AMD Advanced Micro Devices Am29SL800CT150WBIB, Am29SL800CT150WBI, Am29SL800CT150WBCB, Am29SL800CT150WBC, Am29SL800CT150FIB Datasheet

...

PRELIMINARY

Am29SL800C

8 Megabi t (1 M x 8-Bit/51 2 K x 16-Bit)

CMOS 1.8 Volt-only Super Low Volta ge Flash Memory

DISTINCTIVE CHARACTERISTICS

■ Single p ower supply operation

— 1.8 to 2.2 V for read, program, and erase

operations

— Ideal for battery-powered applications

■ Manufactured on 0.32 µm process technology

— Compatible with 0.35 µm Am29SL800B device

■ High performance

— Access times as fast as 100 ns

■ Ultra low power consumption (typical values at

5 MHz)

— 65 nA Automatic Sleep Mode current

— 65 nA standby mode current

— 5 mA read current

— 10 mA program/erase current

■ Flexible sector architecture

— One 16 Kbyte, two 8 Kbyte, one 32 Kbyte, and

fifteen 64 Kbyte sectors (byte mode)

— One 8 Kword, two 4 Kword, one 16 Kword, and

fifteen 32 Kword sectors (word mode)

— Supports full chip erase

— Sector Protection features:

A hardwar e me tho d of lockin g a sec to r to

prevent any program or erase operations wi thin

that sector

Sectors can be locked in-system or via

programming equipment

T emporary Sector Unprotect feature allows code

changes in previously locked sectors

■ Unlock Bypass Program Command

— Reduces overall programming time when

issui ng mult iple program command sequences

■ Top or bottom boot block configurations

available

■ Embedded Algorithms

— Embedded Erase algorithm automatically

preprograms and erases the entire chip or any

combination of designated sectors

— Embedded Program algorithm automatically

writes and verifies data at specified addresses

■ Minimum 1,000,000 write cycle guarantee per

sector

■ Package option

— 48-pin TSOP

— 48-ball FBGA

■ Compatibility with JEDEC standards

— Pinout and software compatible with single-

power supply Flash

— Superior inadvertent write protection

■ Data# Polling a nd toggle bits

— Provides a software method of detecting

program or erase operation completion

■ Ready/Bu sy # pin (RY/BY#)

— Provides a hardware method of detecting

program or erase cycle completion

■ Erase Sus pe nd /Er as e R es ume

— Suspends an erase operation to read data from,

or program data to, a sector th at is not being

erased, then resumes the erase operation

■ Hardware reset pin (RESET#)

— Hardware method to reset the device to reading

array data

This do c um ent contains information on a product under d evel opment at A dvanced Mi c r o Devices. The inform ation

is intended to help you evaluate this product. AMD reserves the right to change or discontinue work on this proposed

product without notice.

Refer to AMD’s Website (www.amd.com) for the latest information.

Publication# 22230 Rev: A Amendment/0

Issu e Dat e: August 1998

PRELIMINARY

GENERAL DESCRIPTION

The Am 29SL 800C i s an 8 M bit, 1.8 V vol t-only Flas h

memory organized as 1,048,576 bytes or 524,288

words. The d evice is offe red in 48 -pin TSOP and 48 ball FBGA packages. The word-wide data (x16)

appears on DQ15–DQ0; the byte-wide (x8) data

appear s on DQ7– DQ0. T his de vice is d esigne d to be

programmed and erased in-system with a single 1.8

volt V

The device c an also be program med in standard

EPROM programmers.

The standard device offers access times of 100, 120,

and 150 ns, allowing high speed microprocessors to

operate without wait states. To eliminate bus contention

the device has separate chip enable (CE#), write

enable (WE#) and output enable (OE#) controls.

The de vi ce re q ui r es on l y a single 1.8 volt power sup-

ply for both read and write functions. Internally generated and regulated voltage s are provided for th e

program and erase operations.

The device is entirely command set compatible with the

JEDEC single-power-supply Flash standard. Commands are written to the command register using

standard microprocessor write timings. Register contents serve as input to an internal state-machine that

controls the erase and programming circuitr y. Write

cycles also internally latch addresses and data needed

for the programming and erase operations. Reading

data ou t of the d evice is simi lar to re ading fr om othe r

Flash or EPRO M devices .

Device pro gram m ing oc cu rs by executing the program

command sequence. This initiates the Embedded

Program algorithm—an internal algorithm that automatically times the program pulse widths and verifies

proper cell margin. The Unlock Bypass mode facilitates faster programming times by requiring only two

write cycles to program data instead of four.

Device erasure occurs by ex ecuting the erase command

sequence. This initiates the Embedded Erase algorithm—an i nternal algo rithm tha t automatically prep rograms the array (if it is not already programmed) before

executing the erase operation. During erase, the device

automatically times the erase pulse widths and verifies

proper cell margin.

supply. No VPP is for wr ite or era se oper ations .

CC

The ho st system ca n detect whe ther a progra m or

erase op eration is co mp lete by ob ser vin g t he RY/BY#

pin, or by reading the DQ7 (Data# Polling) and DQ6

(toggle ) st atus bit s. After a program or erase cycle has

been completed, the device is ready to read array data

or accept another command.

The sector erase architecture allows memory sectors

to be erased and reprogrammed without affecting the

data contents of other sectors. The device is fully

eras ed when shipped f r om the factory.

Hardware data protection measures includ e a low

V

detector that auto matically inhibits write opera-

CC

tions during power transitions. The hardware sector

protection feature disables both program and erase

operatio ns in any com binatio n of the s ectors of m emory. This can be achieved in-system or via programming equipment.

The Erase Suspend feature enables the user to put

erase on ho ld for any pe r i od of tim e to rea d da ta fr om ,

or program d ata to, any secto r that is not se lected for

erasure. True background erase can thus be achieved.

The hardware RESET# pin terminates any operation

in progress and resets the internal state machine to

reading array data. T he RESET# pin ma y b e tied to t he

system rese t circuitr y. A system reset would thus a lso

reset the device, enabling the system micropr ocessor

to read the boot-up firmware from the Flash memory.

The device offers two power-saving features. When addresses have been stable for a specified amount of

time, the device enters the automatic sleep mode.

The system can also place the device into the standby

mode. Power consumption is greatly reduced in both

these modes.

AMD’s Flash technology combines years of Flash

memory manufacturing experience to produce the

highest levels of quality, reliability and cost effectiveness. The device electrically erases all bit s with in

a sector simultaneously via Fowler-Nordheim tunneling. The data is programmed using hot electron

injection.

