AMD Advanced Micro Devices AM28F020A-200JCB, AM28F020A-200FIB, AM28F020A-200FI, AM28F020A-200FEB, AM28F020A-200FE Datasheet

...

FINAL

Am28F020A

2 Megabit (256 K x 8-Bit)

CMOS 12.0 Volt, Bulk Erase Flash Memory with Embedded Algorithms

■

DISTINCTIVE CHARACTERISTICS

■

High performance

— Access times as fast as 70 ns

■

CMOS low power consumption

— 30 mA max imum active current

— 100 µA maximum standby current

— No data retention power consumption

■

Compatible with JEDEC-standard byte-wide

32-pin EPROM pinouts

— 32-pin PDIP

— 32-pin PLCC

— 32-pin TSOP

■

100,000 write/erase cycles minimum

■

Write and erase voltage 12.0 V ±5%

Latch-up protected to 100 mA from

–1 V to V

■

Embedded Erase Electrical Bulk Chip Erase

— Five seconds typical chip erase, including

pre-programming

■

Embedded Program

— 14 µs typical byte program, including time-out

— 4 seconds typical chip program

■

Command regist er architecture for

microprocessor/microcontroller compatible

write interface

■

On-chi p add r es s and dat a latches

■

Advanced CMOS flash memory technology

— Low cost single transistor memory cell

■

Embed ded al gori thms f or com plet ely self -ti med

write /er as e op er a tio n s

CC

+1 V

GENERAL DESCRIPTION

The Am 28F02 0A is a 2 Mega bit F lash me mor y orga nize d as 25 6 Kb y tes of 8 bit s ea ch. AM D’s Flash memories offer the most cost-effective and reliable read/

write non-volat ile random access memory. The

Am28F020A is packaged in 32-pin PDIP, PLCC, and

TSOP v ers ions . It i s des ign ed to be repr ogr amme d and

erased in-system or in standard EPROM programmers.

The Am28F020A is erased when shipped from

the factory.

The standard Am28F020A offers access times of as

fast as 70 ns, allow ing h igh s peed m icr oproc esso rs to

operate without wait states. To eliminate bus contention, the device has separate chip enable (CE#) and

output enable (OE#) controls.

AMD’s Flash memories augment EPROM funct ionality

with i n-circuit elec trical e rasure and programming. The

Am28F020A uses a command register to manage this

functionality. The command register allows for 100%

TTL level control inputs and fixed power supply levels

during erase and programming, while maintaining

maximum EPROM compatibility.

The Am28F020A is compatible with the AMD

Am28F256A, Am28F512A, and Am28F010A Flash

memor ies. A ll devices in the Am28Fx xx family follow

the JEDEC 32-pin pinout standard. In addition, all

devices within this family that offer Embedded Algorithms use the same command set. This offers

designers the flexibility to retain the same device footprint and command set, at any density between

256 Kbits and 2 Mbits.

AMD’s Flash technology reliably stores memory contents even after 100,000 erase and program cycles.

The AMD cell is designed to optimize the erase and

programming mechanisms. In addition, the combination of advanced tunnel oxide processing and low

internal ele ctric fiel ds f or er ase an d prog ra mming operations produce s reliab le cyc ling. The Am28F0 20A uses

a 12.0±5% VPP supply in put to p erfor m the e rase an d

programming functions.

The highest degree of latch-up protection is achieved

with AMD’s prop r ietary non -e pi pr oc e ss. Lat ch- up pro tection is provided for stresses up to 100 mA on

address and data pins from –1 V to VCC +1 V.

AMD’s Flash technology combines years of EPROM

and EEPROM experience to produce the highest levels

of quality, reliability, and cost effectiveness. Th e

Am28F0 20A elec trica lly era ses a ll bits simult ane ously

using Fowler-Nordheim t unneling. The bytes are

programmed one byte at a time using the EPROM

programming mechanism of hot electron injection.

Publication#

Issu e Date:

Rev: DAmendment/

17502

January 1998

+1

Embedded Program

The Am28F020A is byte programmable using the

Embedde d P ro gram algorithm, whi c h do es no t req uir e

the system to tim e- out o r verif y th e da ta progra mmed .

The typi cal r oom te mper at ure pr og ram ming time of this

device is four seconds.

Comparing Embedded Algorithms with Flasherase and Flashrite Algorithms

Embedded Erase

The entire device is bulk erased using the Embedded

Erase al gorithm , which au tomaticall y program s the

entire array prior to electrical erase. The timing and verification of electrical erase are controlled internal to the

devi ce . Typical er asu re tim e at ro om te mper at ure is fiv e

seconds, including preprogramming.

Embedded

Programming

Algorithm vs.

Flashrite

Programming

Algorithm

Embedded Erase

Algorithm vs.

Flasherase Erase

Algorithm

Am28F020A with

Embedded Algorithms

AMD’s Embedded Programming algorithm

requires the user to only write a program

set-up command and a program command

(program data and address). The device

automatically times the programming

pulse width, verifies the programming, and

counts the number of sequences. A status

bit, Data# Polling, provides the user with

the programming operation status.

AMD’s Embedded Erase algorithm

requires the user to only write an erase setup command and erase command. The

device automatically pre-programs and

verifies the entire array. The device then

automatically times the erase pulse width,

verifies the erase operation, and counts

the number of sequences. A status bit,

Data# Polling, provides the user with the

erase operation status.

Am28F020 using AMD Flashrite

and Flasherase Algorithms

The Flashrite Programming algorithm requires the

user to write a program set-up command, a program

command, (program data and address), and a

program verify command, followed by a read and

compare operation. The user is required to time the

programming pulse width in order to issue the

program verify command. An integrated stop timer

prevents any possibility of overprogramming.

Upon completion of this sequence, the data is read

back from the device and compared by the user with

the data intended to be written; if there is not a

match, the sequence is repeated until there is a

match or the sequence has been repeated 25 times.

The Flasherase Erase algorithm requires the device

to be completely programmed prior to executing an

erase command.

To invoke the erase operation, the user writes an

erase set-up command, an erase command, and an

erase verify command. The user is required to time

the erase pulse width in order to issue the erase

verify command. An integrated stop timer prevents

any possibility of overerasure.

Upon completion of this sequence, the data is read

back from the device and compared by the user with

erased data. If there is not a match, the sequence is

repeated until there is a match or the sequence has

been repeated 1,000 times.

Commands are written to the c ommand reg ister u si ng

standard microprocessor write timings. Register contents serve as input to an internal state-machine,

which controls the erase and programming cir cuitry.

During write cycles, the command register internally

latches addresses and data needed for the programming and erase operations. For system design

simplification, the Am28F010A is designed to support

either WE# or CE# controlled writes. During a system

write cycle, addresses are latched on the falling edge

of WE# or CE#, whichever occurs last. Data is latched

on the rising edge of WE# or CE#, whichever occurs

first. To simplify the following discussion, the WE# pin

is used as the write cycle control pin throughout the

rest of this text. All setup and hold times are with

respect to the WE# signal.

2 Am28F020A

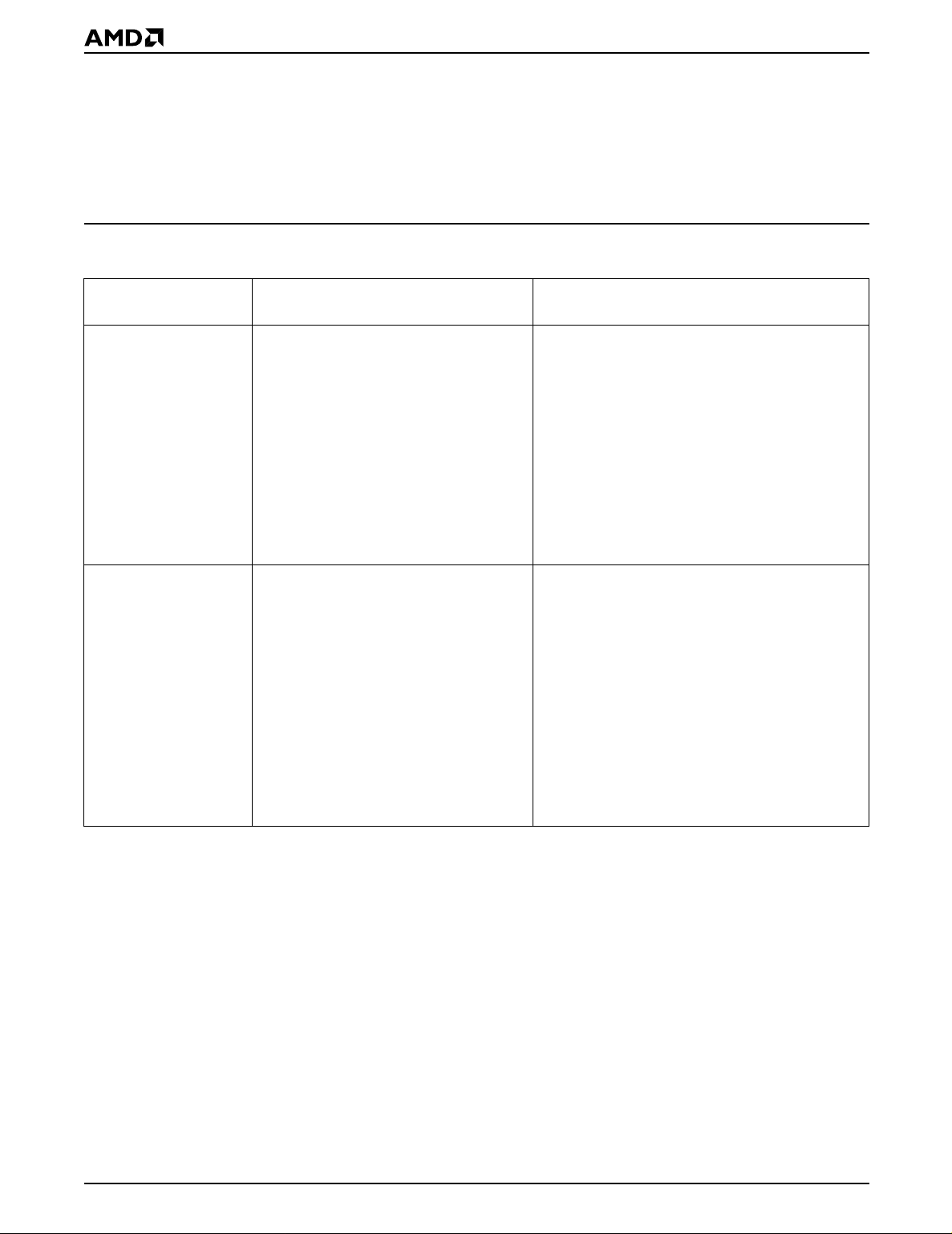

PRODUCT SELECTOR GUIDE

g

g

Family Part Number

Speed Options (V

CC

= 5.0 V ± 10%)

