Page 1

INSTALLATION INSTRUCTIONS

For Two-Piece Toilets with

Repertoire 2266/2280

Heritage 2176

Antiquity 2262/2264

Ellisse 2184

Infinity 2316/2319

Cascada 2321/2323

Cadet 2798/2898

Reminiscence 2311

Cadet Specifier 2783/2883

™

2000

Thank you for selecting American Standard - the benchmark of fine quality for over 100 years. To ensure this product

is installed properly, please read these instructions carefully before you begin. (Certain installations may require

professional help.) Also be sure your installation conforms to local codes.

!

CAUTION: PRODUCT IS FRAGILE. TO AVOID BREAKAGE AND POSSIBLE INJURY HANDLE WITH CARE!

NOTE:

Pictures may not exactly define contour of china and components.

RECOMMENDED TOOLS AND MATERIALS

Putty Knife Regular Screwdriver Adjustable Wrench Sealant Tape Measure

Hacksaw Wax Ring/Gasket Flexible Supply Tube Closet Bolts Carpenters Level

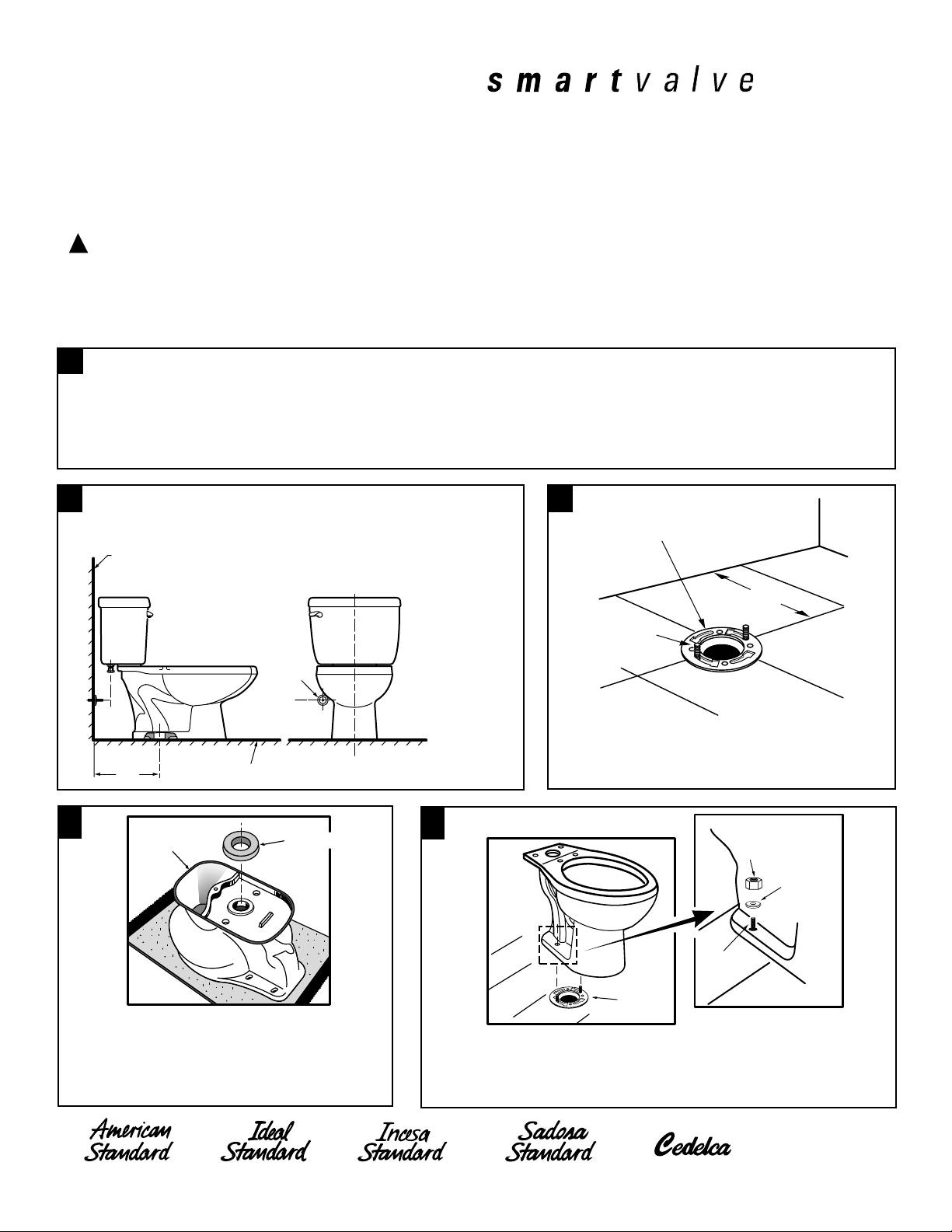

1 REMOVE OLD TOILET

a. Close toilet supply valve and flush tank completely. Towel or sponge remaining water from tank and bowl.

b. Disconnect and remove supply line. NOTE:

c. Remove old mounting hardware, remove toilet and plug floor waste opening to prevent escaping sewer gases.

