American Dryer AD-75V User Manual

AD-75V Installation Manual

Phase 7 (S.A.F.E.) / Dual Timer / Mechanical Coin

W ARNING: For your safety the information in

this manual must be followed to minimize the

risk of fire or explosion or to prevent property

damage, personal injury or death.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

— WHA T TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Clear the room, building or area of all

occupants.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the fire department.

— Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

AVERTISSEMENT: Assurez-vous de bien

suivre les instructions données dans cette notice

pour réduire au minimum le risque d’incendie

ou d’explosion ou pour éviter tout dommage

matériel, toute blessure ou la mort.

— Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inflammables à

proximité de cet appareil ou de tout autre

appareil.

— QUE F AIRE SI VOUS SENTEZ UNE ODEUR

DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur . Ne pas

vous servir des téléphones se trouvant dans

le bâtiment.

• Évacuez la pièce, le bâtiment ou la zone.

• Appelez immédiatement votre fournisseur

de gaz depuis un voisin. Suivez les

instructions du fournisseur .

• Si vous ne pouvez rejoindre le fournisseur

de gaz, appelez le service des incendies.

— L ’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualifié

ou par le fournisseur de gaz.

American Dryer Corporation

88 Currant Road

Fall River MA 02720-4781 USA

T elephone: (508) 678-9000 / Fax: (508) 678-9447

e-mail: techsupport@amdry.com

www .amdry.com

ADC Part No. 113231

Retain This Manual In A Safe Place For Future Reference

American Dryer Corporation products embody advanced concepts in engineering, design, and safety. If this product is

properly maintained, it will provide many years of efficient, trouble free, and most importantly , safe operation.

ONLY qualified technicians should service this equipment.

OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or specified in the installation manual included with

the dryer.

The following “FOR YOUR SAFETY” caution must be posted near the dryer in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

W e have tried to make this manual as complete as possible and hope you will find it useful. ADC reserves the right to make

changes from time to time, without notice or obligation, in prices, specifications, colors, and material, and to change or

discontinue models. The illustrations included in this manual may not depict your particular dryer exactly.

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence

ni d’autres vapeurs ou liquides

inflammables à proximité de cet

appareil ou de tout autre appareil.

Important

For your convenience, log the following information:

DA TE OF PURCHASE ______________________________________________MODEL NO. _____________________

RESELLER’S NAME _______________________________________________________________________________

Serial Number(s) ________________________________________________________________________________

AD-75V

________________________________________________________________________________

________________________________________________________________________________

Replacement parts can be obtained from your reseller or the ADC factory. When ordering replacement parts from the factory ,

you can F AX your order to ADC at (508) 678-9447 or telephone your order directly to the ADC Parts Department at (508)

678-9000. Please specify the dryer model number and serial number in addition to the description and part number, so that

your order is processed accurately and promptly.

“IMPORT ANT NOTE TO PURCHASER”

Information must be obtained from your local gas supplier on the instructions

to be followed if the user smells gas. These instructions must be posted in a

prominent location near the dryer .

IMPORTANT

YOU MUST DISCONNECT AND LOCK OUT THE ELECTRIC SUPPL Y AND THE GAS

SUPPLY OR THE STEAM SUPPLY BEFORE ANY COVERS OR GUARDS ARE

REMOVED FROM THE MACHINE TO ALLOW ACCESS FOR CLEANING,

ADJUSTING, INSTALLATION, OR TESTING OF ANY EQUIPMENT PER OSHA

(Occupational Safety and Health Administration) ST ANDARDS.

«Attention: Au moment de l’entretien des

“Caution: Label all wires prior to

disconnection when servicing controls. W iring

errors can cause improper operation.”

commandes, étiquetez tous les fils avant de

les débrancher. Des erreurs de câblage

peuvent entraîner un fonctionnement

inadéquat et dangereux.»

CAUTION

DR YERS SHOULD NEVER BE LEFT UNA TTENDED WHILE IN OPERA TION.

W ARNING

CHILDREN SHOULD NOT BE ALLOWED TO PLA Y ON OR NEAR THE DR YER(S).

CHILDREN

SHOULD BE SUPERVISED IF NEAR DRYERS IN OPERA TION.

FOR YOUR SAFETY

DO NOT DR Y MOP HEADS IN THE DRYER.

DO NOT USE DR YER IN THE PRESENCE OF DR Y CLEANING FUMES.

W ARNING

UNDER NO CIRCUMSTANCES should the dryer door switches, lint drawer switch or

the heat safety circuit ever be disabled.

WARNING

The dryer must never be operated with any of the back guards, outer tops, or service

panels removed. PERSONAL INJURY OR FIRE COULD RESUL T.

WARNING

DRYER MUST NEVER BE OPERATED WITHOUT THE LINT FILTER/SCREEN IN

PLACE, EVEN IF AN EXTERNAL LINT COLLECTION SYSTEM IS USED.

IMPORT ANT

PLEASE OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment and/or

specified in the installation manual included with the dryer.

Dryer must not be installed or stored in an area where it

The wiring diagram for the dryer is located in the front electrical control box area.

will be exposed to water or weather.

IMPORT ANT

Dryer must be installed in a location/environment, which the ambient temperature

remains between 40° F (4.44° C) and 130° F (54.44° C).

