American Dynamics ADMPLT16, ADMPLT16C2, ADMPLT16C3, ADMPLT32, ADMPLT32C2 Installation

...

MegaPowerTM LT

Matrix Switcher/Controller System

ADMPLT16

ADMPLT32

ADMPLT16C2

ADMPLT16C3

ADMPLT32C2

ADMPLT32C3

Installation and Operation Instructions

MegaPower LT

Notice

The information in this manual was current when published. The manufacturer reserves the right to

revise and improve its products. All specifications are therefore subject to change without notice.

Copyright

Under copyright laws, the contents of this manual may not be copied, photocopied, reproduced,

translated or reduced to any electronic medium or machine-readable form, in whole or in part,

without prior written consent of American Dynamics Video Products Division.

© Copyright 2003

American Dynamics Video Products Division

6795 Flanders Drive San Diego, CA 92121 U.S.A.

Trademarks

MegaPower™ is a trademark of American Dynamics Video Products Division.

Trademarked names are used throughout this manual. Rather than place a symbol at each occurrence,

trademarked names are designated with initial capitalization. Inclusion or exclusion is not a judgment

on the validity or legal status of the term.

Important Information

Before proceeding, please read and observe all instructions and warnings contained in this manual.

Retain this manual with the original bill of sale for future reference and, if necessary, warranty

service.

When unpacking your new American Dynamics product, check for missing or damaged items. If

any item is missing, or if damage is evident, DO NOT INSTALL OR OPERATE THIS PRODUCT.

Contact your dealer for assistance.

NOTE

This product is supplied with a printed English manual. The manual is also provided in other

languages (French, Spanish and German) on the included CD.

For your Records

Complete the following product purchase information. The factory requests this information when

contacted for technical support. It is also valuable in case of loss or theft.

Purchase Date: __________________________

Serial Number: __________________________

ii

Matrix Installation and Operation

INSTALLA TION IS ONL Y TO BE CARRIED OUT BY COMPETENT, QUALIFIED AND EXPERIENCED PERSONNEL.

WIRE IN ACCORDANCE WITH COUNTRY OF INSTALLATION NATIONAL WIRING REGULATIONS.

ACCESS CAN ONLY BE GAINED BY SERVICE PERSONS. THERE ARE NO USER-ACCESS AREAS. ACCESS

BY SERVICE PERSONS CAN ONLY BE GAINED BY THE USE OF AN APPROPRIATE TOOL.

THE EQUIPMENT SUPPLIED WITH THIS MANUAL IS DESIGNED FOR USE IN GENERAL PURPOSE CCTV

INSTALLATION AND HAS NO OTHER FUNCTION. DO NOT EXCEED THE VOLTAGE AND TEMPERATURE

LIMITS GIVEN IN THE SPECIFICATIONS. ONLY USE YOUR MATRIX IN A CLEAN, DRY, DUST-FREE

ENVIRONMENT.

TO REDUCE RISK OF ELECTRIC SHOCK, DO NOT REMOVE COVER. NO USER SERVICEABLE P ARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

THE MEGAPOWER LT MUST ONLY BE POWERED BY THE CLASS 2 INSULATED UL LISTED 15 WATT LPS

SUPPLY (MP-PSU) PROVIDED.

POWER ISOLATION MUST BE PROVIDED VIA THE: PLUG; APPLIANCE COUPLER; ISOLATING SWITCH;

CIRCUIT BREAKER, OR AN EQUIVALENT ELECTRICAL DEVICE IN CLOSE PROXIMITY TO THE EQUIPMENT.

A 3 AMP FUSE IN THE UK PLUG PROVIDES PROTECTION AGAINST OVERLOAD AND SHORT CIRCUIT. IN

AREAS WHERE A UK PLUG IS NOT APPROPRIATE, SIMILIAR PROTECTION MUST BE PROVIDED IN THE

INSTALLATION.

Electrical Safety

British Standard BSEN60950:2001 Safety of information technology equipment Including electrical business

equipment.

Underwriters Laboratories Inc. UL1950 Safety of information technology equipment, including electrical business

equipment.

Canadian Standards Association CAN/CSA C22.2 No. 950-95.

Radio Frequency Emissions

British Standard EN50081-1:1992 Electromagnetic compatibility - Emission. Part 1. Residential, commercial and

light industry.

British Standard BSEN55022:1998 Limits and methods of measurement of radio disturbance characteristics of

information technology equipment.

Immunity

British Standard BSEN50130-4 Alarm Systems Part 4 Electromagnetic compatibility Product family standard: Immunity requirements for components of fire, intruder and social alarm systems.

EU Conformance Statement

A Declaration of Conformity in accordance with the above EU standards has been made and is on file with the

manufacturer. The manufacturer declares that the product supplied with this document is complaint with the provisions of the EMC Directive 89/336 EEC, the Low Voltage Directive LVD 73/23 EEC, the CE Marking Directive 93/68

EEC and all associated amendments.

Regulatory Notices

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

iii

MegaPower LT

L’INST ALLA TION NE SAURAIT ÊTRE EFFECTUÉE QUE P AR UN PERSONNEL QUALIFIÉ ET EXPÉRIMENTÉ. BRANCHER

ET RACCORDER EN CONFORMITÉ A VEC LES RÉGLEMENT A TIONS EN VIGUEUR DANS LE P A YS OÙ EST INST ALLÉE

L’UNITÉ.

L’ACCÈS NE PEUT ÊTRE OBTENU QUE PAR LES TECHNICIENS DE MAINTENANCE. L’ACCÈS DOIT ÊTRE

STRICTEMENT INTERDIT À TOUT UTILISATEUR. L’ACCÈS PAR LES TECHNICIENS DE MAINTENANCE NE PEUT

ÊTRE EFFECTUÉ QU’À L’AIDE D’UN OUTIL APPROPRIÉ.

L’ÉQUIPEMENT FOURNI A VEC LE PRÉSENT MANUEL EST CONÇU POUR ÊTRE UTILISÉ DANS LE CADRE GÉNÉRAL

DE LA SURVEILLANCE PAR CAMÉRA À CIRCUIT FERMÉ (CCTV) ET N’A AUCUNE AUTRE FONCTION. NE PAS

DÉPASSER LES SEUILS DE TENSION ET DE TEMPÉRATURE INDIQUÉS DANS LES CARACTÉRISTIQUES

TECHNIQUES. N’UTILISER L’UNITÉ MA TRIX QU’EN ENVIRONNEMENT PROPRE, SEC ET EXEMPT DE POUSSIÈRE.

POUR RÉDUIRE LES RISQUES D’ÉLECTROCUTION, NE PAS DÉPOSER LE COUVERCLE. AUCUN COMPOSANT NE

PEUT ÊTRE RÉP ARÉ P AR L ’UTILISA TEUR. F AIRE APPEL À UN TECHNICIEN DE MAINTENANCE COMPÉTENT.

POUR PRÉVENIR TOUT RISQUE D’INCENDIE OU D’ÉLECTROCUTION, NE P AS EXPOSER CETTE UNITÉ À LA PLUIE

NI À L’HUMIDITÉ.

L’UNITÉ MEGAPOWER LT DOIT ÊTRE ALIMENTÉE PAR LE GROUPE DE CLASSE 2 UL ISOLÉ 15 WATTS (MP-PSU)

FOURNI.

L’ISOLATION DOIT ÊTRE ASSURÉE PAR LE BIAIS DE LA PRISE, DU COUPLEUR DE L’UNITÉ, DU COMMUTATEUR

ISOLANT , DU FUSIBLE PI DE TOUT DISPOSITIF ÉLECTRIQUE ÉQUIV ALENT À PROXIMITÉ RAPPROCHÉE DE L ’UNITÉ.

UN FUSIBLE DE 3 A DANS LA PRISE BRIT ANNIQUE ASSURE LA PROTECTION CONTRE LES SURCHARGES ET LES

COURTS-CIRCUITS. DANS LES P AYS OÙ UNE PRISE BRIT ANNIQUE NE CONVIENT PAS, UNE PROTECTION SIMILAIRE

DOIT ÊTRE APPOR TÉE LORS DE L’INST ALLA TION.

Sécurité électrique

Norme britannique BSEN60950:2001 : sécurité des équipements informatiques, notamment les équipements électriques

commerciaux.

Underwriters Laboratories Inc. UL1950 – Sécurité des équipements informatiques, y compris les équipements électriques à

usage professionnel.

Canadian Standards Association CAN/CSA C22.2 No. 950-95.

Émission de fréquences radio

Norme européenne EN50081-1:1992 – Compatibilité électromagnétique - Émissions. Section 1. Usage résidentiel, commercial

et industriel limité.

Norme britannique BSEN55022:1998 : limites et méthodes de mesure des caractéristiques de perturbation radio des

équipements informatiques.