d. Remove closet bolts from flange and clean away old wax, putty, etc. from base area.

NOTE:

Mounting surface must be clean and level before new toilet is installed!

If replacing valve, first shut off main water supply!

FINISHED WALL

A

SEALANT

ROUGHING-IN DIMENSIONS:

NOTE:

Distance from wall to closet flange centerline must

be as listed below:

For 4110 Tanks: A = 254mm (10")

For 4114 Tanks: A = 356mm (14")

For all other Tanks: A = 305mm (12")

SUPPLY

AS

REQ'D.

FINISHED

FLOOR

WAX RING

32

CLOSET FLANGE

A

CLOSET BOLTS

INSTALL CLOSET BOLTS

Install closet bolts in flange channel, turn 90°, and slide

into place 6" (152 mm) apart and parallel to wall.

SAVE FOR FUTURE USE

54

NUT

TAPERED

WASHER

INSTALL WAX SEAL

Invert toilet on floor (cushion to prevent damage), and

install wax ring evenly around waste flange (horn), with

tapered end of ring facing toilet. Apply a thin bead of

sealant around toilet base.

Product names listed herein are trademarks of American Standard Inc.

© American Standard Inc. 1999

CLOSET

BOLT

FLANGE

POSITION TOILET ON FLANGE

a. Unplug floor waste opening and install toilet on closet flange so bolts project

through mounting holes.

b. Loosely install retainer washers and nuts. Side of washers marked "THIS

SIDE UP"

must

face up!