Table of Contents

SECTION I

SAFETY PRECAUTIONS .............................................................................................................................. 2

SECTION II

SPECIFICATIONS/COMPONENT IDENTIFICATION ......................................................................... 4

A. Specifications .......................................................................................................................................... 4

B. Component Identification ..................................................................................................... ................... 6

SECTION III

INSTALLATION PROCEDURES ................................................................................................................ 8

A. Location Requirements...........................................................................................................................8

B. Unpacking/Setting Up............................................................................................................................. 9

C. Dryer Enclosure Requirements ............................................................................................................10

D. Fresh Air Supply Requirements............................................................................................................ 1 1

E. Exhaust Requirements.......................................................................................................................... 12

F. Electrical Information ...........................................................................................................................15

G. Gas Information .................................................................................................................................... 19

H. Steam Information ................................................................................................................................ 23

I. Fire Suppression Water Connection ..................................................................................................... 2 6

J. Preparation for Operation/Start-Up......................................................................................................29

K. Preoperational Test.......................................................................................................... ..................... 29

L. Preoperational Instructions ................................................................................................................... 3 2

M. Shutdown Instructions .......................................................................................................................... 3 3

SECTION IV

SERVICE/PARTS INFORMATION ........................................................................................................... 3 4

A. Service .................................................................................................................................................. 34

B. Parts...................................................................................................................................................... 34

SECTION V

WARRANTY INFORMATION ................................................................................................................... 3 5

A. Returning Warranty Cards ...................................................................................................................35

B. Warranty ............................................................................................................................................... 35

C. Returning Warranty Parts ..................................................................................................... ................ 35

SECTION VI

ROUTINE MAINTENANCE ...................................................................................................................... 3 7

A . Cleaning ................................................................................................................................................ 37

B. Adjustments .......................................................................................................................................... 38

C. Lubrication ............................................................................................................................................ 38

SECTION VII

PROCEDURE FOR FUNCTIONAL CHECK OF REPLACEMENT COMPONENTS ................... 39

SECTION VIII

DATA LABEL INFORMATION ................................................................................................................. 4 2

SECTION IX

MANUAL RESET BURNER HI-LIMIT INSTRUCTIONS .................................................................. 4 3

A. Phase 7 ................................................................................................................................................. 43

B. Dual Timer ............................................................................................................................................ 4 3

SECTION I

SAFETY PRECAUTIONS

W ARNING: For your safety, the information in this manual must be followed to minimize the risk of

fire or explosion or to prevent property damage, personal injury , or loss of life.

W ARNING: The dryer must never be operated with any of the back guards, outer tops, or

service panels removed. PERSONAL INJUR Y OR FIRE COULD RESUL T.

1. DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

2. Purchaser/user should consult the local gas supplier for proper instructions to be followed in the event the

user smells gas. The instructions should be posted in a prominent location.

3. WHAT TO DO IF YOU SMELL GAS:

a. DO NOT try to light any appliance.

b. DO NOT touch any electrical switch.

c. DO NOT use any phone in your building.

d. Clear the room, building, or area of

e. Immediately call your gas supplier from a neighbor’ s phone. Follow the gas supplier’s instructions.

f. If you

4. Installation and service must be performed by a qualified installer, service agency, or gas supplier.

5. Dryer(s) must be exhausted to the outdoors.

6. Although ADC produces a very versatile dryer, there are some articles that, due to fabric composition or

cleaning method, should not be dried in it.

cannot reach your gas supplier, call the fire department.

ALL occupants.

WARNING: Dry only water washed fabrics. DO NOT dry articles spotted or washed in dry

cleaning solvents, a combustible detergent, or “all purpose” cleaner . EXPLOSION

COULD RESUL T.

W ARNING: DO NOT dry rags or articles coated or contaminated with gasoline, kerosene, oil, paint,

or wax. EXPLOSION COULD RESUL T.

W ARNING: DO NOT dry mop heads. Contamination by wax or flammable solvents will create a

fire hazard.

W ARNING: DO NOT use heat for drying articles that contain plastic, foam, sponge rubber, or

similarly textured rubber materials. Drying in a heated basket (tumbler) may damage

plastics or rubber and may be a fire hazard.

2 American Dryer Corp. 113231-4

7. A program should be established for the inspection and cleaning of lint in the heating unit area, exhaust

ductwork, and inside the dryer. The frequency of inspection and cleaning can best be determined from

experience at each location.

WARNING: The collection of lint in the burner area and exhaust ductwork can create a potential fire

hazard.

8. For personal safety, the dryer must be electrically grounded in accordance with local codes and/or the

National Electrical Code ANSI/NFPA NO. 70-LATEST EDITION or in Canada, the Canadian Electrical

Codes Parts 1 & 2 CSA C22.1-1990 or LATEST EDITION.

NOTE: Failure to electrically ground the dryer properly will VOID THE W ARRANTY .

9. UNDER NO CIRCUMST ANCES should the dryer door switches, lint drawer switch, or the heat safety

circuit ever be disabled.

W ARNING: PERSONAL INJURY OR FIRE COULD RESUL T SHOULD THE DR YER

DOOR SWITCHES, LINT DRAWER SWITCH, OR THE HEA T SAFETY

CIRCUIT EVER BE DISABLED.

10. This dryer is not to be used in the presence of dry cleaning solvents or fumes.

11. Remove articles from the dryer as soon as the drying cycle has been completed.

WARNING: Articles left in the dryer after the drying and cooling cycles have been completed can

create a fire hazard.

12. DO NOT operate steam dryers with more than 125 psi (8.62 bar) steam pressure. Excessive steam

pressure can damage steam coil and/or harm personnel.

13. Replace leaking flexible hoses or other steam fixtures immediately. DO NOT operate the dryer with

leaking flexible hoses. PERSONAL INJURY MAY RESULT.

14. READ AND FOLLOW

DRYER.

15. For safety, proper operation, and optimum performance, the dryer must not be operated with a load less

than sixty-six percent (66%), 50 lb (22.67 kg) of its rated capacity.

ALL CAUTION AND DIRECTION LABELS ATTACHED TO THE

W ARNING: YOU MUST DISCONNECT AND LOCK OUT THE ELECTRIC SUPPL Y

AND THE GAS SUPPL Y OR THE STEAM SUPPL Y BEFORE ANY COVERS

OR GUARDS ARE REMOVED FROM THE MACHINE TO ALLOW

ACCESS FOR CLEANING , ADJUSTING, INST ALLA TION, OR TESTING OF

ANY EQUIPMENT PER OSHA (Occupational Safety and Health Administration)

ST ANDARDS.

IMPORTANT : Dryer must be installed in a location/environment, which the ambient

temperature remains between 40° F (4.44° C) and 130° F (54.44° C).

