American Standard 2TEE3D49A1000A, 2TEE3D31A1000A, 4TEE3D40A1000A, 4TEE3D31A1000A, 4TEE3D37A1000A Installer's Manual

...

Installer’s Guide

▲

▲

18-GE10D1-5

Convertible Variable Speed – Air Handlers 2 1/2 - 5 Ton

with Integrated Whole House Air Cleaner

2/4TEE3D31A1000A, 2/4TEE3D37A1000A, 2/4TEE3D40A1000A,

2/4TEE3D49A1000A, 2/4TEE3D65A1000A

WARNING:

ALL phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES

IMPORTANT — This Document is customer property and is to remain with this unit. Please return to service information

pack upon completion of work.

A. GENERAL INFORMATION

!

THIS INFORMATION IS FOR USE BY INDIVIDUALS

HAVING ADEQUATE BACKGROUNDS OF ELECTRICAL

AND MECHANICAL EXPERIENCE. ANY ATTEMPT TO

REPAIR A CENTRAL AIR CONDITIONING PRODUCT

MAY RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE. THE MANUFACTURER OR SELLER

CANNOT BE RESPONSIBLE FOR THE INTERPRETATION OF THIS INFORMATION, NOR CAN IT ASSUME

ANY LIABILITY IN CONNECTION WITH ITS USE.

!

To prevent shortening its service life, the air handler

should not be used during the finishing phases of construction. The low return air temperatures can lead to

the formation of condensate. Condensate in the presence of chlorides and fluorides from paint, varnish,

stains, adhesives, cleaning compounds, and cement

creates a corrosive condition which may cause rapid

deterioration of the cabinet and internal components.

HAZARDOUS VOLTAGE - DISCONNECT POWER BEFORE SERVICING

CONTENTS

WARNING

CAUTION

General Information .............................................. 1

Installation Limitations & Recommendations ...................... 1

Two Piece Cabinet Disassembly ........................ 4

Unit Installation ...................................................... 4

Vertical Upflow ....................................................................... 4

Vertical Downflow ................................................................... 5

Horizontal Left ........................................................................ 9

Horizontal Right ................................................................... 10

Duct Connection ................................................... 10

Refrigerant Piping ............................................... 13

Brazing to Evaporator Section ......................... 1 3

Condensate Drain Piping .................................... 13

Electrical - Wiring ................................................. 14

Airflow Adjustment ............................................... 15

Maintenance Check Out Procedure ................ 16

This unit is equipped with an integrated high efficiency

Whole House Air Cleaner. Careful consideration must

be taken in the installation process to avoid personal injury or equipment damage. These instructions do not

cover all variations in systems or provide for every possible contingency. Should further information be desired

or particular problems arise which are not covered sufficiently by this manual, contact your local distributor or

the manufacturer as listed on the air handler nameplate.

These Air Handlers are shipped from the factory in the

upflow or horizontal right configuration and are fully

convertible to downflow or horizontal left. Refer to Section C beginning on page 4 for additional information.

INSPECTION

Check carefully for any shipping damage. This must be

reported to and claims made against the transportation

company immediately. Check to be sure all major components are in the unit. Any missing parts should be reported to your supplier at once, and replaced with authorized parts only.

Cleaning the COLLECTION CELL .................. 1 6

Cleaning the FIELD CHARGER ........................ 17

Hook Up Diagrams ............................................... 18

Outline Drawings ................................................. 20

Checkout Procedures .......................................... 23

INSTALLATION LIMITATIONS & RECOMMENDATIONS

The general location of the air handler is normally selected by the architect, contractor and/or home owner

for the most effective application and satisfaction.

NOTE: Condensation may occur on the surface of the

air handler when installed in an unconditioned location. When units are installed in unconditioned spaces,

verify that all electrical and refrigerant line penetrations

on the air handler are sealed completely.

Installer’s Guide

▲

These air handlers are suitable for installation in a

closet, alcove or utility room with free, non-ducted, air

return, using the area space as a return air plenum.

With ducted supply air, if the minimum clearances to

combustible materials and service access are observed,

the above installations are suitable.

This area may also be used for other purposes, including an electric hot water heater- but in no case shall

a fossil fuel device be installed and/or operated in

the same closet, alcove or utility room.

In addition, these air handlers are suitable for installation in an attic, garage or crawl space with ducted supply and return air.

This equipment has been evaluated in accordance with

the U.S. Department of Housing and Urban Development code. Air handler is Suitable for mobile home/

manufactured housing use. Unit is also approved for

modular homes.

For proper installation the following items must be considered:

1. If adequate power is available and correct according

to nameplate specifications.

2. Prior to unit installation, a heavy gauge steel

plate is attached to the bottom of the unit for

protection during shipping and handling.

Leave this plate in place until the unit is

ready to be connected to ductwork.

3. Insulate all ducts, particularly if unit is located outside of the conditioned space.

4. Pursuant to Florida Building Code 13-610.2.A.2.1,

this unit meets the criteria for a factory sealed

air handler.

5. To ensure maximum efficiency and system performance, the existing supply and return duct system

static pressures must not exceed the total available

static pressure of the air handler. Reference ACCA

Manual D, Manual S and Manual RS along with the

air handler Product Data and Service Facts for additional information.

6. It is recommended that the outline drawing be studied and dimensions properly noted and checked

against selected installation site. By noting in advance which knockouts are to be used, proper clearance allowances can be made for installation and future service.

7. Allow a minimum of 21 inches clearance in front

of the air handler to permit removal of COLLECTION CELL and FIELD CHARGER.

8. Do not install air handler where air cleaner can be

exposed to UV light.

9. When the air handler with supplementary heater is

to be installed in the downflow position on combustible flooring an accessory sub-base (TAYBASE101

for 2/4TEE3D31, TAYBASE100 for 2/4TEE3D37,

TAYBASE102 for 2/4TEE3D40-65) must be used.

See Figure 1.

10. If supplementary heat is to be added, power supply

must be sufficient to carry the load. In addition,

minimum airflow settings, unit and duct clearances

to combustible material must be maintained as

stated on the air handler rating nameplate.

!

CAUTION

For air handlers not equipped with a factory installed

electric heater, a field installed heater is available from

Trane. Only heaters built by Trane are approved for use

in the air handler. These heaters have been designed

and tested in accordance with UL standards to provide

safe and reliable operation. A list of approved heaters

is provided on the air handler rating nameplate. Heaters that are not factory approved could cause damage

and are not covered under equipment warranty.