Saniwares

730451-100 Rev. A

Page 2

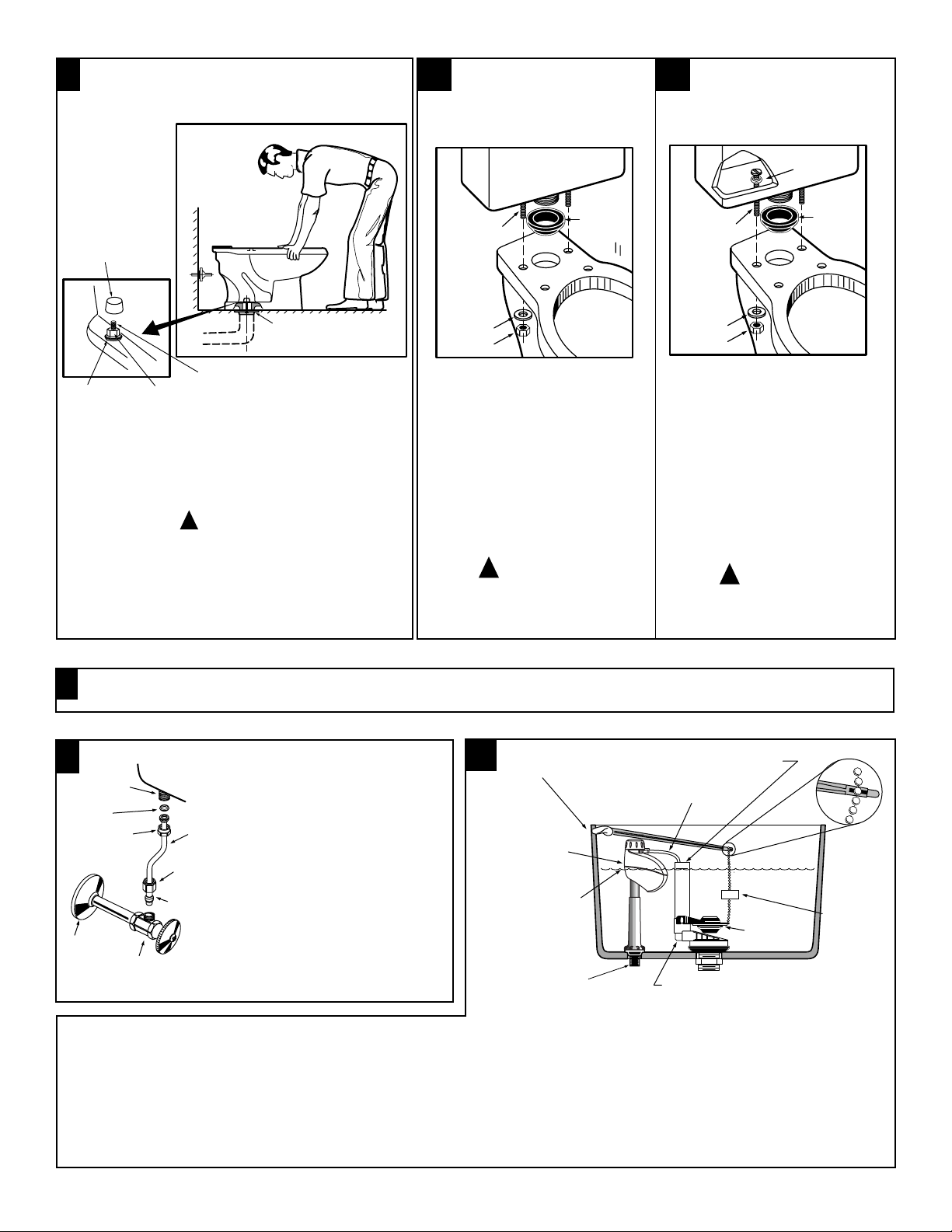

6

7a 7b

BOLT CAP

CLOSET FLANGE

CLOSET BOLT

WASHER

NUT

INSTALL TOILET

a. Position toilet squarely to wall and, with a rocking

motion, press bowl down fully on wax ring and flange.

Alternately tighten nuts until toilet is firmly seated on

floor.

!

CAUTION:

DO NOT OVERTIGHTEN NUTS

OR BASE MAY BE DAMAGED!

b. Install caps on washers. (If necessary, cut bolt height

to size before installing caps.)

c. Smooth off the bead of sealant around base. Remove

excess sealant.

For Tanks/Bowls using Speed

Connect System (Tank

mounting bolts pre-installed).

TANK MTG.

BOLTS PREINSTALLED

WASHER

NUT

INSTALL TANK

a. Install large rubber gasket over

threaded outlet on bottom of tank

and lower tank onto bowl so that

tapered end of gasket fits evenly into

bowl water inlet opening, and tank

mounting bolts go through mounting

holes. Secure with metal washers

and nuts.

b. With tank parallel to wall, alternately

tighten nuts until tank is snugged

down evenly against bowl surface.

!

CAUTION:

DO NOT OVERTIGHTEN NUTS MORE

THAN REQUIRED FOR A SNUG FIT!

RUBBER

GASKET

For all other Tanks/Bowls

RUBBER

WASHER

TANK MTG.

BOLTS

WASHER

NUT

INSTALL TANK

a. Install large rubber gasket over

threaded outlet on bottom of tank

and lower tank onto bowl so that

tapered end of gasket fits evenly into

bowl water inlet opening.

b. Insert tank mounting bolts and

rubber washers from inside tank,

through mounting holes, and secure

with metal washers and nuts.

c. With tank parallel to wall, alternately

tighten nuts until tank is snugged

down evenly against bowl surface.

!

CAUTION:

DO NOT OVERTIGHTEN NUTS MORE

THAN REQUIRED FOR A SNUG FIT!

RUBBER

GASKET

8

INSTALL TOILET SEAT Install toilet seat in accordance with manufacturer's directions.