Immunité

Norme britannique BSEN50130-4 : systèmes d’alarme, 4e partie, compatibilité électromagnétique Norme de famille de produits :

caractéristiques d’immunité des composants des systèmes anti-incendie, anti-intrusion et d’alarme sociaux.

Déclaration de conformité UE

Une déclaration de conformité aux normes ci-dessus de l’Union européenne a été réalisée et est conservée chez le constructeur.

Le constructeur déclare le produit accompagnant ce document conforme aux dispositions de la Directive 89/336 de la CEE

sur la compatibilité électromagnétique, de la directive LVD 73/23 de la CEE sur les basses tensions et de la Directive 93/68

de la CEE et ses modifications sur la marque CE.

Avis réglementaires

Cet équipement est conforme au paragraphe 15 des réglementations de la FCC. Son utilisation est sujette aux deux conditions

suivantes : (1) cet équipement ne doit pas générer d’interférences nuisibles et (2) cet équipement doit accepter les interférences

éventuelles, notamment les interférences susceptibles de provoquer un fonctionnement indésirable.

iv

Matrix Installation and Operation

DIE INSTALLA TION DARF NUR VON KOMPETENTEM, QUALIFIZIERTEM UND ERF AHRENEM PERSONAL AUSGEFÜHRT

WERDEN. DIE VERKABELUNG MUSS GEMÄSS DER AM INSTALLATIONSORT GELTENDEN, NATIONALEN

VERKABELUNGSVORSCHRIFTEN ERFOLGEN.

DER ZUGRIFF IST NUR DEM WARTUNGSPERSONAL MÖGLICH. ES SIND KEINE BENUTZERZUGÄNGLICHEN

BEREICHE VORHANDEN. DER ZUGRIFF DURCH DAS WARTUNGSPERSONAL IST NUR MIT HILFE EINES GEEIGNETEN

WERKZEUGS MÖGLICH.

DIE ZUSAMMEN MIT DIESEM HANDBUCH GELIEFERTE AUSRÜSTUNG IST FÜR DEN GEBRAUCH IN ALLGEMEINEN

CCTV-ANLAGEN KONZIPIERT UND DIENT KEINEM ANDEREN ZWECK. DIE IN DEN TECHNISCHEN DATEN

ANGEGEBENEN SPANNUNGS- UND TEMPERATURGRENZEN DÜRFEN NICHT ÜBERSCHRITTEN WERDEN. DIE

SCHALTMATRIX DARF NUR IN EINER SAUBEREN, TROCKENEN UND STAUBFREIEN UMGEBUNG VERWENDET

WERDEN.

UM DAS RISIKO VON STROMSCHLAG ZU REDUZIEREN, DARF DIE ABDECKUNG NICHT ENTFERNT WERDEN. DAS

GERÄT ENTHÄLT KEINE DURCH DEN BENUTZER WARTBARE TEILE. WARTUNGSARBEITEN DÜRFEN NUR VON

QUALIFIZIERTEM WARTUNGSPERSONAL DURCHGEFÜHRT WERDEN.

ZUM SCHUTZ GEGEN BRAND- ODER STROMSCHLAGGEFAHR DARF DAS GERÄT KEINEM REGEN ODER

FEUCHTIGKEIT AUSGESETZT WERDEN.

DAS MEGAPOWER-LT-SYSTEM DARF NUR ÜBER DIE MITGELIEFERTE, ISOLIERTE, UL-GELISTET 15-WATTVERSORGUNG (MP-PSU) GESPEIST WERDEN.

DIE STROMVERSORGUNG MUSS MITTELS DES FOLGENDEN UNTERBROCHEN WERDEN KÖNNEN: STECKER;

GERÄTEKUPPLUNG; TRENNSCHALTER; SICHERUNG ODER EINE GLEICHWERTIGE ELEKTRISCHE VORRICHTUNG

IN DER NÄHE DER AUSRÜSTUNG.

EINE IM BRITISCHEN NETZSTROMSTECKER UNTERGEBRACHTE 3-AMPERE-SICHERUNG SICHERT DIE

AUSRÜSTUNG GEGEN ÜBERLASTUNG UND KURZSCHLUSS. WO EIN BRITISCHER STECKER NICHT ANGEBRACHT

IST , MUSS EIN ÄHNLICHER SCHUTZ ÜBER DIE INST ALLA TION ERFOLGEN.

Elektrische Sicherheit

British Standard BSEN60950:2001 – Sicherheit von informationstechnischer Ausrüstung, einschließlich elektrischer

Geschäftsausrüstung.

Underwriters Laboratories Inc. UL1950 Sicherheit von informationstechnischer Ausrüstung, einschließlich elektrischer

Geschäftsausrüstung.

Canadian Standards Association CAN/CSA C22.2 No. 950-95.

Funkfrequenzemissionen

Euronorm EN50081-1:1992 Elektromagnetische Kompatibilität – Emission. Teil 1. Wohnbereiche, kommerzielle und

leichtindustrielle Umgebungen.

British Standard BSEN55022:1998 – Messgrenzen und -verfahren für Funkstörungscharakteristiken von

informationstechnischer Ausrüstung.

Immunität

British Standard BSEN50130-4 – Alarmsysteme, T eil 4, elektromagnetischer Kompatibilität sstandard für die Produktgruppe:

Immunitätsanforderungen für Komponenten von Feuer-, Einbruchs- und öffentlichen Alarmsystemen.

EU-Konformitätserklärung

Eine Konformitätserklärung gemäß der o. g. EU-Standards ist erfolgt und liegt beim Hersteller vor. Der Hersteller erklärt,

dass das mit diesem Dokument gelieferte Produkt die Anforderungen der Richtlinie für elektromagnetische Kompatibilität

89/336 EEC, der Richtlinie für Niederspannung LVD 73/23 EEC, der CE-Kennzeichnungsrichtlinie 93/68 EEC und aller

diesbezüglichen Änderungen erfüllt.

Aufsichtsbehördliche Hinweise

Dieses Gerät entspricht T eil 15 der FCC-Richtlinien. Der Betrieb ist vorbehaltlich der beiden folgenden Bedingungen gestattet:

(1) dieses Gerät darf keine schädlichen Störungen verursachen, und (2) dieses Gerät muss alle Störungen akzeptieren,

einschließlich solcher, die den Betrieb beeinträchtigen könnten.

v

MegaPower LT

L’INSTALLAZIONE DEVE ESSERE ESEGUITA ESCLUSIVAMENTE DA PERSONALE COMPETENTE, ESPERTO E

QUALIFICATO. COLLEGARE I CAVI IN CONFORMITÀ ALLE SPECIFICHE NAZIONALI DI INSTALLAZIONE.

L’ACCESSO È CONSENTITO SOLTANTO AL PERSONALE ADDETTO ALLA MANUTENZIONE. NON ESISTONO AREE

ACCESSIBILI DA PARTE DELL’UTENZA. IL PERSONALE ADDETTO ALLA MANUTENZIONE PUÒ ACCEDERE SOLO

UTILIZZANDO UNO STRUMENTO APPROPRIA TO.

L’APP ARECCHIO CUI QUESTO MANUALE SI RIFERISCE È DESTINA TO ALL’USO IN INST ALLAZIONI GENERICHE PER

TV A CIRCUITO CHIUSO E NON HA ALCUNA ALTRA FUNZIONE. NON SUPERARE I LIMITI DI VOLTAGGIO E

TEMPERATURA INDICATI NELLE SPECIFICHE. USARE L’APPARECCHIO ESCLUSIVAMENTE IN AMBIENTI PULITI,

NON UMIDI E NON POLVEROSI.

PER RIDURRE IL RISCHIO DI SHOCK ELETTRICI, NON RIMUOVERE IL COPERCHIO. L’INTERNO NON CONTIENE

PAR TI CHE L ’UTENTE POSSA RIP ARARE. RIVOLGERSI A TECNICI DI ASSISTENZA QUALIFICA TI.

PER EVITARE IL RISCHIO DI INCENDI O SHOCK, NON ESPORRE L ’APPARECCHIO ALLA PIOGGIA O ALL’UMIDITÀ.

IL SISTEMA MEGAPOWER LT DEVE ESSERE ALIMENT ATO ESCLUSIVAMENTE CON L’ALIMENTATORE ISOLAT O DI

CLASSE 2 (CERTIFICA TO UL) A 15 WATT (MP-PSU) ACCLUSO.