NOTE: If air handler is used WITHOUT a supplementary electric heater, a sheetmetal plate is required to

cover the open hole in the airflow system. See Figure

3

.

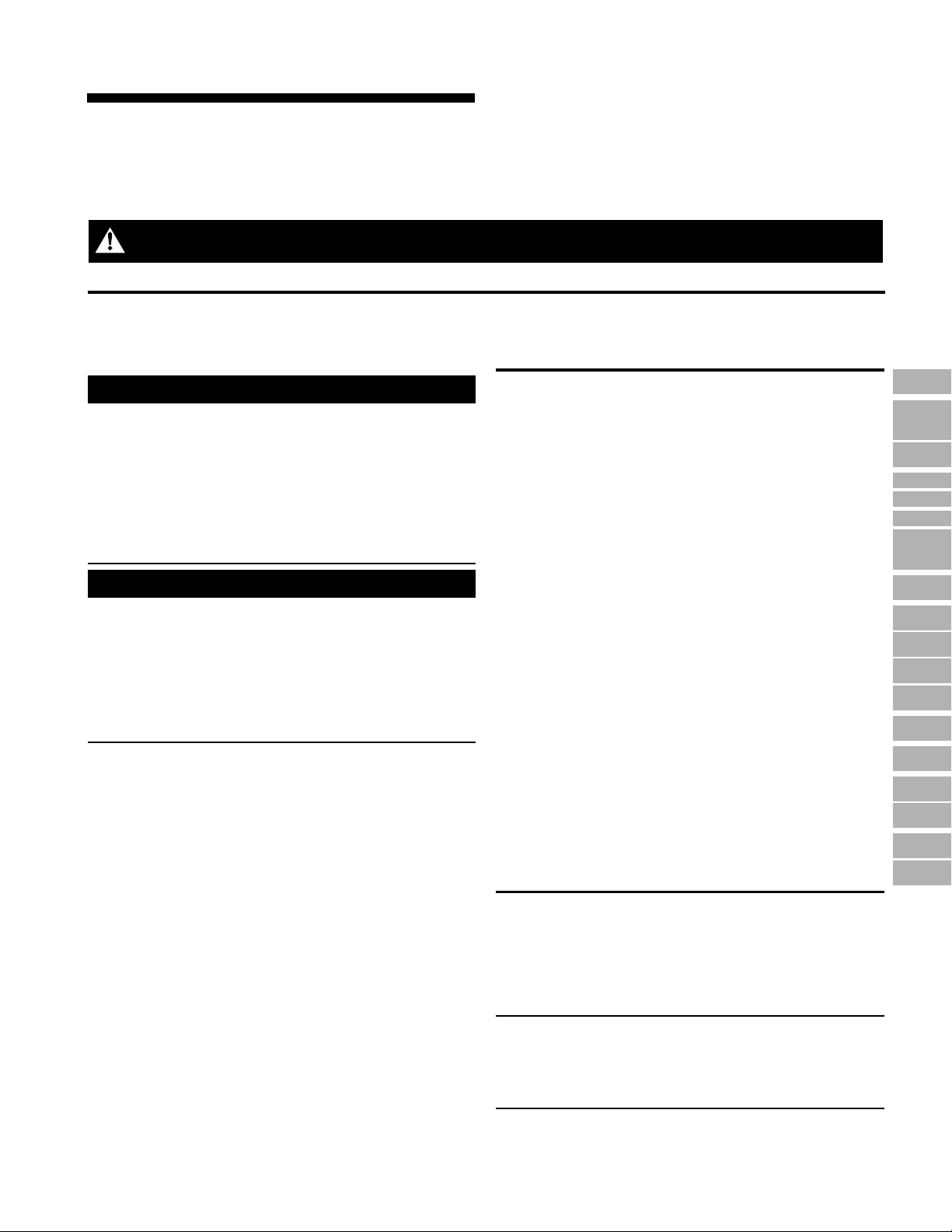

Figure 1

MODEL NO. A B

TAYBASE100 23-3/4 14-13/16

TAYBASE101 21-3/4 14-13/16

TAYBASE102 26-3/4 14-13/16

© 2008 Trane 18-GE10D1-4

AIR HANDLER SUB-BASE

FLOOR OPENING - SIZE

Installer’s Guide

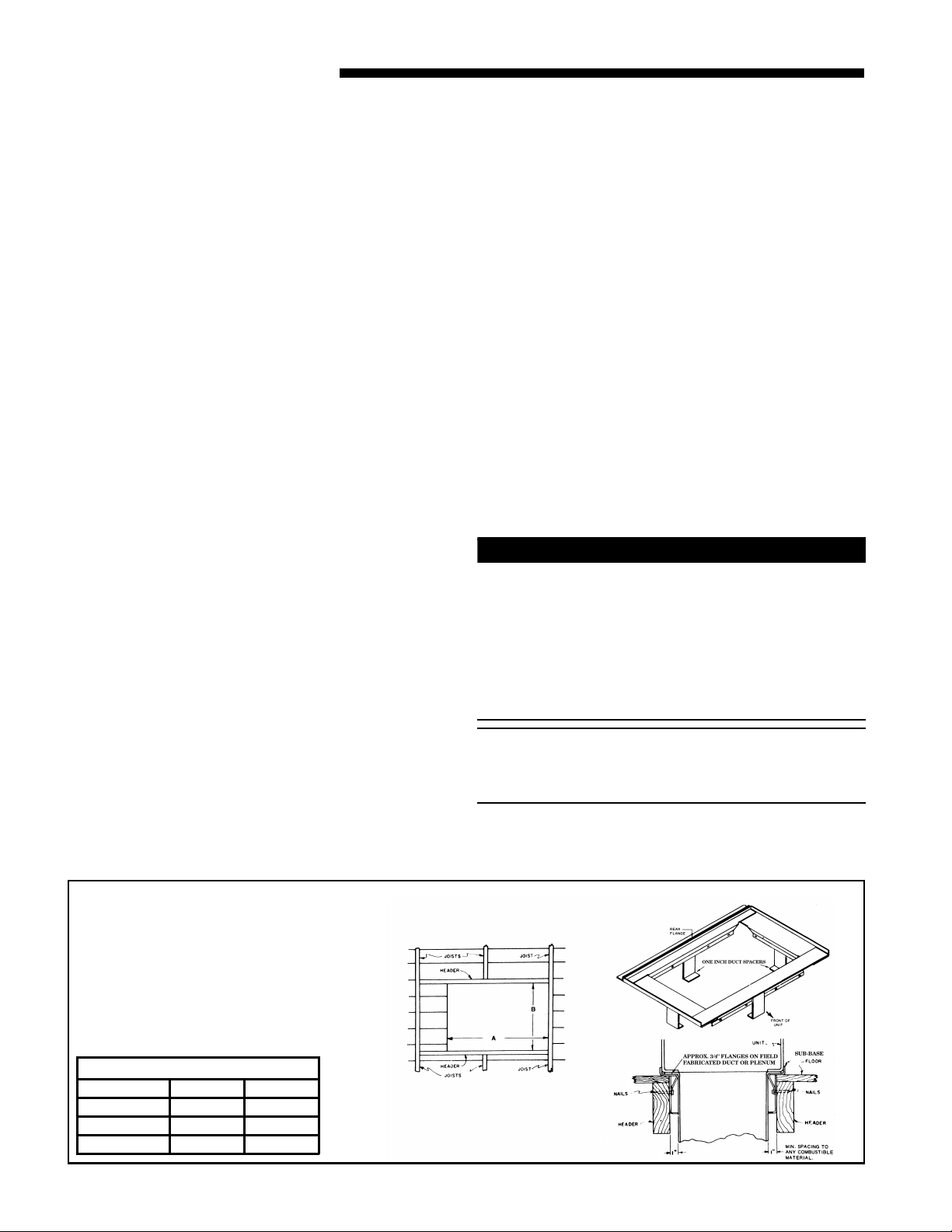

Figure 2

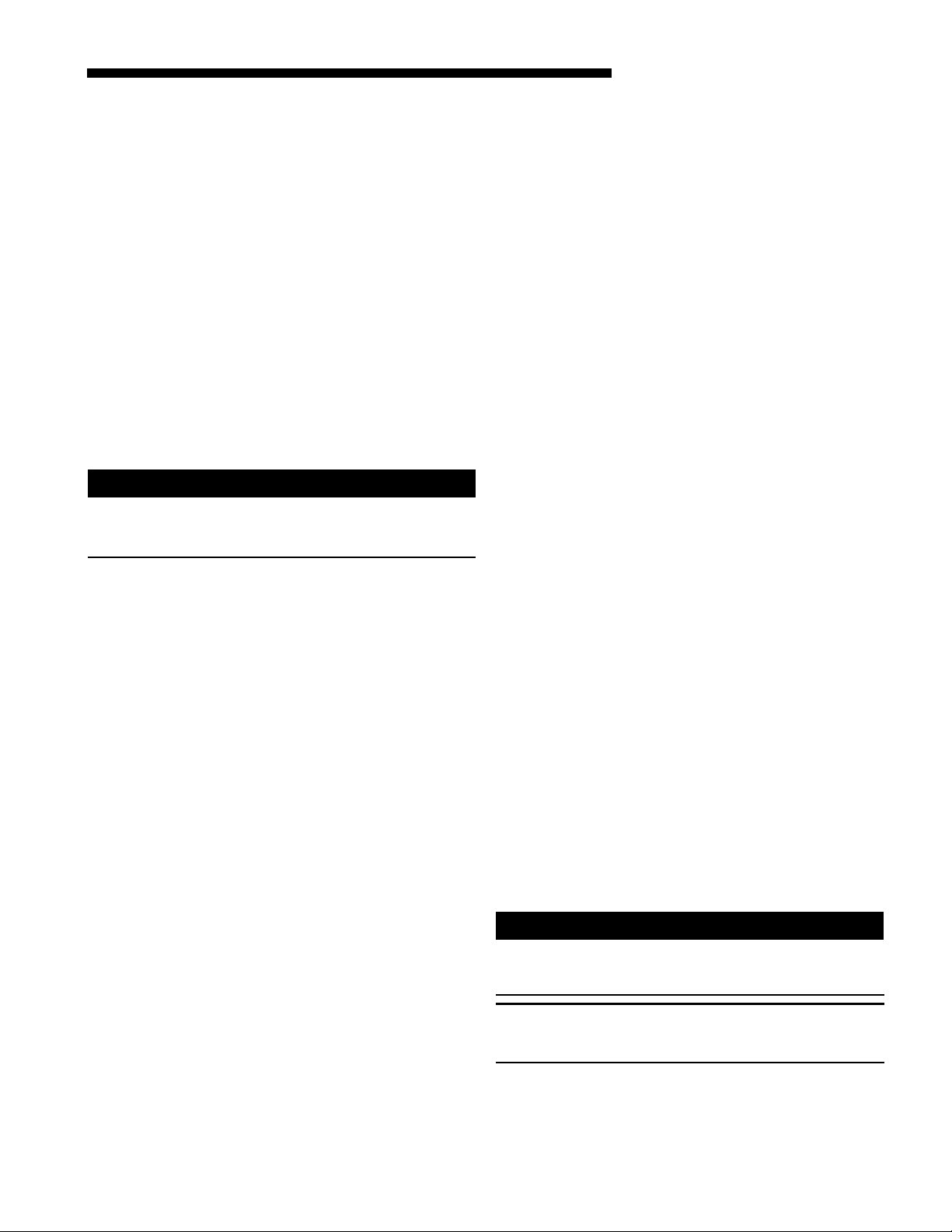

Components of the Integrated Whole House Air Cleaner

1

1) FIELD CHARGER - Charges the contaminants

2) COLLECTION CELL - removes and collects very small

impurities from the air.

3) Power Supply - the solid state power supply converts the

24 Volt AC to the high-voltage, direct current required to

power the FIELD CHARGER and COLLECTION CELL.

4) Safety Switch - cuts off all power to the FIELD CHARGER

and COLLECTION CELL when disengaged.

Check carefully for any shipping damage. This must be

reported to and claims made against the transportation company immediately. Check to be sure all major

components are in the unit. Any missing parts should

be reported to your supplier at once, and replaced with

authorized parts only.

