Page 1

Commander

C10e-PoE/C10p-PoE

Operations

Manual

1

Page 2

FCC Caution and Warnings

Caution:

Before attempting to connect or operate this product, please read the label on the top and bottom.

Note:

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment

generates, uses,

and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful inter ference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

FCC Caution:

To assure continued compliance of this product, do not modify any interface cables when

connecting to computer or peripheral devices. Any changes or modifications not expressly

approved by the party responsible for compliance could void the user’s authority to operate this

equipment.

Warning:

To prevent fire or electric shock hazard, do not expose this device to rain or moisture. This

apparatus shall not be exposed to dripping or splashing and no objects filled with liquids, such as

vases, shall be placed on the apparatus. The lightning flash with arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the presence of un-insulated "dangerous

voltage" within the product's enclosure that may be of sufficient magnitude to constitute a risk of

electric shock to persons. The exclamation point within an equilateral triangle is intended to alert

the user to the presence of important operating and maintenance (servicing) instructions in the

literature accompanying t

h

e

appliance.

This unit has power supplied to it whenever the power

cord is inserted into the power source. The power cord is the main power disconnect for all units.

2

Page 3

Before You Start: Limitations of Liability/ Disclaimer of Warranty/ Safety Instructions

Limitations of Liability:

This Commander Instruction and Operation manual is provided “as is” without warranty of any

kind, either expressed or implied. This includes but is not limited to: implied warranties of

merchantability, or fitness for any reason or purpose. This limitation also includes noninfringement of any third party’s rights.

The reader acknowledges this publication could include technical inaccuracies or typographic

errors. American Fibertek reserves the rights to add or make changes to the product represented in

this manual and to add or change the information presented in this manual as required.

Disclaimer of Warranty:

In no event or under any condition will American Fibertek be liable to any party or persons

for

except

replacement or repair of Commander under the terms and conditions of its stated

warranty. American Fibertek will not be liable for the following conditions:

1. Any damages or losses including, without limitation, direct, indirect or otherwise, any

consequential or exemplary damages that arise out of or related to the Commander.

2. Personal injury or any damage resulting from inappropriate use or negligent on the part of the

user in proper operation as stated by American Fibertek.

3. Unauthorized disassembly, repair, or modification of the product by the user.

4. Any problem, inability to perform to stated specifications, inconvenience, loss or damage

arising from the combination of Commander with third party devices, software, browsers or

interfaces.

5. Any claim or action for damage that is brought about by an individual, or group of individuals,

or organization, due to violations or privacy that result from information, including saved data

that for any reason becomes public.

6. Any claim, problem or consequential inconvenience, loss or damage arising from improper

detection of sensor or alarm functions.

7. Any claim resulting from the loss of data created or stored by Commander caused by the need

to reboot due to improper operation.

8. Any claim resulting from inability to co mmunicate with Commander due to changes made to

third party browsers.

Safety Instructions:

1. Please read these instructions completely prior to operating Commander for the first time.

2. Keep these instructions in a place where they can be referred to as required.

3. Follow all warnings as indicated.

4. Follow all instructions as indicated.

5. Do not use Commander near water or areas of dampness.

6. Clean Commander only using a dry lint free cloth.

7. Do not block any of the ventilation openings.

8. Do not use next to high heat or cold sources that exceed the manufacturer’s environmental

ratings.

9. Do not misuse polarized or grounding type plugs.

10. Do not rem ove the grounding plug.

11. Protect the power cord from being step on or pinched.

12. Only plug the cord into a proper receptacle.

13. Only use accessories and attachments designed for Commander or approved by American

Fibertek.

14. Operate, mount, and transport Commander only in horizontal position.

15. It is recommended that Commander be operated with power sources that include proper EMI,

RFI or power surge protection, or if required the customer take proper steps to assure problems

from these conditions will be minimized.

3

Page 4

Trademarks and Registered Trademarks/ Warnings

Precautions:

1. Logs are held in Commander’s volatile memory. Any loss of power will erase all log data.

2. As Commander is a computer device, it is strongly suggested that it be powered from devices

which offer EMI and RFI protection and power back up,

3. Do not operate Commander beyond its specified temperature, humidity, or power source

ratings. When installing Co mmander make certain th at the following environmental conditions

are maintained:

Temperature: (-40C to + 75C-Industrial Versions) (0C to +70C – Commercial Versions)

Humidity 0% to 95% non Condensing

Power: 100 to 240 VAC @ 50 to 60 Hz

4. Battery Back up:

The back up battery maintains the clock and programming features. The built in battery life is

approximately 2 years and can vary due to operations under external environmental conditions.

5. Cooling Fan

Commander uses a cooling fan in order to protect itself against da mage from high temperature

conditions. The fan should be checked and clean periodically. Make certain the power is off to the

unit when cleaning the fan and that the Event Log has been transferred out of Commander to

prevent information loss.

6. To properly operate Commander, place it on a horizontally surface. When stacking units or

rack mounting multiple units leave at least a space of 1RU (1 7/8 inches) between each unit.

7. Commander allows operators with Admin (Administrator) level permission to download its

programming and upload programming in the event Commander programming is lost. It is

recommended that after programming is complete, it be downloaded and kept in a safe place.

8. For proper viewing of Web screens monitor resolutions of 1024 X 768 are required.

Trademarks and Registered Trademarks:

Microsoft, Windows and Windows XP are registered trademarks of Microsoft Corporation in the

United States and/or foreign countries Other names of corporations and products that are found

this operations

in

manual may be trademarks or registered t rademarks of their respective

companies.

American Fibertek reserves the right to make changes to this manual and the Commander

product it represents without prior notification to existing users. Those pur chasing

Commander are advised to check the American Fibertek web site and/or call American

Fibertek to check on updates.

The distribution and copying of Comma nder firmware and related software; the

disassembly of Commander and its related components for the propose of reverse

engineering and exporting in violation of existing export laws is expressly prohibited.

Commander’s USB connections will only interface with Commander Probes and cannot be

used with any other equipment using USB connections. Plugging in a USB device that

requires bus power can result in disabling or damaging of Commander and violating the

warranty.

Logs are held in volatile memory. Any loss of power can result in a loss of all recorded data.

To prevent this it is strongly suggested that Commander be operated with a back power

supply. Commander also has several modes that allow operators to save complete logs and

sort search results. Commander also provides an Event Log Email mode which will Email

out complete logs

For Commander C10p versions use only Small Format Pluggable fiber modules that are

sold or recommended by the American Fibertek.

on a

regular basis.

4

Page 5

Overview

Model Numbers ....................................................................................................7

Operation...............................................................................................................8

Front Panel ............................................................................................................9

Rear Panel ...........................................................................................................11

Probe Placement..................................................................................................13

Watch Dog Timer ...............................................................................................14

Web Browsers .....................................................................................................15

Screen Refresh & Warnings................................................................................16

Event Pop Ups.....................................................................................................17

Reset to Factory Default .....................................................................................18

IP Address in DHCP ...........................................................................................20

LED Startup Sequence ........................................................................................21

UTC Time ...........................................................................................................22

Sending Email Notices and Files ........................................................................22

System Access

System Access Levels.........................................................................................23

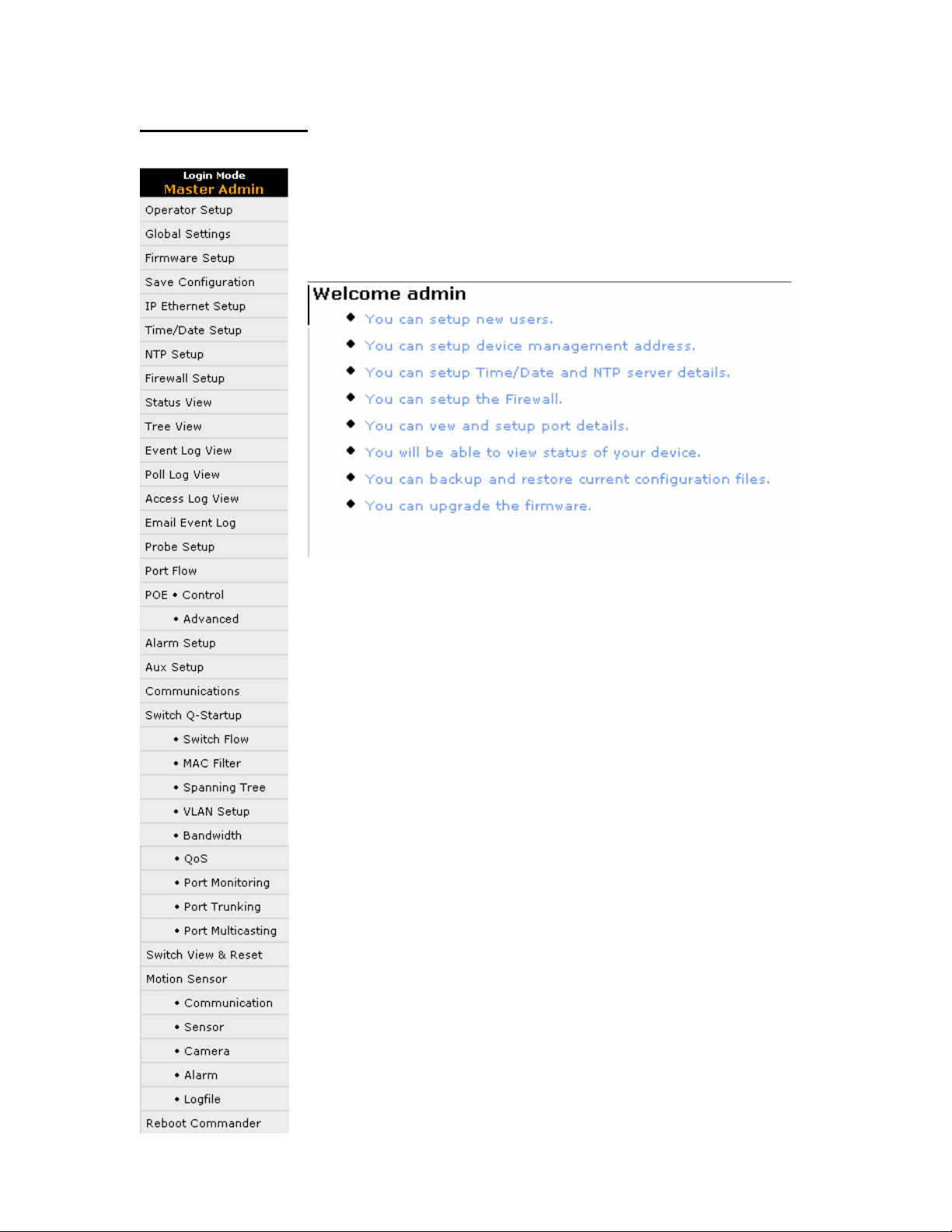

Master Admin Menu ...........................................................................................24

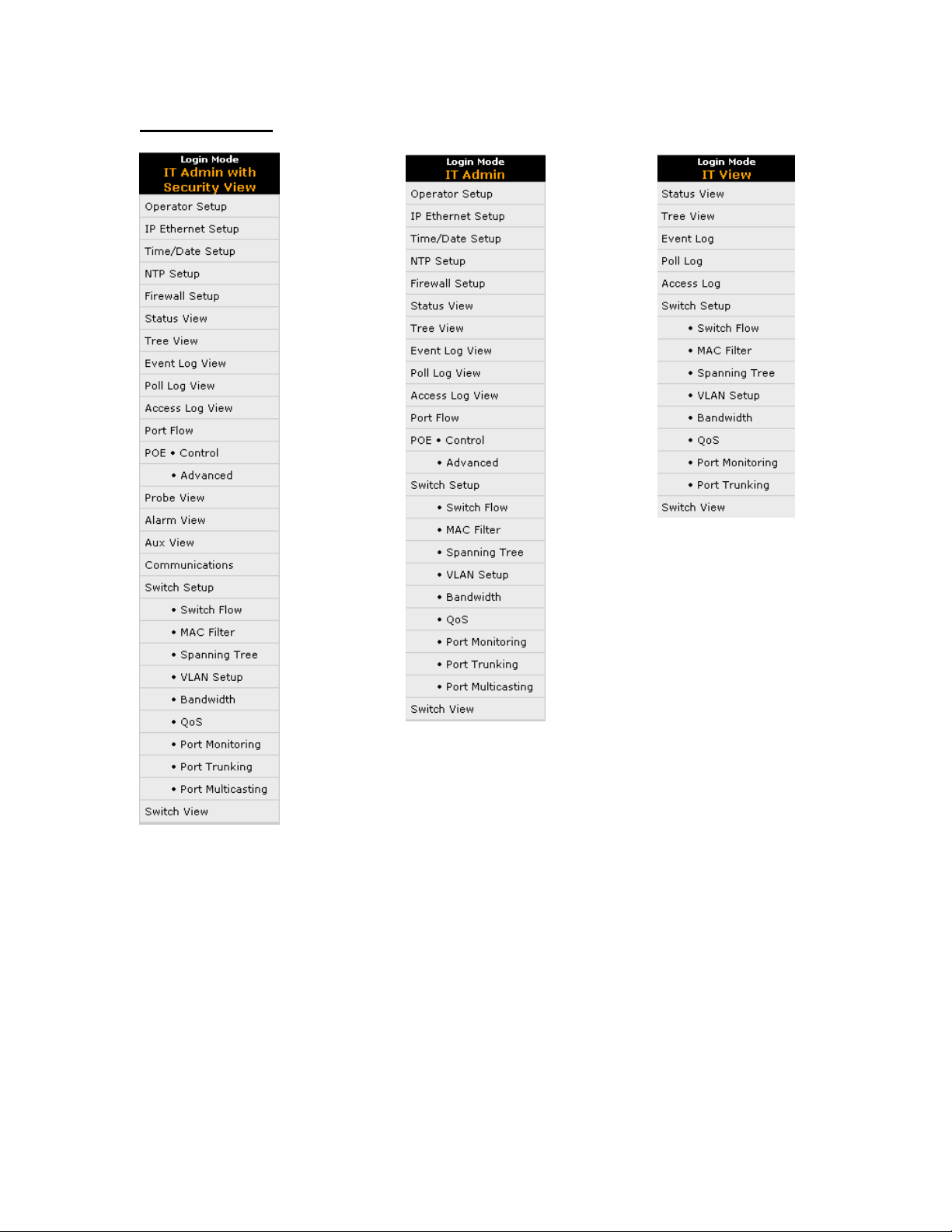

IT Access Menus.................................................................................................25