-70 -90 -120 -150 -200

Am28F020A

Max Access Time (ns) 70 90 120 150 200

CE# (E#) Access (ns) 70 90 120 150 200

OE# (G#) Access (ns) 35 35 50 55 55

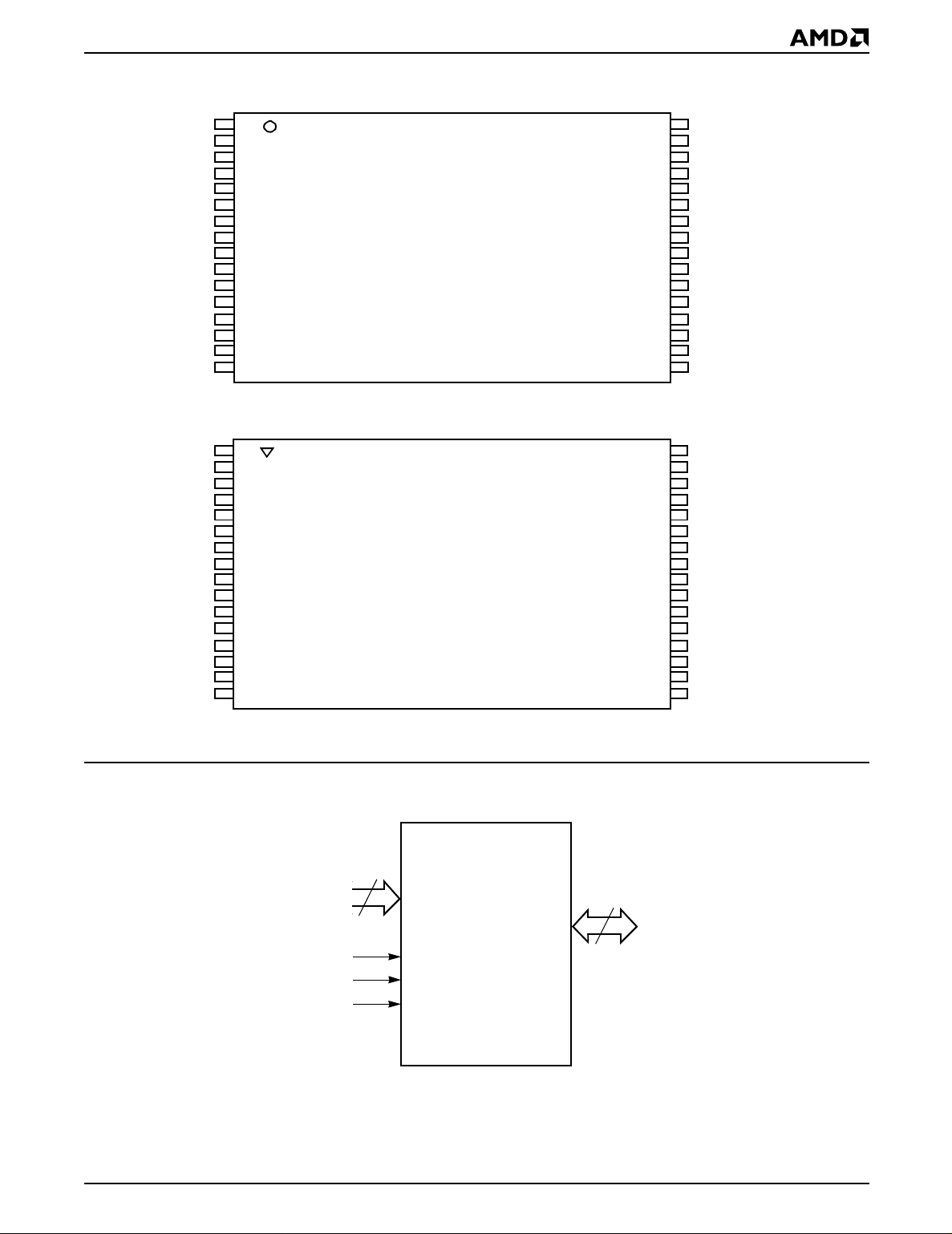

BLOCK DIAGRAM

DQ0–DQ7

V

CC

V

SS

V

PP

WE#

CE#

OE#

State

Control

Command

Re

ister

Program

Volta

Switch

Erase

Voltage

Switch

Input/Output

Buffers

To Array

e

Chip Enable

Output Enable

Logic

A0–A17

Low VCC

Detector

Embedded

Algorithms

Program/Erase

Pulse Timer

Address Latch

Y-Decoder

X-Decoder

Data Latch

Y-Gating

2,097,152

Bit

Cell Matrix

17502D-1

Am28F020A 3

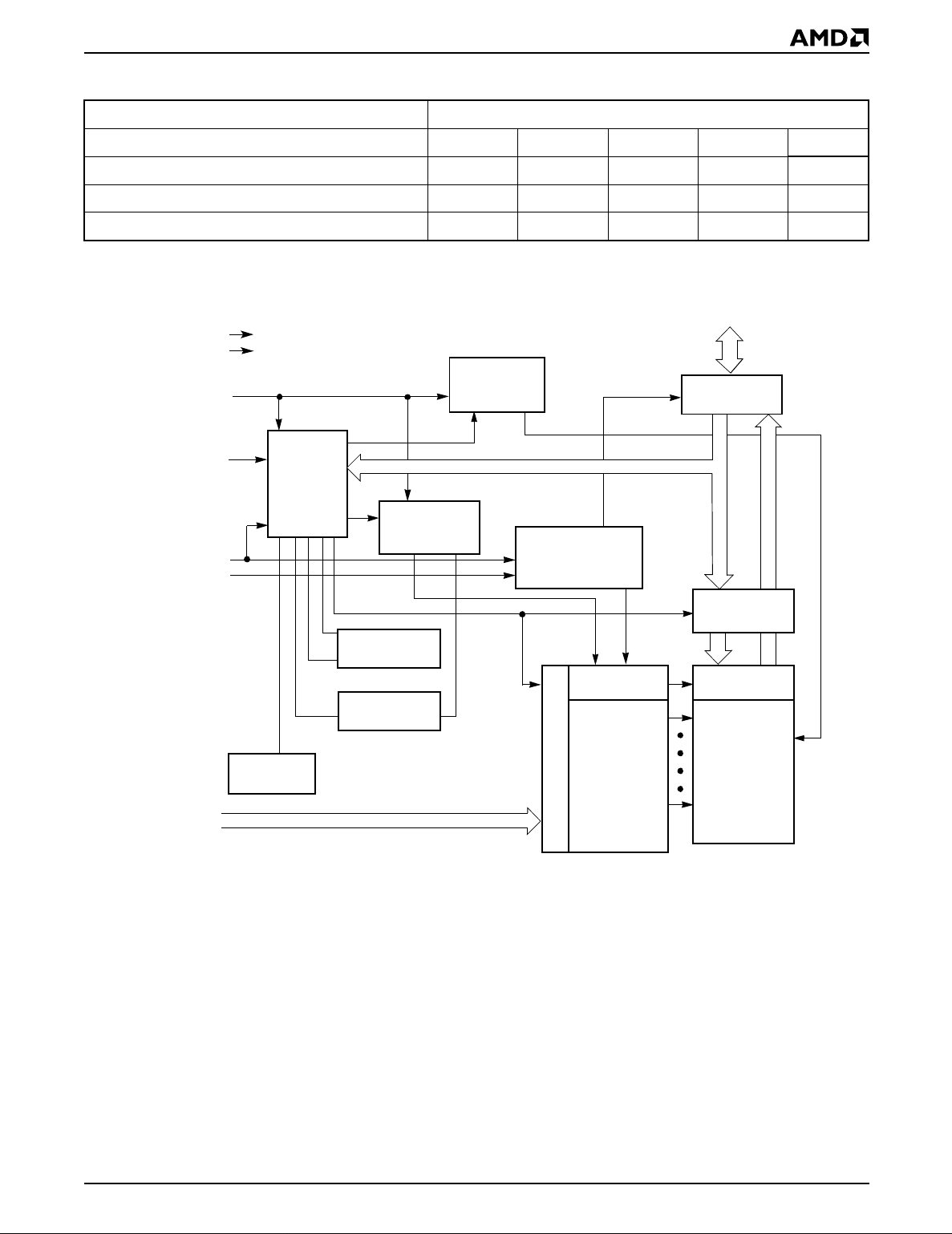

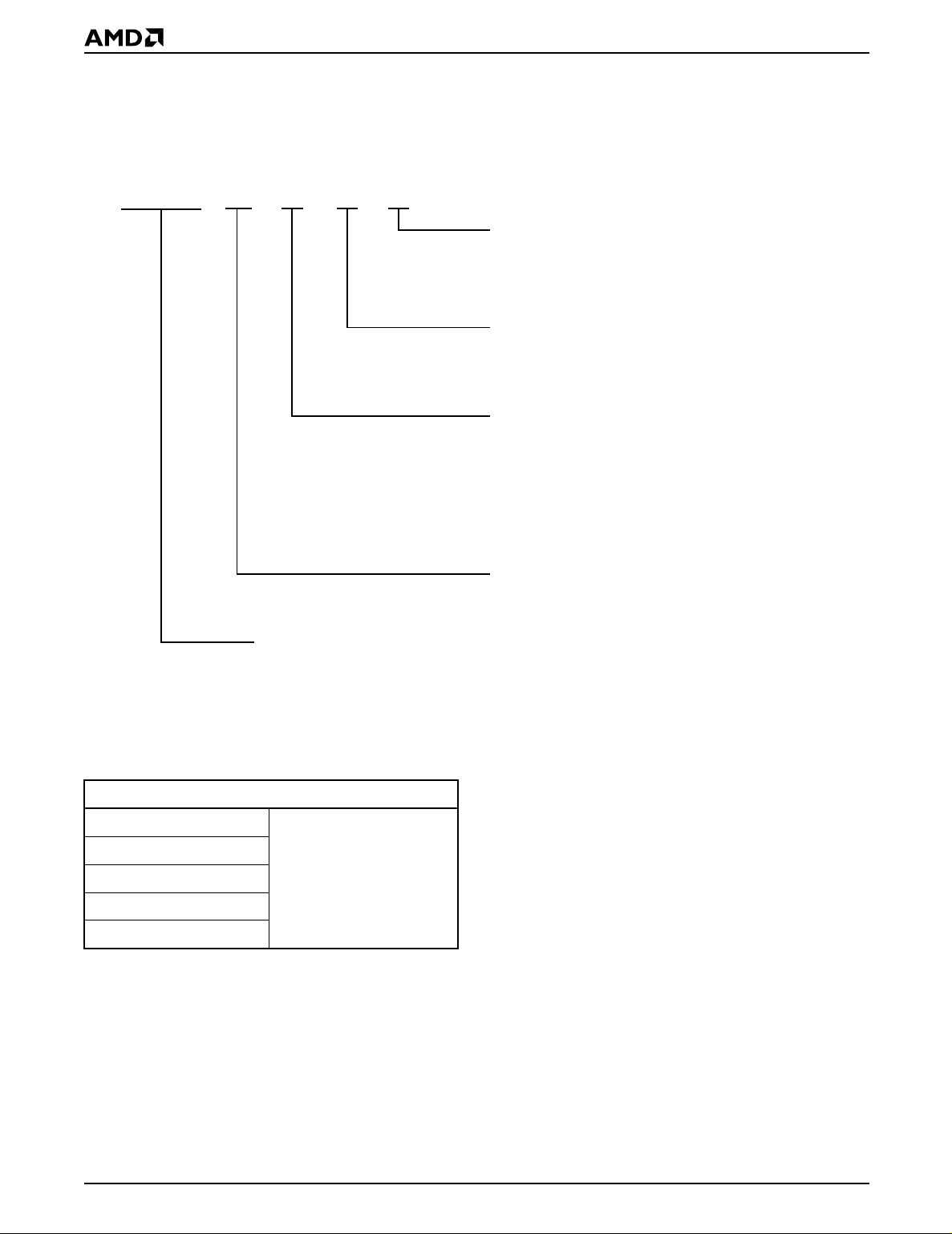

CONNECTION DIAGRAMS

V

PP

A16

A15

A12

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

DQ1

DQ2

V

SS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

PDIP

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

V

CC

WE# (W#)

