Amana VTC093B-0, VTC093B-2, VTC09EB-3, VTC093B-4, VTC123B-0 Product Specifications

...

PRODUCT SPECIFICATIONS

VTC / VTH

VERTICAL TERMINAL

A

IR CONDITIONER AND HEAT PUMP

No other unit in the industry offers so many

extras already built in as standard on every

unit. Don’t settle for anything less than the

Amana® brand Standard Ad van tage!

Evaporator Coil Freeze Pro tec tion

•

Compressor Restart Delay

•

Low Ambient Lock-out

•

Manual Outside Air Damper

•

Wall-mount Thermostat

•

Electrical Disconnect

•

Random Unit Restart

•

Front Desk Control

•

Fan On/Off Delay

•

High-effi ciency Operation

•

Quiet Operation

•

Reliability and Durability

•

¾ Ton through 2 Tons

SS-VTAC www.goodmanmfg.com 5/08

COOLING: 8,350 - 23,800 BTU/H

H

EAT PUMP: 8,120 - 22,800 BTU/H

ELECTRIC HEAT: 5,100 - 34,100 BTU/H

UP TO 3.5 COP

Supersedes 12/07

P

RODUCT SPECIFICATIONS

FEATURES

Front Desk Control

•

Enable or disable each unit from the front desk to save energy

used to con di tion unoccupied rooms.

Fan Delay

•

Allows the evaporator blower to con tin ue running for up to 45 sec .

after the ther mo stat is satisfi ed, maximizing cooling performance.

Random Restart

•

Protects against damage to electrical circuits by preventing all

units from starting at one time after power disruption. Random

restart occurs in 3 to 4 min.

Evaporator Coil Freeze Protection

•

Prevents ice build-up on coils and compressor damage during

the cooling mode. Attached to the coil, a temperature sensor

will de-energize the compressor when freezing conditions are

detected and re-energize the compressor when the coil warms

up again.

Ductable Return Air

•

Permits the con nec tion of return air ductwork using the provid-

ed tabs (usually not required) on the inlet of the evap o ra tor coil.

(Figure 5, pg. 9)

Note: Duct systems and registered sizes must be properly designed for

the CFM and external static pressure rating of the unit.

Adjustable Outside Air (manual)

•

Meets code re quire ments for outside air introduction. The air

vent (Figure 6, pg. 9) allows up to 50 CFM of outside air to be

introduced into the equipment closet. The air mixes with return

air entering the closet through the return air grille.

Note: Negative pressure can be introduced through an external source to

raise the 50 CFM level. Consult with the factory.

Compressor Restart Delay – (3 min.)

•

Ensures that system pressure equalizes before the system re-

starts, so compressor life is extended.

Low Ambient Lockout

•

Locks out compressor at 40ºF and below, thus extending com-

pressor life.

Electrical Dis con nect (Factory-installed)

•

Makes service and maintenance easier.

Filter Brackets (Field-installed)

•

Installed over evaporator coil and shipped with throw-away fi l-

ter (20” x 24” x 1”; see Figure 5, pg. 9).

