American Dryer AQUATEX Parts Diagram

AQUATEX

WET WASH

USER’S MANUAL

American Dryer Corporation

88 Currant Road

Fall River, MA 02720-4781

Telephone: (508) 678-9000 / Fax: (508) 678-9447

e-mail: techsupport@amdry.com

010298BS/tf

ADC Part No. 112196

Retain This Manual In A Safe Place For Future Reference

American Dryer Corporation products embody advanced concepts in engineering, design, and safety. If this product is

properly maintained, it will provide many years of safe, efficient, and trouble-free operation.

ONLY qualified technicians should service this equipment.

OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or specified in the installation/operator's manual

included with the dryer.

The following “FOR YOUR SAFETY ” caution must be posted near the dryer in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline or

other flammable vapors or liquids

in the vicinity of this or any other

appliance.

We have tried to make this manual as complete as possible and hope you will find it useful. ADC reserves the right to make

changes from time to time, without notice or obligation, in prices, specifications, colors, and material, and to change or

discontinue models.

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence

ni d’autres vapeurs ou liquides

inflammables dans le voisinage de cet

appareil ou de yout autre appareil.

Important

For your convenience, log the following information:

DATE OF PURCHASE MODEL NO.

DISTRIBUTORS NAME

Serial Number(s)

Replacement parts can be obtained from your distributor or the ADC factory. When ordering replacement parts from the

factory, you can FAX your order to ADC at (508) 678-9447 or telephone your orders directly to the ADC Parts Department at

(508) 678-9000. Please specify the dryer model number and serial number in addition to the description and part number, so

that your order is processed accurately and promptly.

“IMPORTANT NOTE TO PURCHASER”

Information must be obtained from your local gas supplier on the instructions

to be followed if the user smells gas. These instructions must be posted in a

prominent location near the dryer.

IMPORTANT

YOU MUST DISCONNECT and LOCKOUT THE ELECTRIC SUPPLY and THE GAS

SUPPLY or THE STEAM SUPPLY BEFORE ANY COVERS or GUARDS ARE

REMOVED FROM THE MACHINE TO ALLOW ACCESS FOR CLEANING, ADJUSTING, INSTALLATION, or TESTING OF ANY EQUIPMENT per OSHA (Occupational

Safety and Health Administration) STANDARDS.

«Attention: Lor des opérations d’entretien

“Caution: Label all wires prior to

disconnection when servicing controls. Wiring

errors can cause improper operation.”

des commandes étiqueter tous fils avant

de les déconnecter. Toute erreur de

câblage peut étre une source de danger et

de panne.»

CAUTION

DRYERS SHOULD NEVER BE LEFT UNATTENDED WHILE IN OPERATION.

WARNING

CHILDREN SHOULD NOT BE ALLOWED TO PLAY ON OR NEAR THE DRYER(S).

CHILDREN SHOULD BE SUPERVISED IF NEAR DRYERS IN OPERATION.

FOR YOUR SAFETY

DO NOT DRY MOP HEADS IN THE DRYER.

DO NOT USE DRYER IN THE PRESENCE OF DRY CLEANING FUMES.

WARNING

UNDER NO CIRCUMSTANCES should the door switch or the heat circuit devices

ever be disabled.

WARNING

The dryer must never be operated with any of the back guards, outer tops, or service

panels removed. PERSONAL INJURY or FIRE COULD RESULT.

WARNING

DRYER MUST NEVER BE OPERATED WITHOUT THE LINT FILTER/SCREEN IN

PLACE, EVEN IF AN EXTERNAL LINT COLLECTION SYSTEM IS USED.

IMPORTANT

PLEASE OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment and/or

specified in the installation and operator's manual included with the dryer.

Dryers must not be installed or stored in an area where it will be exposed to water or weather.

The wiring diagram for the dryer is located in the front electrical control box area.

Table of Contents

SECTION I

INTRODUCTION................................................................................................ 3

Wet Wash Microprocessor Drying System .............................................................................................. 3

SECTION II

FEATURES .......................................................................................................... 4

SECTION III

PROGRAM SELECTIONS ................................................................................ 5

A. Preprogrammed Cycles .................................................................................................................... 5

B. Special Drying Cycle (mode) ............................................................................................................ 6

C. Timed (manual) Drying Cycle (mode) ................................................................................................ 6

D. Temperature Selections (Drying Temperatures) .................................................................................. 7

E. Cool Down Cycle:............................................................................................................................ 7

F. L.E.D. Display.................................................................................................................................. 7

G. Cycle In Progress Temperature Display............................................................................................. 8

J. Diagnostics ....................................................................................................................................... 9

K. System Parameters (Program Locations / Review)............................................................................. 9

