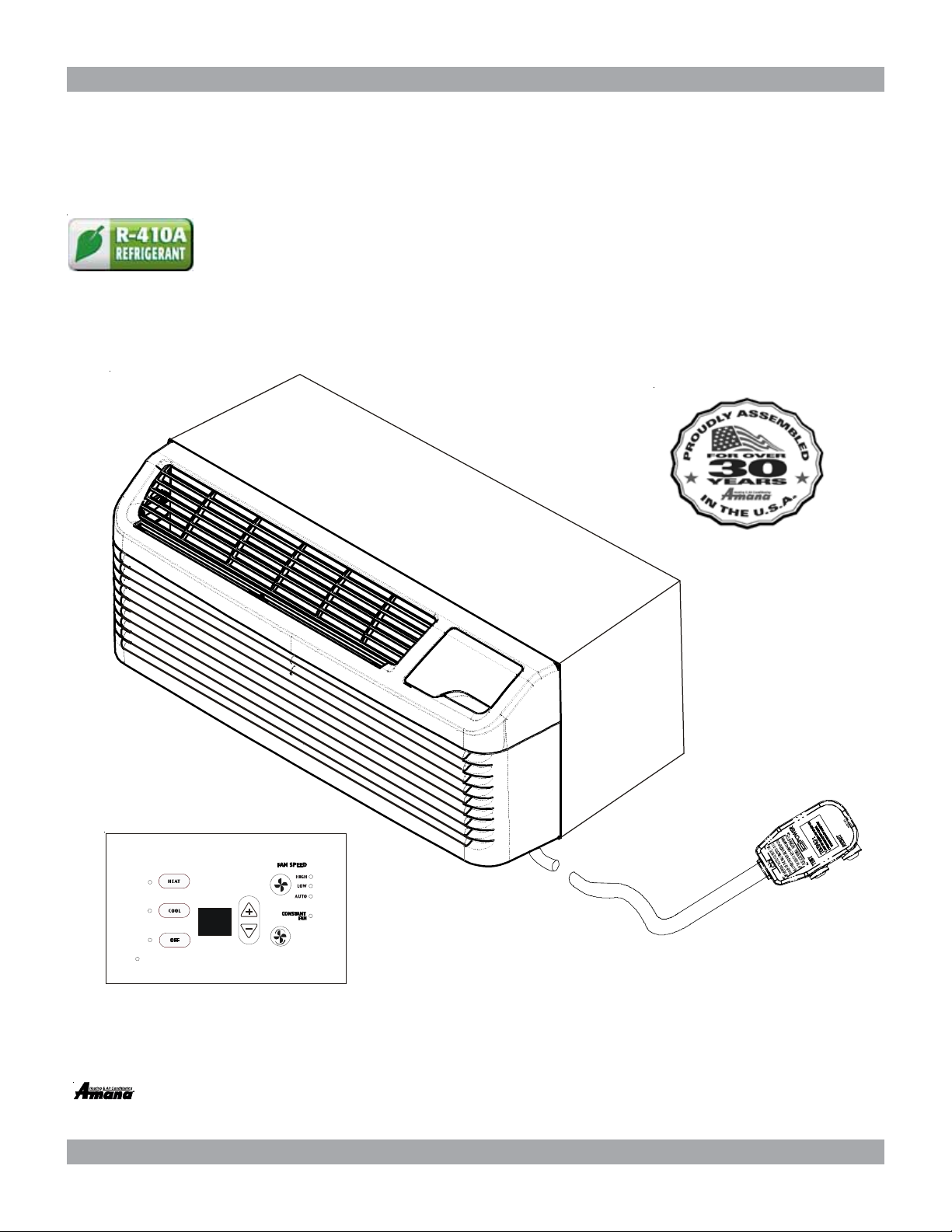

Amana R- 410A Service Manual

Service Instructions

PACKAGE TERMINAL

AIR CONDITIONER/HEAT PUMP

Standard and Remote Applications with LED Control

with R-410A

This manual is to be used by qualified, professionally trained HVAC technicians only.

Goodman does not assume any responsibility for property damage or personal injury

due to improper service procedures or services performed by an unqualified person.

is a registered trademark of Maytag Corporation or its related companies and is used under license to Goodman Company, L.P., Houston, TX. All rights reserved.

© 2010 - 2012 Goodman Company, L.P.

RS4200004r7

November 2012

INDEX

PRODUCT IDENTIFICA TION................................................................................... 4

SPECIFICATIONS ...........................................................................................5-14

PROPER INSTALLATION................................................................................. 15-34

MAINTENANCE........................................................................................... 35-37

OPERATIONS.............................................................................................. 38-42

SERVICING ................................................................................................ 43-60

SCHEMATICS.............................................................................................. 61-82

IMPORTANT INFORMATION

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service technician

who is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing

instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE

SERVICE MANUAL BEFORE BEGINNING REPAIRS.

IMPORTANT NOTICES FOR CONSUMERS AND SERVICERS

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

WARNING

WARNING

INSTALLATION AND REPAIR OF THIS UNIT SHOULD BE PERFORMED ONLY BY INDIVIDUALS MEETING (AT

A MINIMUM) THE REQUIREMENTS OF AN “ENTRY LEVEL TECHNICIAN” AS SPECIFIED BY THE AIRCONDITIONING, HEATING AND REFRIGERATION INSTITUTE (AHRI). ATTEMPTING TO INSTALL OR REPAIR

THIS UNIT WITHOUT SUCH BACKGROUND MAY RESULT IN PRODUCT DAMAGE, PERSONAL INJURY

OR DEATH.