2 Am29SL800C

PRELIMINARY

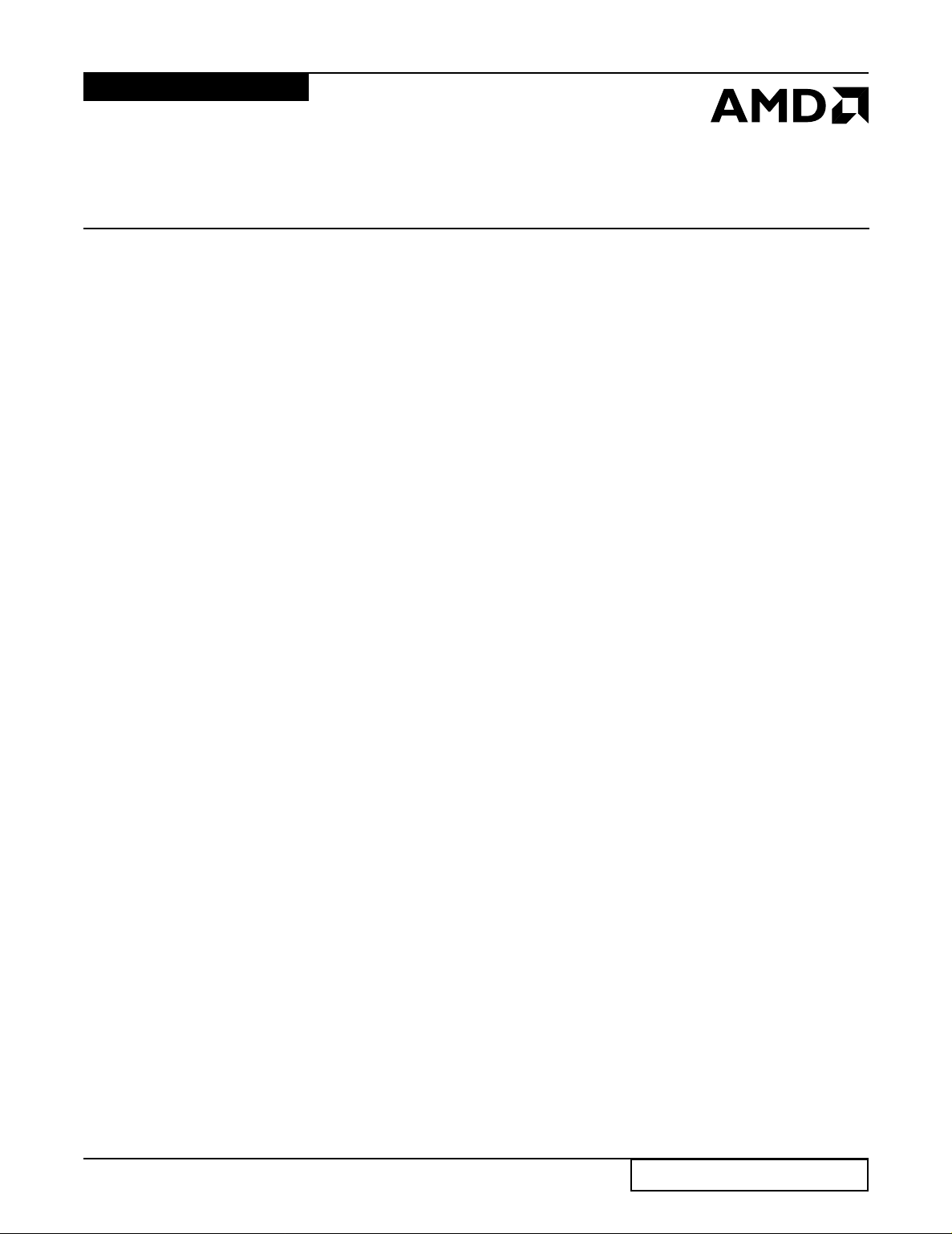

PRODUCT SELECTOR GUIDE

Family Part Number Am29SL800C

Speed Options 100 120 150

Max access time, ns (t

Max CE# access time, ns (tCE) 100 120 150

Max OE# access time, ns (tOE) 35 50 65

) 100 120 150

ACC

Note: See “AC Characteristics” for full specifications.

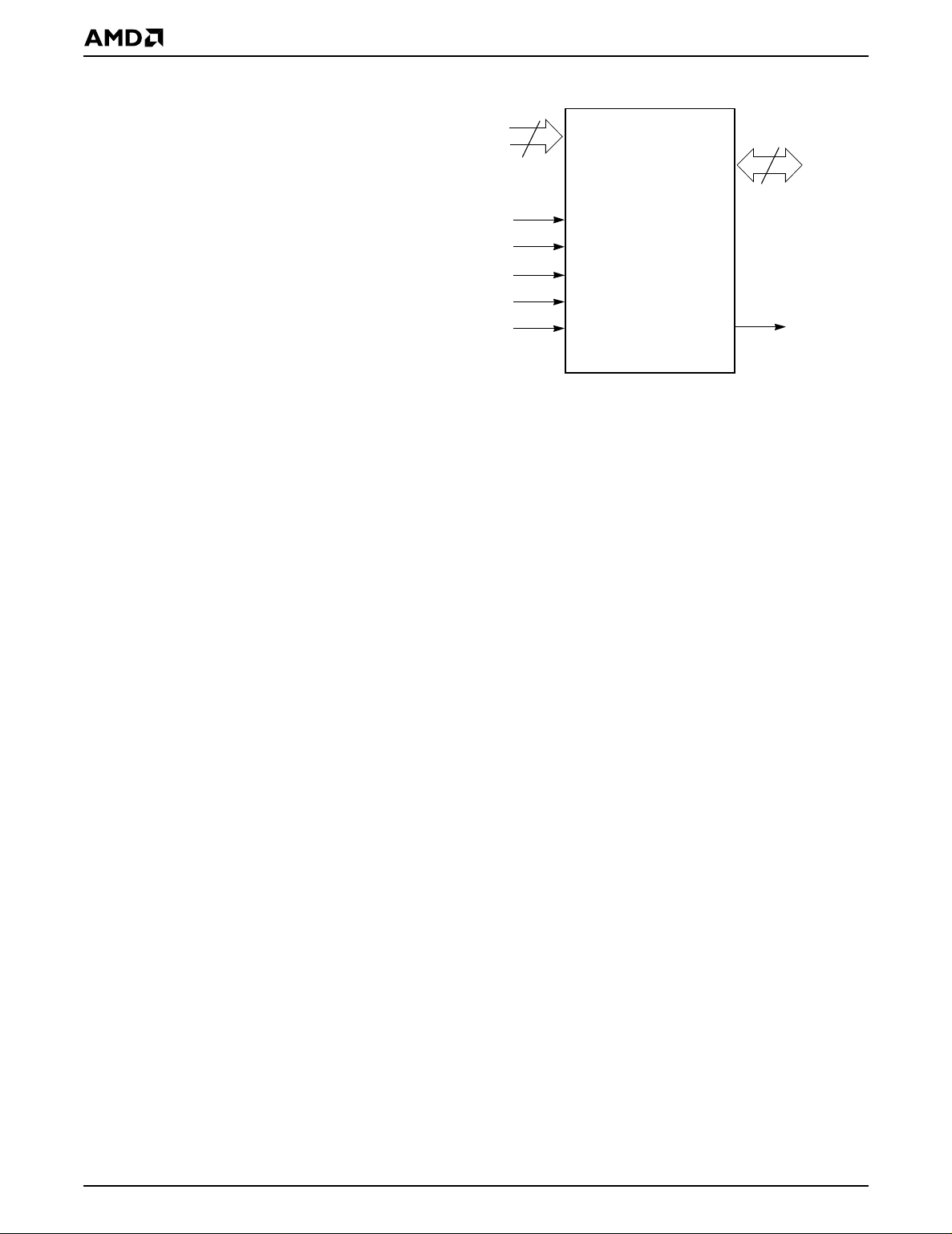

BLOCK DIAGRAM

DQ0

–

DQ15 (A-1)

