American Standard 4A6V0036A1000B, 4A7V0036B1000B, 4A6V0060A1000B, 4A7V0024A1000B, 4A6V0048A1000B Service Facts

...

Scan to see help

videos on this

product

Service Facts

Variable Speed AccuLink™™

Heat Pumps and Air Conditioners

4A6V0024A1000B

4A6V0036A1000B

4A6V0048A1000B

4A6V0060A1000B

4A7V0024A1000B

4A7V0036B1000B

4A7V0048A1000B

4A7V0060A1000B

4A7V0061A1000B

NNoottee:: “Graphics in this document are for representation only.

Actual model may differ in appearance.”

SSAAFFEETTYY WWAARRNNIINNGG

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and

air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered

equipment by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the

literature and on the tags, stickers, and labels that are attached to the equipment.

August 2017

44AA--VV00--SSFF--11GG--EENN

SAFETY SECTION — OUTDOOR

IImmppoorrttaanntt — This document contains a wiring diagram

and service information. This is customer property and

is to remain with this unit. Please return to service

information pack upon completion of work.

WWAARRNNIINNGG

HHAAZZAARRDDOOUUSS VVOOLLTTAAGGEE!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

DDiissccoonnnneecctt aallll eelleeccttrriicc ppoowweerr,, iinncclluuddiinngg rreemmoottee

ddiissccoonnnneeccttss bbeeffoorree sseerrvviicciinngg.. FFoollllooww pprrooppeerr

lloocckkoouutt//ttaaggoouutt pprroocceedduurreess ttoo eennssuurree tthhee ppoowweerr

ccaannnnoott bbee iinnaaddvveerrtteennttllyy eenneerrggiizzeedd..

WWAARRNNIINNGG

RREEFFRRIIGGEERRAANNTT OOIILL!!

AAnnyy aatttteemmpptt ttoo rreeppaaiirr aa cceennttrraall aaiirr ccoonnddiittiioonniinngg

pprroodduucctt mmaayy rreessuulltt iinn pprrooppeerrttyy ddaammaaggee,, sseevveerree

ppeerrssoonnaall iinnjjuurryy,, oorr ddeeaatthh..

TThheessee uunniittss uussee RR--441100AA rreeffrriiggeerraanntt wwhhiicchh ooppeerraatteess

aatt 5500 ttoo 7700%% hhiigghheerr pprreessssuurreess tthhaann RR--2222.. UUssee oonnllyy

RR--441100AA aapppprroovveedd sseerrvviiccee eeqquuiippmmeenntt.. RReeffrriiggeerraanntt

ccyylliinnddeerrss aarree ppaaiinntteedd aa ““RRoossee”” ccoolloorr ttoo iinnddiiccaattee

tthhee ttyyppee ooff rreeffrriiggeerraanntt aanndd mmaayy ccoonnttaaiinn aa ““ddiipp””

ttuubbee ttoo aallllooww ffoorr cchhaarrggiinngg ooff lliiqquuiidd rreeffrriiggeerraanntt iinnttoo

tthhee ssyysstteemm.. AAllll RR--441100AA ssyysstteemmss wwiitthh vvaarriiaabbllee

ssppeeeedd ccoommpprreessssoorrss uussee aa PPVVEE ooiill tthhaatt rreeaaddiillyy

aabbssoorrbbss mmooiissttuurree ffrroomm tthhee aattmmoosspphheerree.. TToo lliimmiitt

tthhiiss ““hhyyggrroossccooppiicc”” aaccttiioonn,, tthhee ssyysstteemm sshhoouulldd

rreemmaaiinn sseeaalleedd wwhheenneevveerr ppoossssiibbllee.. IIff aa ssyysstteemm hhaass

bbeeeenn ooppeenn ttoo tthhee aattmmoosspphheerree ffoorr mmoorree tthhaann 44

hhoouurrss,, tthhee ccoommpprreessssoorr ooiill mmuusstt bbee rreeppllaacceedd.. NNeevveerr

bbrreeaakk aa vvaaccuuuumm wwiitthh aaiirr aanndd aallwwaayyss cchhaannggee tthhee

ddrriieerrss wwhheenn ooppeenniinngg tthhee ssyysstteemm ffoorr ccoommppoonneenntt

rreeppllaacceemmeenntt..

CCAAUUTTIIOONN

HHOOTT SSUURRFFAACCEE!!

MMaayy ccaauussee mmiinnoorr ttoo sseevveerree bbuurrnniinngg.. FFaaiilluurree ttoo

ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn pprrooppeerrttyy

ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

DDoo nnoott ttoouucchh ttoopp ooff ccoommpprreessssoorr..

CCAAUUTTIIOONN

CCOONNTTAAIINNSS RREEFFRRIIGGEERRAANNTT!!

FFaaiilluurree ttoo ffoollllooww pprrooppeerr pprroocceedduurreess ccaann rreessuulltt iinn

ppeerrssoonnaall iillllnneessss oorr iinnjjuurryy oorr sseevveerree eeqquuiippmmeenntt

ddaammaaggee..

SSyysstteemm ccoonnttaaiinnss ooiill aanndd rreeffrriiggeerraanntt uunnddeerr hhiigghh

pprreessssuurree.. RReeccoovveerr rreeffrriiggeerraanntt ttoo rreelliieevvee pprreessssuurree

bbeeffoorree ooppeenniinngg ssyysstteemm..

CCAAUUTTIIOONN

GGRROOUUNNDDIINNGG RREEQQUUIIRREEDD!!

FFaaiilluurree ttoo iinnssppeecctt oorr uussee pprrooppeerr sseerrvviiccee ttoooollss mmaayy

rreessuulltt iinn eeqquuiippmmeenntt ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

RReeccoonnnneecctt aallll ggrroouunnddiinngg ddeevviicceess.. AAllll ppaarrttss ooff tthhiiss

pprroodduucctt tthhaatt aarree ccaappaabbllee ooff ccoonndduuccttiinngg eelleeccttrriiccaall

ccuurrrreenntt aarree ggrroouunnddeedd.. IIff ggrroouunnddiinngg wwiirreess,, ssccrreewwss,,

ssttrraappss,, cclliippss,, nnuuttss,, oorr wwaasshheerrss uusseedd ttoo ccoommpplleettee aa

ppaatthh ttoo ggrroouunndd aarree rreemmoovveedd ffoorr sseerrvviiccee,, tthheeyy mmuusstt

bbee rreettuurrnneedd ttoo tthheeiirr oorriiggiinnaall ppoossiittiioonn aanndd pprrooppeerrllyy

ffaasstteenneedd..

WWAARRNNIINNGG

SSEERRVVIICCEE VVAALLVVEESS!!

FFaaiilluurree ttoo ffoollllooww tthhiiss wwaarrnniinngg wwiillll rreessuulltt iinn aabbrruupptt

rreelleeaassee ooff ssyysstteemm cchhaarrggee aanndd mmaayy rreessuulltt iinn

ppeerrssoonnaall iinnjjuurryy aanndd//oorr pprrooppeerrttyy ddaammaaggee..

EExxttrreemmee ccaauuttiioonn sshhoouulldd bbee eexxeerrcciisseedd wwhheenn

ooppeenniinngg tthhee LLiiqquuiidd LLiinnee SSeerrvviiccee VVaallvvee.. TTuurrnn vvaallvvee

sstteemm ccoouunntteerrcclloocckkwwiissee oonnllyy uunnttiill tthhee sstteemm

ccoonnttaaccttss tthhee rroolllleedd eeddggee.. NNoo ttoorrqquuee iiss rreeqquuiirreedd..

WWAARRNNIINNGG

BBRRAAZZIINNGG RREEQQUUIIRREEDD!!

FFaaiilluurree ttoo iinnssppeecctt lliinneess oorr uussee pprrooppeerr sseerrvviiccee ttoooollss

mmaayy rreessuulltt iinn eeqquuiippmmeenntt ddaammaaggee oorr ppeerrssoonnaall

iinnjjuurryy..

iiff uussiinngg eexxiissttiinngg rreeffrriiggeerraanntt lliinneess mmaakkee cceerrttaaiinn tthhaatt

aallll jjooiinnttss aarree bbrraazzeedd,, nnoott ssoollddeerreedd..

WWAARRNNIINNGG

HHIIGGHH LLEEAAKKAAGGEE CCUURRRREENNTT!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

EEaarrtthh ccoonnnneeccttiioonn eesssseennttiiaall bbeeffoorree ccoonnnneeccttiinngg

eelleeccttrriiccaall ssuuppppllyy..

©2017 Ingersoll Rand

4A-V0-SF-1G-EN

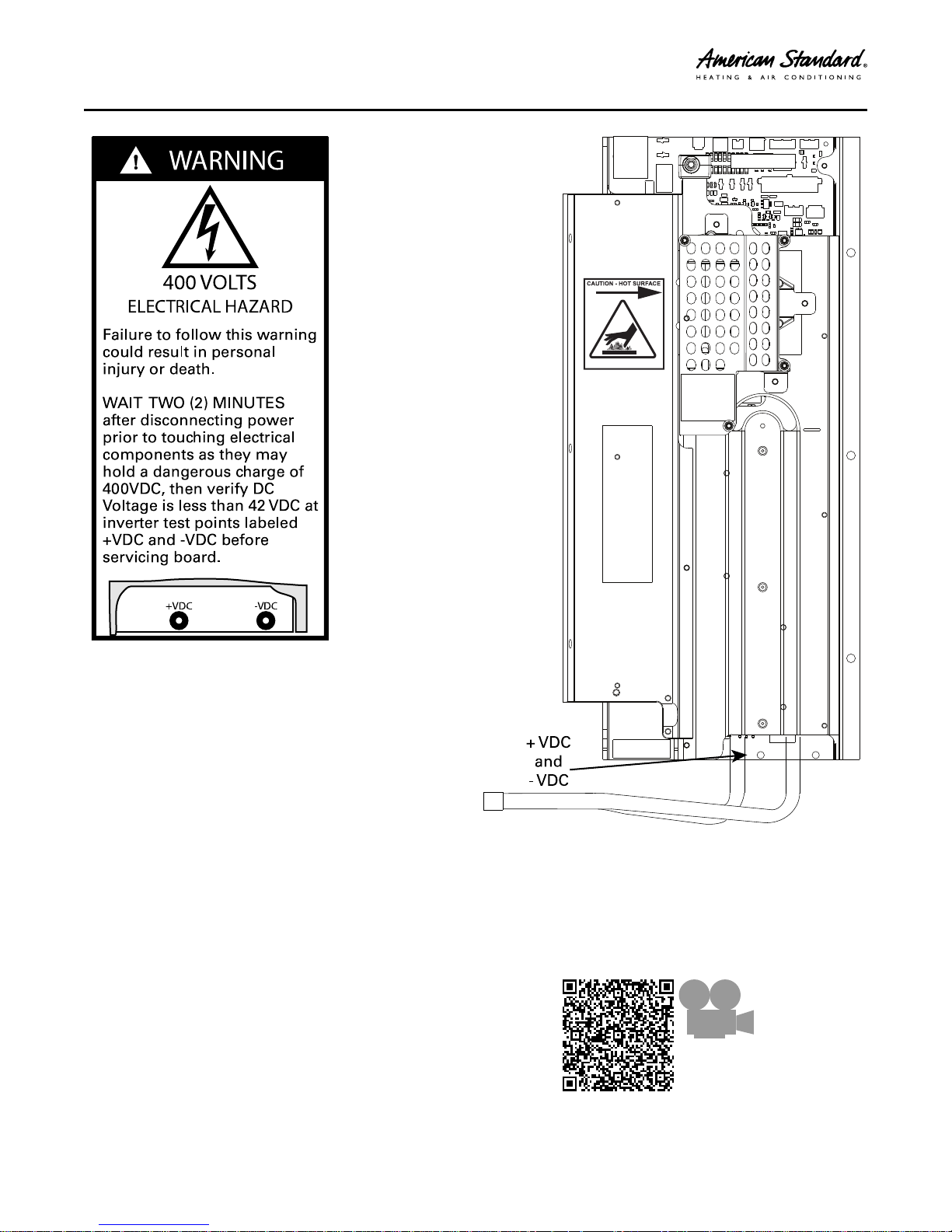

Scan to see an

overview

video

about the IVSC

Board

SSAAFFEETTYY SSEECCTTIIOONN —— OOUUTTDDOOOORR

Approved Combinations for Variable Speed Units

• AZONE 850 Comfort Control, or AZONE 950 with Software Version

3.0 or Higher

• TAM8C or later models

• Platinum SV Furnace

• Platinum ZV Furnace

• Approved System Accessories

Note: See AHRI directory for approved indoor and outdoor model

combinations. Only Trane coils and air handlers are approved

for use with variable speed outdoor units.

4A-V0-SF-1G-EN

Important: Use caution when cleaning outdoor coil to ensure no

water enters the electrical control compartment. When

cleaning coil from inside the compressor compartment,

take special care not to spray water towards the top rows

of the coil near the control panel. Water may enter the

control compartment and drive damaging the

electronics. Disconnect all electric power, including

remote disconnects before servicing.