2

WARNING

THIS AIR CONDITIONER IS NOT MEANT TO PROVIDE

UNATTENDED COOLING OR LIFE SUPPORT FOR

PERSONS OR ANIMALS WHO ARE UNABLE TO

REACT TO THE FAILURE OF THIS PRODUCT.

THE FAILURE OF AN UNATTENDED AIR CONDITIONER MAY RESULT IN EXTREME HEAT IN THE CONDITIONED SPACE CAUSING OVERHEATING OR

DEATH OF PERSONS OR ANIMALS.

PRECAUTIONS MUST BE TAKEN TO WARN OF OR

GUARD AGAINST SUCH AN OCCURENCE.

WARNING

WARNING

GOODMAN WILL NOT BE RESPONSIBLE FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROM

IMPROPER SERVICE OR SERVICE PROCEDURES. IF YOU INSTALL OR PERFORM SERVICE ON THIS UNIT,

YOU ASSUME RESPONSIBILITY FOR ANY PERSONAL INJURY OR PROPERTY DAMAGE WHICH MAY

RESULT. MANY JURISDICTIONS REQUIRE A LICENSE TO INSTALL OR SERVICE HEATING AND AIR

CONDITIONING EQUIPMENT.

To locate an authorized servicer, please consult your telephone book or the dealer

from whom you purchased this product. For further assistance, please contact:

CONSUMER INFORMATION LINE -

AMANA® BRAND PRODUCTS TOLL FREE

1-877-254-4729 (U.S. only)

email us at: customerservice@goodmanmfg.com

fax us at: (713) 856-1821

(Not a technical assistance line for dealers.)

Outside the U.S., call 1-713-861-2500.

(Not a technical assistance line for dealers.)

Your telephone company will bill you for the call.

is a registered trademark of Maytag Corporation or its related companies and is used under license to Goodman Company, L.P., Houston, TX. All rights reserved.

3

PRODUCT IDENTIFICATION

(

)

R

R

F Ant

PTC 07 3 E 35 A X X X

BASIC MODEL TYPE MAJOR/MINO R DESIGN REV.

PTC = Standard Cooler PTAC

PTH = Standard Heat Pump PTHP

DRY = Dehumid Cooler PTAC

COOLI N G CAP A CIT Y

07 = 700 0 BTUH (60 Hz)

09 = 900 0 BTUH (60 Hz)

10 = 100 00 BTUH (50 Hz )

12 = 120 00 BTUH (50 or 60 Hz)

15 = 140 00 BTUH (60 Hz)

RAT E D V OLTAGE

2 = 115V 60 Hz 1Ph

3 = 230/208V 60Hz 1Ph

4 = 265V 60 Hz 1Ph

5 = 240/220V 50Hz 1Ph

DESIGN SERIES

E = R-410A

F = 2012 Calif or nia (12, 000 B t uh only)

G = 2012 R-410A

HEATER SIZE D = Power Door PTC073E35CDXX

00 = no elec tric heat F = Fu se Holder (230/20 8v only) PTC073E35CQVX

15 = 1.5 kW H = Hydronic Heat Capable PTC073E35CDQR

25 = 2.5 kW P = Condensat e Pump (PTH only )

35 = 3.5 kw (2 30/ 208V) Q = Qu iet S TC 31 Chass is

= 3.7kW

50 = 5.0 kW V = Power Vent

265V

FEATURE CODE Examples

A = Standar d Model

C = Corrosion Pro tecti on ( S eacoast)