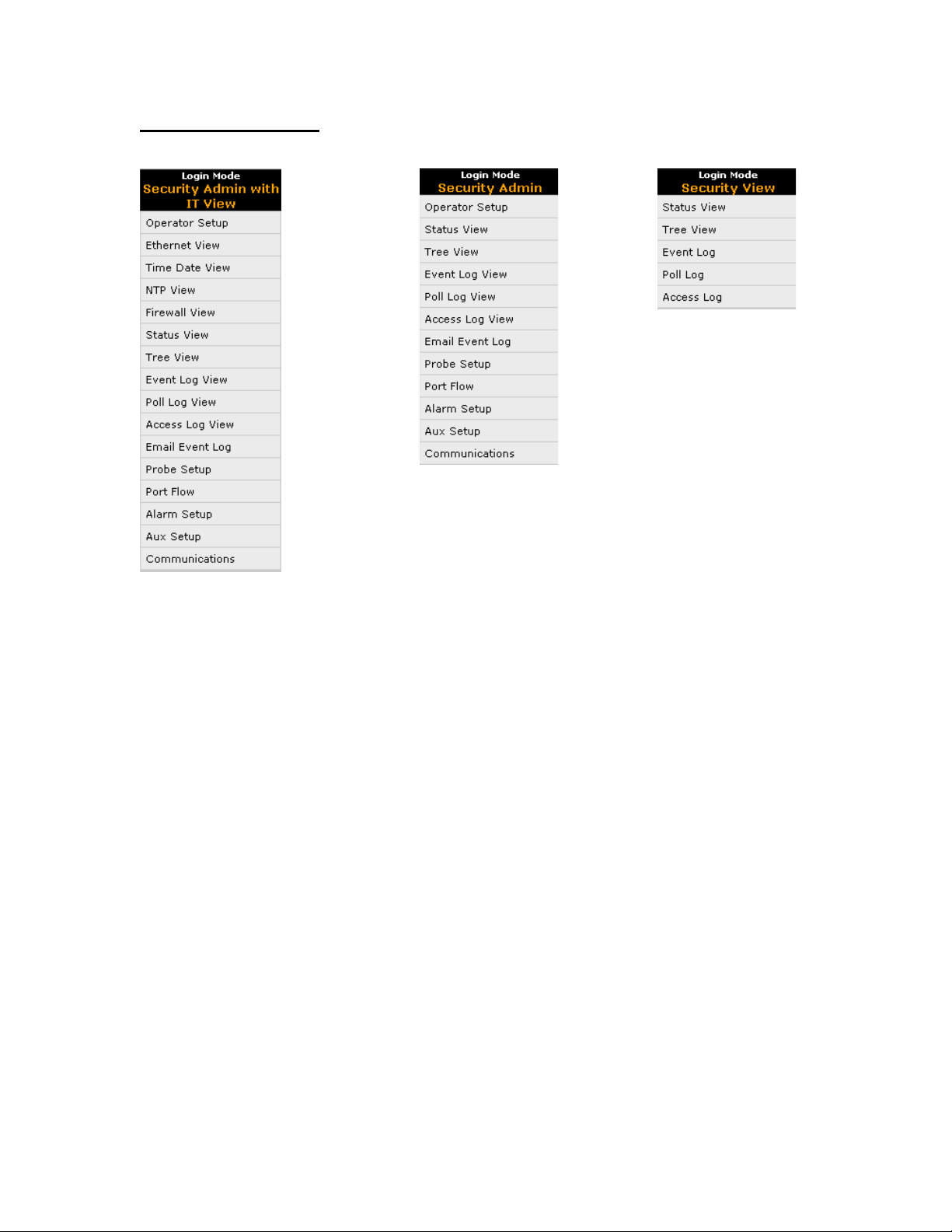

Security Access Menus .......................................................................................26

Logging In and Out .............................................................................................27

Programming

Operator Setup ....................................................................................................28

Global Settings....................................................................................................31

Firmware Setup (Upgrade) .................................................................................34

Save / Restore Configuration ..............................................................................36

IP Settings ...........................................................................................................38

Time & Date .......................................................................................................41

NTP .....................................................................................................................42

Firewall ...............................................................................................................43

Status View .........................................................................................................44

Tree View............................................................................................................52

Log Database ......................................................................................................54

Event & Polling Log ...........................................................................................55

Log Filtering .......................................................................................................60

Access log ...........................................................................................................64

Email Event Log .................................................................................................66

Probe Setup .........................................................................................................67

Port Flow.............................................................................................................74

PoE ......................................................................................................................78

Alarm (Sensor) Setup..........................................................................................80

Aux (Relay) Setup...............................................................................................81

Table of

Contents

5

Page 6

Switch

Communications Ports ........................................................................................82

Switch flow .........................................................................................................83

MAC Tables & Ageing .......................................................................................85

Spanning Tree Protocol.......................................................................................87

VLAN Setup .......................................................................................................89

Bandwidth Management .....................................................................................91

QoS .....................................................................................................................93

Port Monitoring...................................................................................................95

Port Trunking ......................................................................................................97

Port Multicasting.................................................................................................98

Switch View (Statistics)......................................................................................99

Reboot ...........................................................................................................................100

Q&A ...........................................................................................................................101

Default Settings.............................................................................................................103

Email Message Formats ................................................................................................107

Log File Formats...........................................................................................................109

Event & Polling Log Capacities ...................................................................................110

Warranty & Contact Information..................................................................................111

6

Page 7

Overview

Model Numbers

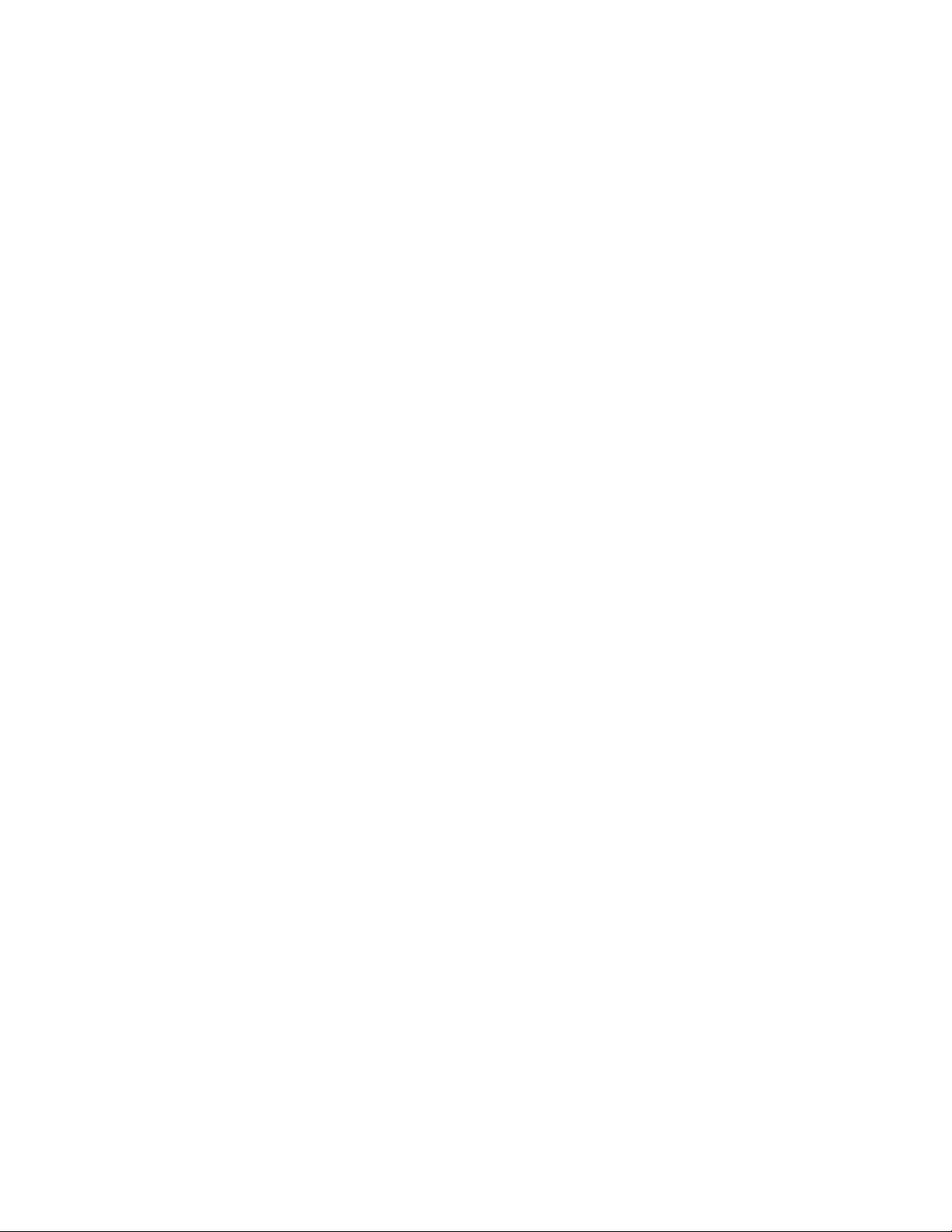

Commander C10 PoE series is available as two model numbers:

C10e-PoE: Is an all copper version and has (8) 10/100 Base T copper Ethernet ports and (2)

10/100/1000 Base T copper Ethernet ports

C10p-PoE: Has (8) 10/100 Base T copper Ethernet ports and (2) open slots for 1000 Base T ports

that use industry standard Small Format Pluggable (SFP) adaptors.

Important Note: C10p versions require optional Small Format Pluggable (SFP) fiber adaptors

into order to operate both 1000 Base T ports. Use only adaptors sold or recommended by

American Fibertek. Use of any other SFP will violate the warranty.

7

Page 8

Operation

Commander is an IP Security Commander’s Center designed for any application that requires

network switching, network traffic monitoring and protecting system components from failure

due to temperature, humidity or the loss of air flow.

Commander’s unique design also provides interfaces for hard

contacts and control of external auxiliary triggers. Commander

Probes are intelligent. They contain a pre-assigned identification

number and are pre-programmed to activate LED # 1 until

reassigned b y an operator. Once programmed for LED and

operations, the programming is maintained within the probe and

will not be lost if the probe is unplugged or transferred to another

Commander.

Records of warning and alarm sensor events are recorded in logs. In addition Commander can be

programmed to poll itself at regular intervals and record its results in a Poll log. Reviewing this

log can help in tracking trends that, while not triggering warning or alarm events might lead to

conditions that significantly affect the life span of mission critical component such as hard drives.

In addition, warnings and alarms triggers as well as logs themselves can be programmed as

emails for alerts and for maintaining logs at remote locations. Commander also provides two

serial communication ports, one for RS 232 and one for RS 485. These ports can be used for data

exchange between Commander and any data storage or data generating source.

Communication time outs and restarts are

operated in the communication menu. The Time

out settings defines the time duration that if no

traffic is sensed, the port will be shut down. The

port can only be accessed by one client at a time.

If the time is set to 0, no time out will occur and the potential remains for the port to be blocked

from additional clients. Master and Security Admin security levels can set and save time out

settings. All security levels with “Security View” access can manually restart communication

ports by point and click on the selected port .

Commander conditions and operations can be viewed via an

easy to operate User Interface. As Commander is its own

server, no external client software is required. As interfacing

to Commander doesn’t require an Active X component, it

can be viewed and operated with most common web

browsers. The Status view screen displays a series o f colors

matching those on the

front panel.

8

Page 9

Commander PoE Front Panel

Power: There are two power indicators, one for power supply and one for power status.

The Power LED illuminates green when power is applied.

The Alarm LED is green for normal operation and will turn red for alarm conditions on any of the

internal temperature monitors or power supply voltage monitors.

Solid Green = Norm al Operation

Solid Red = Alarm Condition Present

Flashing Green= Unit booting up

Ports 1 through 8: Port 9 & 10:

10/100baseTx Ethernet Ports: 1000baseT Ethernet Ports:

Link – Off – No connection Link – Off – No connection

Amber - 10 Mb/s Amber - 10 or 100 Mb/s

Green - 100 Mb/s Green - 1000 Mb/s

Act - Off – No data activity Act - Off – No data activity

Amber Flashing – Data activity

Amber Flashing – Data activity

Alarm In 1, 2: The default alarm condition is a closed contact. If the NC check box is active for

an alarm input, then the alarm condition will be an open contact. Alarm contact LED’s are per

“current status”.

Normal condition - Off

Alarm condition - Red

Auxiliary Out 1,2: Auxiliary contact LED’s are per “current status”.

Normal condition - LED is off

Relay Activated - LED will be red

PoE Status

Each port has an associated indicator for PoE status

PoE Off - Led is off PoE On and Normal – Led is green

PoE Searching – Led is amber PoE fault – Led is red

9

Page 10

Data Ports A (RS232) & B (RS485) LEDs:

There is one Bicolor LED per port. (Port A = RS232, Port B = RS485). When the Tx of the port

is active the LED will turn on Red for 0.25 seconds. When the Rx of the port is active the LED

will turn on Green for 0.25 seconds.

Rx: = Data from TCP to Serial

Tx: = Data from Serial to TCP

Probe Status & Alarm LED’s:

Commander operates by sensing the number and location of probes upon power up. Those ports

with sensor probes connected will be indicated on the front panel. Commander has one direct

USB port but can sense up to 4 probes using a USB hub. The Alarm Sensor will reflect the

condition of any of the probes.

If Commander is powered on and a new probe is plugged in, Commander will sense the new

probe and acknowledge its existence. Probes can be installed or removed without having to power

down Commander. When installing or removing probes, perform a browser refresh.

Front panel Sensor Probe S tatus LED States:

No connection, probe is not present - LED is Off

Probe is connected and communicating - LED is Green

Upon connecting a probe for the first time the Probe Status LED will flash Green to Amber four

times.

Front Panel Sensor Probe Alarm LED indications:

No connection, probe is not present - Off

Probe is connected, no alarm has occurred - Green

Probe is connected, warning state activated - Amber

Probe is connected, alarm state activated - Red

The Probe Alarm LED will indicate the active condition for the duration the alarm or warning. In

the event multiple warning and/or alarm conditions are received by the same probe the LED will

alternate between Orange and Red. At the time when the multiple warning and/or alarm

conditions end, the LED will reflect the color of the warning or alarm mode, if any, that is still

active.

Sensor Probe LED:

Front panel Sensor Probe S tatus LED indicates:

No connection - Off

Probe is connected and ready - Green

Probe is connected and communicating - Am ber

Probe is connected but not communicating - Blinking Red

Upon connecting a probe for the first time the Probe LED will

flash Green to Amber 4 times

If the probe is blinking continuously, it indicates that probe could have a problem.