Input/Output

Buffers

Data

Latch

V

CC

V

SS

RESET#

WE#

BYTE#

CE#

OE#

RY/BY#

State

Control

Command

Register

PGM Voltage

Generator

Sector Switches

Erase Voltage

Generator

Chip Enable

Output Enable

Logic

STB

A0–A18

VCC Detector

Timer

STB

Address Latch

Y-Decoder

X-Decoder

Y-Gating

Cell Matrix

22230A-1

Am29SL800C 3

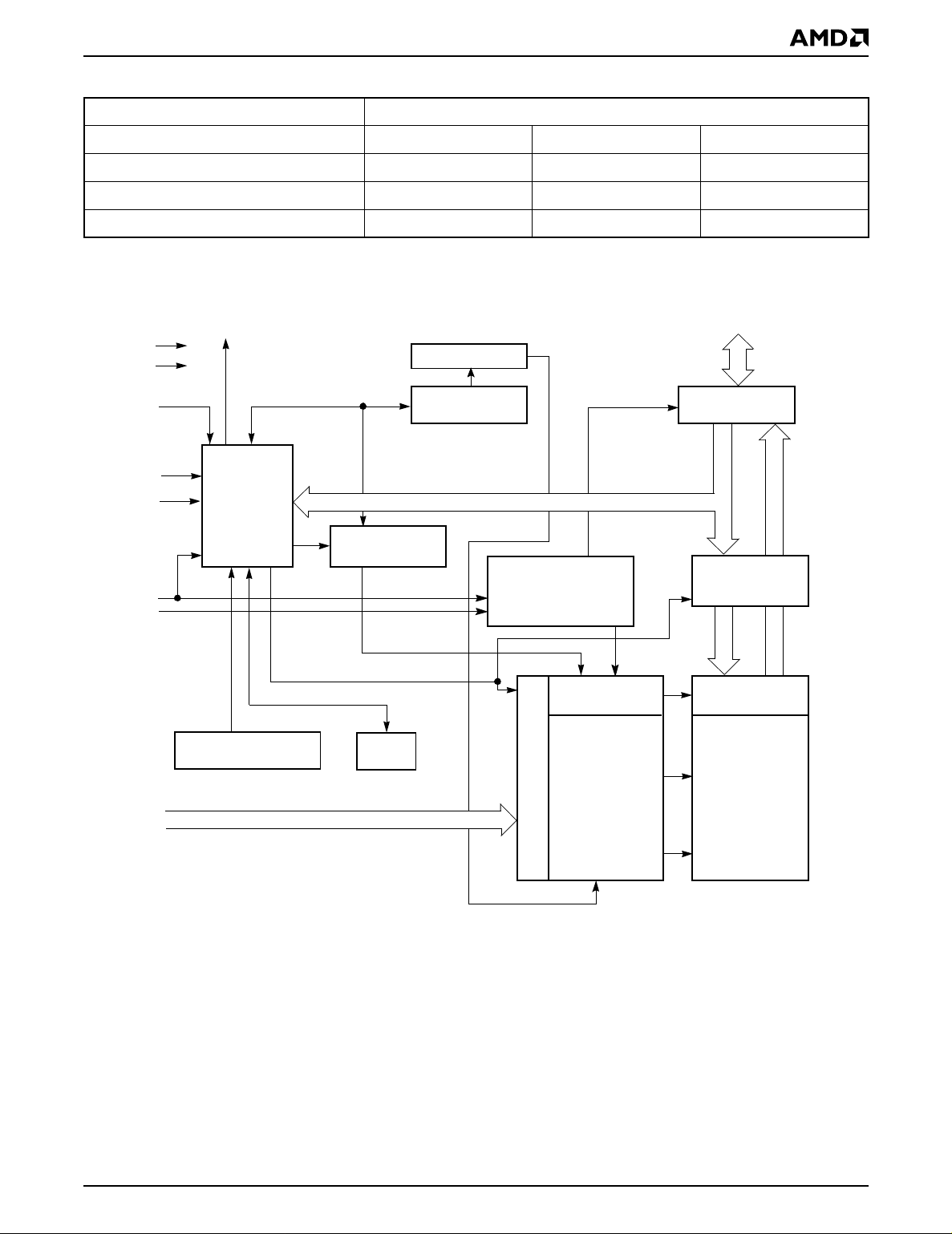

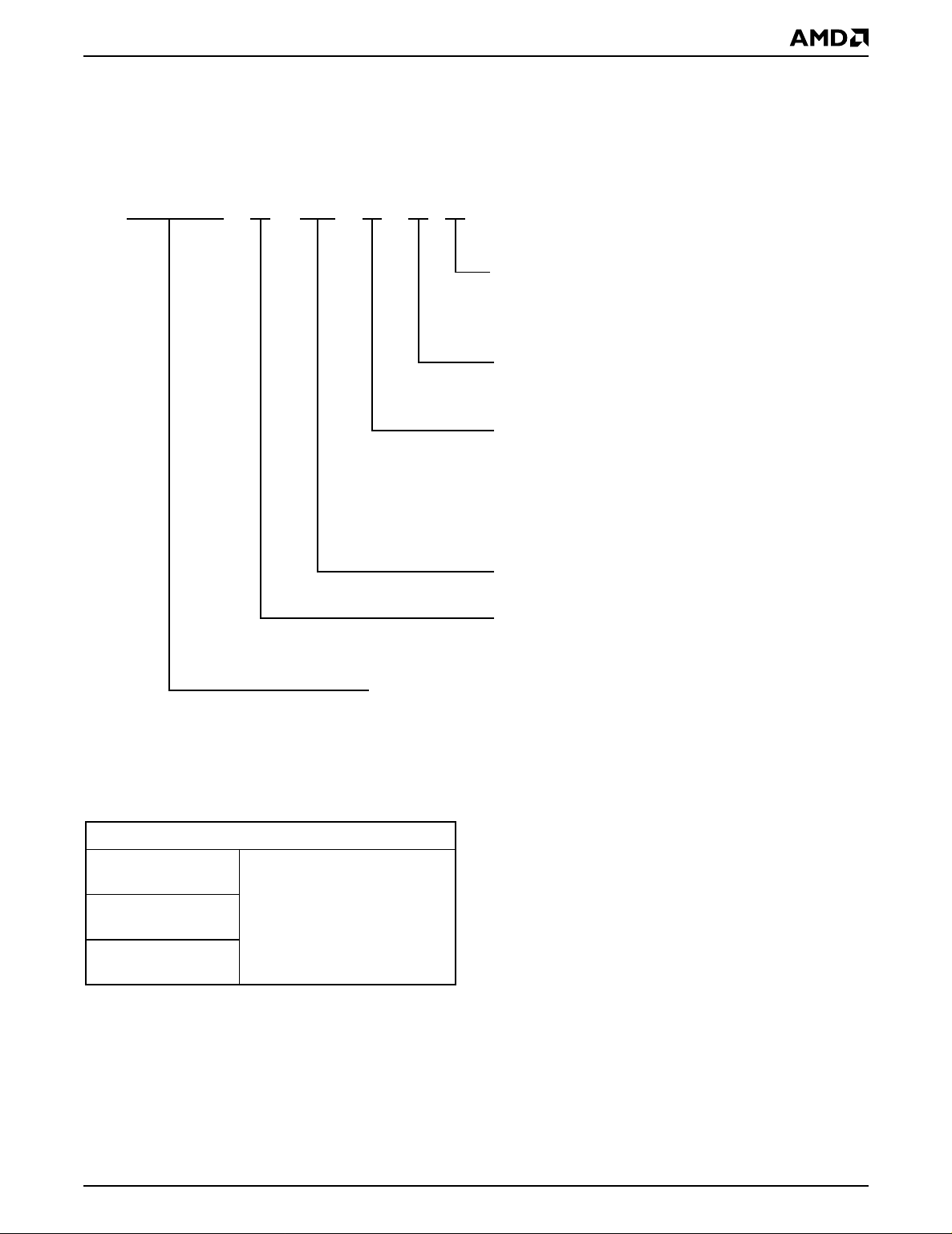

CONNECTION DIAGRAMS

PRELIMINARY

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC

WE#

RESET#

NC

NC

RY/BY#

A18

A17

A7

A6

A5

A4

A3

A2

A1

A16

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

V

SS

CE#

A0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Standard TSOP

Reverse TSOP

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A16

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

V

SS

CE#

A0

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC

WE#

RESET#

NC

NC

RY/BY#

A18

A17

A7

A6

A5

A4

A3

A2

A1

4 Am29SL800C

22230A-2

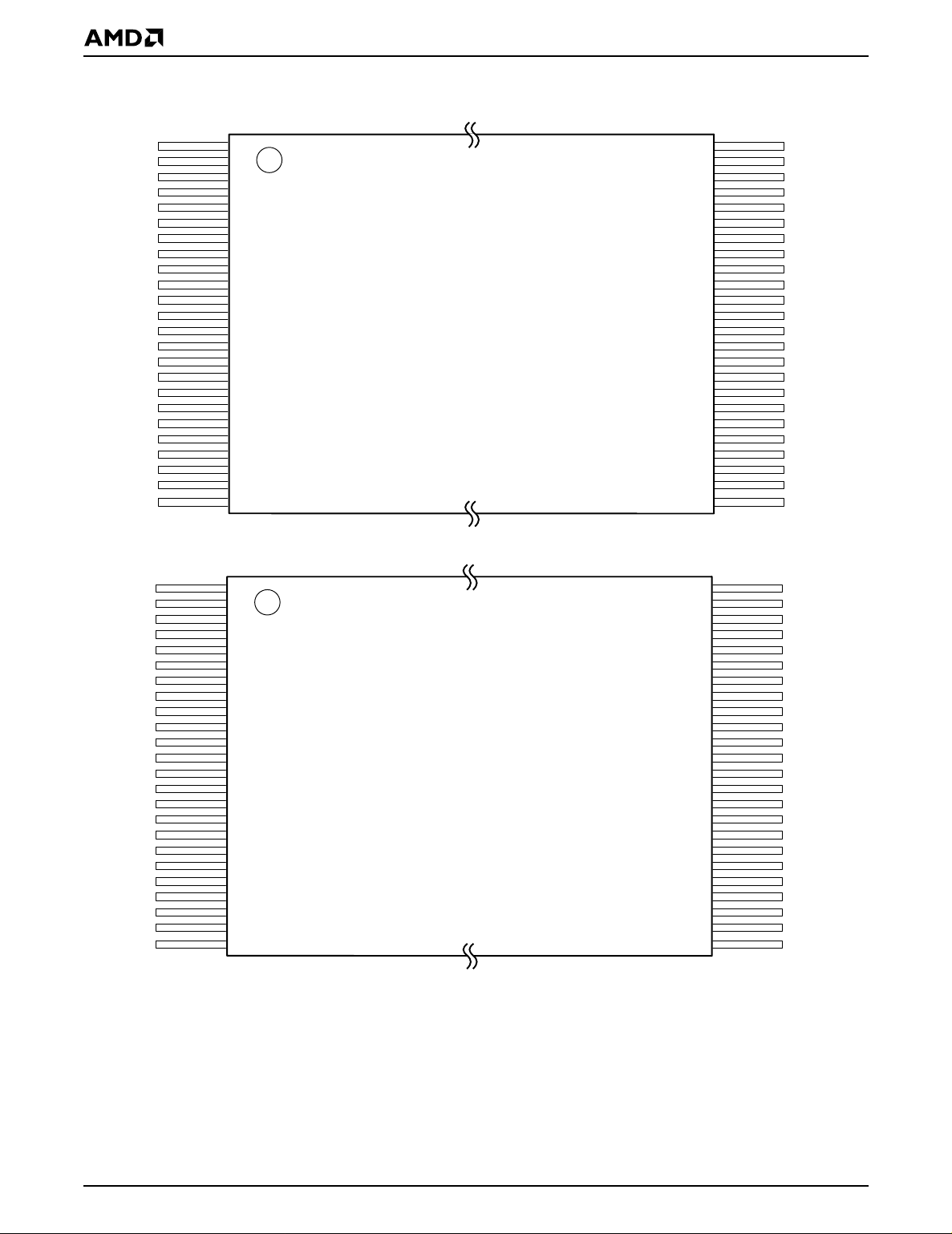

CONNECTION DIAGRAMS

A1 B1 C1 D1 E1 F1 G1 H1

PRELIMINARY

48-Ball FBGA (Bottom View)

A2 B2 C2 D2 E2 F2 G2 H2

A3 B3 C3 D3 E3 F3 G3 H3

A4 B4 C4 D4 E4 F4 G4 H4

A5 B5 C5 D5 E5 F5 G5 H5

A6 B6 C6 D6 E6 F6 G6 H6

Special Handling Instructions for FBGA Packages

Special handling is required for Flash Memory products

in FBGA packages.

CE#A0A1A2A4A3

BYTE#A16A15A14A12A13

OE# V

DQ9 DQ1DQ8DQ0A5A6A17A7

DQ11 DQ3DQ10DQ2NCA18NCRY/BY#

V

CC

DQ13 DQ6DQ14DQ7A11A10A8A9

DQ15/A-1 V

SS

DQ4DQ12DQ5NCNCRESET#WE#

SS

22230A-3

Flash memory devices in FBGA packages may be

damaged if exposed to ultrasonic cleaning methods.

The package and/or data integrity may be compromised

if the package body is exposed to temperatures above

150°C for prolonged periods of time.

Am29SL800C 5

PRELIMINARY

PIN CONFIGURATION

A0–A18 = 19 addresse s

