Page 1

Service

Commercial

Microwave

Oven

This manual replaces RE220002 Rev . 5.

This manual is to be used by qualified appliance

technicians only. Amana does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

Models and manufacturing

numbers in this manual are

located below and on page 4.

A1200S P4020008302

A1225S P1185701M

FS10EVP P4020003901

FS10EVP.000

FS10EVP.A

FS10EVP.B

FS10EVP.C

FS10EVP.D

FS10EVP.E

FS10EVP.F

FS11 P1302104M

FS11EVP P1186001M

FS14EVP P4020004901

FS14EVP.000

FS14EVP.A

FS14EVP.B

FS14EVP.C

FS14EVP.D

FS14EVP.E

FS14EVP.F

FS16EVP P1185901M

FS17 P1302105M

FS17EVP P1185902M

FS20 P1302106M

FS20EVP P1185903M

FSP10 P4020004102

FSP10.A

FSP10.B

FSP10.C

FSP10.D

FSP10.E

FSP10SS P4020004103

FSP11 P1185802M

FSP11 P1302102M

FSP11LW P1302103M

FSP11LW P1185805M

FSP11SS P1185803M

VEND10 P4020004101

VEND10.000

VEND10.A

VEND10.B

VEND10.C

VEND10.F

VEND10.G

VEND10.H

VEND10.J

VEND10.K

VEND10.L

VEND11 P1185801M

VEND11B P1185804M

VEND11 P1302101M

RE220002

Revison 6

March 1999

Page 2

!

!

!

Important Product Information

WA R N ING

Precautions to be observed before and during

servicing to avoid possible exposure to excessive

microwave energy .

(A) Do not operate or allow oven to be operated with

the door open.

(B) Make the following safety checks on all ovens to be

serviced before activating the magnetron or other

microwave source, and make repairs as

necessary:

• Interlock operation

• Proper door closing

• Seal and sealing surfaces (arcing, wear, and other

damage)

• Damage to or loosening of hinges and latches

• Evidence of dropping or abuse

(C) Before turning on microwave power for any service

test or inspection within the microwave generating

compartments, check the magnetron, wave guide

or transmission line, and cavity for proper

alignment, integrity , and connections.

(D) Any defective or misadjusted components in the

interlock, monitor, door seal, and microwave

generation and transmission systems shall be

repaired, replaced, or adjusted by procedures

described in this manual before oven is released to

the consumer.

(E) Check microwave leakage to verify compliance

with the Federal Performance Standard should be

performed on each oven prior to release to the

consumer.

WARNING

To avoid risk of electrical shock, injury, or death, make

sure these grounding instructions are followed.

Grounding Instructions

WA RN IN G

Do not remove grounding prong when installing

grounded appliance in a home or business that does

not have three wire grounding receptacle, under no

condition is grounding prong to be cut off or removed.

It is the personal responsibility of the consumer to

contact a qualified electrician and have properly

grounded three prong wall receptacle installed in

accordance with appropriate electrical codes

Should a two prong adapter plug be required temporarily it

is the personal responsibility of the consumer to have it

replaced with properly grounded three prong receptacle or

the two prong adapter properly grounded by a qualified

electrician in accordance with appropriate electrical codes.

Servicing of Grounded Products

The standard accepted color coding for grounding wires is

GREEN or GREEN WITH YELLOW STRIPE. These

ground leads are NOT to be used as current carrying

conductors. It is extremely important that the technician

replace any and all grounds prior to completion of the

service call. Under no condition should ground wire be left

off causing a potential hazard to technicians and consumer.

WIRING

Good service practice is to never route wiring over terminals and/or sharp edges. This applies to any wiring without

regard to the circuit voltage. Wire insulation material and

thickness is designed and regulated for electrical spacing

purpose only, but cannot always be relied upon because of

possible cuts and/or abrasions, which can occur during

servicing.

RE220002 Rev. 6 2

Page 3

Table of Contents

IMPORTANT PRODUCT INFORMATION........................................................................................................ 2

MODEL AND MANUFACTURING NUMBERS.................................................................................................4

IMPORTANT SAFETY INFORMATION ........................................................................................................... 6

IMPORTANT PRODUCT GROUNDING AND OUTLET INFORMATION ................................................... 7

SPECIFICATIONS............................................................................................................................................ 9

CAUTIONS AND WARNINGS to be Observed During Disassembly and Troubleshooting ............................. 10

GENERAL INFORMATION AND OPERATING INSTRUCTIONS.................................................................... 11

TEST PROCEDURES......................................................................................................................................13

DISASSEMBLY PROCEDURES......................................................................................................... .............21

SERVICE INFORMATION................................................................................................................................28

PROCEDURE FOR MEASURING MICROWAVE ENERGY LEAKAGE ..........................................................29

TROUBLESHOOTING .....................................................................................................................................30

VEND-10, 1 1 PROGRAMMING INSTRUCTIONS ...........................................................................................41

FS-10, 1 1, 14, 16 PROGRAMMING INSTRUCTIONS.....................................................................................45

FSP-10, 1 1 PROGRAMMING INSTRUCTIONS ..............................................................................................48

A1200S, A1225S PROGRAMMING INSTRUCTIONS .................................................................................... 50

SCROLLING MESSAGE PROCEDURE ..........................................................................................................55

WIRING SCHEMATIC/DIAGRAM ....................................................................................................................56

REPLACE MANUAL C-SM033 WITH THIS MANUAL, RE220002.

REV. 1—ADDED MODEL FSP10SS, P4020004103 TO MANUAL. THIS MODEL IS SIMILAR TO MODEL

FSP10, P4020004102.

REV. 2—ADDED MODEL FSP11SS, P1185803M TO MANUAL. THIS MODEL IS SIMILAR TO MODEL

FSP1 1, P1 185802M.

REV. 3—ADDED MODEL VEND1 1B, P1185804M, P1302101M; FSP1 1SS, P1302102M; FSP11L W, P1302103M;

FSP11EVP, P1302104M; FS17EVP, P1302105M; AND FS20EVP, P1302106M T O MANUAL.

REV.4—ADDED MODELS FS17EVP, P1185902M; AND FS20EVP, P1185903M TO THIS MANUAL.

REV. 5—CORRECTED MODEL INDENTIFICATION FS17EVP T O FS17; FS20EVP TO FS20; FSP11EVP TO

FSP11; FS11SS TO FS11; AND VEND11B TO VEND 11 ALONG WITH ASSOCIATED TEXT. ADDED

FSP11L W , P1 185805M.

REV. 6—CORRECTED MODELS ASSIGNED TO WIRING DIAGRAM, AND ADDED NEW CONTROLLER

TESTING PROCEDURE.

3 RE220002 Rev. 6

Page 4

Models and Manufacturing Numbers

NOTE: For easier identification, the MODEL numbers are in alpha numerical order.

MODEL M/N

A1200S P4020008302

A1225S P1185701M

FS10EVP P4020003901

FS10EVP.000

FS10EVP.A

FS10EVP.B

FS10EVP.C

FS10EVP.D

FS10EVP.E

FS10EVP.F

FS11 P1302104M

FS11EVP P1186001M

MODEL M/N

FS14EVP P4020004901

FS14EVP.000

FS14EVP.A

FS14EVP.B

FS14EVP.C

FS14EVP.D

FS14EVP.E

FS14EVP.F

FS16EVP P1185901M

FS17 P1302105M

FS17EVP P1185902M

FS20 P1302106M

FS20EVP P1185903M

FSP10 P4020004102

FSP10.A

FSP10.B

FSP10.C

FSP10.D

FSP10.E

FSP10SS P4020004103

FSP11 P1185802M

FSP11LW P1185805M

FSP11LW P1302103M

FSP11SS P1185803M

MODEL M/N

VEND10 P4020004101

VEND10.000

VEND10.A

VEND10.B

VEND10.C

VEND10.F

VEND10.G

VEND10.H

VEND10.J

VEND10.K

VEND10.L

VEND11 P1185801M

VEND11B P1185804M

VEND11 P1302101M

RE220002 Rev. 6 4

Page 5

Important Information

!

!

!

!

!

Pride and workmanship go into every product to provide our customers with quality products. It is possible,

however, that during its lifetime a product may require service. Products should be serviced only by a qualified

service technician who is familiar with the safety procedures required in the repair and who is equipped with the

proper tools, parts, testing instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION

IN THE APPROPRIATE SERVICE MANUAL BEFORE BEGINNING REPAIRS.

Important Notices for Consumers and Servicers

WARNING

To avoid risk of serious injury or death, repairs should not be attempted by an unauthorized personal, dangerous

conditions (such as exposure to electrical shock) may result.

CAUTION

Amana will not be responsible for any injury or property damage from improper service procedures. If performing

service on your own product, assume responsibility for any personal injury or property damage which may result.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, contact 1 (800) 628-5782 first, if no answer contact the following number.

CONSUMER AFFAIRS DEPT. OR 1 (800) 843-0304

AMANA CALL

AMANA, IOWA 52204

If outside the United States contact:

AMANA

ATTN: CONSUMER AFFAIRS DEPT

2800 220th Trail

AMANA, IOWA 52204, USA

Telephone: (319) 622-5511

Facsimile: (319) 622-2180

TELEX: 4330076 AMANA

CABLE: "AMANA", AMANA, IOWA, USA

Recognize Safety Symbols, Words, and Labels

DANGER

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WA RN IN G

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury or product or property

damage.

5 RE220002 Rev. 6

Page 6

!

Important Safety Information

CAUTION

Do not become exposed to radiation from the

microwave generator or other parts conducting

microwave energy .

Basic design of this microwave oven makes it an

inherently safe device to both use and service. However,

there are some precautions which should be followed

when servicing microwave oven to maintain this safety .

These are as follows:

1. Always operate unit from an adequately grounded

outlet. Do not operate on a two-wire extension cord.

2. Before servicing unit (if unit is operable) perform

microwave leakage test.

3. Oven should never be operated if door does not fit

properly against seal, hinge/hinge bearings are

damaged or broken; choke is damaged, (pieces

missing, etc.); or any other visible damage can be

noted. Check choke area to ensure that this area is

clean and free of all foreign matter . If any above

problems occur take the following steps:

• Tell the user not to operate the oven.

• Contact Amana immediately .

4. If oven operates with door open and produces

microwave energy , take the following steps:

• Tell the user not to operate the oven.

• Contact Amana immediately .

5. Always have oven disconnected when outer case is

removed except when making "live" tests called for in

the service manual. Do not reach into equipment

area while unit is energized. Make all connections for

the test and check them for tightness before plugging

cord into outlet.

6. Always ground capacitors on magnetron filter box

and H.V . capacitor with an insulated-handle

screwdriver before working in high voltage area of

equipment compartment. Some types of failures will

leave a charge in capacitors and the discharge could

cause a reflex action which could make you injure

yourself.

7. In the area of the transformer, capacitor , diode, and

magnetron there is HIGH VOLTAGE. When unit is

operating, keep area clean and free of anything

which could possibly cause an arc or ground, etc.

8. DO NOT for any reason defeat interlock switches,

there is no valid reason for this action at any time; nor

will it be condoned by Amana.