A17

A14

A13

A8

A9

A11

OE# (G#)

A10

CE# (E#)

DQ7

DQ6

DQ5

DQ4

DQ3

17502D-2

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

5

6

7

8

9

10

11

12

13

14

A12

4

DQ1

3

15

DQ2

PLCC

A16

A15

2

17

VSS

1

DQ3

VPP

32

18

DQ4

WE# (W#)

VCC

31 30

19 2016

DQ5

A17

29

28

27

26

25

24

23

22

21

DQ6

A14

A13

A8

A9

A11

OE# (G#)

A10

CE# (E#)

DQ7

17502D-3

Note: Pin 1 is marked for orientation.

4 Am28F020A

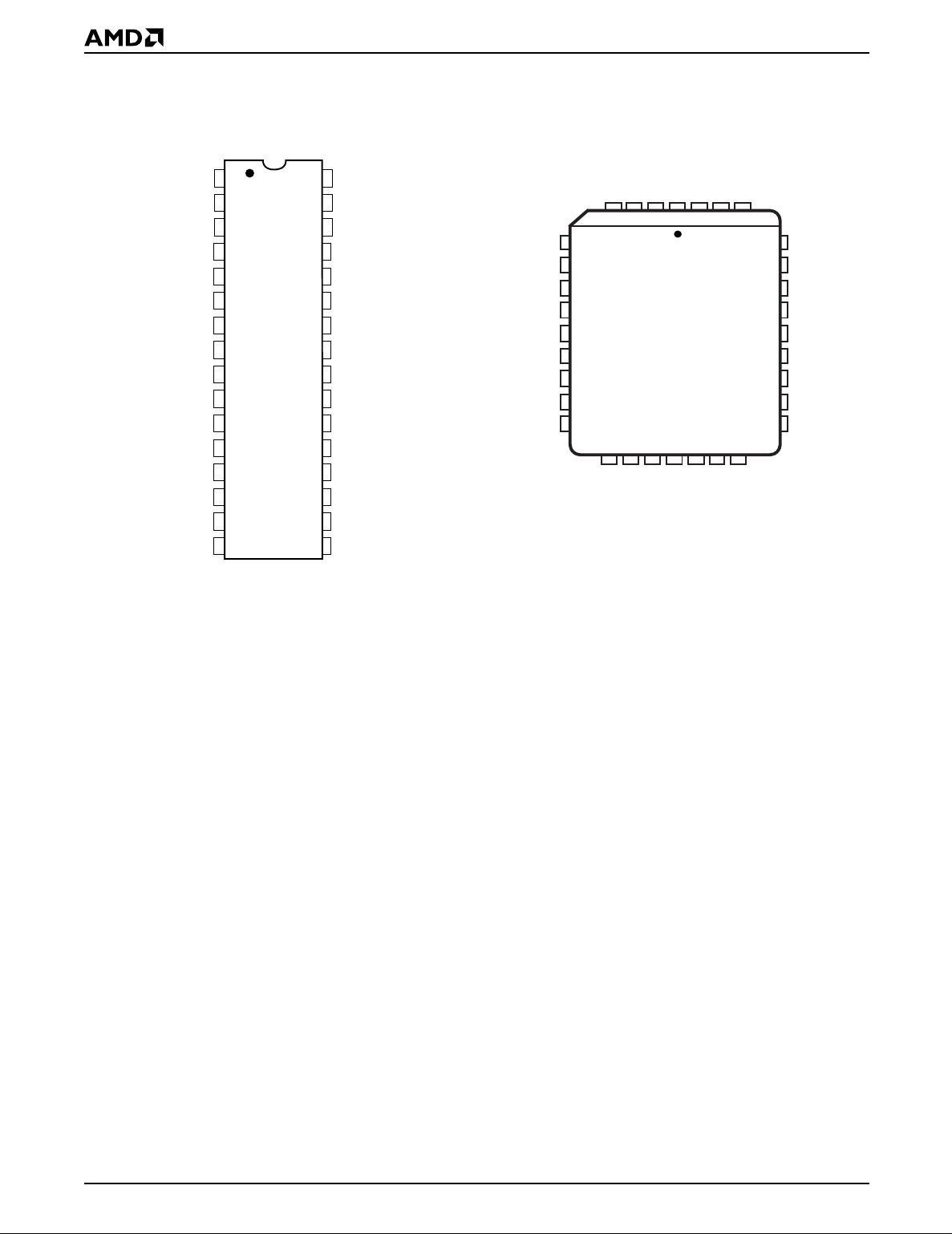

CONNECTION DIAGRAMS (Contin ued)

A11

A9

A8

A13

A14

A17

WE#

V

CC

V

PP

A16

A15

A12

A7

A6

A5

A4

OE#

A10

CE#

D7

D6

D5

D4

D3

V

SS

D2

D1

D0

A0

A1

A2

A3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32-Pin TSOP—Standard Pinout

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

OE#

A10

CE#

D7

D6

D5

D4

D3

V

SS

D2

D1

D0

A0

A1

A2

A3

A11

A9

A8

A13

A14

A17

WE#

V

CC

V

PP

A16

A15

A12

A7

A6

A5

A4

LOGIC SYMBOL

32-Pin TSOP—Reverse Pinout

18

A0–A17

DQ0–DQ7

CE# (E#)

OE# (G#)

WE# (W#)

17502D-4

8

17502D-5

Am28F020A 5

ORDERIN G IN FOR MATION

Standard Products

AMD standard pro ducts are avail able in several packages and operating rang es. The order ing number (Va lid Combinatio n) is

formed by a combination of the following:

AM28F020A -70 J C

DEVICE NUMBER/DESCRIPTION

Am28F020A

2 Megabit (256 K x 8-Bit) CMOS Flash Memory with Embedded Algorithms

B

OPTIONAL PROCESSING

Blank = Standard Processing

B = Burn-In

Contact an AMD representative for more information.

TEMPERATURE RANGE

C = Commercial (0°C to +70°C)

I = Industrial (–40°C to +85°C)

E = Extended (–55°C to +125°C)

PACKAGE TYPE

P = 32-Pin Plastic DIP (PD 032)

J = 32-Pin Rectangular Plastic Leaded Chip

Carrier (PL 032)

E = 32-Pin Thin Small Outline Package (TSOP)

Standard Pinout (TS 032)

F = 32-Pin Thin Small Outline Package (TSOP)

Reverse Pinout (TSR032)

SPEED OPTION

See Product Selector Guide and Valid Combinations

Valid Combinations

AM28F020A-70

AM28F020A-90

AM28F020A-120

AM28F020A-150

AM28F020A-200

PC, PI, PE,

JC, JI, JE,

EC, EI, EE,

FC, FI, FE

Valid Combinations list configurations planned to be supported in volume for this device. Consult the local AMD sales office to confirm availab ility of specific val id combination s and

to check on newly released combinations.

6 Am28F020A

Valid Combinations

PIN DESCRIPTION

A0–A17

Address In puts for memor y lo cations. Inte rnal la tches

hold addresses during write cycles.

CE# (E#)

Chip Enable active low input activates the chip’s control

logic and input buffers. Chip Enable high will deselect

the device and operates the chip in stand-by mode.

DQ0–DQ7

Data Inputs during memory write cycles. Internal

latches hold data during write cycles. Data Outputs

during memory read cycles.

NC

No Conn ect- corre spond ing pin i s no t conn ec ted in ternally to the die.

OE# (G#)

Output Enable active low input gates the outputs of

the device th rough the da ta buffers during me mor y

read cycles. Output Enable is high during command

sequencing and program/erase operations.

V

PP

Program voltage input. VPP must be at hi gh voltag e in

order to write to the command register. The command

register controls all functions required to alter the memory array contents. Memory contents cannot be altered

when VPP ≤ VCC +2 V.

V

CC

Po w er supp ly for de vi ce oper at ion . (5.0 V ± 5% or 10%)

V

SS

Ground.

WE# (W#)

Write Enable active low input controls the write function

of the command register to the memory array. The target address is latched on the falling edge of the Write

Enable pulse and the appropriate data is latched on the

rising edg e of t he pul se. Writ e E nabl e h igh i nhi bit s wri ting to the device.

Am28F020A 7

BASIC PRINCIPLES

The Am28FxxxA family uses 100% TTL-level control

inputs to manage the command regi ster. Erase and

reprogramming op erations use a fixed 12.0 V ± 5%

high voltage input.

Read Only Memory

Without high VPP voltage, the device functions as a

read only memory and operates like a standard

EPROM. Th e control inpu ts still ma nage traditi onal

read, standby, output disable, and Auto select modes.

Command Register

The command register is enabled only when high voltage is applied to the VPP pin. The erase and reprogramming operations are only accessed via the

register. In addition, two-cycle commands are required

for erase and reprogramming op erations. The traditional read, standby, output disable, and Auto select

modes are available via the register.

The device’ s command register is written using standard

microproce ssor wr ite timin gs. The register c ontrols an

interna l state machine that mana ges all device operations. For system design simplification, the device is designed to support either WE# or CE# control led writes.

During a system write cycle, addresses are latched on

the falling edge of WE# or CE# whichever occurs last.

Data is latched on the rising edge of WE# or CE# whichever occur first. To si mplify the following discussion, the

WE# pin is used as t he write cycle control pin throughout

the rest of this text. All setup and hold times are with respect to the WE# signal.