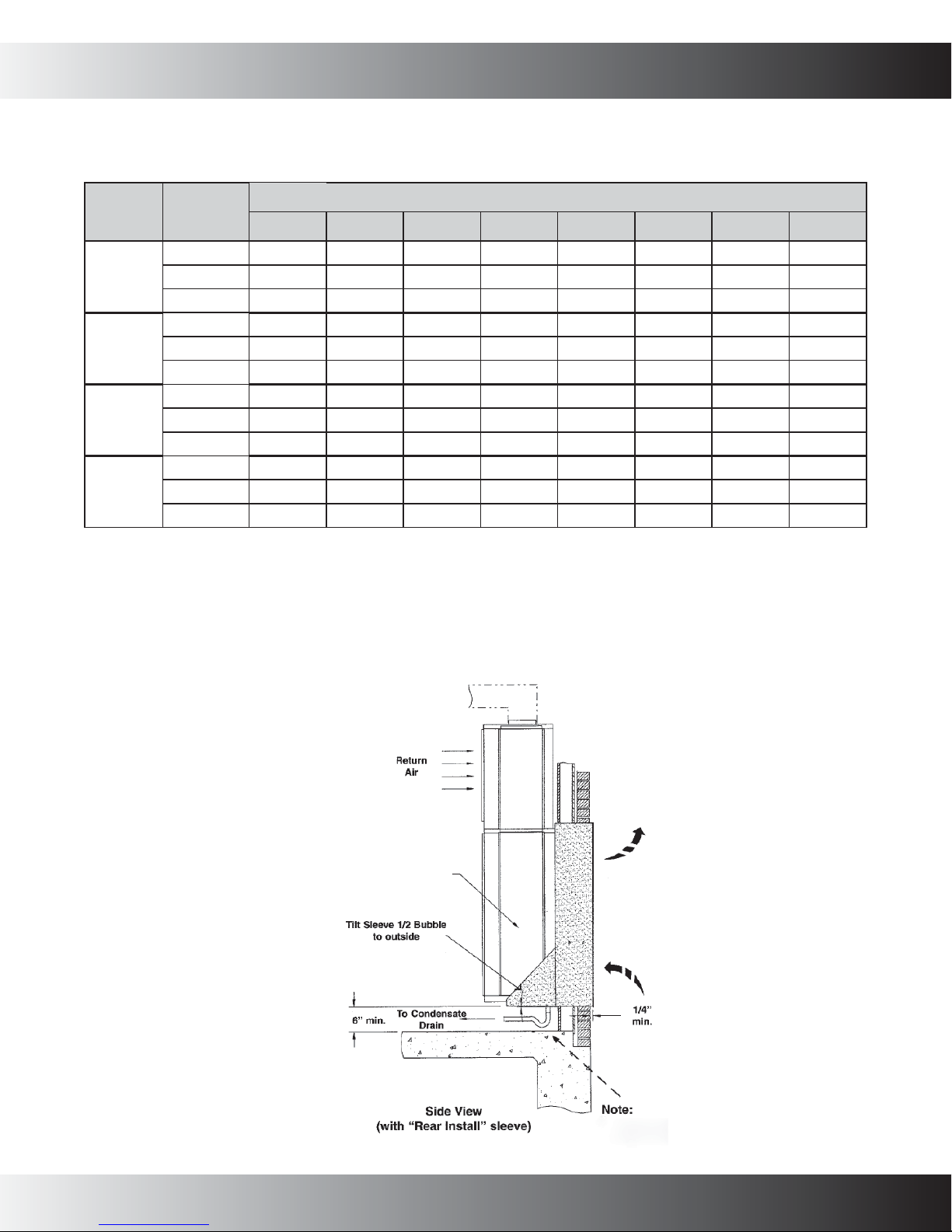

Unique “Sleeve Drain” Condensate System

•

(Factory-installed) – Connects evaporator drain pan to a vertical

pipe connection in the unit’s base pan via a drain line. Evaporator condensate is delivered from the unit to a catch tray in the

wall sleeve and exits the sleeve through the ¾” male NPT fi tting

to allow complete piping of the drain to a condensate riser during the rough-in stage. This eliminates condensate connection

problems when connecting the HVAC drain to the riser after the

HVAC unit is installed in the closet. Unit can be removed for

service without disconnecting the condensate piping. Additional

closet space is not needed to connect the drain.

Secondary Overfl ow

•

Should the primary condensate riser become clogged, water will

fi ll the catch tray and be diverted through the sleeve to the exterior of the building, ensuring no leakage into the interior area.

Rain water entering the sleeve is automatically diverted to the

building exterior.

NOMENCLATURE

VT 09

4,5

3

Product Category Engineering

V Vertical Package Revisions

Terminal Unit

Model Type A Standard Model

C Air Conditioner H Hot Water Model

H Heat Pump

System Cooling Capacity 00 0.0 KW 05 5.0 kW

09 9,000 BTU/h 02 2.0 KW 06 6.0 kW

12 12,000 BTU/h 03 3.0 kW 08 8.0 kW

18 18,000 BTU/h 04 4.0 kW 10 10 kW

24 24,000 BTU/h Hot Water Models (H)