9. Microwave oven should never be operated with:

• Any components removed and/or bypassed

• Any of the safety interlocks are found to be defective

• Any of the seal surfaces are defective, missing, or

damaged

10.To ensure that unit does not emit excessive

microwave leakage and to meet Department of

Health and Human Services guidelines check oven

for microwave leakage using Narda Model 8100,

8200, Holaday HI1500, HI1501, or Simpson 380M

leakage monitor as outlined in instructions. Maximum

leakage level allowed is 4mw/cm2 .

11.If servicer encounters an emission reading over 4mw/

cm2, servicer is to cease repair and contact Amana

Service Department immediately for further direction.

Amana will contact the proper Government Agency

upon verification of test results.

12.Install or locate this equipment ONLY in accordance

with the installation instructions in this manual.

13.Some products such as whole eggs and sealed

containers – for example, closed glass jars – may

explode and SHOULD NOT be HEA TED in this

equipment.

14.Use this equipment ONL Y for its intended use as

described in this manual. Do not use corrosive

chemicals or vapors in this equipment. This type of

equipment is specifically designed to heat or cook. It

is not designed for industrial or laboratory use.

15.As with any equipment, CLOSE SUPERVISION is

necessary when used by CHILDREN.

16.DO NOT operate this equipment if it has a damaged

cord or plug, if it is not working properly , or if it has

been damaged or dropped.

17.This equipment, including power cord, must be

serviced ONLY by qualified service personnel.

Special tools are required to service equipment.

Contact nearest authorized service facility for

examination, repair , or adjustment.

18.DO NOT cover or block any openings on the

equipment.

19.DO NOT store this equipment outdoors. DO NOT

use this product near water – for example, near a

kitchen sink, in a wet basement, or near a swimming

pool, and the like.

20.DO NOT immerse cord or plug in water.

21.Keep cord AWAY from HEATED surfaces.

22.DO NOT let cord hang over edge of table or counter.

RE220002 Rev. 6 6

Page 7

Important Product Grounding and Outlet Information

Typical grounding

type wall receptacle

Typical power supply

cord with 3-prong

grounding plug

Typical type wall receptacle

Typical power supply

cord with 3-prong

grounding plug

Temporary grounding adapter

(NOT used in Canada)

NOTE: 120 V olt, 15 A. Cord and Receptacle shown.

Typical instructions also apply to 120 V, 20 AMP, and

208/240 V cords and receptacles.

Proper grounding and polarization of 120 V wall outlets.

Explanations

Polarization—This means that the larger slot must be

neutral and the small slot must be hot (live).

Mispolarized—The outlet is miswired so that the larger

slot is hot (live) and the smaller slot is neutral.

Grounded—This means the round hole connection is

connected to earth ground through a connection to the

main power panel.

Ungrounded—The round hole connection is not

complete to earth ground and/or the main power panel.

FIGURE 1

For the safety of our customers and the service

technician ALL appliances having a three (3) prong

power cord MUST be connected to a properly polarized

AND grounded wall outlet.

This information was written for those who do not

understand grounding and polarization of a wall outlet.

A 120 Volt wall outlet must always be wired as shown in

Figure 1.

7 RE220002 Rev. 6

Page 8

Important Product Grounding and Outlet Information

!

Test Procedures (2 Methods)

Method 1

Purchase and use a ground monitor (Figure 2, Page 8)

available under Amana Part Number R0193001 or it can

be purchased locally . The lamps inside the monitor

indicates a correctly or incorrectly wired outlet by

instructions imprinted on the monitor body .

Method 2

Voltmeter - (Use scale over 125 Volts A.C.)

Test A - "H" to "N" must indicate line voltage.

Test B - "H" to "G" must indicate line voltage.

Test C - "N" to "G" must indicate zero (0) volts.

If "N" to "G" indicates line voltage the outlet is

mispolarized.

If "H" to "G" indicates zero (0) volts the outlet is not

grounded.

FIGURE 2

WARNING

Wiring changes or grounding of wall outlet are to be

made only by a qualified electrician.

In the event a grounding adaptor (not used in Canada)

has been TEMPORARILY installed the test procedures

described in Methods 1 and 2 above should be used

(Figure 3).

FIGURE 3

NOTE: The green wire or tab should be connected to a

proper ground by a qualified electrician.

General Test Information

Most testing in the manual is conducted with an

ohmmeter using a multiplier scale of X10k (k-thousand

ohms). When using this scale, it is important that your

fingers do not touch the metal parts of the test probes.

To do so will give a false indicate of the ohm reading.

RE220002 Rev. 6 8

Page 9

Specifications

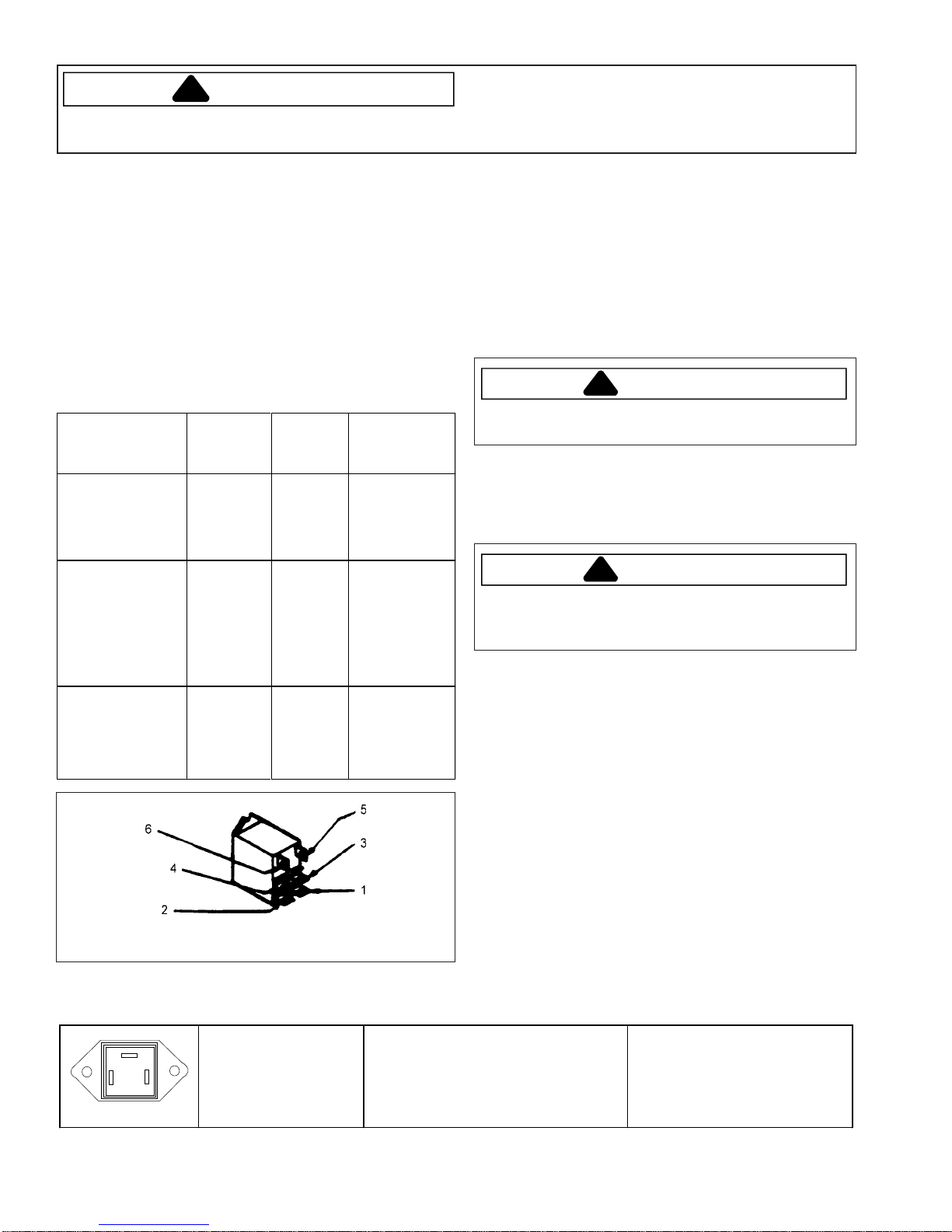

Models

Power Source

Voltage AC

Amperage

(Single Unit)

Frequency

Single Phase

(3 Wire Earthed)

Power Output

Standard Test

IEC 705 Test

Operating Frequen cy

Power Consumption

Standby Condition

Idle Condition

Cook Condition

Dimemsions

Cabinet

Width

Height

Depth

Cooking Cabinet

Capacity

Width

Height

Depth

Power Cord

NEMA

A1200S A1225S FS10EVP

120 120 120 120 208/240 208/240 208/230 208/230 120 120

20 20 20 20 20 20 20 20 20 20

60 Hz 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz

Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

1100 W 1100 W 1100 W 1100 W 1400 W 1500 W 1600 W 1900 W 1100 W 1100 W

1200 W 1200 W 1200 W 1200 W 1500 W 1600 W 1700 W 2000 W 1200 W 1200 W

2450 MHz 2450 MHz 2450 MHz 2450 MHz 2450 MHz 2450 MHz 2450 MHz 2450 MHz 2450 MHz 2450 MHz

0000000000

200 W 200 W 200 W 200 W 300 W 300 W 300 W 300 W 200 W 200 W

2100 W 2100 W 2100 W 2100 W 2800 W 2800 W 2800 W 2800 W 2100 W 2100 W

20.5”

52.1cm

14.9”

37.8cm

21”

53.34cm

.75 cu ft

.02 cu m

12.8”

32.5cm

7.8”

19.8cm

13”

33cm

5-20R 5-20R 5-20R 5-20R 6-20R 6-20R 6-20R 6-20R 5-20R 5-20R

20.5”

52.1cm

14.9”

37.8cm

21”

53.34cm

.75 cu ft

.02 cu m

12.8”

32.5cm

7.8”

19.8cm

13”

33cm

FSP10

FSP11

20.5”

52.1cm

14.9”

37.8cm

21”

53.34cm

.75 cu ft

.02 cu m

12.8”

32.5cm

7.8”

19.8cm

13”

33cm

FS11

FS11EVP

20.5”

52.1cm

14.9”

37.8cm

21”

53.34cm

.75 cu ft

.02 cu m

12.8”

32.5cm

7.8”

19.8cm

13”

33cm

FS14EVP FS16EVP FS17

20.5”

52.1cm

14.9”

37.8cm

21”

53.34cm

.75 cu ft

.02 cu m

12.8”

32.5cm

7.8”

19.8cm

13”

33cm

20.5”

52.1cm

14.9”

37.8cm

53.34cm

.75 cu ft

.02 cu m

12.8”

32.5cm

19.8cm

33cm

21”

7.8”

13”

FS17EVP

20.5”

52.1cm

14.9”

37.8cm

21”

53.34cm

.75 cu ft

.02 cu m

12.8”

32.5cm

7.8”

19.8cm

13”

33cm

FS20

FS20EVP

20.5”

52.1cm

14.9”

37.8cm

21”

53.34cm

.75 cu ft

.02 cu m

12.8”

32.5cm

7.8”

19.8cm

13”

33cm

VEND10 VEND11

20.5”

52.1cm

14.9”

37.8cm

21”

53.34cm

.75 cu ft

.02 cu m

12.8”

32.5cm

7.8”

19.8cm

13”

33cm

20.5”

52.1cm

14.9”

37.8cm

21”

53.34cm

.75 cu ft

.02 cu m

12.8”

32.5cm

7.8”

19.8cm

13”

33cm

Adjust tap connector to either 208 or 230/240 volt source on the following models:

FS14EVP

FS16EVP

FS17

FS17EVP

FS20

FS20EVP

9 RE220002 Rev. 6

Page 10

CAUTIONS and WARNINGS to be Observed During

!