113231-4 www.amdry.com 3

SPECIFICA TIONS/COMPONENT IDENTIFICA TION

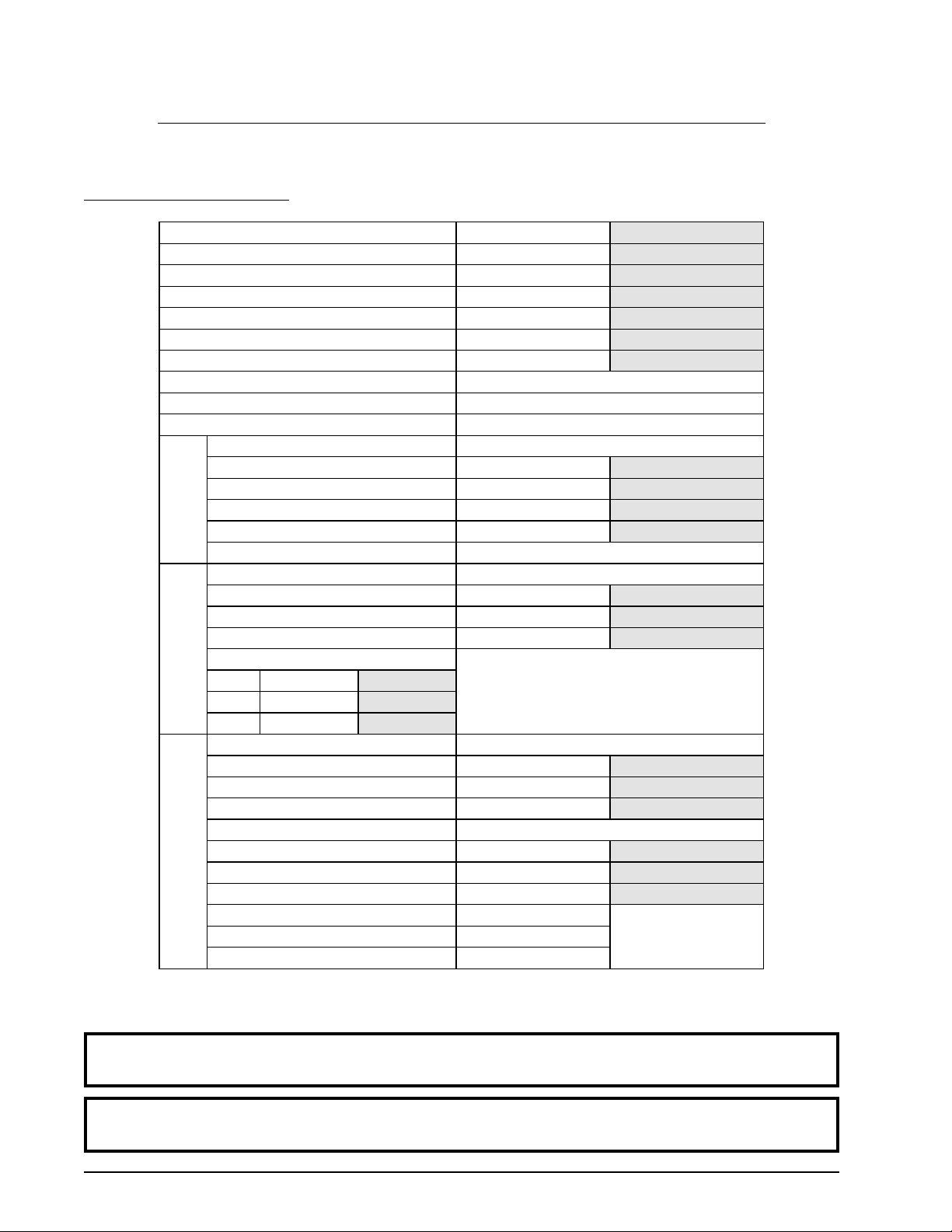

A. SPECIFICATIONS

SECTION II

MAX IMUM CAPA CITY (D RY WEIGHT) 7 5 l b

TUMBLER DIAMETER 37”

TUMBLER DEPTH 36”

TUMBLER VOLUME 22.4 cu f t

TUMBLE R MOTOR 1 hp *

DOOR OPENING (DIAMETER) 21-1/2”

EXHAUST CONNECTION (DIAM ETER) 1 0”

DR YERS PE R 2 0’/4 0’ C ONTAINER 1 0 / 20

DR YERS PE R 4 8’/5 3’ TRUC K 2 4 / 24

WATER C ONNECTION 3/4-11.5 NH

VOLTAGE AVAILABLE 120-480v 1,3ø 2,3,4w 50/60 Hz

APPROX. NE T WEIGHT 74 1 lb

APPROX. SHIPPING WEIGHT 79 3 lb

HEAT INPUT 200,000 Btu/hr

GasElectricSteam

AIRFLOW 9 00 cfm

INLET PIPE CONNECTION 3/4 ” F.N.P.T.

VOLTAGE AVAILABLE 208-480v 3ø 3,4w 50/60 Hz

APPROX. NE T WEIGHT 74 1 lb

APPROX. SHIPPING WEIGHT 79 3 lb

AIRFLOW 9 00 cfm

OVEN SIZE

kW Btu/hr

30 102,433

36 122,919

VOLTAGE AVAILABLE 120-480v 1,3ø 2,3,4w 50/60 Hz

APPROX. NE T WEIGHT 83 6 lb

APPROX. SHIPPING WEIGHT 88 8 lb

COMPRESSED AIR VOLUME 0.7 5 cfh

COMPRESSED AIR CONNECTION 1/8 ” F. N.P.T.

AIRFLOW 9 00 cfm

STEAM CONSUMPTION 2 39 lb/hr

OPERATING STEAM PRESSURE 125 p si ma x

BOILER HP (NORMAL LOAD) 7 Bhp

SUPPLY CONNECTION 1” F.N.P.T.

RETURN CONNECTION 1” F.N.P.T.

Shaded areas are stated in metric equivalents 6/15/04

* For non-reversing models.

kcal/hr

25,812

30,975

34 kg

94 cm

91.5 cm

634.2974 L

0.75 kW

54.6 cm

25.4 cm

336.1 kg

359.7 kg

50,400 kcal/hr

25.48 cmm

336.1 kg

359.7 kg

25.48 cmm

379.2 kg

402.8 kg

0.02 cmh

25.48 cmm

108 kg/hr

8.6 bar

IMPORTANT: Steam dryers must be provided with clean, dry, and regulated 80 psi +/- 10 psi

(5.51 bar +/- 0.69 bar) air supply .

