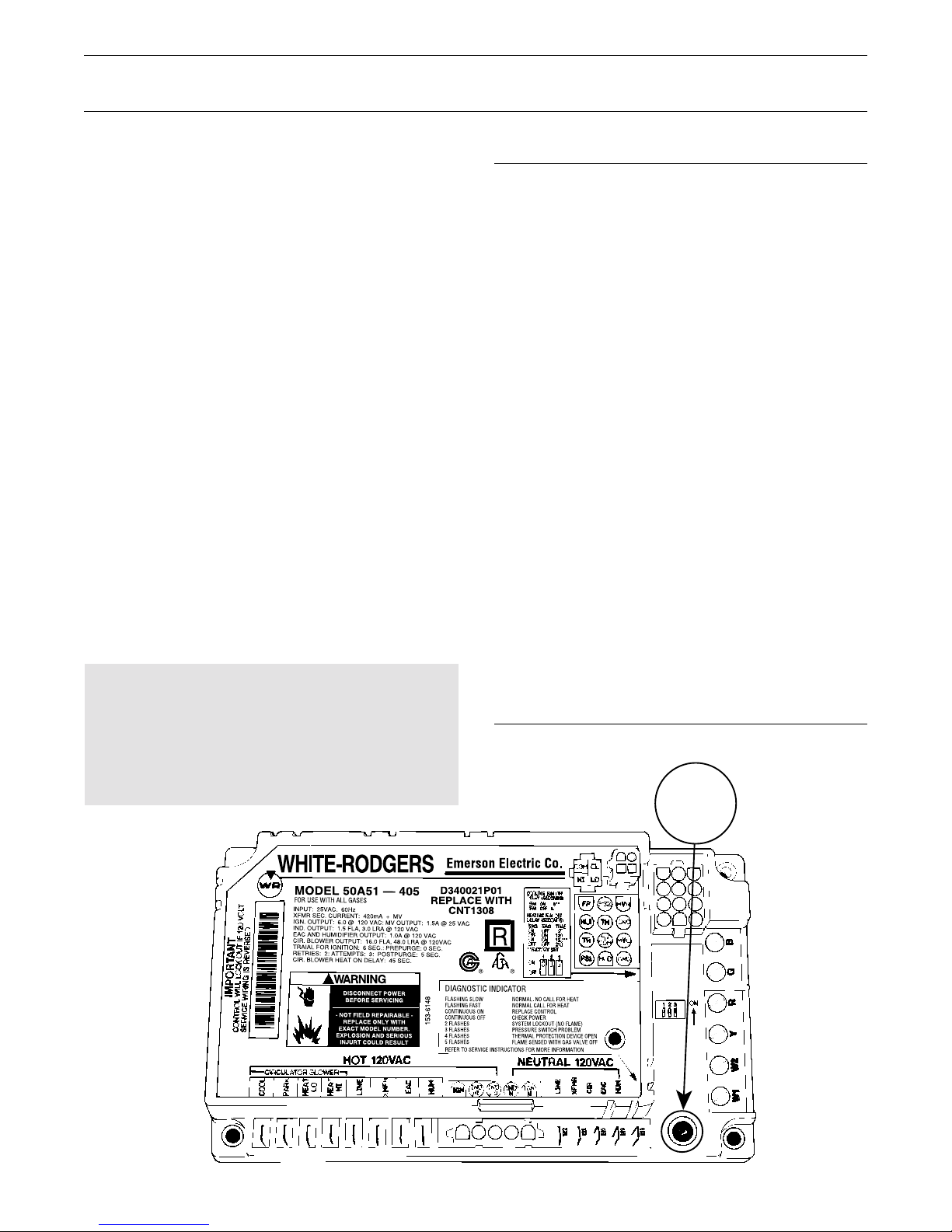

50A51-405 Control

Emerson Electric Co.

S

D340021P01

REPLACE WITH

CNT1308

T

: 1

.5A

@

25

V

A

0 V

@

E

: 0 S

: 5

C

A

C

1

20

V

A

C

E

C

.

S

E

C

.

®®

DIAGNOSTIC INDICATOR

FLASHING SLOW

FLASHING FAST

CONTINU

OU

CO

NTINUOU

153-6148

2 FLASHES

3 FLASHES

4 FLASHES

5 FLASHES

REFER TO SERVICE INSTRUCTIONS FOR MORE INFORMATION

S O

S OFF

N

O

R

M

AL. NO

N

O

R

M

REPLAC

CH

ECK PO

SYSTEM

PR

ESSU

TH

ER

FLAM

AL CALL FO

E CO

LO

R

M

AL P

E SEN

N

E SW

CA

LL FO

R

N

TR

O

W

ER

C

KO

U

T (N

ITCH

R

O

TECTIO

S

ED

W

ITH

123

ON

OFF

R

H

EA

T

H

EAT

L

O

FLAM

E)

P

RO

B

LEM

N

D

EVIC

E O

P

EN

G

AS VA

LVE O

FF

Switch 1 OFF/Jumper cut = 80

Heating Fan Off Delay (seconds)

Switch 2 Switch 3 Time Time1

50A50-571 Control

ON OFF 90 60

OFF ON 120 140

ON ON 1502 1002

Clip

Wire

OFF OFF 210 180

1 I.F.C. Control 50A50-473-474 and 50A51-495/507 use these

harmonized delay times, 50A50-571 heating time delay is

100 seconds.

2 Factory setting.

WHITE–RODGERS

Model 50A50-571

FOR USE WITH ALL GASES

INPUT: 25VAC. 60HZ.

XFMR SEC. CURRENT: 350mA + MV

IGN. OUTPUT: 6.0A @ 120VAC; MV OUTPUT 1.5A @ 24VAC

IND. OUTPUT: 1.5 FLA, 3.0 LRA @ 120VAC

CIR. BLOWER OUTPUT: 14.5 FLA, 25.0 LRA @ 120VAC

TRIAL FOR IGNITION: 4 SEC.; PREPURGE: 0 SEC.

RETRIES: 2; ATTEMPTS: 3; POSTPURGE: 5 SEC.

CIR. BLOWER ON DELAY: HEAT 45 SECONDS.

DISCONNECT POWER

BEFORE SERVICING

-NOT FIELD REPAIRABLEREPLACE ONLY WITH

EXACT MODEL NUMBER.

EXPLOSION AND SERIOUS

INJURY COULD RESULT

CIRCULATOR BLOWER

COOL

HEAT

PARK

PARK

Emerson Electric Co.

D330927P01

REPLACE WITH

CNT 2181

®®

HEATING OFF DELAY (SEC.)

100 SEC.**

COOLING OFF DELAY (SEC.)

0 SEC.**

**FACTORY SETTING

DIAGNOSTIC INDICATOR

FLASHING SLOW

FLASHING FAST

CONTINUOUS ON

CONTINUOUS OFF

156-2822A

2 FLASHES

3 FLASHES

4 FLASHES

5 FLASHES

HOT 120VAC NEUTRAL 120VAC

LINE

XFMR

REFER TO SERVICE INSTRUCTIONS FOR MORE INFORMATION

TP

CUT JUMPER FOR

80 SEC. COOL OFF

DELAY.

NORMAL. NO CALL FOR HEAT

NORMAL. CALL FOR HEAT

INTERNAL CONTROL FAILURE (REPLACE)

NO POWER OR CONTROL FAILURE

SYSTEM LOCKOUT (NO FLAME) CHECK LINE POLARITY

PRESSURE SWITCH PROBLEM

THERMAL PROTECTION DEVICE OPEN

FLAME SENSED WITH GAS VALVE OFF

INDNIGN

IGN

IND

TH FP HLO

TR

MV GND HLI

MV PS

CIR

N

LINE

XFMR

CGRWY

E

8

White-Rodgers Self Diagnostic Features – 50A50/50A51 Series

The integrated furnace control incorporates system

fault analysis for quick gas flow shutoff, coupled with

automatic ignition retry upon sensing a fault correction.

