DR Series

PUSH BUTTON & AUTOMATIC STEEL HAND & HAIR DRYER TECHNICAL SPECIFICATIONS

DR-N, DR-NH Series

White, Push Button

The DR series push button and automatic hand and hair dryers offer exceptional construction, durability and performance. Our best selling series comes standard with a 10-year limited warranty. Options

include a stainless steel cover with satin finish, a fixed nozzle and recessed mounting.

PUSH BUTTON HAND DRYING PUSH BUTTON HAIR DRYING AUTOMATIC HAND DRYING ELECTRICAL RATINGS

Drying Drying Drying

Model Cycle Model Cycle Model Cycle Volts Amps Watts Hertz

DR10N 40 sec DR10NH 80 sec DR10TN Automatic 110-120 15 1725 60

DR20N 30 sec DR20NH 80 sec DR20TN Automatic 110-120 20 2300 60

DR30N 30 sec DR30NH 80 sec DR30TN Automatic 208-240 10 2300 60

DR50N 30 sec DR50NH 80 sec DR50TN Automatic 220-240 10 2300 50*

OPTIONS: Stainless Steel Cover is available on all models by designating (SS) after model number. * 50 Hz for export only.

Fixed Nozzle is an option on all models by designating (F) after model number.

Recess Mounted is available on all models by designating (R) after model number or order kit separately (specify color).

DR-TN Series

White, Automatic

FEATURES/MATERIALS:

• Cover

One piece industrial drawn 16 gauge rein-

forced steel or 18 gage reinforced type 304

stainless steel satin finish.

• Finish

Electrostatically applied white enamel or

stainless steel satin finish. Resistant to chipping and cleaning agents.

• Tamper-Resistant

One tamper-resistant screw and a 3” steel

latch, lock cover securely to base. Air intake

vents, internal shield and side mounted

heating element are for additional safety.

Nozzle & Push Button

•

Chrome plated zinc die castings. 360˚ revolving

nozzle is standard. A fixed nozzle is optional on

all models.

Nameplate

•

Indented and uses universal graphics.

DR-NSS, DR-NHSS

Stainless Steel,

Push Button

DR-TNSS Series

Stainless Steel,

Automatic

DR-TNSSR Series

Stainless Steel,

Automatic, Recessed

MECHANISM:

Motor

•

Instant starting, maintenance-free, brushless motor. 1/10

HP, 3200 RPM, with self lubricating bearings. Protected by

an automatic resetting circuit breaker. Our motor requires

no fuses, oiling or brush replacement - 100% maintenance-free. Has considerably more life and quieter operation than competition using brush type motors.

Timer

•

Push button models use a heavy duty cam-operated timer.

Sealed for protection and has positive stop action. Turn on

with a light touch. Turns off automatically.

Automatic Sensor

•

Automatic models are activated by a 100% solid state

infrared sensor, which automatically turns dryer on and

off. Only runs, when hands are below nozzle, for a maximum of 80 seconds. Sanitary and energy efficient. Has

over 10 times more life than competitor’s using mechanical relay switching.

Heating Element

•

Side mounted for safety and runs in black heat range for

longer life. Element is not accessible through nozzle and is

protected by an automatic resetting circuit breaker (thermostat). It produces an air temperature of 130-145˚F at

a 72˚F ambient room temperature.

Architect’s Specifications

The dryer shall be manufactured by American Dryer to

include a 16 gauge reinforced steel cover with a white

enamel finish or 18 gage reinforced stainless steel cover

with satin finish. Recessed units will include a 16 gauge

steel wall mounting box. Motor shall be a shaded pole,

maintenance-free, brushless type. Motor requires no

brushes, oiling or fuses. This motor shall be thermally overload protected, 1/10 HP, 3200 RPM. Dryer shall deliver 160

CFM at 5500 LFM. Push button dryers shall be activated

by a cam-operated mechanical timer.

