Page 1

Service Procedures

f or the

Model M31, M50, M75 Dry er

Hot Surface Ignitor Gas

American Dryer Corporation

88 Currant Road

Fall River MA 02720-4781 USA

T elephone: (508) 678-9000 / Fax: (508) 678-9447

e-mail: techsupport@amdry.com

www .amdry.com

Part No. 450280

Page 2

Retain This Manual in a Safe Place for Future Refer ence

This product embodies advanced concepts in engineering, design, and safety. If this product is properly

maintained, it will provide many years of safe, efficient, and trouble free operation.

Only qualified technicians should service this equipment.

OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or specified in the installation

manual included with the dryer.

The following “FOR YOUR SAFETY” caution must be posted near the dryer in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline

or other flammable vapors

and liquids in the vicinity of

this or any other appliance.

We have tried to make this manual as complete as possible and hope you will find it useful. The manufacturer

reserves the right to make changes from time to time, without notice or obligation, in prices, specifications,

colors, and material, and to change or discontinue models. The illustrations included in this manual may not

depict your particular dryer exactly .

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence

ni d’autres vapeurs ou liquides

inflammables à proximité de cet

appareil ou de tout autre appareil.

IMPORTANT

For your convenience, log the following information:

DATE OF PURCHASE ______________________________________________ MODEL NO. ____________________________

DISTRIBUTOR’S NAME ___________________________________________________________________________________

SERIAL NUMBER(S) ______________________________________________________________________________________

M31,M50,M75

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

For replacement parts, contact the distributor from which the dryer was purchased or contact:

American Dryer Corporation

88 Currant Road

Fall River MA 02720-4781 USA

Telephone: (508) 678-9000 / Fax: (508) 678-9447

e-mail: techsupport@amdry.com

www.amdry.com

“IMPORT ANT NO TE T O PURCHASER”

Information must be obtained from your local gas supplier on the

instructions to be followed if the user smells gas. These instructions

must be posted in a prominent location near the dryer .

Page 3

IMPORTANT

You must disconnect and lockout the electric

supply and the gas supply or the steam supply

before any covers or guards are removed from

the machine to allow access for cleaning,

adjusting, installation, or testing of any equipment

per OSHA (Occupational Safety and Health

Administration) standards.

Please observe all safety precautions

displayed on the equipment and/or specified in

the installation manual included with the dryer .

CAUTION

Dryer(s) should never be left unattended while in

operation.

T able of Contents

Part Locations and Removal ................4

Lower Front Panel Removal ......................................... 4

Upper Front Panel Removal ......................................... 4

T op Cover Removal....................................................... 4

Lint Box/Blower Assembly Removal............................. 4

Gas V alve/Ignition System Removal............................. 5

Gas V alve/Ignition System Components ...................... 6

Oven Housing Components.......................................... 6

Tumbler Support

Wheel Assembly Replacement .................................... 6

Tumbler Alignment ....................................................... 7

“Caution: Label all wires prior to disconnection

when servicing controls. Wiring errors can cause

improper operation.”

«Attention: Lor des opérations d’entretien des

commandes étiqueter tous fils avant de les

déconnecter. T oute erreur de câblage peut étre

une source de danger et de panne.»

WARNING

Children should not be allowed to play on or near

the dryer(s). Children should be supervised if near

dryer(s) in operation.

Under no circumstances should the dryer door

switch(es), lint door/drawer switch(es), or heat

safety circuit(s) ever be disabled.

The dryer must never be operated with any of the

back guards, outer tops, or service panels

removed. Personal injury or fire could result.

The dryer must never be operated without the lint

filter/screen in place, even if an external lint

collection system is used.

Belt Replacement ........................................................ 8

Placing the Belt ........................................................... 8

M31Belt Replacement.................................................. 9

Placing the Belt ........................................................... 9

Electrical Component Locations........10

Electrical Panel ......................................................... 10

Sail Switch and Axial Probe Assembly ...................... 10

Exhaust Probe, Exhaust Hi-limit,

and Lint Drawer Switch ...............................................11

FOR Y OUR SAFETY

Do not use dryer in the presence of dry

cleaning fumes.

