AMD Advanced Micro Devices AM28F020-90EI, AM28F020-90EEB, AM28F020-90EE, AM28F020-90ECB, AM28F020-70PIB Datasheet

...

FINAL

Am28F020

2 Megabit (256 K x 8-Bit)

CMOS 12.0 Volt, Bulk Erase Flash Memory

DISTINCTIVE CHARACTERISTICS

■

High performance

— Access times as fast as 70 ns

■

CMOS low power consumption

— 30 mA max imum active current

— 100 µA maximum standby current

— No data retention power consumption

■

Compatible with JEDEC-standard byte-wide

32-pin EPROM pinouts

— 32-pin PDIP

— 32-pin PLCC

— 32-pin TSOP

■

10,000 write/erase cycles minimum

■

Write and erase voltage 12.0 V ±5%

■

■

■

■

■

■

■

Latch-up protected to 100 mA from

–1 V to V

Flasherase Electrical Bulk Chip Erase

— One second typical chi p eras e time

Flashrite Programming

— 10 µs typical byte program time

— 4 s typical chip program time

Command regist er architecture for

microprocessor/microcontroller compatible

write interface

On-chi p add r es s and dat a latches

Advanced CMOS flash memory technology

— Low cost single transistor memory cell

Aut o matic write/eras e pulse sto p timer

CC

+1 V

GENERAL DESCRIPTION

The Am28F020 is a 2 Meg abit Flash memory organize d as 25 6 Kb y tes of 8 bit s ea ch. AM D’s Flash memories offer the most cost-effective and reliable read/

write non-volat ile random access memory. The

Am28F0 20 is packaged in 32-pin PDI P, PLCC, and

TSOP v ers ions . It i s des ign ed to be repr ogr amme d and

erased in-system or in standard EPROM programmers.

The Am28F020 is erased when shipped from

the factory.

The stan da rd Am28 F0 20 of f e rs acc es s ti m es of as f as t

as 70 ns, allowing high speed microprocessors to

operate without wait states. To eliminate bus contention, the device has separate chip enable (CE#) and

output enable (OE#) controls.

AMD’s Flash memories augment EPROM funct ionality

with i n-circuit elec trical e rasure and programming. The

Am28F020 uses a command register to manage this

functiona lity, whil e maintai ning a JEDE C-stan dard 32pin pinout. The command register allows for 100% TTL

level control inputs and fixed power supply lev els during

erase and programming, while maintaining maximum

EPROM compatibility.

AMD’s Flash technology reliably stores memory contents even after 10,000 erase and program cycles. The

AMD cell is designed to optimize the erase and pro-

gra mmin g m ec han i sms . I n ad di t io n, th e c o mbin a tio n of

advanced t unnel oxide pr ocessi ng and low in ternal

electric fields for erase and programming operations

produces reliable cycling. The Am28F 020 uses a

12.0±5% VPP supp ly in put to perfor m the Flash erase

and Flashrite functi on s.

The highest degree of latch-up protection is achieved

with AMD’s prop r ietary non -e pi pr oc e ss. Lat ch- up pro tection is provided for stresses up to 100 mA on

address and data pins from –1 V to VCC +1 V.

The Am28F020 is byte programmable using 10 µs

programming pulses in accordance with AMD’s

Flashrite programming algorithm. The typical room

temperature programm ing time of the Am28 F020 is

four seconds. The entire chip is bulk erased using 10

ms erase pulses according to AMD’s Flasherase

algorithm. Typical erasure at room temperature is

accomplished in less than one second. The wi ndowed

package and the 15–20 minutes required for EPROM

erasure using ultraviolet light are eliminated.

Commands are wr itten to the command register using

standard microprocessor write timings. Register contents serve as input to an internal state-machine, which

controls the erase and programming circuitry. During

write cycles, the command register internally latches

Publication#

Issu e Date:

Rev: FAmendment/

14727

January 1998

+2

address es and data neede d for the program ming and

erase operations. For system design simplification, the

Am28F020 is designed to s uppor t either W E# or CE#

controlled writes. During a system write cycle,

addresses are latched on the falling edge of WE# or

CE#, whichever occurs last. Data is latched on the rising

edge of WE# or CE#, whichever occurs first. To simplify

discussion, the WE# pin is used as the write cycle

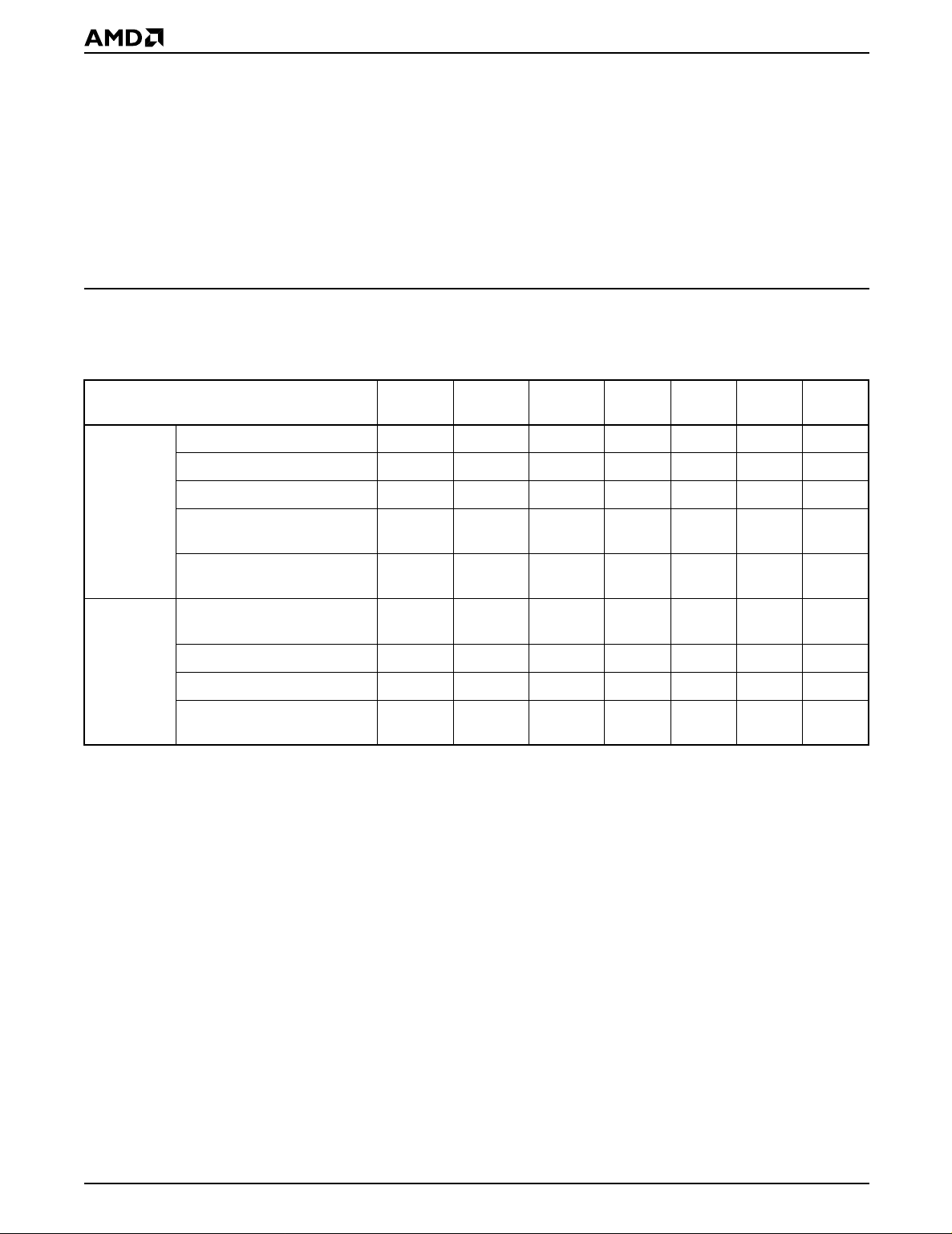

PRODUCT SELECTOR GUIDE

control pin throughout the rest of this data sheet. All

setup and hold times are with respect to the WE# signal.

AMD’s Flash technology combines years of EPROM

and EEPROM experience to produce the highest levels

of quality, reliability, and cost effectiveness. Th e

Am28F020 electrically erases all bits simultaneously

using Fowler-Nordheim tunneling. The bytes are programmed one byte at a time using the EPROM

programming mechanism of hot electron injection.

Family Part Number

Speed Options (VCC = 5.0 V ± 10%)