Mounting Heights:

Suggested mounting heights from floor to bottom of dryer:

MEN WOMEN CHILDREN HANDICAPPED

“DR-N” Hand Dryer... 42” (107cm) 40” (102cm) 30-40” (76-102cm) 34” (86cm)

“DR-NH” Hair Dryer... 72” (183cm) 68” (173cm) 46-68” (117-173cm) 52” (132cm)

Dimensions:

Surface Mounted 11” 9-1/4” 6-5/8” 16 lbs. (7kg)

Recessed Mounted 14-1/8” 14-1/8” 3-3/8” 23 lbs. (10kg)

WIDTH HEIGHT DEPTH

NET WEIGHT

Cover shall be attached with one tamper-resistant bolt and

a 3” steel latch which locks it securely to base. Tamperresistant air intake vents, internal shield and side mounted

heating element are for additional safety. Heating ele-

ment is protected by an automatic resetting circuit breaker.

Nozzle and push button shall be zinc die castings with a

chrome plated finish. Nozzle shall revolve 360˚ unless

specified as fixed position. UL and C-UL listed. Made in the

U.S.A.

Installation (Surface Mount)

(Refer to recessed instructions for recessed mounting)

WARNING: DISCONNECT POWER BEFORE INSTALLING

1. To remove cover, remove special Allen screw using wrench

supplied. Place a hand on each side of cover and pull bottom

toward you about 1/4 inch, then push cover up toward top of

dryer, releasing cover from mounting plate latch. Lift cover off

mounting plate by pulling forward at the bottom and upward at

the same time. DO NOT FORCE COVER OFF.

2. Dryers should be placed at least 2 feet (61cm) apart and at

least 12” (30cm) from washbasin. Do not install dryers over

washbasin. Hold the backplate to the wall at the suggested

mounting height. Measure from bottom edge of backplate to the

floor.

3. Mark the locations of the four mounting holes and the conduit entrance location on the wall. (The conduit entrance is the

proper hole diameter for 1/2 inch (13mm) conduit.)