OVERVIEW OF ERASE/PROGRAM OPERATIONS

Embedded

AMD now makes erasure extremely simple and reliable. The Embedded Erase algorithm requires the user

to only write an erase setup command and erase command. The d evice will autom atically pre-pr ogram and

verify the entir e array. The device automatical ly times

the erase pulse width, provides the erase verify and

counts the number of sequences. A status bit, Data#

Polling, provides feedback to the user as to the status

of the erase operation.

Erase Algorithm

Embedded Programming Algorithm

AMD now makes programming extremely simple and

reliable. The Embedded P rogramming algorith m re-

quires the user to on ly writ e a pr ogr am s etu p comma nd

and a program comm and. The device automatically

times the programm ing puls e width, provi des the p rogram verify and counts the number of sequences. A

status bit, Data# Polling, provides feedback to the user

as to the status of the programming operation.

DATA PROTECTION

The device is designed to offer protection aga inst acci dental erasure or programming ca used by spurious

system level signals that may exist during power transitions . The d evice po wers up in it s r ea d onl y st at e . A ls o,

with its control register architecture, alteration of the

memory contents only occurs after successful completion of specific command sequences.

The device al so i ncor pora tes s everal feat ures t o pre vent inadvertent write cycles resulting from V

power-up and power-down transitions or system noise.

CC

Low VCC Write Inhibit

To avoid initiation of a write cycle during VCC power -up

and power-d own, the d evice locks out wr ite cycl es for

VCC < V

ages). When VCC < V

abled, all internal program/erase circuits are disabled,

and the device resets to the read mode. The device ignores all writes until V

that the control pins are in the correct logic state when

VCC > V

(see DC characteristics section for volt-

LKO

to prevent unintentional writes.

LKO

, the command register is dis-

LKO

> V

CC

. The user m ust ensure

LKO

Write Pulse “Glitch” Protection

Noise pulses of less than 10 ns (typical) on OE#, CE#

or WE# will not initiate a write cycle.

Logical Inhibit

Writing is inhibited by holding any one of OE# = VIL,

CE# = VIH or WE# = VIH. To initiate a wri te cycle CE#

and WE# must be a logical zero while OE# is a logical

one.

Power-Up Write Inhibit

Power-up of th e device with W E# = CE # = VIL and

OE# = VIH will not a ccept comman ds on the r ising

edge of WE#. The internal state ma chine is automatically reset to the read mode on power-up.

8 Am28F020A

FUNCTIONAL DESCRIPTION

Description Of User Modes

Table 1. Am28F0 20A Device Bus Operations (Notes 7 and 8)

Read-Only

Read/Write

CE

Operation

(E#)

Read V

Standby V

Output Disable V

Auto-select Manufacturer

Code (Note 2)

Auto-select Device

Code (Note 2)

Read V

Standby (Note 5) V

Output Disable V

Write V

V

V

OE

#

(G#)

IL

IH

IL

IL

IL

IL

IH

IL

IL

V

V

V

V

V

V

V

WE

#

(W#)

IL

XV

XXV

V

IH

IL

IL

IL

IH

V

IH

V

IH

V

IH

XXV

V

IH

IH

IH

V

IL

V

#

PP

(Note 1) A0 A9 I/O

PPL

PPL

V

PPL

V

PPL

V

PPL

V

PPH

PPH

V

PPH

V

PPH

A0 A9 D

X X HIGH Z

X X HIGH Z

V

V

IL

V

IH

ID

(Note 3)

V

ID

(Note 3)

A0 A9

X X HIGH Z

X X HIGH Z

A0 A9

Legend:

X = Don’t care, where Don’t Care is either V

of V

. 0 V < An < VCC + 2 V, (normal TTL or CMOS input levels, where n = 0 or 9).

PPH

or VIH levels. V

IL

= VPP < VCC + 2 V. See DC Characteristics for voltage levels

PPL

Notes:

1. V

may be grounded, connected with a resistor to ground, or < VCC + 2.0 V. V

PPL

the device. Refer to the DC characteristics. When VPP = V

, memory contents can be read but not written or erased.

PPL

is the programming voltage specified for

PPH

2. Manufacturer and device codes may also be accessed via a command register write sequence. Refer to Table 2.

3. 11.5 < V

4. Read operation with V

5. With V

6. Refer to Table 3 for valid D

7. All inputs are Don’t Care unless otherwise stated, where Don’t Care is either V

addresses except A

8. If V

< 13.0 V. Minimum VID rise time and fall time (between 0 and VID voltages) is 500 ns.

ID

= V

PP

at high voltage, the standby current is ICC + IPP (standby).

PP

and A0 must be held at VIL.

9

1.0 Volt, the voltage difference between VPP and VCC should not exceed 10.0 volts. Also, the Am28F256 has a VPP

≤

CC

may access array data or the Auto select codes.

PPH

during a write operation.

IN

or VIH levels. In the Auto select mode all

IL

rise time and fall time specification of 500 ns minimum.

OUT

CODE

(01h)

CODE

(29h)

D

OUT

(Note 4)

D

IN

(Note 6)

Am28F020A 9

READ-ONLY MODE

When VPP is less than V

is inactive. The device can either read array or autoselect data, or be standby mode.

+ 2 V, the comm and regis ter

CC

Read

The device f unc t ion s as a r ea d o nly m em ory wh en V

< V

+ 2 V . The de v ice ha s tw o con tro l fu ncti ons . Bo th

CC

must be satisfied in order to output data. CE# controls

power to the d evice. This pin sh ould be used for specific device selection. OE# controls the device outputs

and shou ld be used to gate data to the output pin s if a

device is selected.

Address access time t

is equal to the delay from

ACC

stable addresses to valid ou tput data. Th e ch i p en able

access time tCE is the delay from stable addresses and

stable CE# to valid data at the output pins. The output

enable access time is the delay from the falling edge of

OE# to valid dat a at the o utp ut pins (assumi n g th e ad dresses have been stable at least t

ACC

- tOE).

PP

Standby Mode

The device has two standby modes. The CMOS

standby mode (CE# input held at V

sumes less than 100 µA of curren t. TTL standby mode

(CE# is held at VIH) reduces the current requirements

to less than 1 m A . When in the stan dby mo de the outputs are in a high impedance state, independent of the

OE# input.

If the device is deselected during eras ure, programming, or p rogram/erase verificati on, the device will

draw active current until the operation is terminated.

± 0.5 V), con-

CC

Output Dis a ble

Output from the device is disabled when OE# is at a

logic high level. When disabled, output pins are in a

high impedance state.

Auto Select

Flash memories can be programmed in-system or in a

standard PROM programmer. The device may be soldered to the circuit board upon receipt of shipment and

programmed in-system. Alternatively, the device may

initially be programmed in a PROM programmer pr ior

to soldering the device to the board.

The Auto se l e ct m od e allows th e r e ad in g ou t of a bin a ry

code from the device that will identify its manufacturer and

type. This mode is intended for the purpose of automatically matching the device to be programmed with its corresponding pr ogramming algorithm . This mode is

functio nal ove r the entir e temperat ure range of the devi ce.

Programming In A PROM Programmer

To activate thi s mode, the programmin g equipm ent

must force VID (11.5 V to 13.0 V ) on addre ss A9 . Two

identi fie r b yte s ma y th en be seq uence d fr om th e de vi ce

outputs by toggling address A0 from VIL to VIH. All other

address lines must be held at VIL, and VPP must be

less than or equal to VCC + 2.0 V while using this Auto

select mode. Byte 0 (A0 = VIL) repr esen ts th e man uf acturer code and byte 1 (A0 = VIH) the device identifier

code. For the device the two bytes are given in the table

2 of the device data sheet. All identifiers for manufacturer and device codes will exhibit o dd parity with th e

MSB (DQ7) defined as the parity bit.

Table 2. (Am28F020A Auto Select Code

Type A0

Manufacturer Code V

Device Code V

10 Am28F020A

Code

(HEX)

IL

IH

01

29

ERASE, PROGRAM, AND READ MODE

When VPP is equal to 12.0 V ± 5%, the command register is active. All fu nctions ar e available. Tha t is, the

device can program, erase, read array or autoselect

data, or be standby mode.

Write Operations

High voltage must be applied to the VPP pin in orde r to

activate the command register. Data written to the register serves as input to the internal state machine. The

output of the state machine determines the operational

function of the device.

The command register does not occupy an addressable memory locat ion. The re giste r is a latch t hat stor es

the com mand , along with th e addr ess and data in formation needed to execute the command. The register

is written by bringing WE# and CE# to VIL, while OE#

is at VIH. Addresses are latched on the falling edge of

WE#, while data is latched on the rising edge of the

WE# pulse. Standard microprocessor write timings are

used.

The device requires the OE# pin to be VIH for write operations. This condition eliminates the possibility for

bus contention during programming operations. In

order to write, OE# must be VIH, and CE# and WE#

must be VIL. If any pin is not in the correct state a write

command will not be executed.

Refer to AC Write Characteristics and the Erase/Programming Waveforms for specific timing parameters.

Command Definitions

The contents of the command register default to 00h

(Read Mode) in the absence of high v oltage appl ied to

the VPP pin. The d evice op erates as a read only

memory. High voltage on the VPP pin enables the

command register. Device operations are selected by

writing specific dat a code s into t he command regi st er .

Table 3 in the de vice d ata sheet defi nes thes e regi ster

commands.

Read Command

Memor y conte nts can be acces sed via th e read com mand when VPP is high. To read from the device, write

00h into the command register. Standard microprocessor read cycles access data from the memory. The device will remain in the read mode until the command

register contents are altered.

The comma nd register defaults to 00h (r ead mode)

upon VPP power -up . The 00h (Rea d Mode ) regis ter default helps ensure that inadvertent alteration of the

memory contents does not occur during the VPP power

transition. Refer to the AC Read Characteristics and

Waveform s for the spec ifi c timi n g para m ete rs.

Table 3. Am28F020A Command Definitions

First Bus Cycle Second Bus Cycle

Operation

Command

Read Memory (Note 4) Write X 00h/FFh Read RA RD

Read Auto select Write X 80h or 90h Read 00h/01h 01h/29h

Embedded Erase Set-up/

Embedded Erase

Embedded Program Set-up/

Embedded Program

Reset (Note 4) Write X 00h/FFh Write X 00h/FFh

Notes:

1. Bus operations are defined in Table 1.

2. RA = Address of the memory location to be read.

PA = Address of the memory location to be programmed.

Addresses are latched on the falling edge of the WE

X = Don’t care.

3. RD = Data read from location RA during read operation.

PD = Data to be programmed at location PA. Data latched on the rising edge of WE

4. Please reference Reset Command section.

(Note 1)

Write X 30h Write X 30h

Write X 10h or 50h Write PA PD

Address

(Note 2)

pulse.

#

Data

(Note 3)

Operation

(Note 1)

.

#

Address

Note 2)

Data

(Note 3)

Am28F020A 11

FLASH MEMORY PROGRAM/ERASE OPERATIONS

Embedded Erase Algorithm

The auto matic chi p erase does no t requ ire the device

to be entirely pre-programmed prior to executing the

Embedded set-up erase command and Embedded

erase command. Upon executing the Embedded erase

command the device automatically will program and

verify the entire memory for an all zero data pattern.