DQ0–DQ14 = 15 data inputs/out pu ts

DQ15/A-1 = DQ15 (data input/output, word mode),

A-1 (LSB addre s s input, byte mode)

BYTE# = Selects 8-bit o r 16-bit mode

CE# = Chip enable

OE# = Output enable

WE# = Write en able

RESET# = Hardware reset pin, active low

RY/BY# = Ready/Busy# output

V

= 1.8–2.2 V single power supply

CC

V

SS

NC = Pin not connected internally

= Device ground

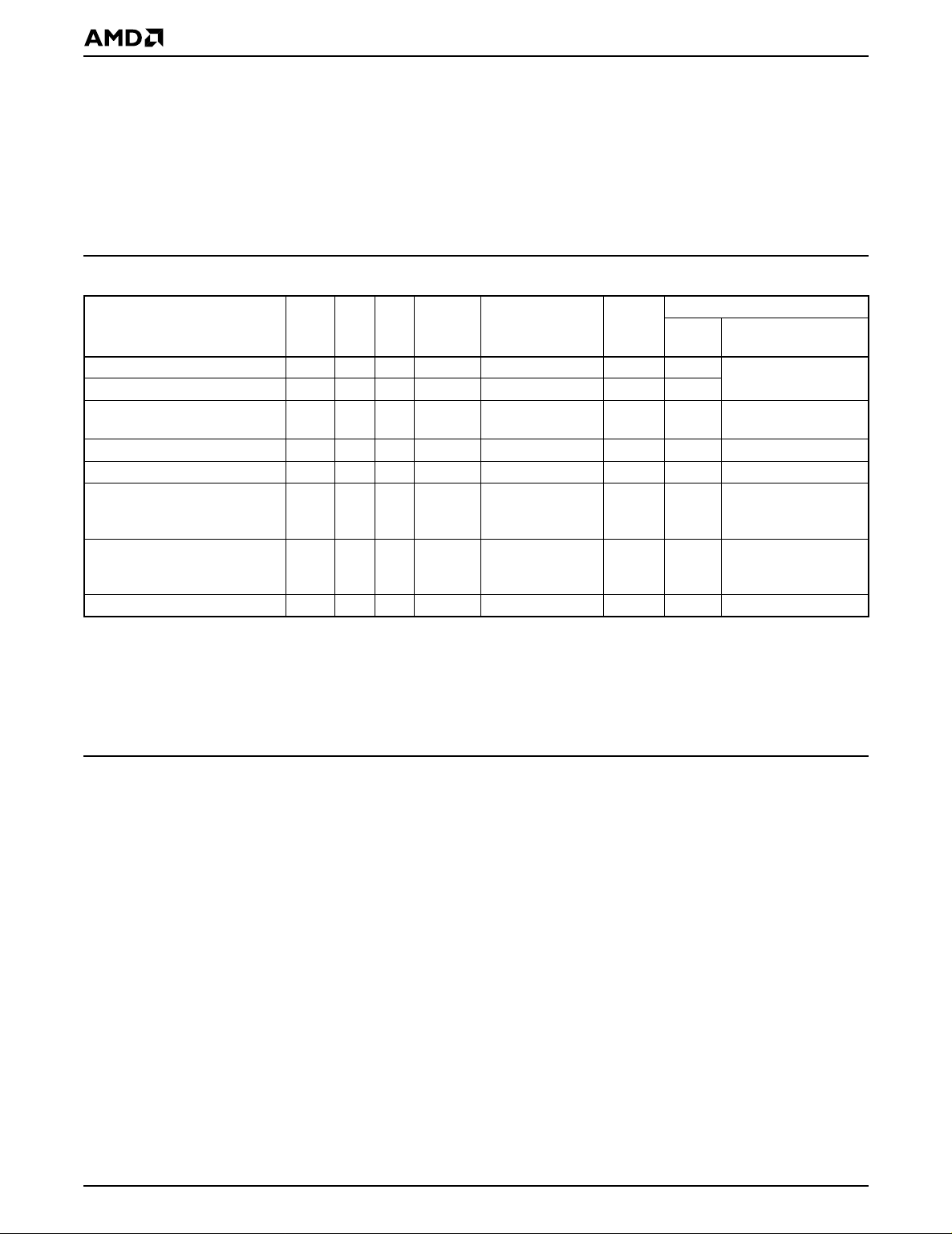

LOGIC SYMBOL

19

A0–A18

CE#

OE#

WE#

RESET#

BYTE# RY/BY#

16 or 8

DQ0–DQ15

(A-1)

22230A-4

6 Am29SL800C

PRELIMINARY

ORDERING INFORMATION

Standard Products

AMD stan dard produc ts ar e available in several pack ages an d opera ting ranges. Th e orde r numbe r (Valid Comb ination) is formed by a combination of the elements below.

CE100Am29SL800C T

OPTIONAL PROCESSING

Blank = Standard Processing

B = Burn-in

(Contact an AMD representative for more information)

TEMPERATURE RANGE

C=Commercial (0°C to +70°C)

I = Industrial (–40°C to +85°C)

PACKAGE TYPE

E = 48-Pin Thin Small Outline Package (TSOP)

Standard Pinout (TS 048)

F = 48-Pin Thin Small Outline Package (TSOP)

Reverse Pinout (TSR048)

WB = 48-ball Fine-Pitch Ball Grid Array (FBGA)

0.80 mm pitch, 6 x 9 mm package

Am29SL800CT100,

Am29SL800CB100

Am29SL800CT120,

Am29SL800CB120

Am29SL800CT150,

Am29SL800CB150

Valid Combinations

EC, EI, FC, FI, WBC, WBI

SPEED OPTION

See Product Selector Guide and Valid Combinations

BOOT CODE SECTOR ARCHITECTURE

T = Top Sector

B = Bottom Sector

DEVICE NUMBER/DE SCRIP TION

Am29SL800C

8 Megabit (1 M x 8-Bit/512 K x 16-Bit) CMOS Flash Memory

1.8 Volt-only Read, Program, and Erase

Valid Combinations

Valid Combinations list configurations planned to be supported in volume for this device. Consult the local AMD sales

office to confirm availability of specific valid combinations and

to check on newly released combinations.