Voltage Design Series

3 230/208v-60 Hz-1 Ph A Unit manufactured prior to 01/2006

B

3

7

6 8,9

A11AC

03

101,2

Option Code

230v-208v Models

0A 2-row coil 0B 3-row coil

B Unit meets 2006 DOE requirement

Electric Heat

2 www.goodmanmfg.com SS-VTAC

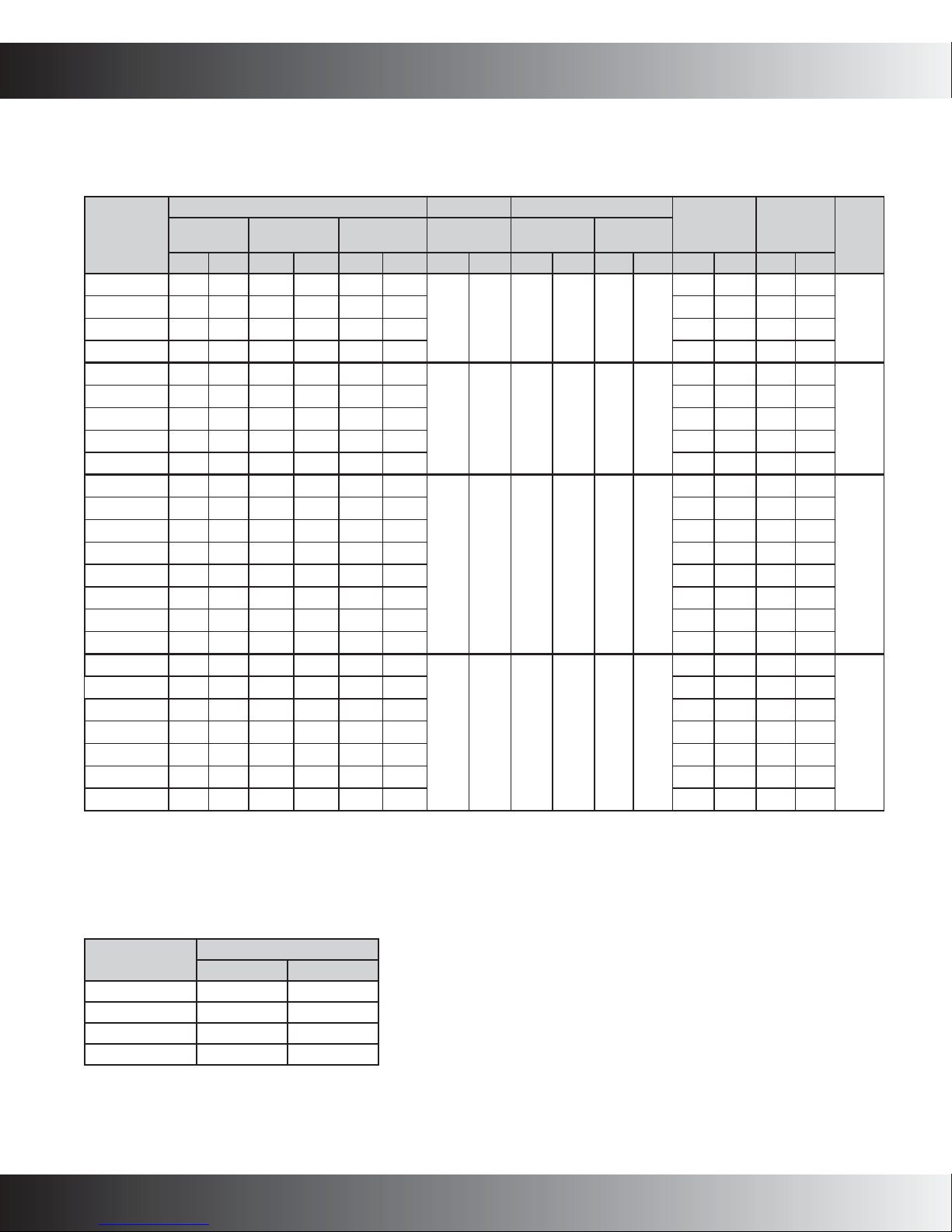

VTC MODEL SPECIFICATIONS—COOLING/ELECTRIC HEAT

ELECTRICAL DATA (208/240V-1 PH-60HZ)