The integrated furnace control tests for internal

and external faults before allowing a heating

sequence to begin. The external check includes all

safety devices and pressure switches, making

certain that they are in their proper normally open

or normally closed position. If a fault is detected

by the control, it will immediately enter into a

fault mode and flash the LED light according to

the fault detected, see LED Flash Rate table at right.

The control will remain in the fault mode until the

problem is corrected. Once the fault is cleared, the

control will start the heating sequence as long as the

call for heat still exists.

The control has an expanded diagnostic feature that

monitors system performance. If a fault is detected

during operation, the control will de-energize the gas

valve and flash the diagnostic LED according to the

fault detected (see LED flash rate Table 3).

The control will automatically reset a lock-out due

to loss of flame. See I.F.C. Timing Table for reset time,

see page 10.

Important:

The control is mounted in the blower section.

Do not remove blower door before checking

flash rate of LED. Sight glass is provided on

upflow models in the blower door panel to prevent

resetting control and loss of diagnostics.

LED Flash Rate

Normal Operation

• The LED will flash for 1 second at power-up

• the LED will flash “FAST”, 1/4 second “ON” and

1/4 second “OFF”, during a call for heat

• The LED will flash “SLOW”, 1/4 second “ON” and

3/4 seconds “OFF” with system in stand-by

(power on).

Note: The LED will flash “ON” for approximately

1/4 second, then “OFF” for approximately 1/4 second.

The pause between groups of flashes is approximately

2 seconds.

Fault Diagnostic

Continuous ON – Internal Fault, or grounded

sensor (Lockout)

2 Flashes – System Lockout – No Flame1

3 Flashes – Pressure Switch Error

4 Flashes – Thermal Protection

Device Open

5 Flashes – Flame Sensing With Gas Valve

De-Energized

(Stuck Open)

1 This fault will be caused if the hot leg and neutral leg of

the 120 volt A.C. power legs are reversed.

Diagnostic

LED

(Red)

!

9

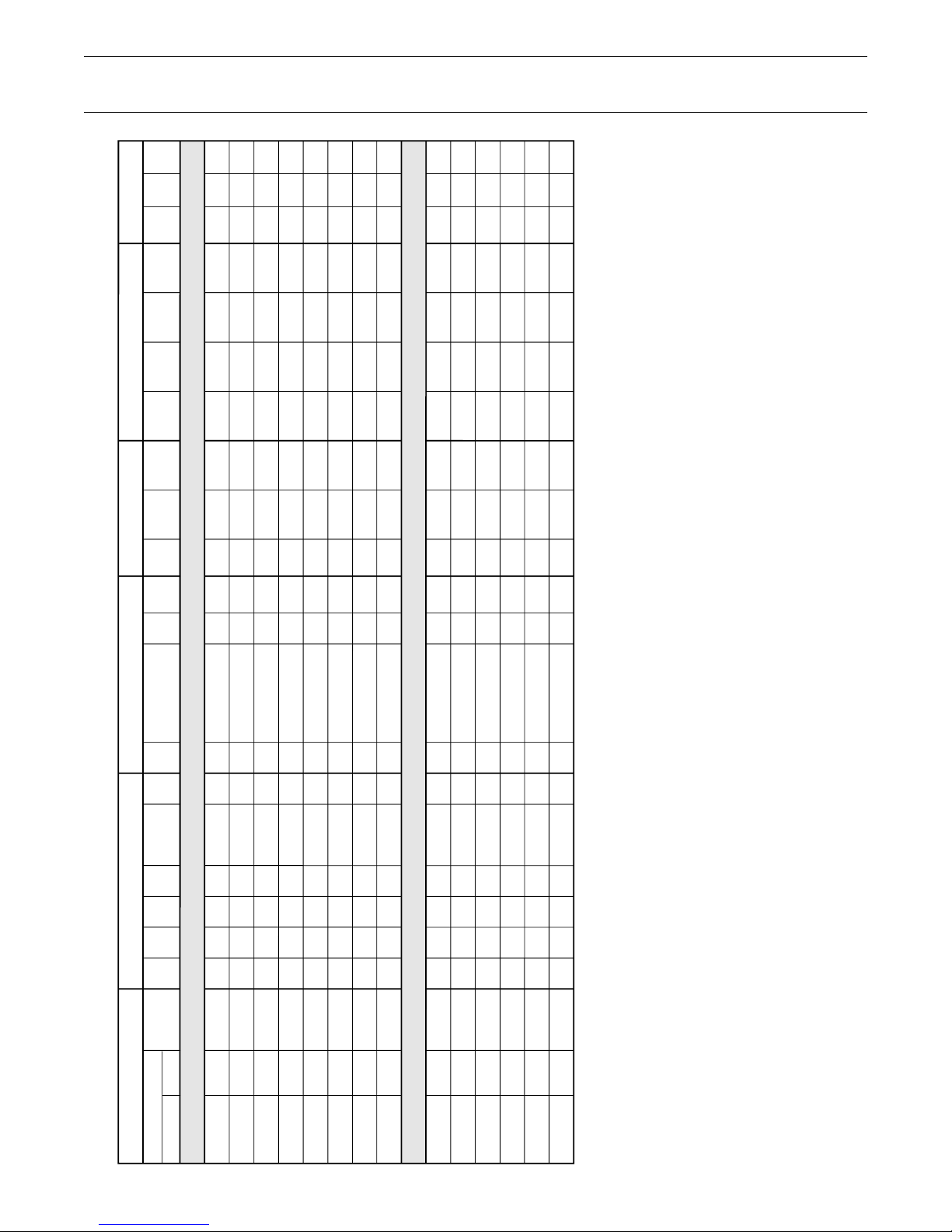

White-Rodgers Integrated Furnace Control Timing

90, 120, 150, 180

90, 120, 150, 180

90, 120, 150, 180

90, 120, 150, 180

60, 100, 140, 180

60, 100, 140, 180

100

100

90, 120, 150, 180

60, 100, 140, 180

90, 120, 150, 180

90, 120, 150, 180

60, 100, 140, 180

60, 100, 140, 180

IFC Timings

50A50-405

50A50-406

50A50-471

50A50-472

50A50-473

50A50-474

50A50-5712

50A55-5710

50A51-405

50A51-495

50A51-505

50A51-506

50A51-507

50A61-625

1 Stage IFC’s

2 Stage IFC’s

E93 – E6

E93 – E6

E90 – E2

E90 – E2

E3

E3

E1 – E2

E91

E93 – E3

E3

E90

E90 & 91

E90

E94

CNT1309

CNT1616

CNT1848

CNT1849

CNT2182

CNT2183

CNT2181

CNT2789

CNT1308

CNT2184

CNT1523

CNT1819

CNT2223

CNT2536

0

0

0

0

0

0

0

0

0

0

0

0

0

0

60

60

60

60

60

60

60

60

120

60

30

30

60

60

5

5

5

5

5

5

5

5

5

5

5

5

5

5

3

3

1

1

1

1

1

1

3

1

3

3

1

1

6

6

4

4

4

4

4

4

6

4

6

6

4

4

NA

8

30

30

30

30

30

30

NA

NA

0

30

30

30

45

45

45

45

45

45

45

45

45

45

45

45

45

45

0

0

0

0

2

2

2

0

0

2

0

0

0

0

0/80

0/80

0/80

0/80

0/80

0/80

0/80

0/80

0/80

0/80

7

7

7

7

2

2

2

2

2

2

2

2

2

2

2

2

2

2

4

4

4

4

10

10

10

10

4

10

4

4

10

10

120

120

120

120

60

60

60

60

120

60

120

120

60

60

17

17

17

17

17

17

17

17

17

17

17

17

17

20

27

27

1

1

1

1

1

1

27

1

27

27

1

9

17

17

11

11

11

11

11

11

17

11

17

17

11

11

27

27

21

21

21

21

21

21

27

21

27

27

21

21

5

5

5

6

5

5

5

5

5

5

5

X

X

X

X

X

X

X

X

X

X

X

Part I.D. Safety Times (Seconds)

White-Rodgers

Model Revs.