-70 -90 -120 -150 -200

Am28F020

Max Access Time (ns) 70 90 120 150 200

(E#) Access (ns) 70 90 120 150 200

CE

#

(G#) Access (ns) 35 35 50 55 55

OE

#

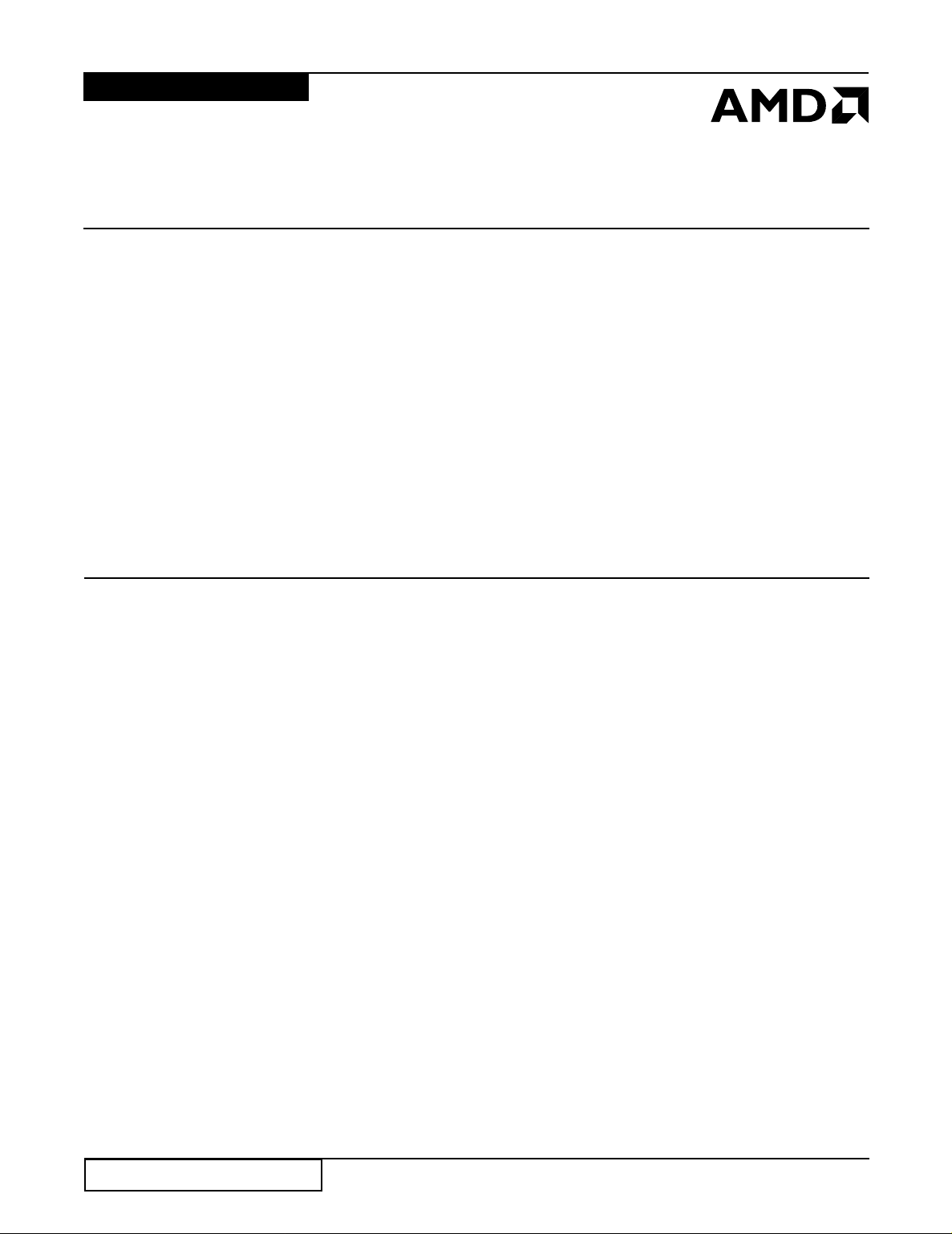

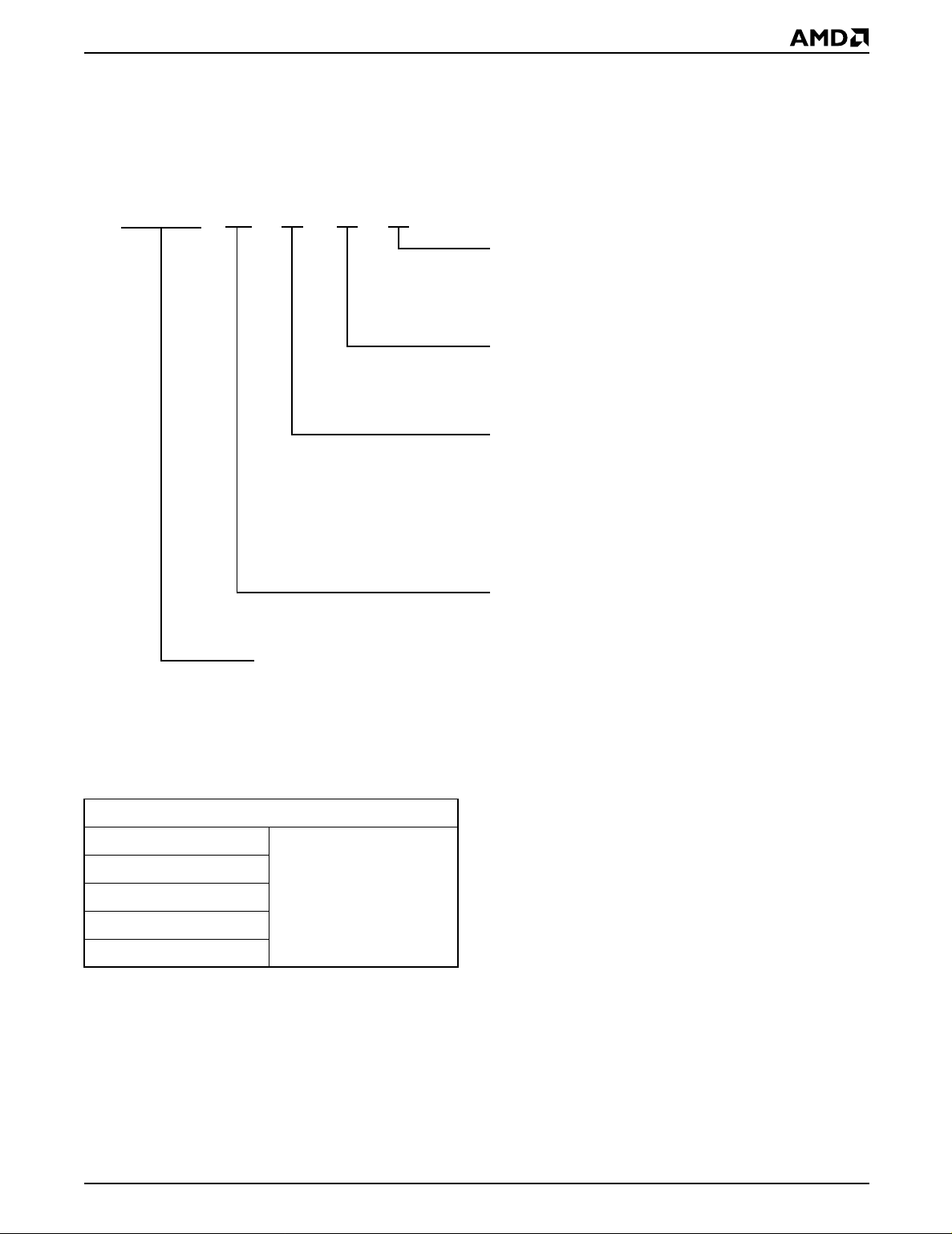

BLOCK DIAGRAM

DQ0–DQ7

V

CC

V

SS

V

PP

WE#

CE#

OE#

State

Control

Command

Register

Program

Voltage

Switch

Erase

Voltage

Switch

Input/Output

Buffers

To Array

Chip Enable

Output Enable

Logic

Program/Erase

Pulse Timer

Low VCC

Detector

A0–A17

2 Am28F020

Address Latch

Y-Decoder

X-Decoder

Data Latch

Y-Gating

2,097,152

Bit

Cell Matrix

14727F-1

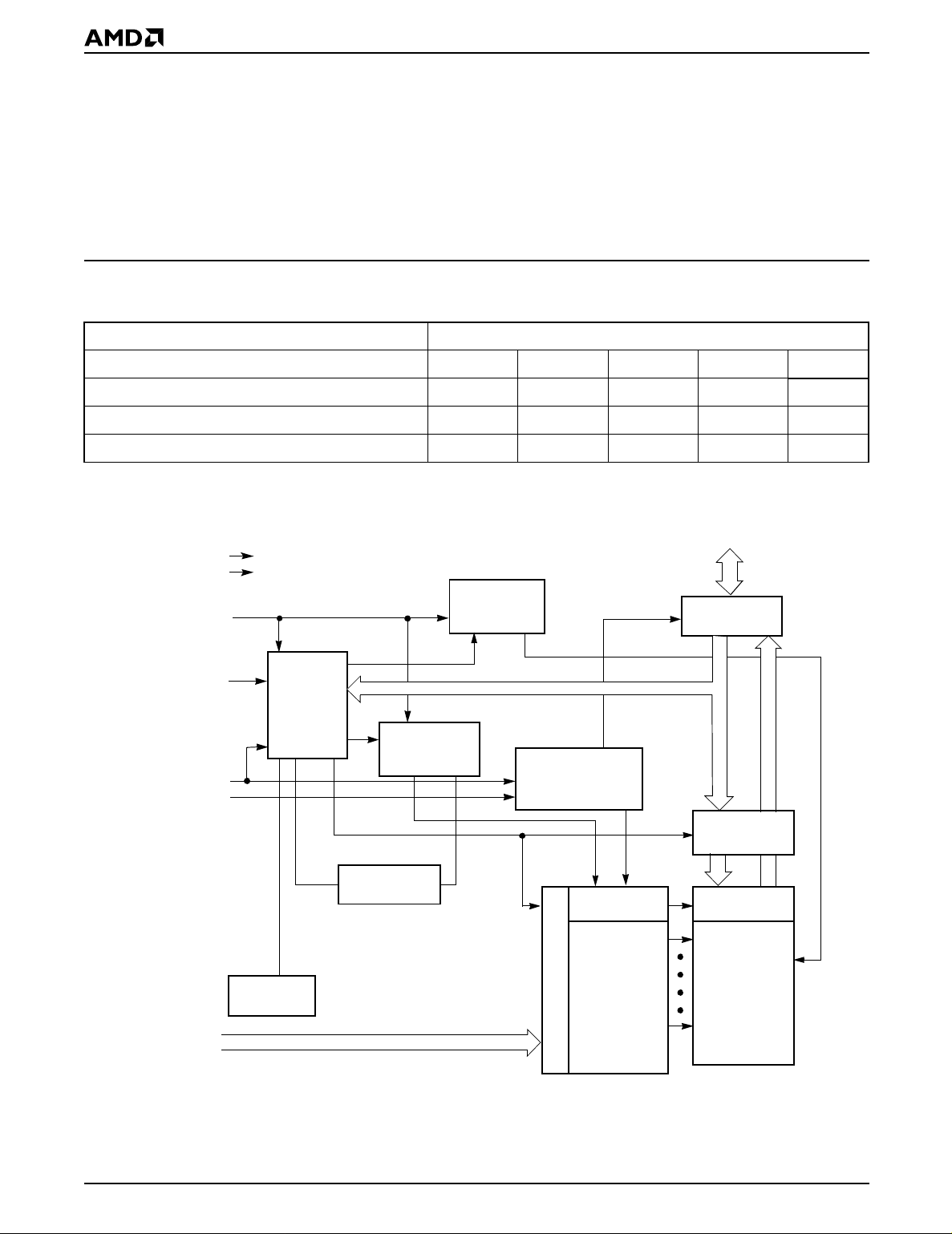

CONNECTION DIAGRAMS

PDIP

V

PP

A16

A15

A12

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

DQ1

DQ2

V

SS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

CE

14727F-2

V

CC

WE# (W#)