3

4

2

IF AIRHANDLER IS USED

SUPPLEMENTARY HEATER, A PLATE IS REQUIRED TO COVER

THE OPEN HOLE IN THE AIR FLOW SYSTEM

1"

4"

3/8"

WITHOUT

17"

ACCESSORY BAY99X123

Figure 3

A FACTORY FURNISHED

1/4" HOLES (4)

6"

From Dwg. 21B140413

11. If the unit is installed without a return air duct, applicable local codes may limit this air handler to installation only in a single story residence & within

conditioned space.

12. If the outdoor unit is to be installed later, or by others, then installation of the air handler must be

made to allow access for refrigerant lines, or attach

refrigerant lines to air handler when installing.

13. Make sure there are provisions for installing condensate drain lines.

14. If side, front or rear return is required, air handler

must be elevated or placed on a plenum

(TAYPLNM100 or 101). Connecting return duct directly to the side, front or rear of the cabinet is not

approved.

15. Route refrigerant & condensate drain lines away

from air handler so they do not interfere with access panels and COLLECTION CELL removal.

16. When external accessories are used, the additional

height and width requirements must be considered

in the overall space needed.

17. These units are not approved for outdoor installation.

18. These units are approved for draw-through application

only.

19. DO NOT use silicon based sealant. This causes a

coating on the FIELD CHARGER pins that will decrease the efficiency of the air cleaner.

NOTE: No atomizing style humidifier is allowed in the

return plenum with the use of this unit.

20. Flow-through Bypass Humidifiers

Excessive bypass air may cause water blow-off,

which will adversely affect system operation and air

cleaner performance. To verify bypass airflow, follow the Bypass Humidifier Pre-Installation Checkout and Set-Up Procedures available through your

local distributor. Ask for publication number 18CH37D1-1.

18-GE10D1-4 3

Installer’s Guide

▲

Steam and Flow-through Fan Power Ductmounted Humidifiers

Follow the humidifier installation instructions.

These should only be installed on the supply air

side of the system.

Other Duct Mounted Humidifiers are Not recommended for installation with the air

cleaner.

21. Unit installation must include either a return air

duct or grill that prevents accidental access to pins.

For upflow open air intake applications that do not

have a grill or return air duct, installation will require the use of either BAYPLNM120, TASB215,

TASB235, or TASB260 depending on cabinet size.

TASB accessories can be purchaed from:

Miami Tech Inc.

3611 NW 74 Street

Miami, Florida 33147

Phone: 800-339-2290

Fax: 305-693-6152

www.miamitech.com

TASB215 for use with 21.5" cabinets 2/4TEE3D31

TASB235 for use with 23.5" cabinets 2/4TEE3D37

TASB260 for use with 26.0" cabinets 2/4TEE3D40,49,

and 65

22. A PRE-FILTER is not required to be installed with

the air handler containing a Whole House Air

Cleaner. If the use of a PRE-FILTER is desired, it

must be installed at least 6" away from the Whole

House Air Cleaner.

