American Standard 4205.000, 4205.001 User Manual

Installation

Instructions

4205.000

4205.001

SINGLE CONTROL KITCHEN FAUCETS

Thank you for selecting American-Standard...

the benchmark of fine quality for over 100 years.

To ensure that your installation proceeds smoothly-please read these instructions carefully before you begin.

TOOLS REQUIRED

Certified to comply with ASME A112.18.1M

M968420 REV. 1.1

Channel Locks

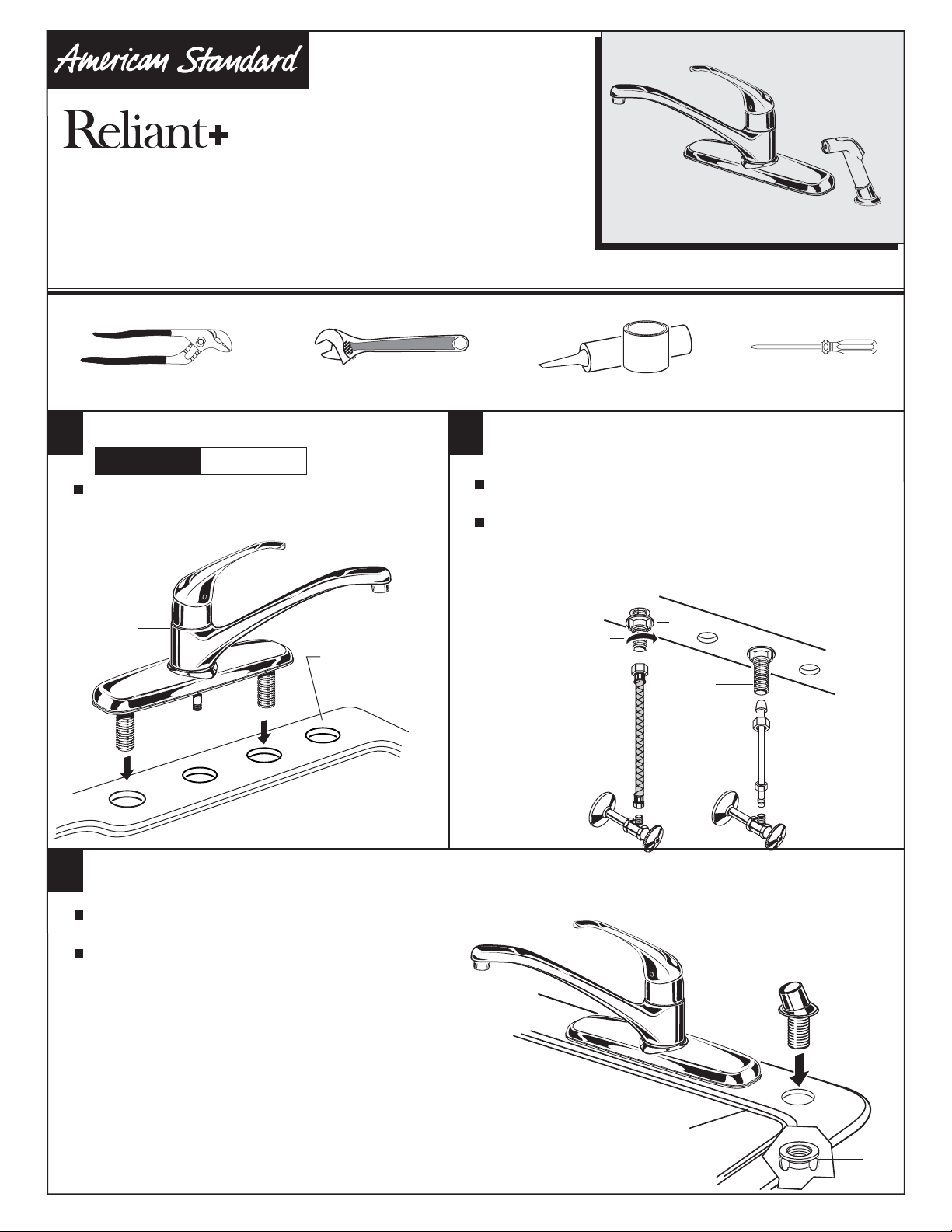

INSTALL FAUCET

1

CAUTION

Install FAUCET (1) on sink. (No sealant is required

unless mounting deck on SINK is uneven).