Part

Number

Circulator Delays (Seconds)

Pre

Purge

Inter

Purge

Post

Purge

IAP

3

Trial for

Ignition

IND

Off

4

Heat

On

Heat Off

(Factory Set)

Auto Reset

Cool

On

Cool

Off

No. of

Retries

No. of

Recycles

Reset

Time (min.)

Ignitor Warm-Up (Seconds)

Accessories

Initial

Warm-Up

Retry

Warm-Up

Minimum

Warm-Up

Maximum

Warm-Up HUM EAC

Twin

Plug

Notes:

The ignitor starts with a 17 second heat-up timing. After 64 successful cycles, the timing will be shortened each cycle by 1 se

cond until 11 seconds is reached.

If a cycle fails to prove flame, the time will increase by 2 seconds to 13 seconds, then to 15 and so on, up to 21 seconds. 11

min. and 21 max. If a lockout or power loss occurs, the count starts over.

50A50-571 IFC uses a jumper that must be cut to obtain Cool Off Delay. Factory shipped with Jumper not cut = No Cool Off Delay.

IAP = Ignition After Proving. (The amount of time that the ignitor remains energized after the Main Burner Flame is sensed).

IND Off = Time that the Inducer is deenergized after a fault (LED 3 Flash) to allow condensate water (if any) in the Housing to

drain.

Humidifier is energized when the Inducer and the Heat Speed are energized. (“ON” after Heat On Delay – “OFF” after Post Purge).

Humidifier is energized with the Inducer Only. (“ON” with call for heat – “OFF” after Post Purge.)

Time delay to OFF is controlled by the ICM-2 motor control board, DIP switches number 5 and 6.

Prior to E-4 – N/A, E4 and later is 30 seconds.

Ignition warm up – 20 seconds, retry 20 seconds. (Varies voltage on ignitor by 2% reduction on successful cycles)

If cycle fails, then retry, 6% increase. If lockout or power loss, the count starts over.

1

2

3

4

5

6

7

8

9

0

7 Flashes –

8 Flashes –

Slow Flash –

Fast Flash –

Continuous On –

Gas Valve Circuit Error.

Low Flame Sense Signal.

Normal, No Call For Heat Present.

Normal, Call For Heat Present.

Internal Control Failure.

Diagnostic Indicator Flash Codes:

2 Flashes – System Lockout (Retries or Recycles Exceeded).

3 Flashes – Pressure Switch Stuck Open or Closed.

4 Flashes – Open High Temperature Limit Switch.

5 Flashes – Flame Sensed Without Gas Valve.

6 Flashes – 115 Volt AC Power Reversed.

10

White-Rodgers

50A50/50A51 Fault Diagnostics

System Lockout (Loss Of Flame)

When the Control fails to detect a flame current

signal during the trial for ignition period,1 the gas

valve and ignitor will be de-energized and the retry

sequence initiated. During the retry sequence, the

induced draft motor will be energized for an interpurge period.1 The ignition sequence will be restarted

with an additional period1 of ignitor warm-up time

following the interpurge period. The Control will

retry the ignition sequence 2 consecutive times

(3 total) before system lockout.

IMPORTANT

IGNITION CONTROL IS POLARITY SENSITIVE.

HOT LEG OF 120 VOLT POWER SUPPLY

MUST BE CONNECTED TO THE BLACK LINE

POWER LEAD AS INDICATED ON WIRING

DIAGRAM OR IGNITION LOCKOUT WILL OCCUR.

The initial ignition sequence will be recycled, or

repeated, if the flame is sensed and then lost after

10 seconds. The Control retry counter will be reset

if the flame is sustained for longer than 10 seconds

during an ignition recycle attempt. The system will

lockout if the flame is not sustained after the 4th or 10th1

ignition recycle attempt.

A momentary loss of gas supply, flame blowout, or a

shorted or open flame sensor will be sensed

within 0.7 seconds during a normal heating cycle.

The Control will then de-energize the gas valve and

recycle the ignition sequence. As long as the call

for heat still exists, a normal heating operation

will resume if the gas supply returns or the fault

condition is corrected before the 4th or 10th1 ignition

recycle. Otherwise, the Control will go into system lockout.

When a system lockout occurs, the Control de-energizes

the gas valve, energizes the induced draft motor (low

speed on 50A51 Controls) and energizes the indoor blower

on heat speed. The diagnostic LED will begin flashing 2

times to indicate a system lockout due to loss of flame.

If a momentary (50 milliseconds, or longer) loss

of system power occurs during a normal heating

cycle, the gas valve will be de-energized. When the

power is restored, the gas valve will remain de-energized

and the ignition sequence restarted as long as the call

for heat still exists.

When the Control has gone into system lockout

due to loss of flame, the Control must reset before

the system will restart the heating operation. The

Control may be manually reset by setting the

thermostat system switch to OFF and then ON

again within 1 to 21 seconds or by interrupting

system power to the Control for longer than 1 second.

The 50A50 and 50A51 Series Controls automatically

reset a system lockout condition after one or two

hours.1

Pressure Switch Problem

Single-Stage Systems

When a call for heat is received and the pressure

switch contacts are sensed closed before the induced

draft motor is energized, the Control will delay energizing

the induced draft motor, stop the ignition sequence

and begin flashing the diagnostic LED 3 times to indicate

a pressure switch problem. When the pressure switch

contacts open, a normal ignition sequence will begin after

the contacts close again and the 3 flash fault will return

to steady fast flash to indicate a normal call for heat.

When a call for heat is received and the pressure

switch contacts are sensed open after the induced

draft motor is energized, the Control will not allow the

gas valve to open. The ignition sequence will be

stopped and the diagnostic LED begins flashing

3 times to indicate a pressure switch problem. If this

occurs, the problem may be induced draft motor

failure or excessive pressure against the blower outlet

and not allowing the pressure switch contacts to

close. When the pressure switch contacts close, a normal

ignition sequence will begin and the 3 flash fault will

return to a steady fast flash to indicate a normal call

for heat.

If the control senses the pressure switch contacts are

open during a normal heating cycle, the gas valve will

be de-energized to remove the flame and the system

shutdown sequence initiated, induced draft motor will

continue to run. This problem may also be due to

induced draft motor failure or high wind. The Control

will begin flashing the diagnostic LED 3 times to

indicate a pressure switch problem. When the

pressure switch contacts close, a normal ignition

sequence will begin and the 3 flash fault will return to

a steady fast flash to indicate a normal call for heat.

1 See Integrated Furnace Control Label or Timing Chart.

11

White-Rodgers

50A50/50A51 Fault Diagnostics

50A50-405/406 Prior To Revision E4

If the condensate drain is blocked on condensing

(90%) furnace models, either by debris, improper

draining, or by freezing condensate, the pressure

switch contacts will open. When the Control senses

the pressure switch contacts are open, the gas valve

will be de-energized to remove the flame and the

system shutdown sequence initiated. The Control will

begin flashing the diagnostic LED 3 times to indicate

a pressure switch problem. The system will remain

shutdown until the condensate drain has been cleared

and the condensate flows freely. When the pressure

switch contacts close, a normal ignition sequence will

begin and the 3 flash fault will return to a steady fast

flash to indicate a normal call for heat.

During a normal heating cycle, if the 50A50-405/406

Rev. E4-E6/471/472/473/474/571 Control senses the

pressure switch contacts are closed and then open the

gas valve will be de-energized to remove the flame, if

the pressure switch does not reclose in 60 seconds the

induced draft motor will be de-energized for 30 seconds.

After the 30 second delay, a normal ignition sequence

will begin. On condensing (90%) models, the delay

allows any condensate, that may be blocking the

pressure switch sensing tube, time to drain. On 80%

models, the delay provides another attempt for the

induced draft motor to reach maximum speed and

close the pressure switch contacts.

