AMD Advanced Micro Devices AM29F100T-120DWI1, AM29F100T-120DWE1, AM29F100T-120DWC1, AM29F100T-120DTI1, AM29F100T-120DTE1 Datasheet

...

SUPPLEMENT

Publication# 21235 Rev: B Amendment/0

Issue Date: January 1998

Am29F100 Known Good Die

1 Megabit (128 K x 8-Bit/64 K x 16-Bit)

CMOS 5.0 Volt-only, Boot Sector Flash Memory—Die Revision 1

DISTINCTIVE CHARACTERISTICS

■ Single power supply operation

—5.0 V ± 10% for read, erase, and program

operations

— Simplifies system-level power requirements

■ High performance

— 120 ns maximum access time

■ Low power consumption

— 20 mA typical active read current for byte mode

— 28 mA typical active read current for word mode

— 30 mA typical program/erase current

— 25 µA typical standby current

■ Flexible sector architecture

— One 16 Kbyte, two 8 Kbyte, one 32 Kbyte, and

one 64 Kbyte sectors (byte mode)

— One 8 Kword, two 4 Kword, one 16 Kword, and

one 32 Kword sectors (word mode)

— Any combination of sectors can be erased

— Supports full chip erase

■ Top or bottom boot block configurations

available

■ Sector protection

— Hardware-based feature that disables/re-

enables program and erase operations in any

combination of sectors

— Sector protection/unprotection can be

implemented using standard PROM

programming equipment

— Temporary Sector Unprotect feature allows in-

system code changes in protected sectors

■ Embedded Algorithms

— Embedded Erase algorithm automatically

pre-programs and erases the chip or any

combination of designated sector

— Embedded Program algorithm automatically

programs and verifies data at specified address

■ Minimum 100,000 program/erase cycles

guaranteed

■ Compatible with JEDEC standards

— Pinout and software compatible with

single-power-supply flash

— Superior inadvertent write protection

■ Data Polling and Toggle Bits

— Provides a software method of detecting

program or erase cycle completion

■ Ready/Busy pin (RY/BY#)

— Provides a hardware method for detecting

program or erase cycle completion

■ Erase Suspend/Erase Resume

— Suspends an erase operation to read data fr om,

or program data to, a sector that is not being

erased, then resumes the erase operation

■ Hardware RESET# pin

— Hardware method of resetting the device to

reading array data

■ T ested to datasheet specifications at

temperature

■ Quality and reliability levels equivalent to

standard packaged components

2 Am29F100 Known Good Die

SUPPLEMENT

GENERAL DESCRIPTION

The Am29F100 in Known Good Die (KGD) form is a 1

Mbit, 5.0 Volt -only Flash memory . AMD defines KGD as

standard product in die form, tested for functionality

and speed. AMD KGD products have the same reliability and quality as AMD products in packaged form.

Am29F100 Features

The Am29F100 is a 1 Mbit, 5.0 V olt-only Flash memory

organized as 131,072 bytes or 65,536 words. Wordwide data appears on DQ0-DQ15; byte-wide data on

DQ0-DQ7. The device is designed to be programmed

in-system with the standard system 5.0 Volt V

CC

sup-

ply. A 12.0 volt V

PP

is not required for program or erase

operations. The device can also be programmed or

erased in standard EPROM programmers.

To eliminate bus contention the device has separate

chip enable (CE#), write ena ble (WE# ) and ou tput enable (OE#) controls.

The device requires only a single 5.0 volt power sup-

ply for both read and write functions. Internally generated and regulated voltages are provided for the

program and erase operations.

The device is entirely command set compatible with the

JEDEC single-power-supply Flash standard. Commands are written to the command register using standard microprocessor write timings. Register contents

serve as input to an internal state machi ne that controls

the erase and programming circuitry. Write cycles also

internally latch addresses and data needed for t he programming and erase operations. Reading data out of

the device is similar to reading from other Flash or

EPROM devices.

Device programming occurs by executing the program

command sequence. This invokes the Embedded

Program algorithm—an internal algorithm that automatically times the program pulse widths and verifies

proper cell margin.

Device erasure occurs by executing the erase command sequence. This invokes the Embedded Erase

algorithm—an internal algorithm that automatically preprograms the array (if it is not already programmed) before executing the erase operation. During erase, the

device automatically times the erase pulse widths and

verifies proper cell margin.

The host system c an detect whether a program or

erase operation is complete by observing the RY/BY#

pin, or by re ading the DQ7 (D ata# Polling) and DQ6

(toggle) status bits. After a program or erase cycle

has been completed, the device is ready to read array

data or accept another command.

The Erase Suspend feature enables the sys tem to put

erase on hold for any period of time to read data from,

or program data to, a sector that is not being erased.

The sec tor erase arc hitecture allows memory sectors

to be erased and reprogrammed without affecting the

data contents of other sectors. The device is erased

when shipped from the factory.

The hardware data protection m easures include a

low V

CC

detector automatically inhibits write operat ions

during power transitions. The hardware sector pro-

tection feature disables both program and erase operations in any combination of the sectors of memory,

and is implemented using standard EPROM programmers. The temporary sector unprotect feature allows

in-system changes to protected sectors.