Am29SL800C 7

PRELIMINARY

DEVICE BUS OPERATIONS

This section describes the requirements and use of the

device bus operat ions, whi ch are init iated thro ugh the

internal command register. The command register itself does not occupy any addressable memory location. The register is composed of latches that store the

comman ds, along with the add ress an d data infor mation needed to execute the command. The contents of

Table 1. Am29SL800C Device Bus Operations

Operation CE# OE# WE# RESET#

Read L L H H A

Write L H L H A

V

±

Standby

Output Disable L H H H X High-Z High-Z High-Z

Reset X X X L X High-Z High-Z High-Z

Sector Protect (Note 2) L H L V

Sector Unprotect (Note 2) L H L V

Temporary Sector Unprotect X X X V

Legend:

L = Logic Low = V

Notes:

1. Addresses are A18:A0 in word mode (BYTE# = V

2. The sector protect and sector unprotect functions may also be implemented via programming equipment. See the “Sector

Protection/Unprotection” section.

, H = Logic High = VIH, VID = 10 ± 1.0 V, X = Don’t Care, AIN = Address In, DIN = Data In, D

IL

CC

0.3 V

XX

VCC ±

0.3 V

ID

ID

ID

), A18:A-1 in byte mode (BYTE# = VIL).

IH

the register serve as inputs to the internal state machine. The state machine outputs dictate the function of

the device. Table 1 lists th e d evice bus o pe ratio ns, th e

inputs and control lev els they require, and the resulting

output. The following s ubsections describe each of

these operations in further detail.

DQ8–DQ15

Addresses

(Note 1)

IN

IN

X High-Z High-Z High-Z

Sector Address,

A6 = L, A1 = H,

A0 = L

Sector Address,

A6 = H, A1 = H,

A0 = L

A

IN

DQ0–

DQ7

D

OUT

D

IN

D

IN

D

IN

D

IN

BYTE#

= V

IH

D

OUT

D

IN

XX

XX

D

IN

BYTE#

= V

IL

DQ8–DQ14 = High-Z,

DQ15 = A-1

High-Z

= Data Out

OUT

W ord/Byte Configuration

The BY TE# p in contr ol s whethe r the device data I/O pins

DQ15–DQ0 operate in the byte or word configuration. If the

BYTE# pin is set at logic ‘1’, the device is in word configuration, DQ 15–DQ0 are ac tive and con trolled by CE # and

OE#.

If the BYTE# pin is set at logic ‘0’, the device is in byte configuration, and only data I/O pins DQ0–DQ7 are active and

controlled by CE# and OE#. The data I/O pins DQ8–DQ14

are tri-stated, and the DQ15 pin is used as an input for the

LSB (A-1) address function.

Requirements for Reading Array Data

The internal state machine is set for reading array data

upon device power-up, or after a hardware reset. This ensures that no spurious alteration of the memory content occurs during the power transition. No co mmand is

necessary in this mode to obtain array data. Standard microproce ssor read cy cles tha t asse rt valid ad dresse s on

the device address inputs produce valid data on the device

data outputs. The device remains enabled for read access

until the command register contents are altered.

See “Reading Array Data” for m ore informati on. Refer to

the AC Read Operations table for timing specifications and

to Figure 13 for the timing diagram. I

teristics table represents the active current specification for

reading array data.

To read array data from the outputs, the system must driv e

the CE# and OE# pins to V

selects the device. OE# is the output control and gates

array data to the ou tput pins. W E# shoul d rem ain at V

The BYTE# pin determines whether the device outputs

array data in words or bytes.

. CE# is the power control and

IL

Writing Commands/Command Sequences

To write a command or command seque nce (whic h in-

.

IH

cludes programming data to the device and erasing sectors

of memory), the syste m must drive WE# and CE# to V

and OE# to V

8 Am29SL800C

in the DC Charac-

CC1

,

.

IH

IL

PRELIMINARY

For program operatio ns, the BYTE# pin deter mines

whether the dev ice accepts program data in bytes or

words. Refer to “Word/Byte Configuration” for more information.

The device features an Unlock Bypass mode to facilitate

faster programming. Once the device enters the Unlock

Bypass mode, only two write cycles are required to program a word or byte, instead of four. The “Word/Byte Program Command Sequence” section has details on

programming data to the device using bo th stand ard and

Unlock Bypass command sequences.

An erase operation can erase one sector, multiple sectors,

or the enti re device. Tables 2 and 3 indica te the add ress

space that eac h sector oc cup ie s. A “s ector addr ess ” co nsists of the address bits required to uniquely select a sector.

The “Command Definitions” section has details on erasing

a sector or the entire chip, or suspending/resuming the

erase operation.

After the system writes the autoselect command sequence, the device enters the autoselect mode. The system can then read autoselect codes from the internal

register (whic h is separate from the me mory array) on

DQ7–DQ0. Standard read cycle timings apply in this mode.

Refer to the Autoselect Mode and Autoselect Command

Sequence sections for more information.

I

in the DC Characteristics table repres ents the active

CC2

current speci fic ation fo r the w rite mode . T he “ AC Ch aracteristics” section contains timing specification tables and

timing diagrams for write operations.

Program and Erase Operation Status

During an erase or program operation, the system may

check the status of the operation by reading the status bits

on DQ7–DQ0. Standard read cycle timings and I

CC

read

specificat ions ap ply. Refer to “Write Opera tion Status” for

more information, and to “AC Characteristics” for timing diagrams.

Standby Mode

When the system is not reading or writing to the device, it

can plac e t he device in th e stan dby mo de. In th is m ode,

current consumption is greatly reduced, and the outputs

are placed in the high impedance state, independent of the

OE# input.

The device enters the CMOS standby mode when the CE#

and RESET# pins are both held at V

this is a more restricted voltage range than V

RESET# are held at V

, but not within V

IH

vice will be in the standby mode, but the standby current will

be greater. The device requires standard access time (t

for re ad ac ces s when th e devic e is i n ei ther of t hese

standby modes, before it is ready to read data.

The device also enters the standby mode when the RESET# pin is driven low. Ref er to the next section, RESET#:

Hardware Reset Pin.

± 0.3 V. (Note that

CC

.) If CE# and

IH

± 0.3 V, the de-

CC

CE

If the device is deselected during erasure or programming,

the de vice dra w s act ive cur r e nt unt i l the o p er a t io n is completed.

I

in the DC Characteristics table represents the standby

CC3

current specification.

Aut oma ti c S lee p Mod e

The automatic sleep mode minimizes Flash device energy

consumption. The device automatically enables this mode

when addresses remain stable for t

ACC

automatic sleep mode is independent of the CE#, WE#,

and OE# control signals. Standard address access timings

provide new data when addresses are changed. Whi le in

sleep mode, output data is latched and always a vailable to

the system. I

in the DC Characteristics table represents

CC4

the automatic sleep mode current specification.

RESET#: Hardware Rese t Pi n

The RESET# pin provides a hardware method of resetting

the device to reading array data. When the RESET# pin is

driven low for at l east a p er io d o f t

ately terminates any operation in progress, tristates all

output pins, and ignores all read/write commands for the

duration of the RESET# pulse. The device also resets the

internal state machine to reading array data. The operation

that was interrupted should be reinitiated once the device is

ready to accept another command sequence, to ensure

data integrity.

Current is reduced for the duration of the RESET# pulse.

When RESET# is held at V

CMOS standby current (I

not within V

±0.3 V, the standby current will be greater.

SS

SS

). If RESET# is held at VIL but

CC4

The RESET# pin may be tied to the system reset circuitry.

A system reset woul d thus also rese t the Fla sh memor y,

enabling the system to read the boot-up firmware from the

Flash m e mory.

If RESET# is asserted during a program or erase operation, the RY/BY# pin remains a “0” (busy) until the internal

reset operation is complete, which requires a time of

t

(during Embedded Algorithms). The system can

READY

thus monitor RY/BY# to determine whether the reset operation is complete. If RESET# is asserted when a program

or erase operation is not executing (RY/BY# pin is “1”), the

reset operation is completed within a time of t

during Embedded Algorithms). The system can read data

t

after the RESET# pin returns to VIH.