A17

A14

A13

A8

A9

A11

(G#)

OE

#

A10

(E#)

#

DQ7

DQ6

DQ5

DQ4

DQ3

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

5

6

7

8

9

10

11

12

13

14

A12

4

DQ1

15

A15

3

DQ2

PLCC

A16

2

17

SS

V

PP

V

VCCWE# (W#)

31 30

1

32

19 2016

18

DQ4

DQ3

DQ5

A17

29

28

27

26

25

24

23

22

21

DQ6

A14

A13

A8

A9

A11

OE# (G#)

A10

CE# (E#)

DQ7

14727F-3

Note: Pin 1 is marked for orientation.

Am28F020 3

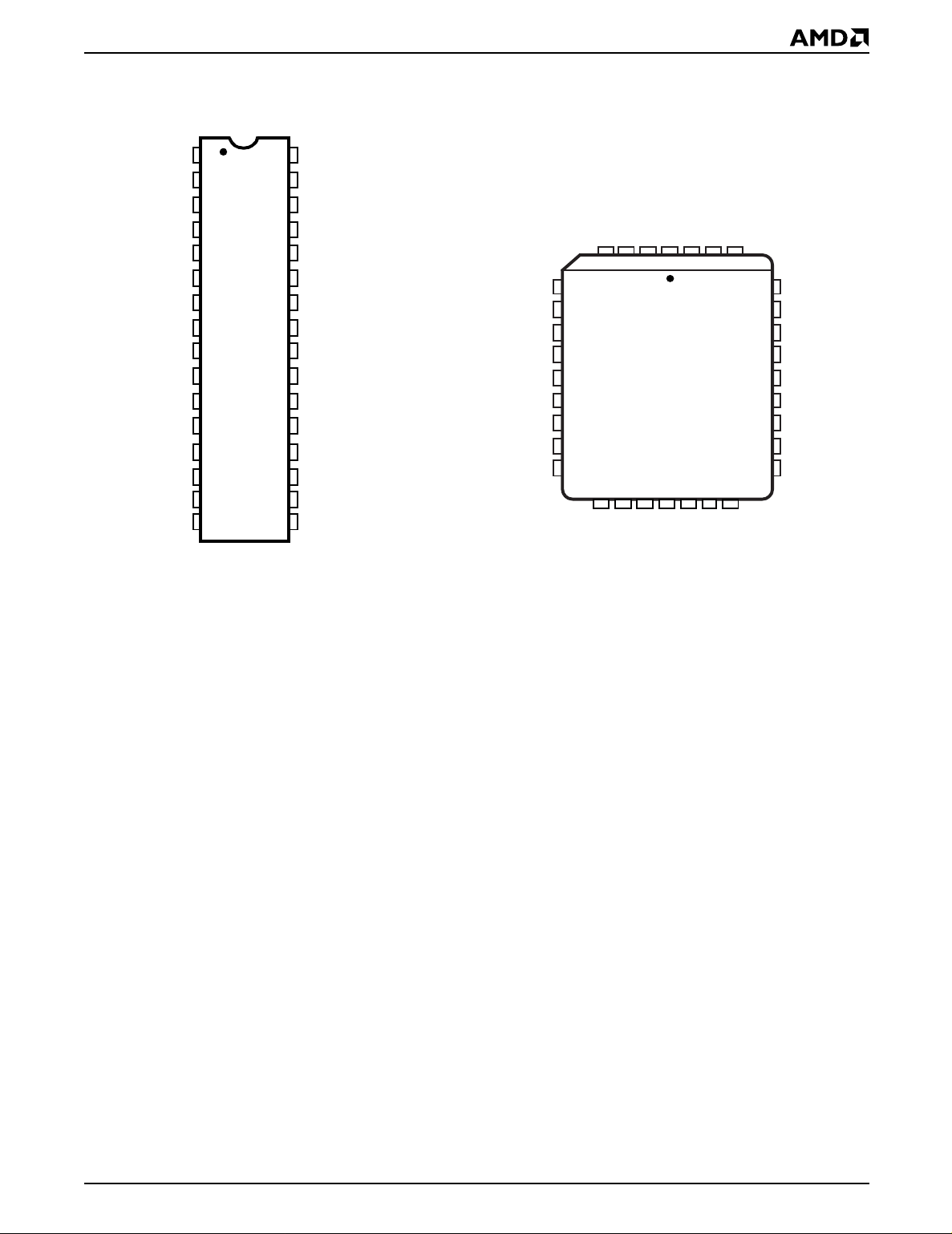

CONNECTION DIAGRAMS (continued)

PP

1

2

3

4

5

6

7

#

8

9

10

11

12

13

14

15

16

32-P in TS OP—St an dard Pino u t

#

1

2

#

3

4

5

6

7

8

9

10

11

12

13

14

15

16

A11

A13

A14

A17

WE

V

V

A16

A15

A12

OE

A10

CE

V

A9

A8

CC

A7

A6

A5

A4

D7

D6

D5

D4

D3

SS

D2

D1

D0

A0

A1

A2

A3

TSOP

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

OE

A10

CE

D7

D6

D5

D4

D3

V

SS

D2

D1

D0

A0

A1

A2

A3

A11

A9

A8

A13

A14

A17

WE

V

CC

V

PP

A16

A15

A12

A7

A6

A5

A4

#

#

#

32-Pin TSOP—Reverse Pinout

LOGIC SYMBOL

18

A0–A17

DQ0–DQ7

CE

(E)

#

OE# (G#)

WE# (W#)

4 Am28F020

14727F-4

8

14727F-5

ORDERIN G IN FOR MATION

Standard Products

AMD standard pro ducts are avail able in several packages and operating rang es. The order ing number (Va lid Combinatio n) is

formed by a combination of the following:

AM28F020 -70 J C

DEVICE NUMBER/DESCRIPTION

Am28F020

2 Megabit (256 K x 8-Bit) CMOS Flash Memory

B

OPTIONAL PROCESSING

Blank = Standard Processing

B = Burn-In

Contact an AMD representative for more information.