The system is

timing during these operations.

not

required to provide any controls or

has been achieved for the memory array (no erase verify command is required). Th e margin voltages are internally generated in the same manner as when the

standard erase verif y command is used.

The Embedded Erase Set-Up command is a command

only ope ration that s tages the devic e for automatic

electrical erasure of all bytes in the array. Embedded

Erase Setup is performed by writing 30h to the command re gister.

When the device is automatically verified to contain an

all zero patte rn , a self -tim ed ch ip erase and verify begin. The erase and verify operation are complete when

the data on DQ7 is “1" (see Write Operation Status section) atw hich time the device returns to Read mode.

The system is not required to provide any control or

timing during these operations.

When using th e Embedded Erase algorithm, the erase

automatically terminates when adequate erase margin

Apply V

Write Embedded Erase Setup Command

Write Embedded Erase Command

Data# Poll from Device

To commence automatic chip erase, the command 30h

must be written again to the command register. The automatic erase begins on the rising edge of the WE and

terminates when the data on DQ7 is “1" (see Write Operation Status section) at which time the device returns

to Read mode.

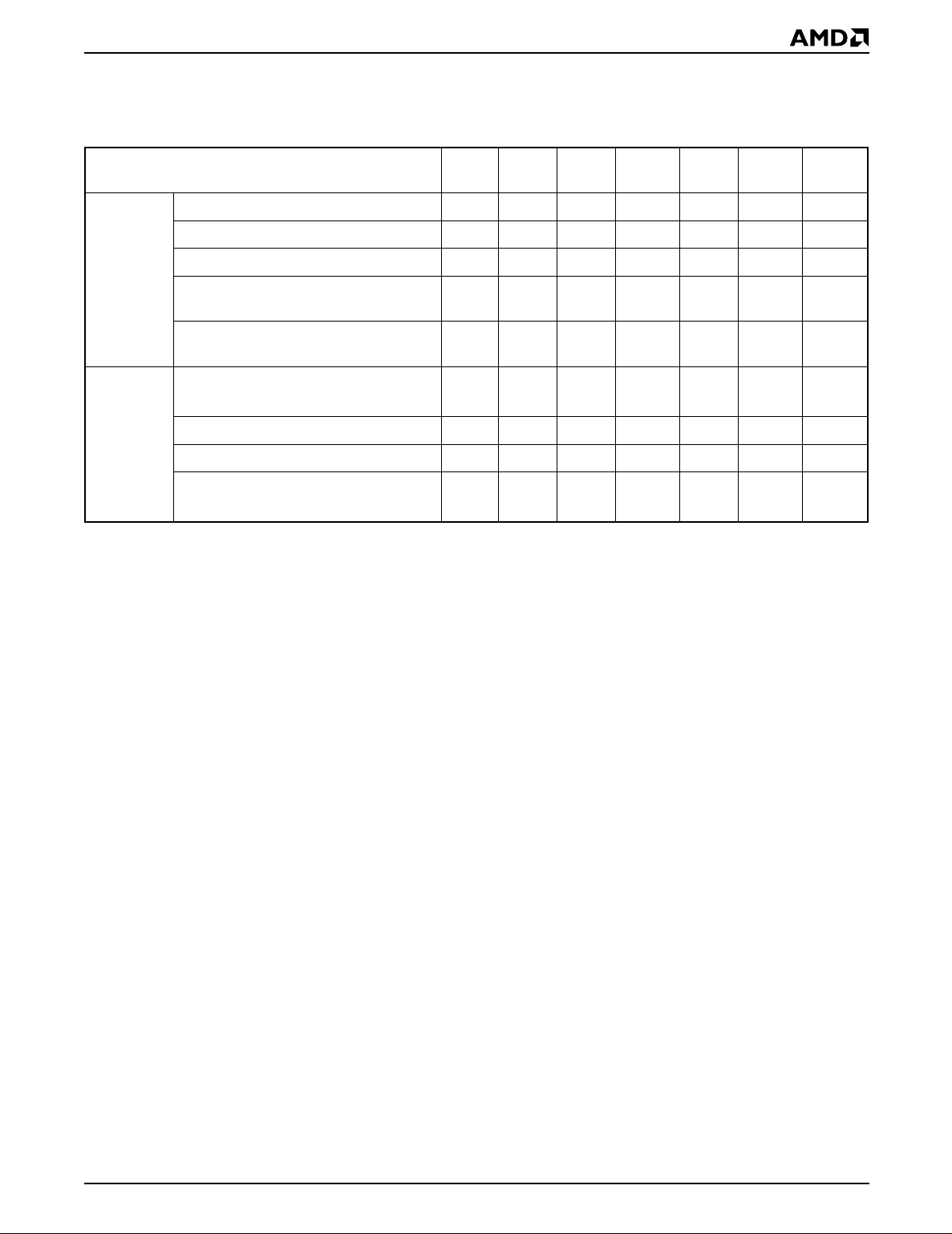

Figure 1 and Table 4 illustrate the Embedded Erase algorithm, a typical command string and bus operation.

START

PPH

Erasure Completed

Figure 1. Embedded Erase Algorithm

Table 4. Embedded Erase Algorithm

Bus Operations Command Comments

Standby Wait for V

Write

Read Data

Standby Compare Output to FFh

Read Available for Read Operations

See AC and DC Characteristics for values of V

Note:

switchable. When V

to Functional Description.

Embedded Erase Setup Command Data = 30h

Embedded Erase Command Data = 30h

parameters. The V

is switched, V

PP

may be ground, no connect with a resistor tied to ground, or less than VCC + 2.0 V. Refer

PPL

PP

Ramp to V

PP

Polling to Verify Erasure

#

power supply can be hard-wired to the device or

PP

(see Note)

PPH

12 Am28F020A

17502D-6

Embedded Programming Algorithm

The Embedded Program Setup is a command only operation that st ages the device for autom atic p rogram ming. Embedd ed Program Setup is performed by

writing 10h or 50h to the command register.

Once the Embedded Setup Program operation is performed, the next WE# pulse causes a transition to an

active pro gr amming oper ati on. Addres ses are l atch ed

on the falling edge of CE# or WE# pulse, whichever

happens later. Data is latched on the rising edge of

WE# or CE#, whiche ver hap pens fir st. The rising edge

Apply V

Write Embedded Setup Program Command

Write Embedded

of WE# also begins the programming operation. The

system is not required to provide further controls or

timings. The device will auto matically provide an adequate internally generated program pulse and verify

margin. Th e automatic programmi ng operation is

completed when the dat a on DQ7 is equiv alent to dat a

written to this bit (see Write Operat ion Stat us section)

at which time the device returns to Read mode.

Figure 2 and Table 5 illustrate the Embedded Program

algorithm, a typical command string, and bus operation.

START

PPH

Program Command (A/D)

Data# Poll Device

Increment Address

No

Last Address

Yes

Programming Completed

Figure 2. Embedded Programming Algorithm

Table 5. Embedded Programming Algorithm

Bus Operations Command Comments

Standby Wait for V

Write Embedded Program Setup Command Data = 10h or 50h

Write Embedded Program Command Valid Address/Data

Read Data

Read Available for Read Operations

Ramp to V

PP

Polling to Verify Completion

#

(see Note)

PPH

17502D-7

Note: See AC and DC Characteristics for values of V

switchable. When V

to Functional Description. Device is either powered-down, erase inhibit or program inhibit.

is switched, V

PP

may be ground, no connect with a resistor tied to ground, or less than VCC + 2.0 V. Refer

PPL

parameters. The V

PP

power supply can be hard-wired to the device or

PP

Am28F020A 13

Write Operation Status

Data Polling—DQ7

The device features Data# Polling as a method to indicate to the host system that the Embedded algorithms

are either in progress or completed.

While the Embedded Programming algorithm is in operation, an attempt to read the device at a valid address

will produce the complement of expected Valid data on

DQ7. Upon completion of the Embedded Program algorithm an attempt to read the devi ce at a v alid address will

produce V alid data on D Q7. The Data# P olling f eature i s

valid after the ri sing edge of the secon d WE# pulse of

the two write pulse sequence.

START

While the Embedded Erase algorithm is in operation,

DQ7 will read “0" until the erase operation is completed. Upon completion of the erase operation, the

data on DQ7 will read “1.” The Data# Polling feature is

valid after the rising edge of the second WE# pulse of

the two Write pulse sequence.

The Data# Polling feature is only active during Embedded Programming or erase algorithms.

See Figures 3 and 4 for the Data# Polling timing specifications and diagrams. Data# Polling is the standard

method to check the write operation status, however,

an alternative method is available using Toggle Bit.

No

Read Byte

(DQ0–DQ7)

Addr = VA

DQ7 = Data

?

No

DQ5 = 1

?

Yes

Read Byte

(DQ0–DQ7)

Addr = VA

DQ7 = Data

?

No

VA = Byte address for programming

= XXXXh during chip erase

Yes

Yes

Fail

Note:

DQ7 is rechecked even if DQ5 = “1” because DQ7 may change simultaneously with DQ5 or after DQ5.

Pass

Figure 3. Data# Polling Algorithm

14 Am28F020A

17502D-8

CE#

t

CH

t

t

OE

DF

OE#

t

OEH

WE#

DQ7

t

CE

t

WHWH 3 or 4

DQ7#

DQ0–DQ6 = InvalidDQ0–DQ6

*DQ7 = Valid Data (The device has completed the Embedded operation.)

Figure 4. AC Waveforms for Data# Polling during Embedded Algorithm Operations

*

DQ7 =

Valid Data

t

OH

DQ0–DQ7

Valid Data

High Z

17502D-9

Am28F020A 15

Toggle Bit—DQ6

The device a lso features a “Toggle Bit” as a method t o

indicate to the host system that the Embedded algorithms are either in progress or completed.

Successi ve atte mp ts t o rea d d ata fr om th e d evice at a

valid address, while the Embedded Program algori thm

is in progress, or at any address while the Embedded

Erase algorithm is in progress, will result in DQ 6 toggling between one and zero. Once the Embedded Program or Erase algor ithm is comple ted, DQ6 will sto p

START

toggling to indicate the completi on of either Embedded

operation. Only on the next read cycle will valid data be

obtained. The toggle bit is valid afte r the rising edge of

the fi rst WE # pul se of th e t wo write pu lse s equ ence , u nlike Data# Polling which is valid after the rising edge of

the secon d WE # pu l se. T his featu re a l lows th e us er to

determine if the device is partially through the two write

pulse sequence.

See Figures 5 and 6 for t he Toggle Bit timing specifications and diagrams.

Read Byte

(DQ0–DQ7)

Addr = VA

DQ6 = Toggle

No

Read Byte

(DQ0–DQ7)

Addr = VA

DQ6 = Toggle

VA = Byte address for programming

= XXXXh during chip erase

No

?

