Page 1

Am29DS163D

Data Sheet

July 2003

The following document specifies Spansion memory products that are now offered by both Advanced

Micro Devices and Fujitsu. Although the document is marked with the name of the company that originally developed the specification, these products will be offered to customers of both AMD and

Fujitsu.

Continuity of Specifications

There is no change to this datasheet as a result of offering the device as a Spansion product. Any

changes that have been made are the result of normal datasheet improvement and are noted in the

document revision summary, where supported. Future routine revisions will occur when appropriate,

and changes will be noted in a revision summary.

Continuity of Ordering Part Numbers

AMD and Fujitsu continue to support existing part numbers beginning with “Am” and “MBM”. To order

these products, please use only the Ordering Part Numbers listed in this document.

For More Information

Please contact your local AMD or Fujitsu sales office for additional information about Spansion

memory solutions.

Publication Number 22326 Revision A Amendment +1 Issue Date November 8, 2004

Page 2

THIS PAGE LEFT INTENTIONALLY BLANK.

Page 3

ADVANCE INFORMATION

Am29DS163D

16 Megabit (2 M x 8-Bit/1 M x 16-Bit)

CMOS 1.8 Volt-only, Simultaneous Operation Flash Memory

DISTINCTIVE CHARACTERISTICS

ARCHITECTURAL ADVANTAGES

■ Simultaneous Read/Write operations

— Data can be continuously read from one bank while

executing erase/program functions in other bank

— Zero latency between read and write operations

■ Multiple bank architectures

— Two devices available with different bank sizes (refer

to Table 3)

■ Secured Silicon (SecSi) Sector

— Factory locked and identifiable: 16 bytes available for

secure, random factory Electronic Serial Number;

verifiable as factory locked through autoselect

function. ExpressFlash option allows entire sector to

be available for factory-secured data.

— Customer lockable: Can be read, programmed, or

erased just like other sectors. Once locked, data

cannot be changed.

— 64 Kbyte sector size

■ Zero Power Operation

— Sophisticated power management circuits reduce

power consumed during inactive periods to nearly

zero

■ Package options

— 48-ball FBGA

■ Top or bottom boot block

■ Manufactured on 0.23 µm process technology

■ Compatible with JEDEC standards

— Pinout and software compatible with

single-power-supply flash standard

PERFORMANCE CHARACTERISTICS

■ High performance

— Access time as fast 100 ns

— Program time: 13 µs/word typical utilizing Accelerate function

■ Ultra low power consumption (typical values)

— 1 mA active read current at 1 MHz

— 5 mA active read current at 5 MHz

— 200 nA in standby or automatic sleep mode

■ Minimum 1 million write cycles guaranteed per sector

■ 20 Year data retention at 125°C

— Reliable operation for the life of the system

SOFTWARE FEATURES

■ Data Management Software (DMS)

— AMD-supplied software manages data programming

and erasing, enabling EEPROM emulation

— Eases sector erase limitations

■ Supports Common Flash Memory Interface (CFI)

■ Erase Suspend/Erase Resume

— Suspends erase operations to allow programming in

same bank

■ Data# Polling and Toggle Bits

— Provides a software method of detecting the status of

program or erase cycles

■ Unlock Bypass Program command

— Reduces overall programming time when issuing

multiple program command sequences

HARDWARE FEATURES

■ Any combination of sectors can be erased

■ Ready/Busy# output (RY/BY#)

— Hardware method for detecting program or erase

cycle completion

■ Hardware reset pin (RESET#)

— Hardware method of resetting the internal state

machine to reading array data

■ WP#/ACC input pin

— Write protect (WP#) function allows protection of two

outermost boot sectors, regardless of sector protect status

— Acceleration (ACC) function provides accelerated

program times

■ Sector protection

— Hardware method of locking a sector, either

in-system or using programming equipment, to

prevent any program or erase operation within that

sector

— Temporary Sector Unprotect allows changing data in

protected sectors in-system

This document contains information on a product under development at Advanced Micro Devices. The information

is intended to help you evaluate this product. AMD reserves the right to change or discontinue work on this proposed

product without notice.

Refer to AMD’s Website (www.amd.com) for the latest information.

Publication# 22326 Rev: A Amendment/1

Issue Date: November 8, 2004

Page 4

ADVANCE INFORMATION

GENERAL DESCRIPTION

The Am29DS163D family consists of 16 megabit, 1.8

volt-only flash memory devices, organized as 1,048,576

words of 16 bits each or 2,097,152 bytes of 8 bits each.

Word mode data appears on DQ0–DQ15; byte mode

data appears on DQ0–DQ7. The device is designed to

be programmed in-system with the standard 1.8 volt

VCC supply, and can also be programmed in standard

EPROM programmers.

The device is available with an access time of 100 and

120 ns. The devices are offered in an 48-ball FBGA

package. Standard control pins—chip enable (CE#),

write enable (WE#), and output enable (OE#)—control

normal read and write operations, and avoid bus con

tention issues.

The device requires only a single 1.8 volt power sup-

ply for both read and write functions. Internally

generated and regulated voltages are provided for the

program and erase operations.

Simultaneous Read/Write Operations with

Zero Latency

The Simultaneous Read/Write architecture provides

simultaneous operation by dividing the memory

space into two banks. The device can improve overall

system performance by allowing a host system to program or erase in one bank, then immediately and

simultaneously read from the other bank, with zero latency. This releases the system from waiting for the

completion of program or erase operations.

Am29DS163D Features

The Secured Silicon (SecSi) Sector is an additional

64 Kbyte sector capable of being permanently locked

by AMD or customers. The SecSi Sector Indicator

Bit (DQ7) is permanently set to a 1 if the part is fac-

tory locked, and set to a 0 if customer lockable. This

way, customer lockable parts can never be used to re

place a factory locked part.

Factory locked parts provide several options. The

SecSi Sector may store a secure, random 16 byte

ESN (Electronic Serial Number), customer code (programmed through AMD’s ExpressFlash service), or

both. Customer Lockable parts may utilize the SecSi

Sector as bonus space, reading and writing like any

other flash sector, or may permanently lock their own

code there.

DMS (Data Management Software) allows systems

to easily take advantage of the advanced architecture

of the simultaneous read/write product line by allowing

removal of EEPROM devices. DMS also allows the

system software to be simplified, as it performs all

functions necessary to modify data in file structures,

as opposed to single-byte modifications. To write or

update a particular piece of data (a phone number or

configuration data, for example), the user only needs

to state which piece of data is to be updated, and

where the updated data is located in the system. This

is an advantage compared to systems where

user-written software must keep track of the old data

location, status, logical to physical translation of the

data onto the Flash memory device (or memory de

vices), and more. Using DMS, user-written software

does not need to interface with the Flash memory di

rectly. Instead, the user's software accesses the Flash

memory by calling one of only six functions. AMD provides this software to simplify system design and

software integration efforts.

The device offers complete compatibility with the

JEDEC single-power-supply Flash command set

standard. Commands are written to the command

register using standard microprocessor write timings.

Reading data out of the device is similar to reading

from other Flash or EPROM devices.

The host system can detect whether a program or

erase operation is complete by using the device sta

tus bits: RY/BY# pin, DQ7 (Data# Polling) and

DQ6/DQ2 (toggle bits).

is completed, the device automatically returns to reading array data.

The sector erase architecture allows memory sectors to be erased and reprogrammed without affecting

the data contents of other sectors. The device is fully

erased when shipped from the factory.

Hardware data protection measures include a low

-

detector that automatically inhibits write opera-

V

CC

tions during power transitions. The hardware sector

protection feature disables both program and erase

operations in any combination of the sectors of mem

ory. This is achieved in-system or via programming

equipment.

The device offers two power-saving features. When

addresses are stable for a specified amount of time,

the device enters the automatic sleep mode. The

system can also place the device into the standby

mode. Power consumption is greatly reduced in both

modes.

After a program or erase cycle

-

-

-

-

4 Am29DS163D

Page 5

ADVANCE INFORMATION

TABLE OF CONTENTS

Product Selector Guide . . . . . . . . . . . . . . . . . . . . . 6

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Connection Diagrams . . . . . . . . . . . . . . . . . . . . . . . 7

Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Logic Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . 9

Device Bus Operations . . . . . . . . . . . . . . . . . . . . . 10

Table 1. Am29DS163D Device Bus Operations .............................10

Word/Byte Configuration ........................................................10

Requirements for Reading Array Data ...................................10

Writing Commands/Command Sequences ............................11

Accelerated Program Operation ......................................................11

Autoselect Function s ........................... ................ ................ ............11

Simultaneous Read/Write Operations with Zero Latency .......11

Standby Mode ........................................................................11

Automatic Sleep Mode .................................... .. .....................12

RESET#: Hardware Reset Pin ...............................................12

Output Disable Mode ..............................................................12

Table 2. Am29DS163D Device Bank Divisions ...............................12

Table 3. Top Boot Sector Addresses (Am29DS16xDT) ..................13

SecSi Sector Addresses for Top Boot Device s.............................. 13

Table 5. Bottom Boot Sector Addresses (Am29DS16xDB) ............14

SecSi Sector Addresses for Botto m Boot Device s................. ........ 14

Autoselect Mode ............................................ .. .......................15

Table 7. Am29DS163D Autoselect Codes (High Voltage Method) 15

Sector/Sector Block Protection and Unprotection ..................16

Table 8. Top Boot Sector/Sector Block Addresses

for Protection/Unpro tection ............................... ................ ..............16

Table 9. Bottom Boot Sector/Sector Block Addresses

for Protection/Unpro tection ............................... ................ ..............16

Write Protect (WP#) ................................................................17

Temporary Sector/Sector Block Unprotect .............................17

Figure 1. Temporary Sector Unprotect Operation........................... 17

Figure 2. In-System Sector/Sector Block Protect

and Unprotect Algorithms. ................ ................................ ............... 18

SecSi (Secured Silicon) Sector Flash Memory Region ..........19

Hardware Data Protection ......................................................19

Low VCC Write Inhibit .....................................................................20

Write Pulse “Glitch” Protection ................... ................................ .....20

Logical Inhibit ..................................................................................20

Power-Up Write Inhibit ............... ................................................ .....20

Common Flash Memory Interface (CFI) . . . . . . . 20

Table 10. CFI Query Identification String........................................ 20

System Interface String........................ ................ ........................... 21

Table 12. Device Geometry Definit ion.................... ........................ 21

Table 13. Primary Vendor-Specific Extended Query ...................... 22

Command Definitions . . . . . . . . . . . . . . . . . . . . . . 23

Reading Array Data ................................................................23

Reset Command .....................................................................23

Autoselect Command Sequence ......................... ...................23

Enter SecSi Sector/Exit SecSi Sector Command Sequence ..24

Byte/Word Program Command Sequence .............................24

Unlock Bypass Command Sequence ..............................................24

Figure 3. Program Operat io n.................... ................................ ...... 25

Chip Erase Command Sequence ...........................................25

Sector Erase Command Sequence ...................... .. ................25

Erase Suspend/Erase Resume Commands ........................... 26

Figure 4. Erase Operation............. ................ ................................ . 26

Table 14. Am29DS163D Command Defin itions........................ ...... 27

Write Operation Status . . . . . . . . . . . . . . . . . . . . 28

DQ7: Data# Po l lin g .......... ... .. .............. .. ... .............. .. ... ............28

Figure 5. Data# Polling Algorithm................................................. . 28

RY/BY#: Ready/Busy# ............................................................ 29

DQ6: Toggle Bit I ....................................................................29

Figure 6. Toggle Bit Algorithm........................................................ 29

DQ2: Toggle Bit II ...................................................................30

Reading Toggle Bits DQ6/DQ2 ...............................................30

DQ5: Exceeded Timing Limits ................................................30

DQ3: Sector Era s e Time r ............ ...........................................30

Table 15. Write Operation Sta tus ............. ................ ......................31

Absolute Maximum Ratings . . . . . . . . . . . . . . . . 32

Figure 7. Maximum Negative Overshoot Waveform...................... 32

Figure 8. Maximum Positive Overshoot Waveform....................... 32

Operating Ranges . . . . . . . . . . . . . . . . . . . . . . . . . 32

DC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 9. I

and Automatic Sleep Currents)...................................................... 34

Figure 10. Typical I

Current vs. Time (Showing Active

CC1

vs. Frequency.............. ................ .............. 34

CC1

Test Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 11. Test Setup..................... ................. ................ .............. 35