TEMPERATURE RANGE

C = Commercial (0°C to +70°C)

I = Industrial (–40°C to +85°C)

E = Extended (–55°C to +125°C)

PACKAGE TYPE

P = 32-Pin Plastic DIP (PD 032)

J = 32-Pin Rectangular Plastic Leaded Chip

Carrier (PL 032)

E = 32-Pin Thin Small Outline Package (TSOP)

Standard Pinout (TS 032)

F = 32-Pin Thin Small Outline Package (TSOP)

Reverse Pinout (TSR032)

SPEED OPTION

See Product Selector Guide and Valid Combinations

AM28F020-70

AM28F020-90

AM28F020-120

AM28F020-150

AM28F020-200

Valid Combinations

PC, PI, PE,

JC, JI, JE,

EC, EI, EE,

FC, FI, FE

Valid Combinations

Valid Combinations list configurations planned to be supported in volume for this device. Consult the local AMD sales office to confirm availab ility of specific val id combination s and

to check on newly released combinations.

Am28F020 5

PIN DESCRIPTION

A0–A17

Address In puts for memor y lo cations. Inte rnal la tches

hold addresses during write cycles.

CE# (E#)

Chip Enable active low input activates the chip’s control

logic and input buffers. Chip Enable high will deselect

the device and operates the chip in stand-by mode.

DQ0–DQ7

Data Inputs during memory write cycles. Internal

latches hold data during write cycles. Data Outputs

during memory read cycles.

NC

No Connect-corresponding pin is not connected

internally to the die.

OE# (G#)

Output Enable active low input gates the outputs of the

device through the data buffers during memory read

cycles. Output Enable is high during com mand

sequencing and program/erase operations.

V

CC

Po w er supp ly for de vi ce oper at ion . (5.0 V ± 5% or 10%)

V

PP

Program voltage i nput. VPP must be at hi g h vol ta ge in

order to write to the command register. The command

register controls all functions required to alter the

memory array contents. Memor y contents cannot be

altered when VPP ≤ V

V

SS

Ground

CC

+2 V.

WE# (W#)

Write Enable active low input controls the write function

of the command register to the memory array. The

target address is latched on the falling edge of the

Write Enable pulse and the appropriate data is latched

on the rising edge of the pulse. Write Enable high

inhibits writing to the device.

6 Am28F020

BASIC PRINCIPLES

The device uses 100% TTL-level control inputs to

manage th e command register. Erase and rep rogramming opera tions use a fixed 12.0 V ± 5% high

voltage input.

Read Only Memory

Without high VPP voltage, the device functions as a

read only memory and operates like a standard

EPROM. Th e control inpu ts still ma nage traditi onal

read, standby, output disable, and Auto select modes.

Command Register

The command register is enabled only when high voltage is applied to the VPP pin. The erase and reprogramming operations are only accessed via the

register. In addition, two-cycle commands are required

for erase and reprogramming op erations. The traditional read, standby, output disable, and Auto select

modes are available via the register.

The device’s com mand regi ster is wr itt en us ing standard microprocessor write timings. The register controls an internal state machine that manages all device

operations. For system design simplification, the device is designed to suppor t either WE# or CE# controlled writes. Durin g a system write cy cle, addresses

are latched on the falling edge of WE# or CE# whichever occurs last. Data is latched on the rising edge of

WE# or CE# whichever occur first. To simplify the following discussion, the WE# pin is used as the write

cycle control pin throughout the rest of this text. All

setup and hold times are with respect to the WE# signal.

Overview of Erase/Program Operations

Flasherase™ Sequence

A multiple step command sequence is required to

erase the Flash device (a two-cycle Erase command

and repeated one cycle verify commands).

Note: The Flash memory array must be completely

programmed to 0’s prior to erasure. Refer to the

Flashrite™ Programming Algorithm.

1. Erase S etup: Write the Setup Erase command to

the command register.

2. Erase: Wr it e the Erase com mand (sam e as Setu p

Erase command) to the command register again.

The seco nd comm an d i n it iat es t he er a s e o per at i o n.

The system software routines must now time-out

the erase pulse width (10 ms) prior to issuing the

Erase-ver ify command. An integrate d stop time r

prevents any possibility of overerasure.

3. Erase-Verify: Write the Erase-verify command to

the command register. This command terminates

the erase operation. After the erase operation,

each byte of the array must be verified. Address in-

formation must be supplied with the Erase-verify

command. This command verifies the margin and

outputs t he add re ssed b y te in o rde r to co mpar e th e

array data with FFh data (Byte erased).

After successful data verification the Erase-verify

command is written again with new address information. Each byte of the array is sequentially verified in this manner.

If data of the addressed loca tion is not verified, the

Erase sequence is repe ated until the entire array is

successfully verified or the sequence is repea ted

1000 times.

Flashrite Programming Sequence

A three step command sequence (a two-cycle Program

command and one cycle Verify command ) is required

to pr og r am a byte of t h e Fla sh arr ay. Refe r to th e Fl as hrite Algorit h m.

1. Program Setup: Write the Setup Program com-

mand to the command regist er.

2. Pr ogram: Write the Program command to the com-

mand register with the appropriate Address and

Data. The system software routines must now timeout the program pulse width (10 µs) prior to issuing

the Program-verify command. An integrated stop

timer prevents any possibility of overprogramming.

3. Program-Verify: Write the Program-verify com-

mand t o th e com ma nd register. Thi s command ter minates the programming op eration. In additio n,

this command verifies the margin and outputs the

byte just programmed in order to compare the array

data with the original data programmed. After successful d ata ver ification, the programm ing sequence is initiated again for the next byte address to

be programmed.

If data is n ot verified succes sfully, the Pr ogram sequence is repeated until a successful comparison is

verified or the sequence is repeated 25 times.

Data Protection

The device is designed to offer protection aga inst acci dental erasure or programming ca used by spurious

system level signals that may exist during power transitions . The d evice po wers up in it s r ea d onl y st at e . A ls o,

with its control register architecture, alteration of the

memory contents only occurs after successful completion of specific command sequences.

The device al so i ncor pora tes s everal feat ures t o pre vent inadvertent write cycles resulting fromVCC powerup and power-down transitions or system noise.