Yes

DQ5 = 1

?

Yes

No

?

Yes

Fail

Note:

DQ6 is rechecked even if DQ5 = “1” because DQ6 may stop toggling at the same time as DQ5 changing to “1”.

Pass

Figure 5. Toggle Bit Algorithm

16 Am28F020A

17502D-10

CE#

t

OEH

WE#

OE#

Data

DQ0–DQ7

Note:

*DQ6 stops toggling (The device has completed the Embedded operation.)

DQ6 = DQ6 =

Figure 6. AC Waveforms for Toggle Bit during Embedded Algorithm Operations

*

t

OE

DQ6

Stop Toggling

DQ0–DQ7

Valid

17502D-11

DQ5

Exceeded Timing Limits

DQ5 will indicate if the program or erase time has

exceeded the specified limits. This is a failure condition and the device may not be used again (internal

pulse count exceeded). Under these conditions DQ5

will produce a “1.” The prog ram or era se cycle was not

successfully completed. Data# Polling is the only operating funct ion of the de vi ce under this condition. The

CE# circuit will partially power down the device under

these conditions (to approximately 2 mA). T he OE#

and WE# pins will control the output di sable functions

as described in the Command Definitions table in the

corresponding device data sheet.

Parallel Device Erasure

The Embedded Erase algorithm greatly simplifies parallel device erasure. Since the erase process is internal

to the device, a single erase command can be giv en to

multiple devices concurrently . By implementing a parallel erase al gorithm, total erase time may be minimized.

Note that the Flash memories may erase at different

rates. If this is the case, when a d evice is complete ly

eras ed, use a masking code to prevent further e rasure

(over-erasure). The other devices will continue to erase

until verified. The masking code applied could be the

read command (00h).

Power-Up/Power -Down Seque n ce

The device powers-up in the Read only mode. Power

supply sequencing is not required. Note that if VCC ≤

1.0 Volt, the voltage differen ce betwee n VPP and V

CC

should not exceed 10.0 Volts. Also, the device has a

rise VPP rise time a nd fall time sp ecif icatio n of 500 ns

minimu m.

Reset Command

The Reset comm and initializes the Flash m emor y device to the Read mode. In addition, it also provides the

user with a safe method to abort any device operation

(including program or erase).

The Reset must be written two consecutive times after

the Setup Program command (10h or 50h). This will

reset the device to the Read mode.

Followin g any othe r Fl ash co mman d, w rit e the Rese t

command once to the device. This will safely abort any

previous operation and initialize the device to the Read

mode .

The Setup Program command (10h or 50h) is the only

command that requires a two-sequence reset cycle. The

first Reset command is interpreted as program data.

Howev er , FFh data is considered as n ull data during programming operations (memor y cells are only programmed from a logical “1" to “0") . The secon d Reset

command safely aborts the programming operation and

resets the device to the Read mode.

Memory contents are not altered in any case.

Am28F020A 17

This d etai led i nform ation i s for your refere nce. I t may

prove easier to alw ays issue the Re set comm and two

consecutive times. This eliminates the need to determine if you are in the Setup Program state or not.

In-Sys tem Programming Considerations

Flash mem ories can be pr ogram m ed in -system or in a

standard PROM programmer. The device may be soldered to the circuit board upon receipt of shipment and

programmed in-system. Alternatively, the device may

initiall y be pr ogramme d in a PROM program mer pr ior

to soldering the device to the circuit board.

Auto Select Command

AMD’s Flash memories are designed for use in applications where the local CPU alters memory contents.

In order to correctly program any Flash memories

in-system, manufacturer and device codes must be

accessible while the device resides in the target

system. PROM progr ammers t ypically access the si gnature codes by r aising A9 to a hig h voltag e. How ev er ,

multiplexing high voltage onto address lines is not a

generally desired system design practice.

The device contains an Auto Select operation t o supplement traditional PROM programming methodologies.

The operation is initiated by writing 80h or 90h into the

command register. Following this command, a re ad

cycle address 0000h retriev es the manufacturer code of

01h (AMD). A read cycle from address 00 01h returns

the device code (see the Auto Select Code table of the

corresponding device data sheet). To terminate the operation, it is necessary to write another valid command,

such as Reset (00h or FFh), into the register.

18 Am28F020A

ABSOLUTE MAXIMUM RATINGS

y

Storage T emperature . . . . . . . . . . . . –65°C to +125°C

Ambient Temperature

with Power Applied. . . . . . . . . . . . . . –55°C to +125°C

Voltage with Respect to Ground

All pins except A9 and VPP (Note 1) .–2.0 V to +7.0 V

VCC (Note 1). . . . . . . . . . . . . . . . . . . .–2.0 V to +7.0 V

A9, VPP (Note 2) . . . . . . . . . . . . . . .–2.0 V to +14.0 V

Output Short Circuit Current (Note 3) . . . . . . 200 mA

Notes:

1. Minimum DC voltage on input or I/O pins is –0.5 V . During

voltage transitions, input or I/O pins may overshoot V

–2.0 V for periods of up to 20 ns. Maximum DC voltage on

input or I/O pins is V

input or I/O pins may overshoot to VCC +2.0 V for periods

up to 20 ns.

2. Minimum DC input voltage on pins A9 and V

During voltage transitions, A9 and V

VSS to –2.0 V for periods of up to 20 ns. Maximum DC

input voltage on pin A9 and V

overshoot to 14.0 V for periods up to 20 ns.

3. No more than one output may be shorted to ground at a

time. Duration of the short circuit should not be greater

than one second.

4. Stresses abov e those list ed under “Absol ute Maxim um

Ratings” ma y cause permanent damage to the de vice. This

is a stress r atin g only ; fun ctio nal op era tion of th e de v ice a t

these or any other co nditi ons abov e th ose indi cate d in the

operational sections of this data sheet is not implied.

Exposure of the device to absolute maximum rating

conditions f or ext ended period s ma y aff ect d evi ce relia bility.

+0.5 V . During voltage transitions,

CC

PP

may overshoot

PP

is +13.0 V, which may

PP

to

SS

is –0.5 V.

OPERATING RANGES

Commercial (C) Devices

Ambient Temperature (TA). . . . . . . . . . . .0°C to +70°C

Industrial (I) Devices

Ambient Temperature (TA). . . . . . . . . .–40°C to +85°C

Extended (E) Devices

Ambient Temperature (TA). . . . . . . . .–55°C to +125°C

VCC Supply Voltages

VCC. . . . . . . . . . . . . . . . . . . . . . . . +4.50 V to +5.50 V

VPP Voltages

Read . . . . . . . . . . . . . . . . . . . . . . . . –0.5 V to +12.6 V

Program, Erase, and Verify. . . . . . +11.4 V to +12.6 V

Operating ranges define those limits between which the

functionalit

of the device is guaranteed.

Am28F020A 19

MAXI MUM OVERSHOOT

Maximum Negative Input Overshoot

+0.8 V

–0.5 V

–2.0 V

Maximum Positive Input Overshoot

V

+ 2.0 V

CC

V

+ 0.5 V

CC

2.0 V

20 ns

20 ns

20 ns

20 ns 20 ns

20 ns

17502D-12

Maximum VPP Overshoot

13.5 V

V

+ 0.5 V

CC

17502D-13

20 ns

14.0 V

20 ns 20 ns

17502D-14

20 Am28F020A

DC CHARACTERISTICS over operating range unless otherwise specified

TTL/NMOS Compatible

Parameter

Symbol Parameter Description Test Conditions Min Typ Max Unit

I

LI

I

LO

I

CCS

I

CC1

I

CC2

(Note 4)

I

CC3

(Note 4)

I

PPS

I

PP1

I

PP2

(Note 4)

I

PP3

(Note 4)

V

IL

V

IH

V

OL

Input Leakage Current VCC = VCC Max,

V

= VCC or V

IN

SS

Output Leakage Current VCC = VCC Max,

V

= VCC or V

OUT

SS

VCC Standby Current VCC = VCC Max

CE# = V

V

Active Read Current VCC = VCC Max, CE# = VIL, OE# = V

CC

I

Programming Current CE# = V

V

CC

IH

= 0 mA, at 6 MHz

OUT

IL

0.2 1.0 mA

IH

20 30 mA

20 30 mA

±1.0 µA

±1.0 µA

Programming in Progress

Erase Current CE# = V

V

CC

IL

20 30 mA

Erasure in Progress

VPP Standby Current VPP = V

VPP Read Current VPP = V

= V

V

PP

VPP Programming Current VPP = V

PPL

PPH

PPL

PPH

70 200

10 30 mA

±1.0 µA

µA

±1.0

Programming in Progress

VPP Erase Current VPP = V

PPH

10 30 mA

Erasure in Progress

Input Low Voltage –0.5 0.8 V

Input High Voltage 2.0 VCC + 0.5 V

Output Low Voltage IOL = 5.8 mA

0.45 V

VCC = VCC Min

V

OH1

Output High Voltage IOH = –2.5 mA

2.4 V

VCC = VCC Min

V

I

A9 Auto Select Voltage A9 = V

ID

A9 Auto Select Current A9 = VID Max

ID

ID

11.5 13.0 V

550µA

VCC = VCC Max

V

PPL

VPP during Read-Only

Operations

V

PPH

VPP during Read/Write

Note

: Erase/Program are inhibited when

V

= V

PP

PPL

0.0 VCC +2.0 V

11.4 12.6 V

Operations

V

LKO

Low VCC Lock-out Voltage 3.2 3.7 V

Notes:

1. Caution: the Am28F020A must not be removed from (or inserted into) a socket when V

or VPP is applied. If VCC ≤ 1.0

CC

Volt, the voltage difference between VPP and VCC should not exceed 10.0 Volts. Also, the Am28F020A has a VPP rise time

and fall time specification of 500 ns minimum.

2. I

3. Maximum active power usage is the sum of I

is tested with OE# = VIH to simulate open outputs.

CC1

CC

and I

PP

.