!

!

!

!

!

Disassembly and Troubleshooting

Unlike many other appliances, the microwave oven is

high-voltage, high-current equipment. Though it is free

from danger in ordinary use, extreme care should be

taken during repair .

CAUTION

Servicemen should remove their watches whenever

working close to or replacing the magnetron.

Checking the ground

Do not operate on a 2-wire extension cord. The

microwave oven is designed to be used when grounded,

it is imperative, therefore, to make sure it is grounded

properly before beginning repair work.

WARNING

After the oven is turned off, an electric charge may

remain in the high voltage capacitor . When replacing

or checking parts, remove the power plug from the

outlet and short the terminal of the high voltage

capacitor (terminal of lead wire from diode) to chassis

ground with an insulated handle screwdriver and

discharge.

DANGER

There is high voltage present, with high current

capabilities in the circuits of the high voltage winding

and filament winding of the high voltage transformer . It

is extremely dangerous to work on or near these

circuits with the oven energized. Do not measure the

voltage in the high voltage circuit including filament

voltage of the magnetron.

When parts must be replaced, remove the power cord

from the outlet.

WARNING

When the fuse is blown due to the operation of the

monitor switch, replacement of complete interlock

switch must be performed.

1. This is mandatory. Refer to page 29 for the

necessary adjustments for this switch assembly .

2. When replacing the fuse, confirm that it has the

appropriate rating for these models.

CAUTION

Avoid inserting nails, wire, etc. through and holes in

the unit during operation.

Never insert a wire, nail, or any other metal object

through the lamp holes on the cavity or any other holes

or gaps because such object may work as an antenna

and cause microwave leakage.

Confirm After Repair

1. After repair or replacement of parts, make sure that

the screws of the oven, etc. are neither loose nor

missing.

2. Make sure that all electrical connections are tight

before inserting the plug into the wall outlet.

3. Check for microwave leakage. (Refer to procedure

for measuring microwave leakage.)

WARNING

Never touch any circuit with your hand nor with an

insulated tool during operation.

RE220002 Rev. 6 10

Page 11

General Information and Operating Instructions

!

!

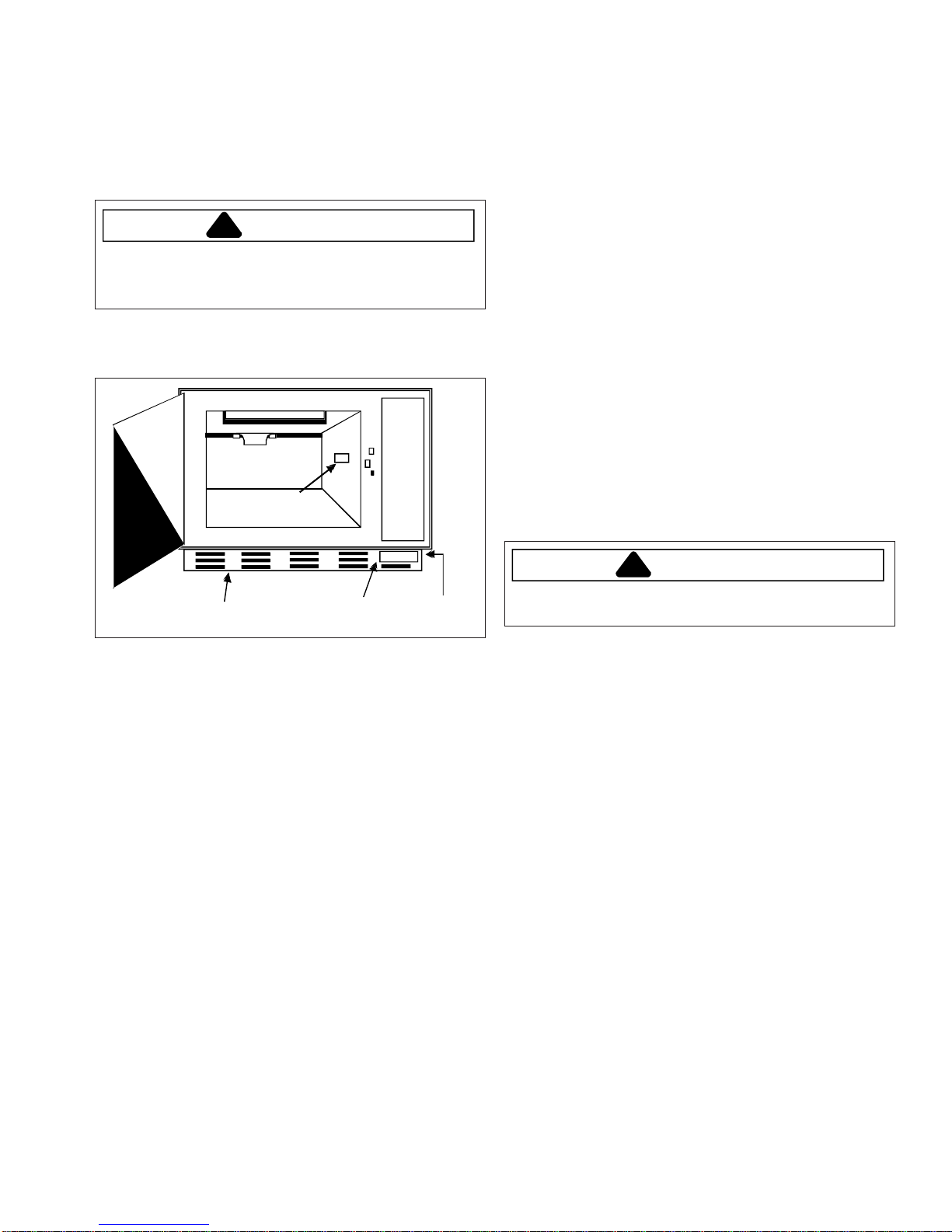

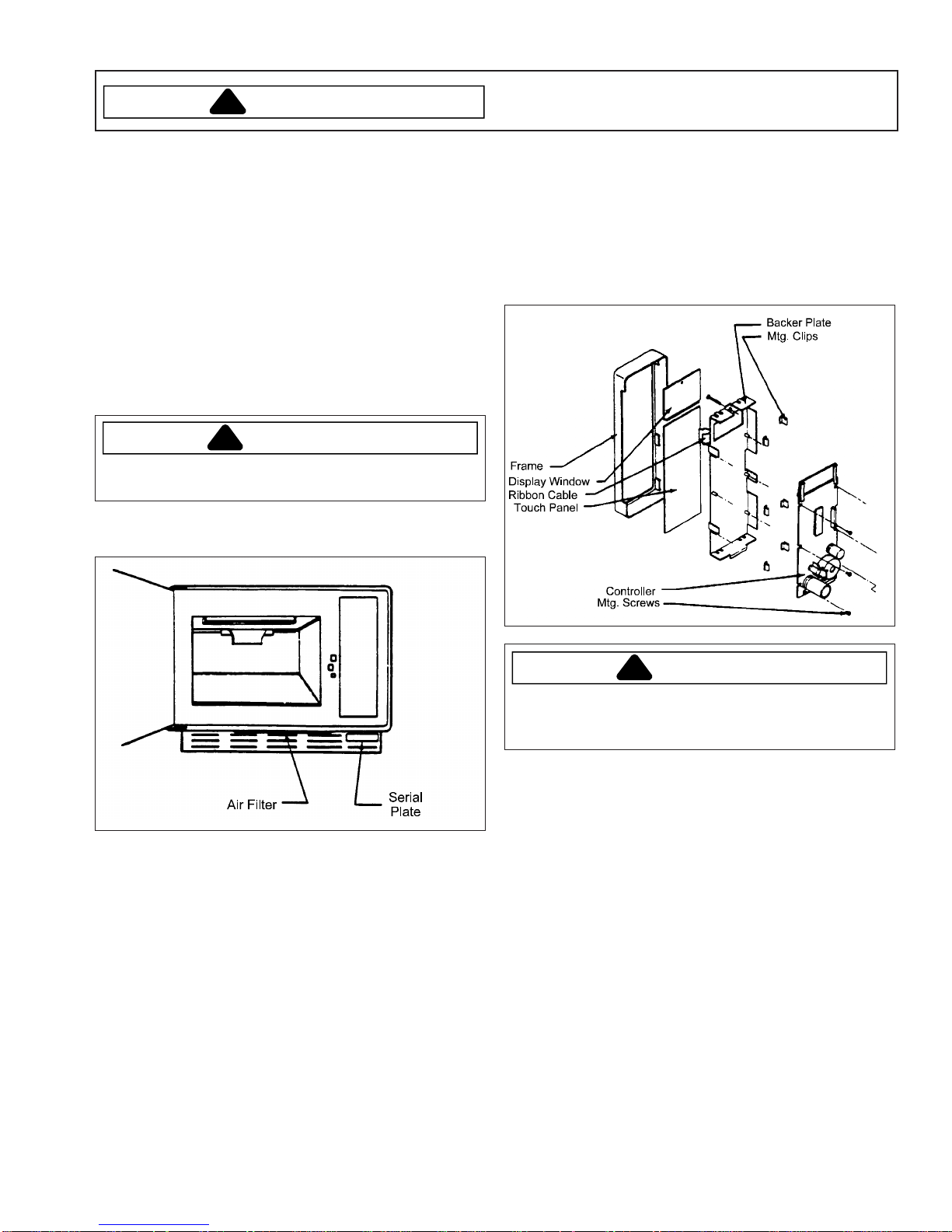

Service Access

Component servicing is done by lowering the back panel,

removing the control panel assembly , and component

module panel. Refer to the disassembly section for

specific components replacement and adjustment

procedures.

WARNING

All component mounting panels must be grounded to

the oven chassis before performing any

troubleshooting.

Serial Plate Location

Some models

5. The FS14EVP , FS16EVP, FS17, FS17EVP, FS20,

FS20EVP oven must be adjusted to the proper supply

voltage. This oven is manufactured preset for 240

volts. If the supply voltage is less than 220 volts,

remove the small cover on the back of the oven and

move the voltage adjusting connector to the 208 volt

tap connector. Incorrect tap setting can cause

component damage.

6. Plug the FS10 EVP, FSP10, FSP11, FSP11SS and

VEND10 oven into a standard 120 volt outlet. Plug the

FS14 EVP, FS16EVP, FS17, FS17EVP, FS20,

FS20EVP into a 208 or 240 volt outlet. Be sure the

electrical outlet is rated for at least 20 amperes and

the microwave oven is the only appliance on the

circuit.

Important Electrical Grounding Instructions

This appliance must be grounded. In the event of an

electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric

current. This appliance is equipped with a cord having a

grounding wire with a grounding plug. The plug must be

plugged into an outlet that is properly installed and

grounded.