PER L’ISOLAMENTO ELETTRICO, SERVIRSI DI: SPINA, ACCOPPIATORE DEL DISPOSITIVO, INTERRUTTORE

ISOLANTE, INTERRUTTORE DI CIRCUITO O DI UN DISPOSITIVO ELETTRICO EQUIVALENTE, INSTALLATO VICINO

ALL’APPARECCHIO,

ALL’INTERNO DELLA SPINA DI TIPO BRITANNICO È PRESENTE UN FUSIBILE DA 3 AMPERE, CHE PROTEGGE DA

SOVRACCARICHI E CORTI CIRCUITI. NEI PAESI IN CUI TALE SPINA NON È UTILIZZABILE, AL MOMENTO

DELL’INST ALLAZIONE SI DEVE PREVEDERE UNA PROTEZIONE ANALOGA.

Sicurezza elettrica

Standard britannico BSEN60950:2001 per la sicurezza delle apparecchiature informatiche, incluse le apparecchiature

elettriche aziendali.

Underwriters Laboratories Inc. UL1950 per la sicurezza delle apparecchiature informatiche, incluse le apparecchiature

elettriche aziendali.

Associazione standard canadesi CAN/CSA C22.2 No. 950-95.

Emissioni in radiofrequenza

Standard europeo EN50081-1:1992, compatibilità elettromagnetica - emissioni. Parte 1. Inst allazioni residenziali, commerciali

e dell’industria leggera.

Standard britannico BSEN55022:1998 per i limiti e i metodi di misurazione delle interferenze radio caratteristiche delle

apparecchiature informatiche.

Inalterabilità

Standard britannico BSEN50130-4 per i sistemi di allarme, parte 4, standard di compatibilità elettromagnetica per la

tipologia di prodotti: requisiti di immunità per sistemi di allarme antincendio, anti-intrusione e di tipo sociale.

Dichiarazione di conformità UE

In base agli standard UE summenzionati, è stata emessa una Dichiarazione di conformità che è archiviata nella sede del

produttore. Il produttore dichiara che il prodotto fornito col presente documento è conforme alle prescrizioni della direttiva

EMC 89/336 CEE, della direttiva sul basso voltaggio LVD 73/23 CEE, della direttiva sul marchio CE 93/68 CEE e di tutte

le relative modifiche.

Avvisi normativi

Questo dispositivo è conforme alle norme FCC, parte 15. Il funzionamento è soggetto alle due condizioni seguenti: (1) Il

dispositivo non deve causare interferenze dannose; (2) il dispositivo deve sostenere le interferenze in ingresso, incluse

quelle che potrebbero determinare un funzionamento non desiderato.

vi

Matrix Installation and Operation

LA INSTALACIÓN DEBERÁ SER REALIZADA EXCLUSIVAMENTE POR PERSONAL COMPETENTE, CUALIFICADO Y

CON EXPERIENCIA. LAS CONEXIONES ELÉCTRICAS SE REALIZARÁN EN CONFORMIDAD CON LA NORMAT IVA

NACIONAL EN MA TERIA DE CABLEADO DE CADA P AÍS.

ACCESO SÓLO AUTORIZADO AL PERSONAL DEL SER VICIO TÉCNICO. NO HA Y ZONAS DE ACCESO P ARA USUARIOS.

EL PERSONAL DEL SERVICIO TÉCNICO SOLAMENTE PODRÁ ACCEDER MEDIANTE EL USO DE UNA HERRAMIENT A

ADECUADA.

EL EQUIPO QUE SE SUMINISTRA JUNT O CON ESTE MANUAL ESTÁ DISEÑADO P ARA USO EN INST ALACIONES DE

CCTV (CIRCUITO CERRADO DE TELEVISIÓPN) DE PROPÓSITO GENERAL Y NO TIENE OTRA FUNCIÓN. NO SUPERE

LOS LÍMITES DE TENSIÓN Y TEMPERA TURA INDICADOS EN LAS ESPCIFICACIONES. USE LA MA TRIZ SOLAMENTE

EN UN AMBIENTE LIMPIO, SECO Y SIN POL VO.

CON EL FIN DE REDUCIR EL RIESGO DE DESCARGA ELÉCTRICA, EVITE RETIRAR LA CUBIER T A. EN EL INTERIOR

NO HAY NINGÚN COMPONENTE QUE PUEDA SER REP ARADO POR EL USUARIO. CUALQUIER REPARACIÓN DEBE

SER REALIZADA POR PERSONAL DE SER VICIO DEBIDAMENTE CUALQUIDFICADO.

PARA EVITAR RIESGO DE INCENDIO O DESCARGA ELÉCTRICA, NO EXPONGA ESTE EQUIPO A L A LLUVIA O A LA

HUMEDAD.

EL MEGAPOWER LT DEBE ALIMENTARSE EXCLUSIVAMENTE CON LA FUENTE DE ALIMENTACIÓN (MP-PSU) DE

15 VA TIOS, CON AISLAMIENTO INCLUIDA EN LA LISTA UL DE CLASE 2, QUE SE SUMINISTRA CON EL EQUIPO.

EL AISLAMIENT O DE LA ALIMENT ACIÓN DEBE REALIZARSE POR MEDIO DE: CONECTOR; ACOPLADOR DEL EQUIPO;

CONMUTADOR DE AISLAMIENTO; DISYUNTOR, O UN DISPOSITIVO ELÉCTRICO EQUIVALENTE SITUADO MUY

PRÓXIMO AL EQUIPO.

EN EL CONECTOR DEL REINO UNIDO, UN FUSIBLE DE 3 A PROPORCIONA PROTECCIÓN CONTRA SOBRECARGA Y

CORTOCIRCUITO. EN LOS LUGARES EN QUE NO SE PUEDEN UTILIZAR CONECTORES DEL REINO UNIDO, SE

DEBE EMPLEAR UNA PROTECCIÓN SIMILAR EN LA INST ALACIÓN.

Seguridad eléctrica

British Standard BSEN60950:2001 Seguridad de equipos informáticos, incluidos equipos eléctricos de uso empresarial.

Underwriters Laboratories Inc. UL1950 Seguridad de equipos informáticos, incluidos equipos eléctricos de uso empresarial.

Canadian Standards Association CAN/CSA C22.2 Nº 950-95.

Emisión de radiofrecuencia

European Standard EN50081-1:1992 Comaptibilidad electromagnética - Emisión. Parte 1. Residencial, comercial e industria

ligera.

British Standard BSEN55022:1998 Límites y métodos de medición de características de interferencias de radio para

equipos informáticos.

Inmunidad

British Standard BSEN50130-4, Parte 4 de sistemas de alarma (Alarm Systems), estándar de compatibilidad

electromagnética para familia de productos: Requisitos de inmunidad para componentes de sistemas de alarma

antiincendios, contra intrusión y sociales.

Declaración de Conformidad de la UE

Se ha realizado la Declaración de conformidad en cumplimiento de las normas de la UE indicadas más arriba. El fabricante

es el depositario de dicha declaración. El fabricante declara que el producto suministrado con esta documentación cumple

las normas estipuladas por la Directiva sobre EMC 89/336 CEE, la Directiva sobre baja tensión LVD 73/23 CEE, la

directiva sobre Marca CE 93/68 CEE y todas las enmiendas asociadas a éstas.

Avisos sobre cumplimiento de la legislación

Este dispositivo cumple la parte 15 de las normas de la FCC. Su utilización está sujeta a las siguientes dos condiciones: (1)

Este equipo no puede provocar interferencias nocivas, y (2) este equipo debe aceptar cualquier interferencia recibida, incluidas

las interferencias que puedan provocar un funcionamiento no deseado.

vii

MegaPower LT

DE INSTALLATIE DIENT ALLEEN TE WORDEN UITGEVOERD DOOR DESKUNDIG, GEKWALIFICEERD EN ERVAREN

PERSONEEL. INSTALLEER VOLGENS DE TER PLEKKE GELDENDE AANSLUITRICHTLIJNEN.

TOEGANG ALLEEN MOGELIJK DOOR SERVICEPERSONEEL. GEEN TOEGANG VOOR EINDGEBRUIKERS.

SERVICEMEDEWERKERS KUNNEN ALLEEN TOEGANG VERKRIJGEN MET BEHULP VAN DAARVOOR GESCHIKT

GEREEDSCHAP.

DE BIJ DEZE HANDLEIDING GELEVERDE APPARATUUR IS ONTWORPEN VOOR GEBRUIK IN ALGEMENE CCTVINSTALLATIES EN HEEFT VERDER GEEN ANDERE FUNCTIE. STEL DE APPARATUUR NIET BLOOT AAN VOL TAGES

EN TEMPERATUREN BOVEN DE AANGEGEVEN LIMIET. GEBRUIK UW MATRIX ALLEEN IN EEN SCHONE, DROGE,

STOFVRIJE OMGEVING .