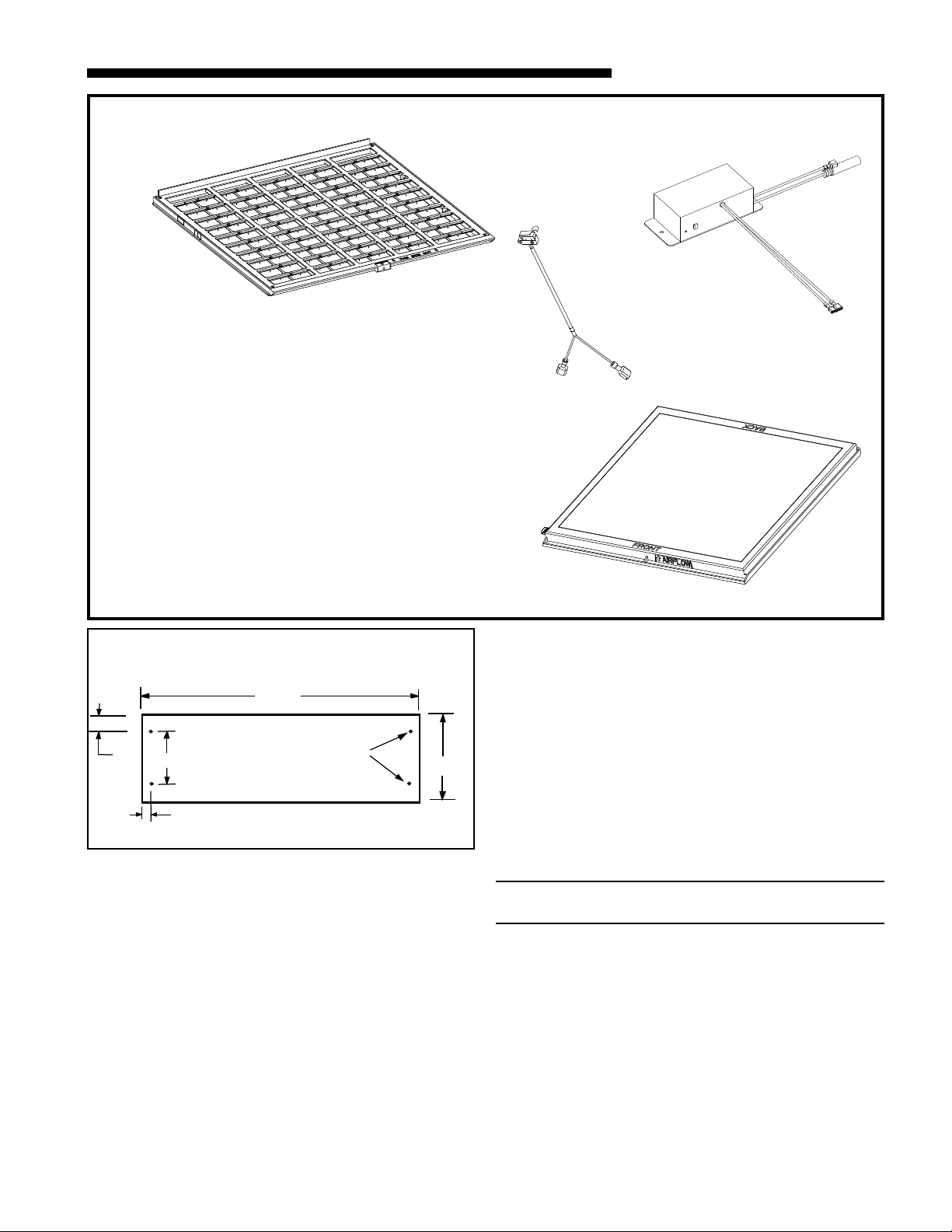

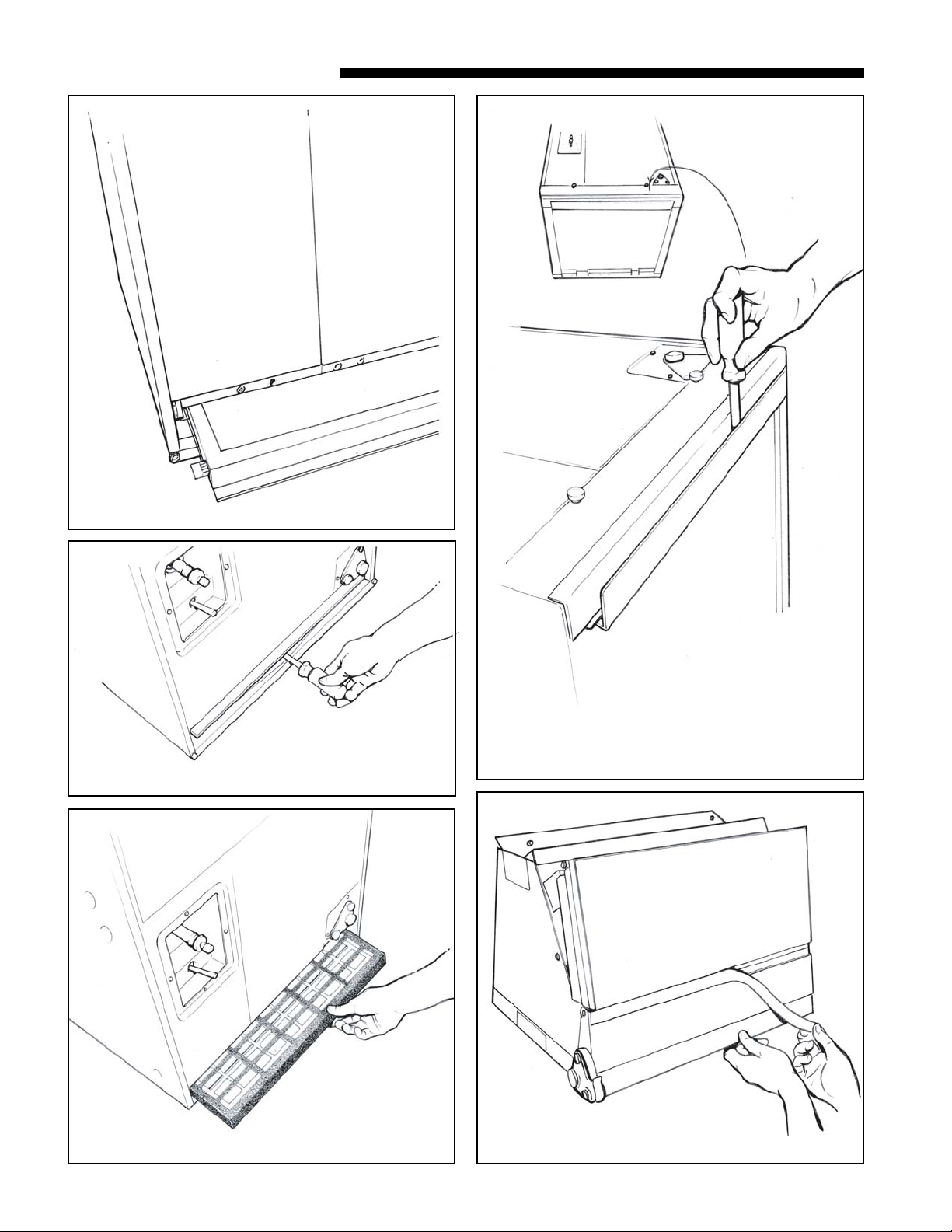

B. TWO PIECE CABINET DISASSEMBLY

(OPTIONAL)

NOTE: For easier installation into tight areas, the 4

and 5 ton air handlers can be disassembled and reas-

sembled after moved to an attic or other space.

Steps for disassembly and reassembly (See Figures 4

and 5)

1. Disconnect wiring.

2. Remove center bracket.

3. Remove blower assembly.

4. Remove coil.

5. Cut foil tape - minimum 3" foil tape.

6. Remove top 8 screws. See Figure 3.

7. Lift upper section.

8. Set air handler in place.

9. Attach screws - insure gaskets are aligned

along flange.

10. Use foil tape to seal - use minimum 3" foil tape.

11. Insert coil.

12. Reinstall blower assembly.

13. Reinstall center bracket.

14. Reconnect wiring.

NOTE: In Downflow, remove coil before blower by

reversing steps 4 and 5.