RH

Refer to the AC Characteristics tables for RESET# parameters and to Figure 14 for the timing diagram.

Output Disable Mode

)

When the OE# input is at VIH, output from the device is disabled. The out put pi ns are plac ed in the high impedan ce

state.

, the device immedi-

RP

±0.3 V, the device draws

+ 50 ns. The

(not

READY

Am29SL800C 9

PRELIMINARY

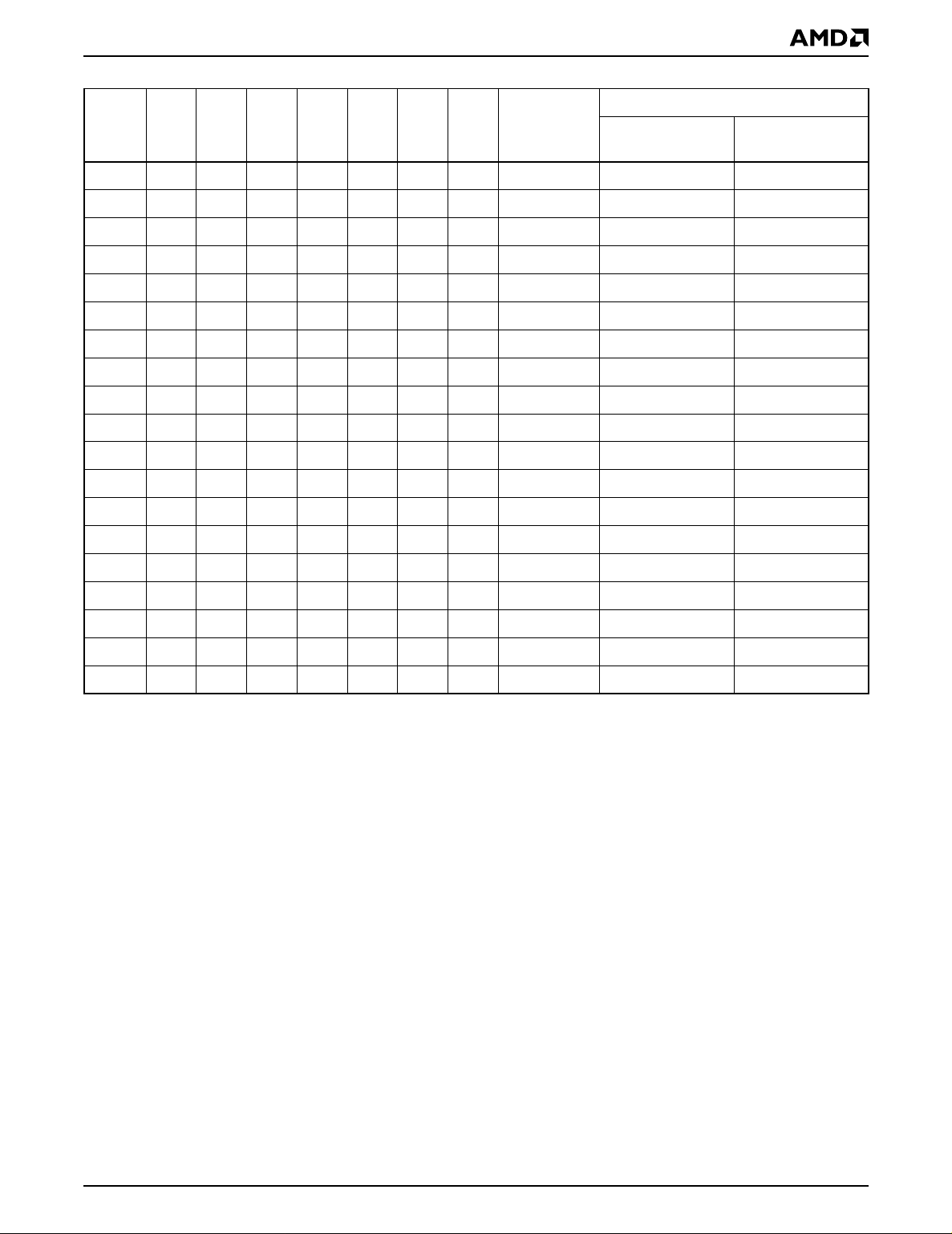

Table 2. Am29SL800CT Top Boot Block Sector Address Table

Sector Size

(Kbytes/

Sector A18 A17 A16 A15 A14 A13 A12

SA00000XXX 64/32 00000h–0FFFFh 00000h–07FFFh

SA10001XXX 64/32 10000h–1FFFFh 08000h–0FFFFh

SA20010XXX 64/32 20000h–2FFFFh 10000h–17FFFh

SA30011XXX 64/32 30000h–3FFFFh 18000h–1FFFFh

SA40100XXX 64/32 40000h–4FFFFh 20000h–27FFFh

SA50101XXX 64/32 50000h–5FFFFh 28000h–2FFFFh

SA60110XXX 64/32 60000h–6FFFFh 30000h–37FFFh

SA70111XXX 64/32 70000h–7FFFFh 38000h–3FFFFh

SA81000XXX 64/32 80000h–8FFFFh 40000h–47FFFh

SA91001XXX 64/32 90000h–9FFFFh 48000h–4FFFFh

SA10 1010XXX 64/32 A0000h–AFFFFh 50000h–57FFFh

SA11 1011XXX 64/32 B0000h–BFFFFh 58000h–5FFFFh

SA12 1100XXX 64/32C0000h–CFFFFh 60000h–67FFFh

SA13 1101XXX 64/32D0000h–DFFFFh 68000h–6FFFFh

Kwords)

Address Range (in hexadecimal)

(x8)

Address Range

(x16)

Address Range

SA14 1110XXX 64/32 E0000h–EFFFFh 70000h–77FFFh

SA15 11110XX 32/16 F0000h–F7FFFh 78000h–7BFFFh

SA16 1111100 8/4 F8000h–F9FFFh 7C000h–7CFFFh

SA17 1111101 8/4 FA000h–FBFFFh 7D000h–7DFFFh

SA18 111111X 16/8 FC000h–FFFFFh 7E000h–7FFFFh

10 Am29SL800C

PRELIMINARY

Table 3. Am29SL800CB Bottom Boot Block Sector Address Table

Sector Size

(Kbytes/

Sector A18 A17 A16 A15 A14 A13 A12

SA0000000X 16/8 00000h–03FFFh 00000h–01FFFh

SA10000010 8/4 04000h–05FFFh 02000h–02FFFh

SA20000011 8/4 06000h–07FFFh 03000h–03FFFh

SA300001XX 32/16 08000h–0FFFFh 04000h–07FFFh

SA40001XXX 64/32 10000h–1FFFFh 08000h–0FFFFh

SA50010XXX 64/32 20000h–2FFFFh 10000h–17FFFh

SA60011XXX 64/32 30000h–3FFFFh 18000h–1FFFFh

SA70100XXX 64/32 40000h–4FFFFh 20000h–27FFFh

SA80101XXX 64/32 50000h–5FFFFh 28000h–2FFFFh

SA90110XXX 64/32 60000h–6FFFFh 30000h–37FFFh

SA10 0111XXX 64/32 70000h–7FFFFh 38000h–3FFFFh

SA11 1000XXX 64/32 80000h–8FFFFh 40000h–47FFFh

Kwords)

Address Range (in hexadecimal)

(x8)

Address Range

(x16)

Address Range

SA12 1001XXX 64/32 90000h–9FFFFh 48000h–4FFFFh

SA13 1010XXX 64/32 A0000h–AFFFFh 50000h–57FFFh

SA14 1011XXX 64/32 B0000h–BFFFFh 58000h–5FFFFh

SA15 1100XXX 64/32C0000h–CFFFFh 60000h–67FFFh

SA16 1101XXX 64/32D0000h–DFFFFh 68000h–6FFFFh

SA17 1110XXX 64/32 E0000h–EFFFFh 70000h–77FFFh

SA18 1111XXX 64/32 F0000h–FFFFFh 78000h–7FFFFh

Note for Tables 2 and 3: Address range is A18:A-1 in byte mode and A18:A0 in word mode. See “Word/Byte Configuration”

section for more information.