Table 16. Test Specifications ................... ................ ................ ......35

Figure 12. Input Waveforms and Measurement Levels ................. 35

AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 13. Read Operation Timings. ........ .............................. ........ 36

Figure 14. Reset Timings............................................................... 37

Word/Byte Configuration (BYTE#) ..........................................38

Figure 15. BYTE# Timings for Read Operations............................ 38

Figure 16. BYTE# Timings for Write Operations............................ 38

Erase and Program Operations .............................................. 39

Figure 17. Program Operation Timings.......................................... 40

Figure 18. Accelerated Program Timing Diagram.......................... 40

Figure 19. Chip/Sector Erase Operation Timings.......................... 41

Figure 20. Back-to-back Read/Write Cycle Timings ...................... 42

Figure 21. Data# Polling Timings (During Embedded Algorithms) . 42

Figure 22. Toggle Bit Timings (During Embedded Algorithms)...... 43

Figure 23. DQ2 vs. DQ6............................ ................................ ..... 43

Temporary Sector/Sector Block Unprotect .............................44

Figure 24. Temporary Sector/Sector Block

Unprotect Timing Diagr a m.............. ................. ................ .............. 44

Figure 25. Sector/Sector Block Protect/Unprotect Timing Diagram 45

Alternate CE# Controlled Erase and Program O perations .....46

Figure 26. Alternate CE# Controlled Write

(Erase/Program) Operati o n Timings............. ................................ . 47

Erase And Programming Performance . . . . . . . 48

Latchup Characteristics . . . . . . . . . . . . . . . . . . . . 48

Data Retention. . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . 49

FBA048—48-Ball Fine-Pitch Ball Grid Array (FBGA)

6 x 8 mm package ...................................................... ...........49