1

Turn off water at

main supply.

SINK OR DECK

Plumbers' Putty or CaulkingAdjustable Wrench Phillips Screwdriver

SECURE FAUCET AND MAKE

2

WATER SUPPLY CONNECTIONS

NOTE: FLEXIBLE SUPPLIES (3, 4) HAVE TO BE PURCHASED SEPARATELY

Secure FAUCET (1) with ATTACHMENT NUTS (2) supplied.

(HAND TIGHTEN).

Connect water supply to FAUCET (1) with 1/2" IPS FLEXIBLE

SUPPLIES (3) or 3/8"O.D. BULL-NOSE RISERS (4). Use

adjustable wrench to tighten connections. Do not over tighten.

Be careful not to kink copper supply when bending.

Use tubing cutter to cut to proper length.

(HAND TIGHTEN)

3

2

1

COUPLING NUT

4

FERRULE

FITTING WITH SPRAY

3

Place SPRAY HOLDER (1) into separate hole

of SINK (2) and assemble NUT (3) onto shank.

From underside of SINK (2) and hand tighten

NUT (3).

1

2

3

FITTING WITH SPRAY

0

1

2

3

4

5

6

4

7

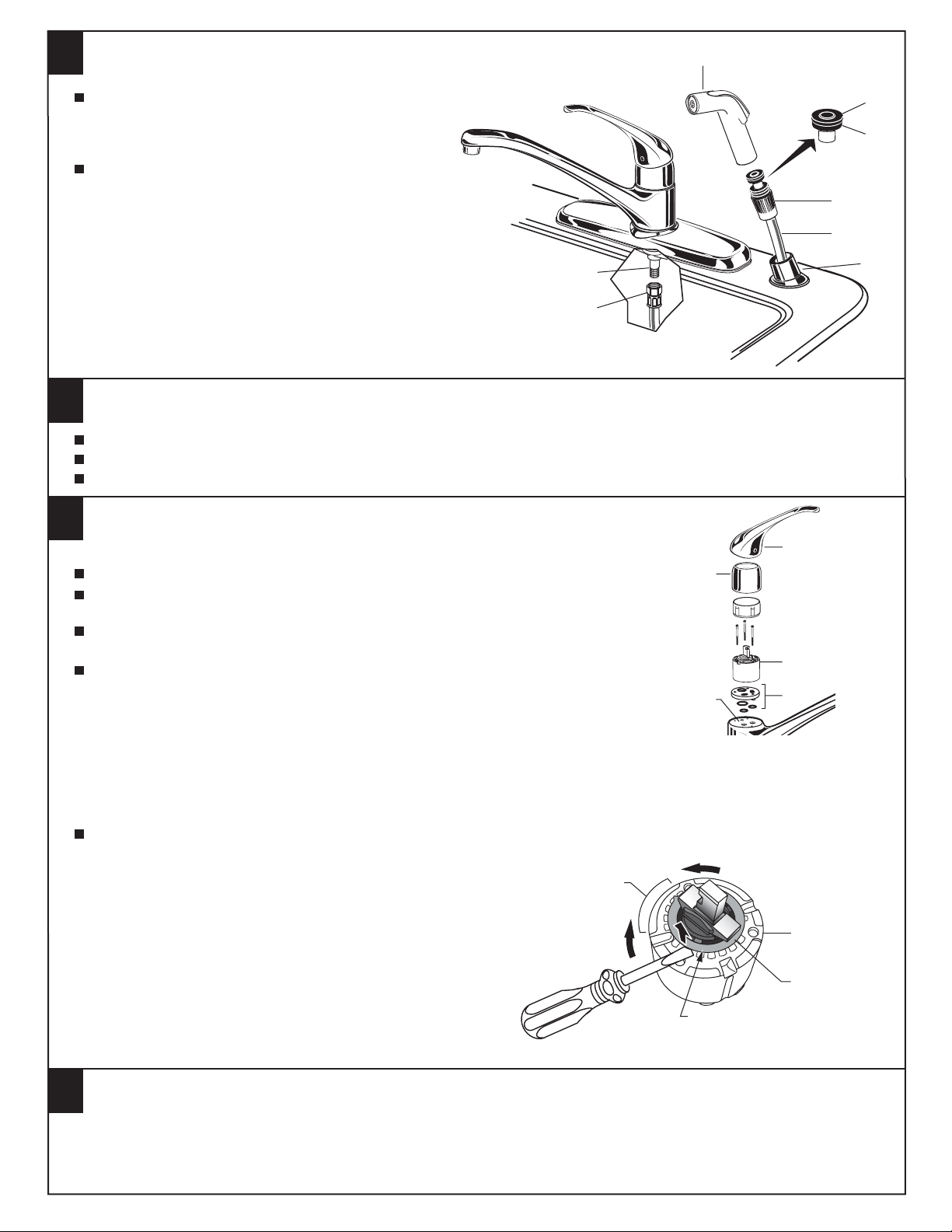

Feed SPRAY HOSE (1) through SPRAY HOLDER (2)

and attach COUPLING NUT (3) of HOSE (1) to

HOSE ADAPTOR (4) on valve body. Tighten

COUPLING NUT (3) firmly.

Make certain that SPACER WASHER (5) and

RUBBER WASHER (6) are attached to

SPRAY HOSE (1) and thread SPRAY HEAD (7)

to NUT (8).

4

3

TEST INSTALLED FAUCET

5

Remove AERATOR. With handles in OFF position, turn on water supplies and check all connections for leaks.

Operate HANDLE to flush water lines thoroughly. Rotate SPOUT in both directions. Replace AERATOR.

Direct SPRAY HEAD into sink and activate SPRAY. Check HOSE connections for leaks.

SERVICE

6

If faucet drips proceed as follows:

Turn VALVE in OFF position.