10

Page 11

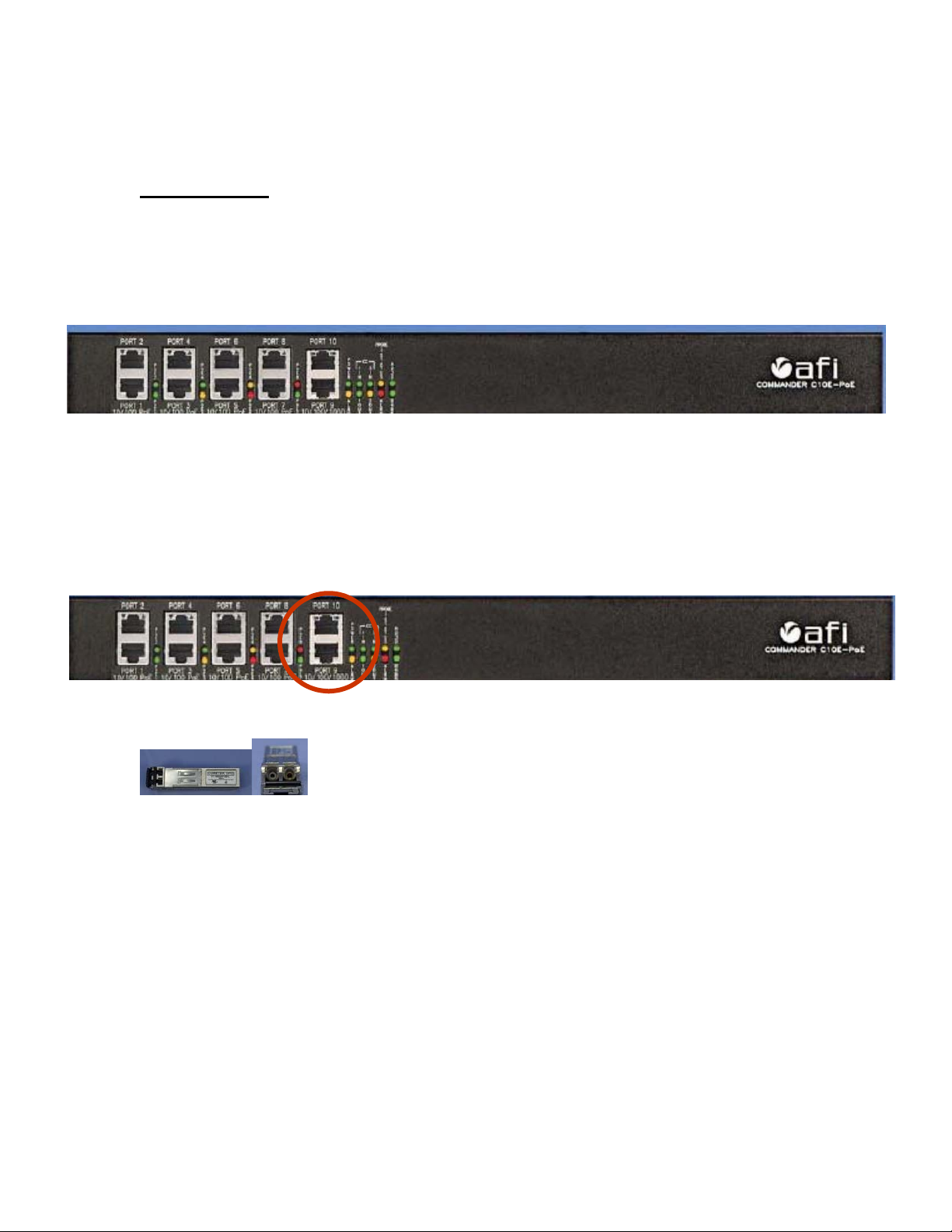

Commander PoE Rear Panel

1 2 3 4 5 6

1. Power connection: 100-240 VAC @ 50 to 60 Hz.

2. Alarm Inputs 1, 2: A potential free contact closure can be used as an alarm input. These

may be programmed as Normally Open or Normally Closed.

3. Auxiliary Outputs 1, 2: This port is triggered by the alarm inputs, sensor warning and

alar

ms as

programmed by the operator. Active durations are also programmable. In

addition Auxiliaries can be manually turned on or off via the web browser interface.

4. Sensor Probe Input: Sensor probes connect directly to the USB ports using a mini to

standard USB cable. Once connected Commander will automatically read the

identification data from the probe and enter it in its data base. Commander can accept up

to 4 sensor probes using a standard USB Hub. It is recommended the hub be self powered

Each USB cable requires a Ferrite RFI reducer is required to meet FCC

compliance standards.

5. Serial Data Port A RS232: A standard DB 9 connector is use for RS 232 bidirectional

communication and can be use to read d ata fro m or transmit data to external devices such

as access control panels and cash registers.

6. Serial Data Port B RS485: The RJ 11 connection is use for bidirectional RS485

communications and can be used to read data from or transmit data to external devices

such as access control panels and cash registers and can be used to control devices such

as PTZ domes

Notes on RS 232 and RS 485:

Both ports are compliant to RFC 2217. In order for a Windows program to recognize these ports,

an RFC2217 compliant driver must b e installed on the computer. A Hardware Serial Port

shareware program is included on the CD supplied with the unit.

AFI Pilot software programs contain RS 232 and RS 485 port

communications as standard features when a Commander is installed

as a device.

Rear panel LEDs mirror the functions of front panel LEDs

11

Page 12

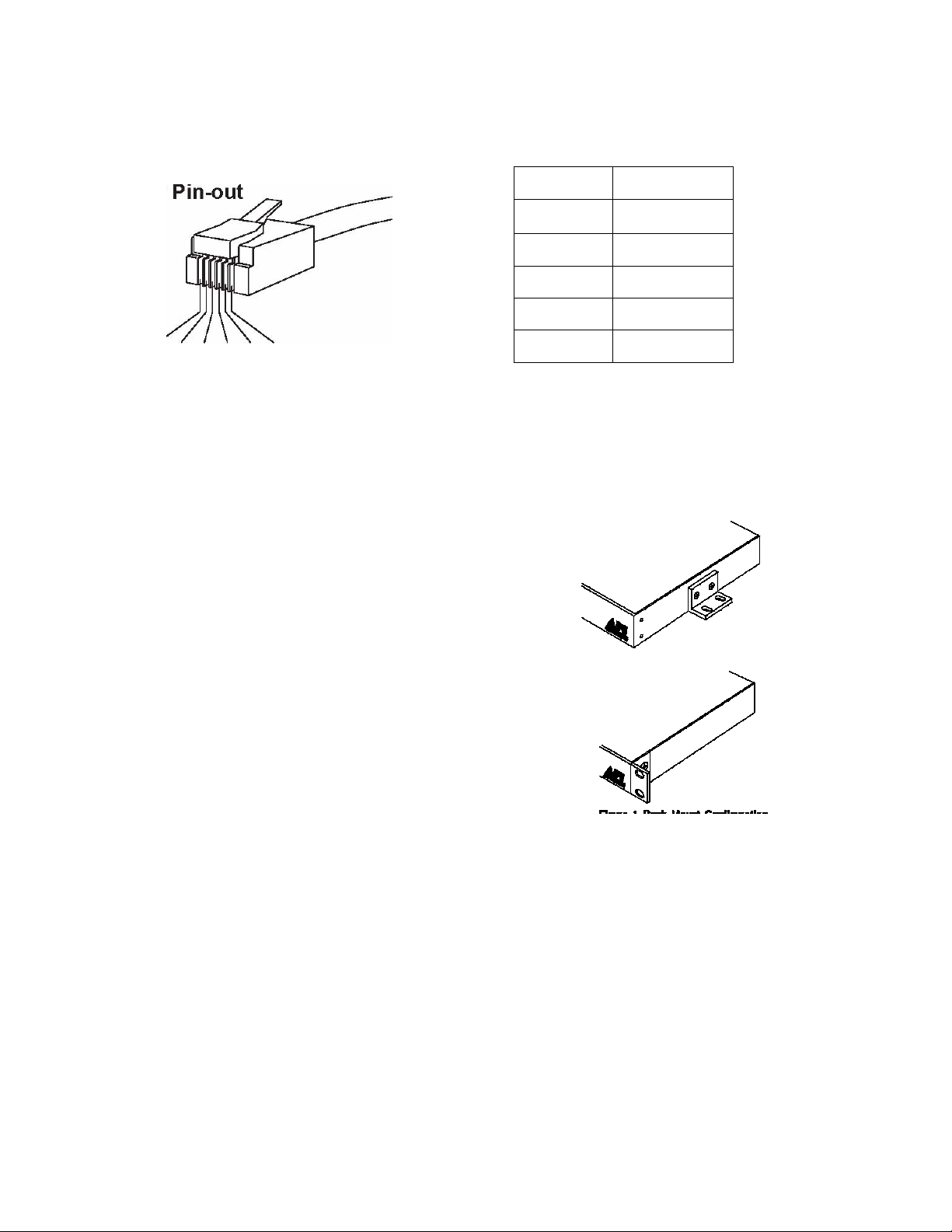

RS485 Connector

The RS232 connections is a standard DB9 DTE configuration

1 - 6

1

Common

2

IN -

3

IN +

4

OUT +

5

OUT -

6

Common

Installation

Mounting

To install the Commander it is first necessary to mount

the rack flanges to the unit. Two mounting flanges are

supplied with each Commander. For flush mounting,

install the ears with the #10 flathead screws provided

There are two rack mounting options. A single

Commander can be installed in a rack using the half

rack mounting kit C10-HRM. Two Commanders may

be rack mounted side by side with a C10-FRM kit.

For rack mounting the ears are installed on the sides of

the unit with the surfaces that have oval holes flush

with the front of the unit as in Figure 1. Mount the ears

with the #10 flathead screws provided. To mount in

the rack cabinet, use mounting screws that are

appropriate for the rack cabinet being used.

Power Source

The internal power supply accepts universal line voltage. Any mains supply from (85 to 264

VAC), (47 to 63 Hz) may be used without modification or adjustment. A universal

connector

is provided on the rear of the unit to facilitate connection to the power mains.

Power Connection

The unit is supplied (in the US and UK only) with a three conductor power cord. The “ground”

conductor is directly connected to the chassis.

power

12

Page 13

Probe Placement

Temperature and Humidity Reading: (P-TA and P-TAH)

Place the probe between 1-3 inches from the device so that heat will flow directly towards the

sensor. Probes can be directly mounted to a chassis using double sided tape or Velcro.

For Airflow Read

ing:

Place the probe between 1-3 inches from the device so airflow will flow perpendicular to each

sensor tip.

For Rack Mounting:

AFI provides an optional rack mount kit P-RM. Sensor probes plug directly into a goose head

mount providing actual positioning. The P-RM mounts directly to most racks taking up a 1RU

space.

Connecting Environmental Sensing Probes:

Sensor probes are connected to Commander using a standard USB to mini USB cable. When

using the R-RM the Commander probe is directly connected to the mount. The cable is connected

to the rear of the mounting arm. In both cases the maximum distance is 25 feet or 7.6 meters.

In order to comply with FCC radiation requirements, the ferrite clamp

provided with the USB cable must be positioned approximately 2 inches

from the side connected directly to Commander.

Probes can be inserted and removed while Commander is powered on. If an email address has

been programmed in the Global Settings an email alert will be sent.

13

Page 14

Commander’s status can be viewed via LED’s located on Commander’s front panel or via a

Graphic User Interface provided as part of Commander’s web services. As some operators may

also want to view current Sensor probe status and no t just exceptions, a Sensor Status mode is

provided. Using this mode the front panel probe LED’s will indicate status in the same method as

the probe itself. Actual response will be dependent on your network speed.

Alarm Alerts: Watch Dog Timer Operation

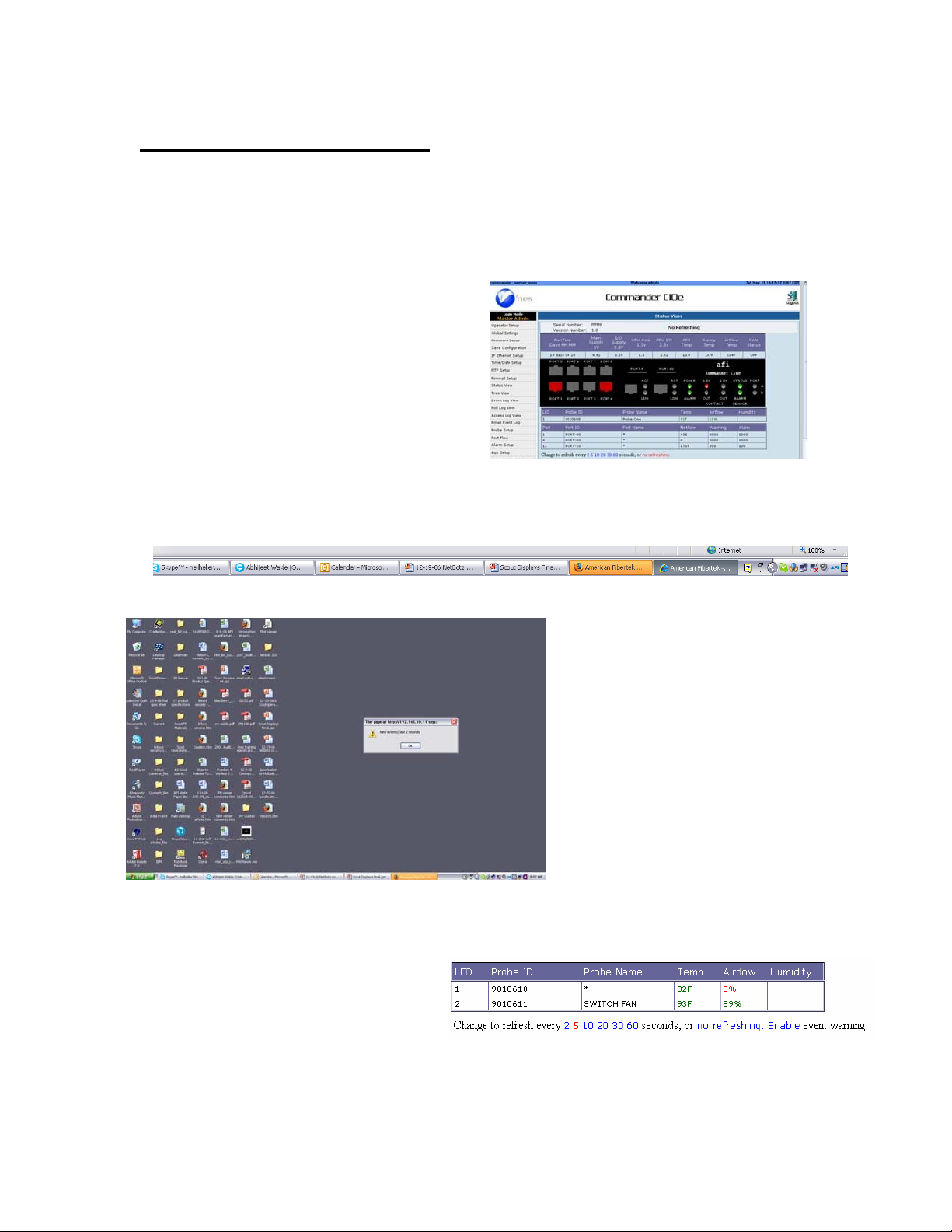

Watch Dog Timer:

Commander contains a watch dog timer that will monitor the internal system. In the event

Commander cannot properly operate for more than two minutes, the system will wait until the

condition no longer exists and reboot itself.