Revision Summary . . . . . . . . . . . . . . . . . . . . . . . . 50

Am29DS163D 5

Page 6

ADVANCE INFORMATION

PRODUCT SELECTOR GUIDE

Part Number Am29DS163D

Speed Option Standard Voltage Range: VCC = 1.8–2.2 V 100 120

Max Access Time (ns) 100 120

CE# Access (ns) 100 120

OE# Access (ns) 35 50

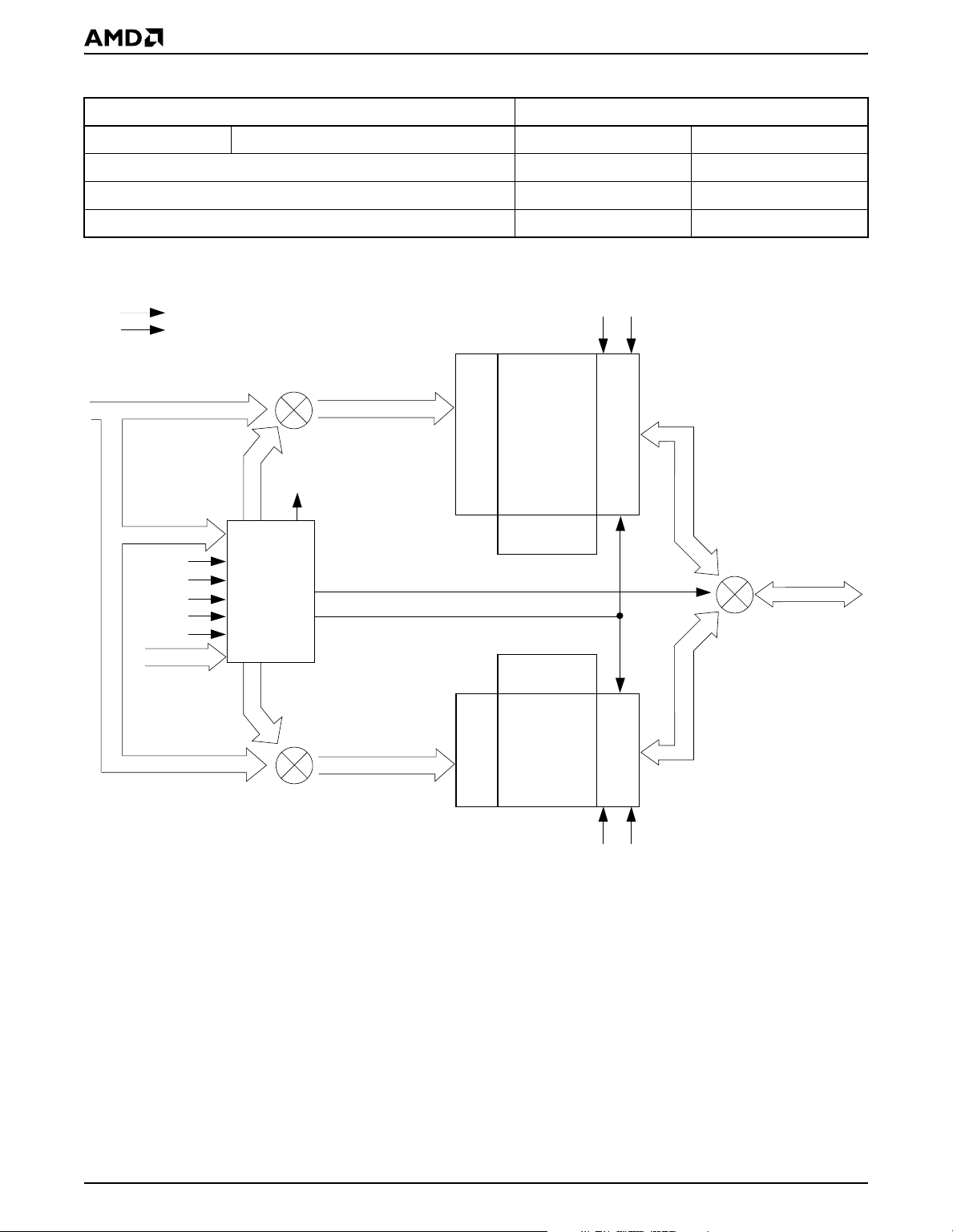

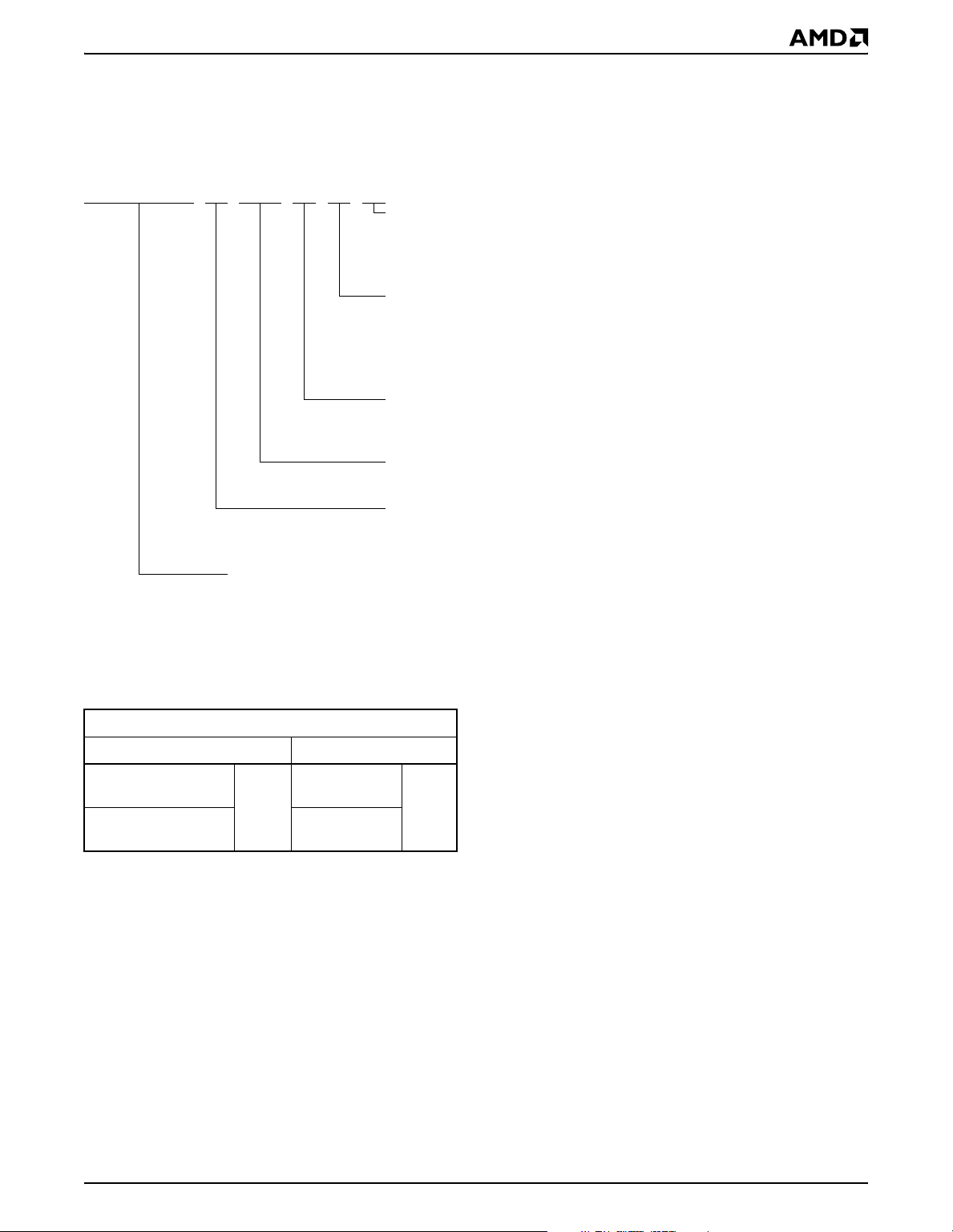

BLOCK DIAGRAM

V

CC

V

SS

OE# BYTE#

A0–A19

A0–A19

RESET#

WE#

CE#

BYTE#

WP#/ACC

DQ0–DQ15

A0–A19

RY/BY#

A0–A19A0–A19

STATE

CONTROL

&

COMMAND

REGISTER

Upper Bank Address

Lower Bank Address

Y-Decoder

Status

Control

Y-Decoder

Upper Bank

X-Decoder

X-Decoder

Lower Bank

Latches and Control Logic

Latches and

Control Logic

OE# BYTE#

DQ0–DQ15

DQ0–DQ15 DQ0–DQ15

6 Am29DS163D

Page 7

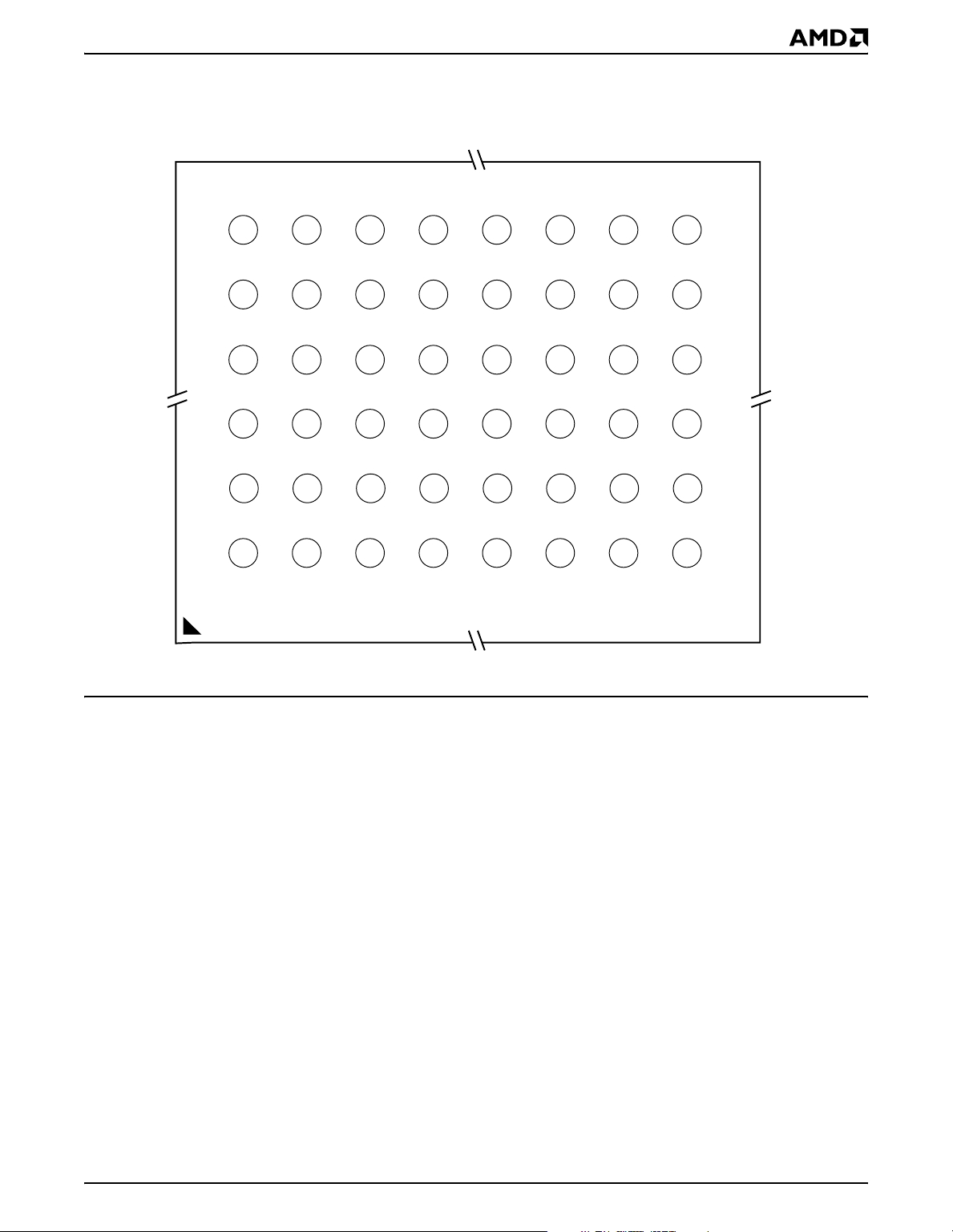

CONNECTION DIAGRAMS

A6 B6 C6 D6 E6 F6 G6 H6

A5 B5 C5 D5 E5 F5 G5 H5

A4 B4 C4 D4 E4 F4 G4 H4

A3 B3 C3 D3 E3 F3 G3 H3

A2 B2 C2 D2 E2 F2 G2 H2

ADVANCE INFORMATION

48-Ball FBGA

Top View, Balls Facing Down

BYTE#A16A15A14A12A13

DQ15/A-1

DQ13 DQ6DQ14DQ7A11A10A8A9

V

CC

DQ11 DQ3DQ10DQ2NCA18WP#/ACCRY/BY#

DQ9 DQ1DQ8DQ0A5A6A17A7

V

SS

DQ4DQ12DQ5A19NCRESET#WE#

A1 B1 C1 D1 E1 F1 G1 H1

Special Handling Instructions for FBGA

Package

Special handling is required for Flash Memory products in FBGA packages.

CE#A0A1A2A4A3

OE#

V

SS

Flash memory devices in FBGA packages may be

damaged if exposed to ultrasonic cleaning methods.

The package and/or data integrity may be compromised if the package body is exposed to temperatures

above 150°C for prolonged periods of time.

Am29DS163D 7

Page 8

ADVANCE INFORMATION

PIN DESCRIPTION

A0–A19 = 20 Addresses

DQ0–DQ14 = 15 Data Inputs/Outputs

DQ15/A-1 = DQ15 (Data Input/Output, word

mode), A-1 (LSB Address Input, byte

mode)

CE# = Chip Enable

OE# = Output Enable

WE# = Write Enable

WP#/ACC = Hardware Write Protect/

Acceleration Pin

RESET# = Hardware Reset Pin, Active Low

BYTE# = Selects 8-bit or 16-bit mode

RY/BY# = Ready/Busy Output

VCC = 1.8 volt-only single power supply

(see Product Selector Guide for speed

options and voltage supply tolerances)

V

SS

NC = Pin Not Connected Internally

= Device Ground

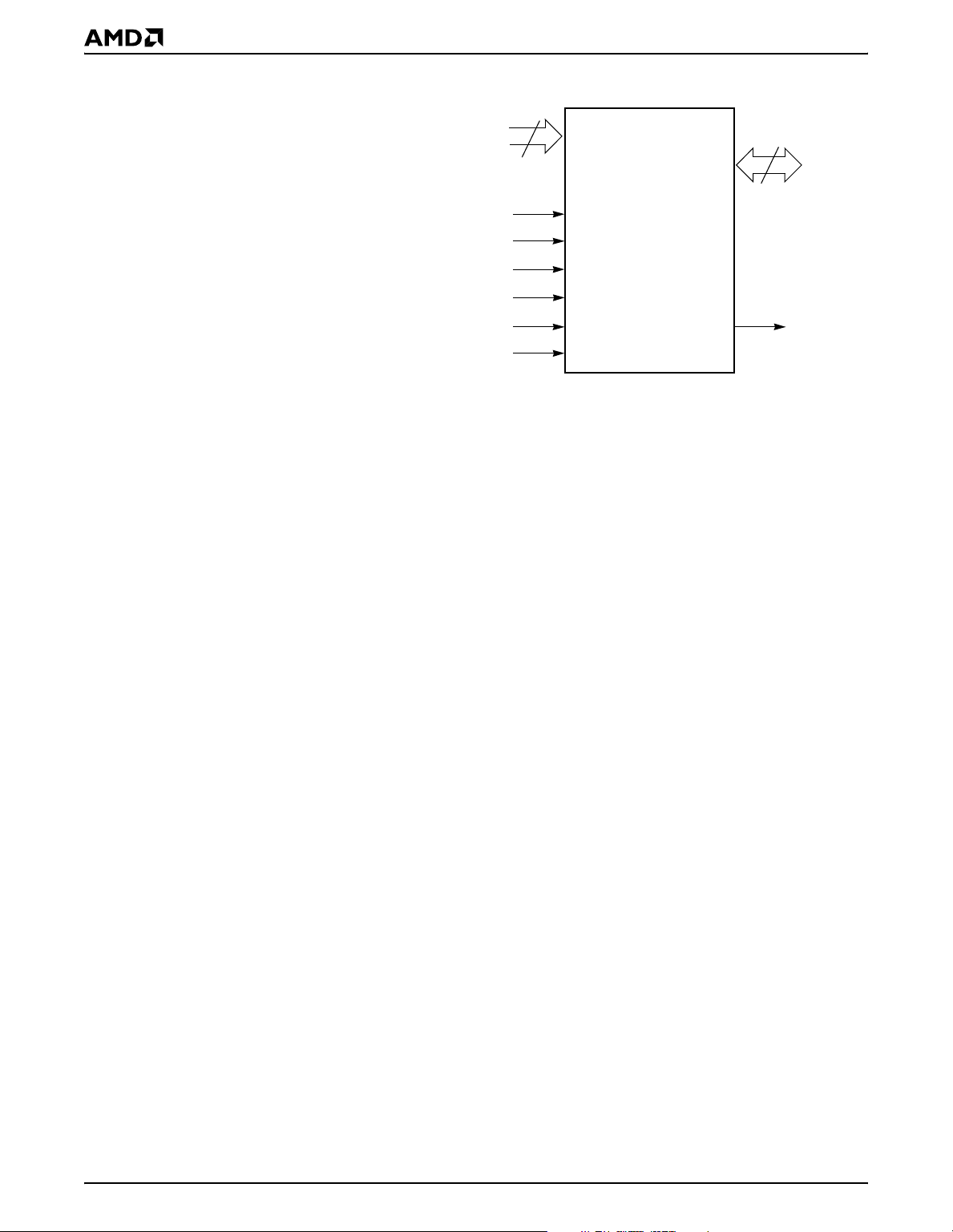

LOGIC SYMBOL

20

A0–A19

CE#

OE#

WE#

WP#/ACC

RESET#

BYTE#

16 or 8

DQ0–DQ15

(A-1)

RY/BY#

8 Am29DS163D

Page 9

ADVANCE INFORMATION

ORDERING INFORMATION

Standard Products

AMD standard products are available in several packages and operating ranges. The order number (Valid

Combination) is formed by a combination of the following:

Am29DS163D T 100 E I

OPTIONAL PROCESSING

Blank = Standard Processing

N = 16-byte ESN devices

(Contact an AMD representative for more information)

TEMPERATURE RANGE

I = Industrial (–40°C to +85°C)

E = Extended (–55°C to +125°C)

F = Industrial (-40oC to +85oC) with Pb-free Package

K = Extended (-55oC to +125oC) with Pb-free Package

PACKAGE TYPE

WA = 48-Ball Fine-Pitch Ball Grid Array (FBGA)

0.80 mm pitch, 6 x 8 mm package (FBA048)

SPEED OPTION

See Product Selector Guide and Valid Combinations

Valid Combinations for FBGA Packages

Order Number Package Marking

Am29DS163DT100,

Am29DS163DB100

Am29DS163DT120,

Am29DS163DB120

BOOT CODE SECTOR ARCHITECTURE

T = Top sector

B = Bottom sector

DEVICE NUMBER/DESCRIPTION

Am29DS163D

16Megabit (2 M x 8-Bit/1 M x 16-Bit) CMOS Flash Memory

1.8 Volt-only Read, Program, and Erase

Valid Combinations list configurations planned to be supported in

volume for this device. Consult the local AMD sales office to con

WAI,

WAE,

WAF,

WAK

S163DT10V,

S163DB10V

S163DT12V,

S163DB12V

I, E,

F, K

firm availability of specific valid combinations and to check on

newly released combinations.

Valid Combinations

-

Am29DS163D 9

Page 10

ADVANCE INFORMATION

DEVICE BUS OPERATIONS

This section describes the requirements and use of

the device bus operations, which are initiated through

the internal command register. The command register

itself does not occupy any addressable memory location. The register is a latch used to store the

commands, along with the address and data informa

tion needed to execute the command. The contents of

Tab l e 1. Am29DS163D Device Bus Operations

-

the register serve as inputs to the internal state machine. The state machine outputs dictate the function

of the device. Tab l e 1 lists the device bus operations,

the inputs and control levels they require, and the resulting output. The following subsections describe

each of these operations in further detail.

DQ8–DQ15

Addresses

Operation CE# OE# WE# RESET# WP#/ACC

(Note 2)

Read L L H H L/H A

Write L H L H (Note 3) A

Standby

VCC ±

0.3 V

X X

VCC ±

0.3 V

H X High-Z High-Z High-Z

IN

IN

DQ0–

DQ7

D

OUT

D

IN

BYTE#

= V

IH

D

OUT

D

IN

BYTE#

= V

IL

DQ8–DQ14 = High-Z,

DQ15 = A-1

Output Disable L H H H L/H X High-Z High-Z High-Z

Reset X X X L L/H X High-Z High-Z High-Z

Sector Protect (Note 2) L H L V

Sector Unprotect (Note 2) L H L V

Temporary Sector Unprotect X X X V

ID

ID

ID

L/H

(Note 3)

(Note 3) A

SA, A6 = L,

A1 = H, A0 = L

SA, A6 = H,

A1 = H, A0 = L

IN

D

IN

D

IN

D

IN

X X

X X

D

IN

High-Z

Legend: L = Logic Low = VIL, H = Logic High = VIH, VID = 9.0–11.0 V, VHH = 9.0 ± 0.5 V, X = Don’t Care, SA = Sector Address,

A

= Address In, DIN = Data In, D

IN

= Data Out

OUT

Notes:

1. Addresses are A19:A0 in word mode (BYTE# = VIH), A19:A-1 in byte mode (BYTE# = VIL).

2. The sector protect and sector unprotect functions may also be implemented via programming equipment. See “Sector/Sector

Block Protection and Unprotection” on page 16.

3. If WP#/ACC = VIL, the two outermost boot sectors remain protected. If WP#/ACC = VIH, the two outermost boot sector

protection depends on whether they were last protected or unprotected using the method described in

Protection and Unprotection” on page 16. If WP#/ACC = V

all sectors are unprotected.

HH,

“Sector/Sector Block

Word/Byte Configuration

The BYTE# pin controls whether the device data I/O

pins operate in the byte or word configuration. If the

BYTE# pin is set at logic ‘1’, the device is in word configuration, DQ0–DQ15 are active and controlled by

CE# and OE#.