3

SSAAFFEETTYY SSEECCTTIIOONN —— OOUUTTDDOOOORR

Table 1. Operating Range

Cooling 55° F to 120° F

Table 1. Operating Range (continued)

Heating -10° F to 66° F

4

4A-V0-SF-1G-EN

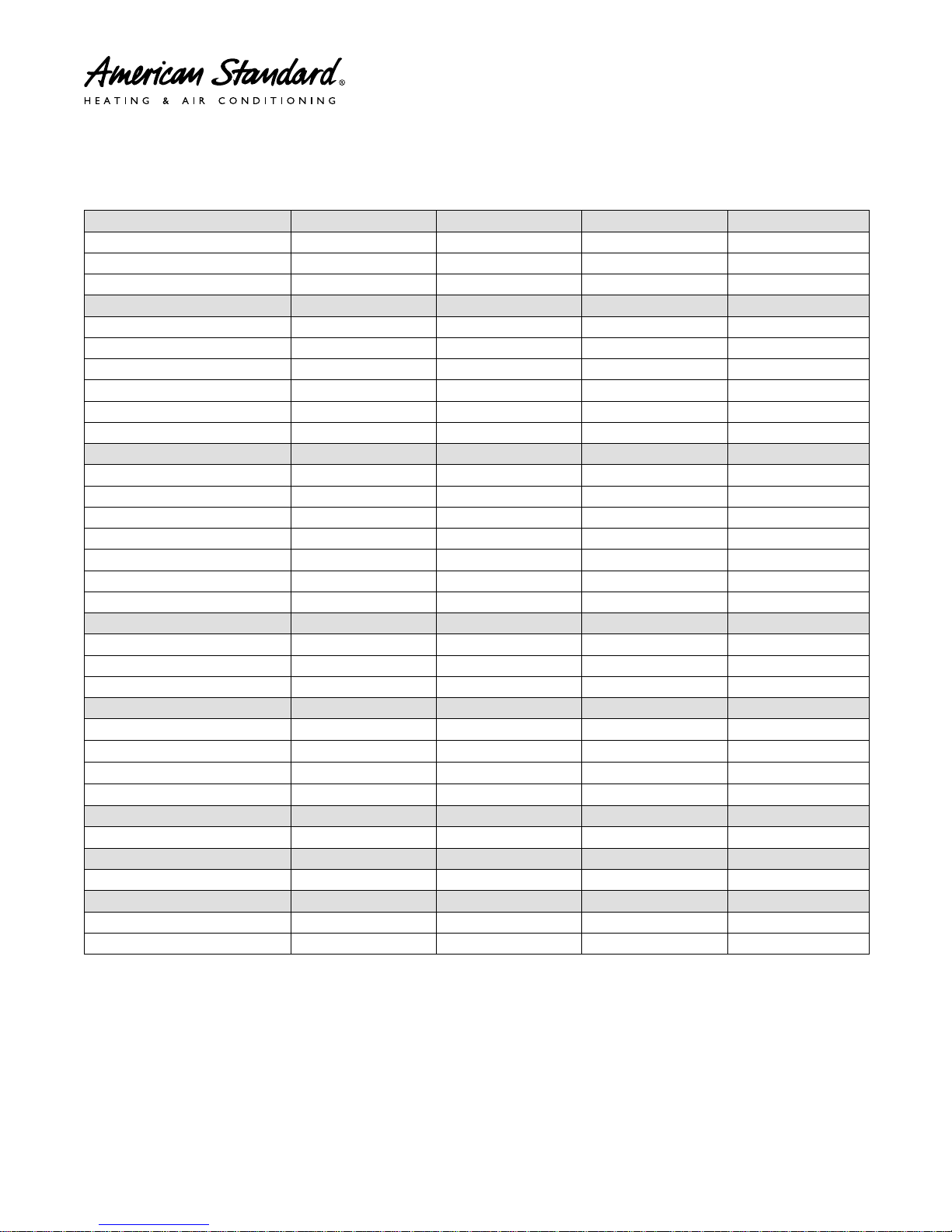

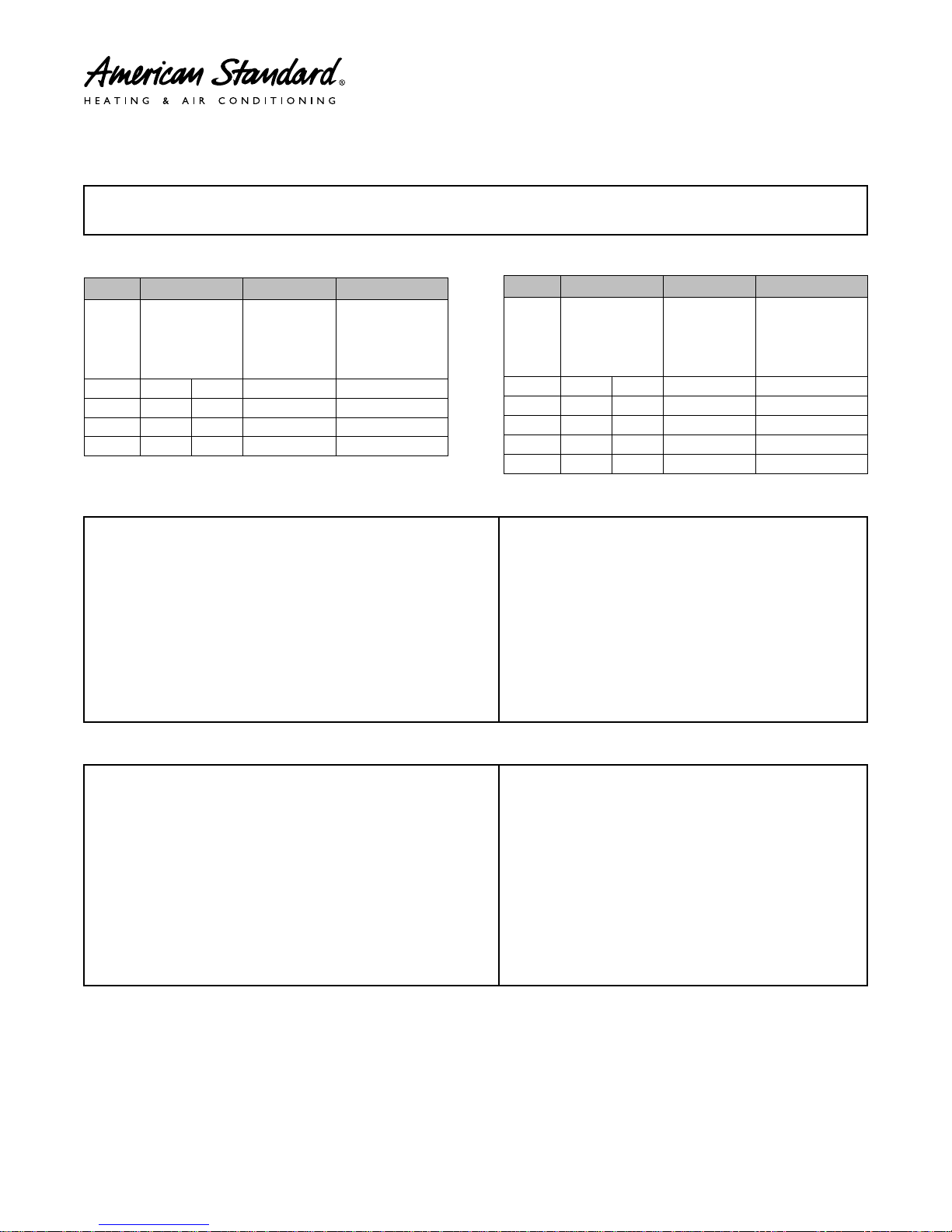

Product Specifications

HEAT PUMP MODELS

OUTDOOR UNIT

POWER CONNS. — V/PH/HZ

MIN. BRCH. CIR. AMPACITY 17.0 26.0 29.0 37.0

BR. CIR. PROT. RTG. — MAX. (AMPS)

COMPRESSOR SCROLL SCROLL SCROLL SCROLL

NO. USED — NO. SPEEDS 1–VARIABLE 1–VARIABLE 1–VARIABLE 1–VARIABLE

R.L. AMPS

FACTORY INSTALLED

START COMPONENTS

INSULATION/SOUND BLANKET

COMPRESSOR HEAT YES YES YES YES

OUTDOOR FAN

DIA. (IN.) — NO. USED

TYPE DRIVE — NO. SPEEDS DIRECT — VARIABLE DIRECT — VARIABLE DIRECT — VARIABLE DIRECT — VARIABLE

CFM @ 0.0 IN. W.G.

NO. MOTORS — HP

MOTOR SPEED R.P.M. 200 — 1200 200 — 1200 200 — 1200 200 — 1200

VOLTS/PH/HZ 208/230/1/60 208/230/1/60 208/230/1/60 208/230/1/60

F.L. AMPS 2.8 2.8 2.8 2.8

OUTDOOR COIL — TYPE SPINE FIN™ SPINE FIN™ SPINE FIN™ SPINE FIN™

ROWS — F.P.I. 1 — 24 1 — 24 1 — 24 1 — 24

FACE AREA (SQ. FT.)

TUBE SIZE (IN.)

REFRIGERANT R410–A R410–A R410–A R410–A

LBS. — R-410A (O.D. UNIT)

FACTORY SUPPLIED YES YES YES YES

LINE SIZE — IN. O.D. GAS

LINE SIZE — IN. O.D. LIQ.

CHARGING SPECIFICATIONS

SUBCOOLING 10° 9° 10° 10°

DIMENSIONS H X W X D H X W X D H X W X D H X W X D

CRATED (IN.)

WEIGHT

SHIPPING (LBS.)

NET (LBS.)

(a)

Certified in accordance with the Air-Source Unitary Air-conditioner Equipment certification program, which is based on AHRI standard 210/240.

(b)

Rated in accordance with AHRI standard 270/275.

(c)

Calculated in accordance with Natl. Elec. Codes. Use only HACR circuit breakers or fuses.

(d)

This value shown for compressor RLA on the unit nameplate and on this specification sheet is used to compute minimum branch circuit ampacity and max.

fuse size. The value shown is the branch circuit selection current.

(e)

No means no start components. Yes means quick start kit components. PTC means positive temperature coefficient starter.

(f)

Standard Air — Dry Coil — Outdoor

(g)

This value approximate. For more precise value see unit nameplate.

(h)

Max. linear length 150 ft.; Max. lift — Suction 50 ft.; Max. lift — Liquid 50 ft.

(i)

Max length of refrigerant lines from outdoor to indoor unit MUST NOT exceed 80 feet. The max vertical change MUST NOT exceed 10 feet. See footnote (h)

if 7/8” suction line is used.

(a) (b)

(d)

— L.R. AMPS

4A6V0024A1000B 4A6V0036A1000B 4A6V0048A1000B 4A6V0060A1000B

(c)

208/230/1/60 208/230/1/60 208/230/1/60 208/230/1/60

25 40 45 50

11.5 — 10.2 18.4 — 10.2 21.1 — 12.0 27.5 — 12.0

(e)

NA NA NA NA

YES YES YES YES

23 — 1 27.5 — 1 27.5 — 1 27.5 — 1

(f)

2680 3670 4517 4757

1 — 1/3 1 — 1/3 1 — 1/3 1 — 1/3

19.77 27.87 27.87 30.80

3/8 3/8 3/8 3/8

(g)

(h)

7 lb — 6 oz 9 lb — 8 oz 10 lb — 12 oz 11 lb — 14 oz

5/8

(h)

3/4

(h)

7/8

(h)

1 – 1/8

(i)

3/8 3/8 3/8 3/8

46 X 30.1 X 33 46.4 X 35.1 X 38.7 46.4 X 35.1 X 38.7 51 X 35.1 X 38.7

225 263 275 285

204 238 250 259

4A-V0-SF-1G-EN

5

PPrroodduucctt SSppeecciiffiiccaattiioonnss

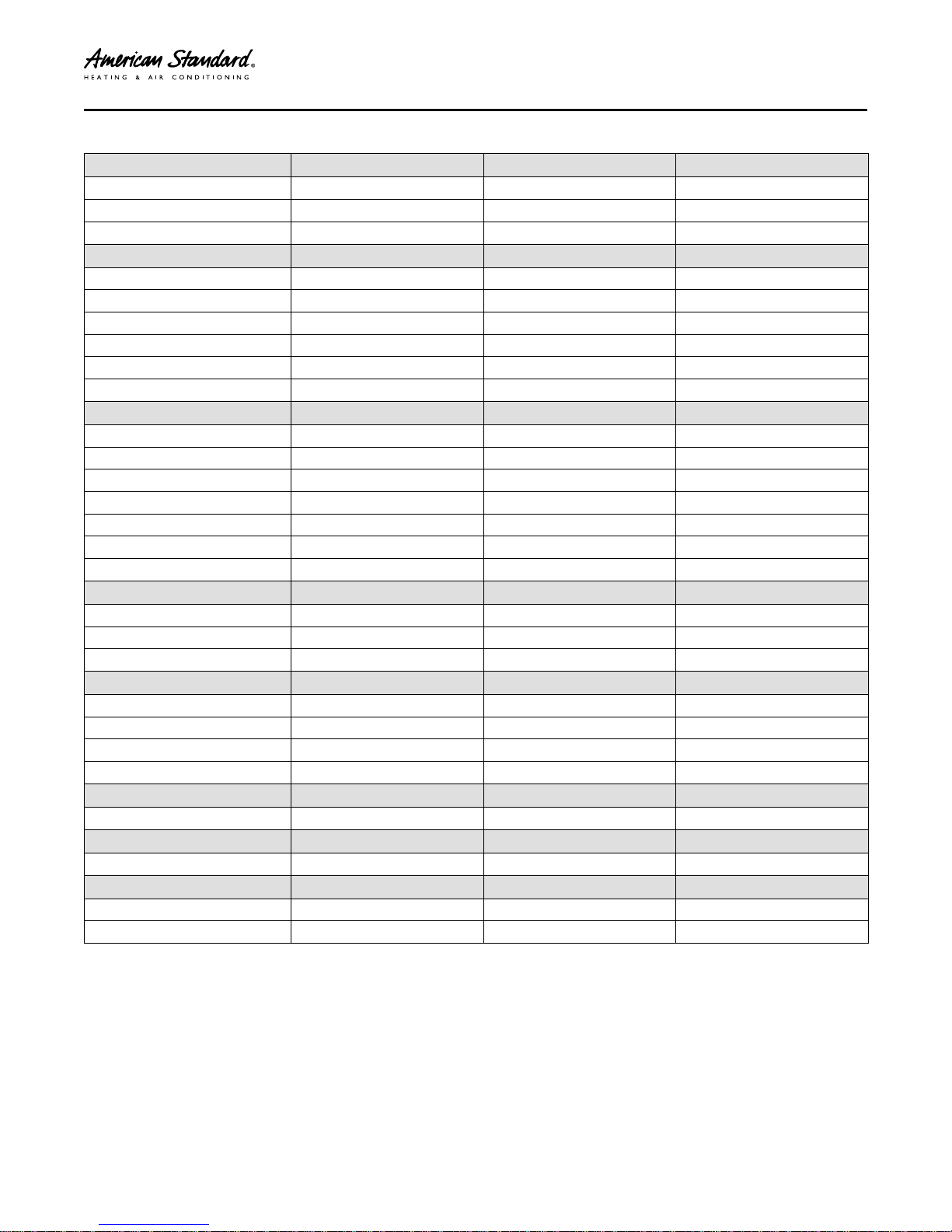

AIR CONDITIONER MODELS

OUTDOOR UNIT

POWER CONNS. — V/PH/HZ

MIN. BRCH. CIR. AMPACITY 17.0 18.0 23.0

BR. CIR. PROT. RTG. — MAX. (AMPS)

COMPRESSOR SCROLL SCROLL SCROLL

NO. USED — NO. SPEEDS 1–VARIABLE 1–VARIABLE 1–VARIABLE

R.L. AMPS

FACTORY INSTALLED

START COMPONENTS

INSULATION/SOUND BLANKET

COMPRESSOR HEAT YES YES YES

OUTDOOR FAN

DIA. (IN.) — NO. USED

TYPE DRIVE — NO. SPEEDS DIRECT — VARIABLE DIRECT — VARIABLE DIRECT — VARIABLE

CFM @ 0.0 IN. W.G.