Filter

Some models

Installation Instructions

1. Unpack the oven carefully and examine it for shipping

damage. If damage is evident, notify the local carrier

immediately and file a damage claim. Menumaster

assumes no liability for damage incurred in transit.

2. If the oven has been stored in an extremely cold area,

wait several hours before plugging the oven into an

outlet.

3. Remove all material from the oven interior.

4. Place the oven in the chosen location. Make sure

there is at least one inch of clearance on the top and

side and the air intake (filter) is not close to a high

temperature source. Example: A deep fat fryer.

WARNING

Improper use of the grounding plug can result in a risk

of electric shock.

Consult a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if

doubt exists as to whether the appliance is properly

grounded.

If it is necessary to use an extension cord, use only a

three-wire extension cord that has a three-blade grounding

plug, and a three-slot receptacle that will accept the plug

on the appliance. The marked rating of the extension

cord shall be equal to or greater than the electrical rating

of the appliance.

7. Verify correct operation by performing system

diagnosis test.

11 RE220002 Rev. 6

Page 12

General Information and Operating Instructions

Operation of FS10EVP, FS11EVP, FSP10,

FSP10SS, FSP11, FSP11SS, FS14EVP,

FS16EVP and VEND10.C, .F, .G, .H, .J, .K, .L,

VEND10, VEND11, A1200S, A1225S

These models can be operated two ways:

A. Preprogrammed operation.

1. Open oven door , place food on shelf and close door .

2. Push one of the buttons 1-0. The display will

indicate the number of the button in use, the

percentage of power, and the total programmed

time. The time will count down in the display .

NOTE: If "two stage cooking" has been preprogrammed,

it is normal for the % power indicator light to shift

from defrost to another power level during the

heating cycle.

3. When the time expires, an audible tone will sound.

Open oven door and remove food. If no buttons are

pushed after the last heating cycle, the oven will

shut down in 60 seconds.

If the door is not completely latched and a button is

pushed, an audible tone will sound, the colon may flash,

but no number will appear in the display .

T o change programmed items or power levels, see

programming instructions.

If a button is programmed for zero time, on early models

nothing will happen when that button is pushed. On

newer models an audible tone may sound but no numbers

will appear in the display .

B. Change time operation.

NOTE: On early models, this feature may be deactivated

as part of the programming instructions.

1. Open oven door, place food on shelf and close door .

2. Push the change time button.

3. Use button 1 to 0 to enter the desire time.

Example: Time desired is 2:40. Push button 2,

then, 4, then, 0. The display will show 2:40.

4. Push the desired power level button. The heating

cycle will begin, the oven will count down to zero

and an audible tone will sound.

Use of the "change time" feature will not disturb the times

or power levels preset on button 1-0.

Operation of VEND10.A, .B

1. Open oven door, place food on shelf and close door .

2. Push one of button 1-7. The display will indicate the

number of the button in use, "cook" or "defrost", and

the total programmed time. The time will count down

in the display .

NOTE: If "two stage cooking" has been preprogrammed,

it is normal for the % power indicator light to shift

from defrost to cook during the heating cycle.

3. When the time expires, an audible tone will sound.

Open oven door and remove food. If no buttons are

pushed after the last heating cycle, the oven will shut

down in 60 seconds.

If the door is not completely latched and a button is

pushed, an audible tone will sound, the colon may flash,

but no number will appear in the display .

T o change programmed times or power levels, see

programming instructions.

If a button is programmed for zero time, on early models

nothing will happen when that button is pushed. On

newer models an audible tone may sound but no number

will appear in the display .

Preventive Maintenance

NOTE: Do not use scouring pads, powders or other

abrasive materials on any of the oven surfaces.

Regularly

1. Wipe up all spillage as it occurs.

2. Do not allow food particles or grease to collect on the

plastic stirrer cover and light cover or on the inner door

and oven cavity front surfaces. A build-up of food or

grease in these areas can result in damage to the

surfaces as well as in loss of cooking power.

Daily

1. Wipe the plastic stirrer cover and oven light cover with

a cloth or sponge dampened in a mild detergent

solution.

2. Wipe all surfaces in the oven cavity with the

dampened cloth or sponge and then dry with a clean

cloth.

3. Wipe the inner door surface and oven cavity front with

a mild detergent solution, making sure to remove all

food particles.

Weekly

1. Remove the air intake filter and wash it in hot water to

remove grease and dust that collects and obstructs

the air flow.

2. Check the door assembly for hinge and latch

tightness.

Semi-Annually

1. Perform radio frequency (r.f.) leakage test. Test

anytime r .f. leakage is suspected or maintenance is

performed on door assembly , interlock system, or

magnetron.

2. Verify correct operation by performing System

Diagnosis.

Servicer Perspective

All references to components are as viewed from the rear

of the oven.

RE220002 Rev. 6 12

Page 13

!

Test Procedures

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

DANGER

Before touching any oven components or wiring,

capacitor

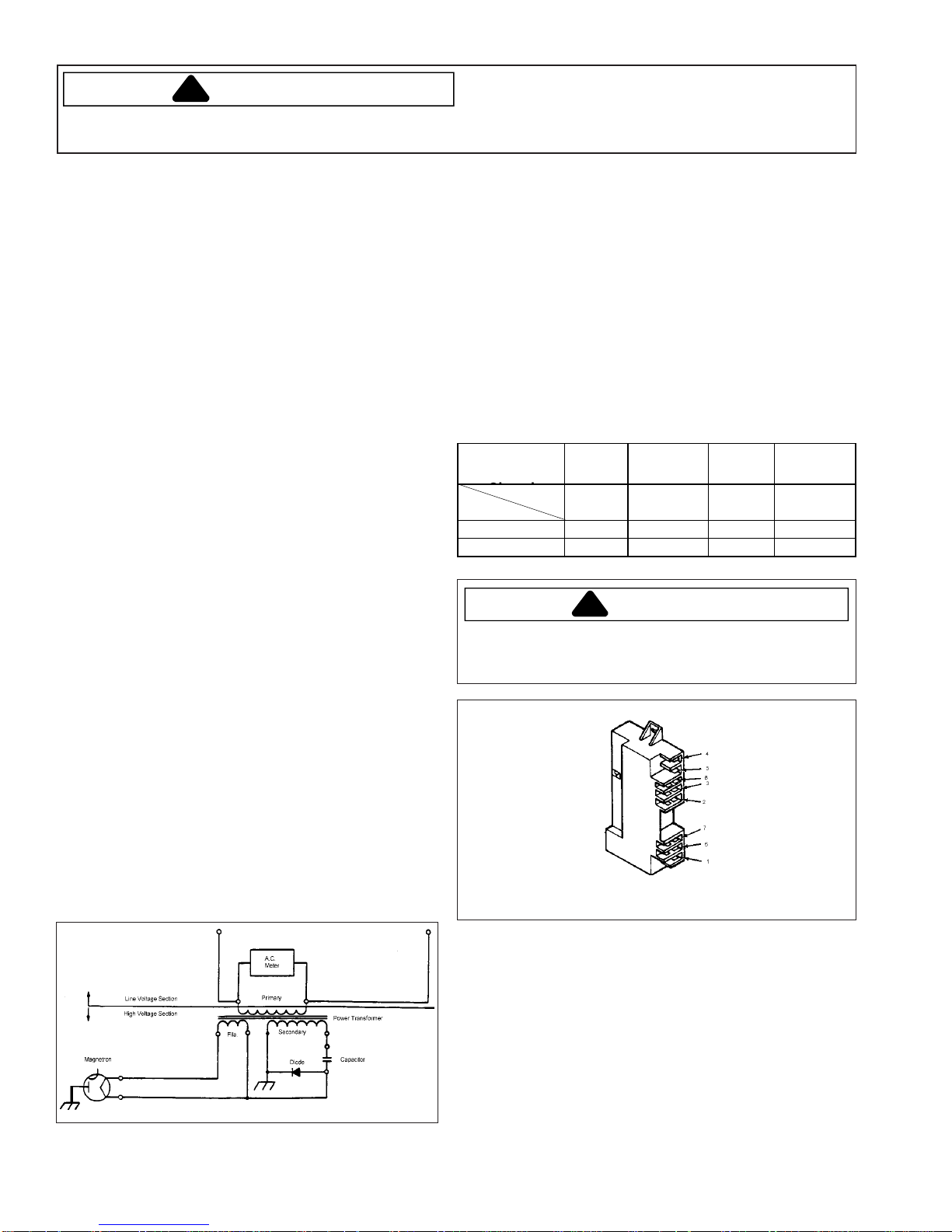

High Voltage Component Test Chart

by shorting across the capacitor terminals with an insulated handle screwdriver.

COMPONENT TEST SET-UP NORMAL READING (Approximate)

CAPACITOR DISCHARGE THE CAPACITOR BETWEEN TERMINALS: Analo

Remove wires from capacitor terminals

and connect ohmmeter, set on hi

resistance scale to terminals.

always

High voltages are present during the cook cycle.

Extreme caution should be observed at all times.

unplug the oven from its power source and

should momentarily deflect toward zero

hest

then return a resistance

ohms. If no deflection occurs, or if

continuous deflection occurs, replace

capacitor.

reater than 5 meg

discharge the

meter

Also check between each terminal and

the capacitor case.

DIODE DISCHARGE THE CAPACITOR Isolate the

TYPE I It is not necessary to remove the mountin

TYPE II

MAGNETRON DISCHARGE THE CAPACITOR BETWEEN TERMINALS :

POWER TRANSFORMER DISCHARGE THE CAPACITOR

diode by disconnectin

type I diodes remove both wires. On type II

diodes disconnect one wire to diode.

screw.

Connect ohmmeter, set on hi

resistance scale, to diode terminals.

Reverse meter leads for second testin

On type I diodes, test from each terminal

to

round.

Remove wires from ma

connect ohmmeter to its terminals.

Also check between each terminal

and

round.

To check primary windin

from terminals (marked 1 & 2 FS-10 EVP,

VEND-10, or COM & 208 OR 240

FS-14 EVP). Connect ohmmeter between

primary terminals.

the wiring. On

hest

netron and

, remove wires

TERMINAL TO CASE: Infinite resistance.

Infinite resistance should be measured in

one direction and 50,000 to 200,000 ohms

in the opposite direction:

NOTE: Ohmmeter must be an analo

and contain a battery of 6 volts minimum.

EACH TERMINAL TO GROUND:

.

(Type I only) Infinite resistance.

Less than 1 ohm.

EACH TERMINAL TO GROUND:

Infinite resistance.

NOTE: This test is not conclusive. If the

oven does not heat and all other

components test

ma

netron and retest.

PRIMARY: Less than 1 ohm

ood replace the

meter

Check from each primary terminal to

Also check hi

wire from either secondary terminal marked

HI or LO terminal and oven chassis

To check filament windin

filament leads 3 & 4 and measure

resistance across leads.

Also check between each terminal

and

h voltage winding, remove

s, remove

round.

round. EACH TERMINAL TO GROUND:

round.