Low VCC Write Inhibit

To avoid initiation of a write cycle during VCC power-up

and power-d own, the d evice locks out wr ite cycl es for

Am28F020 7

VCC < V

voltages) . Wh en VCC < V

disabled, all internal program/erase circuits are

disabled , an d th e d evice resets to the r ea d m od e. Th e

device ignores all writes until VCC > V

must ensure that the control pins are in the correct logic

state wh en VCC > V

Write Pulse “Glitch” Protection

Noise pul se s of less than 10 ns (typical) on OE#, CE#

or WE# will not initiate a write cycle.

(see DC Characteristics section for

LKO

LKO

, the comm an d r eg i ster i s

LKO

LKO

to prevent uninitentional writes.

. The user

Logical Inhibit

Writing is inhibited by holding an y one of OE# = VIL, CE#

= VIH or WE# = VIH. To initiate a write cycle CE# a nd

WE# must be a logical zero while OE# is a logical one.

Power- U p Wr ite Inhibi t

Power-up of the device with W E# = CE# = VIL and

OE# = VIH will not accept commands on the r ising

edge of WE#. The internal state machine is automatically reset to the read mode on power-up.

FUNCTIONAL DESCRIPTION

Description of User Modes

Table 1. Am28F020 Device Bus Operations

Operation CE# (E#)OE# (G#)WE# (W#)

VPP

(Note 1) A0 A9 I/O

Read-Only

Read/Write

Read V

Standby V

Output Disable V

Auto-Select Manufacturer

Code (Note 2)

Auto-Select Device Code

(Note 2)

Read V

Standby (Note 5) V

Output Disable V

Write V

IL

IH

IL

V

IL

V

IL

IL

IH

IL

IL

V

IL

XXV

V

IH

V

IL

V

IL

V

IL

XXV

V

IH

V

IH

XV

V

IH

V

IH

V

IH

V

IH

V

IH

V

IL

V

V

V

V

V

V

PPL

PPL

PPL

PPL

PPL

PPH

PPH

PPH

PPH

A0 A9 D

X X HIGH Z

X X HIGH Z

V

IL

V

IH

VID

(Note 3)

VID

(Note 3)

A0 A9

X X HIGH Z

X X HIGH Z

A0 A9

Legend:

X = Don’t care, where Don’t Care is either V

of V

. 0 V < An < VCC + 2 V, (normal TTL or CMOS input levels, where n = 0 or 9).

PPH

or VIH levels. V

IL

= VPP ≤ VCC + 2 V. See DC Characteristics for voltage levels

PPL

Notes:

1. V

may be grounded, connected with a resistor to ground, or < VCC + 2.0 V. V

PPL

the device. Refer to the DC characteristics. When V

PP

= V

, memory contents can be read but not written or erased.

PPL

is the programming voltage specified for

PPH

2. Manufacturer and device codes may also be accessed via a command register write sequence. Refer to Table 2.

3. 11.5 < V

4. Read operation with V

5. With V

6. Refer to Table 3 for valid D

7. All inputs are Don’t Care unless otherwise stated, where Don’t Care is either V

< 13.0 V. Minimum VID rise time and fall time (between 0 and VID voltages) is 500 ns.

ID

= V

PP

at high voltage, the standby current is ICC + IPP (standby).

PP

may access array data or the Auto select codes.

PPH

during a write operation.

IN

or VIH levels. In the Auto select mode all

IL

addresses except A9 and A0 must be held at VIL.

8. If V

1.0 Volt, the voltage difference between VPP and VCC should not exceed 10.0 volts. Also, the Am28F010 has a VPP

≤

CC

rise time and fall time specification of 500 ns minimum.

OUT

CODE

(01h)

CODE

(2Ah)

D

OUT

(Note 4)

D

IN

(Note 6)

8 Am28F020

READ ONLY MODE

When VPP is less than V

is inactive. The device can either read array or autoselect data, or be standby mode.

+ 2 V, the comm and regis ter

CC

Read

The device f unc t ion s as a r ea d o nly m em ory wh en V

< V

+ 2 V . The de v ice ha s tw o con tro l fu ncti ons . Bo th

CC

must be satisfied in order to output data. CE# controls

power to the d evice. This pin sh ould be used for specific device sele ctio n. OE# c ontro ls the device ou tputs

and shou ld be used to gate data to the output pin s if a

device is selected.

Address access time t

is equal to the delay from

ACC

stable addresses to valid ou tput data. Th e ch i p en able

access time tCE is the delay from stable addresses and

stable CE# to valid data at the output pins. The output

enable access time is the delay from the falling edge of

OE# to valid data at the output pins (assuming the addresses have been stable at least t

ACC–tOE

).

PP

Standby Mode

The device has two standby modes. The CMOS

standby mode (CE# input held at V

sumes less t han 100 µA o f c urr ent . TTL s ta ndb y mode

(CE# is held at VIH) reduces the current requirements

to less than 1mA. When in the standby mode the outputs are in a h igh imp eda nce s ta te , i nde pend ent of th e

OE# input.

If the device is deselected during eras ure, programming, or p rogram/erase verificati on, the device will

draw active current until the operation is terminated.

CC

±

0.5 V), con-

Output Dis a ble

Output from the device is disabled when OE# is at a

logic high level. When disabled, output pins are in a

high impedance state.

Auto Select

Flash memories can be programmed in-system or in a

standard PROM programmer. The device may be soldered to the circuit board upon receipt of shipment and

programmed in-system. Alternatively, the device may

initially be programmed in a PROM programmer pr ior

to soldering the device to the board.

The Auto select mode allows the reading out of a binary

code from the device that will identify its manufacturer

and type. T his mode is i ntended for the pu rpose

of automatically matching the device to be programmed with its corresp onding programming algorithm. This mode is functional over the entire

temperature range of the device.

Programming In a PROM Programmer

To activate thi s mode, the programmin g equipm ent

must force VID (11.5 V to 13.0 V ) on addre ss A9 . Two

identi fie r b yte s ma y th en be seq uence d fr om th e de vi ce

outpu ts b y t oggli ng addr ess A0 from VIL to VIH. All other

address lines must be held at VIL, and VPP must be

less than or equal to VCC + 2.0 V while using this Auto

select mode. Byte 0 (A0 = VIL) repr esen ts th e man uf acturer code and byte 1 (A0 = VIH) the device identifier

code. For the device these two bytes are given in Table

2 of the device data sheet. All identifiers for manufacturer and device codes will exhibit o dd parity with th e

MSB (DQ7) defined as the parity bit.