If the BYTE# pin is set at logic ‘0’, the device is in byte

configuration, and only data I/O pins DQ0–DQ7 are

active and controlled by CE# and OE#. The data I/O

pins DQ8–DQ14 are tri-stated, and the DQ15 pin is

used as an input for the LSB (A-1) address function.

Requirements for Reading Array Data

To read array data from the outputs, the system must

drive the CE# and OE# pins to VIL. CE# is the power

control and selects the device. OE# is the output control and gates array data to the output pins. WE#

should remain at VIH. The BYTE# pin determines

whether the device outputs array data in words or

bytes.

The internal state machine is set for reading array data

upon device power-up, or after a hardware reset. This

ensures that no spurious alteration of the memory

content occurs during the power transition. No com

mand is necessary in this mode to obtain array data.

Standard microprocessor read cycles that assert valid

10 Am29DS163D

-

Page 11

ADVANCE INFORMATION

addresses on the device address inputs produce valid

data on the device data outputs. Each bank remains

enabled for read access until the command register

contents are altered.

See “Requirements for Reading Array Data” on

page 10 for more information. Refer to the Ta bl e on

page 36 for timing specifications and to Figure 13, on

page 36 for the timing diagram. I

in the DC Charac-

CC1

teristics table represents the active current

specification for reading array data.

Writing Commands/Command Sequences

To write a command or command sequence (which includes programming data to the device and erasing

sectors of memory), the system must drive WE# and

CE# to V

For program operations, the BYTE# pin determines

whether the device accepts program data in bytes or

words. Refer to “Word/Byte Configuration” on page 10

for more information.

The device features an Unlock Bypass mode to facili-

tate faster programming. Once a bank enters the

Unlock Bypass mode, only two write cycles are required to program a word or byte, instead of four. The

“Word/Byte Configuration” section contains details on

programming data to the device using both standard

and Unlock Bypass command sequences.

An erase operation can erase one sector, multiple sectors, or the entire device. Table 3 on page 13 to

Tab l e 6 on page 14 indicate the address space that

each sector occupies. The device address space is divided into two banks: Bank 1 contains the

boot/parameter sectors, and Bank 2 contains the

larger, code sectors of uniform size. A “bank address”

is the address bits required to uniquely select a bank.

Similarly, a “sector address” is the address bits required to uniquely select a sector.

I

CC2

tive current specification for the write mode. The “AC

Characteristics” on page 36 section contains timing

specification tables and timing diagrams for write

operations.

Accelerated Program Operation

The device offers accelerated program operations

through the ACC function. This is one of two functions

provided by the WP#/ACC pin. This function is primarily intended to allow faster manufacturing throughput

at the factory.

If the system asserts VHH on this pin, the device automatically enters the aforementioned Unlock Bypass

mode, temporarily unprotects any protected sectors,

and uses the higher voltage on the pin to reduce the

time required for program operations. The system

, and OE# to VIH.

IL

in the DC Characteristics table represents the ac-

would use a two-cycle program command sequence

as required by the Unlock Bypass mode. Removing

V

from the WP#/ACC pin returns the device to nor-

HH

mal operation. Note that the WP#/ACC pin must not be

at VHH for operations other than accelerated programming, or device damage may result. In addition, the

WP#/ACC pin must not be left floating or unconnected;

inconsistent behavior of the device may result.

Autoselect Functions

If the system writes the autoselect command sequence, the device enters the autoselect mode. The

system can then read autoselect codes from the inter

nal register (which is separate from the memory array)

on DQ7–DQ0. Standard read cycle timings apply in

this mode. Refer to

“Autoselect Mode” on page 15 and

“Autoselect Command Sequence” on page 23 for

more information.

Simultaneous Read/Write Operations with

Zero

Latency

This device is capable of reading data from one bank

of memory while programming or erasing in the other

bank of memory. An erase operation may also be suspended to read from or program to another location

within the same bank (except the sector being

erased). Figure 20, on page 42 shows how read and

write cycles may be initiated for simultaneous operation with zero latency. I

CC6

and I

in the DC

CC7

Characteristics table represent the current specifications for read-while-program and read-while-erase,

respectively.

Standby Mode

When the system is not reading or writing to the device, it can place the device in the standby mode. In

this mode, current consumption is greatly reduced,

and the outputs are placed in the high impedance

state, independent of the OE# input.

The device enters the CMOS standby mode when the

CE# and RESET# pins are both held at VCC ± 0.3 V.

(Note that this is a more restricted voltage range than

VIH.) If CE# and RESET# are held at VIH, but not within

VCC ± 0.3 V, the device is in the standby mode, but the

standby current is greater. The device requires standard access time (tCE) for read access when the

device is in either of these standby modes, before it is

ready to read data.

If the device is deselected during erasure or programming, the device draws active current until the

operation is completed.

I

in the DC Characteristics table represents the

CC3

standby current specification.

-

Am29DS163D 11

Page 12

ADVANCE INFORMATION

Automatic Sleep Mode

The automatic sleep mode minimizes Flash device energy consumption. The device automatically enables

this mode when addresses remain stable for t

ACC

+

30 ns. The automatic sleep mode is independent of

the CE#, WE#, and OE# control signals. Standard ad

dress access timings provide new data when

addresses are changed. While in sleep mode, output

data is latched and always available to the system.

I

in the “DC Characteristics” on page 33 represents

CC4

the automatic sleep mode current specification.

RESET#: Hardware Reset Pin

The RESET# pin provides a hardware method of resetting the device to reading array data. When the

RESET# pin is driven low for at least a period of t

the device immediately terminates any operation in

progress, tristates all output pins, and ignores all

read/write commands for the duration of the RESET#

pulse. The device also resets the internal state ma

chine to reading array data. The operation that was

interrupted should be reinitiated once the device is

ready to accept another command sequence, to en

sure data integrity.

Current is reduced for the duration of the RESET#

pulse. When RESET# is held at V

draws CMOS standby current (I

±0.3 V, the device

SS

). If RESET# is held

CC4

RP

,

-

-

at V

but not within VSS±0.3 V, the standby current is

IL

greater.

The RESET# pin may be tied to the system reset circuitry. A system reset would thus also reset the Flash

memory, enabling the system to read the boot-up firmware from the Flash memory.

If RESET# is asserted during a program or erase operation, the RY/BY# pin remains a “0” (busy) until the

internal reset operation is complete, which requires a

time of t

(during Embedded Algorithms). The sys-

READY

tem can thus monitor RY/BY# to determine whether

the reset operation is complete. If RESET# is asserted

when a program or erase operation is not executing

(RY/BY# pin is “1”), the reset operation is completed

within a time of t

(not during Embedded Algo-

READY

rithms). The system can read data tRH after the

RESET# pin returns to VIH.

Refer to “AC Characteristics” on page 36 for RESET#

parameters and to Figure 14, on page 37 for the timing

diagram.

Output Disable Mode

When the OE# input is at VIH, output from the device is

disabled. The output pins are placed in the high

impedance state.