SCREWS 5-8

LOCATED ON

LEFT SIDE

2

1

3

4

Figure 4 Closeup of Spear Locations

Figure 5

2 Piece Wrapper Spear

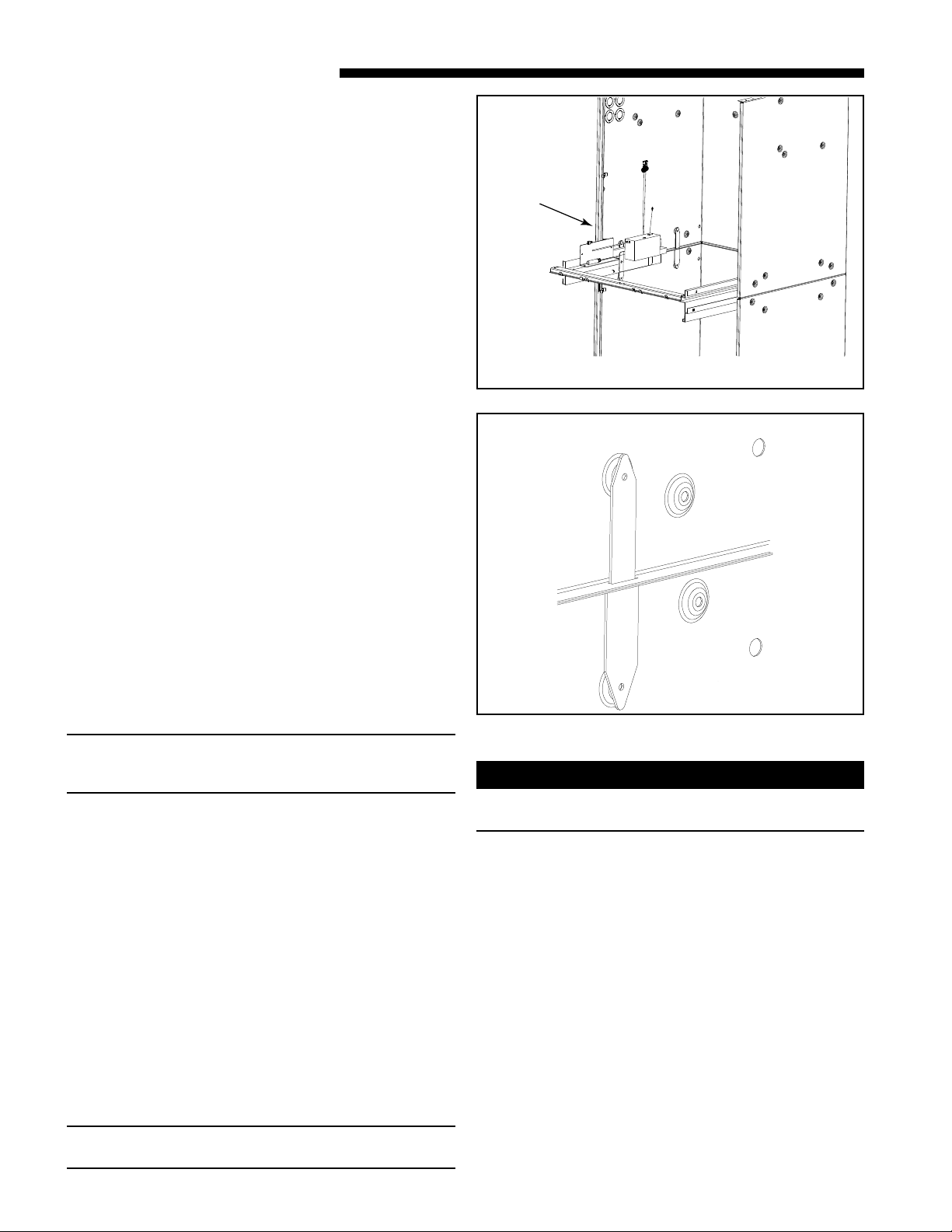

C. UNIT INSTALLATION

UPFLOW

!

CAUTION

When unit is installed in non-ducted applications,

BAYPLNM120 must be used.

a. Before installing unit, remove thumbscrews to

the filter panel. Carefully remove the COLLECTION CELL by grasping the leading edge of the

frame. See Figure 6. Set aside in a safe place until the unit is set in place and ready to start up.

b. Use a 5/16" nutdriver to remove the screws hold-

ing the FIELD CHARGER retainer and take out

both. Slightly lift the FIELD CHARGER and carefully remove. Set aside in a safe place until the

unit is set in place and ready to start up. See Figures 7 and 8.

c. Position unit to remove the bottom protector

plate by laying the unit on its back. Use a flat

blade screwdriver between the protector plate

and the unit to pry apart. See Figure 9. Gently

pull the plate towards the front of the unit to remove.

4 18-GE10D1-5

Installer’s Guide

▲

▲

d. For maximum efficiency, the horizontal drip

tray should be removed. See Figures 10, 11 and

12. Tray removal requires that the coil be removed by sliding the coil out on the coil channel

supports. For the TEE3D40-65 units, there is a

coil support tab at the top of the coil connected to

the case that must be removed first. Remove 1

inch insulation strip covering the lip of the drip

tray. The tray is detached by removing the two

screws at the drain pan. Remove the two screws

holding the two brackets at the top of the coil.

Remove drip tray by gently breaking the seal between the drip tray and drain pan.