Pressure Switch Problem

50A51-405 Two Stage and 50A51-505 Two Stage

Variable-Speed Systems

On systems using 50A51-405 two-stage and 50A51-505

two-stage variable-speed Controls, the first stage

pressure switch fault diagnostic operation is the same

as the 50A50-405/-406 Controls. (Prior to Revision E4.)

During a normal 1st stage heating cycle, when the

thermostat calls for 2nd stage heat, there will be a

30 second delay between 1st and 2nd stage heat. If

the thermostat calls for 1st and 2nd stage heat at the

same time, there will be a 10 minute delay between

1st and 2nd stage heat.

If the 1st stage pressure switch closes and then opens

during the ignitor warm-up period, the Control will

begin flashing the diagnostic LED 3 times to indicate

a pressure switch problem and wait 10 seconds for

the pressure switch contacts to close. If the 1st stage

pressure switch contacts close, a normal ignition

sequence will resume and the 3 flash fault will return

to a steady fast flash to indicate a normal call for heat.

If the 1st stage pressure switch contacts do not close in

10 seconds, the induced draft motor is energized to high

speed in an attempt to close the contacts. When the

contacts close, a normal ignition sequence will

resume and the induced draft motor will remain

energized on high speed until the flame is sensed for

a minimum of 10 seconds. The induced draft motor

will then be energized to low speed and the 3 flash

fault will return to steady fast flash to indicate a normal

call for heat. If the 1st stage pressure switch contacts

do not remain closed and the ignition sequence has

been recycled for the 4th time, the Control will go into

system lockout and begin flashing the diagnostic

LED 2 times to indicate a system lockout due to loss

of flame.

During a 2nd stage call for heat, if the 2nd stage

pressure switch contacts do not close within the

30 second delay between stages, the Control will

de-energize the gas valve to remove the flame and

begin flashing the diagnostic LED 3 times to indicate

a pressure switch problem. After the Control senses

the loss of flame, a 3 minute error timer will be

started and the shutdown sequence initiated as if

the call for heat were removed. The induced draft

motor will remain energized on high speed for a

5 second postpurge and the (selected) indoor blower

“off” delay timer will begin.

After the 3 minute error time delay, the Control will

restart the heating cycle if the thermostat is still

calling for 1st and 2nd stage heat. If the 2nd stage

pressure switch contacts still have not closed after the

10 minute delay between stages, the Control will

repeat the above shutdown sequence as long as the

thermostat calls for 2nd stage heat.

During the 1st stage ignition sequence, the induced

draft motor will always be energized to high speed. When

the Control senses the 1st stage pressure switch closed,

the induced draft motor is energized to low speed.

1 See Integrated Furnace Control Label or Timing Chart.

12

White-Rodgers

50A50/50A51 Fault Diagnostics

Pressure Switch Problem

50A51-495/-506/-507 Two Stage Variable-Speed Systems

The induced draft motor will always be energized to

high speed. The induced draft motor will be energized

to low speed when the Control senses the 1st stage

pressure switch contacts have closed.

If the 1st stage pressure switch contacts open during

a normal 1st stage heating cycle, the gas valve will

be de-energized to remove the flame and the induced

draft motor will be energized to high speed for

10 minutes. If the 1st stage pressure switch contacts

close during the 10 minute high speed purge, the

Control will restart the ignition sequence. If the

1st stage pressure switch contacts remain closed after

10 minutes, the induced draft motor will be energized

to low speed and a normal heating operation will

continue. If the pressure switch contacts do not close

after 10 minutes, the induced draft motor will be

energized again to high speed for 10 minutes and the

diagnostic LED will begin flashing 3 times to indicate

a pressure switch problem. Recycling the induced

draft motor will continue as long as a 1st stage call

for heat exists and the Control will not go into lockout.

The 2nd stage pressure switch fault diagnostic

operation is the same as 50A51-405/-505 Controls.

Thermal Protection Devices

At any time during a call for heat, if the Control senses

the high temperature limit (and/or aux. limit) or flame

roll out switch(es) are open, the gas valve is de-energized,

the induced draft motor is energized (low speed on

50A51 Controls), and the indoor blower is energized

to run on heat speed.

On models utilizing fusible link devices, the fusible

link is a single use device and must be replaced

if it has opened. However, if the temperature

the fusible link senses is approaching the trip

temperature but does not exceed it, the contacts may

open and close intermittently. The Control will initiate

another ignition sequence upon the closure of the

intermittent fusible link.

Flame Sensed With Gas Valve Off

At any time the Control senses a flame current signal

without a call for heat or when the gas valve is

de-energized, the induced draft motor is energized

(low speed on 50A51 Controls), and the indoor blower

is energized to run on heat speed.1 The Control will

go into system lockout and will not reset until this

fault is corrected. The diagnostic LED will begin

flashing 5 times to indicate the flame sensed with the

gas valve de-energized.

1 See Integrated Furnace Control Label or Timing Chart.

White-Rodgers

PARK LINE-HPARKCOOL-H

E17

E28 E27 E13

HEAT-H XFMR-H

E16 E18 E14

C4

CNT2789

K1

E4

YWR G C

1

1

2

3

4

DS2

ONOFF

DS1

50A55-571/-474 Self Diagnostic Features

Slow Flash – Normal, No Call For Heat Present.

LINE-N

E4

K5K3K2

XFMR-N

CIR-N

E7

E8

E9

E10

E11

Diagnostic Indicator Flash Codes:

2 Flashes – System Lockout (Retries or Recycles Exceeded).

3 Flashes – Pressure Switch Stuck Open or Closed.

K6

E1

4 Flashes – Open High Temperature Limit Switch.

5 Flashes – Flame Sensed Without Gas Valve.

6 Flashes – 115 Volt AC Power Reversed.

7 Flashes – Gas Valve Circuit Error.

FUSE

1

8 Flashes – Low Flame Sense Signal.

See Pages 14 and 15 for Sequence of Operation and

Wire Schematic.

1 Fuse only on 474 Model and Dip Switches replace jumpers.

Fast Flash – Normal, Call For Heat Present.

Continuous On – Internal Control Failure.