NO. MOTORS — HP

MOTOR SPEED R.P.M. 200 — 1200 200 — 1200 200 — 1200

VOLTS/PH/HZ 208/230/1/60 208/230/1/60 208/230/1/60

F.L. AMPS 2.8 2.8 2.8

OUTDOOR COIL — TYPE SPINE FIN™ SPINE FIN™ SPINE FIN™

ROWS — F.P.I. 1 — 24 1 — 24 1 — 24

FACE AREA (SQ. FT.)

TUBE SIZE (IN.)

REFRIGERANT R410–A R410–A R410–A

LBS. — R-410A (O.D. UNIT)

FACTORY SUPPLIED YES YES YES

LINE SIZE — IN. O.D. GAS

LINE SIZE — IN. O.D. LIQ.

CHARGING SPECIFICATIONS

SUBCOOLING 10° 10° 10°

DIMENSIONS H X W X D H X W X D H X W X D

CRATED (IN.)

WEIGHT

SHIPPING (LBS.)

NET (LBS.)

(a)

Certified in accordance with the Air-Source Unitary Air-conditioner Equipment certification program, which is based on AHRI standard 210/240.

(b)

Rated in accordance with AHRI standard 270/275.

(c)

Calculated in accordance with Natl. Elec. Codes. Use only HACR circuit breakers or fuses.

(d)

This value shown for compressor RLA on the unit nameplate and on this specification sheet is used to compute minimum branch circuit ampacity and max.

fuse size. The value shown is the branch circuit selection current.

(e)

No means no start components. Yes means quick start kit components. PTC means positive temperature coefficient starter.

(f)

Standard Air — Dry Coil — Outdoor

(g)

This value approximate. For more precise value see unit nameplate.

(h)

Max. linear length 150 ft.; Max. lift — Suction 50 ft.; Max. lift — Liquid 50 ft.

(a) (b)

(d)

— L.R. AMPS

4A7V0024A1000B 4A7V0036B1000B 4A7V0048A1000B

(c)

208/230/1/60 208/230/1/60 208/230/1/60

25 25 35

11.5 — 10.2 12.4 — 10.2 16.0 — 12.0

(e)

NA NA NA

YES YES YES

23 — 1 23 — 1 27.5 — 1

(f)

2680 2850 4560

1 — 1/3 1 — 1/3 1 — 1/3

19.77 23.75 27.87

3/8 3/8 3/8

(g)

(h)

7 lb — 6 oz 9 lb — 6 oz 11 lb — 1 oz

5/8

(h)

3/4

(h)

7/8

(h)

3/8 3/8 3/8

46 X 30.1 X 33 46.4 X 35.1 X 38.7 46.4 X 35.1 X 38.7

217 248 270

196 225 245

6

4A-V0-SF-1G-EN

PPrroodduucctt SSppeecciiffiiccaattiioonnss

AIR CONDITIONER MODELS

OUTDOOR UNIT

POWER CONNS. — V/PH/HZ

MIN. BRCH. CIR. AMPACITY 27.0 27.0

BR. CIR. PROT. RTG. — MAX. (AMPS)

COMPRESSOR SCROLL SCROLL

NO. USED — NO. SPEEDS 1–VARIABLE 1–VARIABLE

R.L. AMPS

FACTORY INSTALLED

START COMPONENTS

INSULATION/SOUND BLANKET

COMPRESSOR HEAT YES YES

OUTDOOR FAN

DIA. (IN.) — NO. USED

TYPE DRIVE — NO. SPEEDS DIRECT — VARIABLE DIRECT — VARIABLE

CFM @ 0.0 IN. W.G.

NO. MOTORS — HP

MOTOR SPEED R.P.M. 200 — 1200 200 — 1200

VOLTS/PH/HZ 208/230/1/60 208/230/1/60

F.L. AMPS 2.8 2.8

OUTDOOR COIL — TYPE SPINE FIN™ SPINE FIN™

ROWS — F.P.I. 1 — 24 2 — 24

FACE AREA (SQ. FT.)

TUBE SIZE (IN.)

REFRIGERANT R410–A R410–A

LBS. — R-410A (O.D. UNIT)

FACTORY SUPPLIED YES YES

LINE SIZE — IN. O.D. GAS

LINE SIZE — IN. O.D. LIQ.

CHARGING SPECIFICATIONS

SUBCOOLING 10° 7.5°

DIMENSIONS H X W X D H X W X D

CRATED (IN.)

WEIGHT

SHIPPING (LBS.)

NET (LBS.)

(a)

Certified in accordance with the Air-Source Unitary Air-conditioner Equipment certification program, which is based on AHRI standard 210/240.

(b)

Rated in accordance with AHRI standard 270/275.

(c)

Calculated in accordance with Natl. Elec. Codes. Use only HACR circuit breakers or fuses.

(d)

This value shown for compressor RLA on the unit nameplate and on this specification sheet is used to compute minimum branch circuit ampacity and max.

fuse size. The value shown is the branch circuit selection current.

(e)

No means no start components. Yes means quick start kit components. PTC means positive temperature coefficient starter.

(f)

Standard Air — Dry Coil — Outdoor

(g)

This value approximate. For more precise value see unit nameplate.

(h)

Max length of refrigerant lines from outdoor to indoor unit MUST NOT exceed 80 feet. The max vertical change MUST NOT exceed 25 feet. See footnote (h)

if 7/8” suction line is used.

(i)

Max length of refrigerant lines from outdoor to indoor unit MUST NOT exceed 80 feet. The max vertical change MUST NOT exceed 25 feet. See footnote (h)

if 7/8" suction line is used.

(a) (b)

(d)

— L.R. AMPS

4A7V0060A1000B 4A7V0061A1000B

(c)

208/230/1/60 208/230/1/60

40 40

19.3 — 12.0 19.3 — 12.0

(e)

NA NA

YES YES

27.5 — 1 27.5 — 1

(f)

4787 4780

1 — 1/3 1 — 1/3

30.80 30.80

3/8 3/8

(g)

(h)

11 lb — 14 oz 12 lb — 7 oz

1 — 1/8

(h)

1–1/8

(i)

3/8 3/8

51 X 35.1 X 38.7 51 X 35.1 X 38.7

284 314

258 288

4A-V0-SF-1G-EN

7

Subcooling Charging in Cooling between 55°° F and 120°°

OD Ambient

American Standard has always recommended

installing American Standard approved matched

indoor and outdoor systems.

All American Standard split systems are AHRI rated

with only TXV or EEV indoor systems.

The benefits of installing approved indoor and outdoor

split systems are maximum efficiency, optimum

performance and the best overall reliability.

The following charging methods are therefore

prescribed for matched systems with indoor TXVs or

EEVs.

1. Subcooling (in the cooling mode) is the only

recommended method of charging between 55°

and 120° ambient temperatures.

2. When charging for ambient temperatures above

120°, charge to 10° subcooling. It is important to

return when outdoor ambient temperature is

between 55° and 120° to verify system charge per

these instructions.

3. For best results — the indoor temperature should

be kept between 70° to 80°. Add system heat if

needed.

4. Locate the designated subcooling target from the

unit nameplate.

5. At startup, or whenever charge is removed or

added, the system must be operated for a minimum

of (20) minutes to stabilize before accurate

measurements can be made.

6. Run the system using the ““CChhaarrggiinngg MMooddee-CCoooolliinngg”” mode found in the 850/950 comfort

control. This is the only approved method for

setting the system charge level.

Measure Liquid Line Temperature and Refrigerant

Pressure at service valves.

7. Determine total refrigerant line length, and height

(lift) if indoor section is above the condenser.

Follow the Subcool Charging Corrections Table to

calculate additional subcooling target value.

8. Locate your liquid line temperature in the left

column of the table, and the intersecting liquid line

gage pressure under the subcool selection column.

Add refrigerant to raise the pressure to match the

table, or remove refrigerant to lower the pressure.

Always wait (20) minutes for the system conditions

to stabilize before adjusting charge again.

9. When system is correctly charged, you can refer to

System Pressure Curves to verify typical

performance.

8

4A-V0-SF-1G-EN

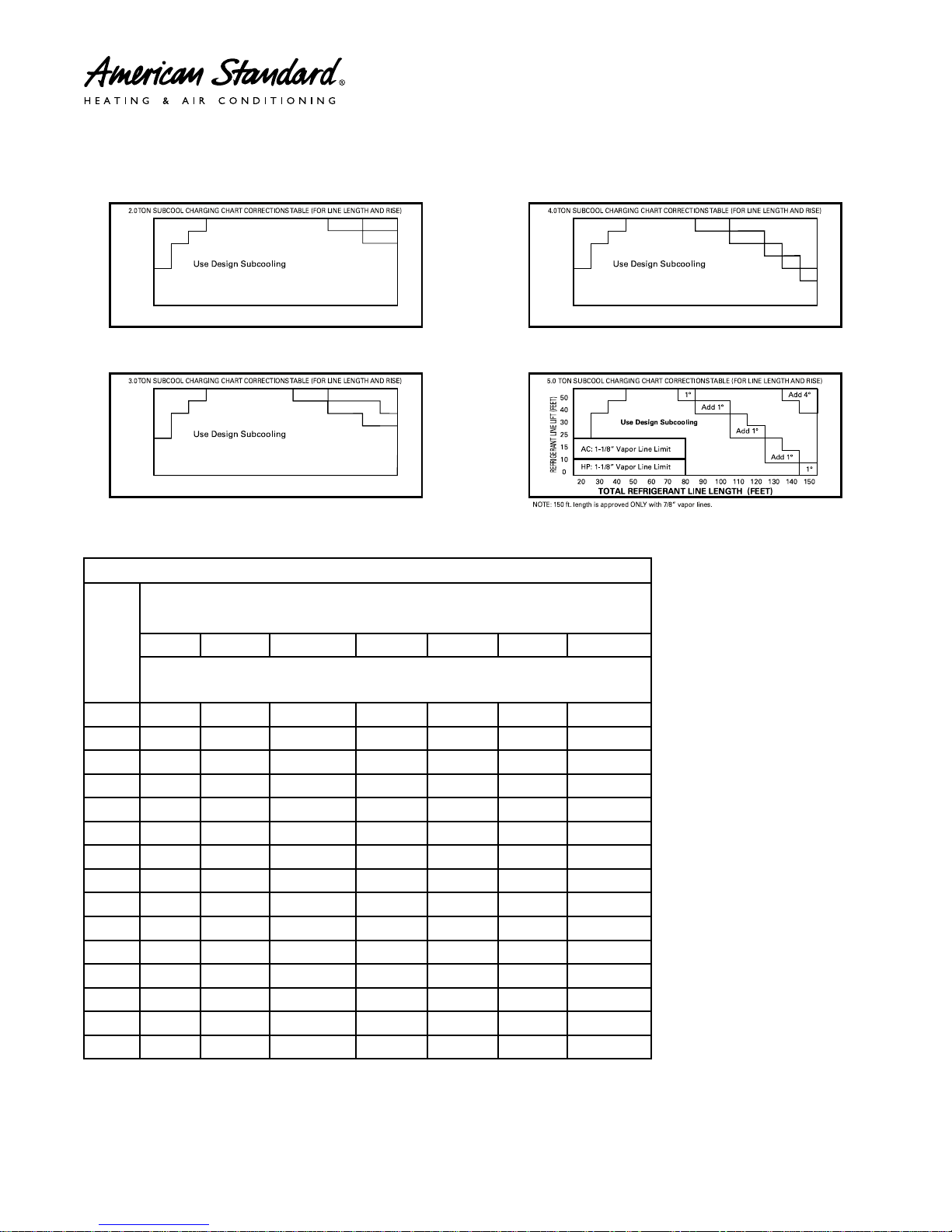

Subcool Charging Correction Charts

TOTAL REFRIGERANT LINE LENGTH (FEET)

Add 1°

Add 1°

Add 2°

70 80 90 100 110 120 130 140 1506050403020

50

40

30

25

15

10

0

REFRIGERANT LINE LIFT (FEET)

TOTAL REFRIGERANT LINE LENGTH (FEET)

Add 1°

Add 1° Add 2°

70 80 90 100 110 120 130 140 1506050403020

50

40

30

25

15

10

0

REFRIGERANT LINE LIFT (FEET)

TOTAL REFRIGERANT LINE LENGTH (FEET)

Add 1°

1°

1°

1°

Add 1°

Add 2°

70 80 90 100 110 120 130 140 1506050403020

50

40

30

25

15

10

0

REFRIGERANT LINE LIFT (FEET)

Add

2°

Figure 1. Subcool Charging Corrections — 2.0 Ton

Figure 2. Subcool Charging Corrections — 3.0 Ton

Refrigerant Charging Chart

R-410A REFRIGERANT CHARGING CHART

DESIGN SUBCOOLING (°F)

LIQUID

TEMP

(°F)

8 9 10 11 12 13 14

LIQUID GAGE PRESSURE (PSI)