Once Commander reboots, all data will have been lost. Many reboot conditions occur due to poor

main power supplies or fluctuations in main line voltage. As with any other computer device, AFI

strongly recommends the use of back up power supply.

Watch Dog Timer Responses:

If the action is due to poor power or power fl uctuations, the Port “B” LED will turn Red

An Email alert “Watch Dog” activated will sent to the address programmed in the Global Settings

when power is returned to Commander. The time will indicate when power was returned.

The first entry in the event log will show as Watchdog with time and date when

conditions

were restored

14

norm

al

Page 15

Web Browsers

Commander does not require an Active X component be loaded on the client computer. As such

Commander is compatible with most web browsers. However, since programming within Web

browsers is not under the control of American Fibertek, the company cannot be held responsible

for the performance of Commander under any given browser.

In addition Graphic User Interface screens and their operation may change from browser to

browser. Their appearance or specific operation may not match the appearance included in this

operation manual.

Commander has been tested with several web browsers; however American Fibertek cannot

account for or be held responsible for changes to web browsers that might affect Commander’s

operation. Internet Explorer and Firefox are the two primary browsers used in the development of

Commander. In some cases even their performance will differ.

In Firefox operation when Commander’s Web page is minimized, the toolbar will change color

on an alert provided Firefox Version 2.0 is used as the browser. Explorer will not perform this

function.

Warning: In order to view a color change to the tool bar (Firefox 2.0 only) and pop up,

Commander must be minimized in the Status View condition, refresh mode and Event Warning

If

enabled.

any of these conditions are not met, no warning will be possible.

15

Page 16

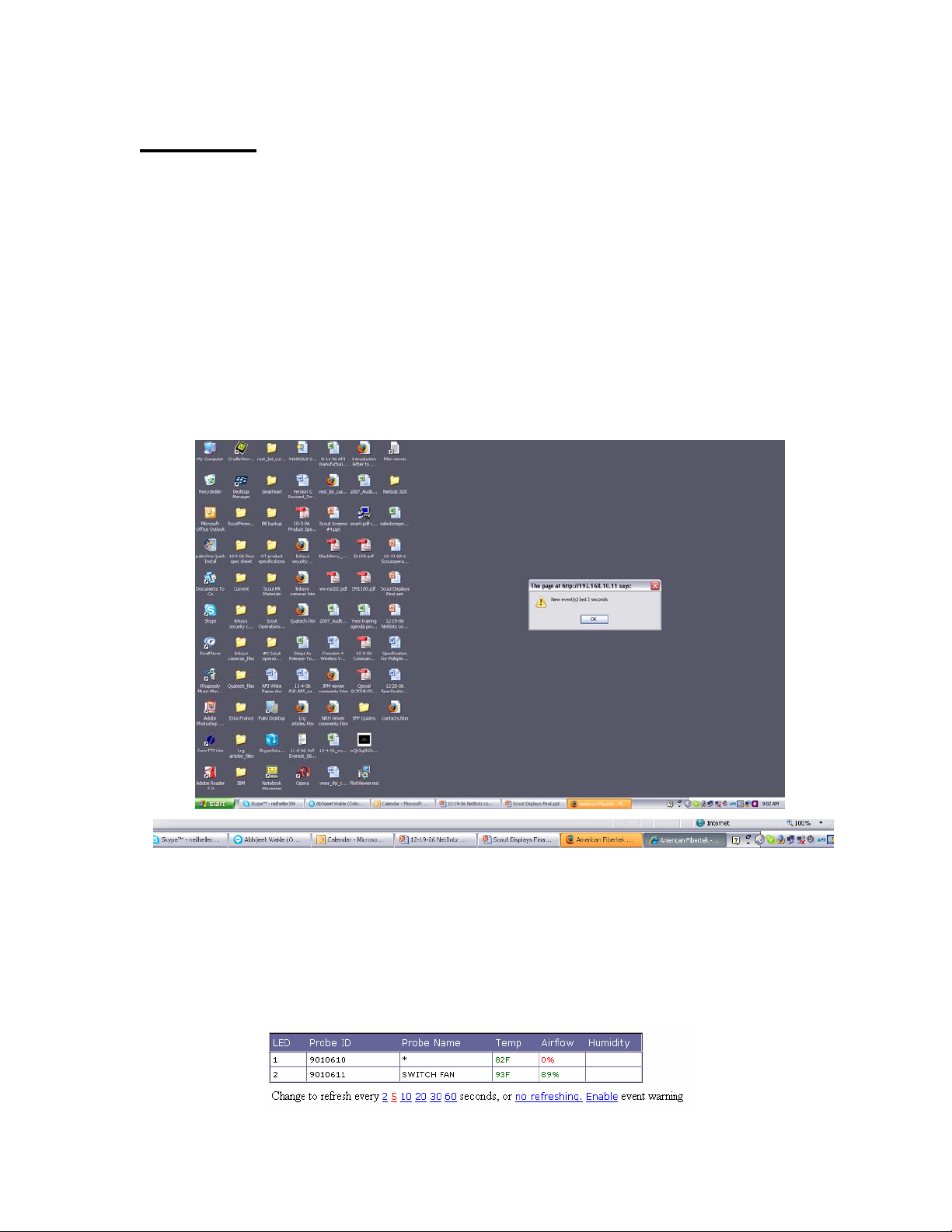

Screen Refresh and Event Warnings

Commander contains a built in web server. No additional software is required to

individual

Commanders. There are two ways to monitor Commander activity.

monitor

Method one is to view a complete .html web page. This allows an operator with the appropriate

permission levels to view different pages and set ups.

All statuses can be monitored by viewing

Commander’s “Status View” page. Up to 10

Clients can individually monitor an individual

Commander. Clients can have an individual

View and perform individual operations.

Method two allows the operator to minimize the html page. In this position Commander will be

represented in the tool bar. When warnings or alarms are present the tool bar will turn orange if

the browser is Firefox

Method two provides a pop up

box which indicates an event has

occurred and the number of events

over a recent period. The operator

can expand the screen to a full

page to view the alarm in more

specific details.

Warning and alert pop ups can be enabled or disabled from the Status View Screen.

Warning: In order to view a color change to the tool bar (Firefox 3.x only) and pop up, the

Commander browser window must be minimized in the Status View condition and must be in the

refresh mode. If either of these conditions are not met, warning pop ups will not be possible

16

Page 17

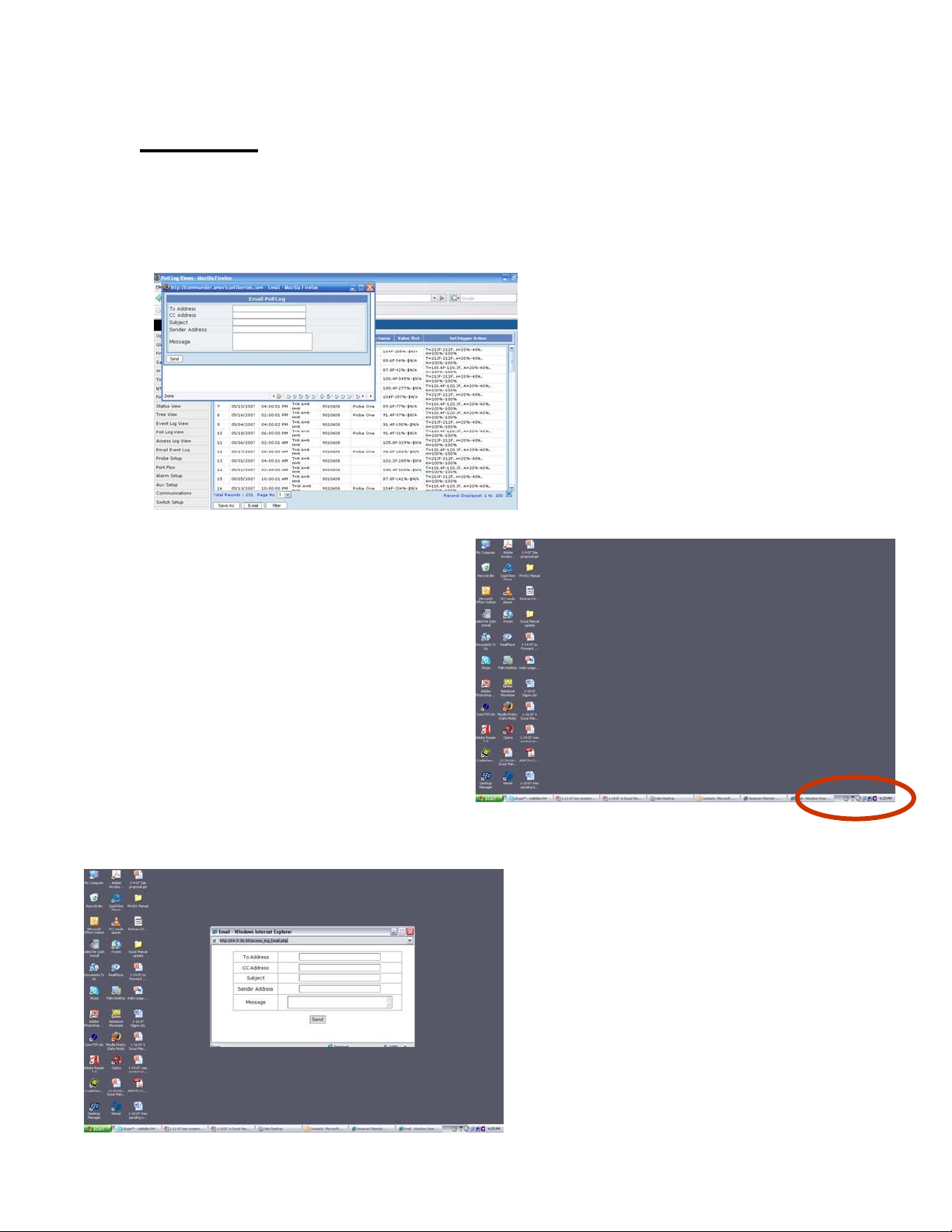

Event Pop Ups

Many of the functions in Commander operates by means of pop ups. Activating a function in

Commander only requires a single mouse click. If more than one mouse click is used or

additional browser functions are opened the potential exists for the pop ups not to appear the in

screen foreground.

Under normal operations the

pop up will appear in the screen

foreground over the main view.

In all cases the pop up will appear in the

tool bar.

If this occurs click the tool bar

to expose the pop up

17

Page 18

Reset to Factory Defaults

If the Master Admin password is changed and lost for any reason, the only recovery method is to

reset Commander back to its defaults. For this reason the following precautions should be taken:

1. Keep a record of all user names an d passwords. IT and Secu rity user names and

passwords are maintained by and can be accessed by the Master Admin. However the

Master Admin user and password is not.

2. Follow the procedures to download and save programmed settings. If a Co mmander reset

is required all programming will b e returned to its default settings. By saving

programming a Master Admin can perform a Restore, returning Commander to its

programmed functions.

3. Save all existing logs by performing either a Save As to a client computer or by emailing

logs. Please note: once a unit is reset to defau lts or powered down all log information is

erased.

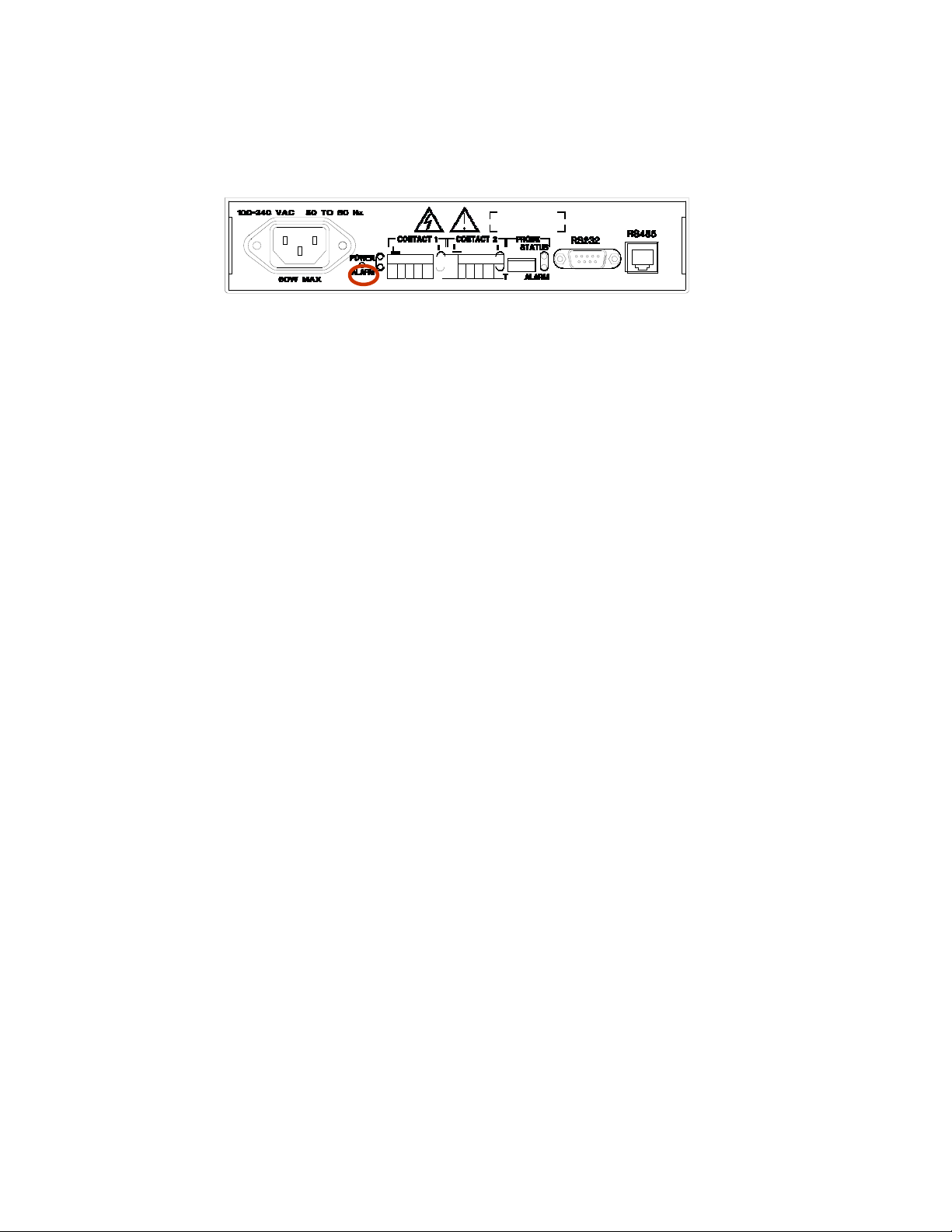

To Reset Commander: Locate the recessed button on the rear panel.