If faucet drips, operate handle several times from "off" to "on".

Do not apply excessive force.

Clogged CARTRIDGE inlets may cause reduced flow in "full on" hot or cold.

To clean inlets, first turn off water supply, then:

Remove HANDLE (1), CAP (2), CARTRIDGE (3), and DISC & SEALS (5).

Clean inlets and MANIFOLD (4). Reassemble CARTRIDGE (3), alternately

tightening screws. Replace CAP and HANDLE. Check flow.

2

4

6

5

8

1

2

1

3

5

HOT LIMIT SAFETY STOP ADJUSTMENT

By restricting handle rotation and limiting the amount of hot water allowed

to mix with the cold, the HOT LIMIT SAFETY STOP reduces risk of accidental

scalding. To set the maximum hot water temperature of your faucets, all you

need to do is adjust the setting on the HOT LIMIT SAFETY STOP.

Use a flat blade screwdriver or your fingers to pull up and rotate

red HOT LIMIT SAFETY STOP (5). Follow Step "A" or "B" to adjust

min./max. discharge temperature. "0" being the hottest to "7"

the coldest temperature setting. Factory set at "0".

PRY RED RING FORWARD

AND ROTATE CLOCKWISE

ADJUSTMENT WHEN

WATER IS TOO COLD

CARE INSTRUCTIONS:

7

SETTING NUMBERS

"B"

"B"

TEMPERATURE

"B"

PRY RED RING FORWARD

AND ROTATE COUNTER-

CLOCKWISE ONE CLICK

"A"

"RED RING"- HOT

LIMIT SAFETY STOP

"A"

"A"

ADJUSTMENT WHEN

WATER IS TOO HOT

6

5

DO: SIMPLY RINSE THE PRODUCT CLEAN WITH CLEAR WATER. DRY WITH A SOFT COTTON FLANNEL CLOTH.

DO NOT: DO NOT CLEAN THE PRODUCT WITH SOAPS, ACID, POLISH, ABRASIVES, HARSH CLEANERS, OR A

CLOTH WITH A COARSE SURFACE.

M968420 REV. 1.1

Loading...

Loading...