Figure 3. Subcool Charging Corrections — 4.0 Ton

Figure 4. Subcool Charging Corrections — 5.0 Ton

55 179 182 185 188 191 195 198

60 195 198 201 204 208 211 215

65 211 215 218 222 225 229 232

70 229 232 236 240 243 247 251

75 247 251 255 259 263 267 271

80 267 271 275 279 283 287 291

85 287 291 296 300 304 309 313

90 309 313 318 322 327 331 336

95 331 336 341 346 351 355 360

100 355 360 365 370 376 381 386

105 381 386 391 396 402 407 413

110 407 413 418 424 429 435 441

115 435 441 446 452 458 464 470

120 464 470 476 482 488 495 501

125 495 501 507 514 520 527 533

4A-V0-SF-1G-EN

9

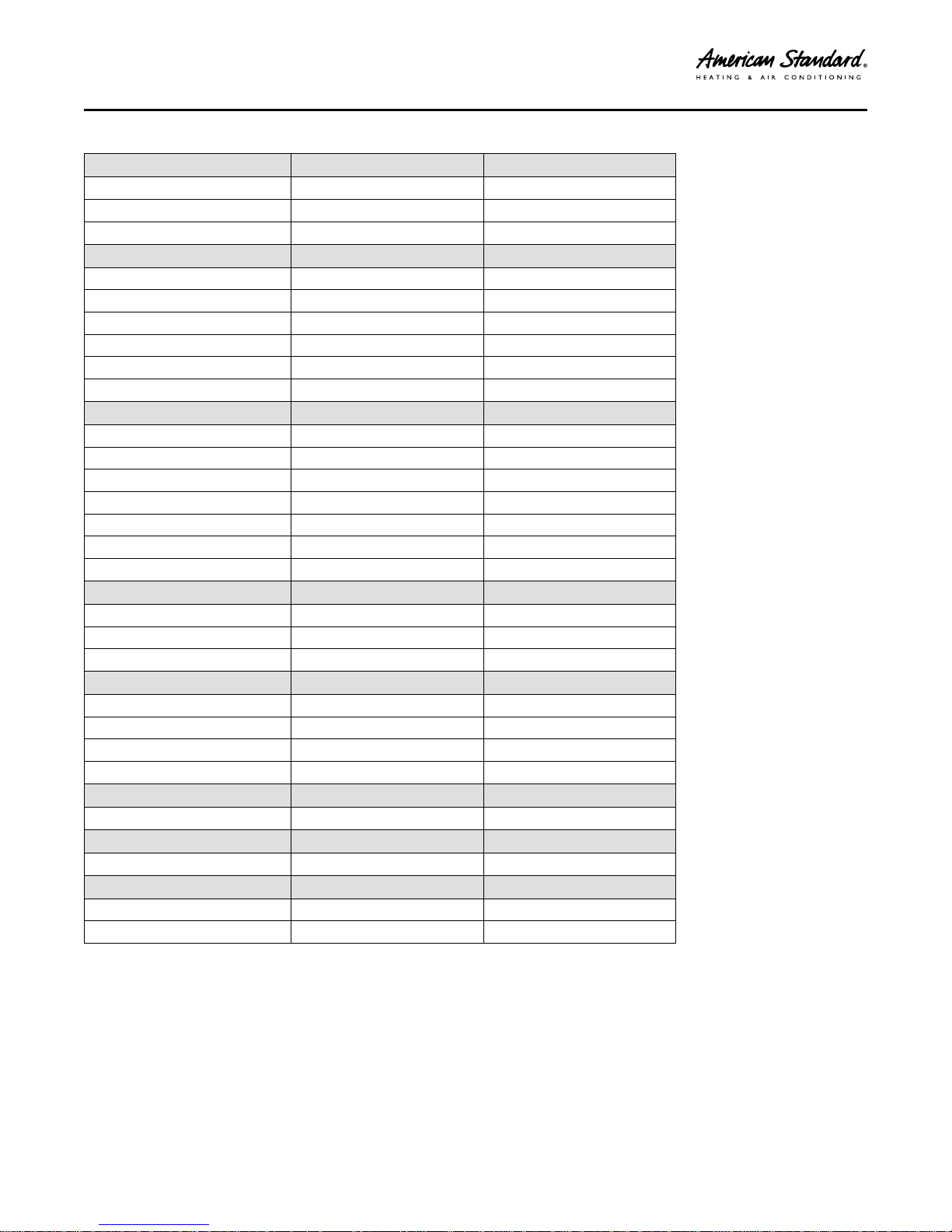

Charging: Weigh-In Method

Weigh-In Method can be used for the initial installation, or anytime a system charge is being replaced. Weigh-In Method can also be used when

power is not available to the equipment site or operating conditions (indoor/outdoor temperatures) are not in range to verify with the

subcooling charging method.

Table 2. Heat Pumps

A

B C D

Table 3. Air Conditioners

A

Charge

multiplier for

interconnecting

refrigerant

Model

Model

Factory

Charge

Charge

adder for

Indoor Coil

tube length

024 7 lb. 6 oz. 6 oz.

036 9 lb. 8 oz. 12 oz.

048 10 lb. 12 oz. 15 oz.

060 11 lb. 14 oz.

1 lb., 2 oz. 0.6 oz/ft

0.6 oz/ft

0.6 oz/ft

0.6 oz/ft

024 7 lb. 6 oz. 6 oz.

036 9 lb. 6 oz. 12 oz.

048 11 lb. 1 oz.

060 11 lb. 14 oz.

061 12 lb. 7 oz.

Table 4. New Installations — Calculating Charge using the Weigh-In method

1. Measure in feet the distance between the outdoor unit and the indoor

unit and record on Line 1. Include the entire length of the line from the

service valve to the IDU.

2. Enter the charge multiplier from Column D.

3. Multiply the total length of refrigerant tubing (Line 1) times the value on

Step 2. Record the result on Line 3 of the Worksheet.

4. Locate the outdoor equipment size in Column A. Record the value shown

in Column C of Table 16 for Heat Pumps or Table 17 for Air Conditioners.

5. Add the values from Step 3 and Step 4 and record the resulting value.

This is the amount of refrigerant to weigh-in prior to opening the service

valves.

New Installation Weigh-In Method Worksheet

1. Line Length (ft) ________________________

2. Value from Column D x ________________________

3. Step 1 x Step 2 = ________________________

4. Charge Adder (column C) + ________________________

5. Refrigerant (Steps 3+4) = ________________________

B C D

Factory

Charge

Charge

adder for

Indoor Coil

1 lb., 0 oz. 0.6 oz/ft

1 lb., 2 oz. 0.6 oz/ft

1 lb., 4 oz. 0.6 oz/ft

Charge

multiplier for

interconnect-

ing refrigerant

tube length

0.6 oz/ft

0.6 oz/ft

Table 5. Sealed-System Repairs — Calculating Charge using the Weigh-In method.

1. Measure in feet the distance between the outdoor unit and the indoor

unit and record on Line 1. Include the entire length of the line from the

service valve to the IDU.

2. Enter the charge multiplier from Column D.

3. Multiply the total length of refrigerant tubing (Line 1) times the value on

Line 2. Record the result on Line 3 of the Worksheet.

4. Locate the outdoor equipment size in Column A. Record the value shown

in Column C of Table 16 for Heat Pumps or Table 17 for Air Conditioners.

5. Record the value in Column B to Line 5 of the Worksheet.

6. Add the values from Step 3, Step 4, and Step 5 and record the resulting

value on Line 6. This is the amount of refrigerant to weigh-in.

Note: The only mode approved for setting or validating system charge is using Charging Mode-Cooling. Charging Mode-Cooling is a variable

speed test mode found in the 850/950 comfort control Technician Menu. Outdoor Temperature must be between 55

Indoor Temperature kept between 70

10

°

F and 80°F.