SECTION IV

OPERATING INSTRUCTIONS ........................................................................10

A. Special Drying Cycle ...................................................................................................................... 10

B. Timed (Manual) Drying Cycle ..........................................................................................................11

SECTION V

L.E.D. DISPLAY / CODES .................................................................................13

A. Display Operating Status ................................................................................................................. 13

B. Microprocessor L.E.D. Displays ..................................................................................................... 14

C. L.E.D. Display Codes..................................................................................................................... 15

SECTION VI

PROGRAMMING INSTRUCTIONS ................................................................16

A. Introduction To Programming .......................................................................................................... 16

B. Programming Flow Charts .............................................................................................................. 17

SECTION VII

FACTORY PRESET PARAMETERS / PROGRAMS .....................................25

Parameters (programs) preset by factory for machines which are controlled through Humidity Sensing. ... 25

System Parameters/Programs ................................................................................................................ 25

SECTION VIII

PROGRAMMING LIMITS................................................................................26

A. Preprogrammed Cycles .................................................................................................................. 26

B. System Parameters (Program Locations) ......................................................................................... 26

SECTION IX

SYSTEM DIAGNOSTICS..................................................................................27

A. Diagnostics (L.E.D. Display) Failure Codes..................................................................................... 27

B. L.E.D. Display Indicators................................................................................................................ 27

C. Microprocessor Control Relay Output L.E.D. Indicators ................................................................. 28

SECTION I

INTRODUCTION

Wet Wash Microprocessor Drying System

The Wet Wash (OPL) Drying System has been designed with super performance in mind to provide for better

temperature regulation, efficiency, performance, and consistency, and faster drying times.

Specifically, Wet Wash Drying System’s higher performance emanates from the following enhancements:

1. The ability to better control the temperature inside the basket (tumbler) throughout the various cycles.

2. The Wet Wash Dryer’s microprocessor controller (computer) responds immediately to any temperature

variations from temperature. The narrower temperature control band greatly increases system efficiency.

3. The Wet Wash Dryer utilizes two (2) Humidity Transmitters. This enables the microprocessor controller to

monitor the relative humidity in both the inlet air stream as well as the exhaust air system of the machine.

Among its many amenities, Wet Wash Drying System has a true Automatic Drying Cycle. The Wet Wash

Drying System (Patent No. 5,649,372) operates the machine at specific programmable dry temperatures while

simultaneously monitoring the humidity in both the inlet and outlet air streams. The dryer will operate at specific

temperature until a Predetermined Differential Humidity Measurement has been reached. The dryer then will

proceed to a second predetermined temperature until that Predetermined Differential Humidity has been reached.

This process is repeated one (1) final time prior to ending the cycle. These RH set points will differ based on the

material type and load size selected.

Utilizing this microprocessor technology, the user simply has to place the load in the dryer and push one single

button to start the drying cycle. The microprocessor controller (computer) will directly monitor the moisture

content in the load and stop the drying cycle automatically. This response is based on the load size and material

type selected.

The Wet Wash Drying System (Patent No. 5,649,372) virtually eliminates all guess work. The microprocessor

controller (computer) compensates for various types of fabrics and load sizes, thus, avoiding damage to fabrics by

overdrying, as well as avoiding wasted time and energy for any given load. Once the microprocessor controller

(computer) determines the load is dry, the microprocessor controller will go into the cool down cycle until the

preprogrammed time, and then shuts the dryer off automatically.

SECTION II

FEATURES

A. Dependable Microprocessor solid state integrated circuitry. To eliminate as many moving parts as

possible.

B. Program changes are easily made at the keyboard - actual programs are viewed at the L.E.D. display

for verification.

C. Special Drying Cycle - computerized monitoring of load dryness for precise, fast, and efficient drying.

D. Timed (manual) Drying Cycle - for special loads, programming allows for a specific amount of time

in minutes for both drying and cool down cycles.

E. Preprogrammed Cycles - The Microprocessor controller can store in its memory six (6) preprogrammed

cycles in either the Special Drying mode or Manual Drying mode.

F. Variable (Programmable) Fabric/Temperature Selections- accommodates the type of fabric to be dried.

G. Controlled Cool Down program - helps eliminate wrinkled loads

H. L.E.D. Display - informs user of cycle status, programs and displays important diagnostic and fault

codes.

I. Anti-Wrinkle Program - helps keep items wrinkle - free when they are not removed from the dryer

promptly at the end of the drying and cooling cycles.

J. Diagnostics - major circuits, including the door switch, microprocessor temperature sensor, as well as

the inlet and outlet relative humidity transmitters.

K. Temperature Conversion Status - temperature related programs can be set in either Fahrenheit or

Celsius. ALL temperatures will automatically convert to the corresponding valves (± 1°F) when

changes are made.

