Page 1

Service Procedures

for the Model 20 Dryers

(AD-20, SL20, CG20, D20, and

STI-8 Dryers GEN II)

ADC Part No. 450261

Page 2

Retain This Manual in a Safe Place for Future Reference

This product embodies advanced concepts in engineering, design, and safety. If this product is properly

maintained, it will provide many years of safe, efficient, and trouble free operation.

Only qualified technicians should service this equipment.

OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or specified in the installation

manual included with the dryer.

The following “FOR YOUR SAFETY” caution must be posted near the dryer in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline

or other flammable vapors

and liquids in the vicinity of

this or any other appliance.

We have tried to make this manual as complete as possible and hope you will find it useful. The manufacturer

reserves the right to make changes from time to time, without notice or obligation, in prices, specifications,

colors, and material, and to change or discontinue models. The illustrations included in this manual may not

depict your particular dryer exactly .

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence

ni d’autres vapeurs ou liquides

inflammables à proximité de cet

appareil ou de tout autre appareil.

IMPORTANT

For your convenience, log the following information:

DATE OF PURCHASE __________________________________________________ MODEL NO. ________________________

RESELLER’S NAME ______________________________________________________________________________________

SERIAL NUMBER(S) ______________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

Replacement parts can be obtained from your reseller or the ADC factory. When ordering replacement part s

from the factory , you can F AX your order to ADC at (508) 678-9447 or telephone your order directly to the ADC

Parts Department at (508) 678-9000. Please specify the dryer model number and serial number in addition

to the description and part number, so that your order is processed accurately and promptly.

IMPORTANT NOTE TO PURCHASER

Information must be obtained from your local gas supplier on the

instructions to be followed if the user smells gas. These instructions

must be posted in a prominent location near the dryer .

Page 3

IMPORTANT

You must disconnect and lockout the electric

supply and the gas supply or the steam supply

before any covers or guards are removed from

the machine to allow access for cleaning,

adjusting, installation, or testing of any equipment

per OSHA (Occupational Safety and Health

Administration) standards.

Please observe all safety precautions displayed

on the equipment and/or specified in the

installation manual included with the dryer .

Table of Contents

Part Locations and Removal ................ 4

Lower Front Panel Removal ......................................... 4

Upper Front Panel Removal ......................................... 4

Back Guard Removal ................................................... 5

T op Cover Removal....................................................... 5

Lint Box / Blower Assembly Removal........................... 5

Gas V alve Removal ...................................................... 7

Oven Removal .............................................................. 7

CAUTION

Dryer(s) should never be left unattended while in

operation.

“Caution: Label all wires prior to disconnection

when servicing controls. Wiring errors can cause

improper operation.”

«Attention: Lor des opérations d’entretien des

commandes étiqueter tous fils avant de les

déconnecter. T oute erreur de câblage peut étre

une source de danger et de panne.»

WARNING

Children should not be allowed to play on or near

the dryer(s). Children should be supervised if near

dryer(s) in operation.

Under no circumstances should the dryer door

switch(es), lint door/drawer switch(es), or heat

safety circuit(s) ever be disabled.

Tumbler Support Wheel Assembly Replacement ......... 8

Tumbler Alignment ....................................................... 9

Electrical Component Locations........ 10

Electrical Panel ......................................................... 10

Oven Contactor .......................................................... 10

Door Switch ............................................................... 10

Fire Suppression System Items and Sail Switch ........11

Direct Sp ark Ignition (DSI) Module ..............................11

Flame-Probe ...............................................................11

Flame-Probe Positioning.............................................1 1

Exhaust Probe, Exhaust Hi-Limit, and Lint Drawer

Switch........................................................................ 1 2

Rotation Switch ......................................................... 12

Belt Installation ................................... 13

The dryer must never be operated with any of the

back guards, outer tops, or service panels

removed. Personal injury or fire could result.

The dryer must never be operated without the lint

filter/screen in place, even if an external lint

collection system is used.

FOR YOUR SAFETY

Do not dry mop heads in the dryer . Do not use

dryer in the presence of dry cleaning fumes.

The dryers must not be installed or stored in

an area where it will be exposed to water

and/or weather.

The wiring diagram for the dryer is located in

the front electrical control box area.