(As a precaution the procedure must be performed during power u p)

!

Power on Commander and wait approximately one minute.

The Port A LED will change to Amber, meaning program is waiting for instruction

Press the reset button for 10 seconds, the Port B LED will turn amber.

Keep pressing the reset button for 2 full seconds longer.

When both Port A and B turn off at the same time the system has reset to its defaults.

This procedure must be followed exactly. If the procedure is not followed as stated, the Port A

LED will turn off after 10 seconds and will not allow any more attempts to reset. To override this

condition Commander must be powered off and on.

Factory Default Settings:

Global Admin Login (Case Sensitive):

User: Admin

Password: Password

IP Address: 192.168.0.246 (Before firmware 20110504: 192.168.10.11)

Net Mask: 255.255.255.0

Gateway: 192.168.0.143 (Before firmware 20110504: 192.168.10.1)

18

Page 19

Resetting Comm ander’s using the RS 232 Port

In some cases it maybe necessary to reset Commander using the RS 232 Port in order to recover

from incorrect IP settings.

!

To reset the RS232 Port:

Connect to the RS232 port with a Null Modem cable.

Set the computer’s terminal program to 115200/8/N/1.

Push the reset button for 4 seconds.

The Port B Led will go Orange when the button is pressed and then Red after the 4 seconds.

The following login will appear:

> AFI Commander Linux

>

> Commander login: root

> Password: (not required)

> Enter the recovery user name

The unit will list the current system time and IP Address with a menu:

>

> Wed Nov 15 15:34:02 EST 2006

> 192.168.10.11 (192.168.0.246)

> >

The settings are as follows:

>

0) Dump current setting

1) Disable Firewall, allow all IPs

2) Set IP to 192.168.10.11 (192.168.0.246)

9) Exit

Select:

Selecting 0 will dump the current status of the Commander device for advanced troubleshooting.

Selecting 1 will disable the firewall until it is set via the web interface.

Selecting 2 will set the IP Address back to the default settings without resetting any other

parameters.

Selecting 9 will set the serial port settings back to default.

19

Page 20

Recovering IP Address when DHCP Is Used

Commander has the ability to be programmed with a fixed IP address and operate in systems

using DHCP. In the latter case Commander’s IP address will change according to the IP address

assigned to it

by

that system’s DHCP server. In order to inform the operator of any such change

in its IP address, Commander will send the new IP to the email address programmed in the Global

Settings.

Please note: The programming of Global Settings is restricted to the Master Admin.

DHCP notification: Commander provides programmable email notification of any IP address

changes. Also, ARP packet with IP and MAC address sent once every minute, may be detected

by using standard freeware such as Wireshark or TCPDUMP. Both methods keep you up to date

on Commanders using DHCP without the need to remove from system or complex external

connections.

20

Page 21

LED Startup Sequence

On power up, Commander will go through a boot process. The front panel LED’s will display

different colors and states as Commander goes through these steps. The following is the normal

sequencing

1) Power LED green: power is applied.

2) The Status LED will alternate between Amber and Green as several boot process occur and

will remain Green when completed:

3) Serial Port A

4) Serial Port B

of these

Kernel is loaded and initialized

Reading real-time clock time

Initializing ramdisk and mounting flash file systems,

Loading the CPU lm85 drivers, and MAC address,

Amber: Ready for reset to factor default.

LED will remain on for 30 seconds to permit reset function.

Off normally. Amber if reset button pressed,

If reset button is pressed longer than two seconds, both Serial Port A and Serial Port B

LED’s will turn off and the system will reset to factor default values.

LED’s after power is applied:

5) The Status LED will alternate between Amber and Green as the boot process continues:

Set up variables including untar web pages, zone files

Setup IP network:

6) The Sensor Status LED will then indicate the final boot steps and will remain off when

complete:

Starting send mail, SSHD, and read probe data.

Mounting NFS if applicable,

Creating new database files and starting database server,

Starting web, ftp, and SNMP servers,

21

Page 22

UTC Time

Time zones, "UT" and "GMT" are indications of "Universal Time" and "Greenwich Mean Time"

respectively and are both semantically identical to "+0000". As Commander can exist on a

network anywhere in the world, it is important to know its time zone location. Please note that

logged dates and times reflect the date and time at the actual location of the Commander and not

at the viewing client.

Sending Email Notices and Files:

At various places in the Commander set up you will be able to input emails addresses for sending

out warnings, alarms, log files, and notices of changes in IP addresses when DHCP is applied.

The

success in

sending out emails is dependent upon your em ail server settings.

If an email is being sent from Commander to an address on the Internet, there are two important

considerations. First your internal network must have a router or gateway to the internet. Second

the

SMTP

server needs to allow the Commander to relay mail or rout the mail to a local user. The

most reliable way is to set up an email account for the Commander.

It is suggested that during the installation of Commander you run a test of all required email

addresses to determine if any problems exist. Ultimately, the solution to these problems will rely

on the programming of your mail server.

Commander has been tested for sending emails to various internet email hosts, however these

providers can change their set ups at any time leading to changes in performance. American

Fibertek does not take responsibility for these changes.

22

Page 23

System

Access

System Access Levels

Commander has three main access levels and seven total login levels. The main access levels are

Master Administrator, IT Administrator, and Security Administrator. The Master Admin can

create

passwords for all IT levels and the Security Admin can create user names and passwords for all

Security levels.

In addition, menus that c onfigure overall operation can only be accessed and set up by the Master

Admin. The separation of IT and Security Administrators allows operations for each to be

isolated

communications without changing or having access to functions affecting security operations and

security directors can make changes to settings affecting security operations without affecting

network communications and operations.

Additional user names and password assignments can be made by the IT Admin which will allow

security users to view, but not change, IT settings. The Security Admin can likewise assign user

names and passwords to IT personnel that will allow them to view, but not change, security

settings.

user names

from

e

ach

and passwords for all levels. The IT Admin can create user names and

other so that an IT administrator can make changes affecting network

23

Page 24

Master Admin Menu

Commander has several modes for operation and set up. All of these can

be found in the operating menu bar which appears on all screens. The

menus available are defined by the access level assig ned to an individual

user. Operator Set Up is restricted to the assigned level access

Each sign in screen contains a “Welcome” message which details the

permissions grated to that access level.

24

Page 25

IT Access Levels

25

Page 26

Security Access Levels

26

Page 27

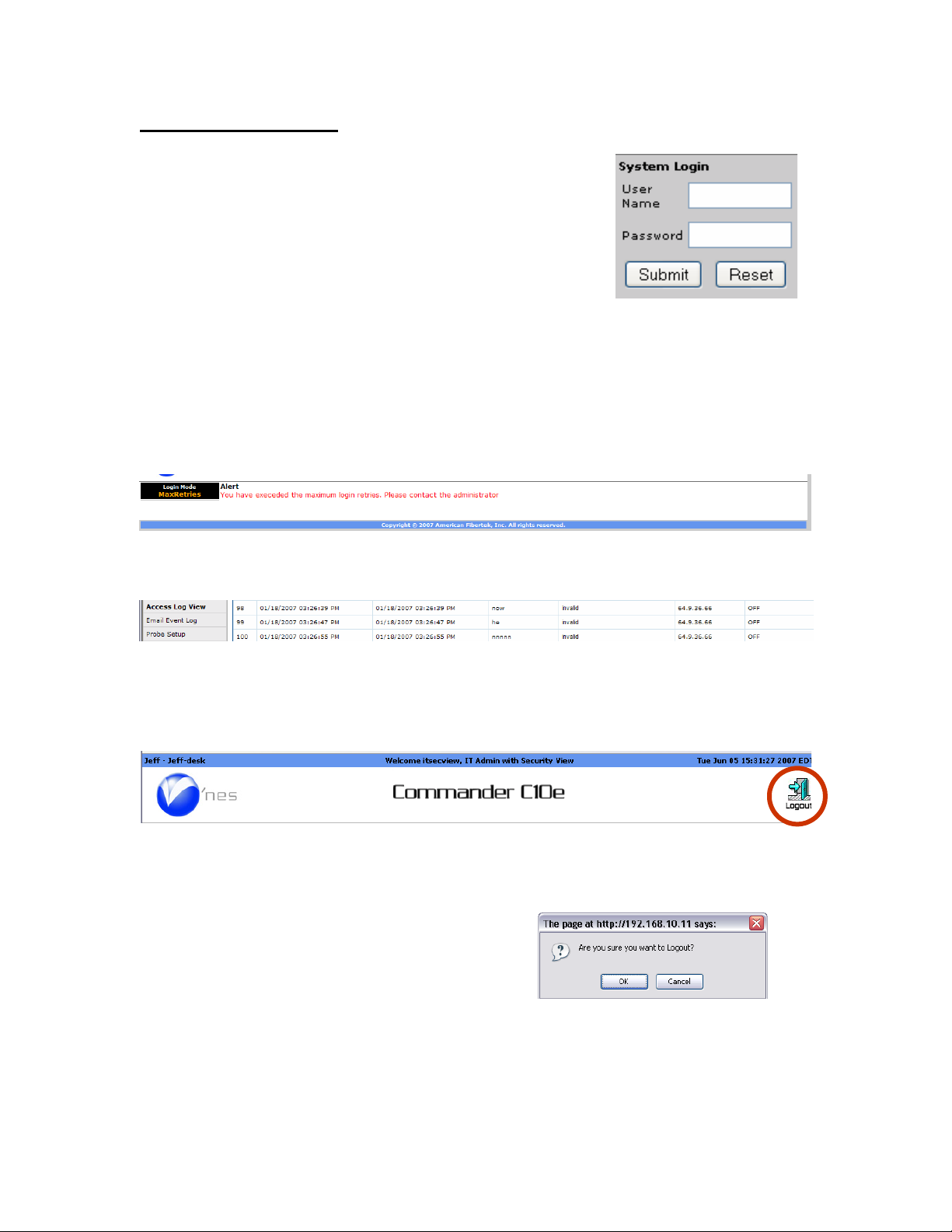

Logging In/ Logging Out

Using a web browser enter the Commander’s IP address (default IP

address in the case of first login) as the URL and the log in screen

will appear. If the location has been previously titled, that name

will

appear.

your

access

name and

Entering the User Name and Password will define

level to the Commander. After entering your user

password,

press Submit. If a mistake is made, press

Reset and reenter the user name and password.

The Master Admin default username is “Admin”. The Master Admin default password is

“Password”. The Master Adm in password should be changed on first login.

Log In Exceeded:

Commander allows three attempts to enter the correct User Name and Password. If on the fourth

attempt the correct name and password are not entered the user will be blocked. Retries can be

attempted after a

5

minute time out period.

When the number of allowable retires is exceeded, the invalid log attem pts will be recorded in the

acce

ss log

showing the date, time and IP address source

Logging Out:

The icon in the upper right hand corner of the screen is used to log out of Commander. Point and

click on the icon to log off. The icon will appear in all operation and programming screens

allowing the log out function at any time.

Auto Logging Out:

If no activity has occurred in twenty (20) minutes, Commander will automatically log out as a

security precaution. To avoid this, after programming is complete, leave Commander operating in

Status View mode with a programmed refresh rate.

As a result of pressing the Log Out icon a pop

up will appear asking if you are sure. Press OK

to log out. Press Cancel to return to the previous

screen.

27

Page 28

Programming

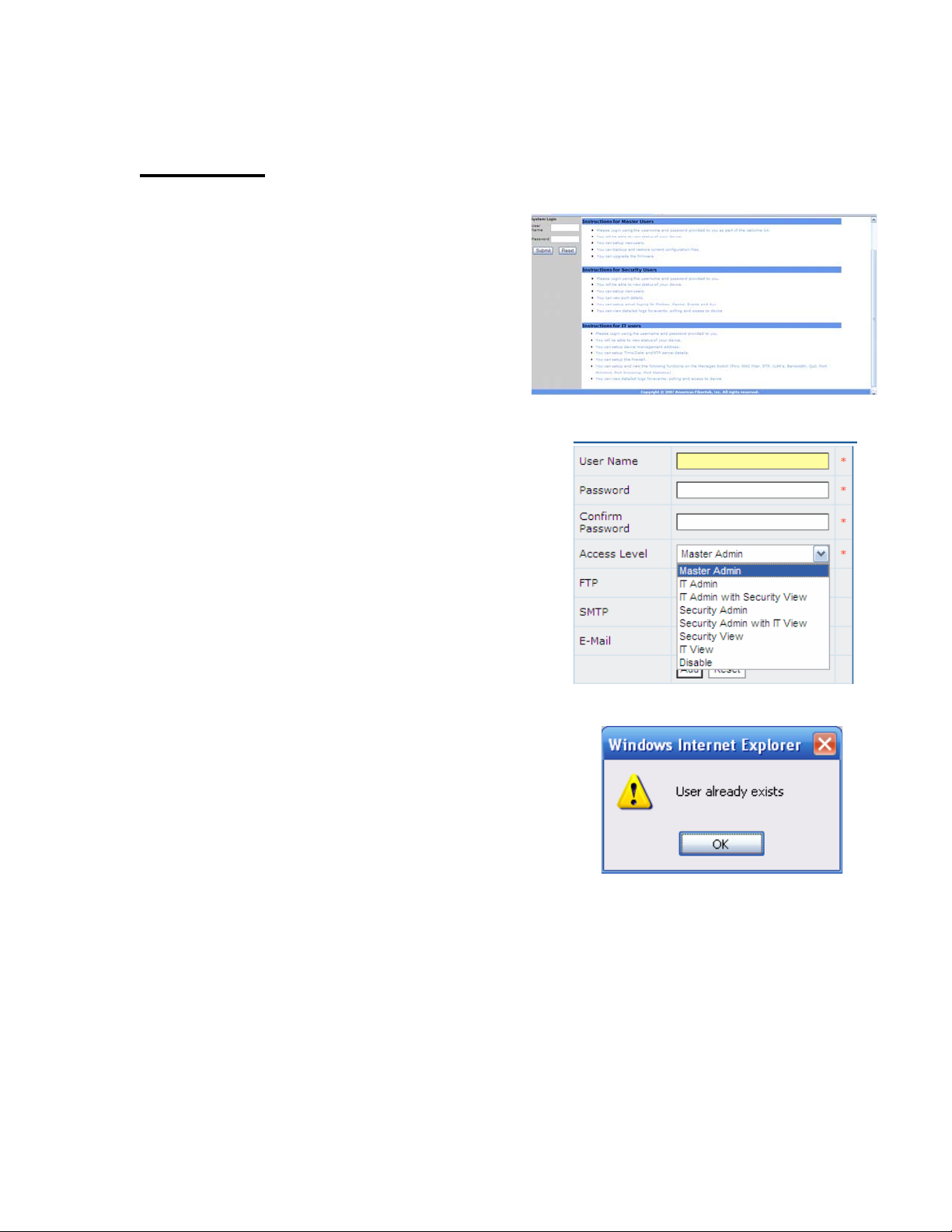

Operator Setup

When first accessing Commander by entering

the correct IP Address, Commander will display

opening screen for entering User Name and

Password. This screen also display the general

permissions for Master Users (Admin), Security

Users and IT Users. Signing in as Master Admin

will display the Master Admin Welcome screen

outlining the general permission levels.