4. Not 100% tested.

Am28F020A 21

DC CHARACTERISTICS

CMOS Compatible

Parameter

Symbol Parameter Description Test Conditions Min Typ Max Unit

I

LI

I

LO

I

CCS

I

CC1

I

CC2

(Note 4)

I

CC3

(Note 4)

I

PPS

I

PP1

I

PP2

(Note 4)

I

PP3

(Note 4)

V

IL

V

IH

V

OL

V

OH1

V

OH2

Input Leakage Current VCC = VCC Max,

V

= VCC or V

IN

SS

Output Leakage Current VCC = VCC Max,

V

= VCC or V

OUT

VCC Standby Current VCC = VCC Max

SS

15 100 mA

±1.0 µA

±1.0 µA

CE# = VCC + 0.5 V

V

Active Read Current VCC = VCC Max, CE# = VIL, OE# = V

CC

Programming Current CE# = V

V

CC

I

= 0 mA, at 6 MHz

OUT

IL

IH

20 30 mA

20 30 mA

Programming in Progress

Erase Current CE# = V

V

CC

IL

20 30 mA

Erasure in Progress

VPP Standby Current VPP = V

VPP Read Current VPP = V

Programming Current VPP = V

V

PP

PPL

PPH

PPH

70 200 µA

10 30 mA

±1.0 µA

Programming in Progress

Erase Current VPP = V

V

PP

PPH

10 30 mA

Erasure in Progress

Input Low Voltage –0.5 0.8 V

Input High Voltage 0.7

V

CC

Output Low Voltage IOL = 5.8 mA

V

= VCC Min

CC

VCC + 0.5 V

0.45 V

Output High Voltage IOH = –2.5 mA, VCC = VCC Min 0.85

V

CC

IOH = –100 µA, VCC = VCC Min VCC

–0.4

V

V

I

A9 Auto Select Voltage A9 = V

ID

A9 Auto Select Current A9 = VID Max

ID

ID

11.5 13.0 V

550µA

VCC = VCC Max

V

PPL

VPP during Read-Only

Operations

V

PPH

VPP during Read/Write

Note

: Erase/Program are inhibited when

VPP = V

PPL

0.0 VCC +2.0 V

11.4 12.6 V

Operations

V

LKO

Low VCC Lock-out Voltage 3.2 3.7 V

Notes:

1. Caution: the Am28F020A must not be removed from (or inserted into) a socket when V

or VPP is applied. If VCC ≤ 1.0

CC

Volt, the voltage difference between VPP and VCC should not exceed 10.0 Volts. Also, the Am28F020A has a VPP rise time

and fall time specification of 500 ns minimum.

2. I

3. Maximum active power usage is the sum of I

is tested with OE# = VIH to simulate open outputs.

CC1

CC

and I

PP

.

4. Not 100% tested.

22 Am28F020A

I

CC

in mA

Active

30

25

20

15

10

°

C

-55

°

C

0

°

C

25

°

C

70

°

C

125

5

0

01 23456789101112

Figure 7. Am28 F0 20 A - Average ICC Active vs. Frequency

TEST CONDITIONS

Device

Under

Test

C

L

Note: Diodes are IN3064 or equivalent

6.2 k

Frequency in MHz

VCC = 5.5 V, Addr essing Pattern = Minmax

Data Pattern = Checkerboard

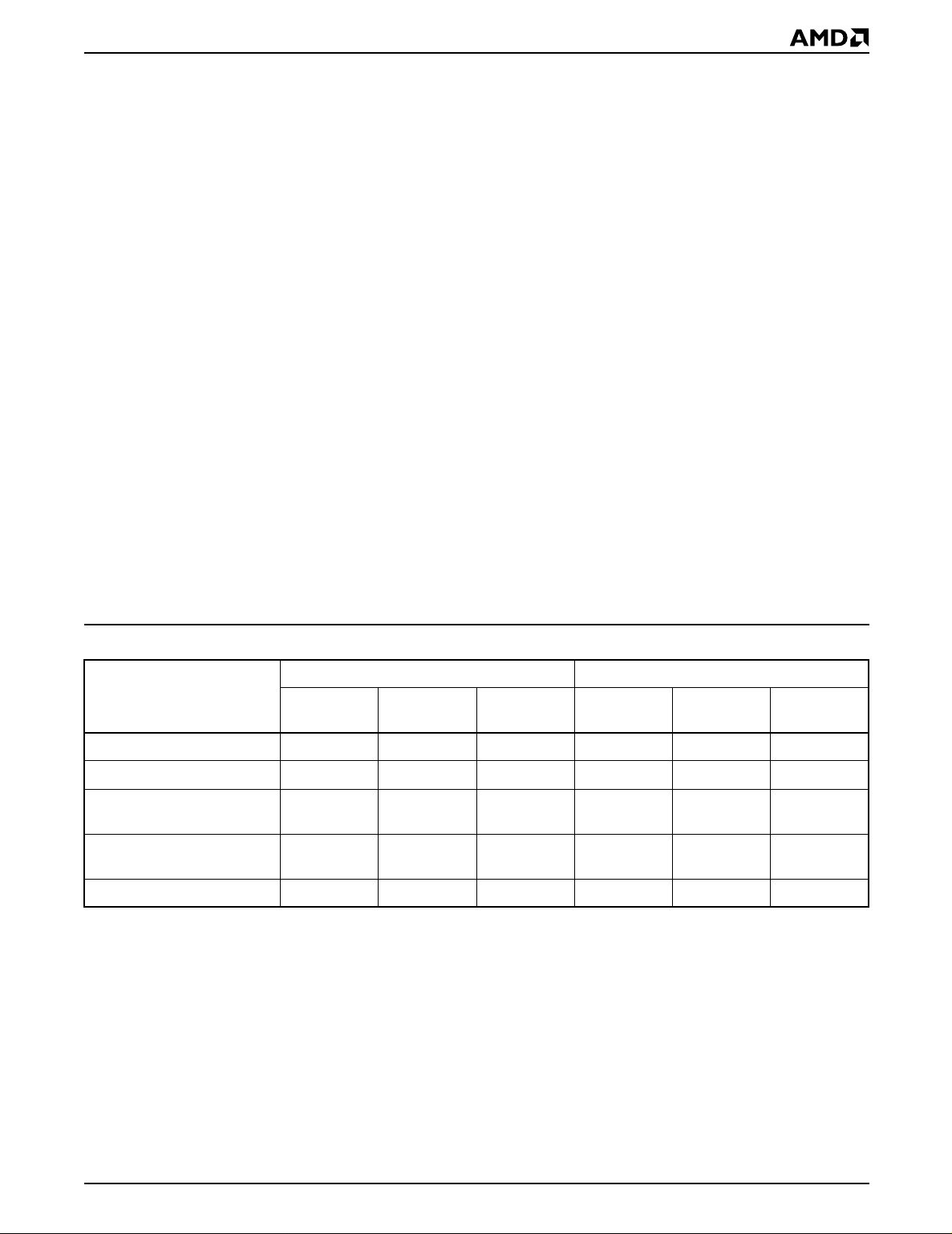

Table 6. Test Specifications

5.0 V

2.7 k

Ω

Ω

17502D-16

Test Condition -70 All others Un it

Output Load 1 TTL gate

Output Load Capacitance, C

(including jig capacitance)

Input Rise and Fall Times

Input Pulse Levels 0.0–3.0 0.45–2.4 V

Input timing measurement

reference levels

Output timing measurement

reference levels

L

30 100 pF

10 ns

≤

1.5 0.8, 2.0 V

1.5 0.8, 2.0 V

17502D-15

Figure 8. Test Setup

Am28F020A 23

SWITCHING TEST WAVEFORMS

s

2.4 V

0.45 V

2.0 V

Test Points

Input Output

2.0 V

0.8 V0.8 V

AC Testing (all speed options except -70): Inputs are driven at

2.4 V for a logic “1” and 0.45 V for a logic “0”. Input pulse rise

and fall times are

10 ns.

≤

3 V

1.5 V

0 V

Input Output

Test Points

1.5 V

AC Testing for -70 devices: Inputs are driven at 3.0 V for a

logic “1” and 0 V for a logic “0”. Input pulse rise and fall time

are ≤10 ns.

17502D-17

SWITCHING CHARACTERISTICS over operating range, unless otherwise specified

AC Character istics—Read-Only Operations

Parameter

Symbols Am28F020A Speed Options

JEDEC Standard Parameter Description -70 -90 -120 -150 -200 Unit

t

AVAV

t

ELQV

t

AVQV

t

GLQVtOE

t

ELQX

t

RC

t

CE

t

ACC

t

LZ

Read Cycle Time (Note 3) Min 70 90 120 150 200 ns

Chip Enable Access Time Max 70 90 120 150 200 ns

Address Access Time Max 70 90 120 150 200 ns

Output Enable Access Time Max 35 35 50 55 55 ns

Chip Enable to Output in Low Z

(2)

Min00000ns

t

EHQZtDF

t

GLQXtOLZ

t

GHQZtDF

t

AXQXtOH

t

VCS

Chip Disable to Output in High Z

(1)

Output Enable to Output in Low Z (2) Min 00000ns

Output Disable to Output in High Z (2) Max 20 20 30 35 35 ns

Output Hold Time From First Address, CE#,

or OE# change (2)

VCC Set-up Time to Valid Read (2) Min 50 50 50 50 50 ns

Notes:

1. Guaranteed by design; not tested.

2. Not 100% tested

24 Am28F020A

Max2020303535ns

Min00000ns

AC Character istics—Write (Erase/Program) Operations

Parameter Symbols Am28F020A Speed Options

JEDEC Standard Description -70 -90 -120 -150 -200 Unit

t

AVAV

t

AVWLtAS

t

WLAXtAH

t

DVWHtDS

t

WHDXtDH

t

OEH

t

GHWL

t

ELWLEtCSE

t

WHEHtCH

t

WLWHtWP

t

WHWLtWPH

t

WHWH3

t

WHWH4

t

VPEL

t

VCS

t

VPPR

t

VPPF

t

LKO

t

WC

Write Cycle Time (4) Min 70 90 120 150 200 ns

Address Setup Time Min 0 0 0 0 0 ns

Address Hold Time Min 45 45 50 60 75 ns

Data Setup Time Min 45 45 50 50 50 ns

Data Hold Time Min 10 10 10 10 10 ns

Output Enable Hold Time for Embedded

Algorithm only

Min 10 10 10 10 10 ns

Read Recovery Time Before Write Min 0 0 0 0 0 ns

CE# Embedded Algorithm Setup Time Min 20 20 20 20 20 ns

CE# Hold Time Min 0 0 0 0 0 ns

Write Pulse Width Min 45 45 50 60 60 ns

Write Pulse Width High Min 20 20 20 20 20 ns

Embedded Program Operation (2) Min 14 14 14 14 14 µs

Embedded Erase Operation (3) Typ 5 5 5 5 5 sec

VPP Setup Time to Chip Enable Low (4) Min 100 100 100 100 100 ns

VCC Setup Time (4) Min 50 50 50 50 50 µs

VPP Rise Time (4) 90% V

VPP Fall Time (4) 90% V

VCC < V

to Reset (4) Min 100 100 100 100 100 ns

LKO

PPH

PPL

Min 500 500 500 500 500 ns

Min 500 500 500 500 500 ns

Notes:

1. Read timing characteristics during read/write operations are the same as during read-only operations. Refer to AC

Characteristics for Read Only operations.

2. Embedded Program Operation of 14 µs consists of 10 µs program pulse and 4 µs write recovery before read. This is the

minimum time for one pass through the programming algorithm.

3. Embedded Erase operation of 5 sec consists of 4 sec array pre-programming time and one sec array erase time. This is a

typical time for one embedded erase operation.