Placing the Belt Back on the Motor Sheave............... 1 5

Page 4

Part Locations and Removal

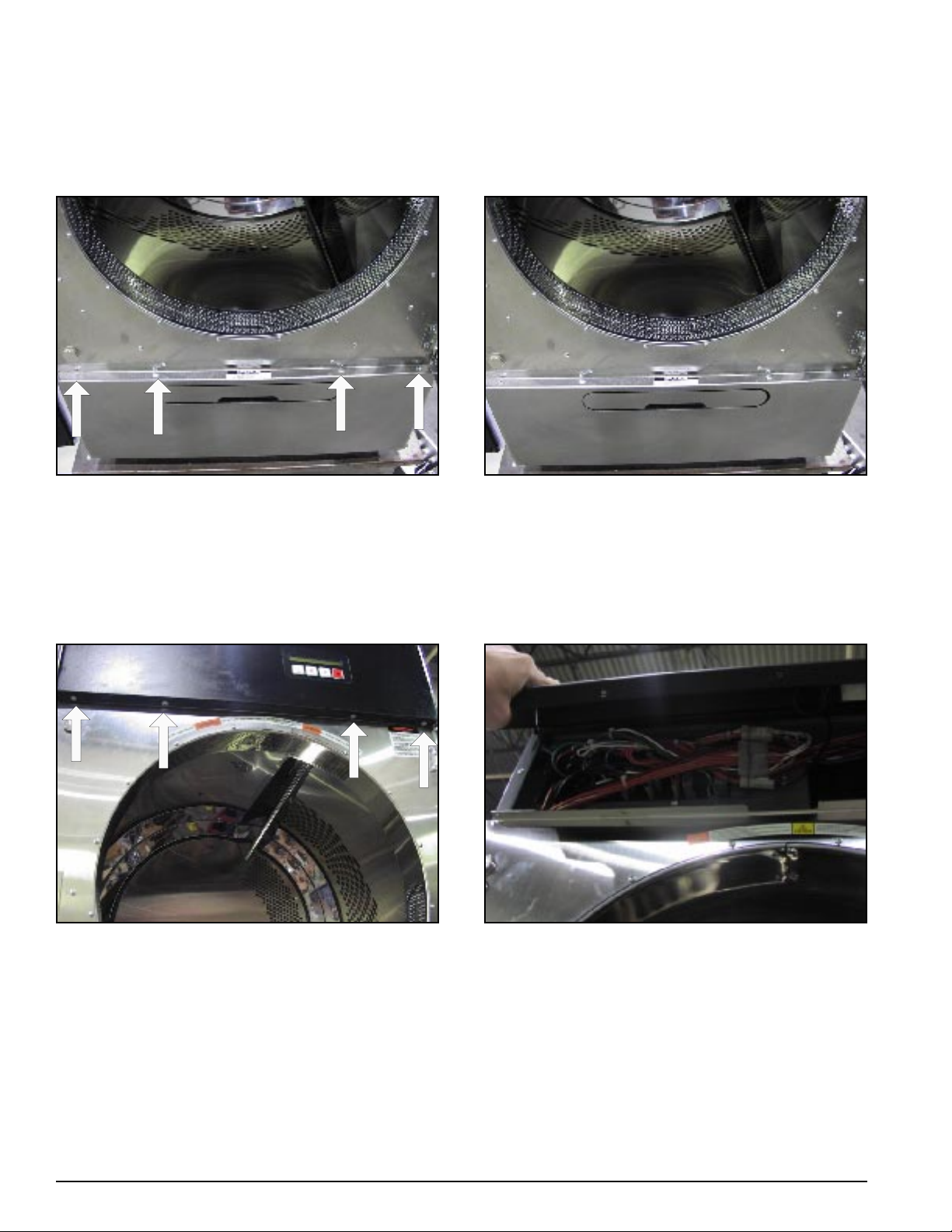

LOWER FRONT PANEL REMOVAL:

Remove the lint drawer. Remove the four screws located just below the loading door . Tilt the top of the panel

out and lift the panel up and away from the dryer.

UPPER FRONT PANEL REMOVAL:

Remove the four screws located just above the loading door. Tilt the bottom of the p anel out and lift the panel

up and away from the dryer.