The Master Admin can assign operator user

names and password for all security levels.

Access to operations is determined by the sign in

security level. Only those levels available to the

specific security level will appear in the mode

select.

If a user name and password has previously been

assigned a pop will indicate the “User already

exists”. Click OK and start the process over.

28

Page 29

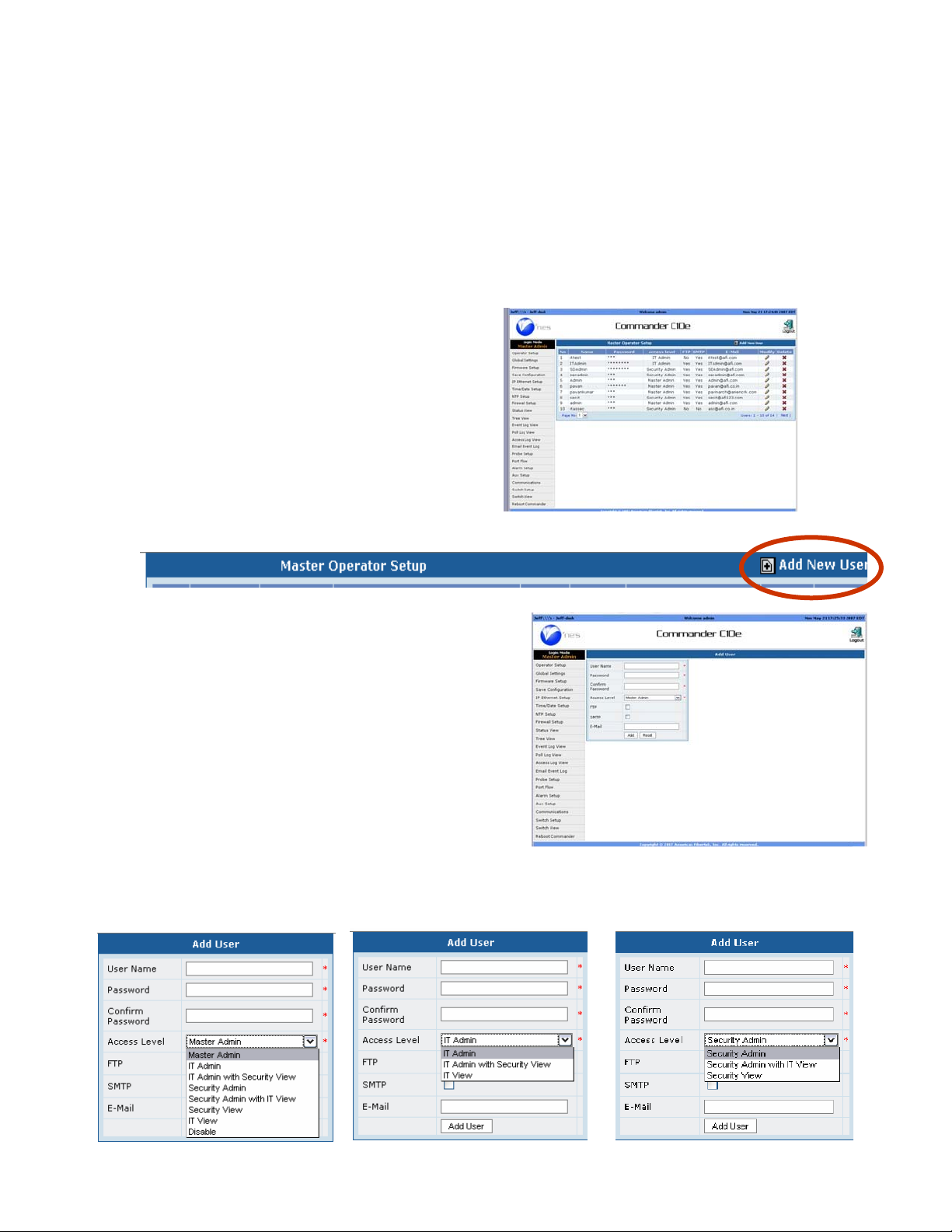

Adding an Operator

Commander allows each of the three Administrators, and seven total security levels. The main

security levels are: Master, IT and Security to assign up to 10 User Names and Passwords for

each category. Assignments can only be made at the authorized level and below. An IT Admin

cannot

and Passwords for any access level.

When entering the Operator Setup mode a

complete list of all User Names and Passwords

allowable at that level will be displayed.

To add a user, point and click on the “Add User” icon

The add user screen will appear. Enter a User

Name, Password, reconfirm the Password

make assignments

in the Master and Security categories. A Master Admin can assign User

User Name is limited to 10 Characters.

Password is limited to 8 Characters .

User and Password assignments will be determined by the Login User Name and Password.

Master Admin IT Admin Security Admin

29

Page 30

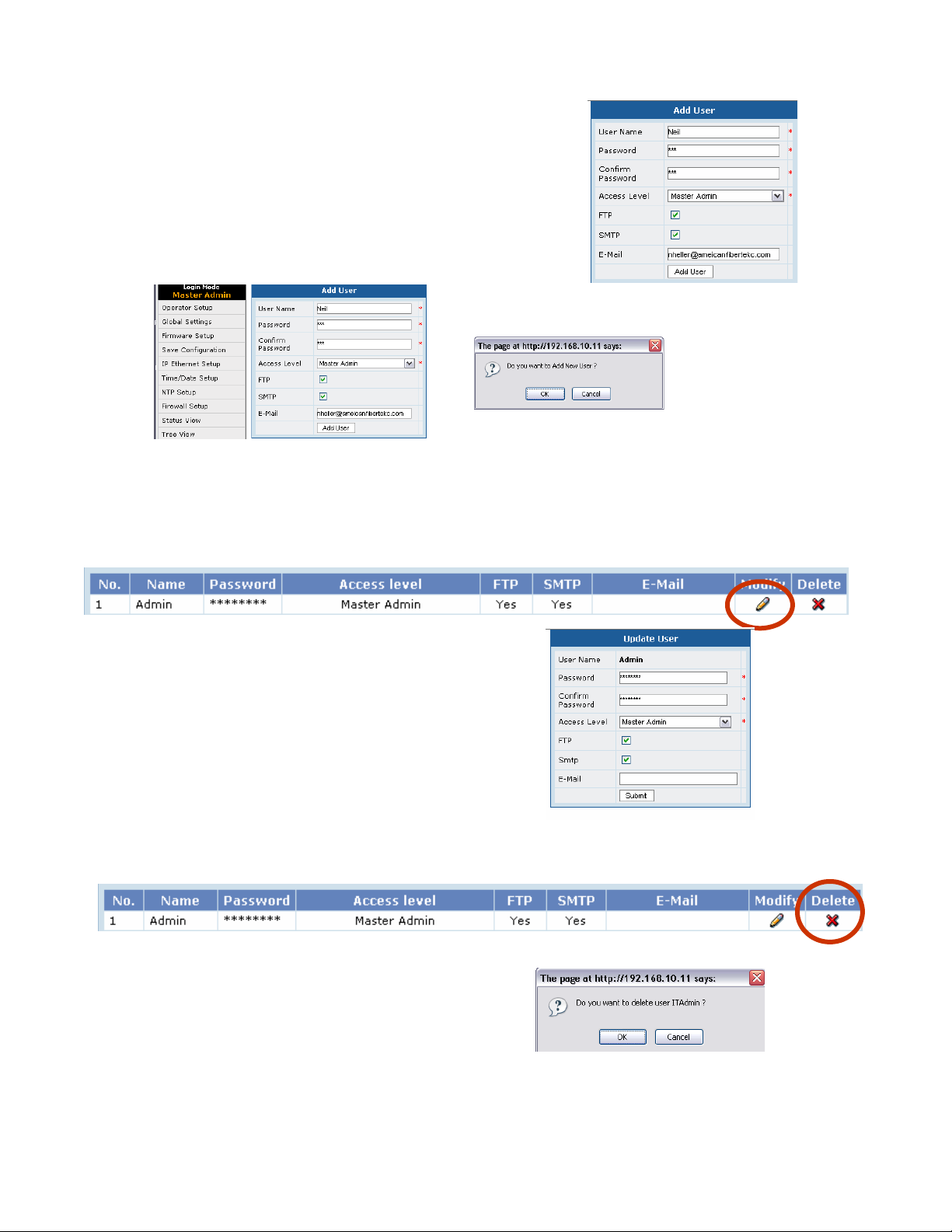

Next Check the FTP and/or SMTP providing

that user permission to FTP and/or Email. Fill in

the

Em

ail address. This will be the specific

email address for that operator. All functions

with email capacity will send their emails to that

address. FTP user name and Password is the

same as the user name and password.

Click the Add User icon and a pop up box will appear asking to confirm your decision. Clicking

OK will complete the process of adding the operator. Clicking Cancel will return to the previous

screen

Operator Set Up-Modifying an Operator

Click on the Modify icon to display the “Update

User” screen. Make any changes as required and

click on the “Submit” button. If the modification

is accepted, the screen will go to the operator set

up.

Operator Set Up-Deleting an Operator

In the Operator Setup click on the “Delete” icon associated with the operator you wish to delete.

A pop box will appear asking you to confirm

your decision. Click OK to delete the operator.

Click on the Cancel button to return to the

previous screen.

30

Page 31

Global Settings

Internal Values and Warnings

Commander monitors its own internal temperature and voltage values. Operating at too high or

too low of these values can r esult in decreasing Commander’ s performance or turning

Commander off. Extreme operating conditions could further result in damaging Commander.

The best precaution against environmental damage to Commander is to properly install and

operate the unit. When mounted in a rack at least 1RU spacing should be provided on both

Commander’s top and bottom. Installations with unstable or questionable power sources should

use back up generators. In all cases the use of filtered power supplies is strongly recommended.

Commander PoE contains two internal fans which are designed to activate at temperatures higher

than

those

that can result in damage to Commander. The use of temperature controlled activation

also contributes to extending fan life as it doesn’t have to operator under proper temperature

conditions.

When these warning levels are reached, Commander will issue email alerts to the address

programmed in Global Settings.

Commander will trigger an internal alarm when any of the following conditions exist:

CPU I/O voltage is less than 2.25 volts or greater than 2.75 volts.

CPU core voltage is less than 1.17 volts or greater than 1.43 volts.

CPU

voltage supply

Main Voltage Supply is less than 4.5 volts or greater than 5.5 volts.

Power Supply tem perature (temp1) is less than -25C or greater than +59C.

Airflow temperature (temp2) is less than -27C or greater than +54C.

CPU temperature (temp3) is less than -16C or greater than +60C.

The internal fan will be turn on when any of the internal temperatures exceed preset limits:

temp1 > 55C or temp2 > 55C or temp3 > 65C

An internal alarm will be issued when any of the internal temperatures exceed preset limits:

temp1 > 60C or temp2 > 60C or temp3 > 70C

These settings are not user adjustable.

is less than 2.97 volts or greater than 3.63 volts.

31

Page 32

Name and Location

Fill in the name and location of your Commander. These names will appear in all logs, emails and

records.

Global Settings: Temperature

Use the drop down menu to select Fahrenheit or

Celsius temperature scale.

Warning-Alarm Delay

Commander probes sample environmental

conditions once every 10 seconds and verify

conditions after 3 samples or 30 seconds.

This

delay is programmable and determines the

duration a condition must be valid prior to

taking any action

Alarm Alerts: To sense an alarm or warning condition a probe is polled three times to avoid any

potential for false alarms. As each poll is 10 seconds the total time to confirm if a condition is

valid is

30 seconds.

To further avoid false alarms the Master Admin can program a WarningAlarm delay which will require the condition be valid for the total programmed time prior to

taking any action.

Global Settings: Sensor Status

This setting is used to display sensor sta tus when

communication occurs between the sensors and

Commander. It is a notification only and its

operation will not affect warning or alarm

reporting. Use the drop menu to select On or

OFF.

Email Address

This email address will receive the following

information:

1. IP address that occur when Commander is operated in the DHCP mode. When the client

receives a notification IP Address has changed, this new IP Address must be entered in the

client web browser.

2. When an existing Sensor has been unplugged or a new Sensor inserted when Commander is

ON.

3. When Commander senses an internal voltage or temperature warning or alarm condition.

You can enter more than one Email address. Multiple email addresses are separated by a space.

32

Page 33

Modify

When the Global Settings changes are

completed, click the Modify button. A pop up

will appear asking you to confirm your choice.

OK will enter the settings. Cancel will return the

screen to the previous mode.

Global Settings: Modify Complete

When Commander has completed the

modification it will issue a Pop Up. Click OK to

complete the process

33

Page 34

Firmware Upgrade

Master Admin Firmware Setup

Clicking on the Mode for Firmware Setup will

display the Firmware Setup screen which allows

new firmware to be loaded updating

Commander. The screen will also show a history

of the most recent updates

Firmware Update Browser Button

Clicking on the Browser button will open up the

Browser located on the client computer. The file

to be

uploaded must be located on the client

computer.

Select the file using the same methods as any

Windows ™ program. The valid file will have a

xxxx.tar.gz. Processing of the file is done by

Commander.

After the file is selected press the Upload button

to start the process.

Wrong File Section

If the file selected is not a .tar file the upload

process will not proceed and the following

display will appear.

Major firmware updates require an ISO CD-ROM i mage be downlo aded from our website

www.amercianfibertek.com

instructions on how to upgrade will be displayed on the laptop after it boots.