13 RE220002 Rev. 6

Infinite resistance

HI TO GROUND:

40 to 80 ohms DEPENDING ON

LO TO GROUND: TRANSFORMER

40 to 80 ohms MANUFACTOR

FILAMENT:

Less than 1 ohm

FILAMENT TO GROUND:

Infinite resistance.

Page 14

Test Procedures

!

!

DANGER

Before touching any oven components or wiring,

capacitor

by shorting across the capacitor terminals with an insulated handle screwdriver.

always

High voltages are present during the cook cycle.

Extreme caution should be observed at all times.

unplug the oven from its power source and

discharge the

First Isolation Test (FS14, FS16)

Power output of approximately 700 watts indicates one

high voltage section is functioning normally and one

high voltage section is defective. The following

procedures will isolate the defective high voltage

section.

1. Disconnect and isolate the common wire from the

primary of the left power transformer,

2. Perform power output check.

A. If the output power is normal (550 - 750 watts),

go on to step 3.

B. If low or no power is indicated, the problem is in

the right high voltage section. Perform high

voltage component tests on components of right

high voltage section.

3. Reconnect wire to left transformer.

4. Disconnect and isolate the common wire from the

primary of the right power transformer .

5. Perform power output check.

If low or no power is indicated, the problem is in the

left high voltage section. Perform high voltage

component tests on components of left high voltage

section.

Second Isolation Test

Perform the isolation test when little or no heat is

produced by the oven, but all other operations appear

normal. This test isolates the problem to either the high

voltage section or the line voltage section of the oven.

1. Connect a meter capable of measuring 250volts AC

across the primary of one power transformer .

2. Put the oven into a cook cycle and observe the

voltage reading. Measure the voltage across the

primary of the second power transformer .

Procedure A:

(1line voltage AC) proceed to the high voltage tests in

this section.

Procedure B:

problem is in the line voltage portion of the oven.

If the primary voltages are normal,

If low or no voltage is indicated, the

Interlock switch module tests

The interlock switch module is activated by the door and

door latch assembly. All interlock, monitor and door

sensing functions are performed by this module.

1. Unplug the oven power cord, remove the control panel

assembly, and remove the interlock switch module.

2. Disconnect wire leads from the terminals to be tested

and reinstall the interlock switch module.

3. With an ohmmeter, check continuity between terminals

using the test chart below .

4. If improper indications are given, check the door and

latch for proper activation of switches. If door

activation checks OK, replace Interlock Switch

Module.

X Indicates

Contacts

Termi n al s 8 - 3 6 - 7 1 - 6 4 - 5

Func t ion

Door Open X

Door Closed X X X

Primary

Interlock

Secondary

Interlock

Interlock

Monitor

Door Logic

(Sense)

WARNING

For continued protection against radiation hazard,

replace only with manufactures parts catalog numbered

switch.

Interlock Switch Module

RE220002 Rev. 6 14

Page 15

!

Test Procedures

!

DANGER

Before touching any oven components or wiring,

capacitor

by shorting across the capacitor terminals with an insulated handle screwdriver.

always

High voltages are present during the cook cycle.

Extreme caution should be observed at all times.

unplug the oven from its power source and

discharge the

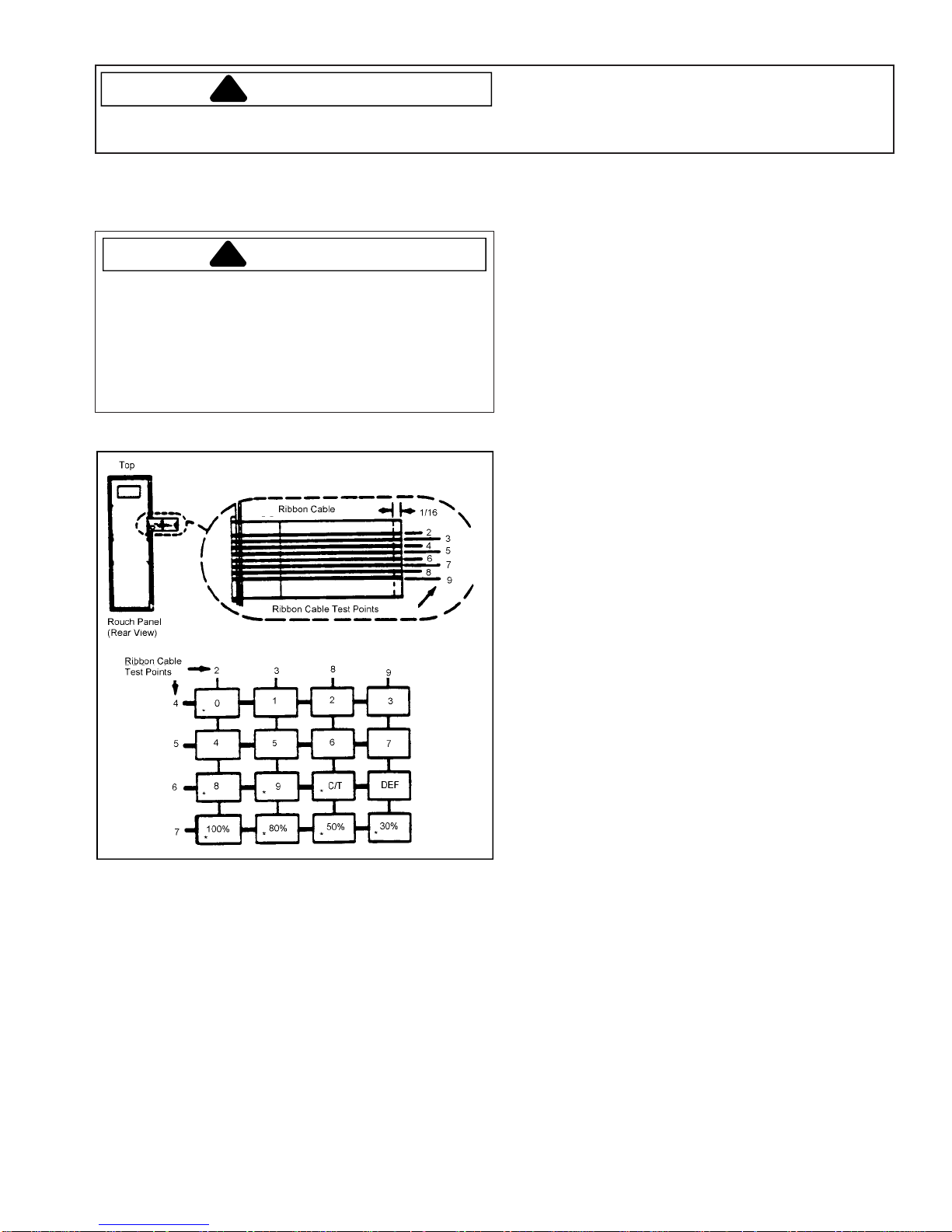

Touch Panel Test

The touch panel operation can be tested with an

ohmmeter on the R x 1 scale.

CAUTION

Over-flexing the ribbon cable will damage the silver

circuit. Pointed test leads cannot be used on ribbon

cable silver circuit or silver circuit will be damaged.

Scratching of the ribbon cable will damage the silver

circuit. Static discharge can damage the controller.

Avoid touching any part of the circuitry on the back of

the controller. Do not bend ribbon cable forward.

1. Unplug the oven power cord and remove the control

panel.

2. Disconnect ribbon cable from circuit board by

applying even pressure to both sides of ribbon cable

and pull outward from ribbon cable connector.

3. Touch ohmmeter test leads to ribbon cable test

points indicated on appropriate test chart.

Resistance should be more than 1 Meg ohms

between ribbon cable test points until a touch panel

pad is depressed. With a touch panel pad

depressed, the resistance between connecting test

points should be less than 100 ohms.

4. If improper indications are given, replace defective

touch panel assembly .

5. Inspect ribbon cable silver circuit; if any silver circuit

is missing from the connector end of the ribbon

cable, evenly trim 1/16" off end of ribbon cable as

shown to assure good electrical connection with

circuit board connector .

6. Apply even pressure to both sides of ribbon cable

while inserting cable into ribbon cable connector.

* These Buttons are not present on VEND-10. VEND10.C has all the

buttons shown except 80%, 50%, and 30% with the 100% button used

as the START button.

15 RE220002 Rev. 6

Page 16

Test Procedures

!

!

DANGER

Before touching any oven components or wiring,

capacitor

by shorting across the capacitor terminals with an insulated handle screwdriver.

always

High voltages are present during the cook cycle.

Extreme caution should be observed at all times.

unplug the oven from its power source and

discharge the

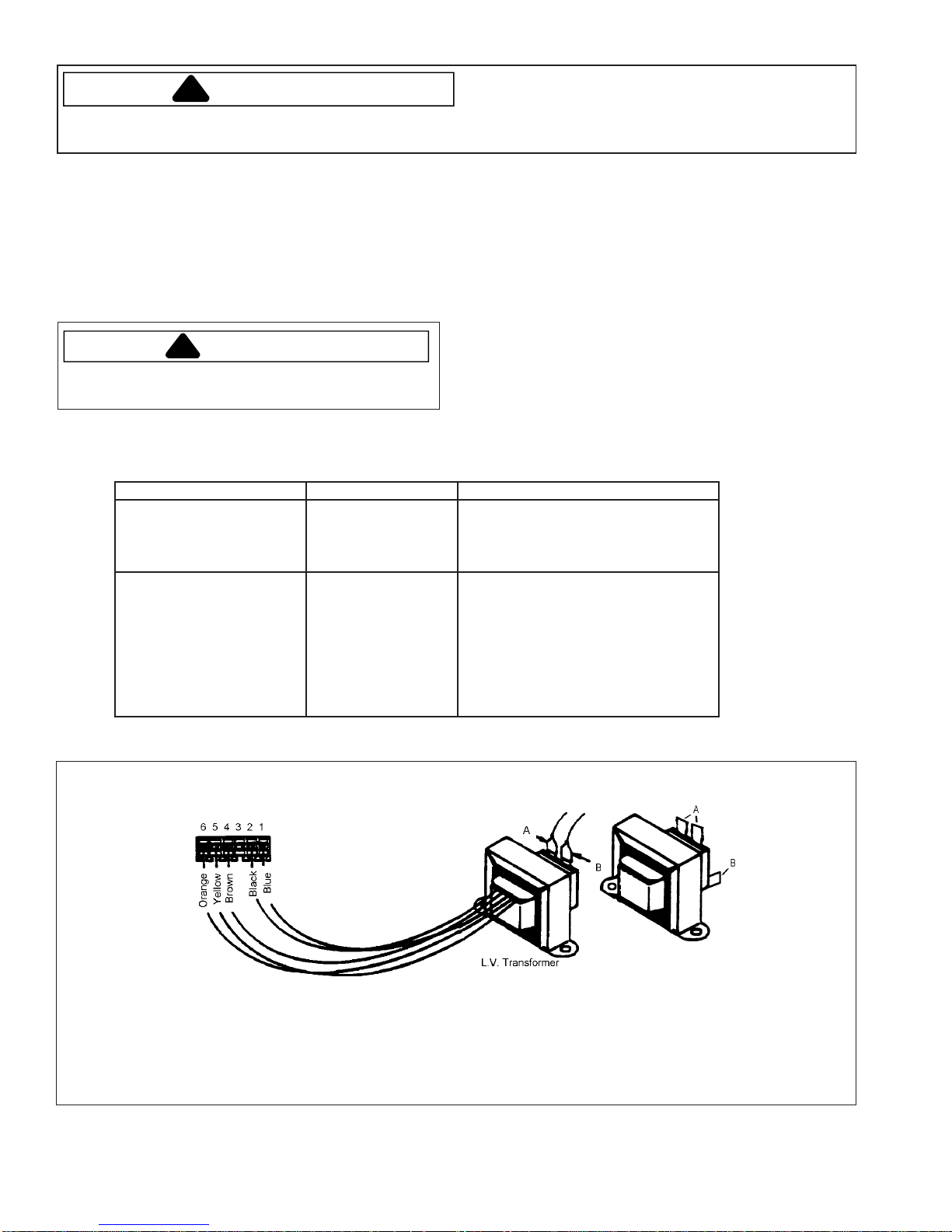

Low Voltage (Controller) Transformer Test

An operational test can be performed to verify proper

operation of the low voltage transformer .