NOTE: ADC reserves the right to make changes in specifications at any time without notice or

obligation.

4 American Dryer Corp. 113231-4

Specifications (Gas, Electric, and Steam)

NOTE: ADC reserves the right to make changes in specifications at any time without notice or

obligation.

113231-4 www.amdry.com 5

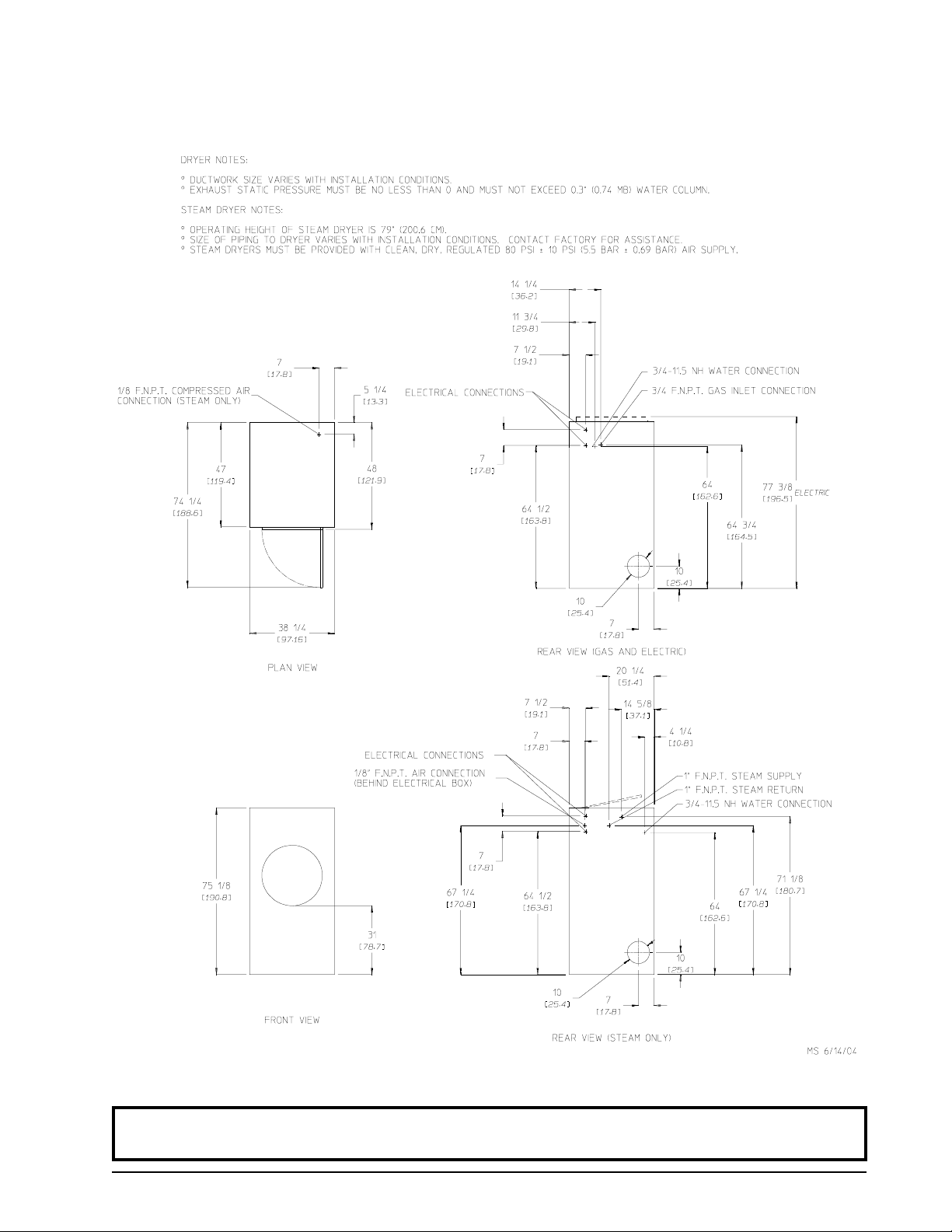

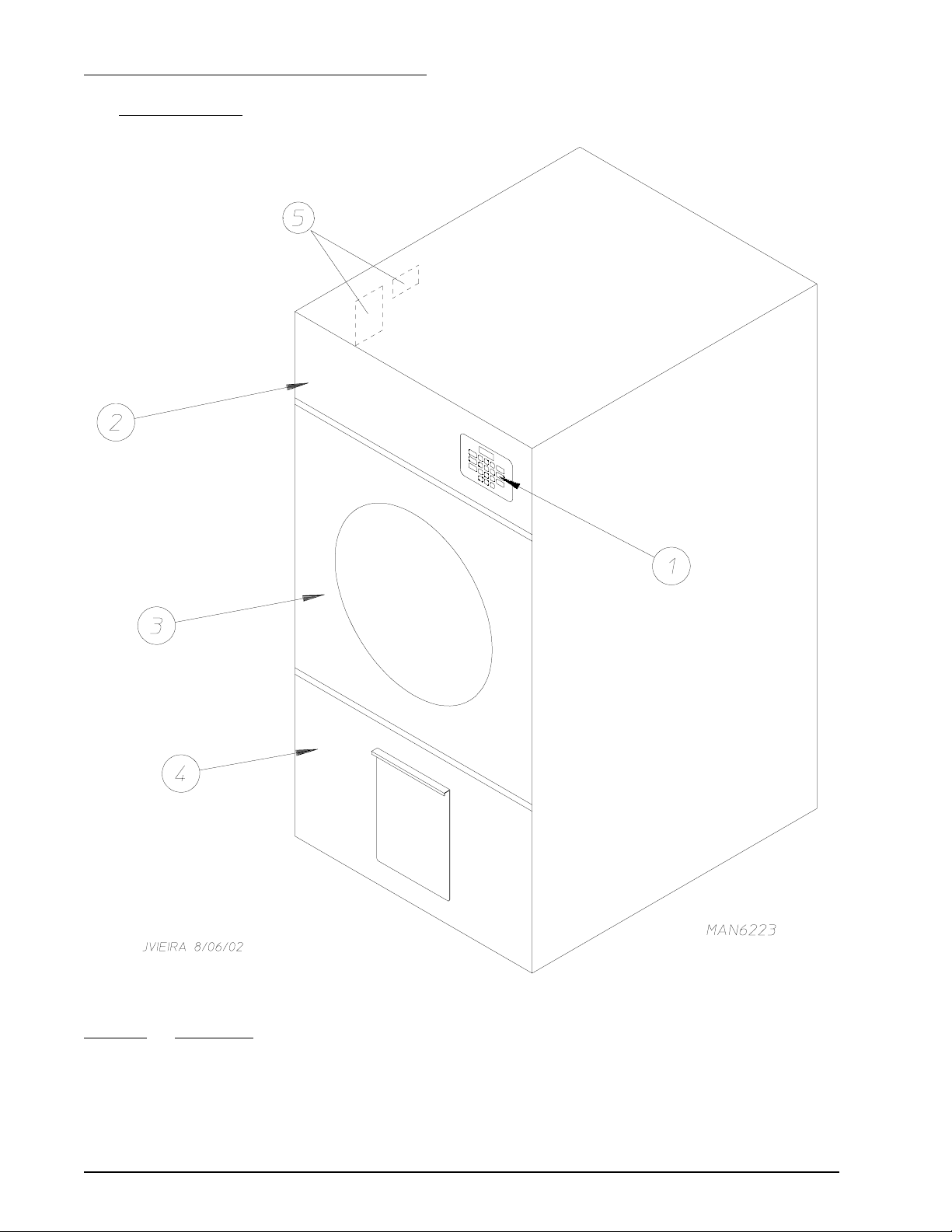

B. COMPONENT IDENTIFICATION

1. Dryer Front View

Illus. No. Description

1 Controls

2 Control (top access) Door Assembly

3 Main Door Assembly

4 Lint Compartment Area