The hardware RESET# pin terminates any operation

in progress and resets the internal state machine to

reading array data. The RESET# pin may be tied to the

system reset circuitry. A system reset would thus also

reset the device, enabling the system microprocessor

to read the boot-up firmware from the Flash memory.

The system can place the device into the standby mode.

Power consumption is greatly reduced in t his mode.

AMD’s Flash technology combines years of Flash

memory manufacturing experience to produce the

highest levels of quality, reliability, and cost

effectiveness. The device electrically erases all bits

within a sector simultaneously via Fowler-Nordheim

tunneling. The bytes are programmed one byte at a

time using the EPROM programming mechanism of

hot electron injection.

ELECTRICAL SPECIFICATIONS

Refer to the Am29F100 data sheet, document number

18926, for full electrical specifications on the

Am29F100.

Am29F100 Known Good Die 3

SUPPLEMENT

PRODUCT SELECTOR GUIDE

DIE PHOTOGRAPH

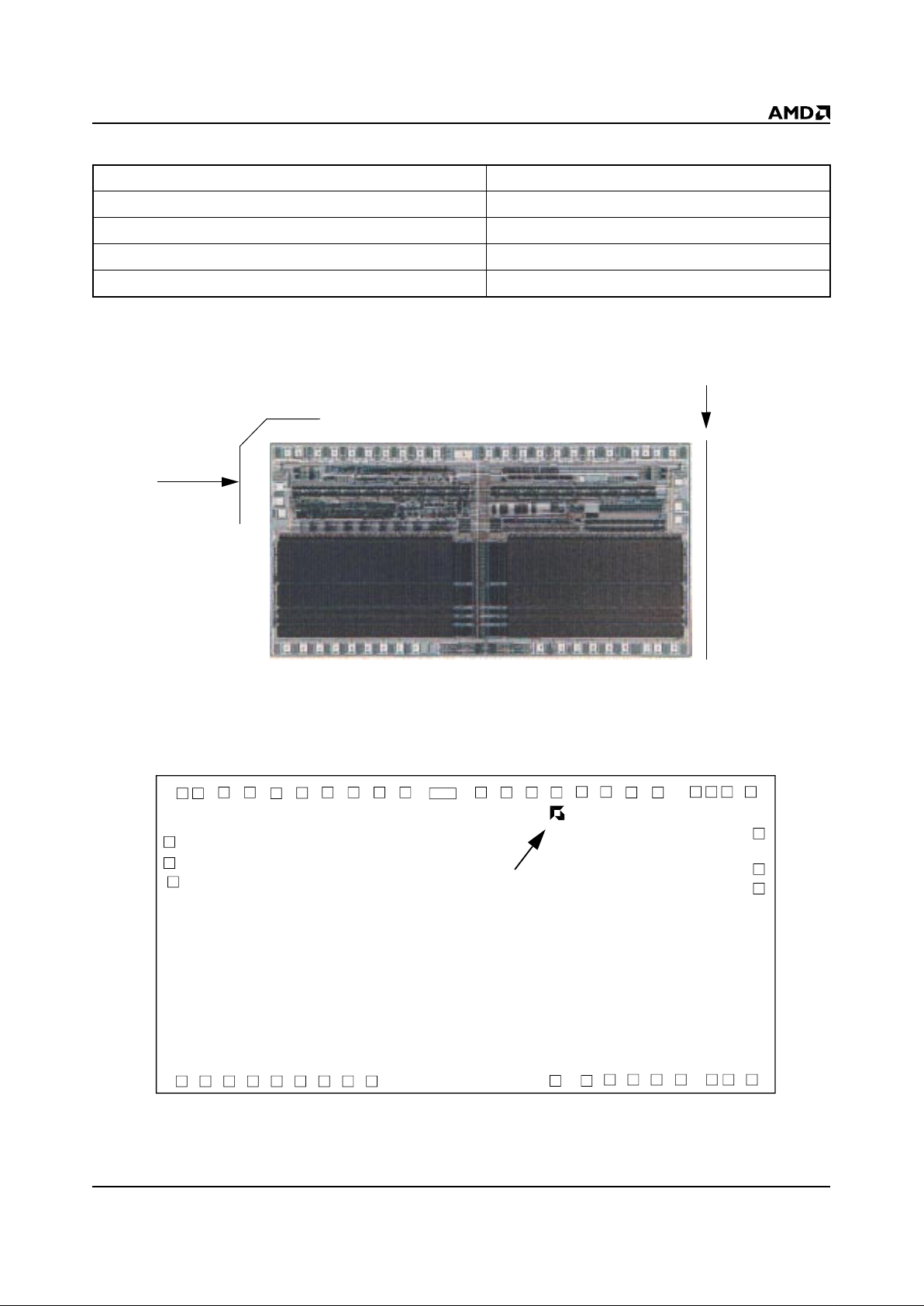

DIE PAD LOCATIONS

Family Part Number Am29F100 KGD

Speed Option (V

CC

= 5.0 V ± 10%) -120

Max Access Time, t

ACC

(ns) 120

Max CE# Access, t

CE

(ns) 120

Max OE# Access, t

OE

(ns) 50

Orientation relative

to top left corner of

Gel-Pak

Orientation relative

to leading edge of

tape and reel

1234567891011

12

13

14

15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

AMD logo locati on

31 32

33

34

35

363738394041424344454647

Loading...

Loading...