=

X = plac e holder

W = Ha rd Wired - PTQC

Use up to 4 as needed

In al phabetical order

enna

A A

PTC073E35AXXX

PTC073E50CXXX

4

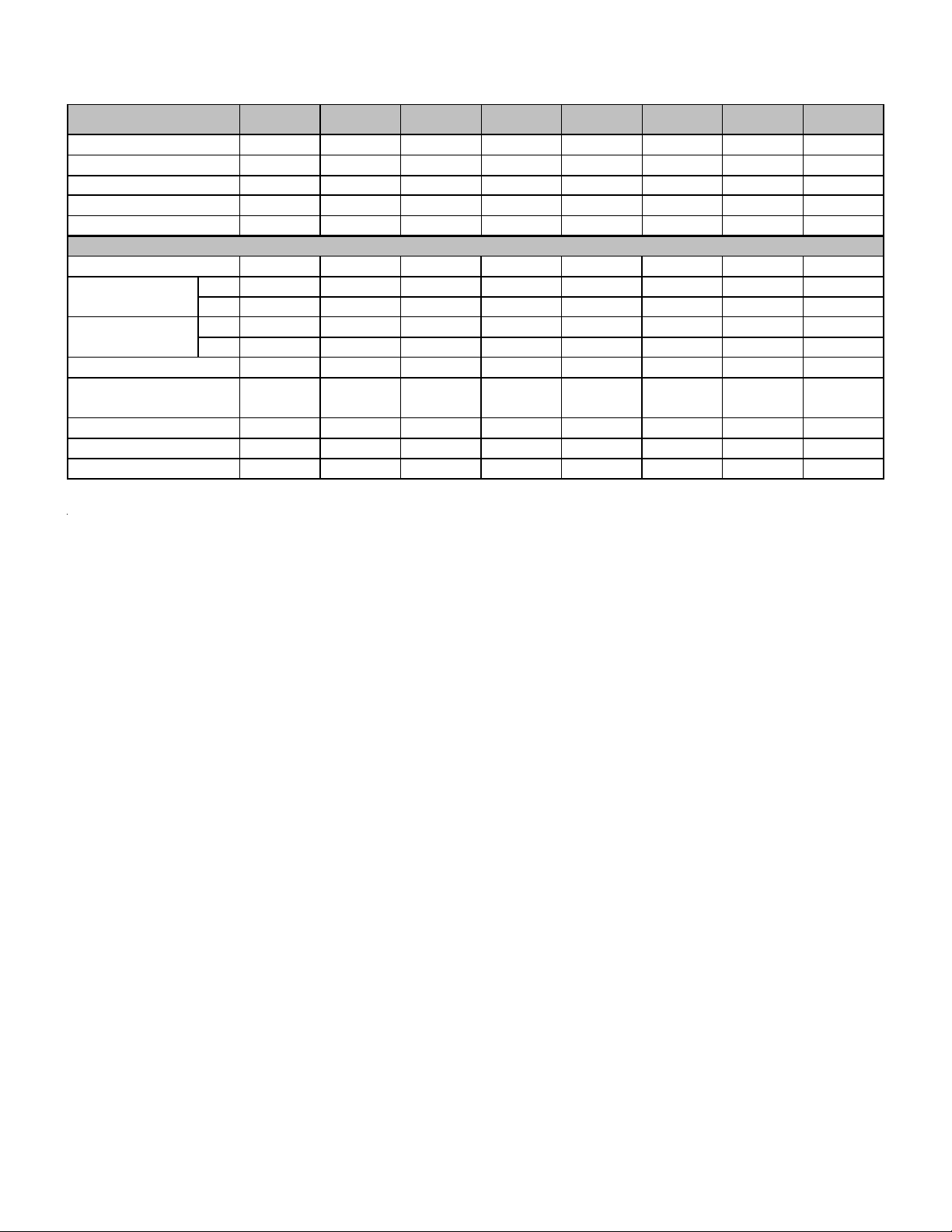

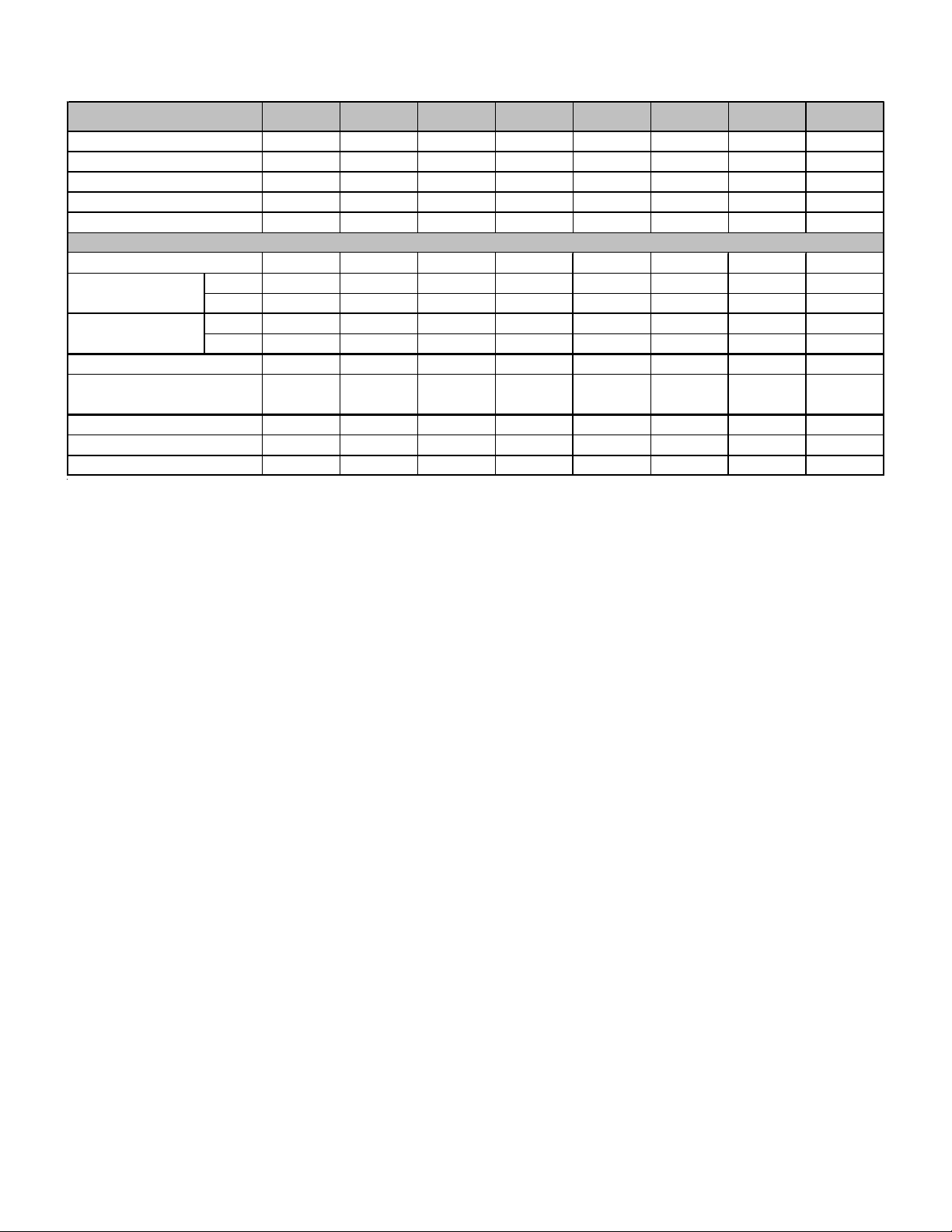

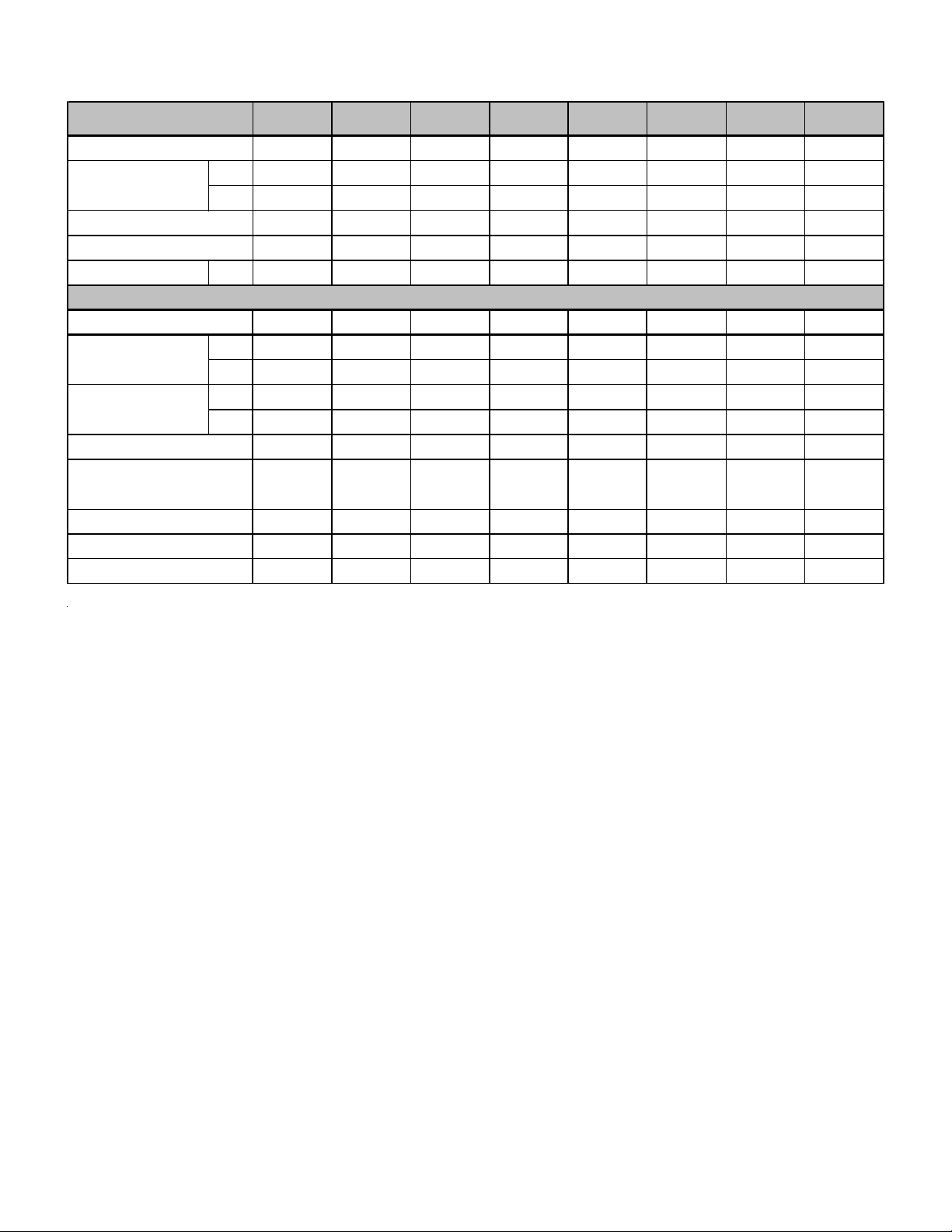

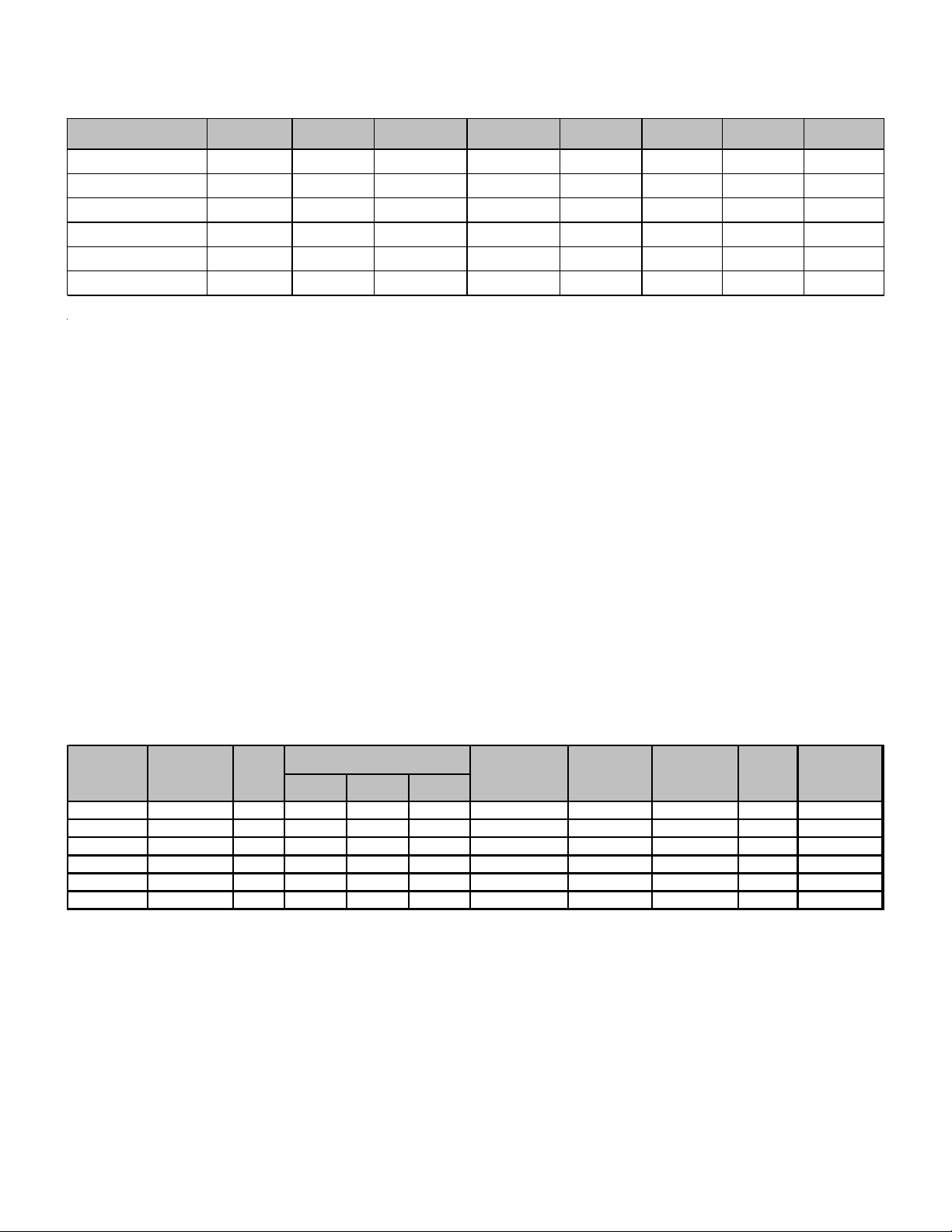

SPECIFICATIONS

PTC E SERIES

COOLING - PTC

6

9

, 8,

Model ¹,

Voltage ¹, ³

Capacity (BTU/h) 7,600 / 7,500 8,700 / 8,500 11,500 / 11,200 14,000 / 13,600 7,600 8,900 11,600 14,000

10

Amps

10

Watts

EER 11.4 / 11.7 11.2 / 11.4 10.3 / 10.1 9.8 / 9.8 11.5 11.1 10.3 9.8

Unit without Electric Heater

Min. Circuit Amps ²,

CFM (Cool/Wet Coil)

CFM (Dry Coi l)

Ventilated Air, CFM (Fan Only)*

Ventilated Air, CFM

Dehumidification (Pints/Hr.)

Net Weight (lbs.)

Ship Weight (lbs.)

4, 10

High 290 290 290 340 290 290 290 340

Low 264 264 264 314 264 264 264 314

High 310 310 310 360 310 310 310 360

Low 282 282 282 332 282 282 282 332

(Compressor & Fan)* 6*6*6*6*6*6*6*6*

PTC PTC PTC P TC PTC PT C PTC PT C

