American Standard 2740.XXX User Manual

COLONY™ 5 x 30 AFR

INTEGRAL APRON WITH

REMOVABLE ACCESS PANEL

FOR ABOVE-FLOOR

ROUGH INSTALLATION

HIGH GLOSS ACRYLIC

SHOWN LESS ALL FITTINGS

2740.XXX SERIES

WHIRLPOOL/BATHING POOL

INSTALLATION INSTRUCTIONS

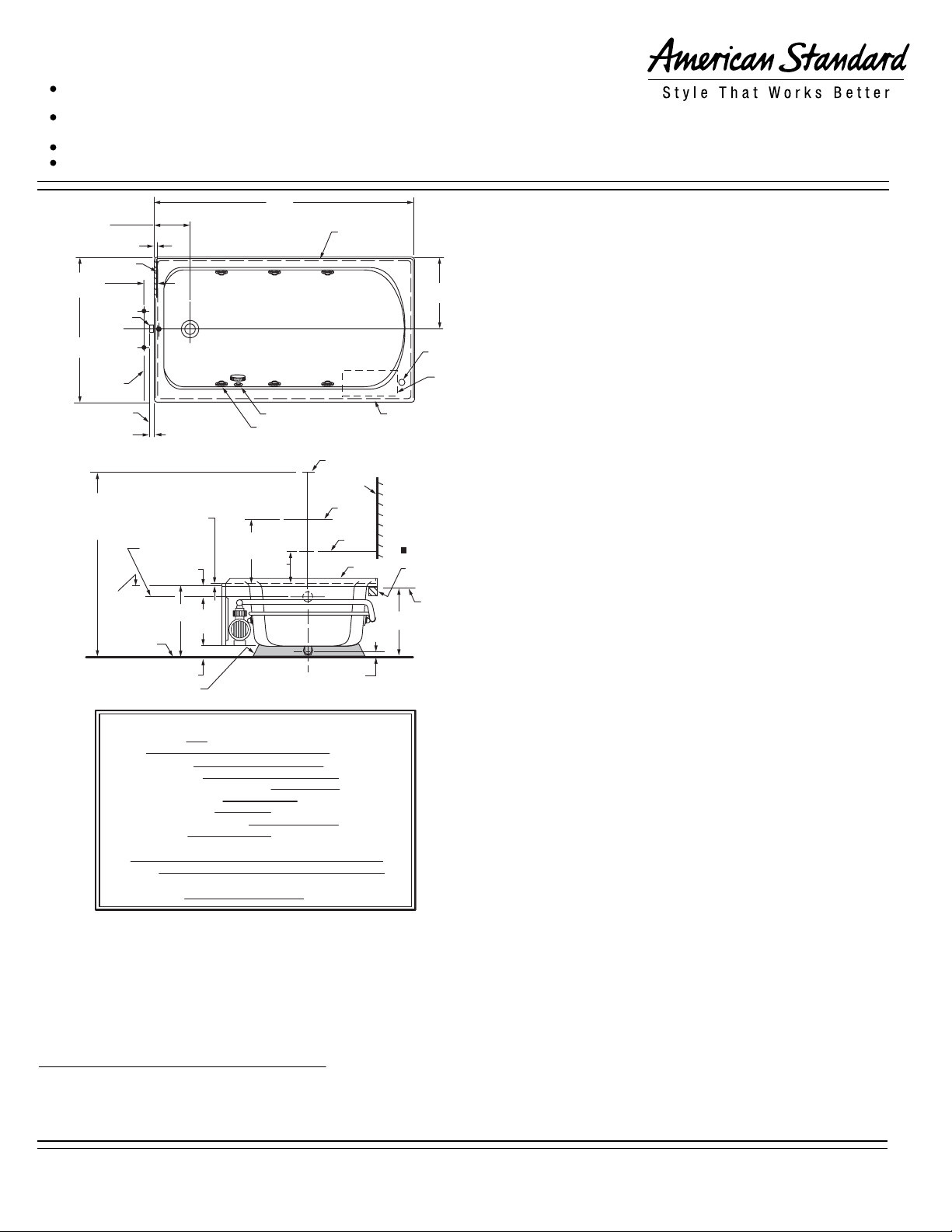

59-7/8

7

(178mm)

C/L OF DRAIN

SEE FITTING

SPECS FOR

DIMENSIONS

(759mm)

HORIZONTAL TAILPIECE

ABOVE FLOOR OUTLET

FINISHED FLOOR

USUALLY BETWEEN

(19mm)

FINISHED

WALL

1-1/2 O.D.

TAILPIECE

29-7/8

C/L OF

SUPPLIES

1-1/2 (38mm)

OPTIONAL TO

65 & 78

(1651 & 1981mm)

TOP OF

DECK

INSTALLED SIZE

WEIGHT

WEIGHT w/WATER

GAL. TO OVERFLOW

WHIRLPOOL MIN. OPERATING VOL.

BATHING WELL AT SUMP

BATHING WELL AT RIM

WATER DEPTH TO OVERFLOW

FLOOR LOADING

(PROJECTED AREA)

PTS.