OM DE KANS OP ELEKTRISCHE SCHOKKEN TE VERMIJDEN, DIENT U DE KAP NIET TE VERWIJDEREN. HET APPARAA T

BEVAT GEEN ONDERDELEN DIE DOOR DE GEBRUIKER KUNNEN WORDEN GEREPAREERD. LAAT ONDERHOUD

UITVOEREN DOOR GEKWALIFICEERD ONDERHOUDSPERSONEEL.

OM DE KANS OP BRAND OF ELEKTRISCHE SCHOKKEN TE VERMIJDEN, DIENT U DIT APP ARAA T NIET AAN REGEN

OF VOCHT BLOOT TE STELLEN.

DE MEGAPOWER LT MAG ALLEEN WORDEN AANGESLOTEN OP DE MEEGELEVERDE, GEÏSOLEERDE (KLASSE-2),

UL-GOEDGEKEURDE 15-WA TT VOEDING (MP-PSU).

DE STROOMISOLATIE DIENT TE WORDEN VERZORGD VIA DE STEKKER, DE APPARAATAANSLUITINGEN, EEN

ISOLEERSCHAKELAAR, EEN STROOMONDERBREKER OF EEN ANDER ELEKTRISCH APP ARAA T IN DE NABIJHEID

VAN DE INST ALLATIE.

IN GROOT-BRITT ANNIË WORDT DE BESCHERMING TEGEN OVERBELASTING EN KORTSLUITING GEREGELD VIA

EEN ZEKERING VAN 3 AMPÈRE IN DE STEKKER. IN GEBIEDEN WAAR EEN BRITSE STEKKER NIET GESCHIKT IS,

DIENT VOOR GELIJKWAARDIGE BESCHERMING TE WORDEN GEZORGD IN DE INST ALLA TIE ZELF.

Elektrische beveiliging

Voldoet aan richtlijn BSEN60950:2001, de veiligheidsnorm voor IT - en elektrische app aratuur van British S tandards.

Voldoet aan richtlijn UL1950, de veiligheidsnorm voor IT - en elektrische app aratuur van Underwriters Laboratories Inc.

Voldoet aan richtlijn CAN/CSA C22.2 No. 950-95 van de Canadian Standards Association.

Radiofrequentiestraling

Voldoet aan richtlijn EN50081-1:1992 inzake elektromagnetische compatibiliteit - S traling. Deel 1. Woonwijken, bedrijven

en lichte industrie.

Voldoet aan richtlijn BSEN55022:1998, de norm inzake de grenzen van en methoden voor het meten van

radiostoringskenmerken van IT-apparatuur van British S tandards.

Immuniteit

Voldoet aan BSEN50130-4, deel 4 van de richtlijn voor de elektromagnetische compatibiliteit van alarmsystemen:

immuniteitsvereisten voor onderdelen in brand-, inbraak- en sociale alarmsystemen.

Verklaring van EU-conformiteit

Er is overeenkomstig de bovenstaande EU-standaards een conformiteitsverklaring opgesteld die kan worden opgevraagd

bij de fabrikant. De fabrikant verklaart dat het bij dit document meegeleverde product voldoet aan de voorwaarden van

EMC-richtlijn 89/336 EEC, Laagspanningsrichtlijn LVD 73/23 EEC, CE-richtlijn 93/68 EEC en alle aanverwante wijzigingen.

Regelgevende opmerkingen

Dit apparaat voldoet aan deel 15 van de FCC-richtlijnen. Werking is onderhevig aan de volgende twee voorwaarden: (1) Dit

apparaat mag geen schadelijke straling veroorzaken, en (2) dit apparaat moet storingen die worden opgevangen kunnen

verwerken, inclusief storingen die ongewenste werking kunnen veroorzaken.

viii

Matrix Installation and Operation

CHAPTER 1: LA YOUT AND INSTALLATION.................................................................................................... 3

Layout and Connections ..................................................................................................................................... 3

Unpacking ........................................................................................................................................................... 5

Installation Guidelines......................................................................................................................................... 5

Mounting the Unit................................................................................................................................................ 6

Sensornet Dome Connections............................................................................................................................ 7

Sensornet Termination and Wiring ..................................................................................................................... 7

Alarm Input Connections .................................................................................................................................... 9

Auxiliary Output Connections ............................................................................................................................. 9

Dip Switch Settings ........................................................................................................................................... 10

Keyboard Dip Switches............................................................................................................................... 10

MegaPower LT Dip Switches ...................................................................................................................... 10

Setting the Keyboard ID.................................................................................................................................... 10

Setting the Keyboard Baud Rate ...................................................................................................................... 11

CHAPTER 2: THE MENU SYSTEM................................................................................................................. 12

Status Levels..................................................................................................................................................... 12

Menu Navigation ............................................................................................................................................... 12

Entering the Menu System ............................................................................................................................... 13

Saving and Exiting ............................................................................................................................................ 14

Administrator and Supervisor Menus ............................................................................................................... 14

Time/Date Menu ............................................................................................................................................... 15

Programming the Time and Date................................................................................................................ 15

DST (Daylight Saving Time)........................................................................................................................ 16

Camera Menu ................................................................................................................................................... 16

Configuring Camera Options ...................................................................................................................... 16

System Menu .................................................................................................................................................... 17

Enabling and Disabling the Program Preset Feature ................................................................................. 17

Changing Pin Numbers............................................................................................................................... 18

Setting Up Partitioning ................................................................................................................................ 19

Configuring Monitor Displays...................................................................................................................... 20

View Menu ........................................................................................................................................................ 21

Programming Views.................................................................................................................................... 21

Using a Keyboard to Recall Views.............................................................................................................. 22

Programming T ours..................................................................................................................................... 23

Linking T ours Together ................................................................................................................................ 24

Using a Keyboard to Recall Tours .............................................................................................................. 24

Cancelling a Tour ........................................................................................................................................ 25

Alarm Menu....................................................................................................................................................... 25

Configuring Global Alarm Settings.............................................................................................................. 26

Specifying Alarm Monitors .......................................................................................................................... 28

Configuring Alarm Inputs ............................................................................................................................ 28

Configuring Auxiliary Outputs ..................................................................................................................... 29

Creating Responses ................................................................................................................................... 30

Mapping Responses to Alarms................................................................................................................... 31

1

MegaPower LT

Mapping Responses to Events ................................................................................................................... 32

Programming an Alarm: A Summary .......................................................................................................... 33

Installer Menu ................................................................................................................................................... 34

Configuring System Options ....................................................................................................................... 34

Assigning Keyboard Priorities..................................................................................................................... 35

Running a Dome Ping................................................................................................................................. 36

Vertical Phase Synchronisation .................................................................................................................. 37

Saving and Restoring Defaults ................................................................................................................... 37

APPENDIX A: FACTORY DEFAULTS ............................................................................................................. 38

APPENDIX B: PASSWORD RECOVERY........................................................................................................ 40

APPENDIX C: SPECIFICATIONS.................................................................................................................... 41

APPENDIX D: ALARMS................................................................................................................................... 42

APPENDIX E: KEYBOARD INST ALLA TION ADDENDUM............................................................................. 43

APPENDIX F: CONNECTION DIAGRAMS ..................................................................................................... 46

2

Chapter 1: Layout and Installation

This chapter describes the layout of the MegaPower LT. It also describes the procedure

that should be followed to unpack, mount, connect and install the unit.

Layout and Connections

The MegaPower L T is a matrix to which video sources and monitor can be connected. By

connecting a keyboard to the MegaPower LT, the matrix can be used to manage the

display of the video sources on the monitors.

Alarm inputs and auxiliary outputs can also be connected to the MegaPower L T, and their

operation can also be controlled using a connected keyboard.

The MegaPower LT stores a menu system through which all connected devices can be

configured.