073E***XXX 093E***XXX 123E***XXX 153E***XXX 074E***XXX 094E***XXX 124E***XXX 154E***XXX

230 / 208 230 / 208 230 / 208 230 / 208 265 265 265 265

3.5 / 3.5 4.1 / 4.1 5.6 / 5.6 7.0 / 7.0 3.0 3.6 4.8 6.0

665 / 640 775 / 745 1,115 / 1,110 1,430 / 1,390 600 800 1,12 5 1,430

4.2 4.9 6.8 8.5 3.6 4.4 5.9 7.4

65* 65* 65* 65* 65* 65* 65* 65*

1.7 2.2 3.6 4.4 1.7 2.2 3.6 4.4

99 103 106 117 99 103 106 116

114 118 123 134 114 118 123 133

* Actual vent CFM performance will vary du e to appl ication and installa tion condit ions.

Notes:

¹ All 265-vo l t models must use an Amana® brand sub- bas e (PT SB4** E) or an Amana® brand hard-wir e kit ( PT PWHWK4 ).

² Minimum C i rcuit Ampac ity (M C A) ratings confo r m to the Nation al Electri c Co de; however, l ocal codes s hould apply.

Minimum voltage on 230 /208-volt models is 1 97 volts; maximum is 253 volts.

³ Minimum voltage on 26 5-vol t models i s 239 volts; maximum is 292 vo l ts.

4

Ove r curre nt prot ection fo r al l units without electr i c heaters i s 15 amps. Over cur rent protection on 265- v olt models must be cartridge-style time-delay fuses

(included and factory-i nstall ed on all Ama na® brand 265-volt ch assis). See heater perf ormance for total MCA.

5

Heating capacity and effi ciency ba sed on unit oper a ti o n w i t h ou t conden s a t e pump; unit automati c ally swi tc hes to el ectr i c heat at approx imately 24°F outd oor ambient.

6

Specify two-digit heater kW size to complete model numbe r.

7

R-410A refrigerant used in all systems.

8

Al l uni ts meet or exceed A SH RAE 90. 1 standard s.

9

Al l uni ts less t han 250 volts hav e a Leak C urrent Detector I nterrupter (LCDI) pow er cord and meet UL 484 st andards.

10

Refer to electric heat pe r formance data fo r total MCA and rec ommended overcurr ent protection. Amps and Watts notation refer s to compresso r only.

EER - Energy Efficiency Ratio per The Air -Conditioning,

Heating, and Refrigeration Institute (AHRI) T est

Procedures and Canadian Standards Association

(CSA) T est Procedures.