9

WATER INLET

WASHER

COUPLING NUT

TRIM

PLATE

VALVE

TANK

FLEXIBLE

SUPPLY

VALVE NUT

COMPRESSION

COLLAR

CONNECT WATER SUPPLY

a. Connect water supply line between

shutoff valve and tank water

inlet fitting. Tighten coupling nuts

securely. Check that refill tube is

inserted into overflow tube.

b. Turn on supply valve and allow

tank to fill until water rises to

shutoff position.

c. Check for leakage at fittings,

tighten or correct as needed.

10

WATER CONTROL

WATER LINE LEVEL

ADJUSTMENTS

a. Adjust water level. Water level should be

adjusted to level indicated on tank by

adjusting valve height.

b. If bowl fails to siphon, an adjustment may be

required with the lift chain. Simply remove the

bead chain from the retainment clip (see Fig.

10A) and take up slack on the chain, and

See Step 11 for valve height adjustment

method

reinsert on lift rod. Make sure the chain is not

too taught.

TRIP LEVER

ASSEMBLY

WATER INLET

OVERFLOW TUBE

REFILL TUBE

Fig. 10A

FLUSH VALVE

FLOAT

FLUSH VALVE

FLAPPER

ASSEMBLY

TOILET REQUIRES THAT THE TANK

REFILLS IN NO LESS THAN ONE MINUTE.

ADJUST WATER SUPPLY VALVE (FIG. 9)

ACCORDINGLY.

- 2 -

730451-100 Rev. A

Page 3

11 12

ADJUST VALVE HEIGHT

RELEASE

LOCK

E

X

T

E

N

D

To change water level, shut off

water supply valve, flush toilet,

twist valve body clockwise to

release lock and extend shank

accordingly.

SHANK

Before turning water on, confirm valve is in

locked position when valve is parallel to back

of toilet tank.

LOCKED

UNLOCKED

13

CARE AND CLEANING

When cleaning your toilet, wash it with mild, soapy water, rinse thoroughly with clear water and dry with a soft cloth. Avoid

detergents, disinfectants, or cleaning products in aerosol cans. NEVER use abrasive scouring powders or abrasive pads

on your toilet seat. Some bathroom chemicals and cosmetics may damage the seat's finish.

!

WARNING: Do not use in-tank cleaners. Products containing chlorine (calcium hypochlorite) can seriously damage fittings

in the tank. This damage can cause leakage and property damage.

American Standard shall not be responsible or liable for any tank fitting damage caused by the use of cleaners

containing chlorine (calcium hypochlorite).

REPAIR PARTS LIST

Repair parts are determined by toilet tank number which can be found

marked inside tank.

NOTE: "XXX" represents color or trim finish options. Specify when ordering.

PART NO.

047242-XXX0A

047192-XXX0A

730283-XXX0A

730288-XXX0A

738172-XXX0A

738170-XXX0A

738171-XXX0A

034783-XXX0A

047227-XXX0A

3198.000

738181-0070A

738138-0070A

047141-0070A

047188-0070A

047158-0070A

730172-0070A

738258-0070A

738159-0070A

738397-0070A

738407-0070A

TRIP LEVER

TRIP LEVER

TRIP LEVER

TRIP LEVER

RIGHT HAND TRIP LEVER

RIGHT HAND TRIP LEVER

RIGHT HAND TRIP LEVER

BOLT CAP KIT (INCL TWO COVERS & WASHERS)

BOLT CAP KIT (INCL TWO COVERS & WASHERS)

SMART VALVE 2000

FLUSH VALVE

FLUSH VALVE

COUPLING KIT, BOWL-TO-TANK

COUPLING KIT, BOWL-TO-TANK

COUPLING KIT, BOWL-TO-TANK

COUPLING KIT, BOWL-TO-TANK

FLAPPER ASSEMBLY

FLAPPER ASSEMBLY

FLAPPER ASSEMBLY

FLAPPER ASSEMBLY

DESCRIPTION

TANK NUMBER

4075 ELLISSE

4065 INFINITY

4057 CASCADA

✔

✔

✔

✔✔✔

✔

✔

✔

✔

✔✔✔

✔

✔✔✔ ✔✔✔✔

✔

✔

✔✔

✔

✔

✔✔

✔

✔

✔✔

4111 REMINISCENCE

4074 HERITAGE

4110 CADET

4094 ANTIQUITY

4095 REPERTOIRE

4112/4114 CADET

✔✔

✔

✔✔✔✔

✔

✔

✔✔✔✔

✔✔

✔✔

✔

✔

✔✔

✔

✔

- 3 -

730451-100 Rev. A

Page 4

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Does not flush a. Water supply valve closed. a. Open valve and allow water to fill tank.

b. Supply line blocked. b. Shut off water supply, disconnect supply line, and inspect

all gaskets and washers. Reassemble.

c. Flush valve chain too loose or c. Readjust chain length as required.

disconnected.

d. Sand or debris lodged in d. Shut off water supply. Remove cap and clean per Fig. 12.

water control.