CUBE (FT

SYSTEM I PUMP 1.1 HP, 9.9 AMPS,120V.

3/4

7/8 WATER

RETENTION

FLANGE

(3 SIDES)

C/L OF

OVERFLOW

3

(76mm)

19-1/4

(489mm)

ROUGH

FLOOR

3-3/4

(95mm)

BATH SUPPORT

MATERIAL

GENERAL SPECIFICATIONS FOR 2740 WHIRLPOOL

3

)

WHIRLPOOL ELECTRICAL SPECIFICATIONS

59-7/8 x 29-7/8 x 19-1/4 (1521 x 759 x 489mm)

(1521mm)

(1) AIR VALVE

(6) JETS

12

(305mm)

OPT.

4

(102mm)

20 x 46 (508 x 1168mm )

25-1/2 x 55-1/2(648 x 1410mm )

39 Lbs./Sq.Ft. (188 Kgs./Sq.m)

C/L OF

SHOWER ARM

480 Lbs. (216 Kgs.)

GENERAL INSTALLATION INFORMATION

Bath may only be installed in a recess type installation.

WATER

RETENTION

FLANGE

(3 SIDES)

FINISHED

WALL

C/L OF

VALVES

C/L OF

SPOUT

TILING

FLANGE

(483mm)

2-1/2

(64mm)

105 Lbs. (47 Kgs.)

45 Gal. (171 L)

38 Gal. (144 L)

11-1/2 (292mm)

20.8

35.3

14-1/8

(359mm)

ON/OFF

SWITCH

PUMP

ACCESS TO PUMP/MOTOR

THROUGH REMOVABLE

FRONT ACCESS PANEL

LEVELING

STRINGER

NOT FOR

SUPPORT

UNDERSIDE

OF DECK

19

THANK YOU...

for selecting an American Standard bath. Your new bath is shipped

to you after careful inspection. The whirlpool version is completely

assembled with pump, motor, and system piping. All you need to

finish the installation are your selected fittings and electrical

connections for a whirlpool.

To insure maximum performance and pleasure from this product,

please follow the instructions and cautions.

List of Required Components (not included):

• Drain 1583.470* • Bath Filler*

* see your American Standard Distributor

List of Required Tools and Supplies:

Tools

• Level

• Tape Measure

• Pipe Wrench

• Slip Joint Pliers

• Screw Driver

• Standard

Woodworking Tools

• Personal Safety

Equipment

• Caulking Gun

GENERAL INSTALLATION INFORMATION

Carefully uncrate and inspect your new bath for any shipping

damage. If such damage is found, report it to your vendor

immediately.

After inspection and during installation, protect the bath from

construction damage. Before installation, and before

enclosing with wallboard, tile, etc., water test the unit and

check for leaks.

If a whirlpool, do not make modifications to the whirlpool system

or remove pump from factory mounting. This could adversely

affect the safety and performance of the whirlpool and void the

warranty. Do not handle or move the whirlpool by the pump,

motor, or piping system.

Fittings (bath filler, shower arm, etc.) are not provided with the

bath and must be ordered separately. Framing and enclosing

materials are provided by others.

Supplies

• Nails

• Putty

• Caulking (waterproof)

• 1 x 3 or 2 x 2

Stringers

• Drop Cloth

• 15 amp GFI

Outlet

• Cement, Plaster,

Grout

IMPORTANT:

Water test unit before installation and enclosure!

Locate studs as required. Insure rough dimensions are proper, plumb and square. For whirlpools, access to pump/motor may be made through

access opening in apron panel. The following procedure must be used for all installations: leveling support stringer should be as indicated. This bath is

not self-supporting and must be supported along it's entire bottom. Support with mortar or grout.

Position bathtub/whirlpool within the recess, check level, front to back, side to side, and shim as necessary.

To secure the tub to wood studs use drywall screws w/washers or roofing nails immediately above the flange of the tub. To secure the tub to steel studs

use 4" drywall screws and flatwashers.

See page 2 for complete installation information.

Caution: Take extra care when driving nails or screws to avoid damaging the tub.

The tile or similar finished floor will be butted against the bottom of the tub apron, also holding the tub in place.

FOR AFTER-SALES SERVICE CALL 1 (800) 442-1902 WEEKDAYS.

752562-100 Rev. H

© AS America, Inc. 2008

All product names listed herein are trademarks

of AS America, Inc. unless otherwise noted.