New Installation Weigh-In Method Worksheet

1. Line Length (ft) ________________________

2. Value from Column D x ________________________

3. Step 1 x Step 2 = ________________________

4. Charge Adder (column C) + ________________________

5. Factory Charge (column B) + ________________________

6. Refrigerant (Steps 3+4+5) = ________________________

°

F and 120°F with

4A-V0-SF-1G-EN

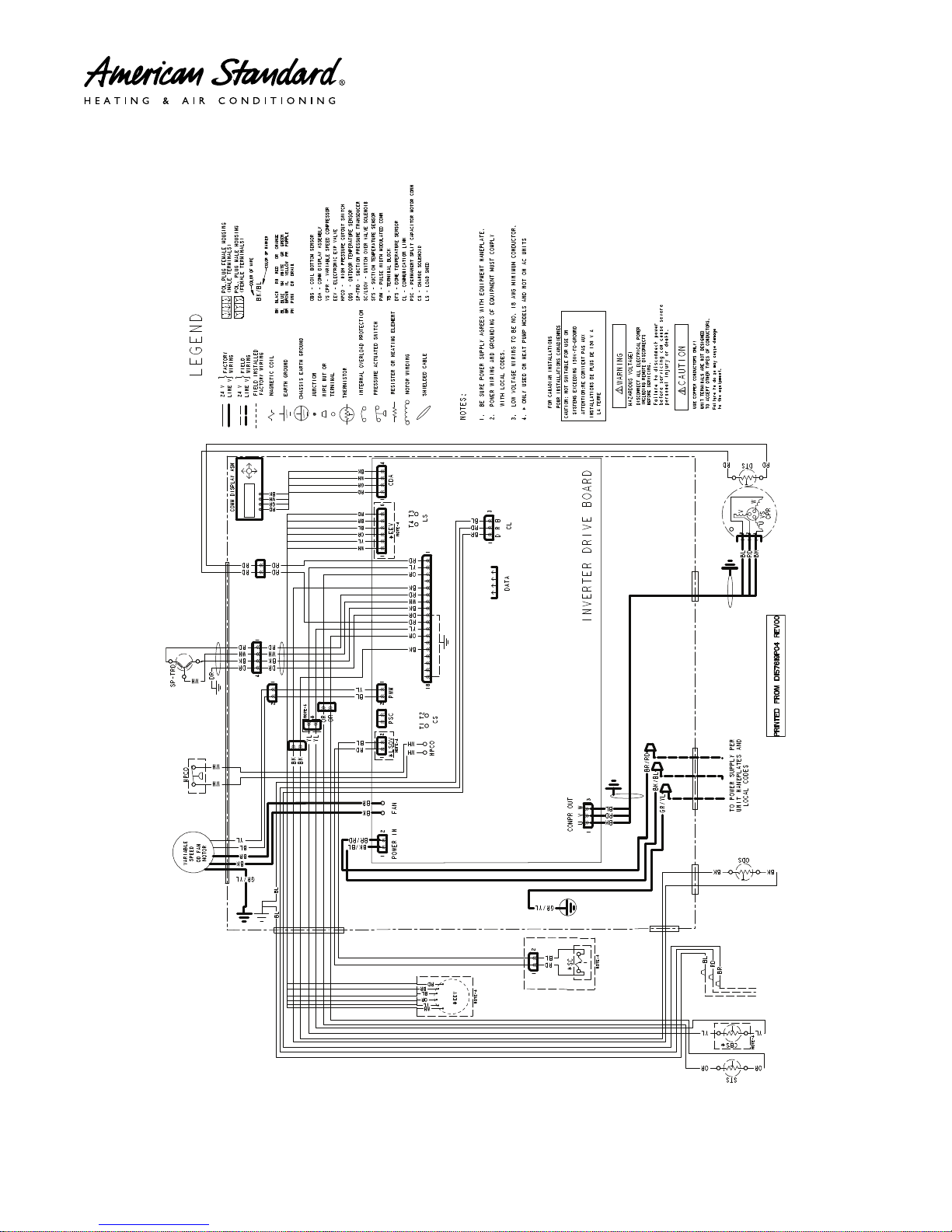

Wiring — D157619P04

4A-V0-SF-1G-EN

11

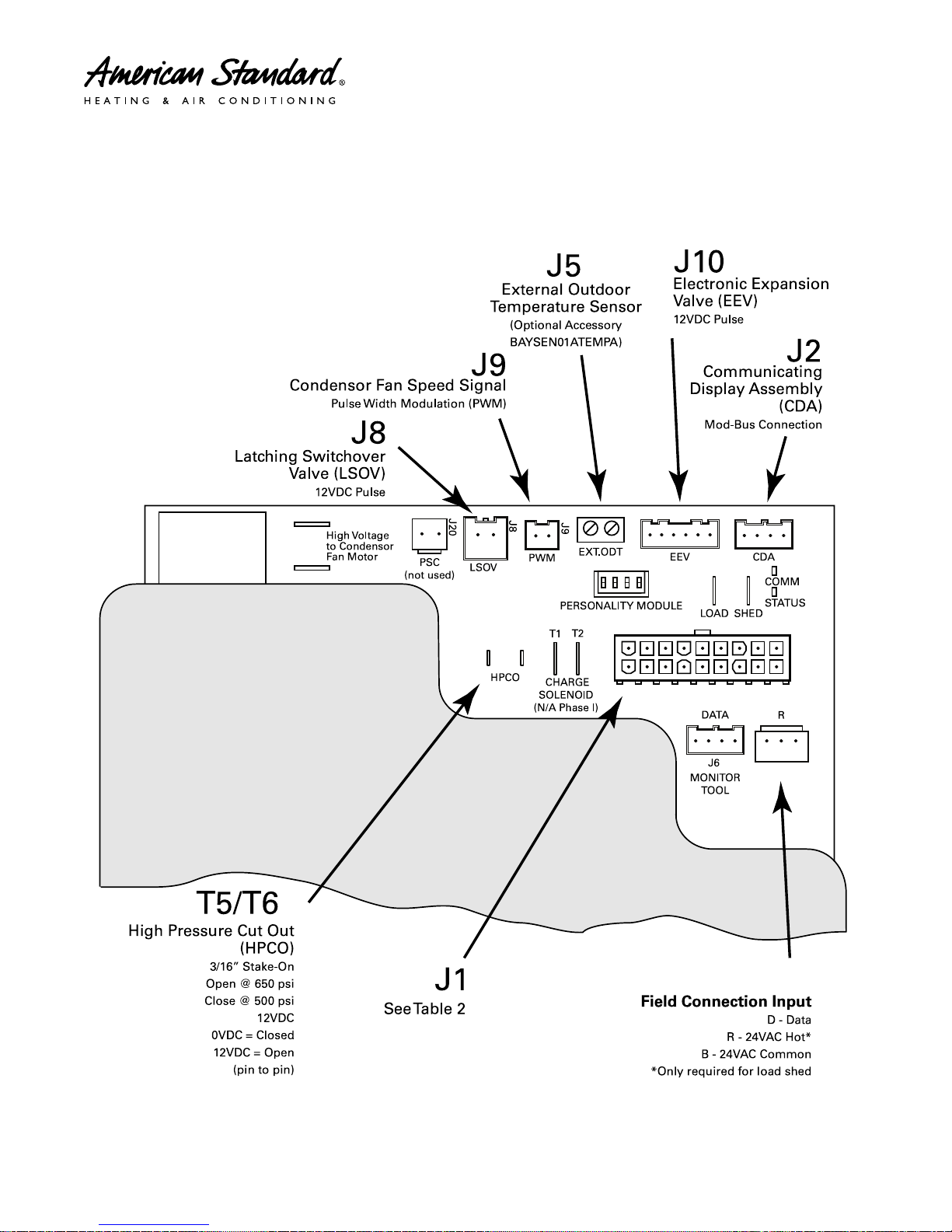

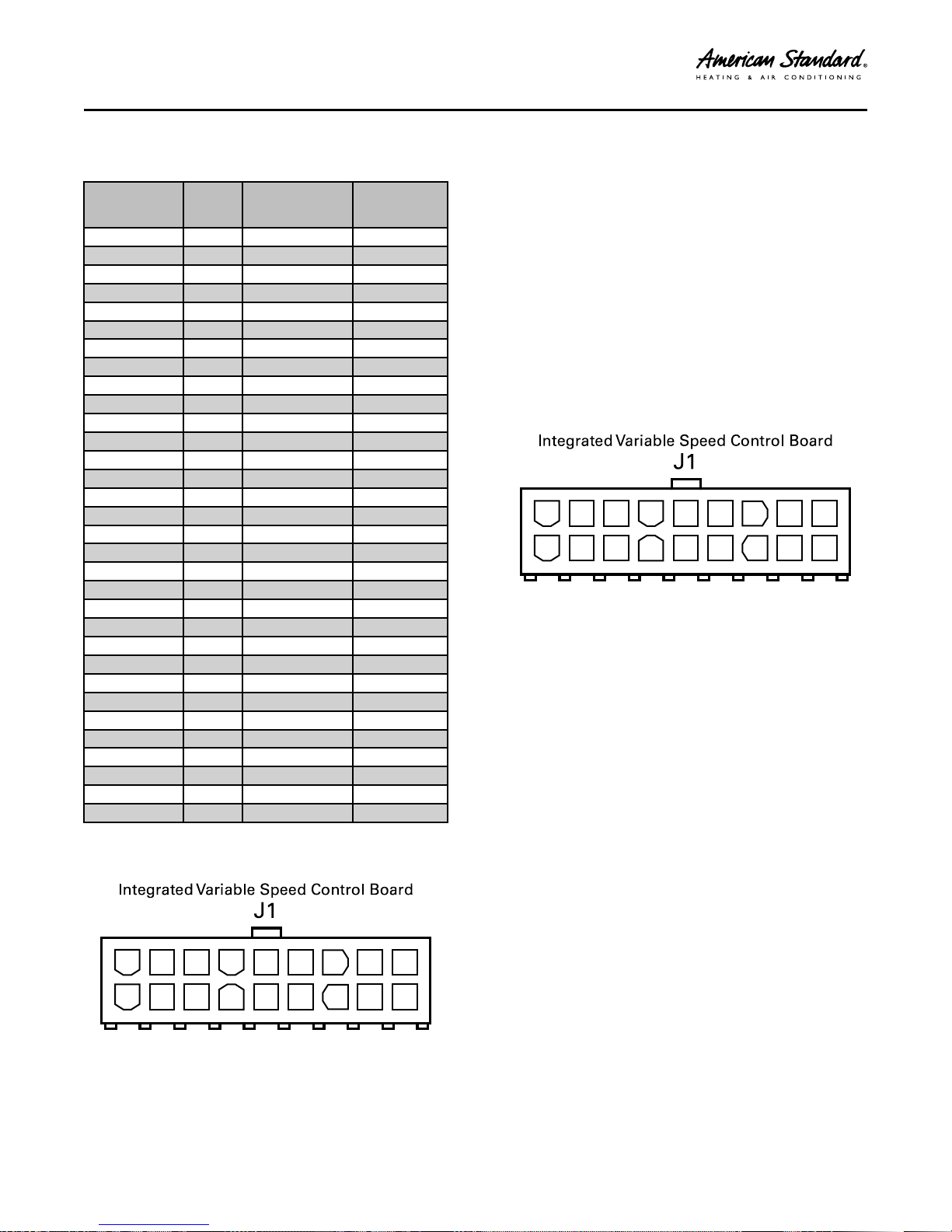

Integrated Variable Speed Control (IVSC) Inputs/

FAN

ALUMINUM COVER PLATE

T4 T3

10

1

18

9

J1

J4

D B

J3

J10

J2

J5

J4

Outputs

AAllssoo RReeffeerrrreedd ttoo aass ““TThhee DDrriivvee””

12

4A-V0-SF-1G-EN

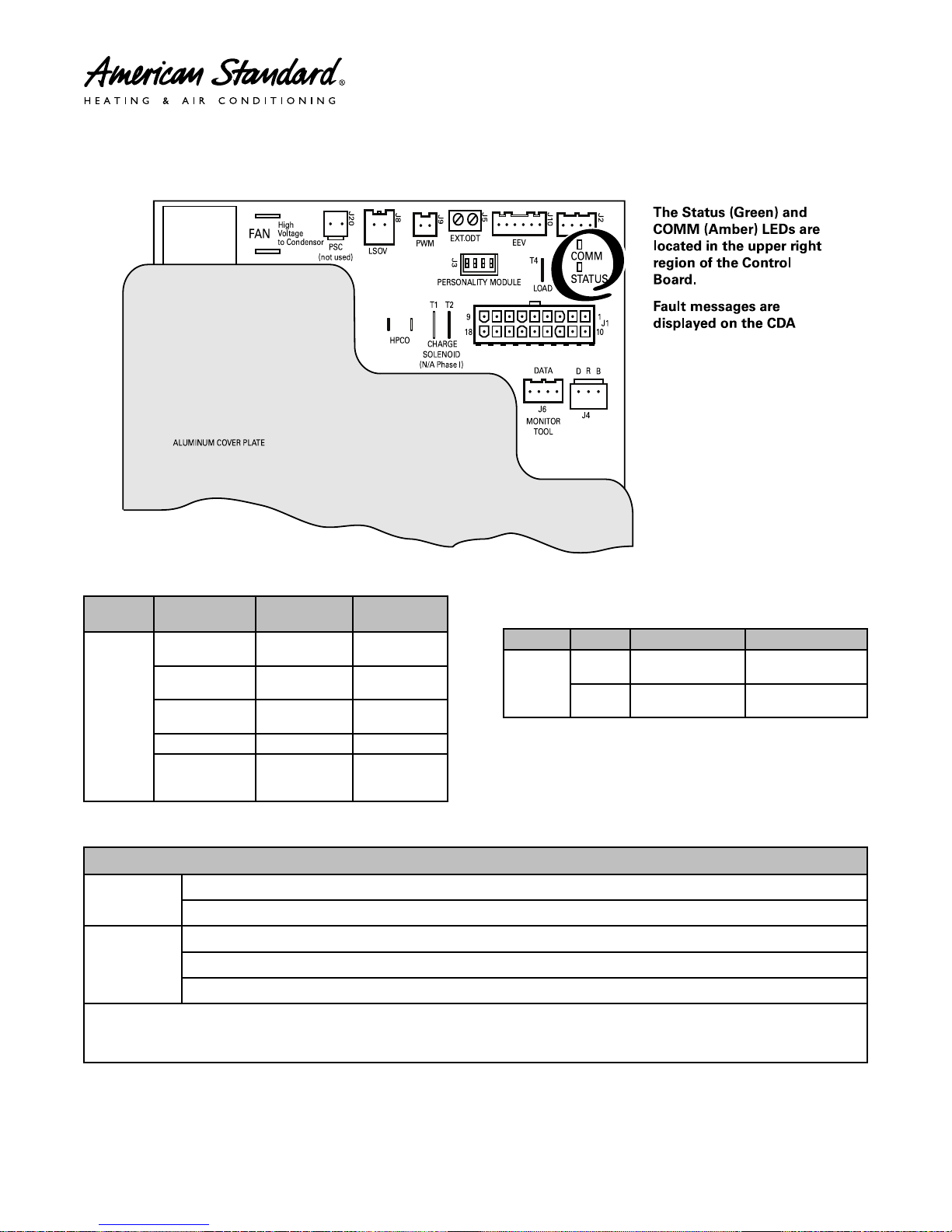

Integrated Variable Speed Control Board

SHED

CDA

STATUS

COMM

T3

LED Indicators

LLEEDD’’SS

LED RATE

MEDIUM

STATUS

(GREEN)

SOLID ON TEST MODE

INTERMITTENT

SLOW

FAST

DESCRIP-

TION

1 TIME PER

SECOND

2 TIMES PER

SECOND

5 TIMES PER

SECOND

1 FLASH

EVERY 4

SECONDS

INDICA-

TION

STANDBY/

IDLE

CALL FOR

CAPACITY

POWER UP

DELAY

HARD

LOCKOUT

LED RATE DESCRIPTION INDICATION

1 TIME PER

DEVICE

5 TIME PER

SECOND

COMM

(AMBER)

SLOW

FAST

DEVICE COUNT

LOSS OF

COMMUNICATION

Sump Heat Control

Sump Heat ON

Sump Heat

OFF

Note: Variable Speed systems are designed so that the compressor and sump heat will not run at the same time. Compressor windings are

used for sump heat. When sump heat is active, line-side current will be approximately 1.5 amps. The CDA MONITOR MENU has a field for

DRIVE >> DRIVE AMPS which can also be used to verify operation of sump heat.

4A-V0-SF-1G-EN

At power up; when outdoor temperature is below 85° F

When outdoor temperature is below 80° F and compressor dome temperature is less than the outdoor ambient temperature

When the outdoor temperature goes above 85° F (Sump Heat remains OFF until outdoor temperature drops below 80° F)

Anytime the compressor is running

For 50 minutes after each compressor run cycle.

Sump Heat Control Guidelines

13

Sequence of Operation

CCoonnttrrooll OOppeerraattiioonnaall OOvveerrvviieeww

Operation of the communicating, variable speed

outdoor unit is managed and monitored by a micro

processor based Integrated Variable Speed Control

(IVSC) located in the control box of the outdoor unit.

This component is also referred to as “The Drive”. Heat

and Cool demand messages are transmitted from the

comfort control over the data line from the comfort

control to the indoor and outdoor sections of the

system. System mode and capacity requests are

received by the outdoor IVSC and responded to by

providing control outputs to the switch-over valve

(SOV) solenoid coil, electronic expansion valve (EEV)

stepper motor, condenser fan motor and compressor.

Operating conditions and system commands such as

compressor percent demand, indoor airflow, EEV

starting position, defrost (For auxiliary heat), outdoor

temperature and alerts are transmitted from the

outdoor control over the data line to the rest of the

communicating system. Additional data that is

communicated to the rest of the system includes the

type of equipment installed (variable speed, unit size in

nominal tonnage, heat pump or air conditioner) which

is used during the Auto Discover function to set indoor

airflow and configure the comfort control for the

equipment installed

The IVSC has two Light Emitting Diodes (LED) used for

indicating operating status and verifying

communications. The STATUS LED flash rate indicates

if the system is in standby (or idle), receiving capacity

demand from the comfort control, in a test mode or in a

lockout condition. The COMM LED indicates successful

communications by flashing a device count which can

be used to verify how many communicating devices

are connected to the data line.

A Communicating Display Assembly (CDA) is

connected to the IVSC and is used to monitor,

configure, test and provide feedback about the system.

speed and hold steady for a minimum dwell period to

ensure proper oil return. This dwell period will typically

last for 1 minute but for initial start ups, after power is

first applied, the dwell period is 15 minutes. The startup

operation will progress to normal operation once this

dwell period is completed. With stage one demand and

minimum compressor RPM, the system will duty cycle

as needed to provide the required capacity requested

from the comfort control. The default duty cycle setting

for stage one demand is 3 Cycles per Hour (CPH). See

the Advanced Settings in the 850/950 Installation Guide

for more information on CPH.

With any start up, a Pulse Width Modulation (PWM)

signal is sent from the J9 plug of the IVSC to the

outdoor fan motor to run at the required matching

speed.

Should system load value rise above 100, stage two

demand is sent from the communicating comfort

control to the outdoor control and the IVSC will

respond by entering the modulating region of

compressor and outdoor fan operation. As load value

increases or decreases in the modulating region, so

will the compressor, outdoor fan and indoor blower

speeds to continuously deliver the capacity requested

by the comfort control and meet the demand of the

structural load. All indoor CFM demand messages will

be sent from the IVSC to the indoor unit so that the

blower motor will run with matching modulating

speeds. The System Report Screen (Located in the 850/

950’s Technician Access menu) or the Monitor Menu

(Located in the outdoor CDA Technicians Control

menu) can be used to view the compressor demand, in

percentage, while in the modulating range.

As system load value drops below 100, stage two

demand is satisfied and the communicating comfort

control returns system operation to stage one demand

and the system will begin to duty cycle as needed to

provide the requested capacity.

CCoooolliinngg MMooddee ((AA//CC aanndd HHeeaatt PPuummpp))

When a request for cooling capacity is sent from the

communicating comfort control to the outdoor unit, the

IVSC will respond by flashing the STATUS LED two

times per second and the CDA will display COOLING in

the SYSTEM STATUS home screen. The IVSC will

calculate the required running speed for the

compressor and outdoor fan based on the current load

value and stage demand sent from the comfort control.

Load values under 100 will generate stage one demand

and the IVSC will generate power to produce the

minimum compressor RPM. Additionally, a CFM

demand message is sent from the outdoor IVSC to the

indoor unit for matching indoor airflow.

Regardless of the load value or stage demand, the

outdoor system will start and ramp to a target startup

14

HHeeaatt PPuummpp CCoooolliinngg MMooddee ooff OOppeerraattiioonn

In addition to stage and demand operating sequences

outlined in the Cooling Mode description, when a heat

pump system receives a demand message for cooling,

the Switch Over Valve (SOV) solenoid will be pulsed to

position the valve for cooling. Latching Switch Over

Valve (LSOV) technology is standard with variable

speed outdoor heat pumps. By utilizing components

designed to hold the pilot pin of the SOV in place, the

valve will maintain the cooling or heating position even

when power is removed. Maintaining valve position, or

Latching, is accomplished with the help of a magnet

mounted in the solenoid coil or a spring manufactured

internal to the SOV. To initiate the SOV position, a12

Volt DC pulse is sent from the J8 plug located on the

IVSC to the solenoid coil at the start of each call for

capacity. Polarity of the DC pulse is critical to the

4A-V0-SF-1G-EN

SSeeqquueennccee ooff OOppeerraattiioonn

direction the valve’s pilot pin will be set. Always follow

the red and blue color coding to ensure proper polarity.

Heat pumps are also equipped with an Electronic

Expansion Valve (EEV) which will be set to the “Check

Valve Position” and drive wide open. The EEV does not

provide refrigeration control in the cooling mode of

operation.

HHeeaatt PPuummpp HHeeaattiinngg MMooddee ooff OOppeerraattiioonn

When a request for heating capacity is sent from the

communicating comfort control to the outdoor unit, the

IVSC will respond by flashing the STATUS LED two

times per second and the CDA will display HEATING in

the SYSTEM STATUS home screen.

In the heating mode of operation the LSOV solenoid

will be pulsed to position the valve for heating at the

start of each call for capacity.

During heating mode, the EEV will be in the controlling

state. Refrigerant flow is managed by incrementally

opening or closing the valve to control compressor

superheat under a wide range of conditions. Superheat

is calculated with feedback to the IVSC from a suction

line temperature sensor and a suction line pressure

transducer. The IVSC will target 10 degrees (+/-2) of

superheat and drive a valve position by periodically

pulsing the stepper motor and then monitoring

compressor superheat results. Control signals to the

EEV stepper motor are 12 volt DC pulses from J10 on

the IVSC. The EEV step position and compressor

superheat can be monitored through the CDA monitor

menu during runtime operation. The IVSC will close the

EEV with every OFF cycle and drive the valve to wide

open during defrost or cooling mode of operation.

NNoottee:: When a heat pump system is first powered up,

the EEV produces an audible sound (soft

ratcheting sound) as the valve drives to the

closed position.

DDeeffrroosstt MMooddee ffrroomm CCyycclliinngg--SSttaaggee

When the system is operating in cycling-stage and the

control initiates a Defrost, the indoor control

simultaneously:

• De-energizes the PWM signal to the outdoor fan

motor,

• Drives the OD EEV to full open and,

• Commands the SOV to change to the cooling mode.

There is a brief switchover time-delay (to allow

refrigerant pressures to stabilize) before the

compressor is commanded to run at Maximum Speed

Cooling to perform Defrost.