The dryers must not be installed or stored in

an area where it will be exposed to water

and/or weather.

The wiring diagram for the dryer is located in

the front electrical control box area.

Page 4

Par t Locations and Removal

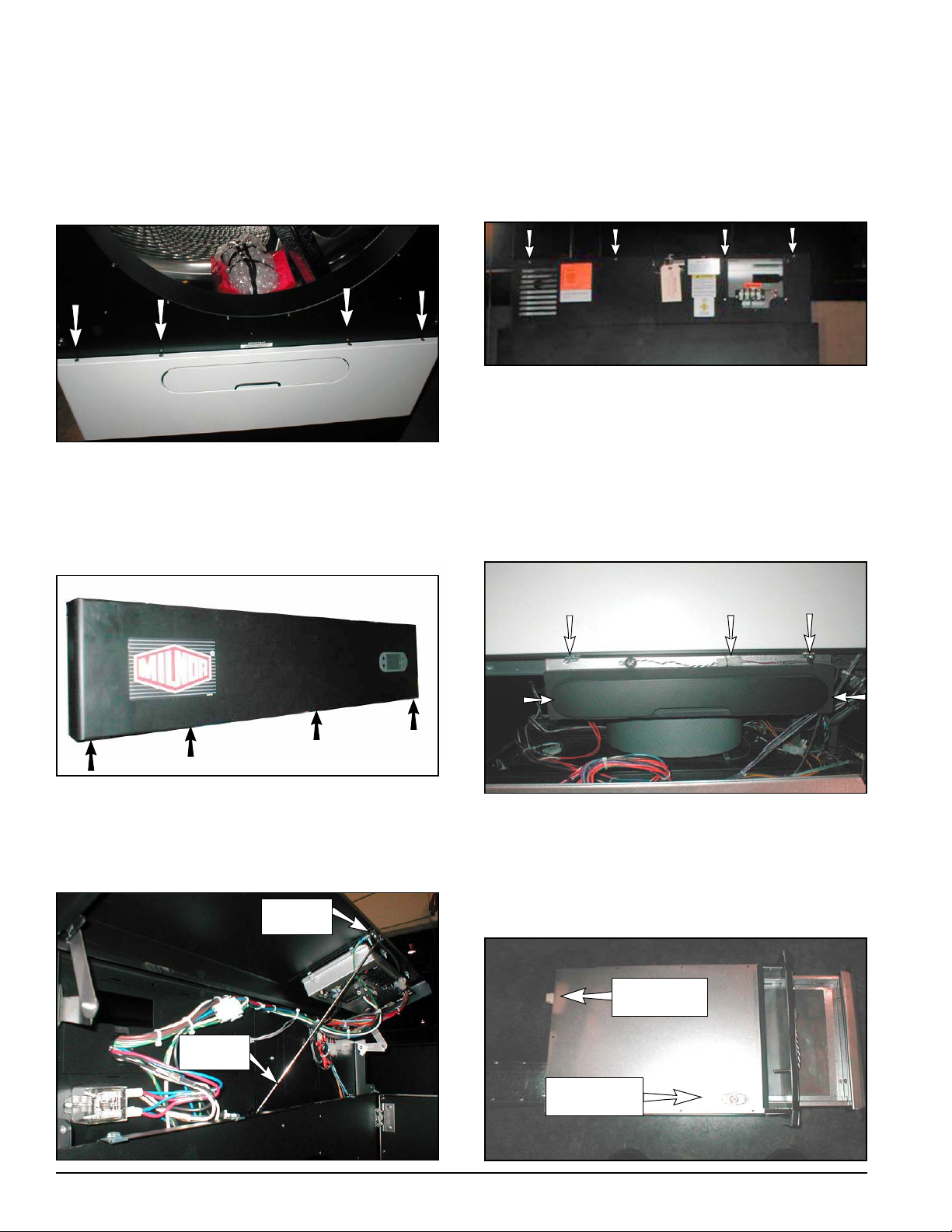

LOWER FRONT PANEL REMOVAL:

Remove the lint drawer. Remove the four screws

located just below the loading door. Tilt the top of

the panel out and lift the panel up and away from the

dryer.