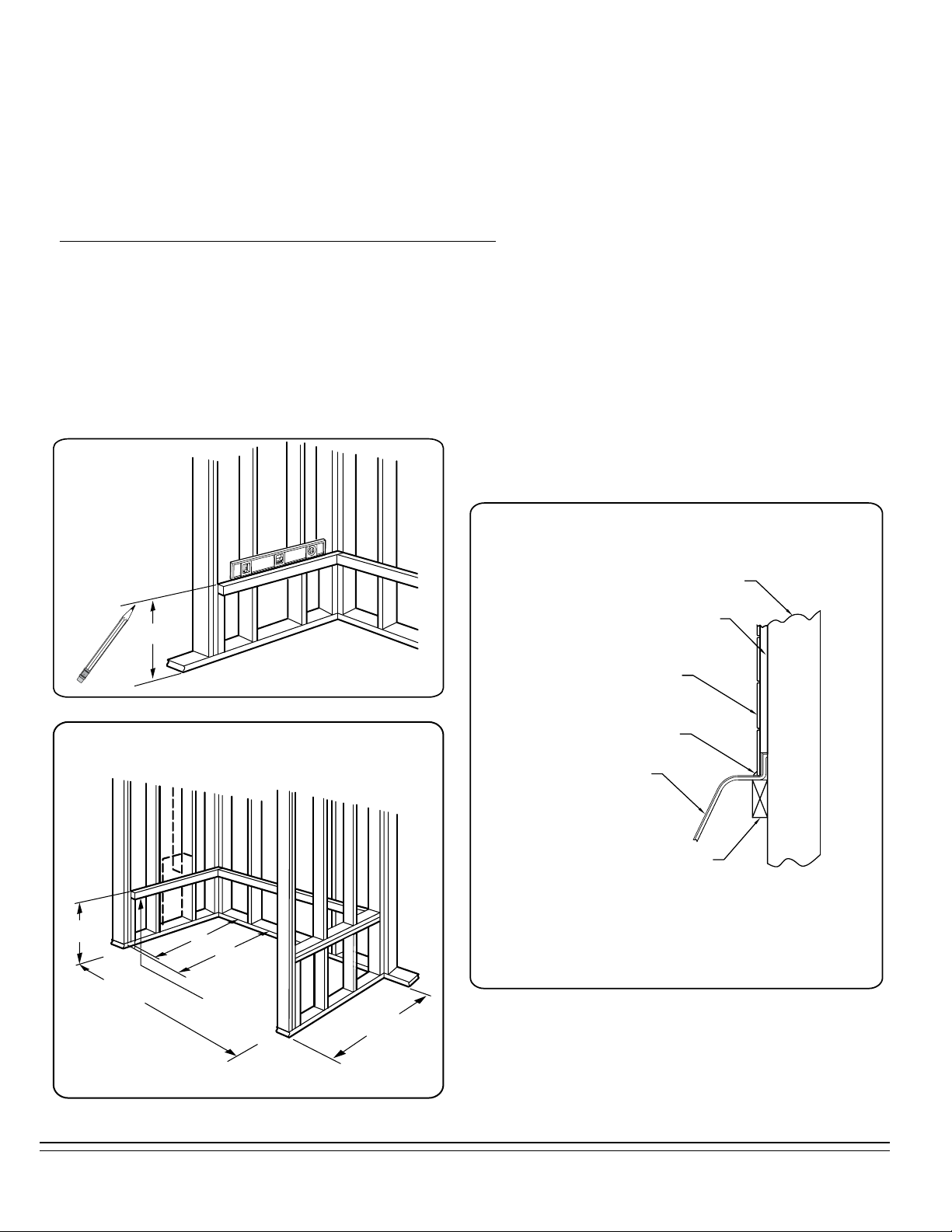

INSTALLATION AND FRAMING INSTRUCTIONS

Locate studs as required. Ensure roughing-in dimensions are proper, plumb and square. Access to Pump/Motor may be

made through the access opening in the apron panel. It is strongly recommended that an additional opening be provided

for access to the drain components.

NOTE: The apron may be used as the primary access opening.

1. As shown in Fig. 1, mark the position of the underside of the deck by tracing a line onto the studs at the height indicated,

using a level or other suitable straight edge.

2. With the top of the stringer touching the traced line, attach the stringer to the studs.

3. Install drain components to the whirlpool or bath following the manufacturers instructions.

4. THIS BATH MUST BE SUPPORTED ALONG ITS ENTIRE BOTTOM.

We recommend the use of mortar as bedding

material (sand is not recommended). Apply enough bedding to support the complete bottom of the bath. After the

bedding has been poured, and before it sets, position whirlpool or bath within recess until the rim is leveled against the

leveling stringers (see "Typical Recess Installation") shown below. The rim of the bath MUST NOT support weight.

Allow the bedding material to completey harden before applying weight to the rim or bottom of the bath. Any finish

material such as tile or wall board must be self-supporting if it contacts the deck of the bath.

FIG. 1

19

(483mm)

TYPICAL RECESS INSTALLATION

19

(483mm)

60-3/16

(1529mm)

0

3

62mm)

(7

(813mm)

TUB

LEVELING

STRINGERS

32

WIDTH

34 Typ.

(864mm)

SUGGESTED WHIRLPOOL/BATH INSTALLATION METHOD

Stud

(Wood or Steel)

Waterproof Dry Wall

or Cement Board

Finished Wall

Sealant

Tub

Leveling Stringer

1 x 3 (25 x 76mm) WOOD

SECURE THE BATH TO THE STUDS AS SHOWN FOR

WOOD OR STEEL STUD CONSTRUCTION.

752562-100 Rev. H 2

Loading...

Loading...