COP - Coefficient of Performance per AHRI Test

Procedures

5

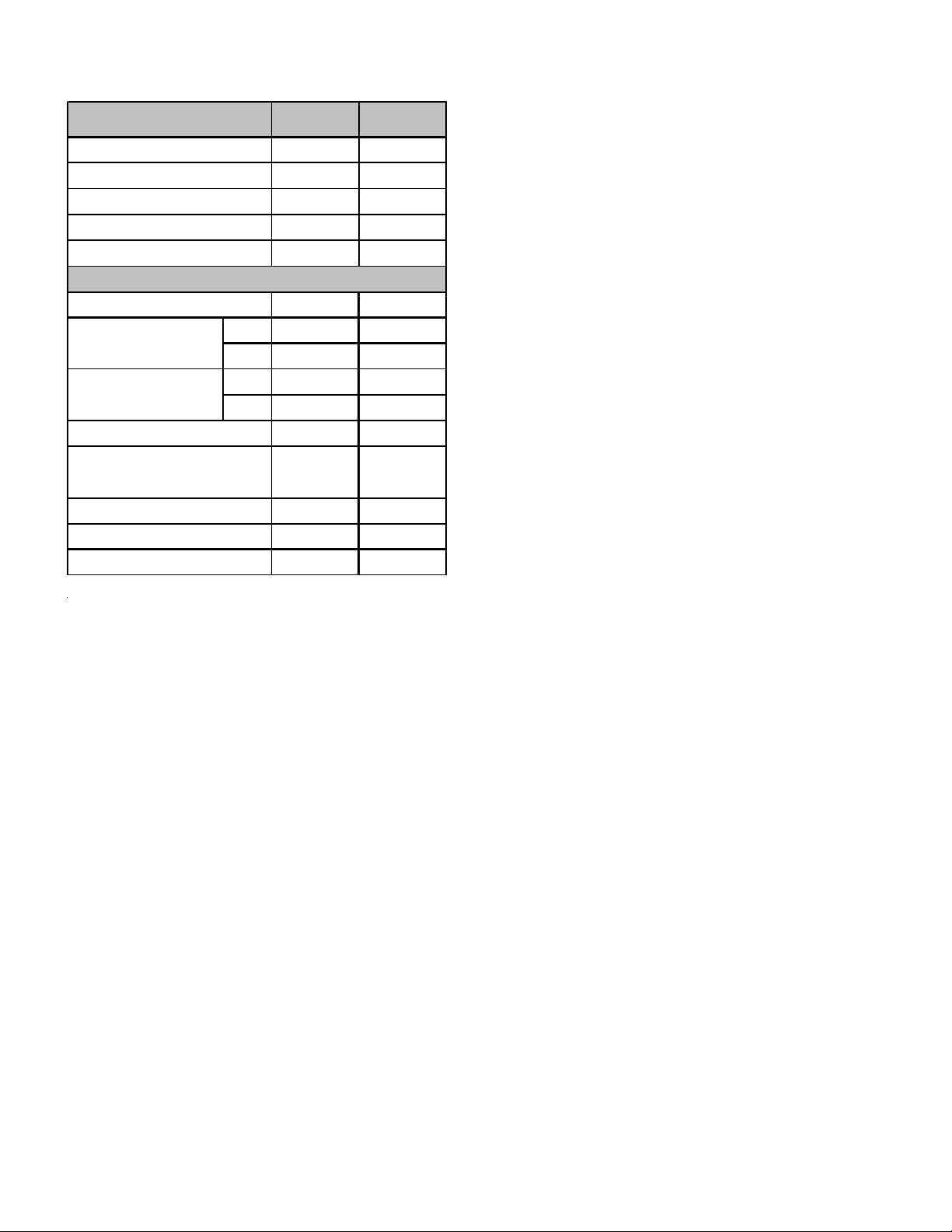

SPECIFICATIONS

PTC G SERIES

COOLING - PTC

6

9

, 8,

Model ¹,

Voltage ¹, ³

Capacity (BTU/h) 7,700 / 7,700 9,000 / 9,000 11,700 / 11,500 15,000 / 14,700 7,700 9,000 12,000 14,800

10

Amps

10

Watts

EER 11.5 / 11.7 11.2 / 11.5 10.3 / 10.4 10.0 / 10.0 11.5 11.3 10.3 10.0

Unit without Electric Heater

Min. Circuit Amps ²,

CFM (Cool/Wet Coil)

CFM (Dry Coil)

Ventilated Air, CF M (Fan Only)*

Ventilated Air, CFM

Dehumidification (Pints/Hr.)

Net Weight (lbs.)

Ship Weight (lbs.)

4, 10

High 290 290 290 340 290 290 290 340

Low 264 264 264 314 264 264 264 314

High 310 310 310 360 310 310 310 360

Low 282 282 282 332 282 282 282 332

(Compressor & Fan)* 6*6*6*6*6*6*6*6*

* Actual vent CFM performance will vary du e to appl ication and installa tion condit ions.

Notes:

¹ All 265-vo l t models must use an Amana® brand sub- bas e (PT SB4** E) or an Amana® brand hard-wir e kit ( PT PWHWK4 ).

² Minimum C i rcuit Ampac ity (M C A) ratings confo r m to the Nation al Electri c Co de; however, l ocal codes s hould apply.

Minimum voltage on 230 /208-volt models is 1 97 volts; maximum is 253 volts.

³ Minimum voltage on 26 5-vol t models i s 239 volts; maximum is 292 vo l ts.