Poor or

sluggish flush a. Bowl water level too low. a. Check that refill tube is connected to water control and

inserted into tank overflow without being kinked or damaged.

b. Supply valve partly closed. b. Open supply valve fully. Be sure that proper supply tube

size is used.

c. Partially clogged trapway and/or c. Remove obstruction. Consult a plumber if necessary.

drain pipe and/or vent.

d. Supply pressure too low. d. Normal supply pressure must be at least 20 psi.

Toilet leaks a. Poor supply line connection. a. Review Step 9 of installation procedure.

b. Poor bowl to tank/floor connection. b. Review Step 4 through 7 of installation procedure.

Toilet does not a. Flush valve chain too tight, holding a. Readjust chain length as needed.

shut off flush valve open.

b. Flush valve seat and/or flapper worn b. Replace flapper/flush valve assembly, as needed.

or deformed.

c. Sand or debris lodged in water control. c. Shut off water supply. Remove cap and clean per Fig. 12.

Fig. 12

Turn off water SUPPLY

VALVE and flush toilet.

Remove VALVE TOP CAP

turning counterclockwise

while holding valve body.

REMOVE

VALVE

TOP CAP

RUBBER

SEAL

Rinse with water.

Replace VALVE TOP

CAP by hand tightening

in clockwise direction

while holding valve body.

Do not over tighten.

VALVE

TOP

CAP

TIGHTEN

Confirm Smart Valve

Inspect RUBBER SEAL

and remove debris.

is in locked position

before turning on

water supply.

Replacement RUBBER

SEAL model number

8298.000B is available.

AMERICAN-STANDARD ONE-YEAR LIMITED WARRANTY

If inspection of this American-Standard plumbing product, within one year after its initial purchase, confirms that it is defective in materials or workmanship, American-Standard

will repair or, at its option, exchange the product for a similar model.

This warranty does not apply to local building code compliance. Since local building codes vary considerably, the purchaser of this product should check with a local building

or plumbing contractor to insure local code compliance before installation.

This warranty shall be void if the product has been moved from its initial place of installation; if it has been subjected to faulty maintenance, abuse, misuse, accident or other

damage; if it was not installed in accordance with American-Standard's instructions; or if it has been modified in a manner inconsistent with the product as shipped by AmericanStandard.

American-Standard's option to repair or exchange the product under this warranty does not cover any labor or other costs of removal or installation, nor shall American-

Standard be responsible for any other incidental or consequential damages attributable to a product defect or to the repair or exchange of a defective product, all of

which are expressly excluded from this warranty. (Some states or provinces do not allow the exclusion or limitation of implied warranties, so this exclusion may not apply to

you.)

This warranty gives you specific legal rights. You may have other statutory rights that vary from state to state or from province to province, in which case this warranty does not

affect such statutory rights.

For service under this warranty, it is suggested that a claim be made through the contractor or dealer from or through whom the product was purchased, or that a service request

(including a description of the product model and of the defect) be sent to the following address:

Check operation

of toilet.

In the United States:

American Standard Inc.,

P.O. Box 6820

Piscataway, New Jersey 08855

Attention: Director of Consumer Affairs

For residents of the United States, warranty information may also be

obtained by calling the following toll free number: (800) 223-0068

730451-100 Rev. A

In Canada:

American-Standard,

1401 Dupont Street,

Toronto, Ontario

Canada M6H 2B1

Toll Free: (800) 387-0369

Toronto Area: (416) 536-5609

- 4 -

In Mexico:

Customer Service Manager

Ideal Standard, S.A. de C.V.

Via Morelos #330

Col. Santa Clara

Ecatepec 55540 Edo. Mexico

Loading...

Loading...