4 American Dryer Corp. 450261-2

Page 5

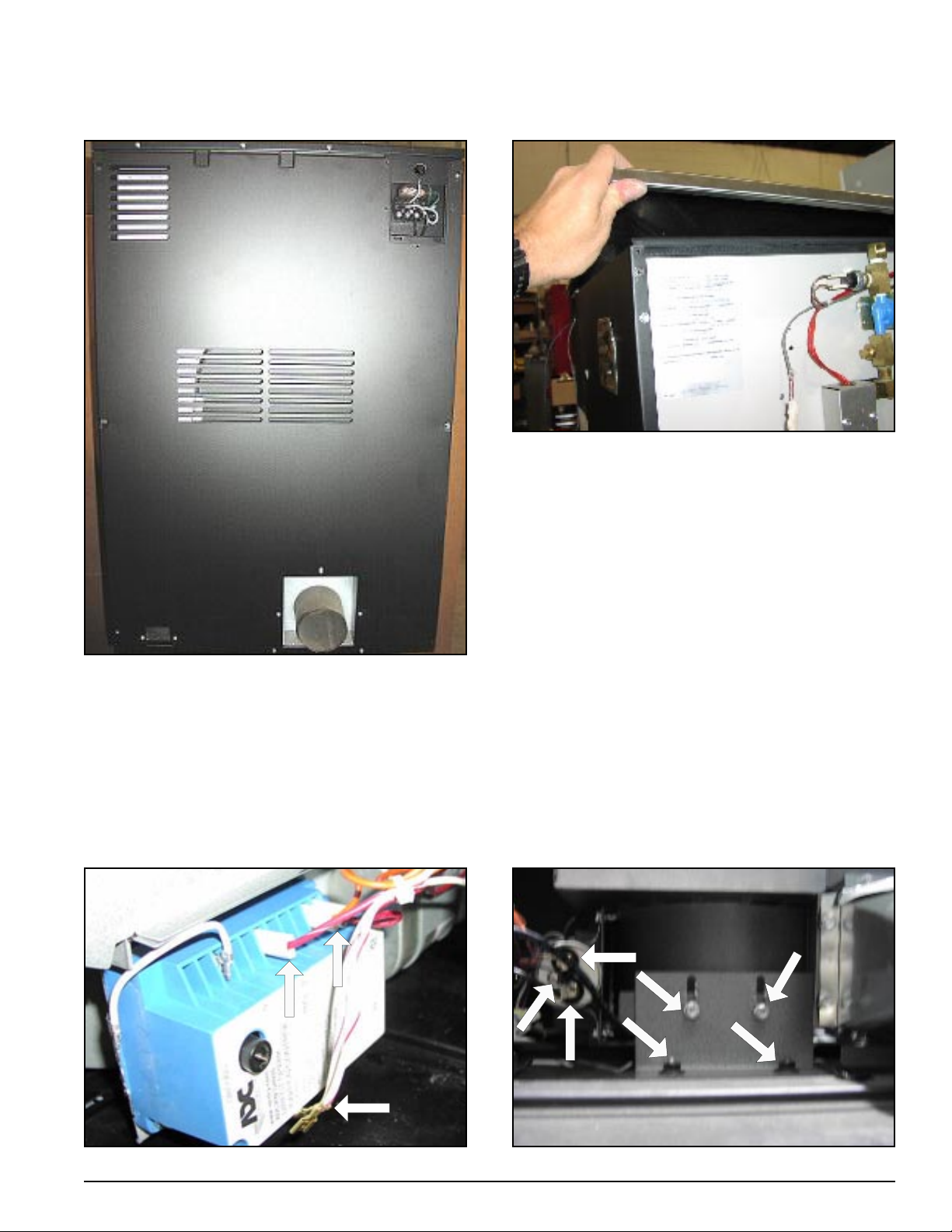

BACK GUARD REMOV AL:

TOP COVER REMOVAL:

Remove all facing visible screws.

With the back guard removed, the top is removed

by pulling it toward the rear of the dryer and up.

LINT BOX / BLOWER ASSEMBLY REMOVAL:

Unplug wires from Direct Spark Ignition (DSI)

module.

450261-2 www.amdry.com 5

Remove screws and nuts at the rear of the lint box.

Unplug wires from the capacitor.

Page 6

LINT BOX / BLOWER ASSEMBLY REMOVAL (continued):

Remove two screws just above the lint drawer.

Unplug three connections at the left of the lint box.

The lint box may now be pulled out through the front

of the dryer.

Pull the lint box down from the front and out slightly .

T o remove motorized impellor assembly , remove five

screws and four nuts shown at the arrows.

Lift off cover and pull motorized impellor assembly out through the opening.