4

Ove r curre nt prot ection fo r al l units without electr i c heaters i s 15 amps. Over cur rent protection on 265- v olt models must be cartridge-style time-delay fuses

(included and factory-i nstall ed on all Ama na® brand 265-volt ch assis). See heater perf ormance for total MCA.

5

Heating capacity and effi ciency ba sed on unit oper a ti o n w i t h ou t conden s a t e pump; unit automati c ally swi tc hes to el ectr i c heat at approx imately 24°F outd oor ambient.

6

Specify two-digit heater kW size to complete model numbe r.

7

R-410A refrigerant used in all systems.

8

Al l uni ts meet or exceed A SH RAE 90. 1 standard s.

9

Al l uni ts less t han 250 volts hav e a Leak C urrent Detector I nterrupter (LCDI) pow er cord and meet UL 484 st andards.

10

Refer to electric heat pe r formance data fo r total MCA and rec ommended overcurr ent protection. Amps and Watts notation refer s to compresso r only.

PTCPTCPTCPTCPTCPTCPTCPTC

073G***XXX 093G** *XXX 123G***XXX 153G***XXX 074G***XXX 094G** *XXX 124G** *XXX 154G***XXX

230 / 208 230 / 208 230 / 208 230 / 208 265 265 265 265

3.5 / 3.5 4.1 / 4.1 5.6 / 5.6 7.0 / 7.0 3.0 3.6 4.8 6.0

670 / 660 805 / 785 1,135 / 1,105 1,500 / 1,470 670 795 1,165 1,480

4.2 4.9 6.8 8.5 3.6 4.4 5.9 7.4

65* 65* 65* 65* 65* 65* 65* 65*

1.7 2.2 3.6 4.4 1.7 2.2 3.6 4.4

98 102 102 113 98 102 102 113

113 117 119 130 113 117 119 130

EER - Energy Efficiency Ratio per The Air -Conditioning,

Heating, and Refrigeration Institute (AHRI) T est

Procedures and Canadian Standards Association

(CSA) T est Procedures.

COP - Coefficient of Performance per AHRI Test

Procedures

6

SPECIFICATIONS

COOLING - DRY

6

Model ¹,

Voltage ¹, ³

Capacity (BTU/h)

, 8,

9

DRY E SERIES

DRY

093E***XXX

230 / 208

8800/8600

Amps

Watts

EER

10

10

4.2/4.2

805/775

10.9/11.1

Unit without Electric Heater

Min. Circui t Amps ²,

CFM (Cool/Wet Coil)

CFM (Dry Coil)

4, 10

High 280

Low 2 60

High 310

Low 2 80

Ventilated Air, CFM (Fan Only)*

Ventil ated Ai r, CFM (Compressor & Fan)*

Dehum idification (Pints/Hr.)

Net Weight (lbs.)

Ship Weight (lbs.)

* Actual vent CFM performance will vary du e to appl icati on and i ns tallatio n condi tions.

Notes:

¹ All 265-vo l t models must use an Amana® brand sub- bas e (PT SB4** E) or an Amana® brand hard-wir e kit ( PTPWHWK4).

² Minimum C i rcuit Ampac ity (M C A) ratings confo r m to the Nation al Electri c Co de; howe ver, l ocal codes s hould apply.

Minimum voltage on 230 /208-volt models i s 197 volts; m aximum is 253 vol ts.

³ Minimum voltage on 26 5-vol t models i s 239 volts; maximum is 292 vo l ts.

4

Ove r curre nt prot ection fo r al l units without el ectri c heaters is 15 am ps. Over c urrent pr otection o n 265-vol t models must be cartridge-style time-delay fuses

(included and factory-i nstall ed on all Ama na® brand 265-volt ch assis). See heater perf ormance for total MCA.

5

Heating capacity and effi ciency ba sed on unit ope ration wit hout cond ens ate pum p; uni t autom ati cally swi tc hes to el ectric he at at approximately 24°F outd oor ambient.

6

Specify two-digit heater kW size to complete model number.

7

R-410A refrigerant used in all systems.

8

Al l uni ts meet or exceed A SH R AE 90.1 standard s.

9

Al l uni ts less t han 250 volts hav e a Leak Curr ent Detector Interrupt er (LCDI) pow er cord and meet UL 484 st andards.

10

Refer to electric heat pe r formance data fo r total MCA and recom mended overcurr ent protection. Amps and Watts notation refer s to compresso r only.

5.1

65*

6*

2.8

103

118

EER - Energy Efficiency Ratio per The Air -Conditioning,

Heating, and Refrigeration Institute (AHRI) T est

Procedures and Canadian Standards Association

(CSA) T est Procedures.

COP - Coefficient of Performance per AHRI Test

Procedures

7

SPECIFICATIONS

DRY G SERIES

DRY DRY

093G***XXX 094G***XXX

230 / 208 265

Voltage ¹, ³

Model ¹,

6

9

, 8,

C apacity ( BTU/h) 8800/8600 8800

Amps

Watts

10

10

4.7 / 4.7 4.3

785 / 770 785

EER 11.2 / 11.2 11.2

Unit without Electric Heater

Min. Circuit Amps ²,

CFM (Cool/Wet Coil)

4, 10

High 280 280

5.6 5.1

Low 260 2 60

CFM (Dry Coil)

High 310 310

Low 280 2 80

Ventilated Air, CFM (Fan Only)*

Ventilated Air, CFM (Compressor & Fan)*

Dehumidification (Pints/Hr.)

Net Weight (lbs.)

Ship Weight (lbs.)

65* 65*

6* 6*

2.8 2.8

103 103

118 118

* Actual vent CFM performance will vary du e to appl ication and installa tion condit ions.