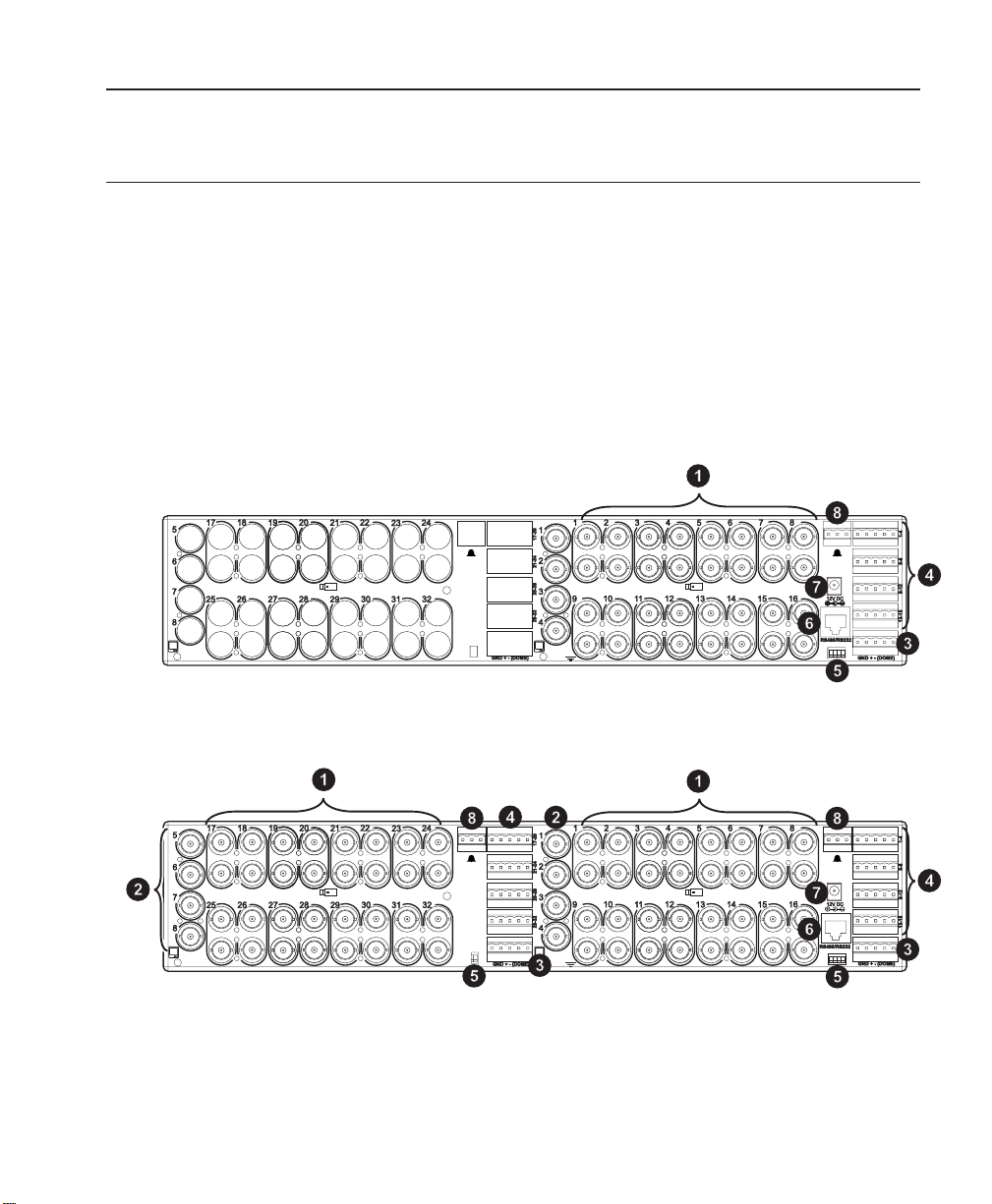

MegaPower LT (16x4)

Matrix Installation and Operation

MegaPower LT (32x8)

3

MegaPower LT

Video Inputs

The 32x8 unit has 32 video input connections. The 16x4 unit has 16 video input connections.

They are BNC loop-through connectors with automatic termination. Each connector is

labelled on the unit.

Video Outputs

The 32x8 unit has 8 video output connections. The 16x4 unit has 4 video output connections.

Connect output connector 1 to monitor 1, output connector 2 to monitor 2, etc. Each

connector is labelled on the unit.

Dome Control

The unit has a connection for RS485 Sensornet dome cameras. Up to 32 dome cameras

can be looped from this connection. See page 7 for more details.

Alarm Inputs

The alarm input connectors are of a plug assembly type. Each plug has one ground

connection and four alarm input connections. The MegaPower L T 32x8 can have up to 32

alarm inputs while the MegaPower LT 16x4 can have up to 16. See page 9 for more

details.

Dip Switches

These dip switches are used for RS485 network and dome camera control biasing and

termination. See page 10 for more details.

Remote Keyboard

The unit can be connected to RS232 and RS485 remote keyboards via a RJ45 connector.

It provides an upload/download function for UTC and matrix devices.

Power Connection

The unit is powered via the supplied UL listed, class 2 LPS 12V DC power supply. Cable

retention is provided.

Auxiliary Outputs

The auxiliary output connector is of a plug assembly type. There are a maximum of two

voltage-free output relays available, providing normally-open and normally-closed contacts

(maximum rating 24V, 2A resistive load). See page 9 for more details.

IMPORT ANT NOTE

In the event of power interruption, the MegaPower L T will lose current camera and monitor

selections and revert to its default settings upon reconnection of the supply.

All monitor and camera pairings must be re-entered if required. However, any tours or

views that were active do not need to be re-entered as they will restart.

If this recovery action is not sufficient for the application, it is recommended that the unit

and its associated equipment is supplied from a secure and uninterruptible power supply .

4

Unpacking

Matrix Installation and Operation

The packaging should contain the following items. Check all product codes on the label.

If you have an incorrect item or it is damaged then inform your supplier and the carriers

immediately. If the equipment is incorrect or damaged, do not attempt to use it.

• The MegaPower LT unit

• MP-PSU power supply unit

• UK cable and plug - plug to BS1363 fitted with a 3 Amp standard fuse and IEC C7

• USA cable and plug - UL listed 18 AWG SPT cable with USA NEMA 1-15 P plug and

IEC C7

• Standard mainland European cable and plug - UL listed 18 AWG SPT cable with 2

pin EUROPLUG EN 50075 2.5 A 250 Volt plug and IEC C7

• 7 foot/2 meters long category 5 connecting cord terminated with RJ45 connectors

(MP-CBL)

• Two mounting brackets with screws

• These instructions and a CD holding the manual in other languages

• ADCC0200 keyboard (ADMPLT16C2 and ADMPLT32C2 only)

• ADCC0300 keyboard (ADMPLT16C3 and ADMPLT32C3 only)

Kits are available (ADCCACPSN and ADCCACPSP) when multiple network keyboards

are used. This kit includes:

• MP-KMI Keyboard Matrix Interface

• 7 foot/2 meters long category 5 connecting cord terminated with RJ45 connectors

(MP-CBL)

• MP-PSU power supply unit

For multiple network keyboard installations, Belden network cable (Belden 8761 or

equivalent single twisted pair, screened, 22 AWG) may be required. This is to be provided

by the installer.

Installation Guidelines

Installation of all CCTV equipment is to be carried out to national or international electrical

codes. For a more detailed reference, refer to:

• United States - National Fire Protection Association (NFP A70), United S tates National

Electrical Code.

• Canada - Canadian Electrical Code, part 1, CSA C22.1.

• Other Countries - International Electromechanical Commission (IEC) 60364, Part 1

through Part 7.