P

RODUCT SPECIFICATIONS

Model

VTC093B-0

VTC093B-2

VTC09EB-3

VTC093B-4

VTC123B-0

VTC123B-2

VTC123B-3

VTC123B-4

VTC123B-5

VTC183B-0

VTC183B-2

VTC183B-3

VTC183B-4

VTC183B-5

VTC183B-6

VTC183B-8

VTC183B-10

VTC243B-0

VTC243B-3

VTC243B-4

VTC243B-5

VTC243B-6

VTC243B-8

VTC243B-10

Electric Heat Data Blower Data Condenser Data

kW BTU/h

240V 208V 240V 208V 240V 208V AMPS HP RLA LRA FLA HP 208V 230V 208V 230V

0 0.0 0.0 0.0 0.0 0.0

2 1.5 6,800 5,100 9.0 7.9 10 12 15 15

3 2.25 10,200 7,700 13.2 11.5 15 18 20 20

4 3.0 13,600 10,200 17.4 15.1 19 23 20 25

0 0.0 0.0 0.0 0.0 0.0

2 1.5 6,800 5,100 9.0 7.9 10 12 15 15

3 2.25 10,200 7,700 13.2 11.5 15 18 20 20

4 3.0 13,600 10,200 17.4 15.1 19 23 20 25

5 3.75 17,000 12,800 22.0 19.0 24 28 25 30

0 0.0 0.0 0.0 0.0 0.0

2 1.5 6,800 5,100 9.2 8.1 13 13 15 15

3 2.25 10,200 7,700 13.4 11.7 15 18 20 20

4 3.0 13,600 10,200 17.5 15.3 19 23 25 25

5 3.75 17,000 12,800 22.0 19.0 24 28 25 30

6 4.5 20,500 15,350 26.0 23.0 28 34 30 35

8 6.0 27,300 20,500 34.0 30.0 37 44 40 45

10 7.5 34,100 25,600 43.0 37.0 47 54 50 60

0 0.0 0.0 0.0 0.0 0.0

3 2.25 10,200 7,700 14.0 12.3 18 18 20 20

4 3.0 13,600 10,200 18.2 15.9 21 24 25 25

5 3.75 17,000 12,800 22.0 20.0 26 28 30 30

6 4.5 20,500 15,350 27.0 23.0 30 34 35 35

8 6.0 27,300 20,500 35.0 30.0 39 45 45 50

10 7.5 34,100 25,600 43.0 38.0 48 55 50 60

Total Heating

Amps

Evaporator

Motor

0.72 1/8 3.7 21 0.5 1/15

0.72 1/8 5.0 24 0.5 1/15

0.87 1/8 9.0 48 0.72 1/10

1.4 1/4 10.5 61 2.3 1/4

Compressor

Condenser

Motor

Minimum

Circuit

Ampacity

7 7 15 15

10 10 15 15

13 13 15 15

18 18 20 20

Maximum

Circuit

Protection

Ship

Weight

245

245

255

255

OOLING PERFORMANCE DATA

C

Model

VTC093B

VTC123B

VTC183B

VTC243B

¹ T ested in accordance with ARI Standard 310/380-93

at 95°F DB/75°F WB outdoors and 80°F DB/67°F

WB indoors.

SS-VTAC www.goodmanmfg.com 3

Standard Ratings

BTU/h EER

8,350 9.3

11,500 9.6

18,900 9.7

23,100 9.1

1

P

RODUCT SPECIFICATIONS

VTC MODEL SPECIFICATIONS—COOLING/ELECTRIC HEAT (CONT.)

BLOWER DATA

Model

VTC093B

VTC123B

VTC183B

VTC243B

Notes:

(1) VTC12, 18- and 24-blower motors are factory-wired for medium (cooling) and low (heating) fan operation.

VTC09 is low speed for both.

(2) VTH12, 18- and 24-blower motors are factory-wired for medium (cooling/heat pump) and low (electric heat) speed operation.

VTH09 is low speed in all modes.

Motor

Speed

Connection

High 490 475 460 450 435 420 400 ---

Med 375 360 350 340 330 315 300 ---

Low 290 280 270 260 240 230 215 ---

High 490 475 460 450 435 420 400 ---

Med 375 360 350 340 330 315 300 ---

Low 290 280 270 260 240 230 215 ---

High 660 655 650 645 640 635 625 610

Med 580 578 575 570 565 560 550 540

Low 485 480 475 470 465 460 455 450

High 1,030 1,000 980 950 920 890 860 820

Med 880 860 840 820 790 760 730 710

Low 770 760 750 740 720 700 680 660

0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40

CFM vs. External Static Pressure

DIMENSIONAL DATA

*See Wall Sleeve Installation

In struc tions for complete

details.

VTC/VTH Unit

4 www.goodmanmfg.com SS-VTAC

"P" Trap Is shown for illustration

purposes only. It may not be

required by local codes.

Loading...

Loading...