1. Disconnect power to the oven and remove the

control panel assembly .

2. With a voltmeter set to appropriate VAC scale,

perform the following test set-ups, measure and

record the voltage indicated on the meter .

WARNING

Do not touch any oven components or wiring during

oven operation.

TEST SET-UPS TEST POINTS NORMAL VOLTAGE (Approximate)

Attach meter leads to wire harness

test points A - B, apply power to

oven and open oven door.

Disconnect power and remove L.V.

transformer connector attached to

the control circuit board and attach

meter leads into harness side of

connector at test points shown in

chart. Apply power to oven and

open oven door.

A & B

2 (Blue) - 4 (Brown

1 (Black) - 6 (Orange)

5 (Yellow) - 6 (Orange)

Procedure A:

If the proper AC voltages were measured

as shown on the test chart, the low voltage transformer

operation is normal.

Procedure B:

If abnormal reading was measured at test

points 2-4, 1-6, 5-6, as indicated on the test chart but

normal voltage was measured at test points A-B, replace

low voltage transformer. If no voltage was measured at

test points A-B, check wire connections and circuit

diagnosis for other possible causes.

120 VAC on all models except

FS14.EVP.00, FS14EVP.A,

and FS14EVP.B which

is 208 - 230 VAC.

2.6 VAC 23 VAC 46 VAC

FSP-11, VEND10, VEND11

RE220002 Rev. 6 16

A1200S, A1225S, FSP10,

FS14EVP,

FS16EVP

Page 17

!

Test Procedures

DANGER

Before touching any oven components or wiring,

capacitor

by shorting across the capacitor terminals with an insulated handle screwdriver.

Drive and Holding Relay Test

Drive relay is on .000 and .A models only

1. Disconnect power to oven, and remove but do not

disconnect the control panel assembly. Lower the

back panel to the service position.

2. Perform test set-ups as indicated on the Test Chart

below.

NOTE: Test "Drive" or "Holding" relays one at a time.

Do not disconnect both relays at the same

time.

NOTE: If necessary, remove the component module

panel assembly to connect test leads. Replace

the module assembly prior to performing all

tests except the first two resistance checks.

always

High voltages are present during the cook cycle.

Extreme caution should be observed at all times.

unplug the oven from its power source and

Drive/Holding Relay

discharge the

TEST SET-UP TEST POINTS

1.2.Disconnect power.

Remove harness leads from

relay terminals 1 & 6

1.2.Reconnect harness leads to

terminals 1 & 6.

Remove harness leads from

terminals 2 & 3, and insulate

to prevent electrical short.

1.2.Reconnect power.

Program oven for 15 seconds

and put oven into a COOK

cycle.

1. DRIVE RELAY

Program oven for 15 seconds

and put oven into a COOK

cycle.

NORMAL READINGS

(Approximate)

1 to 6 250 to 350 ohm Replace the relay and retest

2 to 3 Infinite ohms Replace relay and retest

1 to 6 22 Volts DC Replace the controller and

2 to 3 Less than 1 ohm

during cook and for 60

seconds after cook

cycle, then infinite

ohms.

CORRECTIVE ACTION

retest

Replace the relay and retest.

1. HOLDING RELAY

Plug in oven

2 to 3

Less than 1 ohm for

60 seconds, then

inifinte ohms.

17 RE220002 Rev. 6

Replace the relay and retest

Page 18

Test Procedures

!

!

!

DANGER

Before touching any oven components or wiring,

capacitor

by shorting across the capacitor terminals with an insulated handle screwdriver.

always

High voltages are present during the cook cycle.

Extreme caution should be observed at all times.

unplug the oven from its power source and

discharge the

Holding Relay Test Models

VEND-10 .F, .G, .H, .J, VEND-10, and VEND-11

1. Disconnect power to oven, and remove but do not

disconnect the control panel assembly. Lower the

back panel to the service position.

2. Perform test set-ups as indicated on the Test Chart

below.

NOTE: If necessary, remove the component module

panel assembly to connect test leads. Replace

the module assembly prior to performing all tests

except the first two resistance checks.

TEST SET-UP TERMINAL

TEST

POINT

Di sconnect power.

Remove harness

leads from relay

terminals 5 & 6.

Reconnect harness

leads to terminals 5

& 6. Remove

harness leads from

terminals 1 &3, and

insulate to prevent

electrical short.

Reconnect power.

Program oven for

15 se conds and put

oven into a COOK

cycle.

5 to 6 250 to 350

1 to 3 Infinite

5 to 6 22 VoltsDCReplace the

Holding Relay

NORMAL

READING

ohms

ohms

CORRECTIVE

ACTION

Replace the

relay and

retest.

Replace relay

and retest.

controller and

retest

Triac Module Test

1. Unplug the oven power cord, lower the back panel

and

discharge the capacitor(s).

On FS14, remove

the left magnetron inlet duct.

2.

COMPLETEL Y REMOVE THE HIGH VOLTAGE

LEAD

that connects the capacitor to the transformer

high voltage terminal (marked "HI" or "LO"). On the

FS14EVP also remove the lead between the second

capacitor and high voltage transformer terminal

(marked "HI" or "LO").

WARNING

High voltages are present at the high voltage

secondary terminals during a cook cycle.

3. With a voltmeter capable of measuring 250 VAC,

attach the meter leads to triac terminal MT1 (WHT)

and MT2 (RED). NOTE: Triac harness leads

remain connected.

WARNING

Do not touch any oven components or wiring during

oven operation. Attach meter leads with alligator

clips when making operational tests.

4. Perform the following test; measure and record the

voltage indicated on the meter .

T est Set Up

Set the VEND10 oven to operate on defrost for

one minute. Set the FS10 or FS14 oven to

operate at 50% power level for one minute.

Normal Output Voltage

On VEND10 and FS10 ovens voltage alternates

from 120 V AC to less than 5 VAC. On FS14

ovens alternates from 208/240 volts to less than

5 V AC. FS10 and FS14 alternates approximately

every 6 seconds, VEND10 alternation will vary .

Corrective Action—If abnormal output voltage is

measured.

If controller tests check okay , replace the triac

module and retest.

Triac

MT2

MT1 GATE

This triac is used in

models w ith P130210_M

series

RE220002 Rev. 6 18

Disconnect wires to triac.

Measure re sistance from:

MT1 to MT2

MT1 to Gate

MT2 to Gate

All terminals to ground

Caution - Do not operate oven with

wire to terminal MT2 removed.

Infinite

Approximately 40

Infinite

Infinite

Ω

or more

Page 19

!

Test Procedures

DANGER

Before touching any oven components or wiring,

capacitor

by shorting across the capacitor terminals with an insulated handle screwdriver.

always

High voltages are present during the cook cycle.

Extreme caution should be observed at all times.

unplug the oven from its power source and

discharge the

Controller Triac Drive Test

NOTE: This test is provided for reference only . The

controller self diagnosis test is normally all that

is required to verify normal controller operation.

1. Unplug the oven power cord, lower the back panel

and

discharge the capacitor(s)

remove the left magnetron inlet duct.

2. Connect voltmeter to triac module terminals marked

GRN and BLU.

3. Apply power to the oven and put the oven into a

cook cycle on full (100%) power setting. The meter

should indicate 1 to 6 volts AC during the cook cycle

and zero volts after completion of the cook cycle.

If abnormal readings were measured, replace the controller and retest.

. On some models,

Cook Relay Test

Models VEND -10.000, .A, .B, .C

1. Unplug the oven power cord and remove the control

panel assembly .

2. Disconnect wiring from cook relay terminals.

3. Connect ohmmeter across cook relay terminals A

and B.

4. Meter should indicate approximately 900 ohms.

Procedure A:

ohms, go on to Step 5.

Procedure B:

replace the cook relay and retest.

5. Connect ohmmeter across relay terminals 11 and

12 as shown below .

6. Press and hold test button on cook relay.

Meter should indicate continuity , (0 ohms). If not,

the cook relay is defective.

If meter indicates approximately 900

If improper indications are given,

7. Release test button.

Meter should indicate infinity . If not, the cook relay is

defective.

8. Connect ohmmeter across relay terminals 13 and 14.

9. Repeat steps 6 and 7.

Cook Relay

Stirrer Motor Test

1. Unplug the oven power cord, lower the back panel,

and

discharge the capacitor(s).

remove the left magnetron inlet duct.

2. Connect a meter capable of measuring 120 volts AC

across the input leads to the stirrer motor .

3. Apply power to oven and open oven door.

Meter should indicate approximately 120 volts AC.

Procedure A:

does not operate, replace the motor. (Check the stirrer

blade to be sure it is not binding on stirrer cover.)

Procedure B:

wiring continuity and system diagnosis.

If meter indicates 120 volts AC but motor

If meter indicates zero volts, check oven

On some models,

Blower Motor Test

1. Unplug the oven power cord, lower the back panel,

discharge the capacitor(s).

2. Check the blower wheel to be sure it is not binding or

frozen.

3. Connect a ohmmeter capable of measuring 120 volts

AC across the input leads to the blower motor.

4. Apply power to oven and open oven door.

Meter should indicate approximately 120 volts AC.

Procedure A:

does not operate, replace the motor.

Procedure B:

wiring continuity and system diagnosis.

If meter indicates 120 volts AC but motor

If meter indicates zero volts, check oven

19 RE220002 Rev. 6

Page 20

Test Procedures

!

DANGER

Before touching any oven components or wiring,

capacitor

by shorting across the capacitor terminals with an insulated handle screwdriver.

always

High voltages are present during the cook cycle.

Extreme caution should be observed at all times.

unplug the oven from its power source and

discharge the

Auto T ransformer Test

FS-14EVP and FS-16EVP only

1. Unplug oven power cord and remove but do not

disconnect the control panel assembly .

2. With alligator clips, connect a meter capable of

measuring 250 volts AC across the 0 volt and 240 volt

terminals of the auto transformer.

3. Apply power to the oven and open the oven door. A

normal indication should be 220 to 256 volts AC.

Unplug the oven. If voltages are low or high, check

that the voltage adjusting connector is set for the

proper source voltage.

4. Connector meter across the 0 volt and 120 volt

terminals.