For Models M31,M50,M75

UPPER FRONT PANEL REMOVAL:

Remove the four screws located just above the top

loading door. Tilt the bottom of the p anel out and lift

the panel up and away from the dryer .

For Models M31,M50,M75

TOP COVER REMOVAL:

First remove the back guard, the four screws holding

top cover. Next pull top cover toward the rear of the

dryer and lift up.

For Models M31,M50,M75

LINT BOX/BLOWER ASSEMBLY REMOVAL:

Unplug the motor harness.

For M31, remove two screws above the lint drawer.

For M50, M75, also remove two screws beneath the

gasket on the left and right side of the lint drawer.

Also, unplug the exhaust temperature probe.

Tilt the bottom of the panel out and lift the p anel up.

Align support rod into hole to support control panel.

Disconnect the electrical connections. Remove

screw from hinge to remove the control panel.

Unplug two connections on the exhaust hi-limit at

the left of the lint box. Also disconnect the two

connections for the lint drawer switch, located at the

back of the lint box. The lint box may now be pulled

out through the front of the dryer.

DOOR

SWITCH

SUPPORT

ROD

4 American Dryer Corporation 450 280- 1

For Models M31,M50,M75

LINT DRAWER

SWITCH

EXHAUST

HI-LIMIT

Page 5

GAS VALVE/IGNITION SYSTEM REMOVAL:

Be sure to shut off the gas main and then proceed

to remove electrical connections and screws

indicated. Remove lower front panel. Disconnect

union and screws noted with arrows.

By removing the top screws you will be able to

remove the burner tube. After, removing the top

burner, without damaging the Hot Surface Ignitor,

remove the whole gas valve assembly. Be careful

during assembly not to damage the Hot Surface

Ignitor. Replace assembly in the reverse order.

For Models M31,M50,M75

To remove motorized impellor assembly:

Remove the six hex nuts shown with arrows. Now

pull the blower motor assembly apart from the blower

housing. Remove the four phillips screws shown

with arrows and separate the motorized impellor

from the blower motor mount.

T o remove motorized impellor assembly , remove lint

housing cover, lint screen, and the four screws

shown with arrows. Pull the motorized impellor

assembly out through the opening.

Inspect all wires to be sure all lead directly toward

the front of the dryer. Be sure no wires are caught

on the burner tube or ignitor.

For Models M31,M50,M75

Gas Valve Ingnition System

450280-1 www.amdry.com 5

Page 6

GAS VAL VE/IGNITION SYSTEM COMPONENTS:

For Models M31,M50,M75

IGNITOR

BURNER TUBE

GAS VALVE

OVEN HOUSING COMPONENTS:

Dual Burner M50,M75

TUMBLER SUPPORT

WHEEL ASSEMBLY REPLACEMENT:

The front wheel assemblies can be replaced with

the lower front panel removed. Remove the three

bolts by reaching upward with a socket or box

wrench. The illustration below is provided to show

the location of these wheels as the wheels cannot

easily be seen while standing in front of the dryer .

For Models M31

OVEN CHAMBER

RADIANT

SENSORS

RADIANT SENSOR

HOT SURFACE

IGNITOR

BURNER HIGH-LIMIT

The left rear wheel assembly can be removed with

just the back guard removed. The rear right wheel

requires removing the back guard, heat duct, and

oven. Be sure to mark the position of rear wheel

brackets prior to removal (refer to photo right).

All wheel assemblies are mounted on slots to allow

for alignment of the tumbler. After one or more wheel

assemblies are replaced, the tumbler must be

realigned.

For Models M50,M75

GAS VALVE

HOT SURFACE

IGNITOR

6 American Dryer Corporation 450 280- 1

Page 7

TUMBLER ALIGNMENT:

EXAMPLES:

Proper alignment is achieved by making the gap

between the tumbler and openings in the front and

rear bulkheads equal on all sides.

The front to bulkhead may be checked for accuracy

by using a thickness gauge. The rear gap is not

accessible. Marking the position of the rear wheel

brackets before removing the brackets will help in

replacing the tumbler back into it’s original position

when the wheel brackets are reinstalled.