4. Not 100% tested.

Am28F020A 25

KEY TO SWITCHING WAVEFORMS

WAVEFORM INPUTS OUTPUTS

Don’t Care, Any Change Permitted Changing, State Unknown

Does Not Apply Center Line is High Impedance State (High Z)

SWITCHING WAVEFORMS

Steady

Changing from H to L

Changing from L to H

Addresses

CE# (E#)

OE# (G#)

WE# (W#)

Data (DQ)

5.0 V

V

CC

0 V

Power-up, Standby

t

VCS

High Z High Z

Device and

Address Selection

Addresses Stable

t

WHGL

t

GLQV

t

(tCE)

ELQV

t

(tLZ)

ELQX

t

VCS

t

(t

AVQV

ACC

)

Outputs

Enabled

t

AVAV

(tOE)

t

GLQX

(tRC)

(t

OLZ

Data

Valid

)

Output Valid

t

AXQX (tOH

Standby, Power-down

t

EHQZ

(t

)

DF

t

GHQZ

(t

)

DF

)

Figure 9. AC W avefo rms for Read Operations

26 Am28F020A

17502D-18

SWITCHING WAVEFORMS

Addresses

CE#

OE#

WE#

Data

V

CC

t

GHWL

t

t

VCS

CSE

Embedded

Erase Setup

t

WC

t

WP

t

DS

30h

Embedded

Erase Erase Standby

t

AS

t

AH

t

WHWH3 OR 4

t

WPH

t

DH

30h

Data# Polling

DQ7#

DQ7#

Read

t

RC

t

t

DF

OH

t

OE

t

CE

V

PP

t

VPEL

Note:

#

is the complement of the data written to the device.

DQ7

Figure 10. AC Waveforms for Embedded Erase Operatio n

17502D-19

Am28F020A 27

SWITCHING WAVEFORMS

Addresses

CE#

OE#

WE#

Data

V

CC

Embedded

Program Setup

t

t

VCS

t

CSE

WC

t

WP

t

t

DH

DS

t

GHWL

50h

Embedded

t

WPH

Program

PA

t

AS

t

AH

D

IN

t

WHWH3 OR 4

Data# Polling

PA

DQ7#

DQ7# D

OUT

Read

t

RC

t

t

DF

OH

t

OE

t

CE

V

PP

Notes:

is data input to the device.

1. D

IN

2. DQ7

3. D

#

is the complement of the data written to the device.

is the data written to the device.

OUT

t

VPEL

Figure 11. AC Waveforms for Embedded Programming Operation

17502D-20

28 Am28F020A

AC CHARACTERISTICS—WRITE (ERASE/PROGRAM) OPERATIONS

Alternate CE# Controlled Writes

Parameter Symbols Am28F020A Speed Options

JEDEC Standard Description -70 -90 -120 -150 -200 Unit

t

AVAV

t

AVEL

t

ELAXtAH

t

DVEHtDS

t

EHDXtDH

t

OEH

t

GHEL

t

WLELtWS

t

EHWKtWH

t

ELEHtCP

t

EHELtCPH

t

EHEH3

t

EHEH4

t

VPEL

t

VCS

t

VPPR

t

VPPF

t

LKO

t

t

WC

AS

Write Cycle Time (4) Min 70 90 120 150 200 ns

Address Setup Time Min 0 0 0 0 0 ns

Address Hold Time Min 45 45 50 60 75 ns

Data Setup Time Min 45 45 50 50 50 ns

Data Hold Time Min 10 10 10 10 10 ns

Output Enable Hold Time for Embedded

Algorithm only

Min 10 10 10 10 10 ns

Read Recovery Time Before Write Min 0 0 0 0 0 ns

WE# Setup Time by CE# Min 0 0 0 0 0 ns

WE# Hold Time Min 0 0 0 0 0 ns

Write Pulse Width Min 65 65 70 80 80 ns

Write Pulse Width High Min 20 20 20 20 20 ns

Embedded Program Operation (2) Min 14 14 14 14 14 µs

Embedded Erase Operation (3) Typ 5 5 5 5 5 sec

VPP Setup Time to Chip Enable Low (4) Min 100 100 100 100 100 ns

VCC Setup Time (4) Min 50 50 50 50 50 µs

VPP Rise Time (4) 90% V

VPP Fall Time (4) 90% V

VCC < V

to Reset (4) Min 100 100 100 100 100 ns

LKO

PPH

PPL

Min 500 500 500 500 500 ns

Min 500 500 500 500 500 ns

Notes:

1. Read timing characteristics during read/write operations are the same as during read-only operations. Refer to AC

Characteristics for Read Only operations.

2. Embedded Program Operation of 14 µs consists of 10 µs program pulse and 4 µs write recovery before read. This is the

minimum time for one pass through the programming algorithm.

3. Embedded erase operation of 5 sec consists of 4 sec array pre-programming time and one sec array erase time. This is a

typical time for one embedded erase operation.

4. Not 100% tested.

Am28F020A 29

SWITCHING WAVEFORMS

Addresses

WE#

OE#

CE#

Data

V

CC

t

WS

t

GHEL

Embedded

Program Setup

t

WC

t

CP

50h

t

DS

Embedded

Program

t

CPH

Data# Polling

DQ7#

PA

DQ7#

D

OUT

PA

t

AS

t

AH

t

EHEH3 OR 4

t

DH

D

IN

V

PP

t

VPEL

Notes:

is data input to the device.

1. D

IN

#

2. DQ7

3. D

is the complement of the data written to the device.

is the data written to the device.

OUT

Figure 12. AC Waveforms for Embedded Programming Operatio n Using CE# Controlled Writes

17502D-21

30 Am28F020A

ERASE AND PROGRAMMING PERF ORMANCE

Limits

Typ

Parameter

Chip Erase Time 1 10 sec Excludes 00h programming prior to erasure

Chip Programming Time 4 25 sec Excludes system-level overhead

Write/Erase Cycles 100,000 Cycles

Byte Programming Time 14 µs

(Note 1)

Max

(Note 2) Unit

96

(Note 3)

ms

CommentsMin

Notes:

C, 12 V VPP .

1. 25

°

2. Maximum time specified is lower than worst case. Worst case is derived from the Embedded Algorithm internal counter which

allows for a maximum 6000 pulses for both program and erase operations. Typical worst case for program and erase is

significantly less than the actual device limit.

3. Typical worst case = 84 µs. DQ5 = “1” only after a byte takes longer than 96 ms to program.

LATCHUP CHARACTERISTICS

Parameter Min Max

Input Voltage with respect to V

Input Voltage with respect to V

Current –100 mA +100 mA

on all pins except I/O pins (Including A9 and VPP) –1.0 V 13.5 V

SS

on all pins I/O pins –1.0 V VCC + 1.0 V

SS

Includes all pins except V

. Test conditions: VCC = 5.0 V, one pin at a time.

CC

PIN CAPACITANCE

Parameter

Symbol Parameter Description Test Conditions Typ Max Unit

C

IN

C

OUT

C

IN2

Note: Sampled, not 100% tested. Test conditions T

Input Capacitance VIN = 0 8 10 pF

Output Capacitance V

VPP Input Capacitance VPP = 0 8 12 pF

= 25°C, f = 1.0 MHz.

A

= 0 8 12 pF

OUT

DATA RETENTION

Parameter Test Conditions Min Unit

Minimum Pattern Data Retention Time

150°C10Years

125°C20Years

Am28F020A 31

PHYSICAL DIMENSIONS

PD032—32-Pin Plastic DIP (measured in inches)

1.640

1.670

.120

.160

32

.140

.225

Pin 1 I.D.

.045

.065

.005 MIN

.090

.110

.016

.022

17

.530

.580

16

0°

10°

SEATING PLANE

.015

.060

PL032—32-Pin Plastic Leaded Chip Carrier (measured in inches)

.485

.495

.009

.015

.125

.140

.080

.095

SEATING

PLANE

.013

.021

.050 REF.

SIDE VIEW

.585

.595

.447

.453

Pin 1 I.D.

.547

.553

.026

.032

TOP VIEW

.600

.625

.009

.015

.630

.700

16-038-S_AG

PD 032

EC75

5-28-97 lv

.042

.056

.400

REF.

.490

.530

16-038FPO-5

PL 032

DA79

6-28-94 ae

32 Am28F020A

PHYSICAL DIMENSIONS

TS032—32-Pin Standard Thin Small Outline Package (measured in millimeters)

0.95

1.05

Pin 1 I.D.

1

7.90

8.10

0.50 BSC

1.20

MAX

18.30

18.50

19.80

20.20

0.05

0.15

0.08

0.20

0.10

0°

5°

0.50

0.70

0.21

16-038-TSOP-2

TS 032

DA95

3-25-97 lv

Am28F020A 33

PHYSICAL DIMENSIONS

TSR032—32-Pin Reversed Thin Small Outline Package (measured in millimeters)

0.95

1.05

Pin 1 I.D.

1

7.90

8.10

0.50 BSC

1.20

MAX

18.30

18.50

19.80

20.20

0.05

0.15

0.08

0.20

0.10

0°

5°

0.50

0.70

0.21

16-038-TSOP-2

TSR032

DA95

3-25-97 lv

34 Am28F020A

DATA SHEET REVISION SUMMARY FOR AM28F020A

Revision C+1

Distinctive Characteristics:

High Performan ce:

is now 70 ns.

General Description:

Paragraph 2: Changed fastest speed option to 70 ns.

Product Selector Guide:

Added -70, deleted -95 and -250 speed options.

Ordering Information, Standard Products:

The -70 speed option is now listed in the example.

Valid Combinations:

combinations.

Erase, Program, and Read Mode:

Corrected the subheading to read “VPP = 12.0 V ± 5%”.

Operating Ranges:

VCC Suppl y Voltages:

speed options.

The fastest spee d option available

Added -7 0, de leted -95 and -25 0

Added -70, deleted -95 and -250

AC Characte ris ti cs :

Read Only Operations Characteri stics:

column and test conditi ons.

Deleted -95 and -250 speed options.

AC Characte ris ti cs :

Added the -7 0

Writ e/Erase /Program O perati ons, Alter nate CE# Controlled Writes:

-250 speed options.

Switching Test Waveforms:

In the 3.0 V waveform caption, changed -95 to -70.

Added th e -70 column. D elet ed -95 and

Revision D

Matched formatting to other current data sheets.

Revision D+1

Programming In A PROM Progra mmer:

Deleted the paragraph “(Refer to the AUTO SELECT

paragraph in the ER ASE, PROGRAM, and READ

MODE section for programming the Flash memory device in-system).”

Trademarks

Copyright © 1998 Advanced Micro Devices, Inc. All rights reserved.

ExpressFlash is a trademark of Advanced Micro Devices, Inc.

AMD, the AMD logo, and combinations thereof are registered trademarks of Advanced Micro Devices, Inc.

Product names used in this publication are for identification purposes only and may be trademarks of their respective companies.

Am28F020A 35

Loading...

Loading...