The outdoor control also sends a demand message to

the indoor unit to run the blower at Maximum Speed

Cooling and energize auxiliary heat (if equipped).

Auxiliary heat blower speed may be higher than

Maximum Speed Cooling and will take precedence

during defrost.

The Defrost Mode will be terminated after the OD coil

temperature reaches 47°F or the maximum time

override of 15 minutes has lapsed. At Defrost

termination, the compressor will be commanded to go

to the Defrost Switchover Speed. After the lower speed

is achieved, the SOV position will be changed back to

the heating mode of operation and the OD fan will be

turned back on. Following the refrigerant stabilizing

delay, the compressor will be allowed to run at any

speed commanded by thermostat demand.

The outdoor control will send the necessary pulse

signals to the stepper motor coil returning the EEV to a

controlling position that matches capacity demand and

begin monitoring superheat.

DDeeffrroosstt MMooddee ffrroomm MMoodduullaattiinngg--SSttaaggee

When the system is operating in modulating-stage and

the control initiates a Defrost, the outdoor control

commands the compressor to go to the Defrost

Switchover Speed.

After the lower speed is achieved, the SOV will be

switched into the cooling mode and the control will

simultaneously de-energize the PWM signal to the

outdoor fan motor and drive the OD EEV to full open.

There is a brief switchover time-delay (to allow

refrigerant pressures to stabilize) before the

compressor is commanded to run at Maximum Speed

Cooling to perform Defrost.

The outdoor control also sends a demand message to

the indoor unit to run the blower at Maximum Speed

Cooling and energize auxiliary heat (if equipped).

Auxiliary heat blower speed may be higher than

Maximum Speed Cooling and will take precedence

during defrost.

The CDA will show DEFROST in the Home Screen.

The Defrost Mode will be terminated after the OD coil

temperature reaches 47°F or the maximum time

override of 15 minutes has lapsed. At Defrost

termination, the compressor will be commanded to go

to the Defrost Switchover Speed. After the lower speed

is achieved, the SOV position will be changed back to

the heating mode of operation and the OD fan will be

turned back on. Following the refrigerant stabilizing

delay, the compressor will be allowed to run at any

speed commanded by thermostat demand.

The outdoor control will also send the necessary pulse

signals to the stepper motor coil returning the EEV to a

controlling position that matches capacity demand and

begin monitoring superheat.

The system will stay in the Defrost, Maximum Speed

Cooling even if the comfort control demand changes

from modulating-stage to cycling-stage. However, the

system will shut down if the comfort control demand

message for cycling-stage capacity ends. The system

will continue the current defrost cycle the next time the

comfort control sends a demand message for

compressor heat.

4A-V0-SF-1G-EN

15

Defrost Control (Heat Pump only)

DDeemmaanndd DDeeffrroosstt

The demand defrost control measures heat pump

outdoor ambient temperature with a sensor located

outside the outdoor coil. A second sensor located on

the outdoor coil is used to measure the coil

temperature. The difference between the ambient and

the colder coil temperature is the difference or delta-T

measurement. This delta-T measurement is

representative of the operating state and relative

capacity of the heat pump system. By measuring the

change in delta-T, we can determine the need for

defrost. The coil sensor also serves to sense outdoor

coil temperature for termination of the defrost cycle.

FFaauulltt IIddeennttiiffiiccaattiioonn

A fault condition is indicated by the CDA connected to

the control board inside the heat pump control box.

DDeeffrroosstt EEnnaabblleedd

Demand Defrost is enabled with the following inputs to

the Integrated Variable Speed Control (IVSC):

• Outdoor ambient temperature sensor (ODS-B)

reporting an outdoor temperature at or below 52° F.

• Coil temperature sensor (CBS) reporting a coil

temperature at or below 35° F.

• Heat/Cool Demand (HCD) from the communicating

comfort control for at least two minutes or more.

DDeeffrroosstt IInniittiiaattiioonn

The calculated temperature difference between the

outdoor temperature sensor and the coil temperature

sensor is called Delta T. Defrost can occur once the

current Delta T exceeds the Delta T initiate value. The

Defrost initiate value is calculated using a clean-coil

Delta T x 2.0, plus a temperature bin correction factor.

Initiation Delta T will automatically adjust based on the

outdoor temperature. This adaptive logic assures a

complete defrost for a range of outdoor temperatures.

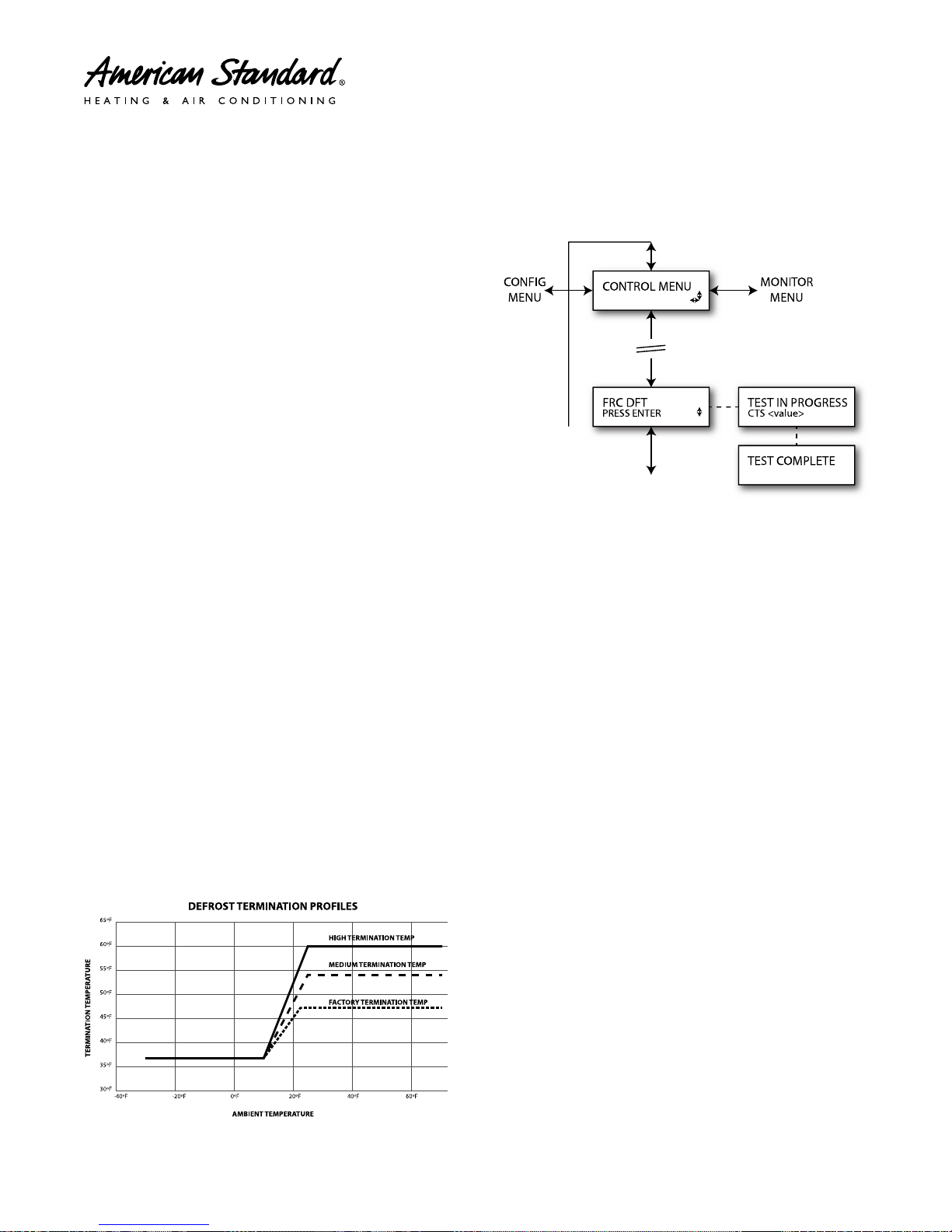

CCDDAA NNaavviiggaattiioonn ttoo FFoorrcceedd DDeeffrroosstt

Figure 5. CDA Mini Menu

NNOOTTEESS:: FFoorrcceedd DDeeffrroosstt

1. System must be running with demand from the

thermostat.

2. FRC DFT TEST can be initiated in heat mode only.

3. Press ENTER to begin forced defrost.

4. Execute Forced Defrost following Forced Defrost

(Defrost terminates on Coil Temperature or

maximum time override of 15 minutes).

5. When test begins, TEST IN PROGRESS displays on

line 1 and Coil Temperature value on line 2.

NNoottee:: Home Screen, under System Status will display

DEFROST.

6. When test is complete, TEST COMPLETE displays

for 10 seconds.

7. If there is a defrost fault condition, test terminates

and sends alert to the alert menu.

8. For more information, refer to the Alert Code Tables

in Service Facts and Technical Service Manual (Pub.

No. 34–4301–01) documents.

NNoottee:: Screens will update as the test proceeds.

16

4A-V0-SF-1G-EN

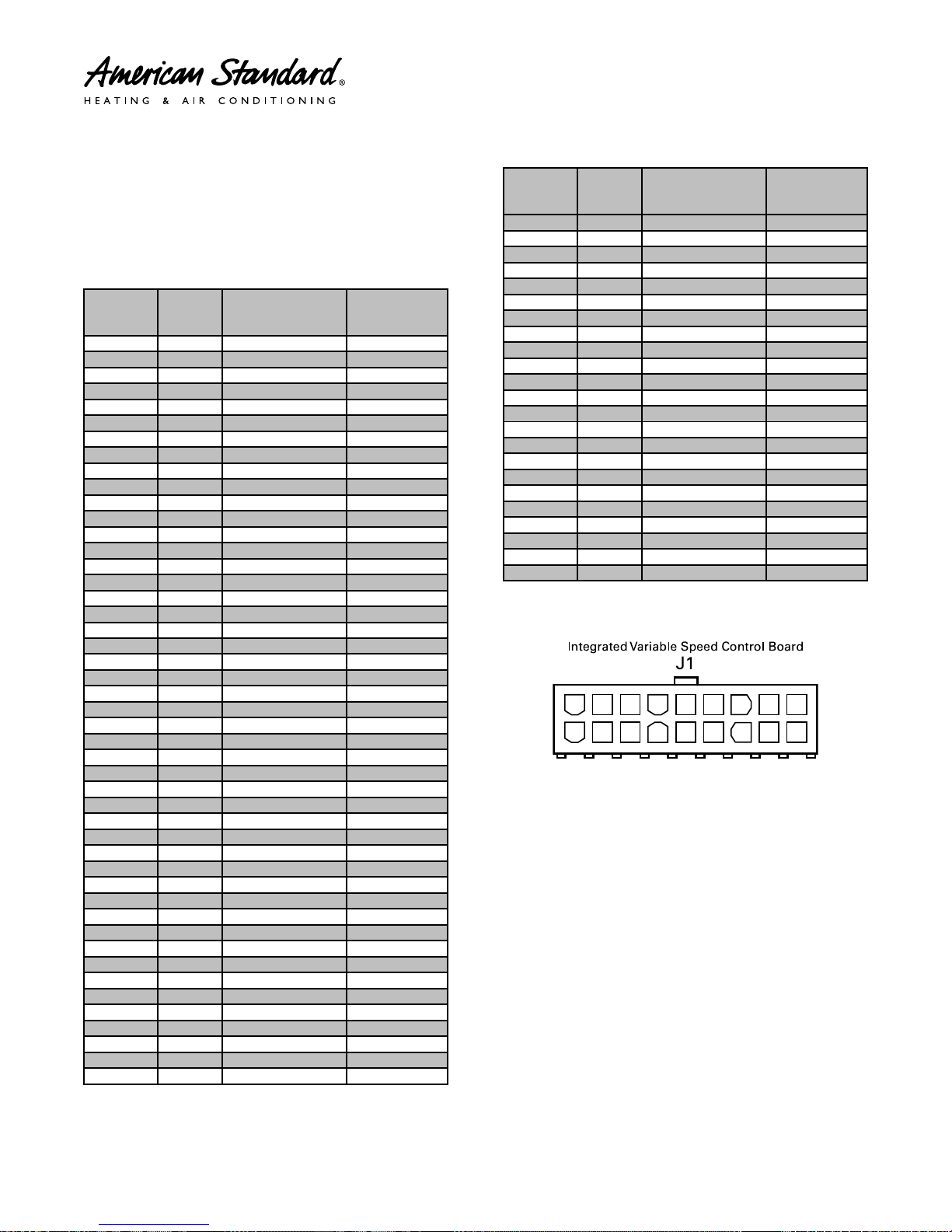

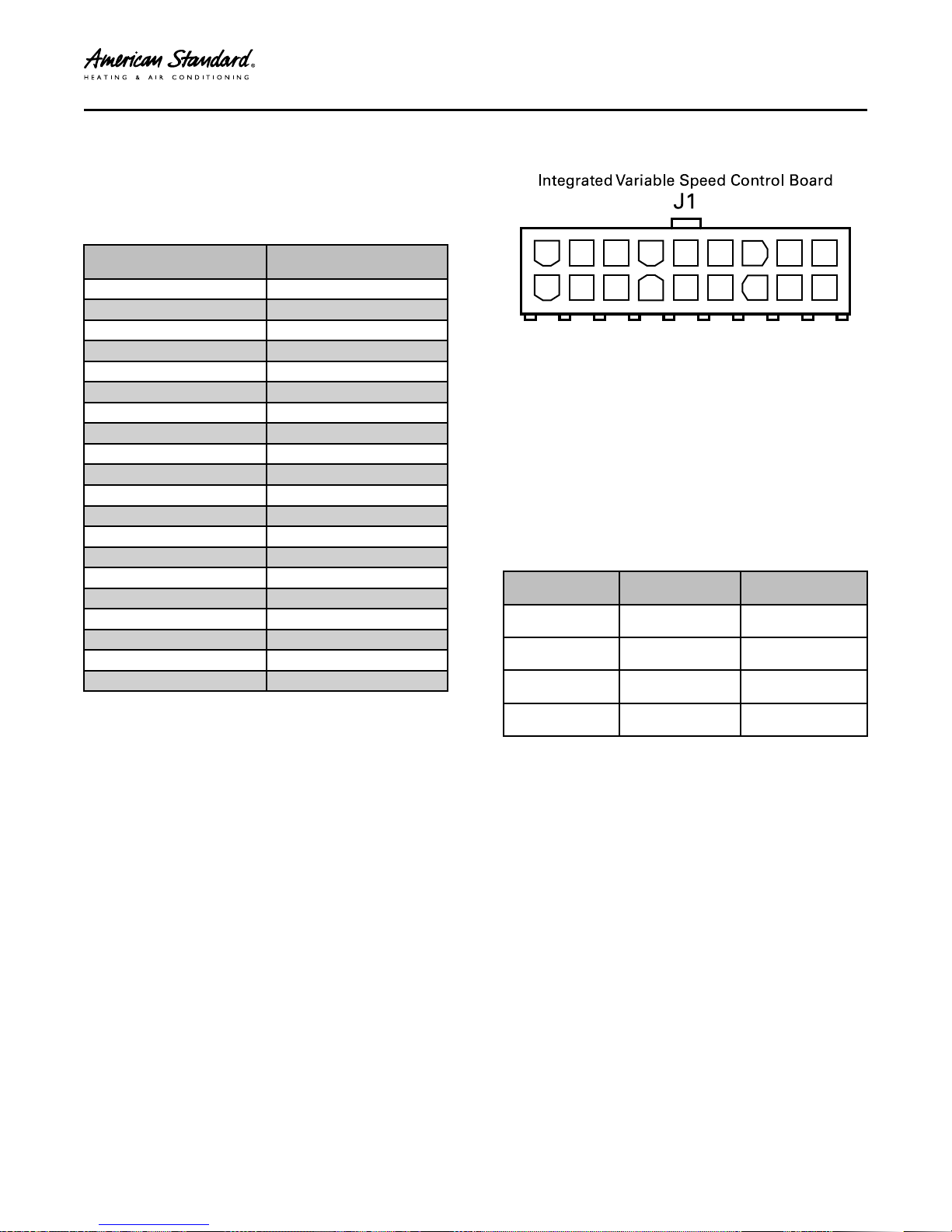

SENSORS

123456789

101112131415161718

Compressor Dome Temperature

This table shows the corresponding voltage, resistance

and temperature readings for the Dome Temperature

Sensor when measured across pins 1 and 10. The

power source for the Dome Temperature Sensor is

3.2VDC.