5 Data Label and Installation Label

6 American Dryer Corp. 113231-4

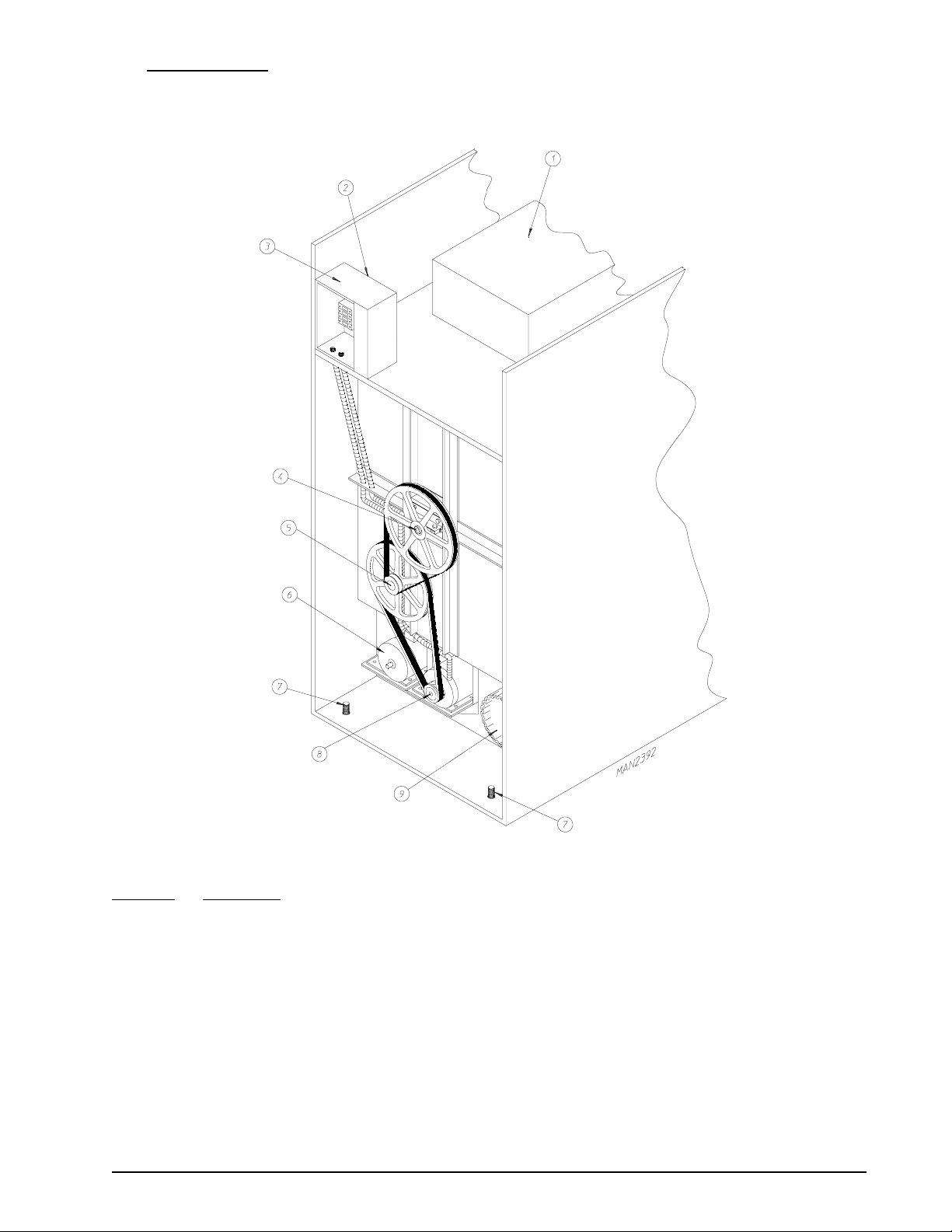

2. Dryer Rear View

Illus. No. Description

1 Heating Unit

2 1/8” Compressed Air Supply Inlet

(NOTE: Behind electric service relay box for steam units only)

3* Electric Service Relay Box

4 Basket (tumbler) Bearing Mount Assembly

5 Idler Bearing Mount Assembly

6 Blower Motor Assembly

7 Leveling Leg (rear)

8 Basket (tumbler) Drive Motor Assembly (reversing models only)

9 Dryer Exhaust

* Electric service connections for gas and steam models are made in this box.