. A CD is burned from this image file and used to boot a laptop. The

34

Page 35

File Doesn’t Match

If the upgrade file is not accepted, the following

alert will appear. Clicking OK will return to the

previous screen and allow the selection process

be repeated.

to

Completing the Upload Process

If the correct file is selected a time bar will

appear at the upper end of the screen indicating

the upload is in process.

Successful completion of the Upload will be

indicated by the following alert box.

Master Admin Save Configuration

Clicking on the Save Configuration Mode button

will display the Save/Restore Configuration

screen. This function allows existing

programming on Commander to be saved to a

client computer.

Restore allows programming from a client

to be restored to Commander.

35

Page 36

Save / Restore Configuration

Clicking the Save button will open up the

Windows™ Save As screen on the client

computer.

The operator only needs to select the destination

folder

Save/Restore Feature: Save

If the save button is selected the system will

automatically create the file and downloaded to

the previously selected destination folder.

The .tar extension will automatically be added

after which the operator can elect to change the

file name.

Caution only file names with .tar extensions can

be uploaded.

Save/Restore Feature: Restore: Open File

The Restore process from the previous screen by

selecting Open.

This will open up the Windows™ dialog box.

Select the folder and file name to be restored.

The file will open with the particular file as indicated by its extension. Make certain if the file is a

valid .tar file, the extension is changed prior to uploadi ng

Save/Restore Feature: Restore: Confirmation

After selecting the file, the Restore button will appear along with an alert

box. Responding Ok will active the Restore function and overwrite

Commander’s existing programming. Clicking Cancel, returns to the

previous screen.

36

Page 37

Save/Restore Feature: Restore:

File Restored

When the Restore function is completed the

“File Restored” alert box will appear.

37

Page 38

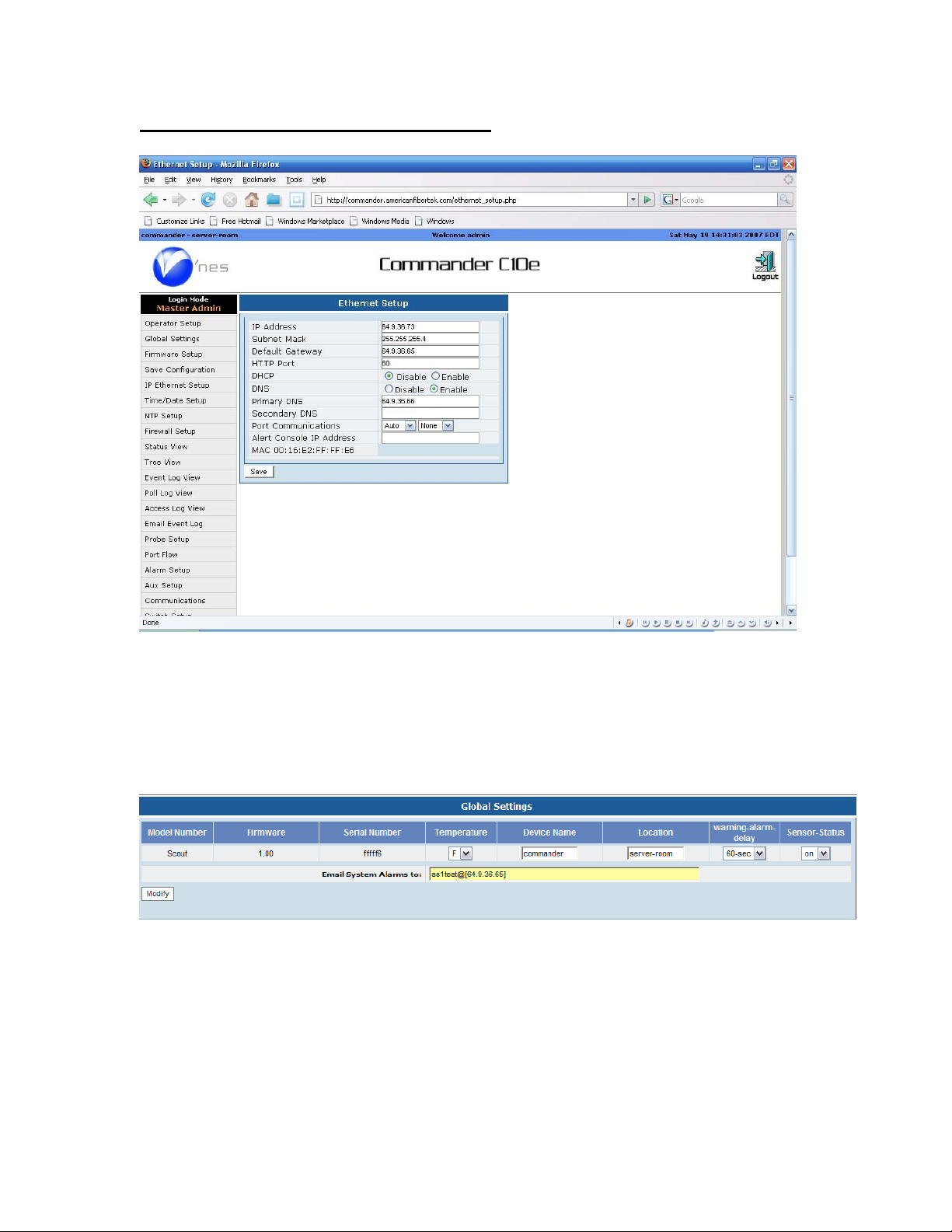

IP Settings

Default IP Settings

Commander’s default settings are displayed to the

right. DHCP is set to off in the default settings and the

default HTTP port is 80.

IP Address: 192.168.10.11

Subnet mask: 255.25.2 55.0

Gateway: 192.168.1.1

HTTP Port

This is the port used to access these setup screens via a

web browser. This setting is restricted to certain ports

as displayed on screen

DHCP

When DHCP is enabled Commander will report any changes in its IP Address to the email

address entered in the Global Settings. (Master Admin function)

DNS

A DNS resolver address is required for SMTP (email) to function. Select Enable and enter at least

one DNS server address.

Port Communications

Port communications is controlled by the switch. See Switch Flow under Switch Setup.

Alert Console IP Address:Port

The Alert Console allows you to program an IP address and port to receive alerts responses to

alarms and warnings. The receiving client computer must allow these alerts to be received. Up to

four addresses and ports may be entered separated by a space.

Network Settings: Saving your settings

Clicking the Save button will result in a pop up

asking you to confirm your settings. Click OK to

confirm. Click Cancel to return to the previous

screen. Remember to make a note of your new

IP Address.

Network Settings: Settings Accepted

When Commander has successfully accepted

your changes it will issue a pop up. Click OK to

continue set up.

38

Page 39

SMTP Settings

Simple Mail Transfer Protocol setup is required

for emails to be sent from the Commander.

There are two methods provided. An internal

SMTP server may be used, or Commander can

connect to a mail server using login account

credentials.

Internal SMPT server will act on its own,

connecting to other mail servers. However,

other servers may not recognize Commander as

a legitimate internet mail server and may refuse

connection. External SMTP server will setup

Commander to act as an email client. This will

require an account on an existing mail server.

Internal SMPT Server

To use the internal mail server, select the “Internal” radio button. Enter the host name for the Commander

to use to identify itself to other mails servers. The values for retry and Duration will set how many times

and for how long Commander will try to send an email before stopping.

External SMPT Server

To use and external mail host, select the “External” radio button. Enter the URL or ip address of the mail

server and optionally the port if not port 25. Some ISPs restrict access to port 25 in order to reduce spam.

Many mail servers provide alternate ports on which to connect. This port would need to be supplied by

your ISP or mail administrator.

Enter the username and password of the account for Commander to use to establish connection. The

default retry is 3, you may enter another value her if necessary.

Email Test Feature

By entering the (To) and (From) addresses in the spaces provide, Commander can send a short test

message using the email setup provided. After entering the information, press the Test button to send. After

a few moments, the Details button may be used to display the SMTP messages in order to aid in

troubleshooting email issues. Knowledge of SMTP transaction messages is helpful.

VPN

The VPN feature will connect to an AFI local device in order to aid in trouble shooting. This is rarely

required.

39

Page 40

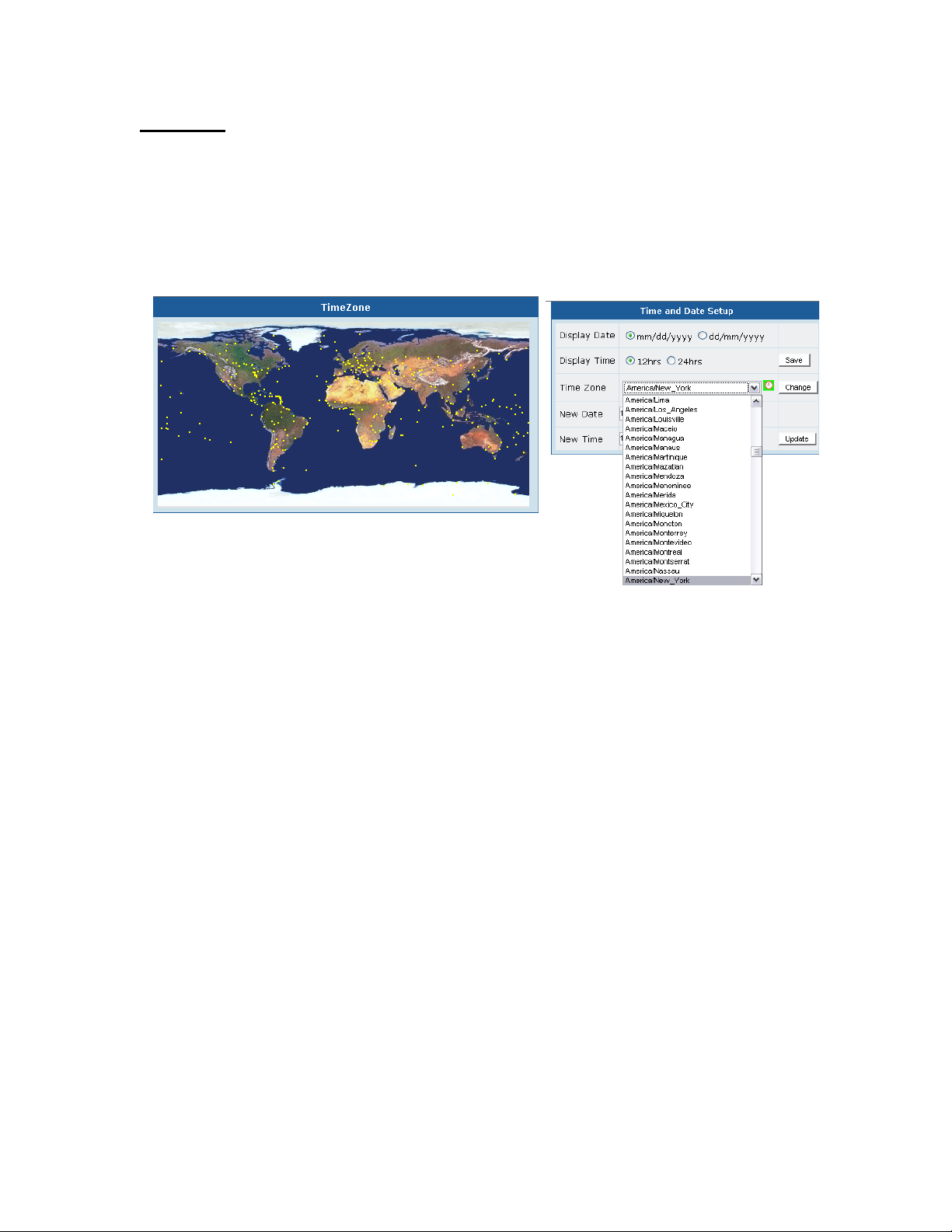

Time & Date

The Time/Date function defines the formats for

date and time, the time zone commander is

functioning within, and the current data

and

time. Start by setting the Date and Time Display

Time/Date Setup: NTP Active

Commander’s time reference can be set by NTP

(Network Time Protocol). If NTP is active the

time date setup will have the appearance to the

You

right.

will not be able to set a new time or

date. The screen will indicate “Using NTP

Time and Date Time Zone Function

Time/Date Setup: Selecting Time Zone

Select the time zone using the drop down menu.

Time/Date Setup: Time Zone Map Function

Click on the clock icon to display a world map.

Each dot on the map represents a time zone.

Moving your mouse over the dot will display the

time zone’s name

Click Change to select and accept the time zone

Time/Date Setup: New setting

Press up “Update” to accept the new time

settings. A pop up will appear informing it

will take 30 seconds to process the change.

Click OK to accept. Cancel will return the

screen to the previous setting.

40

Page 41

NTP

Commander provides three different NTP

settings;

None: NTP is not active. Commander’s internal

real time clock is used as the reference. When

using

make certain the time is correct.

the

internal clock as reference, please

Accept NTP Broadcasts: Commander will accept NTP broadcasts. Use this setting if you are

using a system clock.

Poll NTP Server: Commander will Poll a NTP Server at a specific IP address. This setting can be

used to poll at external NTP source located on the Internet.

NTP Setup: Accept NTP Broadcast

If you want Commander to accept NTP Broadcasts, clock the button and Save. A pop up will ask

you to confirm your selection. Click OK to accept and Cancel to return to the previous screen.

NTP Setup: NTP Broadcast Set

Up Successful

If Commander accepts the update, it will issue a

pop up. Click OK to return to the previous

screen

NTP Setup: Poll NTP Server

If you want Commander to Poll an NTP Server,

begin by confirming the location and access to

the server. Enter the NTP IP Server Address.

Next program the duration you want

Commander to poll the time server.

Finish by clicking “Save”.

NTP Setup: Poll NTP Server Setting Saved

If you want Commander to Poll an NTP Server,

begin by confirming the location and access to

the server. Enter the NTP IP Server Address.

Next

Commander to Poll the server. Finish by

clicking Save.

program

the duration you want

NTP Setup: Poll NTP Server Setting Saved

When Commander has ac cepted the changes it

will issue a pop up. Click OK to accept.

41

Page 42

Firewall

Firewall Setup: A-Opening Screen

Firewalls protect Comman der from acc ess from

outside sources that could data access without

authorization.

Firewall Setup: Adding an Address

To add an address, type the address in the “Mask

IP Address” box. Mask subnet addresses are

based on series of numbers 0-32 with 0

representing the full range. Type in the number

that corresponds to your network.

Click “Add” a pop up box will appear asking

you to confirm your settings. Click OK to accept

or Cancel

to return to the previous screen.

Firewall Setup: Adding an Address-Accepted

When Commander accepts your changes, it will

issue

a pop up. Click OK to accept.

Firewall Setup: Adding an AddressRejected

If you input an invalid addr ess a pop will

appear.