5

MegaPower LT

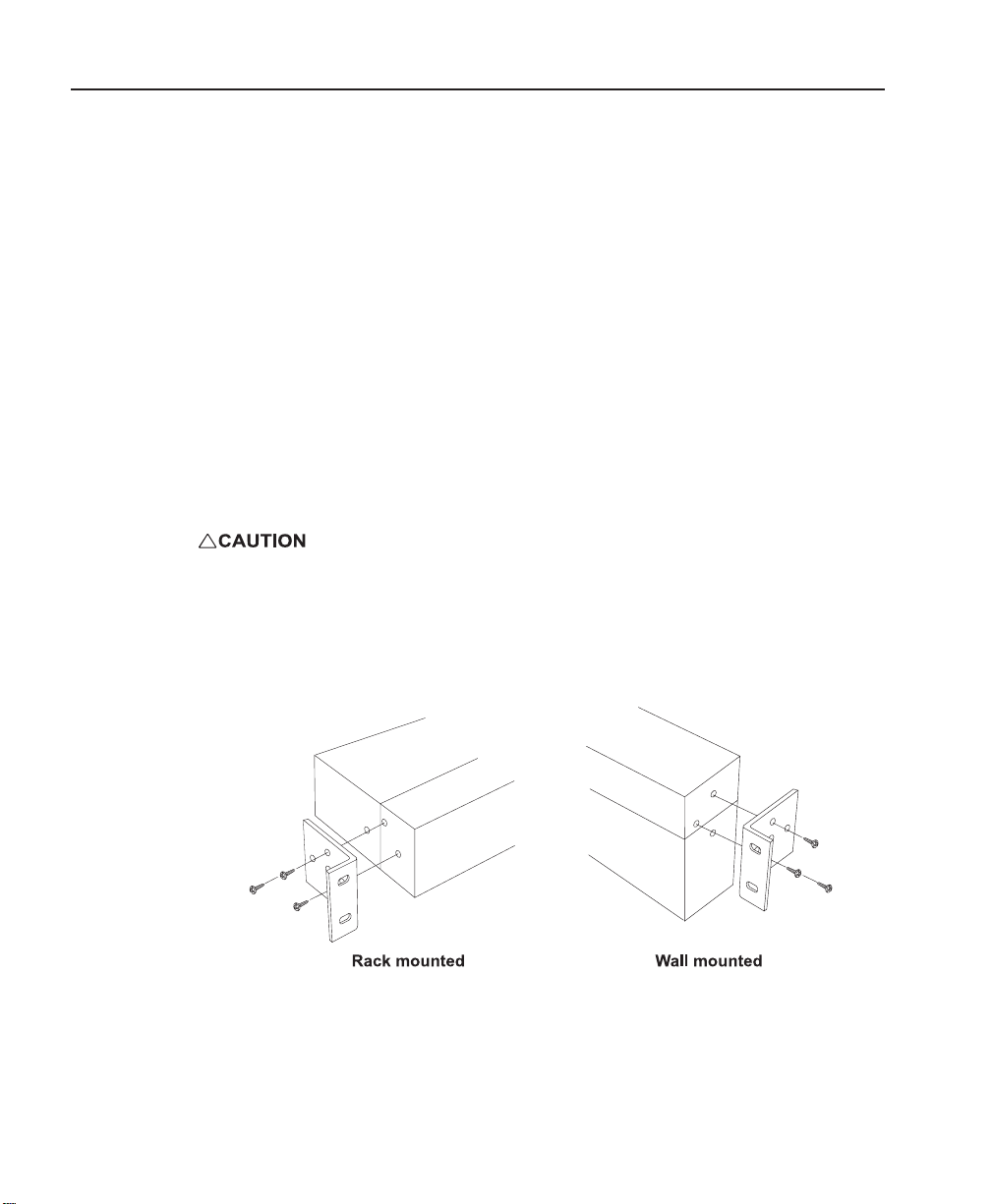

Mounting the Unit

All models of the MegaPower L T unit are equipped with mounting holes and are supplied

with screws and brackets for the optional fitting to a suitable rack or wall. Should the unit

be mounted, particular attention should be paid to ensure that the specification of the

equipment is not compromised. In particular , airflow, access, power isolation, weight and

any possible contamination should be considered, as should the potential for any abuse

that may lead to an operational malfunction or safety violation.

When choosing a suitable location for the unit, ensure:

• An electrical output socket with overload and short circuit protection is located within

a suitable distance for the included MP-PSU power supply.

• The power supply cord cannot become pinched or trapped under a heavy object.

The power cord should be routed so that it is not likely to be walked on.

When fixing the MegaPower LT into a either a 19” rack or onto a wall:

1. Fix the mounting brackets with the screws supplied. See the diagrams shown below

for guidance.

2. Screw the bracket mounted MegaPower LT into a either a 19” rack or onto a wall.

• Screws used to fix the MegaPower L T into either a 19” rack or onto a wall must be of

a suitable size and strength.

• When fixing the MegaPower L T onto a wall, the wall must be durable enough to t ake

the weight of the unit.

6

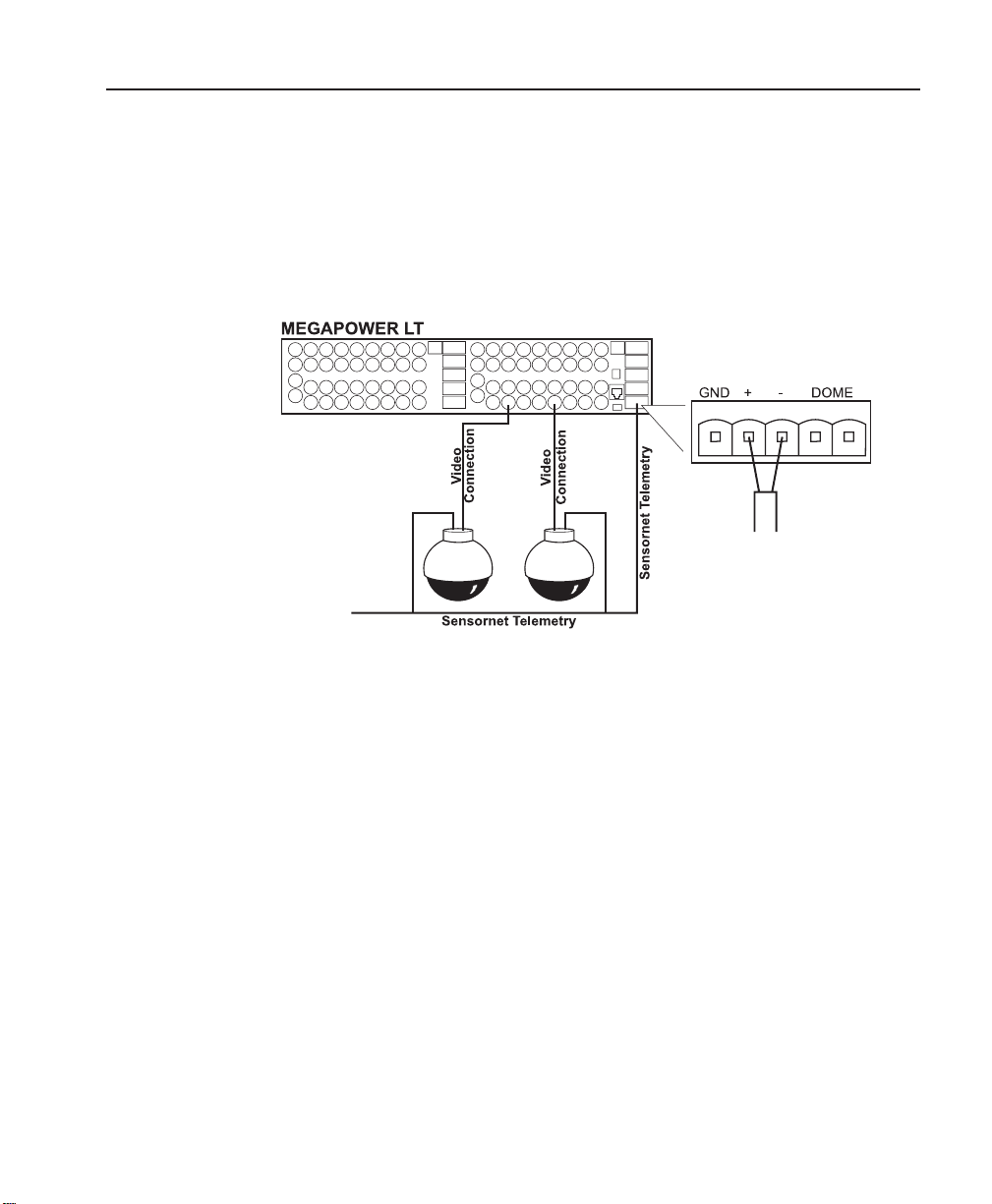

Sensornet Dome Connections

Video inputs that use UTC (AD Up-the-Cable) communication protocol communicate with

the MegaPower LT through the video BNC connection. However, video inputs using

Sensornet telemetry control (i.e., typically Sensornet dome cameras) require a second

connection. For this reason, a telemetry connection is provided for Sensornet dome

cameras (two on MegaPower LT 32x8).

Connect Sensornet dome cameras to the MegaPower LT as shown in the figure below.

Up to 32 data connections can be looped from this connection.

Matrix Installation and Operation

NOTES

• The distance from the MegaPower LT to the last dome must not exceed 3300 feet/

1000 meters. If star wiring is used, this distance will be greatly reduced.

• It may be necessary to terminate the dome control connection using a dip switch on

the MegaPower LT. See page 8 for more details.

• Sensornet dome cameras must be addressed in the menu system. See page 16 for

more details.

Sensornet Termination and Wiring

The following rules must be observed when working with a SensorNet network:

1. Each Sensornet link has a maximum length of 3300 feet/1000 meters (using A WG 22

unshielded twisted-pair cable).

2. There can be a maximum of 32 devices in each Sensornet link.

3. There can be a maximum of 4 repeaters in the path of any 2 devices in a network.

4. In a backbone network configuration, there must always be 2 terminations, one at

each end of the network.

5. In a star network configuration, there must be no more than 4 terminations.

6. Receivers on SensorNet devices will operate satisfactorily at signal levels between

5V and 0.3V (differential peak-to-peak).