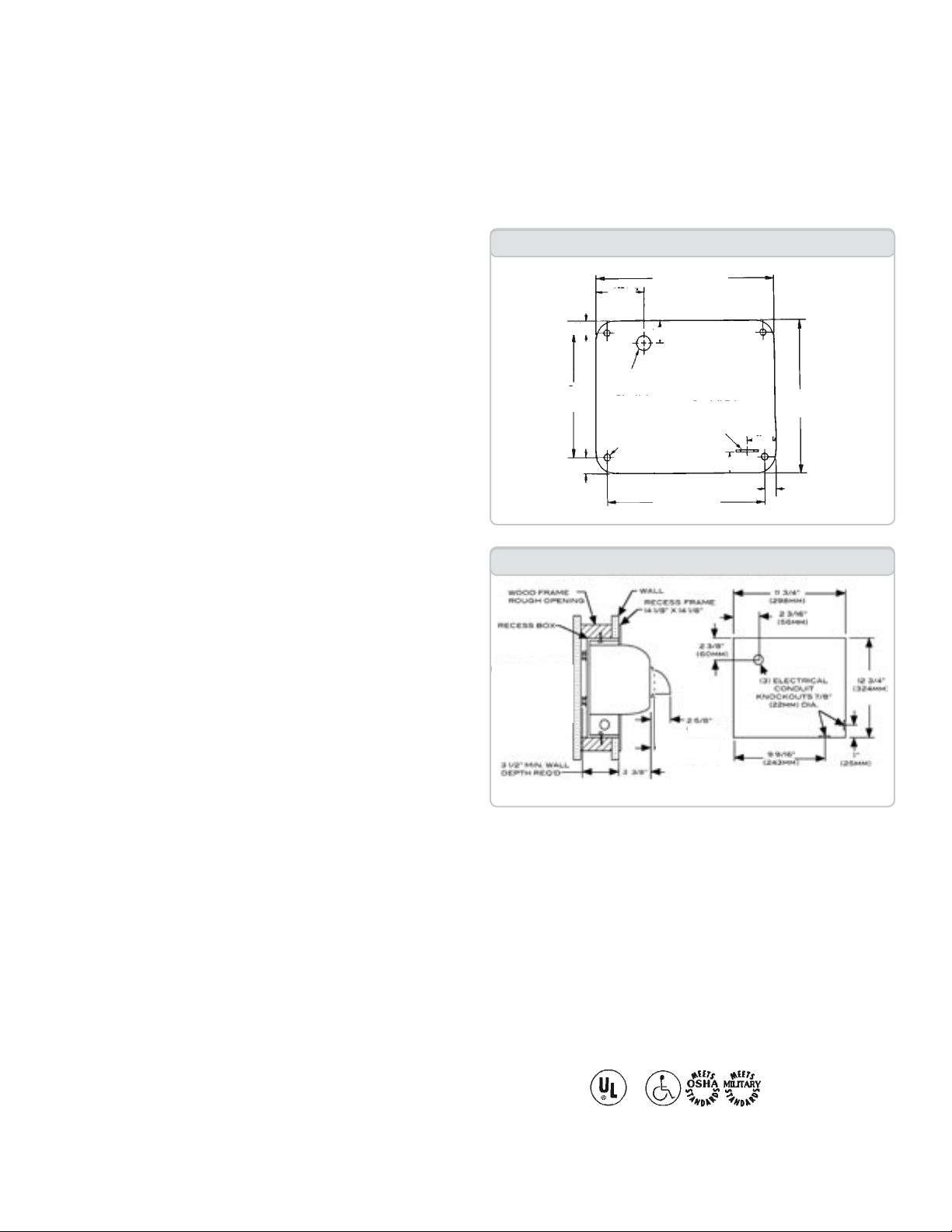

DR Series Surface Mounted

10 13/16

(70 mm)

5/8 (17 mm)

7 7/16

(189 mm)

1 (25 mm)

2 3/4

7/8 (22mm) DIA. IN-WALL

CONDUIT ENTRANCE

(4) MTG HOLES

5/16 DIA. (8 mm)

(274 mm)

1 5/16 (33 mm)

7/8 (22mm) DIA. SURFACE

CONDUIT ENTRANCE

9 1/2

(241 mm)

DR Series Recess Mounted

ROUGH

OPENING

11 3/4” W (30cm)

X

12 3/4” H 932cm)

1 1/4

(32 mm)

5/8

9 1/16

(230 mm)

5/8

(17 mm)

4. Fasten the backplate to the wall where previously marked.

RECOMMENDATION:

Wood wall - No. 16 (M8) wood screws, 2 3/4”(70mm) long

Cement or brick - 1/4” (M6) stud expansion bolts, 3” (76mm)

long

Hollow wall - 1/4” (M6) toggle bolts, length depends on wall

thickness

5. Run service wire to dryer location and connect to terminal

block. IMPORTANT: All units must be supplied with a 3 wire

service. Use No. 12 wire or larger as required by local electrical

code. The ground wire must be connected to the dryer backplate. Unit must be installed by a qualified licensed electrician.

Operating Costs

The only operating cost for the DR series hand dryer is

electricity. Based on a cost of $0.10 per KWH:

Cost per 1,000 hand dryings

DR series = $1.92

Paper Towels = $20.56

Warranty

10-year limited warranty includes same day factory repair

Do not connect any unit to a branch circuit over 20 amps.

Dryers located in shower rooms or other wet locations should be

or part replacement. Sensor 3 years. See owner’s manual

for details.

equipped with ground fault interrupter(s).

6. Carefully replace the cover using tamper-proof bolts sup-

C

US

plied.

American Dryer • 12932 Farmington Road • Livonia • MI • 48150 •U.S.A. • www.americandryer.com

phone (734) 421-2400 • toll free (800) 485-7003 U.S. only • fax (734) 421-5580

© 1999-2006 American Dryer, Inc. All rights reserved. Specifications subject to change without notice. Revised August 2005

Loading...

Loading...