L. Over-Temperature protection if the microprocessor controller senses that the temperature basket

(tumbler) has reached, it will shut the dryer down completely, and a default an overheating problem.

M. Cycle Preview - entire dryer parameters (programs) or the preprogrammed cycles are displayed

for verification upon a coded entry to the keypad.

SECTION III

PROGRAM SELECTIONS

A. Preprogrammed Cycles

The microprocessor controller can store in its memory six (6) preprogrammed cycles (keys “A” through °F”

on the keyboard). This allows the user to have the six (6) most completely used cycles, requiring only the

push of a single keyboard entry to start the dryer.

These preprogrammed cycles can be set either the “Special” Drying Cycles (mode) where the fabric

selection must be chosen or in the timed (manual) drying cycle (mode) where the dryer will operate for the

specific drying time preprogrammed. These cycles can be preprogrammed in any combination.

Once the drying cycle is completed, the microprocessor controller then goes into the cool down cycle, where

the articles are tumbled in room temperature air. Once the preprogrammed cool down cycle is completed,

the dryer will shut off automatically.

With the Anti-wrinkle Program active, when the cooling cycle is completed and the dryer has shut off,

if the main door is not opened, the load will be tumbled without heat (I.E., for twenty (20) seconds

every (2) two minutes. This process is repeated until either the main door is opened or twenty (20)

minutes has elapsed, which ever comes first.

Programmed Cycle Selections:

1. Special Drying Cycle (mode)

A. For optional fabric selections, the microprocessor controller can be preprogrammed to dry the

specific material being put into the dryer.

B. Anti-Wrinkle Program - active or non-active

C. “T - Hi” Drying Temperature - programmable from 100° to 200° F in one degree increments or from 37° to

93° C in one degree increments.

D. “T-Set” Drying Temperature - preprogrammable from 100° to 199° F in one degree increments or from 37°

to 92° C in one degree increments.

E. “T-Lo” Drying temperature - preprogrammable from 100° to 198° F in one degree increments or

from 37° to 91° C in one degree increments.

F. Cool Down Time - Programmable from 0 to 10 minutes in one-minute increments.

2. Timed (manual) Drying Cycle (mode)

A. Anti-wrinkle Program - active or non-active

B. Drying Time - programmable from 0 - 99 minutes in one minute increments.

C. Drying Temperature - programmable from 100° to 215° F in one degree increment or from 37° to

102° C in one degree increments.

D. Cool Down Time - programmable from 0 to 15 minutes in one degree increments.

All six (6) preprogrammed cycles have been programmed by the factory as outlined on pages

However, even though these are the most common cycles used, they should be reviewed to ensure

they the location application or needs. Should changes be found necessary, refer to the programming

section of this manual.

B. Special Drying Cycle (mode)

In this mode, the microprocessor controller determines how much drying time is needed. This is done

because each fabric has its own drying characteristics and the microprocessor drys each fabric

selection at a certain temperature to a specific humidity level. In this mode the load size is important.

At the end of this drying cycle the microprocessor will go into cool down.

Special Drying Cycle (mode) Selections:

1. Fabric Selection - Synt, Suit, Def, Acry, Uool, Coat, Ryan, Nitt, Silc.

2. “T Hi” Drying Temperature - programmable from 100 ° to 200° F in one degree increments or from

37° to 92° in one degree increments

3. “T Set” Drying Temperature - programmable from 100 ° to 199° F in one degree increments or form

37° to 92° in one degree increments.

4. “T Lo” Drying Temperature - programmable from 100° to 198° F in one degree increments or from

37° to 91° C in one degree increments.

5. Cool Down Time - programmable from 0-10 minutes in one degree increments.

6. System Parameter program location - Key # 2

C. Timed (manual) Drying Cycle (mode)

This drying cycle is intended for special loads where a specific amount of drying time and cooling

time is needed.

1. Drying Time - programmable from 0-99 minutes in one - minute increments.

2. Dry Temperature - programmable from 100° to 215° F or from 37° to 102° C in one degree increments.

3. Cool down Time - programmable from 0 -15 minutes in one minute increments.

D. Temperature Selections (Drying Temperatures)

Operating Temperature Selections:

1. Special Drying Cycle (mode) programmable from 100° to 200° F or from 37° to 93° C in one degree

increments.

2. Timed (manual Drying Cycle (mode) programmable from 100° to 215° F or from 37° C to 102° C in

one degree increments.

E. Cool Down Cycle:

1. Special Drying Cycle (mode)

a. Cool Down Time - 0-10 minutes in one minute increments.