Am29SL800C 11

PRELIMINARY

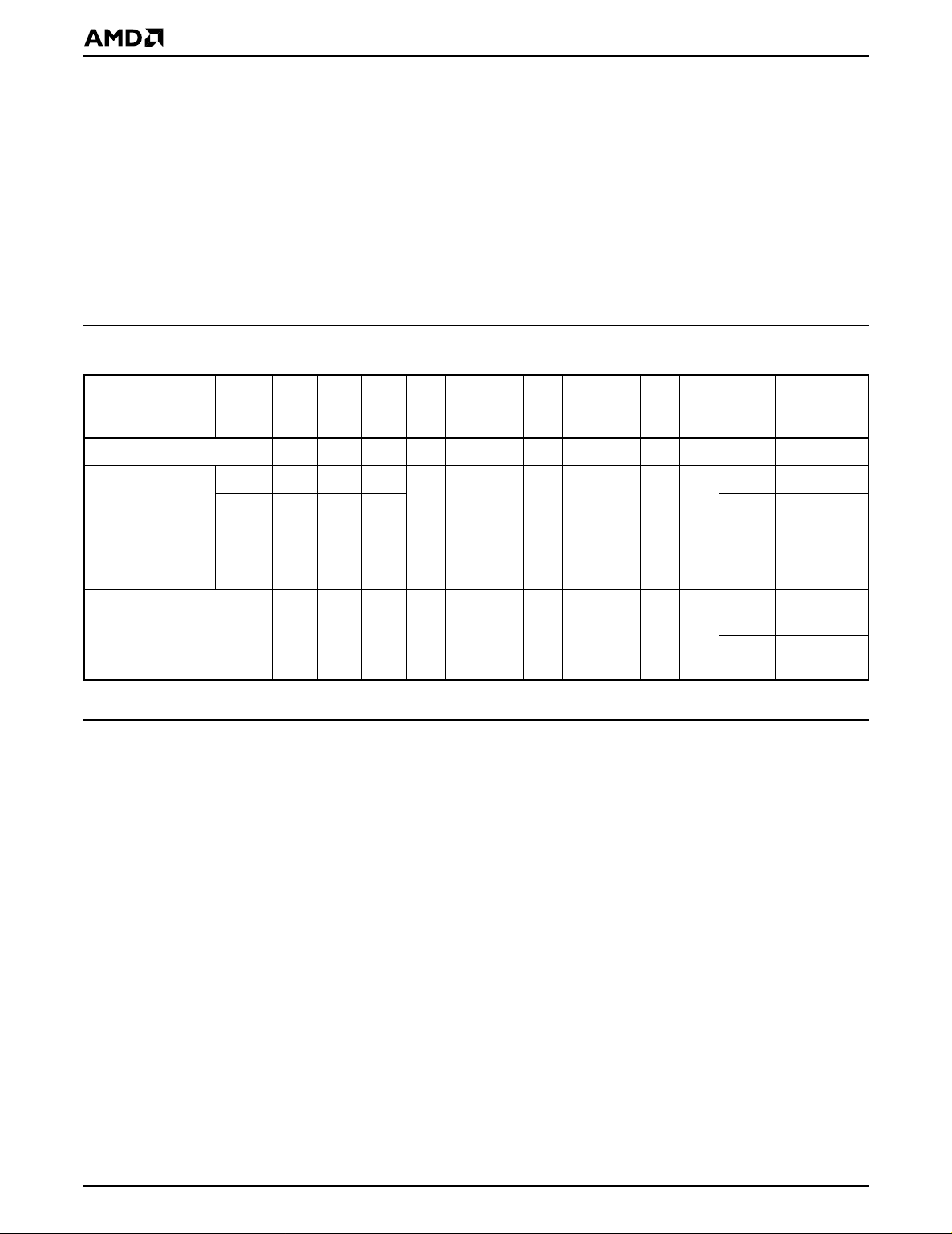

Autoselect Mode

The autoselect mode provides manufacturer and device identification, and sector protection verification,

through identifier codes output on DQ7–DQ0. This

mode is primarily intended for programming equipment

to automatically match a device to be programmed with

its correspo nding programmi ng algorithm . However,

the aut osel ect co des can also be a cces sed in -sy stem

through the command register.

When using programming equipment, the autoselect

mode requires V

A1, and A 0 must be a s shown i n Table 4. In addi tion,

Description Mode CE# OE# WE#

Manufacturer ID: AMD L L H X X V

Device ID:

Am29SL800C

(Top Boot Block)

on address pin A9. Address pins A6,

ID

Table 4. Am29SL800C Autoselect Codes (High Voltage Method)

A11

A18

to

to

A10 A9

A12

Word L L H

Byte L L H X EAh

XXV

when verifying sector protection, the sector address

must appear on the app ropri ate highest or der addres s

bits (see Tables 2 and 3). Table 4 shows the remaining

address bits that are don’t care. When all necessary bits

have been set as required, the programming equipment

may then read the corresp onding identifier cod e on

DQ7–DQ0.

To access the autoselect codes in-system, the host

system can issue the autoselect command via the

comma nd reg ister, as s hown in Table 5. T his meth od

does not require V

. See “Command Definitions” for

ID

details on using the autoselect mode.

A8

to

A7 A6

XLXLL X 01h

ID

XLXLH

ID

A5

to

A2 A1 A0

DQ8

to

DQ15

22h EAh

DQ7

to

DQ0

Device ID:

Am29SL800C

(Bottom Boot Block)

Sector Protection V erification L L H SA X V

L = Logic Low = VIL, H = Logic High = VIH, SA = Sector Address, X = Don’t care.

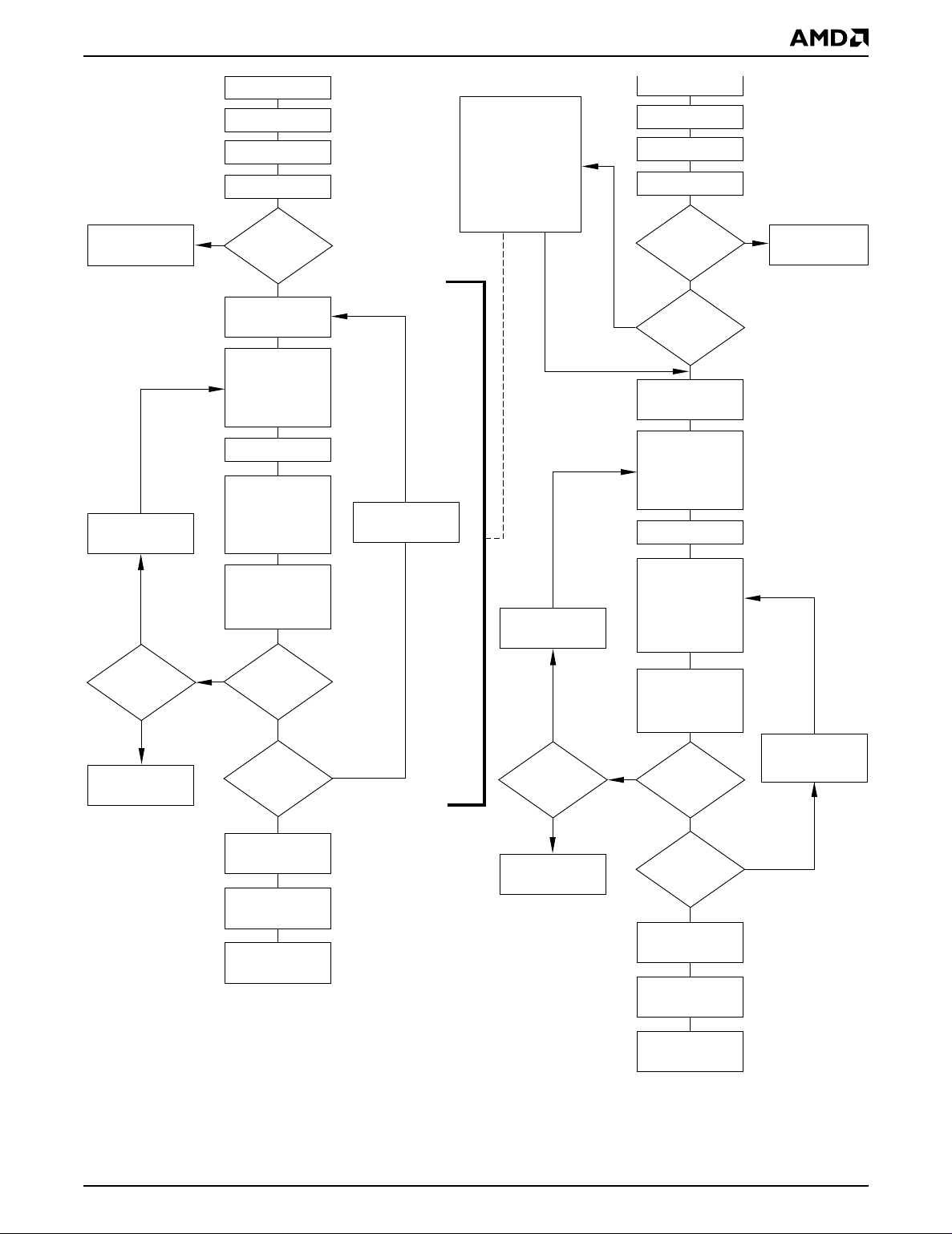

Sector Protection/Unprotection

The h ardwar e sect or p rotec tion fe ature disabl es bot h

program and erase operations in any sector. The hardware sect or unp rotecti on feature r e-enables both p rogram and erase operations in previously protected

sectors. Sector protection/unprotection can be implemente d via two method s.