THERMISTOR

TEMP F TEMP C

-15 -26.11 139453 3.13

-10 -23.33 118062 3.11

-5 -20.56 100258 3.10

0 -17.78 85393 3.08

5 -15.00 72944 3.06

10 -12.22 62487 3.04

15 -9.44 53676 3.02

20 -6.67 46232 2.99

25 -3.89 39925 2.96

30 -1.11 34567 2.93

35 1.67 30003 2.89

40 4.44 26105 2.85

45 7.22 22767 2.80

50 10.00 19903 2.75

55 12.78 17438 2.70

60 15.56 15312 2.64

65 18.33 13475 2.58

70 21.11 11883 2.51

75 23.89 10501 2.45

80 26.67 9298 2.37

85 29.44 8249 2.30

90 32.22 7333 2.22

95 35.00 6530 2.14

100 37.78 5826 2.06

105 40.56 5208 1.97

110 43.33 4663 1.89

115 46.11 4182 1.80

120 48.89 3758 1.72

125 51.67 3382 1.63

130 54.44 3048 1.55

135 57.22 2752 1.47

140 60.00 2488 1.39

145 62.78 2253 1.31

150 65.56 2043 1.24

155 68.33 1856 1.17

160 71.11 1688 1.10

165 73.89 1537 1.03

170 76.67 1402 0.97

175 79.44 1280 0.91

180 82.22 1170 0.85

185 85.00 1071 0.80

190 87.78 982 0.74

195 90.56 901 0.70

200 93.33 828 0.65

205 96.11 762 0.61

210 98.89 702 0.57

215 101.67 647 0.53

RESISTANCE

(OHMS)

VOLTS DC

(PIN TO PIN)

THERMISTOR

TEMP F TEMP C

220 104.44 597 0.50

225 107.22 552 0.47

230 110.00 511 0.44

235 112.78 473 0.41

240 115.56 438 0.38

245 118.33 407 0.36

250 121.11 378 0.33

255 123.89 351 0.31

260 126.67 327 0.29

265 129.44 304 0.27

270 132.22 284 0.26

275 135.00 265 0.24

280 137.78 247 0.23

285 140.56 231 0.21

290 143.33 216 0.20

295 146.11 203 0.19

300 148.89 190 0.18

305 151.67 178 0.17

310 154.44 167 0.16

315 157.22 157 0.15

320 160.00 148 0.14

325 162.78 139 0.13

330 165.56 131 0.12

RESISTANCE

(OHMS)

VOLTS DC

(PIN TO PIN)

Figure 6. Dome Temperature Sensor

Pin 1 & 10 (Red)

A working Compressor Dome Temperature Sensor is

required for:

• Protection (High/Low Temperature)

• Preheating (Sump Heat)

• Outdoor EEV Control

• Diagnostics; Reverse rotation, Flooding, Charge

Level

The Dome Temperature Sensor control contains an

NTC thermistor input for sensing the Compressor

Dome Temperature. The thermistor has a nominal

resistance of ≈ 10k ohms at 75°F. The minimum range

required for the Dome Temperature input is —31°F to

302°F. when measured across pins 1 and 10.

NNoottee:: Secure Installation of Dome Sensor is required

for reliable compressor & system operation.

4A-V0-SF-1G-EN

17

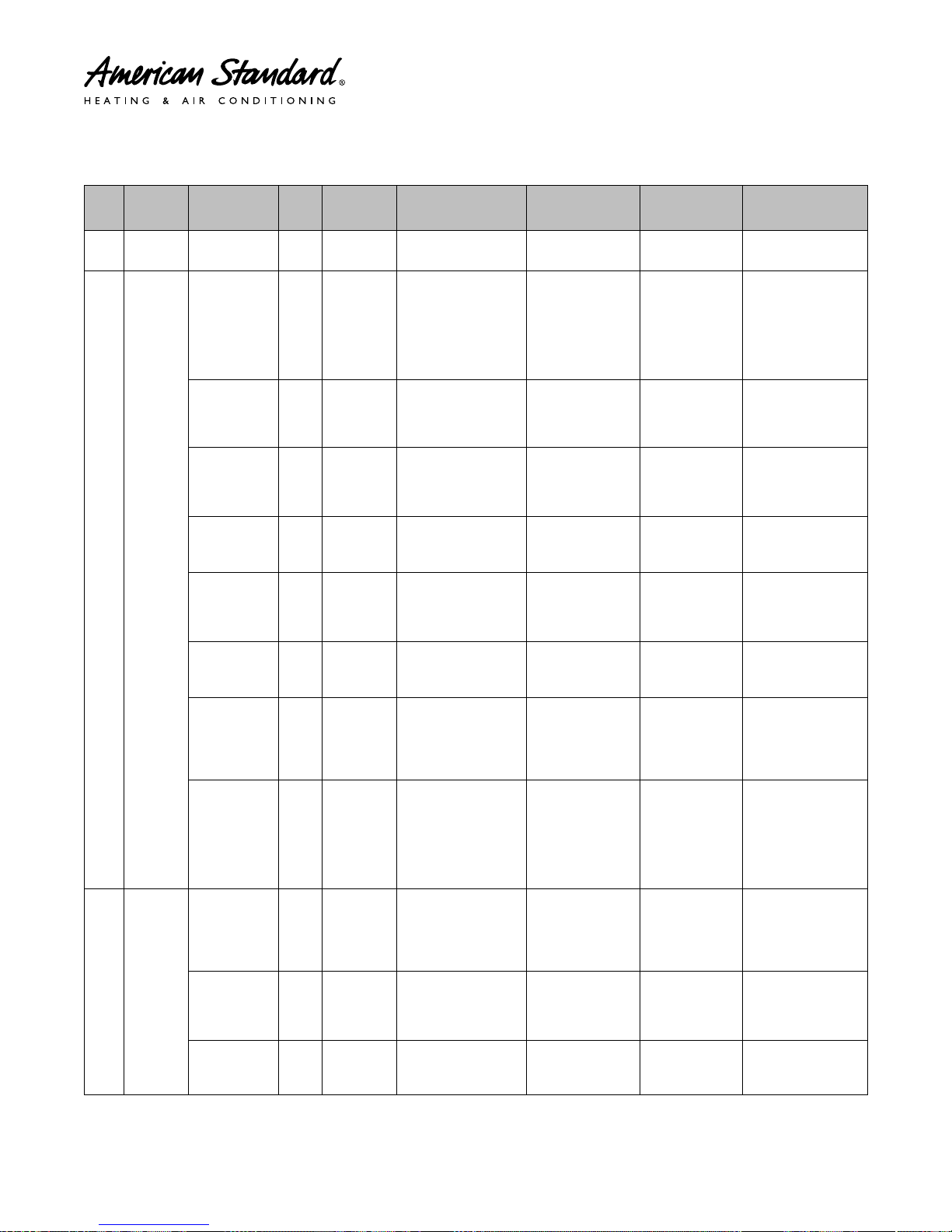

123456789

101112131415161718

SSEENNSSOORRSS

Ambient Temperature Sensor

(ODS)

These tables show the corresponding voltage,

resistance and temperature readings for the Ambient,

Temperature Sensor when measured across pins 5 &

14.

The power source for the Ambient, Coil and Suction

Temperature sensors is 3.2VDC

THERMISTOR

TEMP F TEMP C

-15 -26.11 135976 2.43

-10 -23.33 115112 2.33

-5 -20.56 97745 2.22

0 -17.78 83247 2.11

5 -15.00 71108 1.99

10 -12.22 60916 1.87

15 -9.44 52334 1.75

20 -6.67 45088 1.63

25 -3.89 38952 1.52

30 -1.11 33742 1.40

35 1.67 29307 1.29

40 4.44 25520 1.19

45 7.22 22280 1.09

50 10.00 19499 1.00

55 12.78 17108 0.91

60 15.56 15045 0.83

65 18.33 13262 0.75

70 21.11 11717 0.68

75 23.89 10375 0.62

80 26.67 9207 0.56

85 29.44 8188 0.51

90 32.22 7297 0.46

95 35.00 6516 0.42

100 37.78 5830 0.38

105 40.56 5227 0.35

110 43.33 4695 0.31

115 46.11 4224 0.29

120 48.89 3808 0.26

125 51.67 3439 0.24

130 54.44 3111 0.21

135 57.22 2820 0.20

140 60.00 2559 0.18

RESISTANCE

(OHMS)

VOLTS DC

Figure 7. Ambient Temperature Sensor

Pins 5 & 14 (Black)

The Ambient Temperature Sensor control has an NTC

thermistor input for sensing the outdoor air

temperature and has a nominal resistance of ≈ 10k

ohms at 75°F. The Ambient Temperature is measured

across pins 5 and 14. The minimum range required for

the Ambient Temperature Sensor is —40°F to 140°F.

A working Ambient Temperature Sensor is required for

the following:

• Low Pressure Monitoring

• Defrost (Heat Pump)

• Comfort Control Display (Outdoor Air Temperature)

• Aux Heat Control During Defrost (Heat Pump)

• Aux Heat Lockout

• Compressor Lockout (Heat Pump)

• Oil Management

• Humidifier Dew-Point Control

• OD EEV Startup Position

• ID EEV Startup Position

• Pre Heating (Sump Heat)

• Normal Operation of the ID and OD Fan

• Diagnostics

18

4A-V0-SF-1G-EN

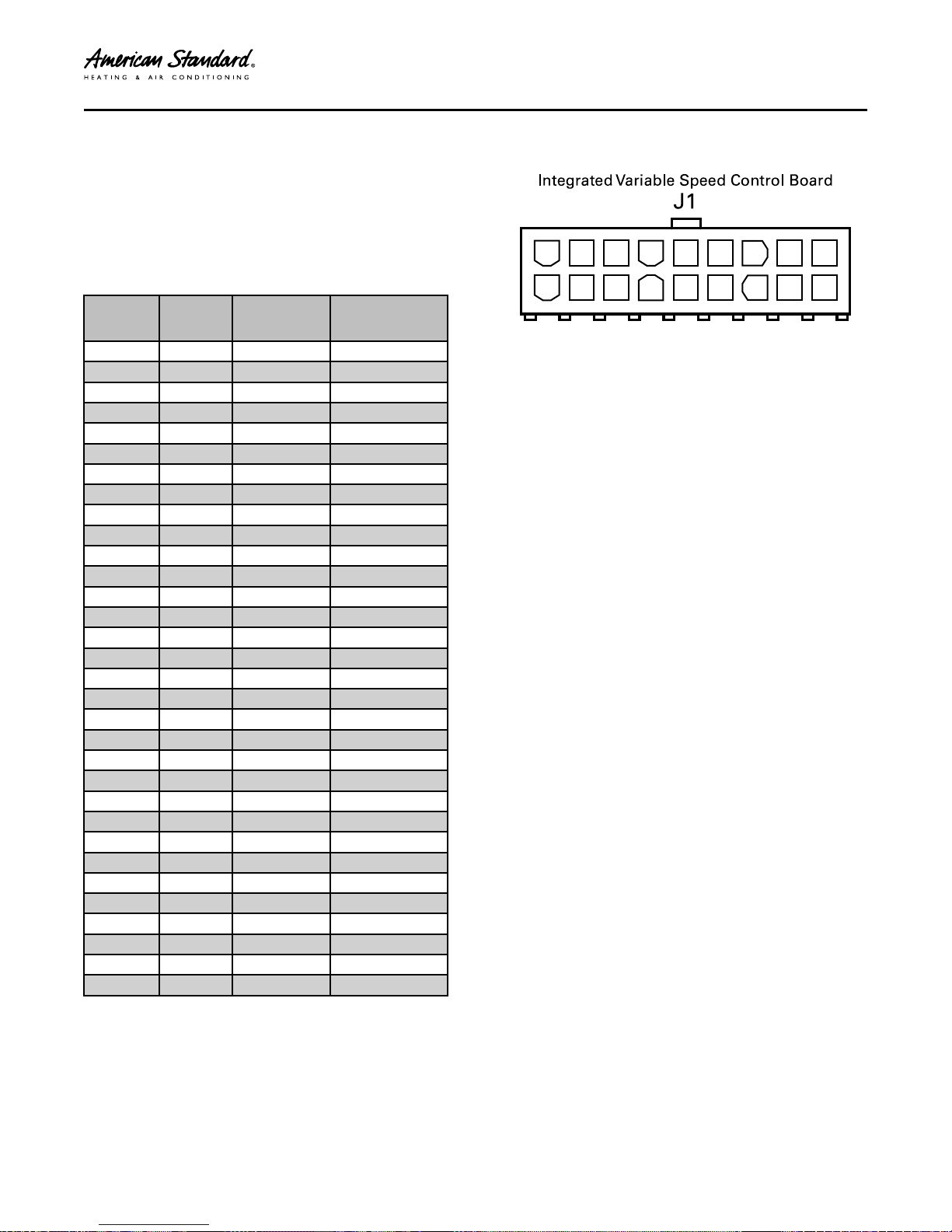

123456789

101112131415161718

123456789

101112131415161718

SSEENNSSOORRSS

Coil and Suction Temperature

Sensor

THERMISTOR

TEMP F TEMP C

-15 -26.11 135976 2.71

-10 -23.33 115112 2.64

-5 -20.56 97745 2.56

0 -17.78 83247 2.48

5 -15.00 71108 2.38

10 -12.22 60916 2.29

15 -9.44 52334 2.19

20 -6.67 45088 2.08

25 -3.89 38952 1.97

30 -1.11 33742 1.86

35 1.67 29307 1.75

40 4.44 25520 1.64

45 7.22 22280 1.53

50 10.00 19499 1.42

55 12.78 17108 1.32

60 15.56 15045 1.22

65 18.33 13262 1.13

70 21.11 11717 1.04

75 23.89 10375 0.96

80 26.67 9207 0.88

85 29.44 8188 0.81

90 32.22 7297 0.74

95 35.00 6516 0.68

100 37.78 5830 0.62

105 40.56 5227 0.57

110 43.33 4695 0.52

115 46.11 4224 0.47

120 48.89 3808 0.43

125 51.67 3439 0.40

130 54.44 3111 0.36

135 57.22 2820 0.33

140 60.00 2559 0.30

RESISTANCE

(OHMS)