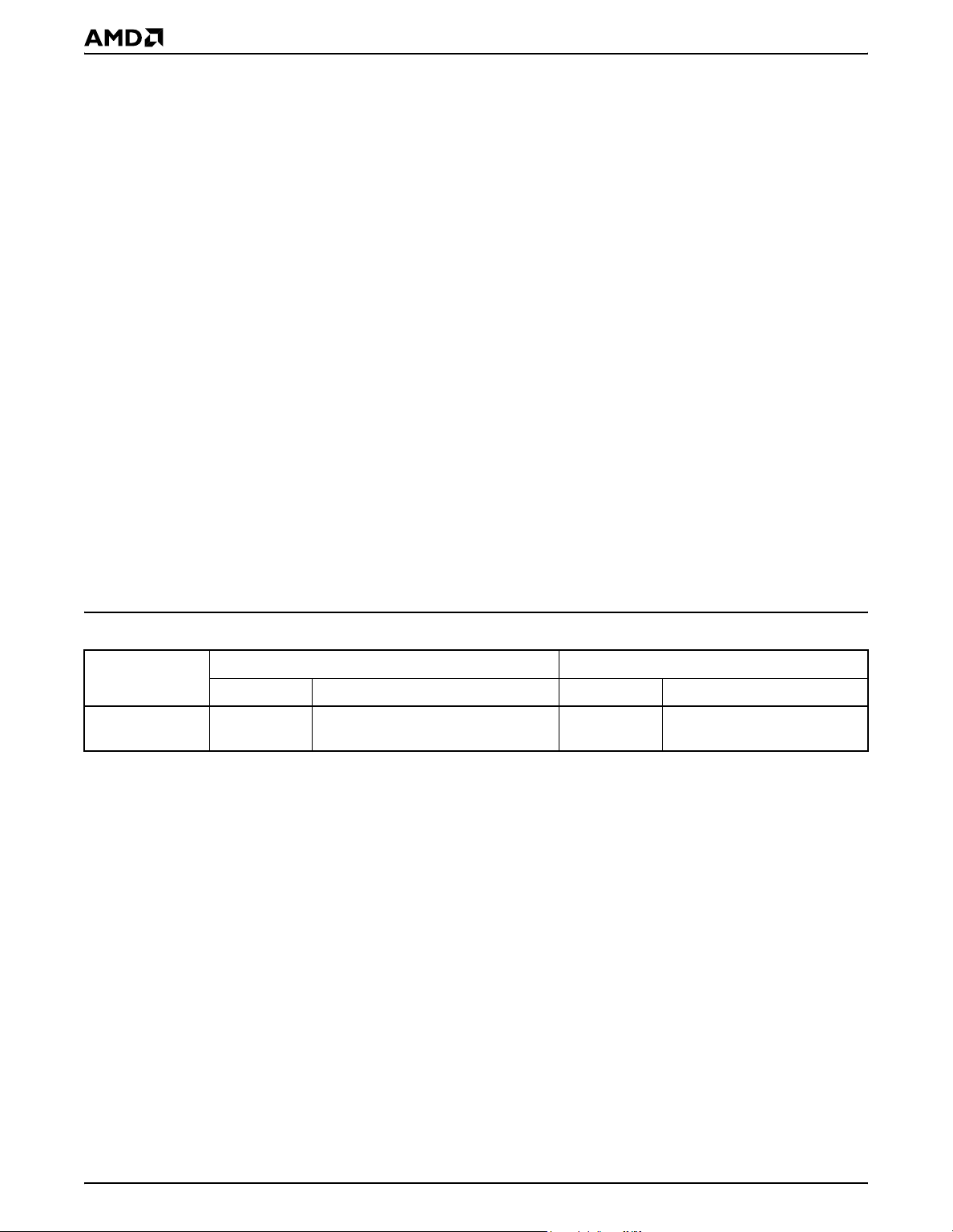

Device

Part Number

Am29DS163D 4 Mbit

Megabits Sector Sizes Megabits Sector Sizes

Table 2. Am29DS163D Device Bank Divisions

Bank 1 Bank 2

Eight 8 Kbyte/4 Kword,

seven 64 Kbyte/32 Kword

12 Mbit

Twenty-four

64 Kbyte/32 Kword

12 Am29DS163D

Page 13

ADVANCE INFORMATION

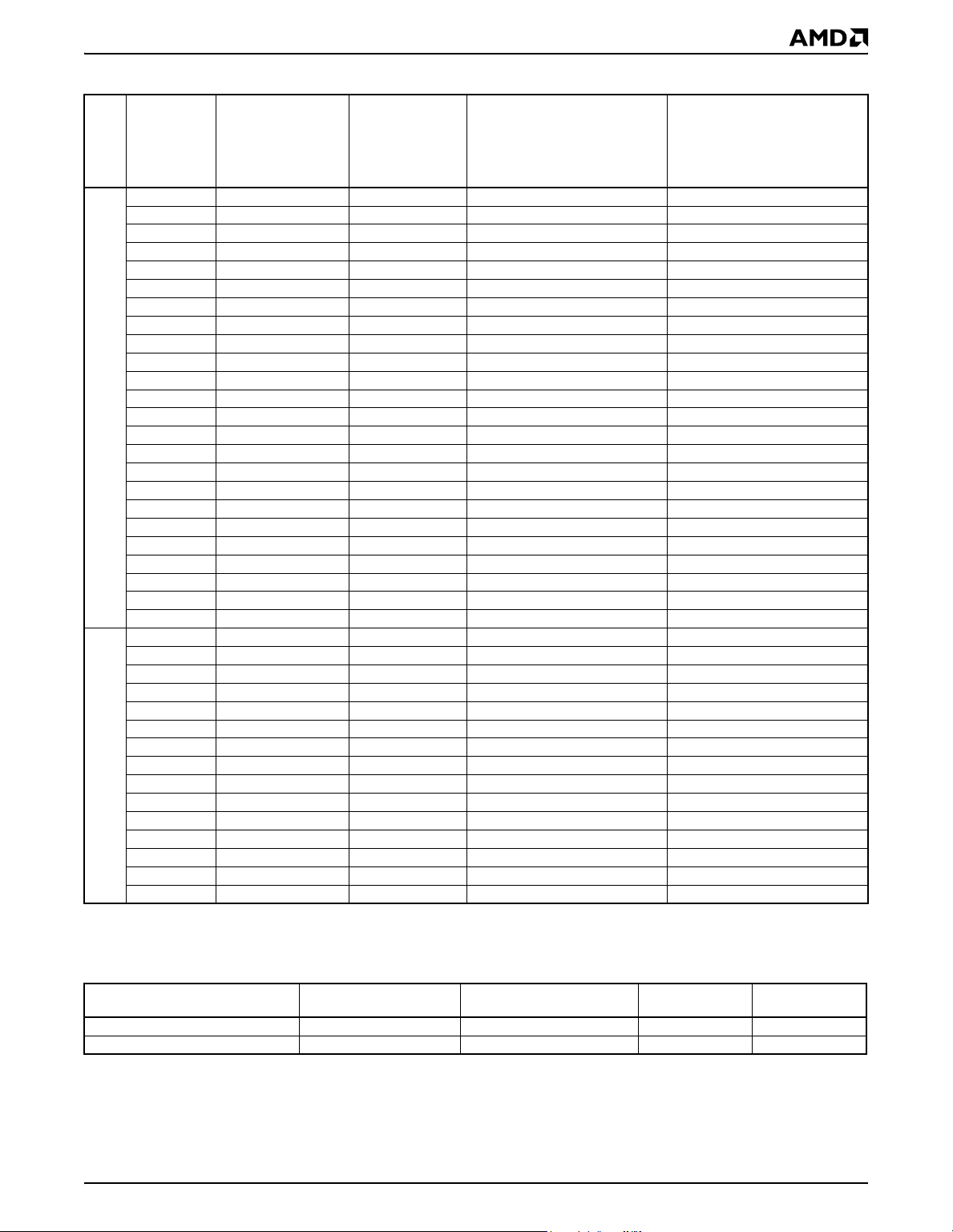

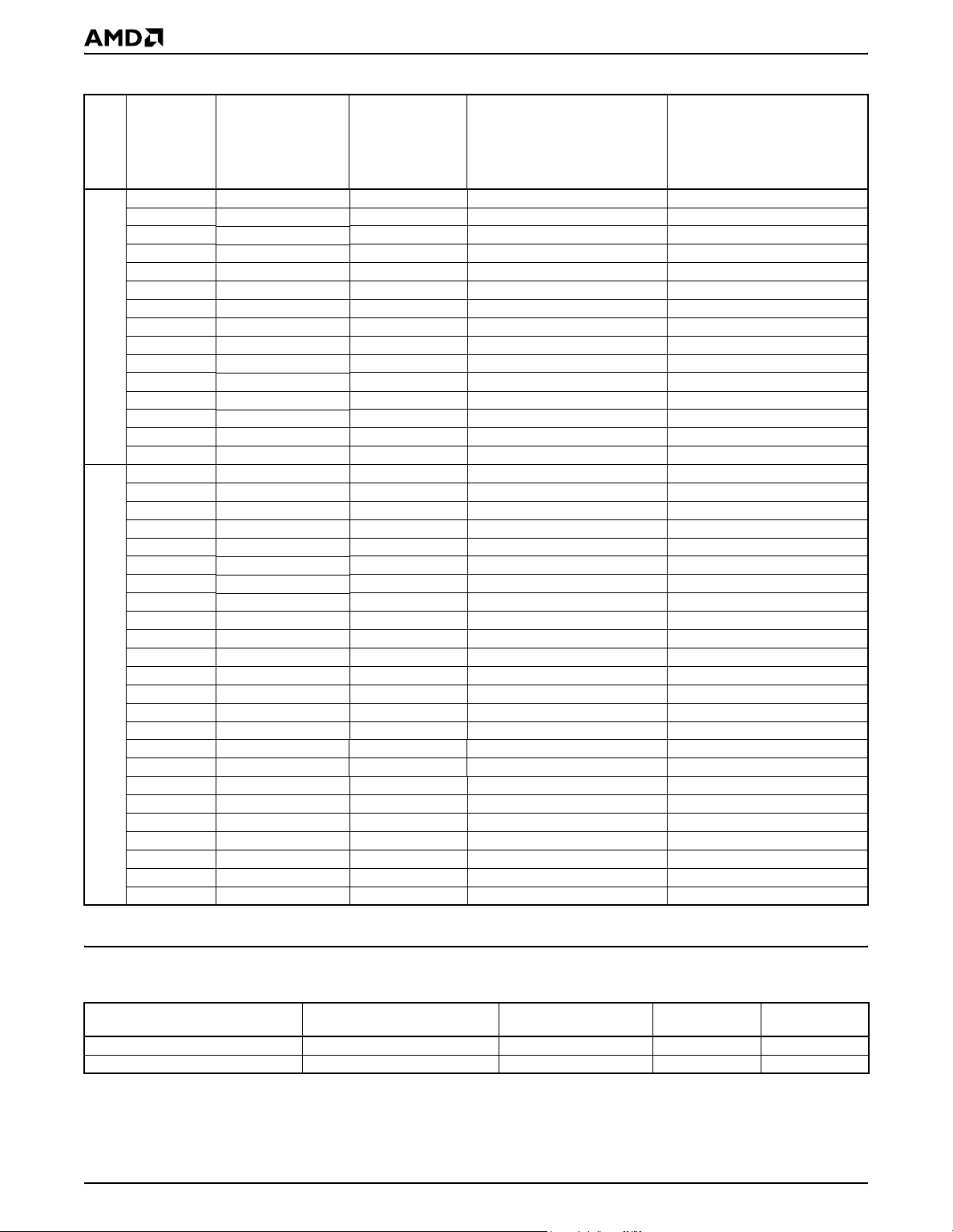

Table 3. Top Boot Sector Addresses (Am29DS16xDT)

Sector

Am29DS163DT

Bank 2

Bank 1

Note: The address range is A19:A-1 in byte mode (BYTE#=VIL) or A19:A0 in word mode (BYTE#=VIH). The bank address bits are A19 and A18 for

Am29DS163DT.

SA0 00000xxx 64/32 000000h-00FFFFh 00000h–07FFFh

SA1 00001xxx 64/32 010000h-01FFFFh 08000h–0FFFFh

SA2 00010xxx 64/32 020000h-02FFFFh 10000h–17FFFh

SA3 00011xxx 64/32 030000h-03FFFFh 18000h–1FFFFh

SA4 00100xxx 64/32 040000h-04FFFFh 20000h–27FFFh

SA5 00101xxx 64/32 050000h-05FFFFh 28000h–2FFFFh

SA6 00110xxx 64/32 060000h-06FFFFh 30000h–37FFFh

SA7 00111xxx 64/32 070000h-07FFFFh 38000h–3FFFFh

SA8 01000xxx 64/32 080000h-08FFFFh 40000h–47FFFh

SA9 01001xxx 64/32 090000h-09FFFFh 48000h–4FFFFh

SA10 01010xxx 64/32 0A0000h-0AFFFFh 50000h–57FFFh

SA11 01011xxx 64/32 0B0000h-0BFFFFh 58000h–5FFFFh

SA12 01100xxx 64/32 0C0000h-0CFFFFh 60000h–67FFFh

SA13 01101xxx 64/32 0D0000h-0DFFFFh 68000h–6FFFFh

SA14 01110xxx 64/32 0E0000h-0EFFFFh 70000h–77FFFh

SA15 01111 xxx 64/32 0F0000h-0FFFFFh 78000h–7FFFFh

SA16 10000xxx 64/32 100000h-10FFFFh 80000h–87FFFh

SA17 10001xxx 64/32 110000h-11FFFFh 88000h–8FFFFh

SA18 10010xxx 64/32 120000h-12FFFFh 90000h–97FFFh

SA19 10011xxx 64/32 130000h-13FFFFh 98000h–9FFFFh

SA20 10100xxx 64/32 140000h-14FFFFh A0000h–A7FFFh

SA21 10101xxx 64/32 150000h-15FFFFh A8000h–AFFFFh

SA22 10110xxx 64/32 160000h-16FFFFh B0000h–B7FFFh

SA23 10111xxx 64/32 170000h-17FFFFh B8000h–BFFFFh

SA24 11000xxx 64/32 180000h-18FFFFh C0000h–C7FFFh

SA25 11001xxx 64/32 190000h-19FFFFh C8000h–CFFFFh

SA26 11010xxx 64/32 1A0000h-1AFFFFh D0000h–D7FFFh

SA27 11011xxx 64/32 1B0000h-1BFFFFh D8000h–DFFFFh

SA28 11100xxx 64/32 1C0000h-1CFFFFh E0000h–E7FFFh

SA29 11101xxx 64/32 1D0000h-1DFFFFh E8000h–EFFFFh

SA30 11110 xxx 64/32 1E0000h-1EFFFFh F0000h–F7FFFh

SA31 11111000 8/4 1F0000h-1F1FFFh F8000h–F8FFFh

SA32 11111001 8/4 1F2000h-1F3FFFh F9000h–F9FFFh

SA33 11111010 8/4 1F4000h-1F5FFFh FA000h–FAFFFh

SA34 111110 11 8/4 1F6000h-1F7FFFh FB000h–FBFFFh

SA35 1111110 0 8/4 1F8000h-1F9FFFh FC000h–FCFFFh

SA36 1111110 1 8/4 1FA000h-1FBFFFh FD000h–FDFFFh

SA37 1111111 0 8/4 1FC000h-1FDFFFh FE000h–FEFFFh

SA38 11111111 8/4 1FE000h-1FFFFFh FF000h–FFFFFh

Sector Address

A19–A12

Sector Size

(Kbytes/Kwords)

(x8)

Address Range

(x16)

Address Ranges

Table 4. SecSi Sector Addresses for Top Boot Devices

SecSi Sector

Entire Sector

Factory Programmed ESN 11111xxx 16 bytes/8 words 1F0000h-1F000Fh F8000h–F8007h

Sector Address

A19–A12

11111xxx 64 Kbytes/32 Kwords 1F0000h-1FFFFFh F8000h–FFFFFh

Size

(x8)

Address Range

(x16)

Address Range

Am29DS163D 13

Page 14

ADVANCE INFORMATION

Table 5. Bottom Boot Sector Addresses (Am29DS16xDB)

Sector

Am29DS163DB

Bank 1

Bank 2

Note: The address range is A19:A-1 in byte mode (BYTE#=VIL) or A19:A0 in word mode (BYTE#=VIH). The bank address bits are A19 and A18 for

Am29DS163DB.