13

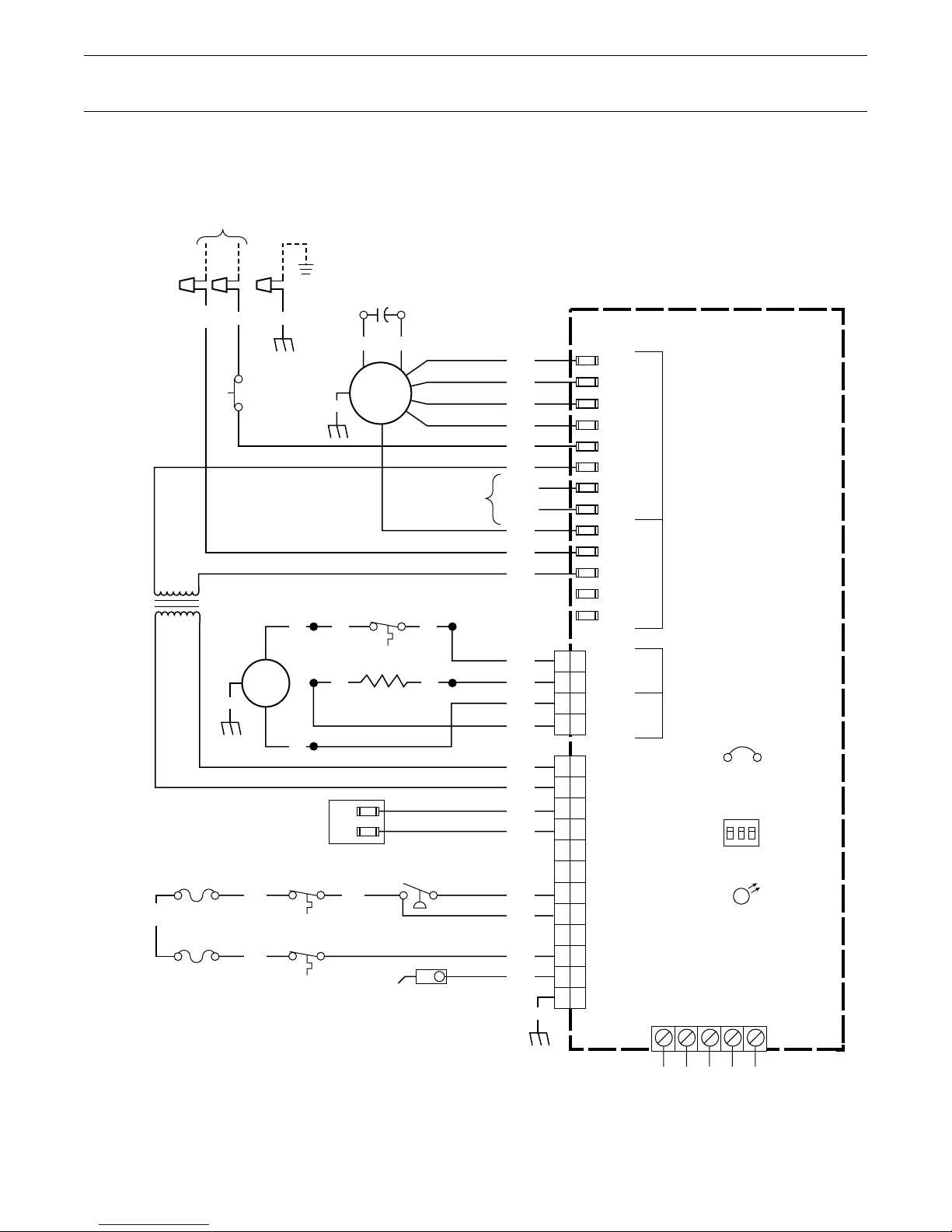

Single Stage 50A50 and 50A55 Sequence of Operation

White-Rodgers Integrated Furnace

Controls 50A50-405/-406/-471/-472/

-473/-474/-571 and 50A55-571/-474

Models

When the disconnect 1 is in the “ON” position, power

is applied through the blower door interlock switch 6

to the control line voltage input terminal 8 and out of

the control to the primary side of the control transformer

“XFMR” 9. The low voltage side of the transformer

supplies 24 volts to the control through terminals

“TH” o and “TR” i. Control terminal “R” ; supplies 24

volts to the “R” terminal of the room thermostat.

Once power is applied, the control flashes the LED

“ON” for 1 second and performs a self check routine.

Following the normal system check, the control

flashes the LED light once per second continuously

(slow flash) while in stand-by.

On a call for heat, 24 volts is applied from the thermostat

terminal “W” to the “W” terminal ; on the control. The

control checks and confirms normally closed contacts at

the temperature cut out “TCO” f, the auxillary limit

(downflow and some upflow/horizontal models), the

flame roll-out fuse link (two fuse links are used on

downflow and upflow/horizontal models) f and j

and normally open contacts of the safety pressure

switch “PS” f. With all safety and control switches

in their proper position, the control will energize the

induced draft motor y and flash the LED light two times

per second continuously (fast flash) during a call for heat.

When the safety pressure switch “PS” f closes, the

control begins the ignition sequence. The hot surface

ignitor y is energized for several seconds (see note)

allowing the thermal element to heat up. The control

then switches on 24 volts to the gas valve “MV” termi-

nals #1 a. The redundant and main solenoids are

energized allowing gas flow and main burner ignition.

When flame current is detected by the control through

its terminal “FP” k, the 45 second indoor blower motor

delay on timing begins. Flame failure response time

is set for 2 seconds. After flame has been established

for ten seconds, the flame failure response time is

reset for 0.7 seconds. If flame current is not sensed by the

control k within the trial for ignition period (see note),

the redundant and main gas valve solenoids a are

de-energized. The control will begin a interpurge

cycle and adds additional seconds to the hot surface

ignitor warm-up timing (see note). The control

energizes the gas valve a for the second attempt to

establish main burner ignition. If flame current is not

sensed by the control on the 2nd retry within the trial

for ignition period (see note), the control will repeat the

previous cycle one additional time before locking out.

At the end of the indoor blower delay on time, line voltage

is applied at the controls terminal “HEAT” 5 energizing

the indoor blower motor at heating fan speed, supplying

warm air to the space.

When the thermostat is satisfied, the gas valve’s redundant

and main solenoids a are de-energized, extinguishing

main burner flame. Once the control senses loss of

flame current (0.7 sec.) k, the induced draft motor t is

de-energized after a five second post purge cycle. The

indoor blower motor delay off timing begins. At the

completion of the fan delay off timing, the indoor

blower motor 5 is de-energized and the cycle

is complete.

Note: See Timing Chart for details or Integrated Furnace

Control Label.

14

Wiring Schematic

Single Stage (White-Rodger’s 50A50 and 50A55 Series Integrated Furnace Controls)

120 VOLT, 60 HZ., 1 PH.

POWER SUPPLY

1

PER LOCAL CODES

2

3

4

5

6

7

8

9

0

q

w

e

r

t

y

u

i

o

p

a

s

d

f

g

h

j

k

l

;

z

N H

BK

WH/1

DOOR

SWITCH

120V

TNS

24V

IND.

MTR.

GR

GND

GAS VALVE

FUSE LINK4

YL/4

FUSE LINK

2 3 4

1 USED ON 90% FURNACE MODELS ONLY.

2 DIRECT VENT MODELS HAVE ONE MANUAL

RESET FLAME ROLL OUT SWITCH INSTEAD

OF TWO, SINGLE-USE FUSIBLE LINKS.

3 USED ON DOWNFLOW/HORIZONTAL AND

UPFLOW/HORIZONTAL MODELS. TCO-B IS

REVERSE FLOW SWITCH.

4 MAY BE A FUSE LINK OR BIMETAL SWITCH.

YL/2

YL/3

GND

GR

GND

GND

BK

WH WH

WH

TCO

TCO-B

3

GR

BK BK

2

1, 3

YL/1

CF

BR

I.D.

BLOWER

MTR.

1

TCO-B

IGNITOR

C

M

PRESSURE

BR

SWITCH

FLAME

SENSOR

OPTIONAL

BK

“A”

“B”

“C”

BK/1

BK/4

BK/3

BK/2

WH

WH/1

WH/4

BK/6

BK/5

WH/6

WH/5

RD

BL/1

RD/1

OR

YL/5

WH

GND

INTEGRATED FURNACE CONTROL

COOL

HEAT

PARK

PARK

LINE

XFMR

EAC

HUM

CIR N

LINE N

XFMR N

EAC N

HUM N

1

IND

2

IGN

3

IND N

4

IGN N

6

BL

YL

GR

TR

3

TH

9

MV

12

MV

4

5

10

PS

7

HLI

11

1

HLO

2

FP

8

GND

50A50-ALL

HOT 120VAC

NEUTRAL 120VAC

HOT

120VAC

NEUTRAL

JUMPER

50A50-571

DIP

SWITCH

ON

OFF

123

DIAGNOSTIC

LED

YWGRC

TO THERMOSTAT

Note: See Integrated Furnace Control on Timing Chart for Control Details.