113231-4 www.amdry.com 7

SECTION III

INST ALLA TION PROCEDURES

Installation should be performed by competent technicians in accordance with local and state codes. In the

absence of these codes, the installation must conform to applicable American National Standards: ANSI Z223.1LATEST EDITION (National Fuel Gas Code) or ANSI/NFPA NO. 70-LATEST EDITION (National Electrical

Code) or in Canada, the installation must conform to applicable Canadian Standards: CAN/CGA-B149.1-M91

(Natural Gas) or CAN/CGA-B149.2-M91 (Liquid Propane [L.P.] Gas) or LATEST EDITION (for General

Installation and Gas Plumbing) or Canadian Electrical Codes Parts 1 & 2 CSA C22.1-1990 or LATEST EDITION

(for Electrical Connections).

A. LOCATION REQUIREMENTS

Before installing the dryer, be sure the location conforms to local codes and ordinances. In the absence of such

codes or ordinances the location must conform with the National Fuel Gas Code ANSI.Z223.1 LATEST

EDITION, or in Canada, the installation must conform to applicable Canadian Standards: CAN/CGA-B149.1M91 (Natural Gas) or CAN/CGA-B149.2-M91 (L.P. Gas) or LATEST EDITION (for General Installation and

Gas Plumbing).

1. The dryer must be installed on a sound level floor capable of supporting its weight. Carpeting must be

removed from the floor area that the dryer is to rest on.

IMPORTANT: “The dryer must be installed on noncombustible floors only.”

2. The dryer must not be installed or stored in an area where it will be exposed to water and/or weather.

3. The dryer is for use in noncombustible locations.

4. Provisions for adequate air supply must be provided as noted in this manual (refer to Fresh Air Supply

Requirements in

5. Clearance provisions must be made from combustible construction as noted in this manual (refer to Dryer

Enclosure Requirements in

6. Provisions must be made for adequate clearances for servicing and for operation as noted in this manual

(refer to Dryer Enclosure Requirements in

7. The dryer must be installed with a proper exhaust duct to the outside as noted in this manual (refer to

Exhaust Requirements in

8. Dryer must be located in an area where correct exhaust venting can be achieved as noted in this manual

(refer to Exhaust Requirements in

Section D).

Section C).

Section C).

Section E).

Section E).

IMPORTANT: Dryer should be located where a minimum amount of exhaust duct will be necessary .

9. The dryer must be installed with adequate clearance for air openings into the combustion chamber.

CAUTION: This dryer produces combustible lint and must be exhausted to the outdoors. Every

6 months, inspect the exhaust ducting and remove any lint buildup.

8 American Dryer Corp. 113231-4

IMPORTANT: Dryer must be installed in a location/environment, which the ambient

temperature remains between 40° F (4.44° C) and 130° F (54.44° C).

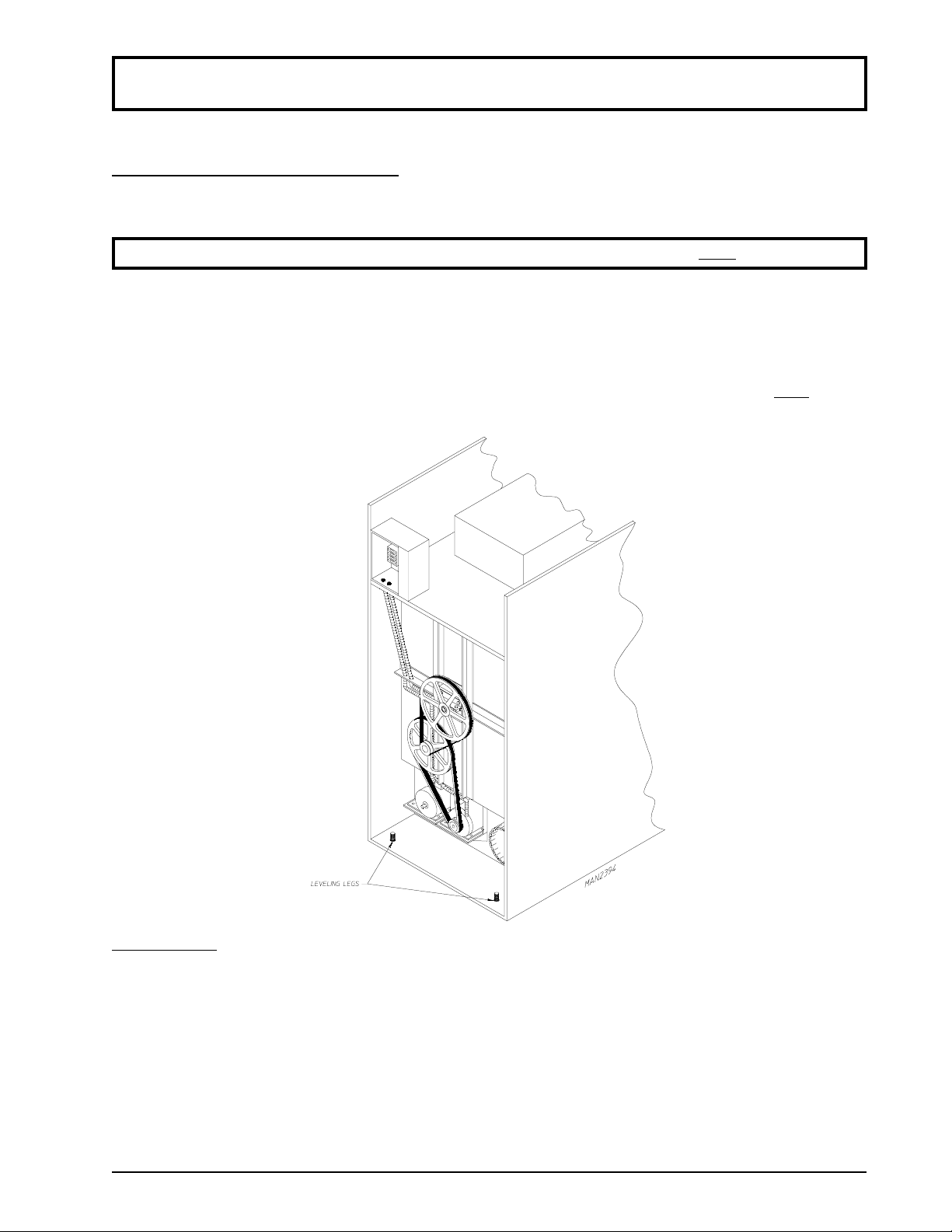

B. UNPACKING/SETTING UP

Remove protective shipping material (i.e., plastic wrap and/or optional shipping box) from dryer.