5. Apply power to the oven, open the oven door and note

the voltage.

6. Disconnect power to the oven. Connect meter across

the 120 volt and 240 volt terminals.

7. Apply power to the oven, open the oven door, note the

voltage and unplug the oven.

V oltages in steps 5 (terminals 0 and 120 volts) and 7

(terminals 120 and 240 volts) should be within 15 volts of

the same and should be approximately half of the input

voltage measured in step 3. If the voltages in steps 5 and

7 differ by more than 15 volts or are not approximately half

the voltage measured in step 3, replace the auto

transformer and retest.

Thermal Protector Test

Unless an overheating condition exists, a continuity

check across the thermal protector contacts should

indicate a closed circuit (< 1 ohm).

1. Magnetron thermal protector

A. Early production units contained resettable

magnetron thermal protectors.

B. Units produced with the following revision levels

do not reset:

FS10EVP.D

FS14EVP.D

FSP10.C

VEND10.F

2. Cavity thermal protectors will not reset.

DISPLAY

Pin 1

D

E

F

C

G

A

B

Connector

Ribbon

conector

K2

Pin 1

K1

New Controller

208–230 V AC units

FS20 P1302106M

FS 17 P1302105M

120 V AC units

FS11 P1302104M

FSP11 P1302102M

FSP11L W P1302103M

VEND11 P1302101M

Pin Description

A—Line voltage to auto transformer

B—Line voltage to K1 connector

C—Line out from controller to high voltage transformers

D—To triac MT1 pin

E—To triac MT2 pin

F—Gate voltage (.8 V AC) to triac

G—Line in to controller relay contact to H.V .

transformer

K1 Connector

Pin 1 to Pin 3—Line voltage to controller

Pin 6 and Pin 7—V oltage to logic switch

Pin 9—Ground

RE220002 Rev. 6 20

Page 21

Disassembly Procedures

!

!

!

WARNING

To avoid risk of electrical shock, personal injury, or death,

disconnect power to unit and discharge capacitor(s)

before following any disassembly procedures.

Back Panel Removal/Service Position

1. Place the oven so there is something to support the

back panel when it is lowered.

2. Remove the four screws and lower the back panel to

an approximate horizontal position. The back panel

is now in the service position.

3. To remove back panel:

FS10 and VEND10

A. Disconnect H.V. wires to capacitor and diode.

B. Disconnect panel to chassis ground wire.

FS14

A. Disconnect panel to chassis ground wire.

B. Remove both voltage adjusting connector

assemblies.

CAUTION

To prevent possible electrical shock, this wire must be

reconnected when the back panel is replaced.

C. Power cord.

Control Panel Disassembly

1. Remove the control panel assembly.

2. Disconnect the ribbon cable by applying even

pressure to both sides of the ribbon cable and pulling

outward from the ribbon cable connector.

3. Remove six screws and remove controller.

4. Pry off six clips and remove panel and display

window.

Cavity Lamp Replacement

1. Unplug the oven.

2. Remove screw and open the lamp access cover.

3. Replace the cavity lamp. Do not overtighten the

lamp.

Control Panel Assembly Removal

1. Loosen the 3/32" allen-head screw located near the

top of the control panel assembly .

2. Pull the control panel assembly forward and

disconnect the two wire connectors from the control

panel assembly .

CAUTION

Static discharge can damage the controller . A void

touching any part of the circuitry on the back of the

controller .

Installation

1. Visually inspect ribbon cable silver circuit; if any silver

circuit is missing from the connector end of the ribbon

cable, evenly trim 1/16" off end of ribbon cable to

assure good electrical connection with ribbon cable

connector.

2. Apply even pressure to both sides of ribbon cable

while inserting cable into ribbon cable connector.

Visually inspect for proper alignment of silver circuit to

connector tabs.

21 RE220002 Rev. 6

Page 22

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death,

disconnect power to unit and discharge capacitor(s)

before following any disassembly procedures.

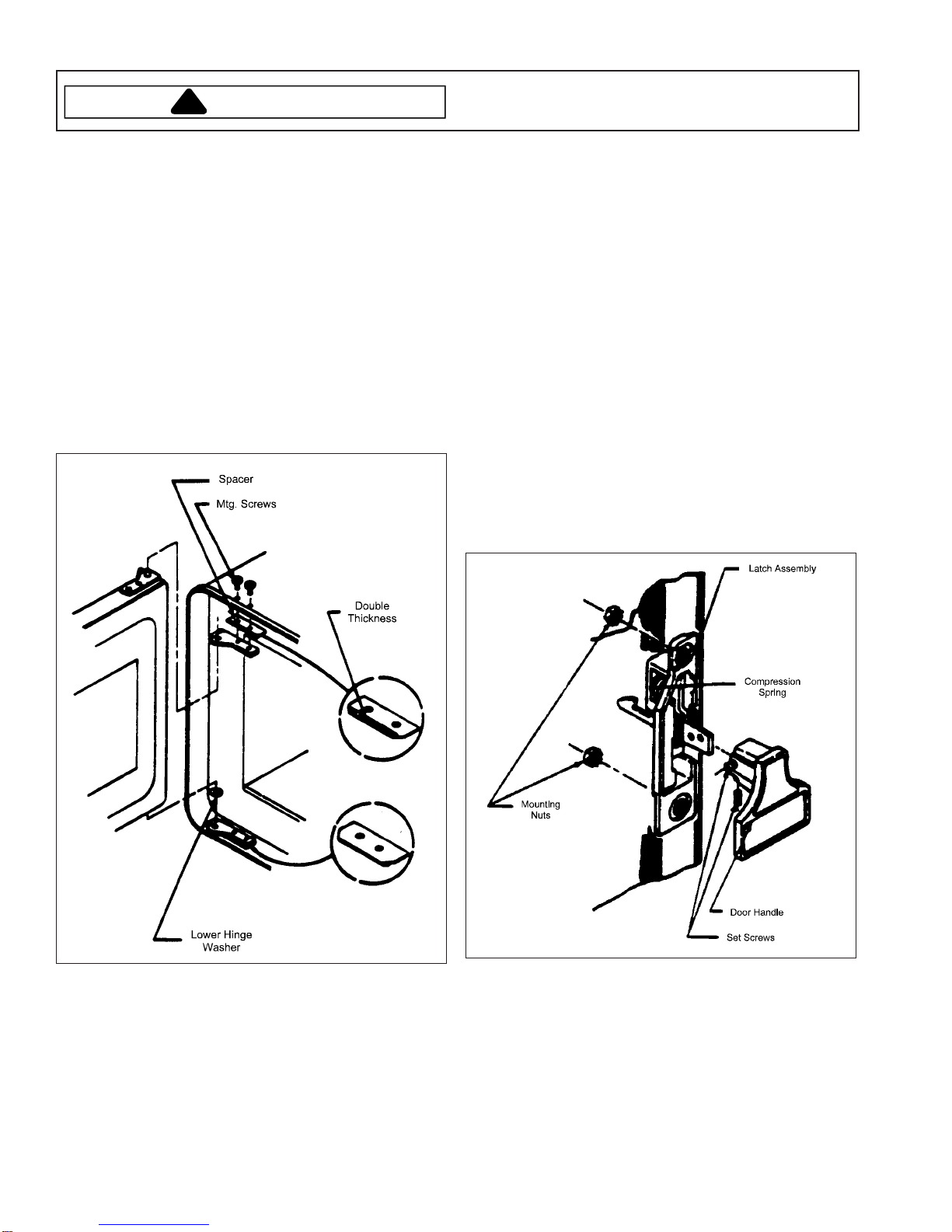

Door Assembly Replacement and

Adjustment

The following door replacement and adjustment

procedures will normally limit radio frequency leakage to

less than 1 mw/cm2 at 5 cm. Although the maximum

allowable leakage is 4 mw/cm2 at 5 cm, effort should be

made to ensure that leakage levels are well below the 4

mw/cm2 at 5 cm.

1. Unplug the power cord.

2. Remove two upper hinge mounting screws.

3. Tilt top of door away from oven and remove door from

oven.

4. Remove lower hinge washer from old door and install

onto new door .

7. Press the door against the cavity faceplate near the

hinges and tighten upper hinge mounting screws.

8. If necessary , adjust the interlock switch module as

described under the INTERLOCK SWITCH MODULE

ADJUSTMENT in this section.

9. Check the oven for proper operation. Check the oven

door operation for radio frequency leakage around

the door with an approved radio frequency measuring

device to ensure less than 4 mw/cm2 emissions at 5

cm. in compliance with U.S. Government

Department of Health and Human Services 21 CFR,

Subchapter J, Performance Standard for Microwave

Ovens.

Door Latch Assembly Replacement

1. Remove door from oven as described in DOOR

REPLACEMENT AND ADJUSTMENT.

2. Disassemble door as described in Door Disassembly.

3. Loosen two set screws and remove door handle.

4. Remove two nuts and remove the door latch

assembly .

5. Install new door into lower hinge, leaving the door 1/2

way open. Place upper hinge and spacer on the top

door pin. Spacer must be installed with the double

thickness toward the oven front and toward the cavity

overhang as shown. Install upper hinge mounting

screws. Leave screws loose.

6. Close oven door.

RE220002 Rev. 6 22

5. Install door latch assembly and reassemble door

using new plastic inner window .

6. Install door on hinges as described under DOOR

REPLACEMENT AND ADJUSTMENT.

7. Check the oven for proper operation. Check for radio

frequency leakage around the door.

Page 23

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death,

disconnect power to unit and discharge capacitor(s)

before following any disassembly procedures.

Interlock Switch Module Adjustment

1. Remove the control panel assembly.

2. Loosen the two screws that mount the interlock

switch module to the cavity assembly .

3. With the oven door closed, align the switch module to

the door hook to provide maximum activation of the

switch actuator .

4. Retighten module mounting screws.

5. Check the oven for proper door closure and switch

operation.

6. Check the oven for proper operation and radio

frequency leakage around the door.

Door Disassembly

1. Remove door from oven as described in DOOR

REPLACEMENT AND ADJUSTMENT in this section.

2. Place door front down on a flat protected surface with

the door handle extending over the edge of the

surface.

3. Peel off the adhesive mounted inner window.

4. Remove door screen mounting screws and remove

door screen.

5. Remove outer window.

6. Remove door filler.

Door Assembly

1. Place door, front down, on a flat protected surface

with the door handle extending over edge of surface.

2. Install outer window.

3. Mount door screen and door filler on outer door.

4. Install door screen mounting screws keeping outer

door as flat as possible.

5. Install adhesive mounted inner window.

6. Install door on hinges as described under DOOR

REPLACEMENT AND ADJUSTMENT in this

section.

7. Check the oven for proper operation. Check for radio

frequency leakage around the door.

Exhaust Transition Duct Replacement

1. Lower the back panel to the service position.

2. Pull the duct toward the oven rear.

3. Rotate the bottom of the duct clockwise to remove.

4. T o replace, insert rib on wrap into slot on top of duct.

Lift up on bottom tabs on duct and rotate bottom of

duct counterclockwise to secure tabs to lower rail on

wrap.

5. Slide duct toward oven front.

23 RE220002 Rev. 6

Page 24

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death,

disconnect power to unit and discharge capacitor(s)

before following any disassembly procedures.