15

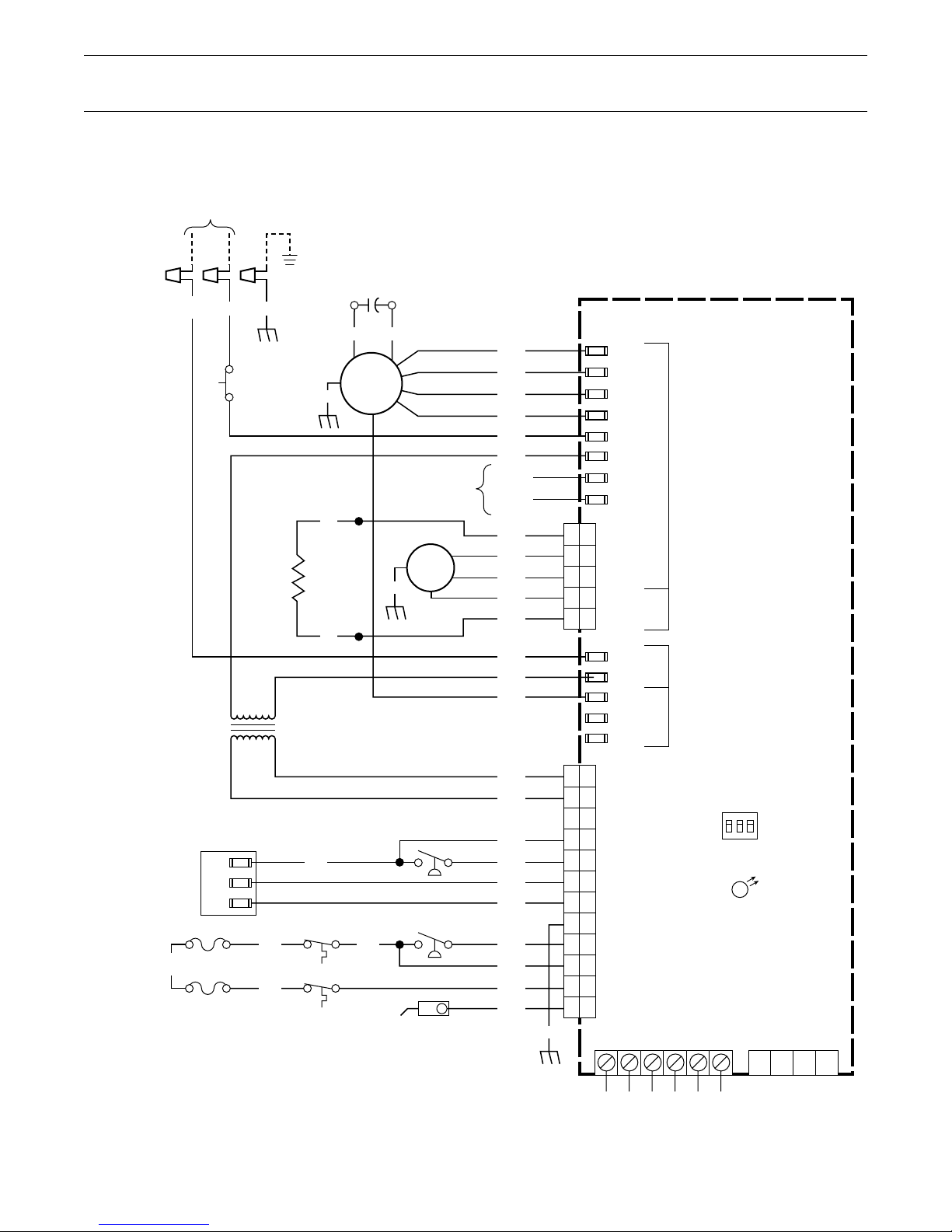

Two Stage 50A51 Sequence of Operation

White-Rodgers Integrated Furnace

Control 50A51-405/-495 Models

When the service disconnect 1 is in the “ON” position,

power is applied through the blower door interlock

switch 6 to the controls line voltage input terminals 8

and out of the control to the primary side of the

control transformer “XFMR” u. The secondary side

of the control transformer supplies 24 volts to the

control through terminal “TH” and “TR” po. Control

terminal “R” ; supplies 24 volts to the “R” terminal

of the room thermostat.

Once power is applied, the control flashes the LED

light “ON” for one second and performs a self check

routine. Following the normal system check, the

control flashes the LED one time per second (slow flash)

continuously while in stand-by.

On a call for heat, 24 volts is applied from the room

thermostats “W1” terminal to the “W1” terminal z

on the control. The control checks and confirms

normally closed contacts at the temperature cut out

“TCO” j, auxillary limit (downflow and some

upflow/horizontal models), the flame roll-out fuse link

(two fuse links are used on downflow and upflow/

horizontal models) l and normally open contacts at

the safety pressure switch #1 j. With all safety and

control switches in their proper position, the control

will energize the induced draft motor on high speed w

and flashes the LED two times per second continuously

(fast flash) during a call for heat.

When safety pressure switch “#1” j closes, the

control switches the induced draft motor to low speed w

and begins the ignition sequence. The hot surface

|ignitor w is energized for several seconds (see note)

allowing the thermal element to heat up. The control

then switches 24 volts to its “MVL” and “MV COM” g

terminals to terminals #1 g and #2 f on the gas

valve. The redundant and main solenoids are energized

allowing gas flow and main burner ignition. When

flame current is sensed by the control through its

“FP” ; terminal, the 45 second indoor blower motor

time delay “ON” begins. Flame failure response time

is set for 2 seconds. After flame has been established

for 10 seconds, the flame failure response time is

reset for 0.7 seconds. If flamed current is not sensed by

the control within the trial for ignition period (see note),

the main valve low and redundant gas valve

solenoids g, a are de-energized. The control will

begin a interpurge cycle and adds additional seconds

to the hot surface ignitor warm-up timing (see note).

The control energizes the gas valve for the second

attempt to establish main burner ignition. If again

flame current is not sensed by the control within the

trial for ignition period (see note), the control will repeat

the previous cycle before locking out. At the end of

the indoor blower motor delay “ON” timing, line

voltage is applied at control terminal “HEAT LO” 6

energizing the indoor blower motor at low heat fan

speed, supplying warm air to the space.

If the temperature in the space continues to fall, the

thermostat second stage contacts “W2” close.

24 volts is switched from thermostat terminal “W2” to

the “W2” terminal z on the control. A 30 second,

2nd stage recognition time delay begins. At the end of

the 30 second delay, the induced draft motor is

switched to high speed w causing pressure switch #2 d

to close. When pressure switch #2 closes, 24 volts is

switched from control terminal “MVH” d to the gas

valve terminal #3 d energizing the second stage

solenoid allowing increased gas flow to the burners.

At the same time, the indoor blower motor is

switched to high heat fan speed 7.

When second stage thermostat contacts “W2” satisfy,

the induced draft motor is switched back to low speed w

causing pressure switch #2 d to open breaking the

circuit to the second stage gas valve solenoid d. Gas

flow is reduced to the burners. The indoor blower

motor will switch back to low heat fan speed after a

30 second delay 6.

When first stage thermostat contacts “W1” satisfy,

the main valve low and the redundant gas valve

solenoids g are de-energized extinguishing main

burner flame. Once the control senses the loss of

flame current (0.7 sec.) ;, the induced draft motor w

is de-energized after a five second post-purge cycle.

The indoor blower motor “OFF” timing begins. At the

end of the indoor blower motor “OFF” timing, the

indoor blower motor is de-energized and the cycle

is complete.

Note: See Timing Chart for details or Integrated Furnace

Control Label.

16

Wiring Schematic

Two Stage Heat (White-Rodgers 50A51 Series Integrated Furnace Control)

120 VOLT, 60 HZ., 1 PH.

POWER SUPPLY

1

PER LOCAL CODES

2

3

4

5

6

7

8

9

0

q

w

e

r

t

y

u

i

o

p

a

s

d

f

g

h

j

k

l

;

z

N H

WH/1

TNS

GAS VALVE

FUSE LINK 2

YL/4

FUSE LINK

1 2

3

2

1

BK

DOOR

SWITCH

IGNITOR

120V

24V

HI

B/C

LO

YL/2

YL/3

GR

GND

GND

1 TCO-B

GND

BR/1

TCO

WH

WH

GR

CF

BR

I.D.

BLOWER

MTR.

YL/1

BR

OPTIONAL

IND.

MTR.