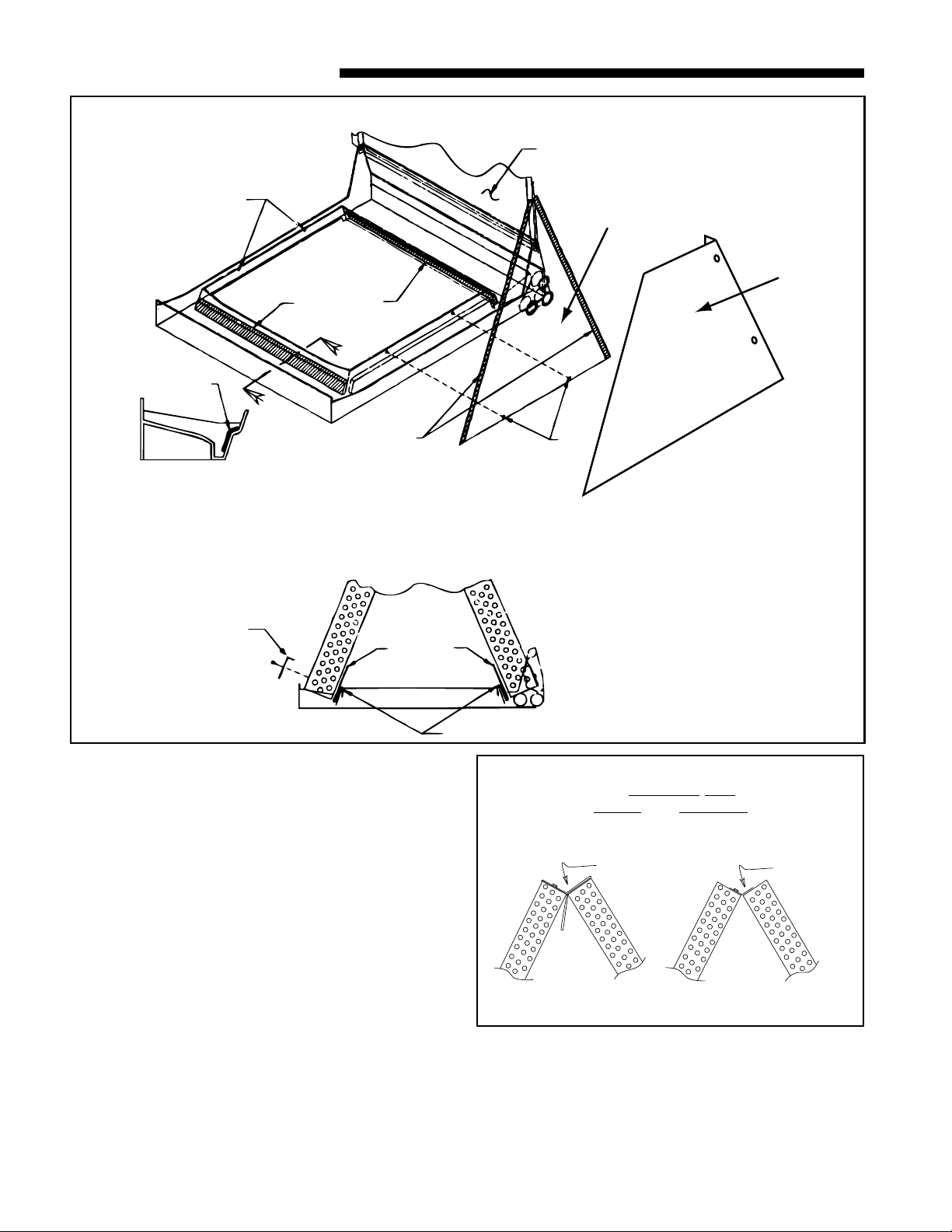

e. Remove the factory installed baffle assembly

from the apex of the coil by using a 5/16"

nutdriver to remove the screws. Replace this

baffle with the factory supplied narrow coil baffle

using the screws removed previously. See Figure

15. Reinstall coil assembly.

!

CAUTION

When installing the narrow coil baffle, make sure to

align the baffle up with the holes so NOT to puncture

the coil tubing.

f. Position unit on Pedestal or other suitable foun-

dation. If Pedestal is not used, a frame strong

enough to support the total weight must be provided. Provide a minimum height of 14 inches for

proper unrestricted airflow. In open return applications, installation requires a BAYPLNM or

TASB stand.

g. If a return air duct is connected to the air han-

dler, it must be the same dimensions as shown in

the outline drawing on page 20.

h. On units with sheetmetal returns: Return

plenum must be flanged. Sheetmetal screws

must be 1/2" in length or shorter. Self-tapping screws are supplied with unit in accessory pack. See Figure 17.

i. No sheetmetal screws may be used to at-

tach return duct work on the side of the

unit.

j. Pedestal and unit should be isolated from the

foundation using a suitable isolating material.

k. Openings where field wiring enters the

cabinet must be completely sealed. Location

of power entry is shown on the Outline Drawing.

Use 2.5" clear stickers provided to seal all unused

electrical knockouts. See Figure 16.

l. After ductwork connections are made, seal air-

tight and per Local codes.

m. Install FIELD CHARGER as shown in Figure 18

(Upflow). Ionizing pins must face downward (into

the return air stream) and electrical contacts

must be on the left side of the unit.

n. Reinstall FIELD CHARGER retainer bracket.

18-GE10D1-5 5

o. Install COLLECTION CELL as shown in Figure

18 (Upflow) so that electrical contacts and actuator tab are on the left side of the unit.

p. Install filter panel with thumbscrews.

DOWNFLOW

a. Before installing unit, remove thumbscrews to

the filter panel. Carefully remove the COLLECTION CELL by grasping the leading edge of the

frame. See Figure 6. Set aside in a safe place until the unit is set in place and ready to start up.

b. Use a 5/16" nutdriver to remove the screw in the

FIELD CHARGER retainer and take out both.

Slightly lift the FIELD CHARGER and carefully

remove. Set aside in a safe place until the unit is

set in place and ready to start up. See Figures 7

and 8.

c. Position unit to remove the bottom protector

plate by laying the unit on its back. Use a flat

blade screwdriver between the protector plate

and the unit to pry apart. See Figure 9. Gently

pull the plate towards the front of the unit to remove.

d. For maximum efficiency, the horizontal drip

tray should be removed. See Figures 10, 11 and

12. Tray removal requires that the coil be removed by sliding the coil out on the coil channel

supports. For the TEE3D40-65 units, there is a

coil support tab at the top of the coil connected to

the case that must be removed first. Remove 1

inch insulation strip covering the lip of the drip

tray. The tray is detached by removing the two

screws at the drain pan and the two screws holding the two brackets at the top of the coil. Remove drip tray by gently breaking the seal between the drip tray and drain pan.

e. Remove the factory installed baffle assembly

from the apex of the coil by using a 5/16"

nutdriver to remove the screw. Replace this

baffle with the factory supplied narrow coil baffle

using the screws removed previously. See Figure

15.

!

CAUTION

When installing the narrow coil baffle, make sure to

align the baffle up with the holes so NOT to puncture

the coil tubing.

NOTE: Installation of the downflow baffle kit included

with unit is required on downflow applications. See

Figure 14.

f. Remove front shield by removing screws on right

side. Make sure to reinstall front shield after

baffle changes. See Figure 14.

g. Detach the coil from the drain pan by removing 4

screws as shown in Figure 14.