IMPORT ANT : Dryer must be transported and handled in an upright position at ALL times.

The dryer can be moved to its final location while still attached to the skid or with the skid removed. T o unskid

the dryer, locate and remove the four (4) bolts securing the base of the dryer to the wooden skid. Two (2) are

at the rear base (remove the back panel for access), and two (2) are located in the bottom of the lint chamber

(remove the lint drawer for access).

With the skid removed, to make it easier to slide the dryer into its final position, slightly lower

leveling legs, so that the dryer will slide on the legs instead of the base frame.

ALL four (4)

Leveling Dryer

The dryer is equipped with four (4) leveling legs, one (1) at each corner of the base. Two (2) are located at the

rear of the dryer base, and two (2) are located in the lint chamber (coop). To increase bearing life and improve

efficiency, the dryer should be tilted slightly to the rear.

113231-4 www.amdry.com 9

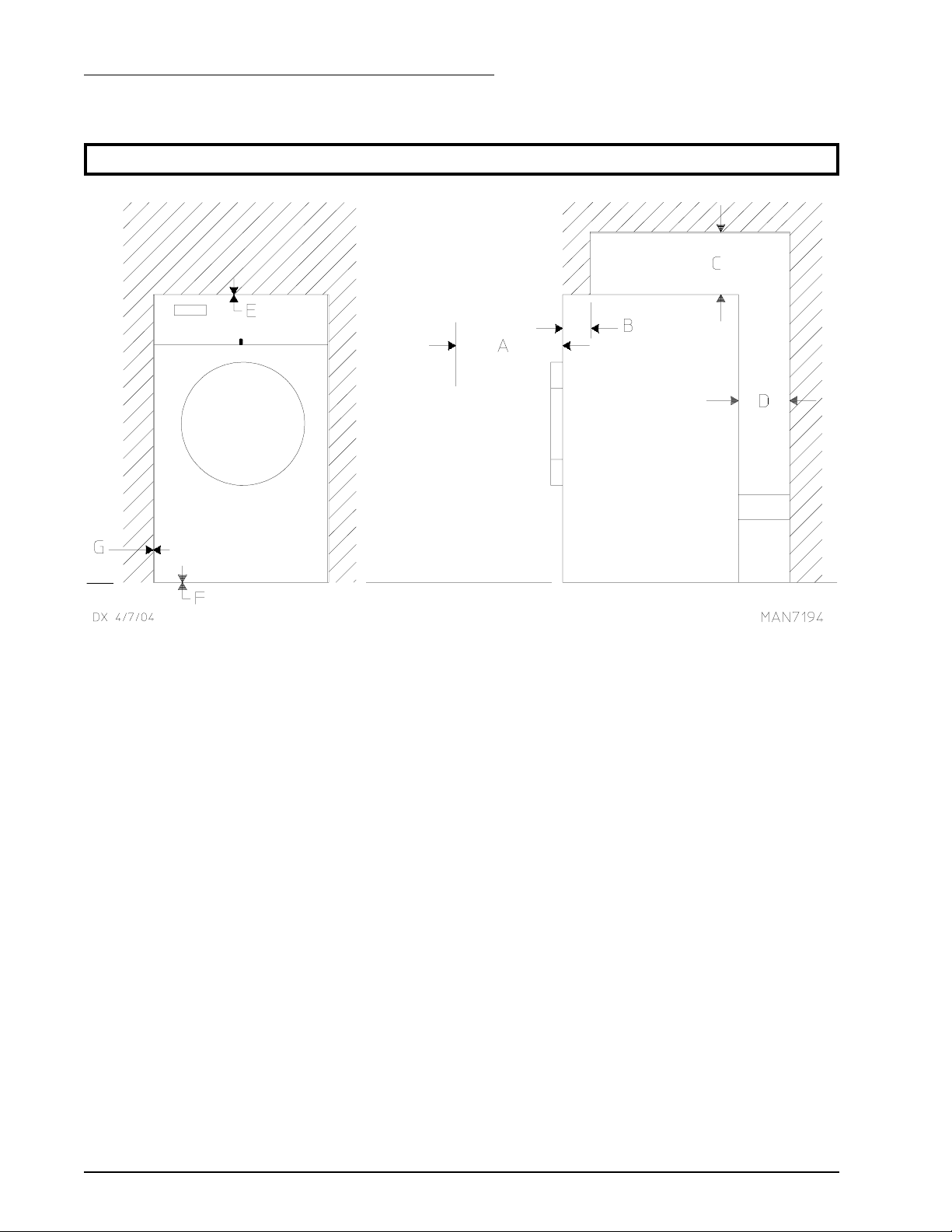

C. DRYER ENCLOSURE REQUIREMENTS

Bulkheads and partitions should be made of noncombustible material.

NOTE: Allowances must be made for opening the control door .

A 30-inches (76.2 cm) for optimum opening of load door.

B The maximum thickness of the bulkhead is 4-inches (10.16 cm). For electric dryers the maximum thickness

of the bulkhead is 1-inch (2.54 cm) within 3-inches (7.62 cm) from the top of the control door.

C For gas and electric dryers a minimum overhead clearance of 12-inches (30.48 cm) is required, providing no

sprinkler is located above the dryer. For steam dryers or if a sprinkler is located above the dryer, 18-inches

(45.72 cm) is required.