2. Timed (manual) Drying Cycle (mode)

a. Cool Down Time - 0-15 minutes in one minute increments

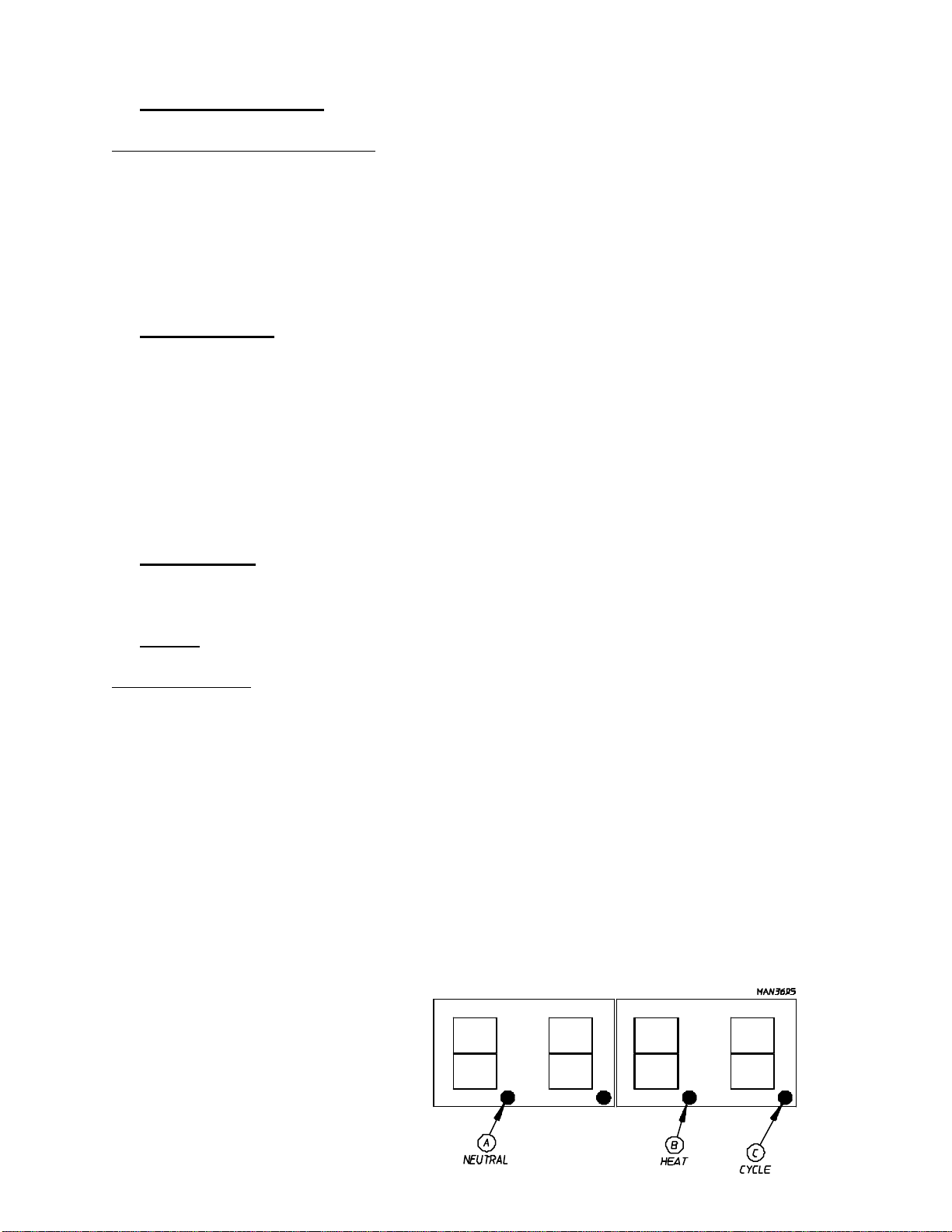

F. L.E.D. Display

The L.E.D. display informs the cycle status, program verification, and displays important diagnostic

and fault codes. A complete listing of the various display codes and their meanings are shown on

page 14 of this manual.

Display Selections:

1. Display Status - while the dryer cycle is in progress, programming allows the display to read only the

cycle in progress or only the basket (tumbler) temperature.

2. Cycle in Progress Display Status.

a. Special Drying Cycle (mode) the L.E.D. display reads time in minutes counting from zero (0) up.

When the computer reaches its specific humidity level it will then go into cool down in minutes.

b. Timed (manual) Cycle (mode) - L.E.D. Display reads drying time and / or cool down time counting

upward as time elapses.

3. Indicator Dots on the Display - dots are an indicator as to the various microprocessor controller output

functions. Additionally, there are also indicators on the back side of the microprocessor controller to

verify the outputs of the relay.

a. Motor Indicator On (Active)

b. Heat On (Active)

c. Cycle in Progress Indicator

Loading...

Loading...