6 American Dryer Corp. 450261-2

Page 7

GAS V AL VE REMOVAL:

OVEN REMOV AL:

Be sure to shut off the gas main and then proceed

to remove electrical connections and screws

indicated. Disconnect union and U-Bolt located just

behind the union and the oven base. The U-Bolt is

more easily accessed through the rear of the dryer.

The gas valve and burner orifice can now be pulled

out through the front of the dryer.

When reinstalling the gas valve be sure to align the

orifice with the opening in the burner tube bracket.

Misaligning and forcing valve inward can drive the

opposite end of the burner tube up against the

flame-probe elements.

The oven can be removed with or without the gas

valve in place.

Be sure to shut off the gas supply to the dryer . The

back guard, heat duct, and lower front panel must

be removed. Remove the gas valve electrical

connections and remove the lint box / blower

assembly. Remove the five screws (shown lower

right) that are holding the burner to the rear bulkhead.

Remove the two oven base nuts. With the lint box

out of the way , the oven can be tilted on its side and

pulled out through the front of the dryer.

Heat Duct

450261-2 www.amdry.com 7

Page 8

TUMBLER SUPPORT

WHEEL ASSEMBLY REPLACEMENT:

The front wheel assemblies can be replaced with

the lower front panel removed. Remove the three

bolts by reaching upward with a socket or box

wrench. The illustration on the right is provided to

show the location of these wheels as the wheels

cannot easily be seen while standing in front of the

dryer.

The left rear wheel assembly can be removed with

just the back guard removed. The rear right wheel

requires removing the back guard, heat duct, and

oven.

All wheel assemblies are mounted on slots to allow

for alignment of the tumbler. After one or more wheel

assemblies are replaced, the tumbler must be

realigned.

8 American Dryer Corp. 450261-2

Page 9

TUMBLER ALIGNMENT:

Proper alignment is achieved by making the gap

between the tumbler and openings in the front and

rear bulkheads equal on all sides.

The gap may be checked for accuracy by using a

thickness gauge.

Adjust the tumbler position by loosening the three

bolts and forcing the wheel assembly toward the

center of the dryer to raise the tumbler and to move

it away from the side. A large screwdriver can

provide the necessary leverage.

Adjustment of the front of the tumbler is made the

same as the rear. The gap on the top, bottom, left

and right are to be made equal by moving the wheel

assemblies.

EXAMPLES:

Below, both wheel assemblies must be moved to

the right in order to move the tumbler right. The left

wheel assembly must move a little more than the

right in order to lift the tumbler.

Below, both wheel assemblies must be moved

inward in order to move the tumbler straight upward.

450261-2 www.amdry.com 9

Page 10

Electrical Component Locations

ELECTRICAL PANEL:

The electrical panel is located behind the front upper panel.

F1

J11

T erminal

Block

A

B

C

Relay 3

Drive

Relay 2

Blower

Relay 1

Door Switch

P14

Transformer

25VAC

OVEN CONTACTOR:

Lower right front of the dryer (electric oven models).

Oven Contactor

J5

DOOR SWITCH:

On upper front panel.

Door Switch

10 American Dryer Corp. 450261-2

Page 11

FIRE SUPPRESSION SYSTEM ITEMS

AND SAIL SWITCH:

Rear of the dryer.

Water

Pressure

Switch

Solenoid

Valve

Sail

Switch

DIRECT SPARK IGNITION (DSI) MODULE:

Lower right front of the dryer to left of the lint box.

Thermistor Probe

FLAME-PROBE:

Under the gas oven and accessed from the rear of

the dryer.

Screw locations at arrows.

DSI Module

FLAME-PROBE POSITIONING:

Viewed from the rear of the dryer with heat duct

removed. Proper spark gap is approximately 1/8”

(3.175 mm) and is located 1/4” (6.325 mm) from

the rear of the left edge of the burner tube as shown.

(Guard against allowing elements to touch the burner

tube.)

NOTE: For clarity the illustration has the flame plate

normally located just after the flame sensing probe

removed.

Flame-probe spark gap

directly over the left

edge of burner tube

Flame-probe

element as shown

Correct positioning of the

flame-probe elements.

450261-2 www.amdry.com 11

Page 12

EXHAUST PROBE, EXHAUST HI-LIMIT,

AND LINT DRAWER SWITCH:

Temperature probe and exhaust hi-limit are

accessible once the lint box is removed. The lint

drawer switch can be removed after the cover has

been removed.

Exhaust Hi-Limit Switch

Exhaust Temperature Probe

ROTATION SWITCH:

Just behind the upper front panel, as viewed from

the rear of the dryer with top removed.