Right Blower Air Duct Replacment

1. Lower the back panel to the service position.

2. Remove the exhaust transition duct.

3. Remove the air diverter by removing the two plastic

push rivets and disconnecting the rear tab from the

slot on the blower air duct.

4. Remove two duct mounting screws from magnetron.

5. Firmly grasp the bottom of the duct and pull it out

(considerable force is required).

6. T o replace, start the top of the duct into the oven at

about a 45° angle. Rotate the bottom of the duct into

position (force is required). When correctly

positioned, the duct fits down over the blower housing

and the mounting holes align with the magnetron.

7. Replace mounting screws, air diverter, and exhaust

transition duct.

Left Blower Air Duct Replacement

(some models only)

1. Lower back panel to the service position.

2. Remove 2 duct mounting screws from magnetron.

3. Lift duct about 1" and rotate duct counter clockwise to

remove.

4. T o replace, tilt back of the duct slightly downward,

insert top of duct near top of wrap and rotate duct

clockwise into place.

5. Place the locating tabs into the blower housing and

install 2 screws into magnetron.

Magnetron Exhaust Duct Replacment

1. Lower the back panel to the service position.

2. Remove two duct toward oven rear to remove.

3. Replace duct and screws.

Magnetron Replacement

1. Remove magnetron inlet and exhaust duct.

2. Disconnect the wires to the magnetron thermal

protector .

3. Disconnect the wires to the magnetron terminals.

4. Remove the blower assembly (some models only).

5. Remove four magnetron mounting nuts.

6. Lower the magnetron. Rotate bottom of the right

magnetron toward the oven rear. Rotate bottom of

left magnetron toward the left side of the oven.

7. Put foam tape on replacement magnetron.

NOTE: When connecting wires to magnetron terminals,

observe polarity per the wiring schematic/

diagram.

NOTE: Radio frequency gasket must be installed

before magnetron is installed.

NOTE: Check oven for leakage to ensure 4 mw/cm2

leakage at 5 cm.

RE220002 Rev. 6 24

Page 25

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death,

disconnect power to unit and discharge capacitor(s)

before following any disassembly procedures.

Blower Replacment

1. Remove magnetron inlet duct.

2. Remove blower motor ground lead screw from the

oven base.

3. Disconnect two blower motor wires.

4. Remove mounting screws and lift out blower

assembly. The left blower assembly (FS14 only) has

two mounting screws located toward the rear of the

oven. The right blower asseembly has two mounting

screws toward the rear of the oven and one mounting

screw near the high voltage transformer.

Component Module Panel Removal

Model VEND-10.000, .A, .B, .C

1. Remove the control panel assembly.

2. Locate the top and bottom release tabs on the panel

harness connector located above and to the rear of

the component module panel. Press the tabs against

the connector housing and pull the connector toward

the oven front to disconnect the connector.

3. Remove two interlock switch module screws and

remove the switch module. Do not disconnect wires

to the switch module.

4. Remove the nut at the top of the component module

panel. Pull the top of the panel away from the cavity

wall until it clears the stud.

5. Pull the component module panel toward the front of

the oven and lift up to separate the two tabs from

slots in the oven base.

6. Slowly pull the interlock switch module and

component module panel through the control panel

opening. Move wires around as required to clear the

opening.

NOTE: After replacement, perform interlock switch

module adjustment. Perform Radio Frequency

Leakage T est Procedures.

Right (Rear) High Voltage Transformer

Replacement

1. Lower the back panel to the service position.

2. Remove the right blower air duct and the magnetron

exhaust duct (FS14 only).

3. Disconnect the transformer leads.

4. Remove four transformer mounting screws.

Left (Side) High Voltage T ransformer

Replacement

1. Lower the back panel to the service position.

2. Remove the left blower air duct and left blower

assembly.

3. Disconnect the transformer leads.

4. Remove two transformer mounting screws.

25 RE220002 Rev. 6

Page 26

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death,

disconnect power to unit and discharge capacitor(s)

before following any disassembly procedures.

Component Module Panel Removal

(Model VEND-10.F, .G, .H, .J, VEND-10, VEND-1 1

1. Remove the control panel assembly.

2. Remove two interlock switch module screws and

remove the switch module. Do not disconnect wires

to the switch module.

3. Remove the nut at the top of the component module

panel. Pull the top of the panel away from the cavity

wall until it clears the stud.

4. Pull the component module panel toward the front of

the oven and lift up to separate the two tabs from

slots in the oven base.

5. Slowly pull the interlock switch module and

component module panel through the control panel

opening. Move wires around as required to clear the

opening.

NOTE: After replacement, perform interlock switch

module adjustment. Perform Radio Frequency

Leakage Test Procedures.

Stirrer Cover Removal

Stirrer Assembly Removal

NOTE: Formed washers were used on early production

only. Formed washers are not used with

replacement stirrer blades.

NOTE: If installed, formed washers must be installed as

shown.

NOTE: Check oven for leakage to ensure less than 4

mw/cm2 leakage at 5 cm.

NOTE: Radio Frequency gasket must be installed as

shown.

RE220002 Rev. 6 26

Page 27

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death,

disconnect power to unit and discharge capacitor(s)

before following any disassembly procedures.

Shelf Replacement

1. Carefully cut through the sealant bead around the

perimeter of the shelf with a single edge razor blade

or a strong, thin knife.

2. Using a thin knife blade or small screwdriver, begin to

pry the shelf SLOWL Y upward at the front edge.

3. Insert a second screwdriver and slowly break the seal

completely until the shelf is free.

4. Clean the old sealant from the cavity base and install

the new shelf.

5. Lay a bead of new sealant around the shelf perimeter.

NOTE: For even seam, spray RTV with water before

removing excess.

6. Clean excess sealant off the shelf with a single edge

razor blade. Allow 24 hours of curing time before

using the oven.

Cavity Replacement

1. Remove the following components of subassemblies

(refer to individual replacement procedures if

necessary):

A. Control panel assembly .

B. Complete door assembly and hinges.

C. Interlock switch module and component module

panel.

D. Stirrer cover, stirrer blade, stirrer motor and light

lens.

E. Air ducts.

F. Back panel assembly; on FS14 disconnect wire

bundle near left transformer.

G. Cavity lamp socket and cavity thermal protector .

2. Drill out five pop rivets that secure the base to the

cavity . (One rivet at each front corner, one rivet just

behind the back of the air filter , and one rivet near

each blower assembly .)

3. Remove cavity assembly from oven base.

4. Remove control panel mounting nut, interlock switch

module mounting clips and back panel mounting clips

from the old cavity and install on the new cavity .

5. Rivet new cavity assembly to base.

6. Install all components or assemblies that were

removed.

7. Adjust door per door adjustment procedure.

8. Check all wire connections for correct location and

tightness.

9. Plug in oven. Run operational check, power test and

Radio Frequency Leakage test.

Cavity Thermal Protector Replacement

1. Lower the back panel to the service position.

2. Remove the screw and open lamp access cover.

3. Remove cavity lamp bulb.

4. Remove screw located above cavity lamp.

5. Pull down on cavity thermal protector.

6. Disconnect cavity thermal protector leads at the

connector near the back panel.

27 RE220002 Rev. 6

Page 28

Magnetron Service Information

Proper Handling of Magnetron Tubes

A magnetron tube must be handled with care. When

handling a tube, always handle by the housing only . Use

caution not to touch or strike the ceramic or metal portion

at the top.

NOTE: The carton used to ship service replacement

tubes is reusable. All inoperative tubes must be

returned to the factory in the carton.

Magnetron Failure Modes

Magnetron failures that have been identified are

generally grouped into the categories shown below:

1. Shorted

a. Air—This is a case where the tube has had the

vacuum envelope destroyed and air has entered

the tube. This will cause internal arcing and high

secondary circuit if high voltage is applied.

b. R.F. Capacitors—May short to chassis. This

condition will also cause loss of high voltage.

2. Open Heater (Filament)—Can be determined by

ohmmeter when the transformer leads are

disconnected. Resistance is normally less than on

OHM; the filament does not short internally . Any tube

removed should be checked since usage tends to

make the filament more fragile. Later handling or

shipping may open the filament and thereby mask the

true failure mode when checked at the factory .

3. Low Power—Caused by "wearout" of emission

characteristics of the directly heated cathode.

Symptoms are: (1) the tube current will take longer

to get to the operating point then a new tube

(normally about 2 - 3 seconds), (2) the tube current

does not get high enough to cause the tube to

oscillate with normal line voltage. The current will be

low, (3) the oven produces low power into a load,

two-thirds or less than normal.

4. Physical Damage—Caused by mishandling of

magnetron tube.

RE220002 Rev. 6 28

Page 29

Procedure for Measuring Microwave Energy Leakage

!

!

Measurement with the Outer Panel

WARNING

Check for radiation leakage before and during every

servicing. Should the leakage be more than 4mW/cm

(to allow for measurement uncertainty) inform Amana

Appliances immediately . After repairing or replacing

any radiation safety device, keep a written record for

future reference, as required by the Department of

Health and Human Services and CDRH regulation.

This requirement must be strickly observed. In

addition, the leakage reading must be recorded on the

servie repair ticket while in the customer's location.

Removed

Whenever you replace the magnetron, measure for

2

radiation leakage before the outer panel is installed and

after all necessary components are replaced or adjusted.

Special care should be taken in measuring around the

magnetron.

DANGER

To avoid risk of severe personal injury or death , avoid

contacting any high voltage components.

Equipment

• Electromagnetic radiation monitor

• Glass thermometer 212°F. or 100°C.

• 600 cc glass beaker

Procedure for Measuring Radiation

Leakage

Note before measuring:

a. Do not exceed meter full scale deflection.

Leakage monitor should initially be set to the

highest scale.

b. To prevent false readings the test probe should be

held by the grip portion of the handle only . The

scan speed is equal to 1" per antenna revolution

of 1" per second if antenna speed is unknown.

Areas to be checked are all seal areas, window ,

and any venting parts.

c. Leakage with the outer panel removed . . . 4mW/

cm2 or less.

d. Leakage for a fully assembled oven with door

normally closed . . . 4mW/cm

e. Leakage for fully assembled oven (before the latch

switch (primary) is interrupted) while pulling the

door . . . 4mW/cm2 or less.

2

or less.

Measurement with a Fully Assembled Oven

After all components, including the outer panel are fully

assembled, measure for radiation leakage around the

door periphery , the door viewing window, the exhaust

opening, and air inlet openings.

Record Keeping and Notification After

Measurement

• After any adjustment or repair to a microwave oven, a

leakage reading must be taken. Record this leakage

reading on the repair ticket even if it is zero.

A copy of the repair ticket and the microwave leakage

reading should be kept by repair facility.

1. Pour 275 ± 15 cc (9 oz. ± 1/2 oz) or 20 ± 5°C. (68°F.

± 9°F.) water in beaker which is graduated to 600 cc

and place the beaker in the center of the oven.

2. Set the radiation monitor to 2450 MHz and use it

following the manufacturer's recommended test procedures to assure correct results.

3. While measuring the leakage, always use the two

inch (5 cm) spacer supplied with the probe.

4. Press the start pad or turn on the timer and with the