Installer’s Guide

Figure 6 COLLECTION CELL Removal

Figure 9 Protector Plate Removal

Figure 7 FIELD CHARGER Retainer Bracket Removal

Figure 8 FIELD CHARGER Removal

6 18-GE10D1-5

Figure 10 Drip Pan Foam Removal

Figure 11 Horizontal Drip Tray Removal

Installer’s Guide

Rail

Figure 12 Drip Tray Bracket Removal

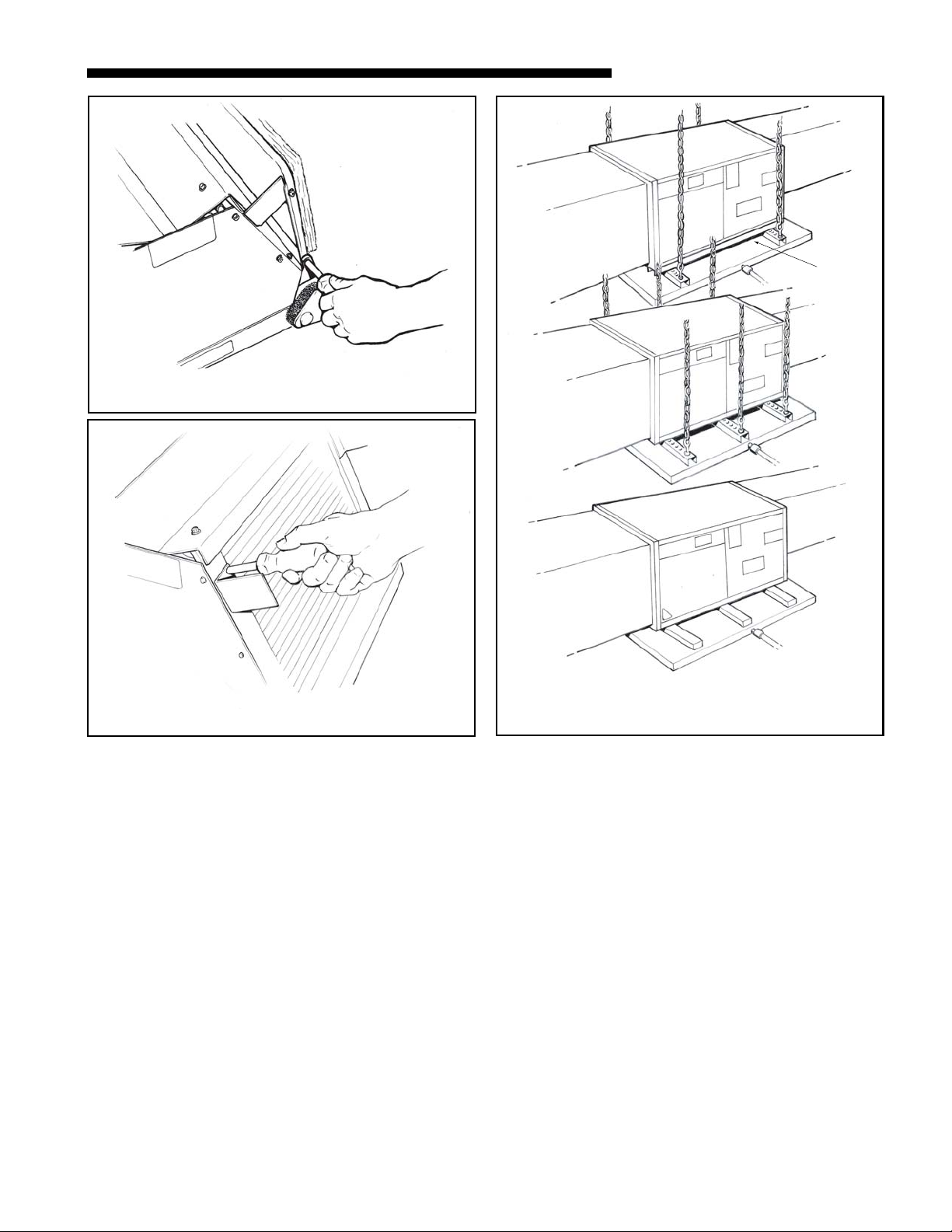

h. Remove the front triangular baffle from the coil

and install the 1/2" wide gasket provided per Figure 14. Trim the gasket length to fit the baffle.

Reinstall the baffle to coil, with gasket material

compressed against the coil.

i. Install the water blow-off baffles provided on each

side of the coil with the flange at the top as

shown in Figure 14. The bottom of the baffle is to

be as close to the bottom of the coil as possible.

j. Install the 7/8" wide gasket in each side of the

drain pan as shown in Figure 14 (sect. X-X).

k. The 5 ton model (2/4TEE3D65) requires 2 water

diverter baffles to be placed underneath the coil

on the inside edge of the drain pan. See Figure

14. Fill the bend in the baffle which fits the inner edge of the drain pan with non-acetic acid

RTV type adhesive/sealant before installing the

Figure 13 Mounting Installation Options

baffle. Ensure sealant is dry/set before reinstalling the coil.

l. The unit is then placed with the blower side

down and the coil is replaced on the coil channel

supports with the drain connections at the bottom. The unit is now in downflow position with

front access. Do not reattach coil support tab.

m. When supplementary heaters are used, accessory

subbase (TAYBASE101 for 2/4TEE3D31, TAYBASE100 for 2/4TEE3D37, and TAYBASE102 for

2/4TEE3D40-65) must be used. See Figure 1.

n. If a return duct is connected to the air handler, it

must be the same dimensions as the return

opening shown in the outline drawing on page

20.

o. On units with sheet metal returns: Return

plenum must be flanged. Sheetmetal screws

must be 1/2" in length or shorter. Self-tapping screws are supplied with the unit in

accessory packet. See Figure 17.

18-GE10D1-5 7

Installer’s Guide

Figure 14 DOWNFLOW BAFFLE KIT

DISCARD

DRIP TRAY

SCREWS TO

REMOVE COIL

7/8" GASKET

SECT. X-X

(TYP. BOTH SIDES)

WATER

BLOW-OFF

BAFFLES

ATTACH WITH

2 SCREWS

EACH SIDE

7/8" GASKET

X

X

1/2" GASKET

INSIDE SURFACE

OF BAFFLE

WATER

DIVERTER

BAFFLES

(5-ton only)

TRIANGULAR

BAFFLE

FRONT

SHIELD

SCREWS TO

REMOVE COIL

p. No sheetmetal screws may be used to at-

tach return ductwork on the side of the

unit.

q. Install FIELD CHARGER as shown in Figure 18

(Downflow). Ionizing pins must face upward (into

the return air stream) and electrical contacts

must be on the right side of the unit.

r. Reinstall FIELD CHARGER retainer bracket.

s. Install COLLECTION CELL as shown in Figure

18 (Downflow) so that electrical contacts and actuator tab are on the right side of the unit.

t. Install filter panel with thumbscrews.

u. Openings where field wiring enters the

cabinet must be completely sealed. Location

of power entry is shown on the outline drawing.

FILL WITH SEALANT

For Maximum Efficiency

Use 2.5" clear stickers provided to seal all unused

electrical knockouts. See Figure 16.

v. After ductwork connections are made, seal air-

tight and per Local codes.

HORIZONTAL LEFT

on

Horizontal Left,

Upflow and Downflow

Remove

and

Discard

Figure 15

Replace

with

Narrow

Baffle

8 18-GE10D1-5

Loading...

Loading...