Click OK to return to the previous screen.

Firewall Setup: Deleting an Address

To delete an existing Firewall Address, select

the address from address box. Clicking on the

address will highlight it. Click the Delete button.

A pop up will appear asking you to confirm your

selection. Click OK to accept or Cancel to return

to the previous screen.

Firewall Setup: Deleting an Address –Accepted

When Commander has accepted the delete, it will

acknowledge by pop up box. Click OK to

accept.

42

Page 43

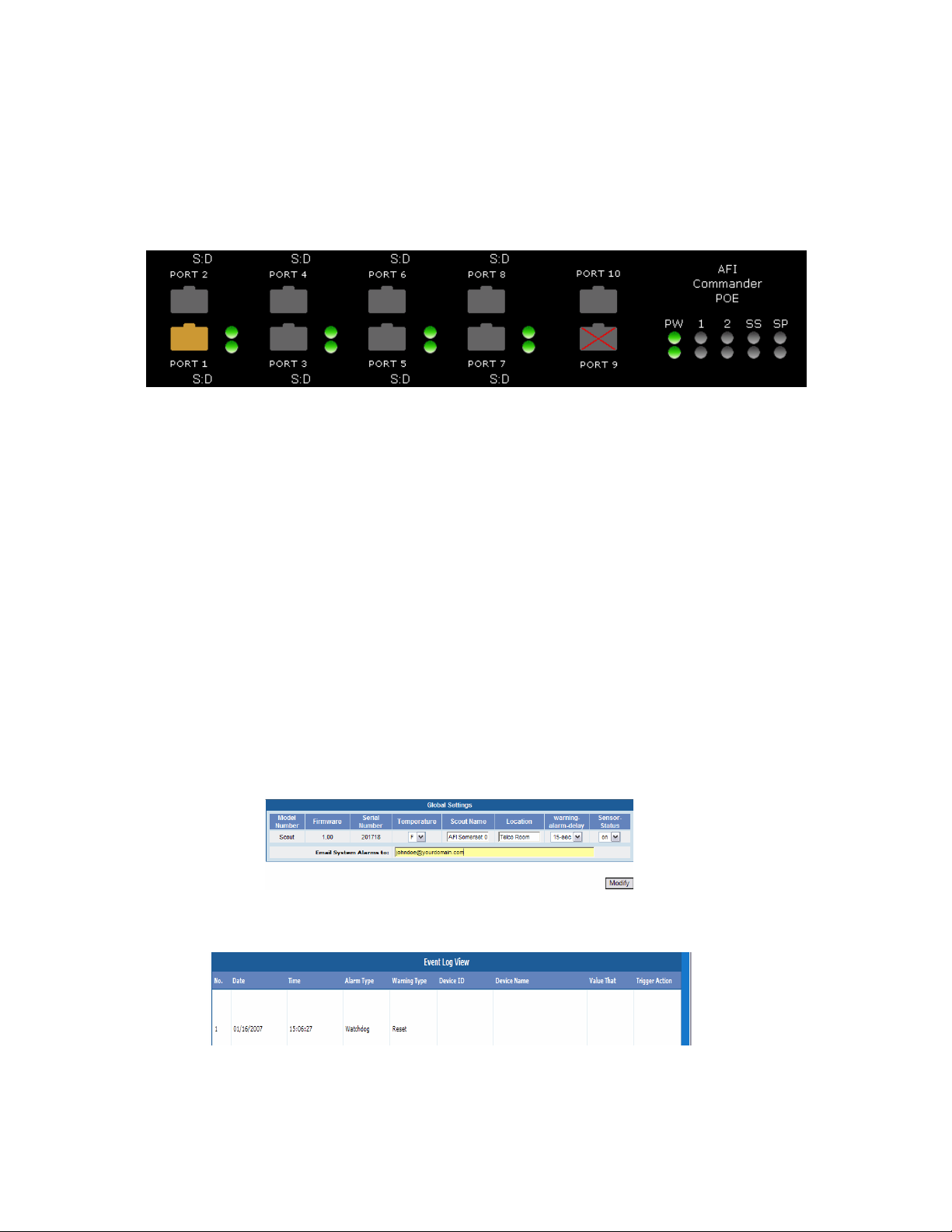

Status View

After logging in the screen will automatically go to the Status View. This view allows all users

the ability to see both the Commander’s internal and external status. A description of the

information displayed is as follows:

2

3

1. Header:

1 2

4

A. Access Level as defined by the operator user name and password.

B. Day, month, time, and year with reference time zone. In the header time is

always displayed in 24 hour format regardless of the actual time display setting.

C. Product name and model number.

D. Device name and location as provided by the operator if previously programmed.

2. Log Out:

Clicking the Log Out icon will ask you to confirm your decision and log out. Logging out is

required to properly record the log out time in the access log.

3. Operator Modes:

The modes that appear are determined by the User Name and Access Level provided at log in.

The active mode will be highlighted

4. Serial number and Firmware version number.

43

Page 44

5

5. Internal Settings:

In addition to monitoring external conditions, Commander monitors itself by reporting internal

voltage and temperature conditions. An internal fan will activate as determined by high

temperature conditions avoiding continues operation and extending its usage life span

Internal Triggers:

Commander will trigger an internal alarm when any of the following conditions exist:

CPU I/O voltage is less than 2.25 volts or greater than 2.75 volts.

CPU core voltage is less than 1.17 volts or greater than 1.43 volts.

voltage supply

CPU

Main Voltage Supply is less than 4.5 volts or greater than 5.5 volts.

Power Supply tem perature (temp1) is less than -25C or greater than 59C. (Temperatures greater

than 59C will trigger the internal fan)

Airflow temperature (temp2) is less than -27C or greater than +54C. (Temperatures greater than

54C will trigger the internal fan)

CPU temperature (temp30 is less than -16C or greater than +60C. (Temperatures greater than

60C will trigger the internal fan)

is less than 2.97 volts or greater than 3.63 volts.

44

Page 45

Port Status Color Code:

Green=Normal connection and data flow

Amber=Port is in warning state

Red=Port is in alarm state

Grey with red X =Port is disabled

Alarm LEDS: (Hard Contact Inputs)

Gray or no color for inactive stat

Red in active state (active duration

dependent

upon auxiliary duration setting.)

is

Auxiliary LEDS:

Gray or no color for inactive state Red in

active state (active duration is dependent

upon auxiliary duration setting.

Status LED:

Gray no probe present

Green probe present/normal operation

Alarm LED:

Gray no probe present

Green probe present/normal operation

Amber = Warning

Red = Alarm

In cases when more than on sensor probe is connected using an external USB hub, the Status

LED will flash in sequence representing the status of each of the probes (up to 4) that are

connected.

Power/Alarm LEDs

Power: Green for normal conditions

Alarm: Red for any internal alarm condition

Communication Port LEDs

Port A (RS 232) Green: Tx is active, Red: Rx is Active

Port B (RS 485) Green: Tx is active, Red: Rx is Active

45

Page 46

IP Address conflict notification

In the event the network has a duplicate IP address on the same LAN, Port A will flash

amber as long as the condition exists. Commander will check this network condition each

minute.

When the condition is no longer present the LED will return to the Off state. When

multiple Scouts or Commanders are operating on the same network, all units will show

this condition.

Probe Status

The Probe status view shows (moving from Left to Right)

LED = represents number assigned to that probe from 1 to 4. LED assignments can change due to

operator programming.

Probe ID = is the permanent number assigned to a probe during manufacturing and cannot be

changed.

Probe Name = the name assigned to the probe by the operator

Temp Airflow Humidity = display the current values and status. Warnings will be displayed in

amber and alarms in red. Warning and alarm values are determined by user set up.

Port Status: PortFlow™

This feature reports traffic at each port. Operators can set a traffic levels to meet quality

and reproduction rates for video streams. Warning and alarms can be set to operator

specified levels.

Port=1 to 11. Ports 1 to 10 represent each of the Ethernet ports. Port 11 monitors

Commander’s internal traffic and does not have warning or alarm settings.

Port ID= is the fix port identification assigned to each port.

Port Name: The name assigned to port by the operator during set up:

Port Flow: Display the value of the traffic as packet flow. Amber=Warning, Red =Alarm.

46

Page 47

Port Numbers: Commander’s port numbers are expressed two ways. The physical ports

are identified as Ports 00 through 10. The logical numbering system is Ports 1-11.

Logical Port 11 is Commander’s internal CPU port. This port carries signals from the

Ethernet switch to the internal processor. If communication is lost from this port, the

switch will lose some functions that require the CPU, such as STP, RSTP and

Multicasting. The CPU port is always connected to the same VLAN as logical Port 1.

Status View: Ports

The Status View is divided into 4 sections.

Internal

Conditions

Environmental: Temperature/Airflow/Humidity

Power: Voltage/Frequency/Power

Port Conditions: PortFlow™

and PoE power level.

Status View: Alarms and Auxiliaries

When hard contract alarms or

auxiliaries are active, they will

be displayed in the Status View

Commander can monitor communications with its probes if the Sensor Status is set to on in the

Global Settings. When set to on the LED will display a solid amber color during the

communication process. Please note in the default setting all probes will only address LED # 1

until the programming has been changed. Global settings are a Master Admin function only.

47

Page 48

Refresh Rate

Commander’s status is viewed over the network on a client computer. Changes can only be

viewed when the client’s web page is refreshed. This section allows the operator to select the

refresh rate duration or no refresh at all. The Refresh status is reflected in the Status View’s

header.

Refresh Rate Enabled/Disabled

This selection enables or disables the client’s status view refresh. Refresh must be enabled to

avoid a

20

minute auto log and to see event warnings. If Commander is in the no refresh rate, the

title will be red.

Event Warning Enabled/Disabled

This selection enables or disables the Event Warning feature. It must be enabled in order to pop

ups when the Commander’s Status View is minimized. It is only available in Refresh mode.

Refresh Rate/Event Warning Status Confirmation

This section will confirm the sections made for items 8,9 and 10. If this confirmation does not

the

reflect

desired operation, please change these settings. If the Event warning is off, it will not

appear in this area.

Commander must be in the refresh mode with events warning enabled in order to see pop ups and

display tool bar warnings.

48

Page 49

Front Panel Manual Auxiliary Operation

Commander’s Auxiliary functions can

be controlled from Status View by

clicking on any of the auxiliary buttons.

When an auxiliary button is selected, a pop up will appear asking the operator to confirm the

selection. If OK is selected the auxiliary will become active. If Cancel is selected Commander

will return to the previous screen.

When OK is selected the auxiliary will become active and the auxiliary LED will change from

grey to RED.

If the auxiliary LED is active, clicking on the

auxiliary will cause a pop up to appear asking to

confirm the decision. If OK is selected the

auxiliary will change from On to Off. If Cancel

is selected Commander will return to t

previous

screen.

Warning: Activating or De-activating the

auxiliary function manually will stop the

previously selected refresh rate and pop up and

tool bar (Firefox only) warnings. The screen

status will change to reflect this. When manually

operating the auxiliary function, Refresh must be

re-programmed.

Rules Governing Manual Auxiliary Operation:

(This function is restricted to Master Admin, IT Admin and Security Admin only)

Sensor Operation:

When an auxiliary is activated by a sensor, the auxiliary can be manually turned off as

However;

if this action is taken when the sensor is still in the alarm or warning condition, it will

described.

continue to be logged as active. The “turn off” time of the auxiliary will be logged as the actual

time when the environmental condition is no longer present and not when the operator terminated

the auxiliary. As environmental conditions may last for long durations this features allows

operations to turn off visual or auditable alerts which maybe annoying if left on for long period.

Hard Contact Alarm Operation: Manually terminating the auxiliary will also terminate the

alarm duration. The time of the term ination will be recorded in the Auxiliary log.

h

e

49

Page 50

Activating an Auxiliary

Commander allows an operator to manually

activate an auxiliary.

Move the mouse over an auxiliary in the off

position. Left click will bring up an alert box

asking to confirm your decision to active the

auxiliary. OK will result in activation. Cancel

will return the screen to the previous mode.

Once an auxiliary is active it can be deactivated.

Acknowledgement:

In order for acknowledgement to respond to an

alarm, it must be programmed as part of the

security set up.

AUX operation: If an AUX is active it will

show as red. The user can extinguish the AUX

by point and right click. A pop up box will

appear

Operation of Alarm Acknowledgements and the effect on Aux duration operations:

“Turn Aux

(number) off? Yes/No

In the case of an sensor warning or alarm the following will occur:

The logical device name will turn Amber in the case of a warning

The logical device name will turn Red in the case of an alarm

This action will continue a s long as the conditi on is valid

If an Auxiliary has been programmed to turn on for a pre-determined period of time, its

logical name representation in the tree will become Red, indication it is active.

An operator with permission will have the ability to terminate the auxiliary output prior

to its programmed time, by the action of moving the mouse over the individual Auxiliary

LED and point and click.

A display block will appear with “Turn aux (number) off? YES/NO.

A YES will De-activate the Auxiliary and return that part of the screen to the tree

display. A NO will return that part of the screen of the tree display.

If YES is selected the following actions will take place:

The auxiliary function will be de-activated and will not become activate again until the

current alarm condition is ended and a new alarm input (programmed to correspond with

that individual auxiliary) is received . The Red indication on that Auxiliary’s logical

name will be terminated and return to its normal non-color state.

50

Page 51

Tree View

Tree View shows the status of sensors, alarm i nputs and auxiliary outputs. These are referred to

as “Logical Devices”.

Tree View Operations

When first clicking on the Tree View, the

Device ID will appear. In the Tree, Commander

is referr ed to as the ‘Physical Device” while the

connections to Commander are referred to as

“Logical Devices”

If an operator has previously named

Commander, that name will appear.

Expanding the Tree will show the show the three

logical devices, Probes, Alarms and Aux

(auxiliary)

Expanding each logical device will display its

name, status as indicated by the color,

assignment to an LED and the number of alarms

or warnings that have occurred.

Views: Tree View- Logical Device Status

Sensor Probes: In the example to the right, the

green circle to the left of probe test 03 indicates

it is currently in the normal mode. The (4)

indicates that probe is assigned to front panel

LED number 4. (Although the LED may be

assigned to 1 through 10, Commander only

displays LED #1 in the front panel.) The number

30 indicates that a combination of 30 alarms and

warnings has occurred.

When a name has previously been assigned to a

logical device, the tree will show that name.

When a name has not been assigned it will

automatically be given the probe ID number.

Port Probes: Are displayed under Probes. The

number in ( ) is the port number displayed after

the Port Name. The number following this is the

number of events that will appear in the

when

active.

log

51

Page 52

Aux (Auxiliary): The indicator to the left indicates the alarm status, Gray for OFF, and Red when