7

MegaPower LT

SensorNet Backbone Network Configuration

SensorNet Star Network Configuration

8

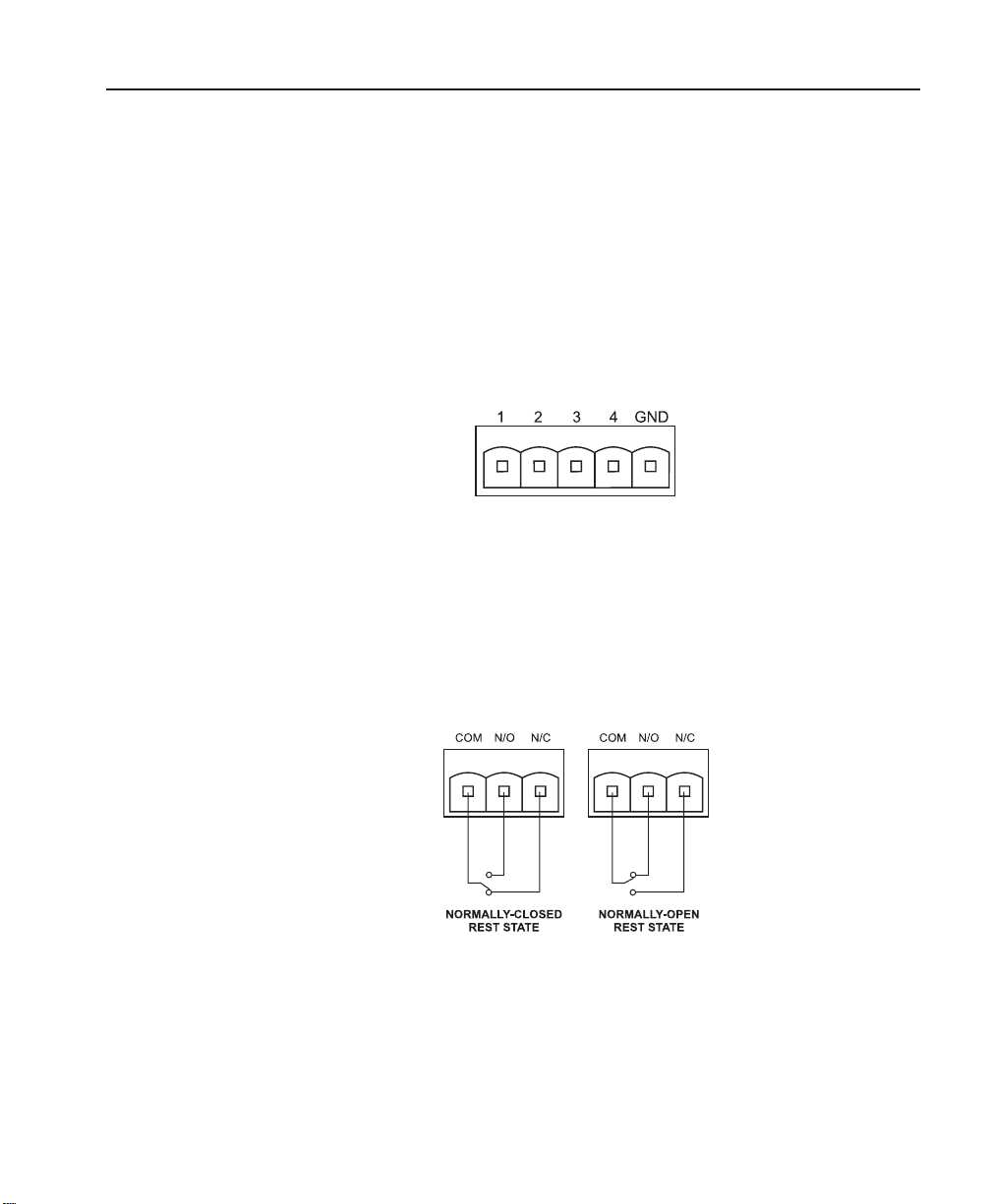

Alarm Input Connections

Each model of MegaPower LT has the same number of alarm inputs as camera inputs.

The alarm inputs are located on removable five way-terminal blocks, with each plug holding

four alarm input connections and one ground connection. The MPLT senses physically

connected alarms (via dry contacts). These inputs can be individually configured in the

menu system as normally-open or normally-closed contacts.

To connect alarm inputs:

1. Remove the required five-way terminal block.

2. Connect each terminal to an alarm relay, with connections made as labelled in the

diagram below:

3. Group the returns and lead them into the ground connection.

4. Return the five-way terminal block to its position on the MegaPower LT.

In the menu system, the alarm input connections are normally-closed by default. If

connecting normally-open alarms, ensure that the alarm input sense is re-configured in

the menu system (see page 34).

Auxiliary Output Connections

MegaPower LT 16x4 models have one auxiliary output and MegaPower LT 32x8 models

have two. T o connect an auxiliary output, remove the three-way terminal block and connect

alarm or auxiliary equipment in one of the relay configurations shown below:

Matrix Installation and Operation

The auxiliary output will operate in the rest state until it is triggered, at which point it will

switch to the active state. Once connected, an auxiliary output can be added to alarm

responses in the menu system so that when an alarm or event occurs, the auxiliary output

will switch to the active state (see page 35).

9

MegaPower LT

Dip Switch Settings

Keyboard Dip Switches

Keyboard have built in network termination and biasing. For most small to medium sized

installations, it should not be necessary to change the switches from their default settings.

Large installations may require network biasing and/or terminating. Please refer to your

keyboard handbook for details.

MegaPower LT Dip Switches

The MegaPower LT dip switches are used for RS485 network and dome camera control

biasing and termination. For most small to medium sized installations, it should not be

necessary to change the switches from their default settings. Large installations may

require network biasing and/or terminating. The default setting for all four switches is OFF

(down).

There is one dome control dip switch to be set on the MegaPower LT 16x4, but the user

must set two dome control dip switches on the MegaPower LT 32x8.

Network Setting Switch 1 Switch 2 Network Setting Switch 3 Dome Control Switch 4

Biased ON ON Terminated ON Terminated ON

Not Biased OFF OFF Not Terminated OFF Not Terminated OFF

Setting the Keyboard ID

Before a user can program the MegaPower LT using the built-in menu system, the

connected keyboard must be given an ID and the baud rate must be set correctly. Each

keyboard in the system needs to have a unique ID. ID’s are from 1 to 8, with ID 1 having

the highest priority. To change the ID of a connected keyboard, follow the steps below:

1. Connect the power to the keyboard.

2. Within 5 seconds of connecting the power, press the SHIFT (

( ) keys simultaneously.

3. The LCD display on the keyboard will display:

Special Config

4. Within 5 seconds, press the REVERSE PLAY (

5. At the "Enter keyboard address" prompt, use the number keys to enter the keyboard

address required (default is 1).

6. Press the ENTER key.

7. Move on to Setting the Keyboard Baud Rate.

) and MENU ESCAPE

) key.

10

Setting the Keyboard Baud Rate

The current keyboard baud rate setting can be seen when the keyboard is powered up.

Optimum performance of the MegaPower LT is achieved by setting the keyboard baud

rate to 19200. To change the baud rate of a connected keyboard, follow the steps below:

1. Connect the power to the keyboard.

2. Within 5 seconds of reconnecting the power, press the SHIFT (

ESCAPE (

3. The LCD display on the keyboard should display:

Special Config

4. Within 5 seconds, press the REWIND ( ) key.

5. At the "1=RS485 2=RS232" prompt, select the required mode and then press the

ENTER key. It should be noted that the default is RS485.

6. The LCD display will show the first baud rate options. Use the 0 key to toggle through

the available options.

7. Press the number key for the desired baud rate.

NOTE

Reducing the baud rate from the optimum setting will reduce the number of keyboards

that can perform telemetry operations at any one time.

) keys simultaneously.

Matrix Installation and Operation

) and MENU

11

MegaPower LT

Chapter 2: The Menu System

The menu system is used to program the MegaPower L T as required using the keyboard.

This chapter give details about how to use the menu system. Menu operation and navigation

is documented for RS485 keyboards. RS232 keyboard functionality may differ.

Status Levels

There are three different user status levels, two of which have access to the menu system.

Operator – only operates the system. No menu access allowed.

Supervisor – is able to modify settings within the Supervisor menu.

Administrator/Installer – has access to all menu items.

Menu Navigation

A keyboard joystick can be used to navigate the menu system. In general, a menu item is

selected and edited as follows:

1. Use Joystick Up/Down movements to move between menu items. The currently

selected menu item will flash.

2. Use the ENTER key or Joystick Right to select a menu item.

3. In the resulting screen, use:

• The Joystick Up/Down movement to move through the menu items in a screen.

• The Joystick Left/Right to toggle through and select the options for a menu item.

• The numerical keys to input numerical data.

• The SHIFT (

change between capital letters and lower-case.

• The MENU ESCAPE (

) key held down whilst using Joystick Up/Down movements to

) key to return to the previous menu.

NOTES

• When menu items are being edited, automatic functions (e.g. alarms and tours)

cease operating.

• Menus can be displayed on any monitor, however only one monitor can display the

menus at once.

• Any operation calling for the use of the SHIFT (

down whilst another key is pressed. This is the same way in which the SHIFT key

operates on a PC keyboard.