VOLTS DC

The Coil Temperature Sensor control has an NTC

thermistor input for sensing the coil temperature. This

reading is used by the defrost algorithm on heat pump

units. The thermistor has a nominal resistance of 10k

ohms at 75°F. The minimum range and resolutions as

measured across pins 2 and 11 required for Coil

Temperature Sensor is —50°F to 150°F

A working Coil Temperature Sensor is required for the

following:

• Defrost Initiation and Termination

• Compressor Sump Heat (Preheating)

• Diagnostics; Charge Level, Indoor/Outdoor Airflow

Figure 9. Suction Temperature Sensor

Pins 3 & 12 (Orange)

The Suction Temperature Sensor control utilizes an

NTC thermistor input for sensing the suction/gas

temperature. The thermistor has a nominal resistance

of ≈ 10k ohms at 75°F. The minimum range and

resolutions as measured across pins 3 and 12 required

for the Suction Temperature Sensor is —50°F to 150°F

A working Suction Temperature Sensor is required for:

• Outdoor EEV Control (Target Super Heat)

• Diagnostics; Charge level, Indoor/Oudoor Airflow

Figure 8. Coil Temperature Sensor

Pins 2 & 11 (Yellow)

4A-V0-SF-1G-EN

19

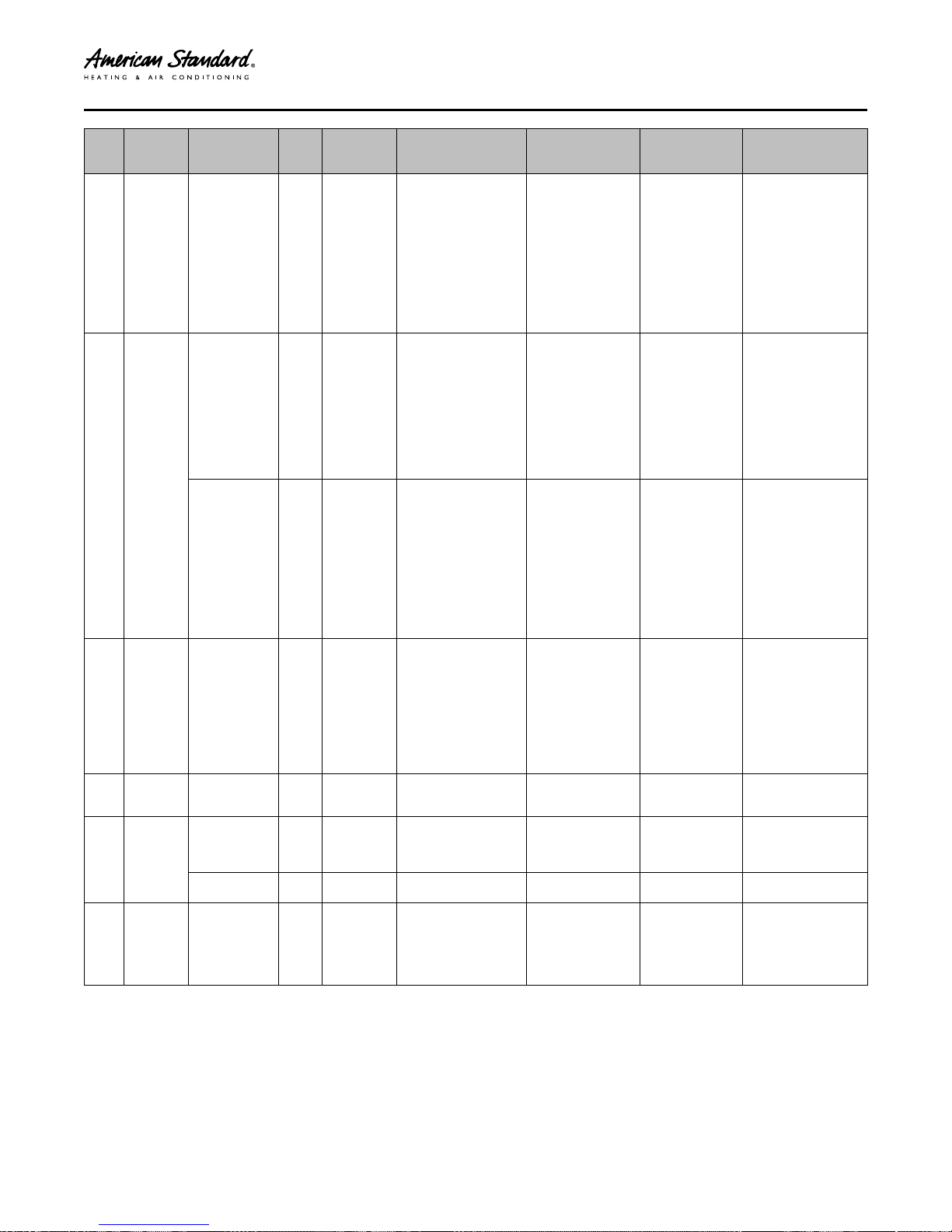

123456789

101112131415161718

SSEENNSSOORRSS

Suction Line Pressure

Transducer

This table shows the corresponding voltage and

pressure readings for the Suction Line Pressure

Transducer when measured across pins 7 and 8.

PRESSURE (PSIG)

10 0.60

20 0.70

31 0.81

41 0.91

51 1.00

60 1.10

70 1.20

82 1.32

92 1.42

101 1.52

111 1.62

120 1.72

130 1.81

140 1.91

152 2.03

161 2.13

171 2.23

181 2.33

190 2.43

200 2.52

VOLTS DC

PIN 7 TO PIN 8

Figure 10. Suction Pressure Transducer

Pins 7 (White) & 8 (Black)

A working Suction Pressure Sensor is required for the

following:

• Start Up (Pressure Limits)

• Low Pressure, Loss of Charge Protection

• Indoor Coil Freeze Protection

• Outdoor EEV Control (Target Super Heat)

• Diagnostics; Reverse Rotation, Charge Level,

Indoor/Outdoor Airflow

The Suction Pressure Transducer control is measured

across pins 7 and 8 and has an active 0–4.9VDC

transducer input for sensing low suction pressure.

DESCRIPTION LOCATION WIRE COLOR

4.9 VDC POWER PIN 6 RED

OUTPUT PIN 7 WHITE

COMMON PIN 8 BLACK

GROUND PIN 9 GREEN

20

4A-V0-SF-1G-EN

Variable Speed Alert Codes

Alert

Code

18

67

68

Alert

Group

Control

Failure

Temp

Sensor

Fault

Defrost

Fault

Display

Assembly

Text

CTRL FLT 4 Err 18.04

AMB T SENSE 0 Err 67.00

COIL T SENSE 1 Err 67.01

EXT T SENSE 3 Err 67.03

DOME T SENSE 4 Err 67.04

DOME T SENSE 5 Err 67.05

SUCT T SENSE 6 Err 67.06

SUCT T SENSE 7 Err 67.07

CDT UNATCHD 8 Err 67.08 Heating - Limp along

DFT FAULT A 0

DFT FAULT B/C

DFT FAULT

A(B/C)

Subalar-

m

1

2

A/TZONE

850/950

N/A

N/A

N/A

State action on

occurrence

Shutdown. Send Err

code to thermostat

and Fault text to CDA

For Cooling mode,

“Assume Ambient

Temp” as per Limp

along mode and

Continue normal

operation. For Heating

mode, go to timed

defrost.

For Cooling mode,

continue normal

operation. For heating

mode, go to timed

defrost.

Cooling - Normal

operation

Cooling - Normal

operation

Heating - Limp along

mode of constant

speed (compressor

speed is limited to

2400 RPM)

Cooling - Normal

operation

Heating - Limp along

mode of constant

speed (Compressor

speed is limited to

2400 RPM, EEV is

locked to safe position)

mode of constant

speed (compressor

speed is limited to

2400 RPM)

As defined in Defrost

algorithm

As defined in Defrost

algorithm

As defined in Defrost

algorithm

State action on

clearance

Resume normal

operation.

With actual

ambient

temperature,

continue normal

operation. For

Heating mode,

follow demand

defrost algorithm

For Cooling mode,

continue normal

operation. For

heating mode, go

to timed defrost.

Continue normal

operation

Continue normal

operation

Ramp up to

demand speed and

resume normal

operation.

Continue normal

operation

Ramp up to

demand speed and

resume normal

operation.

Ramp up to

demand speed and

resume normal

operation.

Continue normal

operation

Continue normal

operation

Continue normal

operation

Alert

Description

Internal control

error is detected

Ambient

Temperature

Sensor alert

Coil Temperature

Sensor alert

External

Temperature

Sensor alert

Dome

Temperature

Sensor is faulted

in Cooling mode

Dome

Temperature

Sensor is faulted

in Heating mode

Suction

Temperature

Sensor is faulted

in Cooling mode

Suction

Temperature

Sensor is faulted

in Heating mode

Compressor

DomeTemperature Sensor not

attached to

Compressor

(Heating Mode)

Defrost Fault A

has been

detected

Defrost Fault B or

C has been

detected

Defrost Fault A

and B or A and C

have been

detected

Possible Cause

Control failure,

replace IVSC

Ambient Sensor outof-range (Open/

Shorted/Missing)

Coil Sensor out-ofrange (Open/

Shorted/Missing)

Ext Sensor out-of

range (Shorted)

Open/ Missing revert

to Ambient Sensor

input

Dome Sensor out-ofrange (Open/

Shorted/Missing)

Dome Sensor out-ofrange (Open/

Shorted/Missing)

Suction Sensor outof-range (Open/

Shorted/Missing)

Suction Sensor outof-range (Open/

Shorted/Missing)

Compressor

DomeTemperature

Sensor not attached

to Compressor

(Heating Mode)

Introduced with

AOCSoftware Version

2, Fall of 2014)

Low heat pump

capacity (Inoperative

compressor, loss of

charge, shorted coil

sensor, open ambient

sensor)

Fault B indicates 10

defrosts terminated

on time override.

Fault C indicates

sensor High Delta T.

Within a given length

of time, both faults

existed

4A-V0-SF-1G-EN

21

VVaarriiaabbllee SSppeeeedd AAlleerrtt CCooddeess

Alert

Code

80

80

88

90

91

106

Alert

Group

High

Pressure

Monitor

Fault

High

Pressure

Monitor

Fault

Ground

fault

Communi-

cation

Busy Fault

Communi-

cation

Fault

External

Shutdown

Fault

Display

Assembly

Text

HP SHORT LO 0 “Wait”

HP HARD LO 1 Err 80.01

HP RED RPS 2 “Wait”

GND FAULT LO 1 Err 88.01

SYS COM BUSY 2 Err 90.02

SYS COM ERR 2 Err 91.02

NO SYS CLK 3 Err 91.03 Shutdown

EXT SW OPEN 1 “Load Shed”

Subalar-

m

A/TZONE

850/950

State action on

5 min of compressor

lockout and send

“WAIT ”to thermostat

Lockout compressor

operation until power

cycle, No system

operation

On restart, after short

lockout, compressor

will operate at reduced

capacity and this alert

is declared. (Message

on Tstat informing of

reduced capacity)

Note: Recover reduced

capacity with each 2 hr

run time window

without an HPCO trip.

Emergency shutdown.

Drive will protect itself.

CLII bus must go idle.

Continue to operate

normally

Shutdown if Heat/Cool

demand message not

received for 3

reporting intervals.

Compressor cooling

operation shall not be

allowed.

occurrence

State action on

clearance

Restart with

reduced capacity.

(Capacity reduced

by 1/5 with each

occurrence)

Can be cleared only

on power cycle.

After power cycle,

the compressor

shall resume

normal operation.

Normal operation

resumes.

Can be cleared only

on power cycle.

After power cycle,

the compressor

shall resume

normal operation.

Resume normal

operation

Resume normal

operation

Resume normal

operation

Resume normal

operation. Cooling

operation allowed.

Alert

Description

High pressure

switch has

tripped resulting

in a High Pressure

Short Lock Out.

(HPCO limit =

650psig)

6 High Pressure

Short Lock Out

events have

occurred

resulting in a High

Pressure Hard

Lock Out. (High

Pressure Limit =

650psig)

High Pressure trip

point has been

exceeded and a 5

minute time out

has been

enforced. Restart

is allowed but

with reduced

capacity.

Grounding issue

from output of

the drive. If the

sum of all three

currents exceeds

10 amp to

ground

Communication

busy

Loss of Heat/Cool

demand message

Loss of Bit Master

External

shutdown switch

is Active and

input at T3 to T4

is open

Possible Cause

Overcharged.

Cooling Mode:

Outdoor Fan Failure,

clogged coil,

recirculation,

excessive high

ambient, non

condensable.

Heating Mode:

Indoor Fan Failure,

clogged coil, non

condensable.

Overcharged.

Cooling Mode:

Outdoor Fan Failure,

clogged coil,

recirculation,

excessive high

ambient, non

condensable. Heating

Mode: Indoor Fan

Failure, clogged coil,

non condensable.

Overcharged.

Cooling Mode:

Outdoor Fan Failure,

clogged coil,

recirculation,

excessive high

ambient, non

condensable.

Heating Mode:

Indoor Fan Failure,

clogged coil, non

condensable.

Burnt winding, faulty

current sensor,

internal board short,

pinched compressor

lead (shorted). Run

Drive Test.

(GoTo “Compressor

Verification”

troubleshooting flow

chart)

R & B to thermostat

reversed polarity

Open/Shorted Data

line Check for

reversed polarity

Bit Master Control

Fault

External Load Shed

device is active with

external switch

configured to Active

and input at T3 to T4

is open

22

4A-V0-SF-1G-EN

Loading...

Loading...