GR

GND

PRESSURE SWITCH

2ND STAGE

PRESSURE SWITCH

1ST STAGE

FLAME

SENSOR

BK

“A”

“B”

“C”

BK/1

BK/4

BK/2

BK/3

BK/5

BK/6

RD/6

WH/6

WH/5

WH/1

WH/4

WH

BL

RD

BR

OR/1

BL/1

RD/1

OR

YL

YL/5

WH

GND

INTEGRATED FURNACE CONTROL

COOL

PARK

HEAT LO

HEAT HI

LINE

XFMR

EAC

HUM

1

IGN

2

IND HI

3

IND LO

4

IND N

5

IGN N

LINE N

XFMR N

CIR N

EAC N

HUM N

9

TR

5

TH

10

GND

2

PS2

1

MVH

8

MVCOM

7

MVL

4

GND

12

PSI

6

HLI

11

HLO

3

FP

GR

W1 W2 Y

50A51-405

HOT 120VAC

NEUTRAL

120VAC

HOT

120VAC

NEUTRAL

GB

R

DIP

SWITCH

123

DIAGNOSTIC

LED

ON

OFF

COMCLHI

LO

1 USED ON DOWNFLOW/HORIZONTAL AND

UPFLOW/HORIZONTAL MODELS. TCO-B IS

REVERSE FLOW SWITCH.

2 MAY BE A FUSE LINK OR BIMETAL SWITCH.

Note: See Integrated Furnace Control on Timing Chart for Control Details.

17

TO THERMOSTAT

FURNACE

TWINNING

CONNECTOR

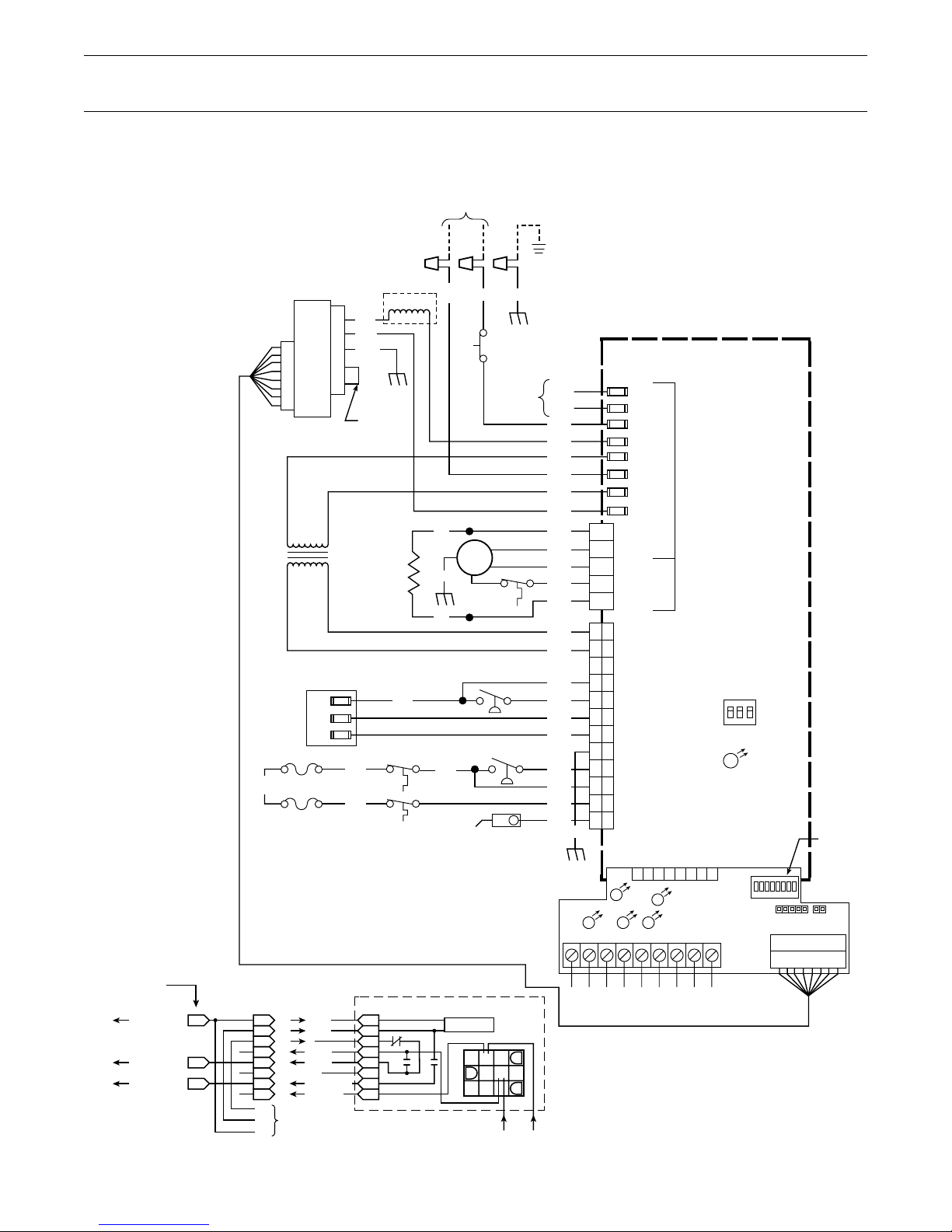

Two Stage Variable Speed Sequence of Operation

White-Rodgers Integrated Furnace

Controls 50A51-505/-506/-507 and

50A61-605 Models

When the service disconnect 1 is in the “ON” position,

power is applied through the blower door interlock

switch 3 to the controls line voltage input terminals 6

and out of the control to the primary side of the

control transformer 9, and from the “ CIRC” 7

terminal to the ECM

side of the control transformer supplies 24 volts to the

control through terminal “TH” and “TR” w, e. Control

terminal “R” g supplies 24 volts to the “R” terminal

of the room thermostat.

Once power is applied, the control flashes the LED

light “ ON” for one second and performs a self

check routine. Following the normal system check, t

he control flashes the LED one time per second (slow flash)

continuously while in stand-by.

On a call for heat, 24 volts is applied from the room

thermostats “W1” terminal to the “W1” terminal g

on the control. The control checks and confirms

normally closed contacts at the temperature cut

out “TCO” a, auxillary limit (downflow and some

upflow/horizontal models), the flame roll-out fuse link

(two fuse links are used on downflow and some

upflow/horizontal models) a and normally open

contacts at the safety pressure switch #1 p. With all

safety and control switches in their proper position,

the control will energize the induced draft motor on

high speed 9 and flashes the LED two times per

second continuously (fast flash) during a call for heat.

When safety pressure switch “#1” p closes, the

control switches the induced draft motor to low

speed 0 and begins the ignition sequence. The hot

surface ignitor 9 is energized for several seconds

allowing the thermal element to heat up. The control

then switches 24 volts to its “MVL” i and “MV

COM” u terminals to terminals #1 i and #2 u on

the gas valve. The redundant and main solenoids are

energized allowing gas flow and main burner ignition.

When flame current is sensed by the control through

its “FP” f terminal, the 45 second indoor blower

motor time delay “ON” begins. Flame failure response

time is set for 2 seconds. After flame has been

established for 10 seconds, the flame failure response

time is reset for 0.7 seconds. If flamed current is not

sensed by the control f within the trial for ignition

period, the main valve low and redundant gas valve

solenoids i are de-energized. The control will begin

a 30 second interpurge cycle and adds additional

TM

Fan Motor 3. The secondary

seconds (see note) to the hot surface ignitor warm-up

timing. The control energizes the gas valve for the

second attempt to establish main burner ignition.

If again flame current is not sensed by the control

within the trial for ignition period (see note), the

control will repeat the previous cycle before locking

out. At the end of the indoor blower motor delay

“ON” timing, the microprocessor will close the

normally open K3 relay contacts j completing a

24 volt signal circuit to pin #15 of the ECM

TM

motor,

signaling it to turn on and run at the low heat blower

speed, supplying warm air to the space. 24 volts

W1 g terminal from the thermostat is also applied

to the ECM

the ECM

TM

motor harness pin #12h, which signals

TM

motor to run at the low heat speed setting.

If the temperature in the space continues to fall, the

thermostat second stage contacts “W2” close.