• When making changes in a screen, use the Joystick Down command to scroll through

the fields, completing each one in turn. Scrolling back up the screen after changes

have been made will cause the changes to be lost.

12

) key requires this key to be held

Entering the Menu System

To enter the menu system, follow the steps below:

1. Select a monitor by entering the monitor number and pressing the MONITOR (

key.

2. In multi-matrix networks it is also necessary to select a unit. To do this, enter the

address of the unit, then hold down the SHIFT (

) key.

(

3. Press the SHIFT ( ) key and the MENU ( ) key together.

4. A screen will be displayed prompting for a password.

5. Enter the pin number using the numerical keys.

The factory default pin numbers for the:

• Supervisor menu is 0, 0, 0, 0.

• Administrator menu is 1, 7, 7, 6.

PIN INVALID is displayed if an incorrect pin number is entered.

Once the pin number has been correctly entered, the Administrator menu or Supervisor

menu is displayed.

NOTES

• It is strongly advised that you change the default passwords as soon as possible in

order to maintain system security. See page 18.

• If a password is lost, a recovery system is available. See Password Recovery on

page 46.

• Only RS-485 Mode will provide different User Levels, i.e.: Admin, Supervisor, etc.

RS-232 Keyboards (ADCC300 & ADCC1100 enter MPLT Menus w/o Password.

(Keyboard Password required for security).

RS-232 Keyboard (ADCC200) does not allow MPLT Menu Entry.

Matrix Installation and Operation

)

) key and press the SITE SELECT

Pin Validation

Enter Pin _ _ _ _

13

MegaPower LT

Saving and Exiting

It is important to know how to save changes in the menu system before they are made.

To save changes to the menu system, follow the steps below:

1. Select the Return to option at the bottom of each screen until the Administrator

menu or Supervisor menu is displayed.

2. Select the Exit Menu option at the bottom of the screen to enter the Exit menu (see

figure above).

3. Either:

• Select Save and exit to save changes made and then exit the menu system.

• Select Exit without saving to exit the menu system without saving the changes

Exit Menu

Save and exit

Exit without saving

Return to Menus

made.

If the menus are left idle for 180 seconds or over the menu will time out without saving.

Administrator and Supervisor Menus

Users with Administrator status level have access to alarm and installation features as

well as all the functions available to the Supervisor.

Administrator Menu

1 Time/Date Menu

2 Camera Menu

3 System Menu

4 View Menu

5 Alarm Menu

6 Installer Menu

Exit Menu

Supervisor Menu

1 Time/Date Menu

2 Camera Menu

3 System Menu

4 View menu

Exit Menu

14

Time/Date Menu

The Time/Date menu is used to program the time and date, and to select whether daylight

saving time should be implemented in the system.

Programming the Time and Date

To program the time and date, follow the steps below:

1. In the Supervisor menu or Administrator menu, select the Time/Date Menu option.

2. In the Time/Date menu, move to the Time format option.

3. Use the right joystick command to select 24H or 12H. Note that in 12 hour format,

4. Move to the Date format option.

5. Use the right joystick command to select mmddyy, ddmmyy or yymmdd. The default

6. Move to the Set time option. The hours parameter is automatically selected.

7. With the hours parameter selected, use the number keys to enter the desired hour in

8. Move to the Set date option.

9. Use the numeric keys to enter the day, month and year . Use the right joystick command

10.When the required changes have been made, select the Apply new time and date

11.To leave the menu, select the Return to Menu option.

Matrix Installation and Operation

1 Time/Date Menu

1.1 Time format :12H

1.2 Date format :mmddyy

1.3 Set time :12:00:00

1.4 Set date :21:06:02

1.5 DST :FORWARD

Apply new time and date

Return to Menu

a.m. times are displayed 09.54 AM and p.m. times are displayed 09.54 PM.

is mmddyy.

a two digit format, i.e. 02, 13, etc. Advance the cursor to the minutes parameter

using the right joystick command and then use the number keys to input the minutes.

The time in this field should always be entered in 24 hour format regardless of how

the time will actually be shown on-screen

to move between each part of the date. The date should be entered in the format that

is currently selected in the Date format field.

option.

15

MegaPower LT

DST (Daylight Saving Time)

The DST menu item is used to select BACK or FORWARD on the day prior to the time

change. The system will then put the clock back or forward by an hour the next time the

time reaches 2 a.m. After the time change has been made, the DST option then

automatically resets to NONE.

NOTE

The unit has a battery-backed clock that retains the correct time, date and all other

programmed data in the event of a loss of power.

Camera Menu

The Camera menu is used to:

• Give each camera input a title.

• Inputs can be enabled or disabled. Disabling the video input will disable camera

• Define the communication type that will be used with each input.

selection from a keyboard.

2 Camera Menu

Input number C1

Title

CAMERA 01

Input :ENABLE

Communication :UTC

Physical address :891

Channel :A

Return to Menu

Configuring Camera Options

To configure camera options, follow the steps below:

1. In the Supervisor menu or Administrator menu, select the Camera Menu option.

2. In the Camera menu, move to the Input number option.

3. Using the number keys, enter the number of the video input to be edited.

4. Move to the Title option. Press enter key to to start editing camera title. Press enter

key when editing is complete.

5. Use the joystick to amend the title. To do this, select the character to be edited using

left/right joystick commands and edit the selected character using up/down joystick

commands. Use the SHIFT (

to change between upper and lower case characters.

6. Move to the Input option.

7. Use the right joystick command to either Enable or Disable the camera video input.

) key in conjunction with up/down joystick commands

16

System Menu

Matrix Installation and Operation

8. Move to the Communication option.

9. Use the right joystick command to select either OFF, UTC, SNET or SNET-V (for

SDU7 and above). Select UTC when AD Up-the-Cable (UTC) protocol is to be used

to communicate with the camera input or select SNET where Sensornet telemetry

control is to be used. Select OFF if the input does not use either of these

communication protocols.

10.If the Communication option is set to SNET, it is necessary to set an address for the

video input in the Physical Address field. The address that is entered must match

the input's local address (e.g., the address set inside the dome camera). It does not

need to match the video input number.

If the Communication option is set to UTC, the Physical address field will be disabled

and the address is automatically set to 891. Note that if a connected dome camera

is using UTC communication, the dome camera address must be set locally to 891.

11.The Channel option is only enabled when the Communication option is set to SNET.

This field should be set to A for MPLT 16 or A and B for MPLT 32. Verify that the

dome data connection is made to the correct port on the rear of the MPLT.

12.Once amendments are complete, select the Return to Menu option.

NOTES

• Video loss can only be reported on the selected camera.

• The feature will disable automatically if the video signal is changed.

The System menu is used to change pin numbers, set up partitioning and to configure

monitor displays. It is also used to enable and disable the Program Preset feature.

3 System Menu

3.1 Change Pins

3.2 Partitioning

3.3 Monitor Display

3.4 Program Preset :YES

Return to Menu

Enabling and Disabling the Program Preset Feature

The Program Preset feature allows the installer the restrict users from altering preset

positions once installation has been completed.

To enable or disable the Program Preset feature, follow the steps below:

1. In the System menu, use the up/down joystick to move to Program Preset.

2. Use the right joystick command to enable (select Yes) or disable (select No) the

Program Preset feature.

17

MegaPower LT

Changing Pin Numbers

The Change Pins screen is used to change administrator and supervisor pin numbers.

3.1 Change Pins

3.1.1 Change Supervisor

3.1.2 Change Administr

Return to System Menu

3.1.1 Change Supervisor

Current Pin ****

New Pin ****

Verification ****

To change a pin number, follow the steps below:

1. In the System menu, select the Change Pins option.

2. In the Change Pins screen, select either the Change Supervisor or Change

Administr option depending on which pin number is to be changed. The relevant

screen is displayed.

3. In the Current Pin field, enter the pin number that is currently used to gain access to

the menu system. The cursor automatically moves to the New Pin field.

4. Enter the new four-digit pin number. The cursor automatically moves to the

Verification field.

5. Re-enter the new pin number.

At this point, if all fields have been completed correctly , the pin number will be changed.

If an incorrect pin number has been entered at any point during the procedure (e.g.,

either the current pin number has been entered incorrectly or the entries in the New

Pin and Verification fields do not match), or if the user does not have the necessary

access privileges, an error message is displayed. At this point, the user will have to

press the ENTER key to return to the Change Pins screen.

NOTES

• It is strongly advised that the factory set default pin numbers are changed as soon

as possible in order to maintain system security. The default Installer pin number is

1776. The default Supervisor pin number is 0000.

• The Administrator can change both the Administrator pin number and the Supervisor

pin number. The Supervisor can only change the supervisor pin number.

• If a password is lost, a recovery system is available. See Password Recovery on

page 40.

18

Loading...

Loading...