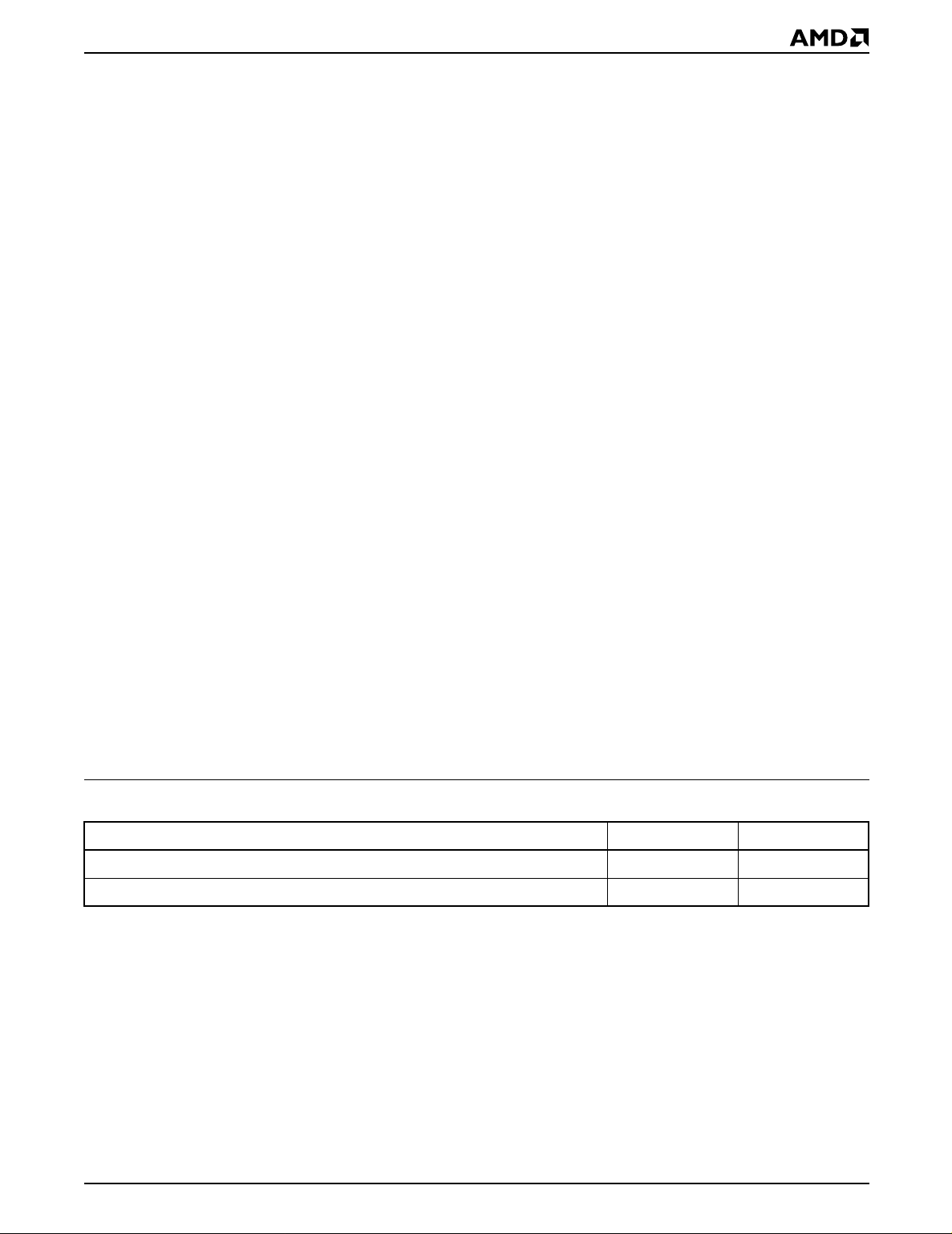

Table 2. Am28F020 Auto Select Code

Type

Manufacturer Code V

Device Code V

Am28F020 9

A0 Code (HEX)

IL

IH

01

2A

ERASE, PROGRAM, AND READ MODE

When VPP is equal to 12.0 V ± 5%, the command register is active. All fu nctions ar e available. Tha t is, the

device can program, erase, read array or autoselect

data, or be standby mode.

Write Operations

High voltage must be applied to the VPP pin in order to

activate the command register. Data written to the register serves as input to the internal state machine. The

output of the state machine determines the operational

function of the device.

Refer to AC Writ e Chara cteris tics and th e Erase/ Programming Waveforms for specific timing parameters.

Command Definitions

The contents of the command register default to 00h

(Read Mode) in the absence of high voltage applied to

the VPP pin. The device opera tes as a rea d only mem ory. High voltage on the VPP pin enables the co mma nd

regist e r. Device op er a t ion s ar e s e lec t e d by writin g s p ecific data codes into the command register. Table 3 defines thes e re gist e r com m and s.

The command register does not occupy an addressable

memory location. The register is a latch that stores the

command, along with the address and data information

needed to execute the command. The register is written

by bringing WE# and CE# to VIL, while OE# is at VIH.

Addresses are latched on the falling edge of WE#, while

data is latched on the rising edge of the WE# pulse.

Standard microprocessor write timings are used.

The device requires the OE# pin to be VIH for write operations. This condition eliminates the possibility for

bus contention during programming operations. In

order to write, OE# must be VIH, and CE# and WE#

must be VIL. If any pin is not in the correct state a write

command will not be executed.

Read Command

Memor y conte nts can be acces sed via th e read com mand when VPP is high. To read from the device, write

00h into the command register. Standard microprocessor read cycles access data from the memory. The device will remain in the read mode until the command

register contents are altered.

The comma nd register defaults to 00h (r ead mode)

upon VPP power -up . The 00h (Re ad Mode ) regis ter default helps ensure that inadvertent alteration of the

memory contents does not occur during the VPP power

transition. Refer to the AC Read Characteristics and

Waveform s for the spec ifi c timi n g para m ete rs.