SA0 00000000 8/4 000000h-001FFFh 00000h-00FFFh

SA1 00000001 8/4 002000h-003FFFh 01000h-01FFFh

SA2 00000010 8/4 004000h-005FFFh 02000h-02FFFh

SA3 00000011 8/4 006000h-007FFFh 03000h-03FFFh

SA4 00000100 8/4 008000h-009FFFh 04000h-04FFFh

SA5 00000101 8/4 00A000h-00BFFFh 05000h-05FFFh

SA6 00000110 8/4 00C000h-00DFFFh 06000h-06FFFh

SA7 00000111 8/4 00E000h-00FFFFh 07000h-07FFFh

SA8 00001XXX 64/32 010000h-01FFFFh 08000h-0FFFFh

SA9 00010XXX 64/32 020000h-02FFFFh 10000h-17FFFh

SA10 00011XXX 64/32 030000h-03FFFFh 18000h-1FFFFh

SA11 00100XXX 64/32 040000h-04FFFFh 20000h-27FFFh

SA12 00101XXX 64/32 050000h-05FFFFh 28000h-2FFFFh

SA13 00110XXX 64/32 060000h-06FFFFh 30000h-37FFFh

SA14 00111XXX 64/32 070000h-07FFFFh 38000h-3FFFFh

SA15 01000XXX 64/32 080000h-08FFFFh 40000h-47FFFh

SA16 01001XXX 64/32 090000h-09FFFFh 48000h-4FFFFh

SA17 01010XXX 64/32 0A0000h-0AFFFFh 50000h-57FFFh

SA18 01011XXX 64/32 0B0000h-0BFFFFh 58000h-5FFFFh

SA19 01100XXX 64/32 0C0000h-0CFFFFh 60000h-67FFFh

SA20 01101XXX 64/32 0D0000h-0DFFFFh 68000h-6FFFFh

SA21 0 1110X XX 64/32 0E0000h-0EFFFFh 70000h-77FFFh

SA22 01111XXX 64/32 0F0000h-0FFFFFh 78000h-7FFFFh

SA23 10000XXX 64/32 100000h-10FFFFh 80000h-87FFFh

SA24 10001XXX 64/32 110000h-11FFFFh 88000h-8FFFFh

SA25 10010XXX 64/32 120000h-12FFFFh 90000h-97FFFh

SA26 10011XXX 64/32 130000h-13FFFFh 98000h-9FFFFh

SA27 10100XXX 64/32 140000h-14FFFFh A0000h-A7FFFh

SA28 10101XXX 64/32 150000h-15FFFFh A8000h-AFFFFh

SA29 10110XXX 64/32 160000h-16FFFFh B0000h-B7FFFh

SA30 10111XXX 64/32 170000h-17FFFFh B8000h-BFFFFh

SA31 11000XXX 64/32 180000h-18FFFFh C0000h-C7FFFh

SA32 11001XXX 64/32 190000h-19FFFFh C8000h-CFFFFh

SA33 11010XXX 64/32 1A0000h-1AFFFFh D0000h-D7FFFh

SA34 11011XXX 64/32 1B0000h-1BFFFFh D8000h-DFFFFh

SA35 111 00X XX 64/32 1C0000h-1CFFFFh E0000h-E7FFFh

SA36 111 01X XX 64/32 1D0000h-1DFFFFh E8000h-EFFFFh

SA37 11110 XX X 64/32 1E0000h-1EFFFFh F0000h-F7FFFh

SA38 11111 XXX 64/32 1F0000h-1FFFFFh F8000h-FFFFFh

Sector Address

A19–A12

Sector Size

(Kbytes/Kwords)

(x8)

Address Range

(x16)

Address Range

Table 6. SecSi Sector Addresses for Bottom Boot Devices

SecSi Sector

Entire Sector 00000XXX 64 Kbytes/32 Kwords 000000h-00FFFFh 00000h-07FFFh

Factory Programmed ESN 00000XXX 16 bytes/8 words 000000h-00000Fh 00000h–00007h

Sector Address

A19–A12

Size

(x8)

Address Range

14 Am29DS163D

(x16)

Address Range

Page 15

ADVANCE INFORMATION

Autoselect Mode

The autoselect mode provides manufacturer and device identification, and sector protection verification,

through identifier codes output on DQ7–DQ0. This

mode is primarily intended for programming equipment to automatically match a device to be

programmed with its corresponding programming al

gorithm. However, the autoselect codes can also be

accessed in-system through the command register.

When using programming equipment, the autoselect

mode requires VID (9.0 V to 11.0 V) on address pin A9.

Address pins A6, A1, and A0 must be as shown in

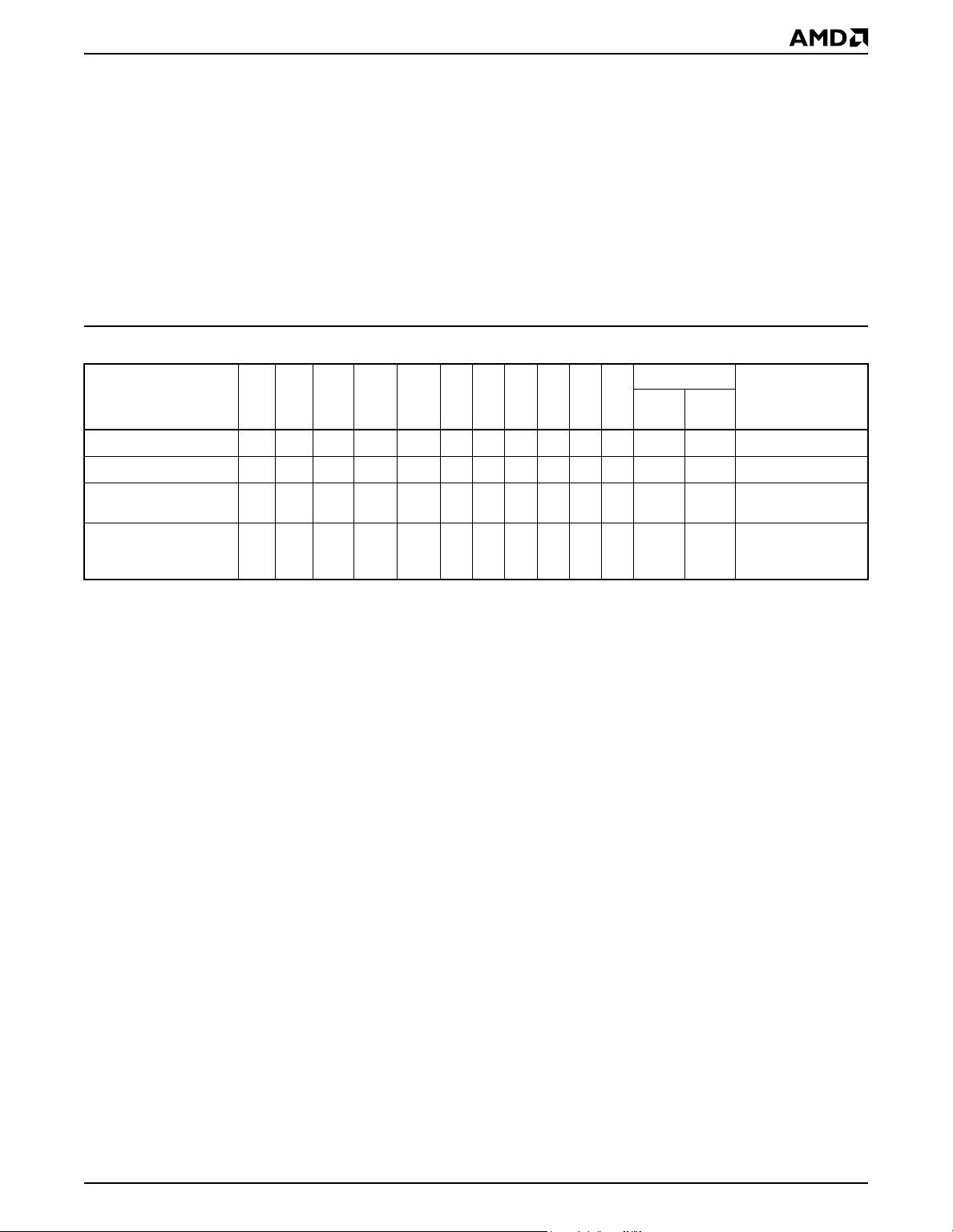

Table 7. Am29DS163D Autoselect Codes (High Voltage Method)

A19

to

Description CE# OE# WE#

Manufacturer ID: AMD L L H BA X

Device ID: Am29DS163D L L H BA X

Sector Protection

Verification

SecSi Sector Indicator Bit

(DQ7)

L L H SA X

L L H BA X

A12

-

A11

to

A10 A9

V

V

V

V

Table 7. In addition, when verifying sector protection,

the sector address must appear on the appropriate

highest order address bits (see Tables 3–6). Ta b l e 7

shows the remaining address bits that are don’t care.

When all necessary bits are set as required, the programming equipment may then read the

corresponding identifier code on DQ7–DQ0.

To access the autoselect codes in-system, the host

system can issue the autoselect command via the

command register, as shown in Table 14. This method

does not require VID. Refer to the Autoselect Command Sequence section for more information.

A8

to

A7

X L X L L X X 01h

ID

X L X L H 22h X 95h (T), 96h (B)

ID

X L X H L X X

ID

X L X H H X X

ID

A6

A5

to

A2

A1 A0

DQ8 to DQ15

BYTE#

= V

IH

BYTE#

= V

IL

01h (protected),

00h (unprotected)

85h (factory locked),

05h (not factory

locked)

DQ7

DQ0

to

Legend: T = Top Boot Block, B = Bottom Boot Block, L = Logic Low = VIL, H = Logic High = VIH, BA = Bank Address, SA =

Sector Address, X = Don’t care.

Am29DS163D 15

Page 16

ADVANCE INFORMATION

Sector/Sector Block Protection and Unprotection

(Note: For the following discussion, the term “sector”

applies to both sectors and sector blocks. A sector

block consists of two or more adjacent sectors that are

protected or unprotected at the same time (see Tables

8 and 9).

Table 8. Top Boot Sector/Sector Block Addresses

for Protection/Unprotection

Sector / Sector

Block

SA0 00000XXX 64 Kbytes

SA1-SA3

SA4-SA7 001XXXXX 256 (4x64) Kbytes

SA8-SA11 010XXXXX 256 (4x64) Kbytes

SA12-SA15 011XXXXX 256 (4x64) Kbytes

SA16-SA19 100XXXXX 256 (4x64) Kbytes

SA20-SA23 101XXXXX 256 (4x64) Kbytes

SA24-SA27 110XXXXX 256 (4x64) Kbytes

SA28-SA30

SA31 11111000 8 Kbytes

SA32 11111001 8 Kbytes

SA33 11111010 8 Kbytes

SA34 111110 11 8 Kbytes

SA35 1111110 0 8 Kbytes

SA36 1111110 1 8 Kbytes

SA37 1111111 0 8 Kbytes

SA38 11111111 8 Kbytes

A19–A12 Sector / Sector Block Size

00001XXX,

00010XXX,

00011XXX

11100XXX,

11101XXX,

11110 XX X

192 (3x64) Kbytes

192 (3x64) Kbytes

Table 9. Bottom Boot Sector/Sector Block

Addresses for Protection/Unprotection

Sector / Sector

Block

SA38 11111X XX 64 Kbytes

SA37-SA35

SA34-SA31 110XXXXX 256 (4x64) Kbytes

SA30-SA27 101XXXXX 256 (4x64) Kbytes

SA26-SA23 100XXXXX 256 (4x64) Kbytes

SA22-SA19 011XXXXX 256 (4x64) Kbytes

SA18-SA15 010XXXXX 256 (4x64) Kbytes

SA14-SA11 001XXXXX 256 (4x64) Kbytes

SA10-SA8

SA7 00000111 8 Kbytes

SA6 00000110 8 Kbytes

SA5 00000101 8 Kbytes

SA4 00000100 8 Kbytes

SA3 00000011 8 Kbytes

SA2 00000010 8 Kbytes

SA1 00000001 8 Kbytes

SA0 00000000 8 Kbytes

A19–A12 Sector / Sector Block Size

11110 XX X,

11101XXX,

11100XXX

00001XXX,

00010XXX,

00011XXX

192 (3x64) Kbytes

192 (3x64) Kbytes

The hardware sector protection feature disables both

program and erase operations in any sector. The hardware sector unprotection feature re-enables both

program and erase operations in previously protected

sectors. Sector protection and unprotection can be implemented via two methods.

The primary method requires VID on the RESET# pin

only, and can be implemented either in-system or via

programming equipment. Figure 2 shows the algo-

rithms and Figure 25 shows the timing diagram. This

method uses standard microprocessor bus cycle timing. For sector unprotect, all unprotected sectors must

first be protected prior to the first sector unprotect

write cycle.

16 Am29DS163D

Page 17

ADVANCE INFORMATION

The alternate method intended only for programming

equipment requires VID on address pin A9 and OE#.

This method is compatible with programmer routines

written for earlier 1.8 volt-only AMD flash devices.

Contact an AMD representative for further details.

The device is shipped with all sectors unprotected.

AMD offers the option of programming and protecting

sectors at its factory prior to shipping the device

through AMD’s ExpressFlash™ Service. Contact an

AMD representative for details.

It is possible to determine whether a sector is protected or unprotected. See the Autoselect Mode

section for details.

Write Protect (WP#)

The Write Protect function provides a hardware

method of protecting certain boot sectors without

using V

WP#/ACC pin.