D Dryer should be positioned 12-inches (30.48 cm) away from the nearest obstruction and 24-inches (60.96

cm) is recommended for ease of installation, maintenance, and service.

E 2-inch (5.08 cm) minimum is required for opening the control door.

F Flooring should be level or below dryer cabinet for ease of removing panels during maintenance.

G Dryers may be positioned sidewall to sidewall, however a 1/16” (1.5875 mm) minimum allowance must be

made for the opening and closing of the control door, along with the removal of panels during maintenance.

10 American Dryer Corp. 113231-4

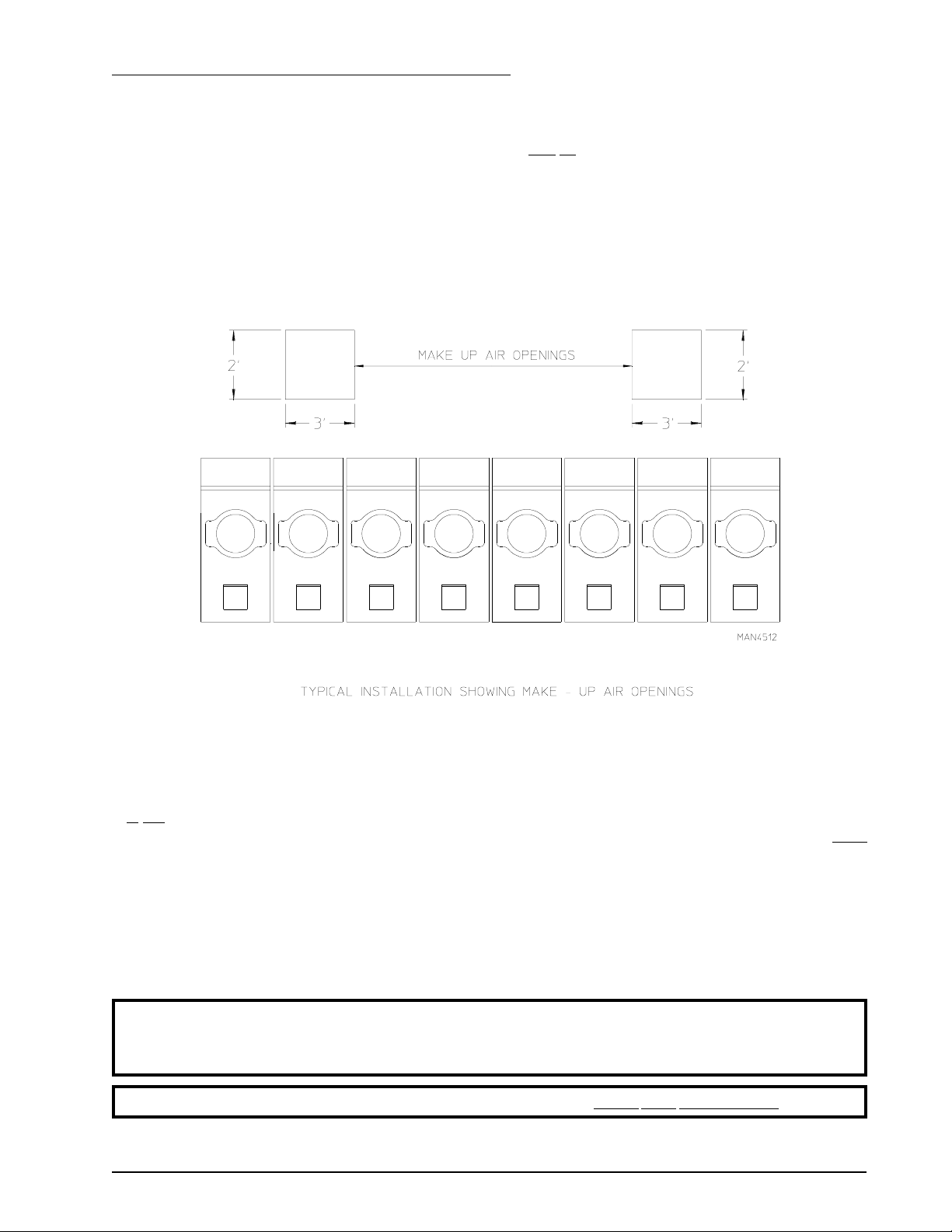

D. FRESH AIR SUPPLY REQUIREMENTS

When the dryer is operating, it draws in room air, heats it, passes this air through the basket (tumbler), and

exhausts it out of the building. Therefore, the room air must be continually replenished from the outdoors. If the

make-up air is inadequate, drying time and drying efficiency

sail switch “fluttering” problems may result, as well as premature motor failure from overheating. The dryer

must be installed with provisions for adequate combustion and make-up air supply .

Air supply (make-up air) must be given careful consideration to ensure proper performance of each dryer . An

airflow of 900 cfm (25.44 cmm) must be supplied to gas dryers and 1,200 cfm (33.98 cmm) for electric or steam

dryers. As a general rule, an unrestricted air entrance from the outdoors (atmosphere) of a minimum of 1-1/2

square feet (0.14 square meters) is required for each dryer.

will be adversely affected. Ignition problems and

To compensate for the use of registers or louvers used over the openings, this area must be increased by

approximately thirty-three percent (33%). Make-up air openings should not be located in an area directly near

where exhaust vents exit the building.

It

is not necessary to have a separate make-up air opening for each dryer. Common make-up air openings are

acceptable. However, they must be set up in such a manner that the make-up air is distributed equally to

the dryers.

EXAMPLE: For a bank of eight (8) dryers, two (2) unrestricted openings measuring 2 feet by 3 feet (0.61

meters by 0.91 meters) are acceptable.

Allowances must be made for remote or constricting passageways or where dryers are located at excessive

altitudes or predominantly low pressure areas.

ALL

IMPORTANT: Make-up air must be provided from a source free of dry cleaning solvent fumes.

Make-up air that is contaminated by dry cleaning solvent fumes will result in

irreparable damage to the motors and other dryer components.

NOTE: Component failure due to dry cleaning solvent fumes will VOID THE W ARRANTY.

113231-4 www.amdry.com 11

Loading...

Loading...