In the illustrations to the right, both wheel assemblies

must be moved to the right in order to move the

tumbler right. The left wheel assembly must move

a little more than the right in order to lift the tumbler .

Adjust the tumbler position by loosening the three

bolts and forcing the wheel assembly toward the

center of the dryer to raise the tumbler and to move

it away from the side. A large screwdriver can

provide the necessary leverage. Adjustment of the

front of the tumbler is made by equalizing the gap

on the top, bottom, left and right by moving the wheel

assemblies.

Below, both wheel assemblies are adjusted correct

and spacing is even on all sides.

450280-1 www.amdry.com 7

Page 8

BELT REPLACEMENT:

Shut off electrical power to the dryer. Lockout and

tag out supply voltages. Follow the steps to remove

front middle panel. Next you will remove either the

front bottom or front upper panel, depending on

pocket you are working on. Remove the belt from

the motor sheave. Next, remove the two screws

fastening the lint coupe to the front panel. Remove

the front panel screws, while holding up the

basket. Tilt the top of the front panel forward. Take

note of position of motor adjustment nut. Spin

counterclockwise to loosen tension. The old belt

can now be removed. Slide the new belt around

basket and push belt to a position close the motor

sheave.

PLACING THE BELT:

Now that the belt is close to the motor sheave (Fig.1),

make sure the motor pivot is at it’s highest point.

Wrap the belt under the motor sheave (Fig.2), then

push the belt over the idler wheel (Fig.3). Once this

has been accomplished make sure to spin the

basket by hand to self align the belt on motor sheave

and idler wheel. Tighten the motor adjustment nut

to position previous set.

FIG. 2

FIG. 1

FIG. 3

8 American Dryer Corporation 450 280- 1

Page 9

M31 BELT REPLACEMENT:

Shut off electrical power to the dryer. Lockout and

tag out supply voltages. Follow the steps to remove

front middle panel. Next you will remove either the

front bottom or front upper panel, depending on

pocket you are working on. Remove the belt from

the motor sheave. Next, remove the two screws

fastening the lint coupe to the front panel. Remove

the front panel screws, while holding up the

basket. Tilt the top of the front panel forward. Take

note of position of motor adjustment nut spin

counterclockwise to loosen tension. The old belt

can now be removed. Slide the new belt around

basket and push belt to a position close the motor

sheave.

PLACING THE BELT

BACK ON THE MOTOR SHEAVE:

Place belt installation tool (BIT -P/N 319582) over belt

(Fig. 1) and rotate in a clockwise direction. While

rotating run BIT under motor sheave (Fig. 2).

Continue to spin BIT , belt will then wrap under motor

sheave (Fig. 3). Remove BIT from dryer (Fig. 4).

Next, you want to rotate basket slowly to ensure it is

on the sheave completely. Tighten the motor

adjustment nut to position previous set.

FIG. 2

FIG. 3

FIG. 1

FIG. 4

450280-1 www.amdry.com 9

Page 10

Electrical Component Locations

ELECTRICAL PANEL:

The electrical panel is located behind the front middle

panel.

For Models M50,M75

DOOR SWITCH

COMPUTER

COVER

For Models M31

REVERSING

RELA Y

SAIL SWITCH AND AXIAL PROBE ASSEMBLY :

Located behind back guard. Access doors are

provided. Back guard does not have to be removed.

For Models M50,M75

BURNER

HIGH LIMIT

SAIL

SWITCH

AXIAL

PROBE

ROTA TIONAL

SENSOR

SWITCH

DOOR

SWITCH

COMPUTER

PANEL

COVER

For Models M31

AXIAL

PROBE

SAIL

SWITCH

10 American Dryer Corporation 450 280- 1

Page 11

EXHAUST PROBE, EXHAUST HI-LIMIT,

AND LINT DRAWER SWITCH:

Temperature probe and exhaust hi-limit are

accessible without the lint box being removed. The

lint drawer switch can be removed after the lint box

is and the cover has been removed.

LINT DRAWER SWITCH

TEMPERATURE

PROBE

EXHAUST

HI-LIMIT

Notes__________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

450280-1 www.amdry.com 11

Page 12

Part No. 450280 1-03/09/06 - 0

Loading...

Loading...