If the system asserts VIL on the WP#/ACC pin, the device disables program and erase functions in the two

“outermost” 8 Kbyte boot sectors independently of

whether those sectors were protected or unprotected

using the method described in

Protection and Unprotection”. The two outermost 8

Kbyte boot sectors are the two sectors containing the

lowest addresses in a bottom-boot-configured device,

or the two sectors containing the highest addresses in

a top-boot-configured device.

. This function is one of two provided by the

ID

“Sector/Sector Block

block consists of two or more adjacent sectors that are

protected or unprotected at the same time (see Tables

8 and 9).

This feature allows temporary unprotection of previously protected sectors to change data in-system. The

Sector Unprotect mode is activated by setting the RE

SET# pin to VID (9.0 – 11.0 V). During this mode,

formerly protected sectors can be programmed or

erased by selecting the sector addresses. Once VID is

removed from the RESET# pin, all the previously protected sectors are protected again. Figure 1 shows the

algorithm, and Figure 24 shows the timing diagrams,

for this feature.

START

RESET# = V

(Note 1)

Perform Erase or

Program Operations

RESET# = V

ID

IH

-

If the system asserts V

on the WP#/ACC pin, the de-

IH

vice reverts to whether the two outermost 8 Kbyte boot

sectors were last set to be protected or unprotected.

That is, sector protection or unprotection for these two

sectors depends on whether they were last protected

or unprotected using the method described in “Sector/Sector Block Protection and Unprotection”.

Note that the WP#/ACC pin must not be left floating or

unconnected; inconsistent behavior of the device may

result.

Temporary Sector/Sector Block Unprotect

(Note: For the following discussion, the term “sector”

applies to both sectors and sector blocks. A sector

Temporary Sector

Unprotect Completed

(Note 2)

Notes:

1. All protected sectors unprotected (If WP#/ACC = V

outermost boot sectors will remain protected).

2. All previously protected sectors are protected once

again.

,

IL

Figure 1. Temporary Sector Unprotect Operation

Am29DS163D 17

Page 18

ADVANCE INFORMATION

r

S

Temporary Sector

Unprotect Mode

Increment

PLSCNT

No

PLSCNT

= 25?

Yes

Device failed

ector Protect

Algorithm

START

PLSCNT = 1

RESET# = V

Wait 1 µs

No

First Write

Cycle = 60h?

Set up sector

address

Sector Protect:

Write 60h to sector

address with

A6 = 0, A1 = 1,

A0 = 0

Wait 150 µs

Verify Sector

Protect: Write 40h

to sector address

with A6 = 0,

A1 = 1, A0 = 0

Read from

sector address

with A6 = 0,

A1 = 1, A0 = 0

No

Data = 01h?

Protect another

sector?

Remove V

from RESET#

Write reset

command

Sector Protect

complete

Yes

Yes

No

START

Protect all sectors:

The indicated portion

of the sector protect

ID

Reset

PLSCNT = 1

Yes

ID

algorithm must be

performed for all

unprotected sectors

prior to issuing the

first sector

unprotect address

Increment

PLSCNT

No

PLSCNT

= 1000?

Yes

Device failed

Sector Unprotect

PLSCNT = 1

RESET# = V

Wait 1 µs

First Write

Cycle = 60h?

No

All sectors

protected?

Set up first sector

address

Sector Unprotect:

Write 60h to sector

address with

A6 = 1, A1 = 1,

A0 = 0

Wait 15 ms

Verify Sector

Unprotect: Write

40h to sector

address with

A6 = 1, A1 = 1,

A0 = 0

Read from

sector address

with A6 = 1,

A1 = 1, A0 = 0

No

Data = 00h?

Last sector

verified?

Remove V

from RESET#

Yes

Yes

Yes

Yes

ID

No

Temporary Secto

Unprotect Mode

Set up

next sector

address

No

ID

Algorithm

Write reset

command

Sector Unprotect

complete

Note: The term “sector” in the figure applies to both sectors and sector blocks.

Figure 2. In-System Sector/Sector Block Protect and Unprotect Algorithms

18 Am29DS163D

Page 19

ADVANCE INFORMATION

SecSi (Secured Silicon) Sector Flash

Memory

The SecSi (Secured Silicon) Sector feature provides

an additional 64Kbyte Flash memory region that en

ables permanent part identification through an

Electronic Serial Number (ESN). An SecSi Sector Indicator Bit indicates whether or not the SecSi Sector is

locked when shipped from the factory. This bit is per

manently set at the factory and cannot be changed,

which prevents cloning of a factory locked part. This

ensures the security of the ESN once the product is

shipped to the field.

AMD offers the device with the SecSi Sector either

factory locked or customer lockable. The factory-locked version is always protected when shipped

from the factory, and the SecSi Sector Indicator Bit is

permanently set to a “1.” The customer-lockable ver

sion is shipped with the unprotected, allowing

customers to utilize the that sector in any manner they

choose. In the customer-lockable version, the SecSi

Sector Indicator Bit is permanently set to a “0.” Thus,

the SecSi Sector Indicator Bit prevents customer-lock

able devices from being used to replace devices that

are factory locked.

The system accesses the SecSi Sector through a

command sequence (see

SecSi Sector Command Sequence” on page 24). After

the system writes the Enter SecSi Sector command

sequence, it may read the SecSi Sector by using the

addresses normally occupied by the boot sectors. This

mode of operation continues until the system issues

the Exit SecSi Sector command sequence, or until

power is removed from the device. On power-up, or

following a hardware reset, the device reverts to sending commands to the boot sectors.

The following restrictions apply to using the SecSi

Sector: Once the device enters the SecSi Sector, any

attempt to initiate program or erase operations in the

array is ignored until the device exits the SecSi Sector.

Conversely, when a program or erase operation in the

array is in progress, the device ignores any attempt to

enter the SecSi Sector until programming or erasing is

complete.

Factory Locked: SecSi Sector Programmed

and Protected at the Factory

In a factory locked device, the SecSi Sector is protected when the device is shipped from the factory.

The SecSi Sector cannot be modified in any way. The

device is available preprogrammed with one of the

following:

■ A random, secure ESN only

■ Customer code through the ExpressFlash service

■ Both a random, secure ESN and customer code

through the ExpressFlash service.

Region

“Enter SecSi Sector/Exit

In devices that have an ESN, a Bottom Boot device

has the 16-byte ESN at addresses 00000h–00007h in

word mode (or 000000h–00000Fh in byte mode). In

the Top Boot device the starting address of the ESN is

at addresses F8000h–F8007h in word mode (or

1F0000h–1F000Fh in byte mode).

Customers may opt to have their code programmed by

AMD through the AMD ExpressFlash service. AMD

programs the customer’s code, with or without the ran-

dom ESN. The devices are then shipped from AMD’s

factory with the permanently locked. Contact an AMD

representative for details on using AMD’s ExpressFlash service.

Customer Lockable: SecSi Sector NOT

Programmed or

If the security feature is not required, the SecSi Sector

-

can be treated as an additional Flash memory space,

expanding the size of the available Flash array by 64

Kbytes. The SecSi Sector can be read, programmed,

and erased as often as required. The SecSi Sector area

can be protected using one of the following procedures:

-

■ Write the three-cycle Enter SecSi Sector Region

command sequence, and then follow the in-system

sector protect algorithm as shown in

cept that RESET# may be at either VIH or VID. This

allows in-system protection of the without raising

any device pin to a high voltage. Note that this

method is only applicable to the SecSi Sector.

■ Write the three-cycle Enter SecSi Sector Region

command sequence, and then use the alternate

method of sector protection described in “Sec-

tor/Sector Block Protection and Unprotection” on

page 16.

Once the SecSi Sector is locked and verified, the system must write the Exit SecSi Sector Region

command sequence to return to reading and writing

the remainder of the array.

The SecSi Sector protection must be used with caution since, once protected, there is no procedure

available for unprotecting the SecSi Sector area and

none of the bits in the SecSi Sector memory space

can be modified in any way. Note also that the multiple

program and erase capability of the customer lockable

version of this device may be subject to change on future device revisions.

Protected at the Factory

Hardware Data Protection

The command sequence requirement of unlock cycles

for programming or erasing provides data protection

against inadvertent writes (refer to Tab le 14 on

page 27 for command definitions). In addition, the fol-

lowing hardware data protection measures prevent

accidental erasure or programming, which might otherwise be caused by spurious system level signals

Figure 2, ex-

Am29DS163D 19

Page 20

ADVANCE INFORMATION

during VCC power-up and power-down transitions, or

from system noise.

Low VCC Write Inhibit

When VCC is less than V

cept any write cycles. This protects data during V

, the device does not ac-

LKO

CC

power-up and power-down. The command register

and all internal program/erase circuits are disabled,

and the device resets to reading array data. Subsequent writes are ignored until VCC is greater than V

LKO

The system must provide the proper signals to the

control pins to prevent unintentional writes when V

is greater than V

LKO

.

CC

Write Pulse “Glitch” Protection

Noise pulses of less than 5 ns (typical) on OE#, CE#

or WE# do not initiate a write cycle.

Logical Inhibit

Write cycles are inhibited by holding any one of OE# =

VIL, CE# = VIH or WE# = VIH. To initiate a write cycle,

CE# and WE# must be a logical zero while OE# is a

logical one.

Power-Up Write Inhibit

If WE# = CE# = VIL and OE# = VIH during power up,

the device does not accept commands on the rising

edge of WE#. The internal state machine is automatically reset to reading array data on power-up.

COMMON FLASH MEMORY INTERFACE (CFI)

The Common Flash Interface (CFI) specification outlines device and host system software interrogation

handshake, which allows specific vendor-specified

software algorithms to be used for entire families of

devices. Software support can then be device-independent, JEDEC ID-independent, and forward- and

backward-compatible for the specified flash device

families. Flash vendors can standardize their existing

interfaces for long-term compatibility.

.

This device enters the CFI Query mode when the system writes the CFI Query command, 98h, to address

55h in word mode (or address AAh in byte mode), any

time the device is ready to read array data. The system can read CFI information at the addresses given

in

Tab le 10 on page 20 to Tab l e 13 on page 22. To ter-

minate reading CFI data, the system must write the

reset command.

The system can also write the CFI query command

when the device is in the autoselect mode. The device

enters the CFI query mode, and the system can read

CFI data at the addresses given in

page 20 to Table 13 on page 22. The system must

write the reset command to return the device to the

autoselect mode.

For further information, please refer to the CFI Specification and CFI Publication 100, available via the

World Wide Web at http://www.amd.com/prod

ucts/nvd/overview/cfi.html. Alternatively, contact an

AMD representative for copies of these documents.

Tab le 10 on

-

Addresses

(Word Mode)

10h

11h

12h

13h

14h

15h

16h

17h

18h

19h

1Ah

Table 10. CFI Query Identification String

Addresses

(Byte Mode) Data Description

20h

22h

24h

26h

28h

2Ah

2Ch

2Eh

30h

32h

34h

0051h

0052h

0059h

0002h

0000h

0040h

0000h

0000h

0000h

0000h

0000h

Query Unique ASCII string “QRY”

Primary OEM Command Set

Address for Primary Extended Table

Alternate OEM Command Set (00h = none exists)

Address for Alternate OEM Extended Table (00h = none exists)

20 Am29DS163D

Page 21

ADVANCE INFORMATION

Table 11 . System Interface String

Addresses

(Word Mode)

1Bh 36h 0018h

1Ch 38h 0022h

1Dh 3Ah 0000h VPP Min. voltage (00h = no VPP pin present)

1Eh 3Ch 0000h VPP Max. voltage (00h = no VPP pin present)

1Fh 3Eh 0004h Typical timeout per single byte/word write 2N µs

20h 40h 0000h Typical timeout for Min. size buffer write 2N µs (00h = not supported)

21h 42h 000Ah Typical timeout per individual block erase 2N ms

22h 44h 0000h Typical timeout for full chip erase 2N ms (00h = not supported)

23h 46h 0005h Max. timeout for byte/word write 2N times typical

24h 48h 0000h Max. timeout for buffer write 2N times typical

25h 4Ah 0004h Max. timeout per individual block erase 2N times typical

26h 4Ch 0000h Max. timeout for full chip erase 2N times typical (00h = not supported)

Addresses

(Byte Mode)

Data Description

VCC Min. (write/erase)

D7–D4: volt, D3–D0: 100 millivolt

VCC Max. (write/erase)

D7–D4: volt, D3–D0: 100 millivolt

Table 12. Device Geometry Definition

Addresses

(Word Mode)