24 volts is switched from thermostat terminal “W2” to

the “W2” terminal g on the control. A 30 second,

2nd stage recognition time delay begins. At the end

of the 30 second delay, the induced draft motor is

switched to high speed 9 causing pressure switch

#2 o to close. When pressure switch #2 closes,

24 volts is switched from control terminal “MVH” o to

the gas valve terminal #3 o energizing the second

stage solenoid allowing increased gas flow to the

burners. At the same time, the microprocessor

closes the normally open K1 relay contacts j

completing a 24 volt signal circuit to pin #13 k of the

TM

ECM

2 motor signaling the indoor blower motor to

run at the high heat blower speed.

When second stage thermostat contacts “W2” satisfy,

the induced draft motor is switched back to low

speed 0 causing pressure switch #2 y to open

breaking the circuit to the second stage gas

valve solenoid y. Gas flow is reduced to the burners.

The indoor ECM

TM

blower motor 4 will be switched

back to the low heat fan speed after a 30 second delay.

When first stage thermostat contacts “W1” satisfy,

the main valve low and the redundant gas valve

solenoids i are de-energized extinguishing main

burner flame. Once the control senses the loss of

flame current (0.7 sec.)f, the induced draft motor 9

is de-energized after a five second post-purge cycle.

The indoor blower motor “OFF” timing begins. At the

end of the indoor blower motor “OFF” timing, the indoor

blower motor is de-energized and the cycle is complete.

Note: See Timing Chart for details or Integrated Furnace

Control Label.

18

Wiring Schematic

Two Stage Variable Speed

Furnace Controls)

1

2

3

4

5

6

7

8

9

0

q

w

e

r

t

y

u

i

o

p

a

s

f

g

TNS

FUSE LINK5

YL/4

FUSE LINK

ECMTM2

BLOWER

MOTOR

120V

24V

GAS VALVE

3

2

1

2 3 5

(White-Rodgers 50A51 and 50A61 Series Integrated

120 VOLT, 60 HZ., 1 PH.

POWER SUPPLY

PER LOCAL CODES

N H

1

LC

5

BK/8

WH/7

4

3

GR/BK

2

1

JUMPER

YL/BK

GND

WH

WH/1

BK

DOOR

SWITCH

OPTIONAL

IND.

MTR.

GR

GND

WH

PRESSURE SWITCH

2ND STAGE

PRESSURE SWITCH

1ST STAGE

YL/1

TCO-C4

FLAME

SENSOR

YL/2

YL/3

IGNITOR

HI

B/C

LO

BR/1

TCO

2 TCO-B

GND

GR

GND

50A51-505/-506

INTEGRATED FURNACE CONTROL

BK/2

BK/3

BK/1

BK/7

BK/4

WH/1

WH/4

WH/7

BK/5

BK/6

RD/6

WH/6

WH/5

BL

RD

BR

OR/1

BL/1

RD/1

OR

YL

YL/5

WH

GR

GND

1

2

3

4

5

9

5

10

2

1

8

7

4

12

6

11

3

CFM

IGN

IND HI

IND LO

IND N

IGN N

TR

TH

GND

PS2

MVH

MVCOM

MVL

GND

PS1

HLI

HLO

FP

P2

EAC

HUM

LINE

CIRC

XFMR

LINE N

XFMR N

CIR N

W1 IN

W2 IN

G IN

R OUT

1234567

FAN

HOT 120VAC

NEUTRAL

120VAC

DIAGNOSTIC

G OUT

N/C

W2 OUT

B OUT

8

DIP

SWITCH

1

23

LED

ON

OFF

ON

OFF

ECMTM FAN CONTROL

R

BK O Y YLOGW1W2B

P1

LVTB

DIP SWITCH

h

j

k

16 WIRE

HARNESS

W1

CFM

G

FAN

ON/OFF

W2

CFM

INTERFACE CONTROL BOARD

AT INTEGRATED CONTROL

P1

2

P1

15

P1

13

PIN CONNECTIONS

P2

1

P2

2

P2

3

P2

4

P2

5

P2

6

P2

7

P2

8

G

TERMINAL

W2

BOARD

W1

W1 IN

W2 IN

G

R OUT

G OUT

N.C.

W2 CFM OUT

B OUT

INTEGRATED FURNACE CONTROL

TYPICAL CONNECTION

8

K3K2K1

1

COMPUTER

19

TR

TH

R B/C

24 VAC IN

TO THERMOSTAT

16 WIRE HARNESS

1 LINE CHOKE NOT USED ON ALL MODELS.

2 USED ON DOWNFLOW/HORIZONTAL AND UPFLOW/HORIZONTAL

MODELS. TCO-B IS REVERSE FLOW SWITCH.

3 DIRECT VENT MODELS HAVE ONE MANUAL RESET FLAME ROLL

OUT SWITCH INSTEAD OF TWO, SINGLE-USE FUSIBLE LINKS,

OR AUTO-RESET BIMETAL SWITCHES MAY BE USED ON SOME MODELS.

4 USE ON 90% FURNACE MODEL ONLY.

5 MAY BE A FUSE LINK OR A BIMETAL SWITCH.

Integrated Control Quick Reference

Service Tips

To the qualified service man, these controls are

very simple and easy to work on. A list of required

service tools needed to work on any solid state

ignition control today are listed below:

A reliable Volt/OHM Multimeter (preferably a

digital with a microamp scale on it). The Microamp

Meter is used to measure flame current.

A U-Tube Water Manometer (or pressure gauge) to

test inlet and out gas valve pressure.

An Incline Manometer with a 0-2" water column scale

to test pressure switches and ductwork static pressure.

1. When the thermostat fan switch is placed in the

“ON” position, the fan will run at heating fan speed.

Low heat fan on two stage 50A51 series controls.

2. In order to obtain cooling air flow, the thermostat

“Y” terminal must be connected to the “Y” terminal

on the control. If the “Y” is not connected, low

heat speed will be activated during a cooling cycle.

3. If a single stage heat thermostat is used with the

50A51 two stage control, there will be a 10 minute

delay between first and second stage heat if W1 and

W2 are jumpered.

8. If a lockout occurs, the control automatically resets

the trial for ignition sequence every one or two hours

provided a call for heat continues to exist. See Timing

Chart , Reset Time Column, for details.

9. To reset control after lockout:

a. Interrupt line voltage power to the control for

a minimum of 1 second.

b. Turn thermostat system switch off and back on

twice within 30 seconds.

10. Voltage input range:

Line 97-132 VAC 50/60HZ – Nominal 120 volts AC

Control 20-30 VAC 50/60HZ – Nominal 24 volts AC

11. 50A50 controls with date codes prior to 9348

require an isolation relay in the “Y” circuit

when used with Add On Heat Pump Plus One kits,

to prevent cold air complaints during defrost.

The control would not allow a cooling (Y) and

heating (W) output at the same time so the control

would de-energize the “W” circuit and there would

be no supplement heat during defrost cycles.

12. The humidifier accessory lead is energized

whenever there is a heating call and the fan is

operating. See IFC Timing Chart for details, page10.

4. The control requires one microamp DC minimum

flame current in order to maintain a call for heat.

5. The control will add seconds to the igniter

heat-up period on second and third trial for ignition

with interpurge between trials. See Integrated

Furnace Control label or Timing Chart for details.

6. Once flame current has been established by the

control for 10 seconds, the retry counter in the control

is reset to zero.

7. If flame current is interrupted, the control will

break current flow to the gas valve and immediately

begin a recycle for ignition without a purge cycle or

increase in igniter warm-up time. If flame current is

interrupted during 2nd stage operation, the recycle

sequence is initiated and Hi fire or 2nd stage will

resume immediately.

13. The electronic air cleaner accessory lead is

energized whenever there is a 24 volt signal on G or Y

or during a heating call when the indoor fan is

operating.

A detailed troubleshooting chart for each model of

the integrated furnace control is included in this

manual to help the service technician work through

abnormal conditions with these controls.

The troubleshooting section with fault charts for all

White-Rodgers controls are located on pages 48

through 62. See page 48 for procedures and chart

references.

20

Loading...

Loading...