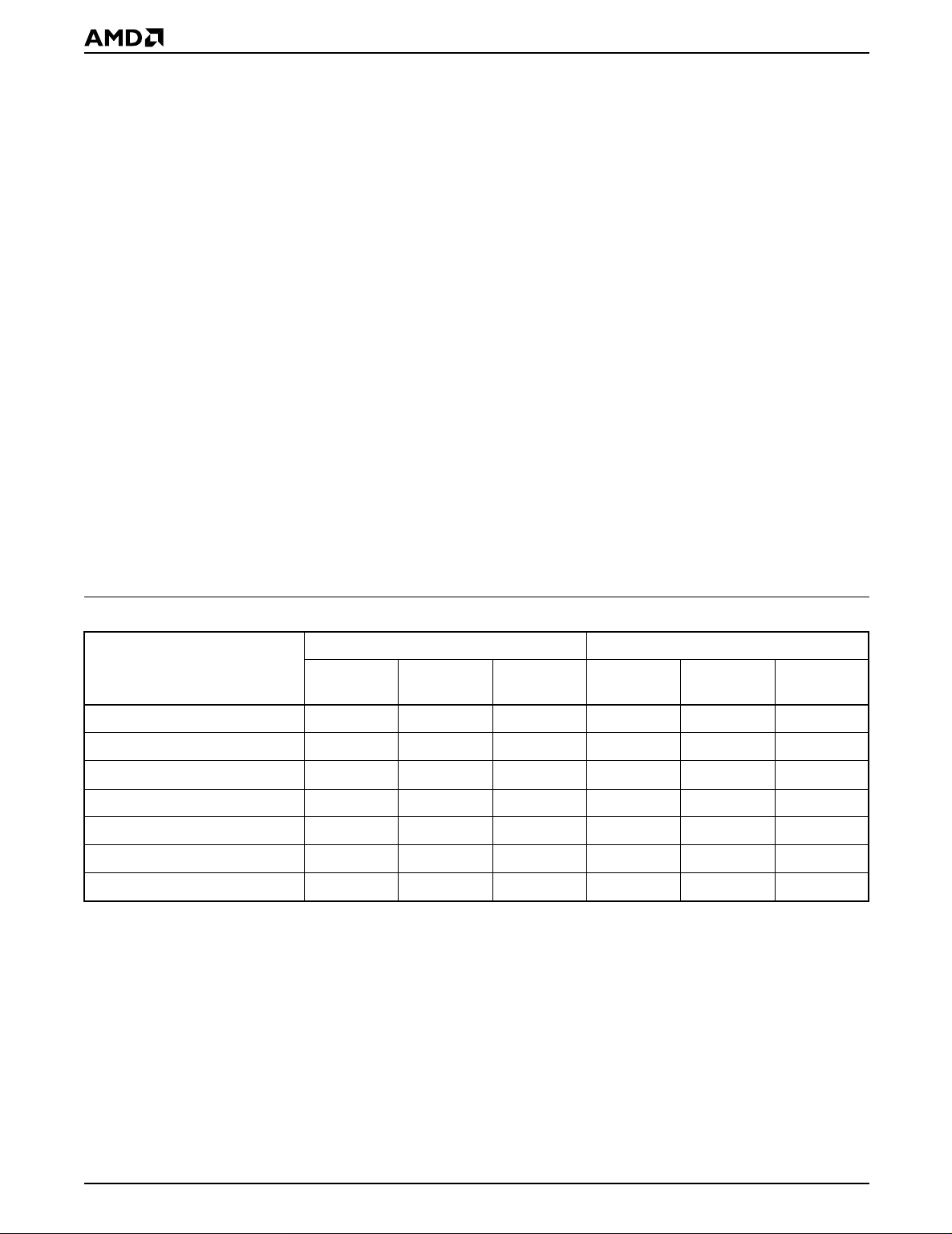

Table 3. Am28F020 Command Definitions

First Bus Cycle Second Bus Cycle

Operation

Command (Note 4)

Read Memory Write X 00h/FFh Read RA RD

Read Auto select Write X 80h or 90h Read 00h/01h 01h/2Ah

Erase Setup/Erase Write Write X 20h Write X 20h

(Note 1)

Address

(Note 2)

Data

(Note 3)

Operation

(Note 1)

Address

(Note 2)

Data

(Note 3)

Erase-Verify Write EA A0h Read X EVD

Program Setup/Program Write X 40h Write PA PD

Program-Verify Write X C0h Read X PVD

Reset Write X FFh Write X FFh

Notes:

1. Bus operations are defined in Table 1.

2. RA = Address of the memory location to be read.

EA = Address of the memory location to be read during erase-verify.

PA = Address of the memory location to be programmed.

X = Don’t care.

Addresses are latched on the falling edge of the WE

3. RD = Data read from location RA during read operation.

EVD = Data Read from location EA during erase-verify.

PD = Data to be programmed at location PA. Data latched on the rising edge of WE

PVD = Data read from location PA during program-verify. PA is latched on the Program command.

4. Refer to the appropriate section for algorithms and timing diagrams.

pulse.

#

.

#

10 Am28F020

FLASHERASE ERASE SEQUENCE

Erase Setup

Erase Setup is the first of a two-cycle erase command.

It is a com mand -only ope ration th at stag es the device

for bulk chip erase. T he array cont ent s are no t altere d

with t his co mma nd . 20 h is wri tte n t o t h e com ma nd re gister in order to perform the Erase Setup operation.

Erase

The seco nd two-cycle e rase comman d initiates th e

bulk erase operation. You must write the Erase command (20h) again to the register. The erase operation

begins with the rising edge of the WE# pulse. The

erase operation mu st be ter minated by writin g a new

command (Erase-verify) to the register .

This two ste p seq uenc e o f the Set up an d E rase c ommands h elps to ensure th at memo ry c ontents are not

accidentally eras ed . Al so, chi p e rasu re ca n only occ u r

when hig h vo ltag e is appl ied to the VPP pin an d al l c o ntrol pins are in their proper state. In absence of this high

voltage, me mor y contents c annot be altere d. Refer to

AC Erase Characteristics and Waveforms for specific

timing parame ters.

Note: The Flash memory device must be fully

programmed to 00h data prior to erasure. This

equalizes the charge on all memory cells ensuring

reliable era sure.

Erase-V erify Command

The erase op eration erases all bytes of the array

in parallel. After the e ras e op era ti on , all byte s mu s t b e

sequentially verified. The Erase-verify operation is initi-

ated b y w ri tin g A 0 h to t he reg i s ter. The byte ad dr es s to

be verified must be supplied with the command. Addresses are latc hed on the falling edge of the WE #

pulse or CE# pulse, whichever occurs later. The rising

edge of the WE# pulse terminates the erase operation.

Margin Verify

During the Erase-verify operation, the device applies

an internally generated margin voltage to the

addressed byte. Reading FFh from the addressed byte

indicates that all bits in the byte are properly erased.

Verify Next Address

You must write the Erase-verify command with the appropriate address to the register prior to verification of

each address. Each new address is latched on the falling edge of WE# or CE# pulse, whichever occurs later.

The process co ntinues for each byte in the memor y

array until a byte does not return FFh data or all the

bytes in the array are accessed and verified.

If an address is not verified to FFh data, the entire chip

is erased again (refer to Erase Setup/Erase). Erase

verifica tion then resumes at the ad dress tha t failed to

verify. Erase is complete when all bytes in the array

have been verified. The device is now ready to be programmed. At this point, the verification operation is terminated by writing a valid command (e.g. Program

Setup) to the command register. Figure 1 and Table 4,

the Flasherase electrical erase algorithm, illustrate how

commands and bus operations are combined to perform electrical erasure. Refer to AC Erase Characteristics and Waveforms for specific timing parameters.

Am28F020 11

Loading...

Loading...