The primary method requires V

only, and can be implemented either in-system or via

Word L L H

Byte L L H X 6Bh

XXV

XLXLH

ID

XLXHL

ID

an AMD represe ntative to request the doc ument containing further details.

The device i s shipped wit h all sector s unprotected .

AMD offers the option of program ming and protectin g

sectors at its factory prior to shipping the device

through AMD’s ExpressFlash™ Service. Contact an

AMD representative for details.

on the RESET# pin

ID

It is possible to determine whether a sector is protected

or unprotected. See “Autoselect Mode” for detail s.

programming equipment. Figure 1 shows the algorithm s and Fig ure 23 shows the ti ming diagram . Thi s

method uses standard microprocessor bus cycle timing. For sector unprotect, all unprotected sectors must

first be protected prior to the first sector unprotect write

cycle.

The alternate method intended only for programming

equipment requires V

on address pin A9 and OE#.

ID

This method is compatible with programmer routines

writte n for ea rli er 3 . 0 v o l t- o nly AMD fl a sh d evice s . Pu blication number 21622 contains further details. Contact

Temporary Sector Unprotect

This feature allows temporary unprotection of previously protected sectors to change data in-system. The

Sector U n pr ot ect m ode i s activated by s ett ing th e RESET# pi n to V

sectors can be programmed or erased by selecting the

sector ad dresses. Once V

SET# pin, all the previously protected sectors are

protected a gain. Figure 2 sh ows the algorithm, a nd

Figure 22 shows the timing diagrams, for this feature.

22h 6Bh

X

X

. During thi s mode, for me rly pr otecte d

ID

is rem oved from th e RE-

ID

01h

(protected)

00h

(unprotected)

12 Am29SL800C

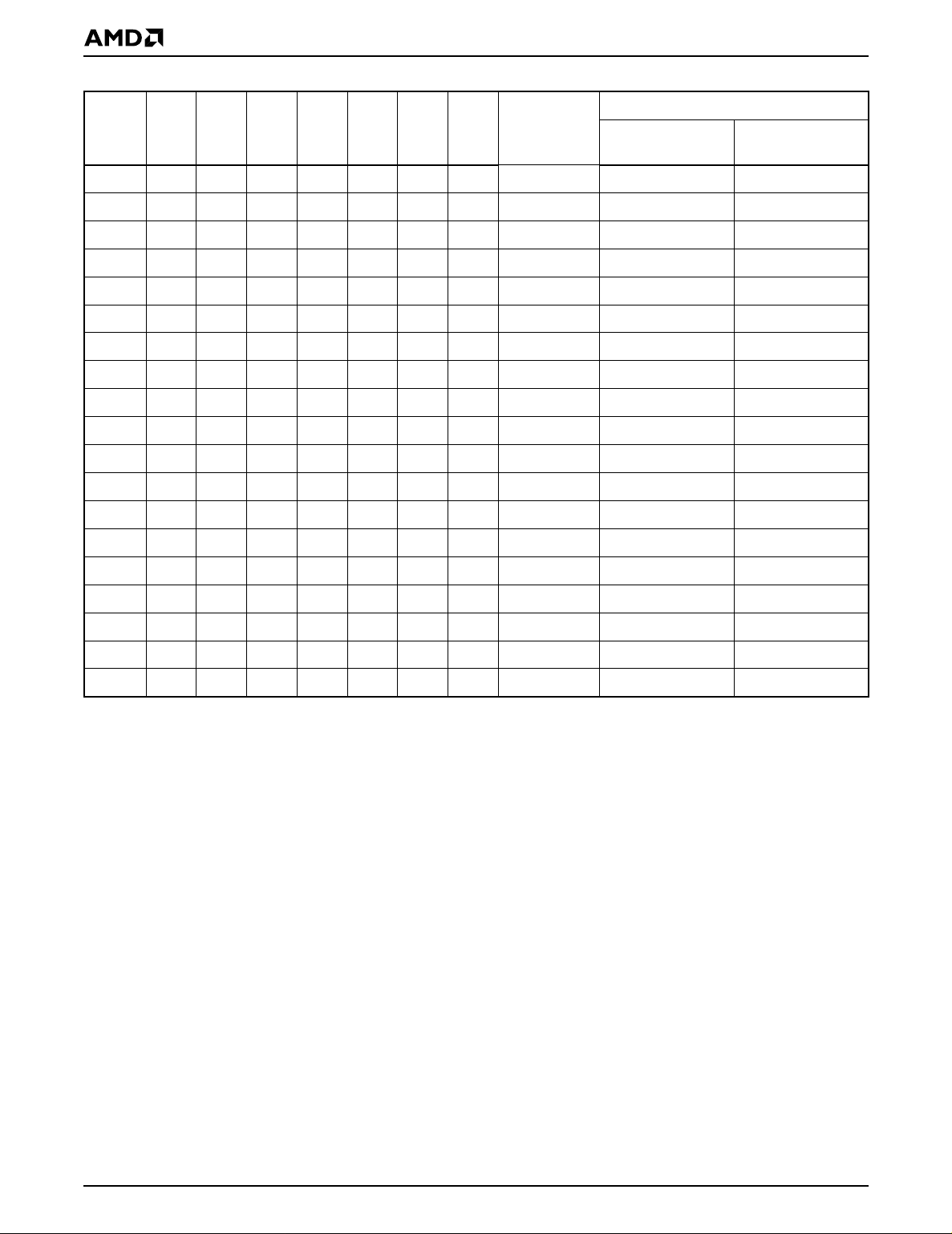

PRELIMINARY

Temporary Sector

Unprotect Mode

Increment

PLSCNT

No

PLSCNT

= 25?

Yes

Device failed

Sector Protect

Algorithm

START

PLSCNT = 1

RESET# = V

Wait 1 µs

No

First Write

Cycle = 60h?

Set up sector

address

Sector Protect:

Write 60h to sector

address with

A6 = 0, A1 = 1,

A0 = 0

Wait 150 µs

Verify Sector

Protect: Write 40h

to sector address

with A6 = 0,

A1 = 1, A0 = 0

Read from

sector address

with A6 = 0,

A1 = 1, A0 = 0

No

Data = 01h?

Protect another

sector?

Remove V

from RESET#

Write reset

command

Sector Protect

complete

Yes

Yes

No

START

Protect all sectors:

The indicated portion

of the sector protect

ID

Reset

PLSCNT = 1

Yes

ID

algorithm must be

performed for all

unprotected sectors

prior to issuing the

first sector

unprotect address

Increment

PLSCNT

No

PLSCNT

= 1000?

Yes

Device failed

Sector Unprotect

PLSCNT = 1

RESET# = V

Wait 1 µs

First Write

Cycle = 60h?

No

All sectors

protected?

Set up first sector

address

Sector Unprotect:

Write 60h to sector

address with

A6 = 1, A1 = 1,

A0 = 0

Wait 15 ms

Verify Sector

Unprotect: Write

40h to sector

address with

A6 = 1, A1 = 1,

A0 = 0

Read from

sector address

with A6 = 1,

A1 = 1, A0 = 0

No

Data = 00h?

Last sector

verified?

Remove V

from RESET#

Yes

Yes

Yes

Yes

ID

No

Temporary Sector

Unprotect Mode

Set up

next sector

address

No

ID

Algorithm

Write reset

command

Sector Unprotect

complete

Figure 1. In-System Sector Protect/Unprotect Algorithms

Am29SL800C 13

22230A-5

Loading...

Loading...