Addresses

(Byte Mode)

Data Description

27h 4Eh 0015h Device Size = 2N byte

28h

29h

2Ah

2Bh

2Ch 58h 0002h Number of Erase Block Regions within device

2Dh

2Eh

2Fh

30h

31h

32h

33h

34h

35h

36h

37h

38h

39h

3Ah

3Bh

3Ch

50h

52h

54h

56h

5Ah

5Ch

5Eh

60h

62h

64h

66h

68h

6Ah

6Ch

6Eh

70h

72h

74h

76h

78h

0002h

0000h

0000h

0000h

0007h

0000h

0020h

0000h

001Eh

0000h

0000h

0001h

0000h

0000h

0000h

0000h

0000h

0000h

0000h

0000h

Flash Device Interface description (refer to CFI publication 100)

Max. number of byte in multi-byte write = 2N

(00h = not supported)

Erase Block Region 1 Information

(refer to the CFI specification or CFI publication 100)

Erase Block Region 2 Information

Erase Block Region 3 Information

Erase Block Region 4 Information

Am29DS163D 21

Page 22

ADVANCE INFORMATION

Table 13. Primary Vendor-Specific Extended Query

Addresses

(Word Mode)

40h

41h

42h

43h 86h 0031h Major version number, ASCII

44h 88h 0032h Minor version number, ASCII

45h 8Ah 0000h

46h 8Ch 0002h

47h 8Eh 0001h

48h 90h 0001h

49h 92h 0004h

4Ah 94h

4Bh 96h 0000h

Addresses

(Byte Mode)

80h

82h

84h

Data Description

0050h

0052h

0049h

00XXh

(See Note)

Query-unique ASCII string “PRI”

Address Sensitive Unlock (Bits 1-0)

0 = Required, 1 = Not Required

Silicon Revision Number (Bits 7-2)

Erase Suspend

0 = Not Supported, 1 = To Read Only, 2 = To Read & Write

Sector Protect

0 = Not Supported, X = Number of sectors in per group

Sector Temporary Unprotect

00 = Not Supported, 01 = Supported

Sector Protect/Unprotect scheme

04 = 29LV800 mode

Simultaneous Operation

00 = Not Supported, X= Number of Sectors in Bank 2 (Uniform Bank)

Burst Mode Type

00 = Not Supported, 01 = Supported

4Ch 98h 0000h

4Dh 9Ah 0085h

4Eh 9Ch 0095h

4Fh 9Eh 000Xh

Note:

The number of sectors in Bank 2 is device dependent.

Am29DS163 = 18h

Page Mode Type

00 = Not Supported, 01 = 4 Word Page, 02 = 8 Word Page

ACC (Acceleration) Supply Minimum

00h = Not Supported, D7-D4: Volt, D3-D0: 100 mV

ACC (Acceleration) Supply Maximum

00h = Not Supported, D7-D4: Volt, D3-D0: 100 mV

Top/Bottom Boot Sector Flag

02h = Bottom Boot Device, 03h = Top Boot Device

22 Am29DS163D

Page 23

ADVANCE INFORMATION

COMMAND DEFINITIONS

Writing specific address and data commands or sequences into the command register initiates device

operations. Tab le 14 on page 27 defines the valid register command sequences. Writing incorrect address

and data values or writing them in the improper se

quence resets the device to reading array data.

All addresses are latched on the falling edge of WE#

or CE#, whichever happens later. All data is latched on

the rising edge of WE# or CE#, whichever happens

first. Refer to the AC Characteristics section for timing

diagrams.

command returns that bank to the erase-sus

pend-read mode. Once programming begins, however,

the device ignores reset commands until the operation

is complete.

-

The reset command may be written between the sequence cycles in an autoselect command sequence.

Once in the autoselect mode, the reset command

must be written to return to reading array data. If a

bank entered the autoselect mode while in the Erase

Suspend mode, writing the reset command returns

that bank to the erase-suspend-read mode.

-

Reading Array Data

The device is automatically set to reading array data

after device power-up. No commands are required to

retrieve data. Each bank is ready to read array data

after completing an Embedded Program or Embedded

Erase algorithm.

After the device accepts an Erase Suspend command,

the corresponding bank enters the erase-sus

pend-read mode, after which the system can read

data from any non-erase-suspended sector within the

same bank. After completing a programming operation

in the Erase Suspend mode, the system may once

again read array data with the same exception. See

the “Erase Suspend/Erase Resume Commands” on

page 26 section for more information.

The system must issue the reset command to return a

bank to the read (or erase-suspend-read) mode if DQ5

goes high during an active program or erase operation, or if the bank is in the autoselect mode. See the

next section, “Reset Command", for more information.

See also “Requirements for Reading Array Data” on

page 10 for more information. Tab le on page 36 pro-

vides the read parameters, and Figure 13, on page 36

shows the timing diagram.

Reset Command

Writing the reset command resets the banks to the

read or erase-suspend-read mode. Address bits are

don’t cares for this command.

The reset command may be written between the sequence cycles in an erase command sequence before

erasing begins. This resets the bank to which the system was writing to reading array data. Once erasure

begins, however, the device ignores reset commands

until the operation is complete.

The reset command may be written between the

sequence cycles in a program command sequence

before programming begins. This resets the bank to

which the system was writing to reading array data. If

the program command sequence is written to a bank

that is in the Erase Suspend mode, writing the reset

If DQ5 goes high during a program or erase operation,

writing the reset command returns the banks to read

ing array data (or erase-suspend-read mode if that

bank was in Erase Suspend).

Autoselect Command Sequence

The autoselect command sequence allows the host

system to access the manufacturer and device codes,

-

and determine whether or not a sector is protected.

Tab le 14 on page 27 shows the address and data re-

quirements. This method is an alternative to that

shown in

PROM programmers and requires VID on address pin

A9. The autoselect command sequence may be written to an address within a bank that is either in the

read or erase-suspend-read mode. The autoselect

command may not be written while the device is actively programming or erasing in the other bank.

The autoselect command sequence is initiated by first

writing two unlock cycles. This is followed by a third

write cycle that contains the bank address and the

autoselect command. The bank then enters the

autoselect mode. The system may read at any address

within the same bank any number of times without initiating another autoselect command sequence. The following table describes the hex address requirements

for the various autoselect functions, and the resulting

data. BA represents the bank address, and SA represents the sector address.

Description

Manufacturer

ID

Device ID (BA) + 01 (BA) + 02

Sector Block

Protect Verify

SecSi Sector

Factory

Protect

* For byte mode, ignore data output bits D8–DQ15.

Tab le 7 on page 15, which is intended for

Word

Address

(BA) + 00 (BA) + 00 01

(SA) + 02 (SA) + 04

(BA) + 03 (BA) + 06

Byte

Address

Read Data*

2295 (top boot)

2296 (bottom boot)

00 (unlocked),

01 (locked)

85 (factory locked)

05 (not factory locked)

-

Am29DS163D 23

Page 24

ADVANCE INFORMATION

The system must write the reset command to return to

reading array data (or erase-suspend-read mode if the

bank was previously in Erase Suspend).

Enter SecSi Sector/Exit SecSi Sector

Command

The system can access the SecSi Sector region by issuing the three-cycle Enter SecSi Sector command

sequence. The device continues to access the SecSi

Sector region until the system issues the four-cycle

Exit SecSi Sector command sequence. The Exit SecSi

Sector command sequence returns the device to normal operation. Ta b l e 14 on page 27 shows the

address and data requirements for both command sequences. See also “SecSi (Secured Silicon) Sector

Flash Memory Region” on page 19 for further informa-

tion. Note that a hardware reset (RESET#=VIL) resets

the device to reading array data.

Sequence

Byte/Word Program Command Sequence

The system may program the device by word or byte,

depending on the state of the BYTE# pin. Program

ming is a four-bus-cycle operation. The program

command sequence is initiated by writing two unlock

write cycles, followed by the program set-up com

mand. The program address and data are written next,

which in turn initiate the Embedded Program algorithm. The system is not required to provide further

controls or timings. The device automatically provides

internally generated program pulses and verifies the

programmed cell margin. Tab le 14 on page 27 shows

the address and data requirements for the byte program command sequence.

When the Embedded Program algorithm is complete,

that bank then returns to reading array data and addresses are no longer latched. The system can

determine the status of the program operation by

using DQ7, DQ6, or RY/BY#. Refer to

tion Status” on page 28 for information on these status

bits.

Any commands written to the device during the Embedded Program Algorithm are ignored. Note that a

hardware reset immediately terminates the program

operation. The program command sequence should

be reinitiated once that bank returns to reading array

data, to ensure data integrity.

Programming is allowed in any sequence and across

sector boundaries. A bit cannot be programmed

from “0” back to a “1.” Attempting to do so may

“Write Opera-

cause that bank to set DQ5 = 1, or cause the DQ7 and

DQ6 status bits to indicate the operation was success

ful. However, a succeeding read shows that the data is

still “0.” Only erase operations can convert a “0” to a

“1.”

Unlock Bypass Command Sequence

The unlock bypass feature allows the system to program bytes or words to a bank faster than using the

standard program command sequence. The unlock

bypass command sequence is initiated by first writing

two unlock cycles. This is followed by a third write

cycle containing the unlock bypass command, 20h.

That bank then enters the unlock bypass mode. A

two-cycle unlock bypass program command sequence

is all that is required to program in this mode. The first

cycle in this sequence contains the unlock bypass program command, A0h; the second cycle contains the

program address and data. Additional data is pro

grammed in the same manner. This mode dispenses

with the initial two unlock cycles required in the stan

dard program command sequence, resulting in faster

total programming time. Ta bl e 14 on page 27 shows

the requirements for the command sequence.

During the unlock bypass mode, only the Unlock By-

pass Program and Unlock Bypass Reset commands

are valid. To exit the unlock bypass mode, the system

must issue the two-cycle unlock bypass reset command sequence. The first cycle must contain the bank

address and the data 90h. The second cycle need

only contain the data 00h. The bank then returns to the

reading array data.

The device offers accelerated program operations

through the WP#/ACC pin. When the system asserts

VHH on the WP#/ACC pin, the device automatically enters the Unlock Bypass mode. The system may then

write the two-cycle Unlock Bypass program command

sequence. The device uses the higher voltage on the

WP#/ACC pin to accelerate the operation. Note that

the WP#/ACC pin must not be at VHH any operation

other than accelerated programming, or device damage may result. In addition, the WP#/ACC pin must not

be left floating or unconnected; inconsistent behavior

of the device may result.

Figure 3, on page 25 illustrates the algorithm for the

program operation. Refer to the “Erase and Program

Operations” on page 39 for parameters, and Figure

17, on page 40 for timing diagrams.

-

-

-

24 Am29DS163D

Page 25

ADVANCE INFORMATION

Any commands written during the chip erase operation

are ignored. However, note that a hardware reset immediately terminates the erase operation. If that

START

occurs, the chip erase command sequence should be

reinitiated once that bank returns to reading array

data, to ensure data integrity.

Write Program

Command Sequence

Data Poll

Embedded

Program

algorithm

in progress

Increment Address

Note: See Table 14 for program command sequence.

No

from System

Verify Data?

Yes

Last Address?

Yes

Programming

Completed

No

Figure 3. Program Operation

Chip Erase Command Sequence

Chip erase is a six bus cycle operation. The chip erase

command sequence is initiated by writing two unlock

cycles, followed by a set-up command. Two additional

unlock write cycles are then followed by the chip erase

command, which in turn invokes the Embedded Erase

algorithm. The device does not require the system to

preprogram prior to erase. The Embedded Erase algo

rithm automatically preprograms and verifies the entire

memory for an all zero data pattern prior to electrical

erase. The system is not required to provide any controls or timings during these operations. Table 14

shows the address and data requirements for the chip

erase command sequence.

When the Embedded Erase algorithm is complete,

that bank returns to reading array data and addresses

are no longer latched. The system can determine the

status of the erase operation by using DQ7, DQ6,

DQ2, or RY/BY#. Refer to the

section for information on these status bits.

Write Operation Status

Figure 4, on page 26 illustrates the algorithm for the

erase operation. Refer to the “Erase and Program Op-

erations” on page 39 tables in the AC Characteristics

section for parameters, and Figure 19, on page 41

section for timing diagrams.

Sector Erase Command Sequence

Sector erase is a six bus cycle operation. The sector

erase command sequence is initiated by writing two