Lint Drawer Switch

Rotation

Switch

Magnet

Rotation

Switch

12 American Dryer Corp. 450261-2

Page 13

Belt Installation

REQUIRED ITEMS:

4 feet of Number 16 or 18 Electrical Wire

Duct Tape

Phillips Screw Driver

5/16” Nut Driver

Electrical Tape

3 foot Section of 1-1/2” Electrical Tubing

One 6-inch Cable Tie

Replacement Belt

Remove the back guard, front upper panel, and front lower panel. Cut the locking end off the plastic wire tie

and use a piece of electrical tape to secure the wire tie to one end of the 4-foot section of electrical wire

(Fig. 1).

FIG . 1

FIG . 2 FIG . 3

Push the wire tie between the tumbler felt and the middle front panel ring at highest position of the tumbler

(Fig. 2). The wire tie must exit beyond the top of the tumbler (Fig. 3). Be careful NOT to damage the rotational

sensor. Take hold of the end of the wire tie, pull it and the electrical wire attached to it until 2 feet of wire

remains hanging inside the tumbler (Fig. 4). Att ach the replacement belt to the end of the electrical wire still

hanging in the tumbler by making a loop in the wire and taping the loop closed with electrical tape (Fig. 5).

Squeeze the belt flat between your fingers (Fig. 6).

FIG . 4

FIG . 5 FIG . 6

450261-2 www.amdry.com 13

Page 14

Pull the belt up through the tumbler felt until there is enough belt to begin to loop the belt around the tumbler

(Fig. 7 and 8). Tape the belt to the outside of the tumbler with duct tape approximately 2-inches from the

outside edge of the tumbler (Fig. 9). Rotate the tumbler slowly in the clockwise direction, while pulling the end

of the belt to the right side of the dryer. Continue to rotate the tumbler clockwise and proceed to t ape the belt

to the outside of the tumbler occasionally , to aid in holding the belt in place (Fig. 10).

FIG . 7

FIG . 8 FIG . 9

Guide the belt over the top of the front right tumbler roller, while continuing to turn the tumbler clockwise (Fig.

1 1). The end will pass between the top of the lint box and the tumbler . Guide the belt over the top of the front

left roller (Fig. 12).

FIG . 10

FIG . 1 1 FIG. 12

Continue to turn the tumbler clockwise while feeding the belt out of the tumbler, until only a few inches are left

in the tumbler. Pull the remaining belt out of the tumbler into the area above the tumbler , until only a few inches

remain in the tumbler (Fig. 13).

FIG . 13

14 American Dryer Corp. 450261-2

FIG . 14

Page 15

Pulling the belt through the tumbler felt gap will tend to flip the felt. Before pulling the last few inches out of the

tumbler, lace the electrical wire back through the loop in the belt (Fig. 13 on the previous p age).

Pull the remaining belt and a couple of inches of wire out of the tumbler and into the area above the tumbler.

Slide the belt to the middle of the tumbler. With the electrical wire pulled tight (Fig. 14 on the previous p age),

rotate the tumbler one or two turns. This should flip the felt back to the original position. Feeling that the felt

is even all the way around the tumbler indicates the felt is back to original position. Remove the electrical wire.

The belt is now wrapped around the tumbler and ready for installation on the drive motor sheave.

PLACING THE BELT BACK ON THE MOTOR SHEAVE:

One proven method used to pull the belt back onto the sheave involves using a two foot length of electrical

conduit (Fig. 15). Preparing the end of the conduit as shown makes it easier to use. Position the belt around

the tumbler and directly above the motor sheave (Fig. 16). Insert the conduit through the belt and onto the

motor sheave (Fig. 17).

FIG . 15

FIG . 16 FIG. 17

While pushing the electrical tubing, pull the end toward the bottom right corner (Fig. 19). From this position,

rotate the conduit clockwise. The belt will move to a position over the motor sheave. Hold the belt against the

motor (Fig. 18). Rotate the conduit one more revolution while pulling the conduit out. The belt should drop

onto the motor sheave. Rotate the tumbler a few turns while manually preventing the belt from falling off the

sheave (Fig. 19). This should center the belt on the tumbler and prevent the belt from being thrown off later.

Replace all dryer panels.

FIG . 18

FIG . 19

450261-2 www.amdry.com 15

Page 16

ADC Part No. 450261 2 - 09/15/05 - 1

Loading...

Loading...