Notes:

¹ All 265-vo l t models must use an Amana® brand sub- bas e (PT SB4** E) or an Amana® brand hard-wir e kit ( PT PWHWK4 ).

² Minimum C i rcuit Ampac ity (M C A) ratings confo r m to the Nation al Electri c Co de; however, l ocal codes s hould apply.

Minimum voltage on 230 /208-volt models is 1 97 volts; maximum is 253 volts.

³ Minimum voltage on 26 5-vol t models i s 239 volts; maximum is 292 vo l ts.

4

Ove r curre nt prot ection fo r al l units without electr i c heaters i s 15 amps. Over cur rent protection on 265- v olt models must be cartridge-style time-delay fuses

(included and factory-i nstall ed on all Ama na® brand 265-volt ch assis). See heater perf ormance for total MCA.

5

Heating capacity and effi ciency ba sed on unit oper a ti o n w i t h ou t conden s a t e pump; unit automati c ally swi tc hes to el ectr i c heat at approx imately 24°F outd oor ambient.

6

Specify two-digit heater kW size to complete model numbe r.

7

R-410A refrigerant used in all systems.

8

Al l uni ts meet or exceed A SH RAE 90. 1 standard s.

9

Al l uni ts less t han 250 volts hav e a Leak C urrent Detector I nterrupter (LCDI) pow er cord and meet UL 484 st andards.

10

Refer to electric heat pe r formance data fo r total MCA and rec ommended overcurr ent protection. Amps and Watts notation refer s to compresso r only.

EER - Energy Efficiency Ratio per The Air -Conditioning,

Heating, and Refrigeration Institute (AHRI) T est

Procedures and Canadian Standards Association

(CSA) T est Procedures.

COP - Coefficient of Performance per AHRI Test

Procedures

8

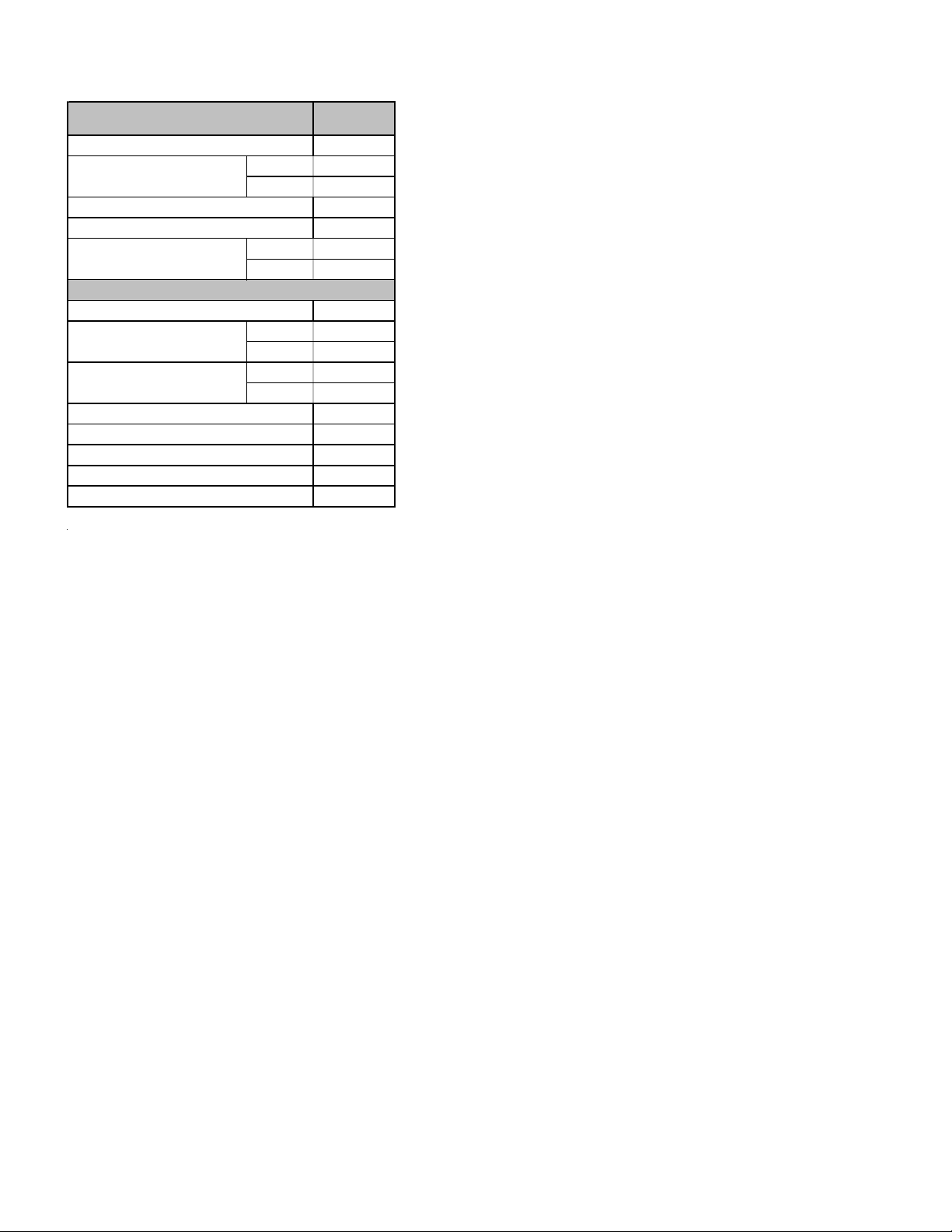

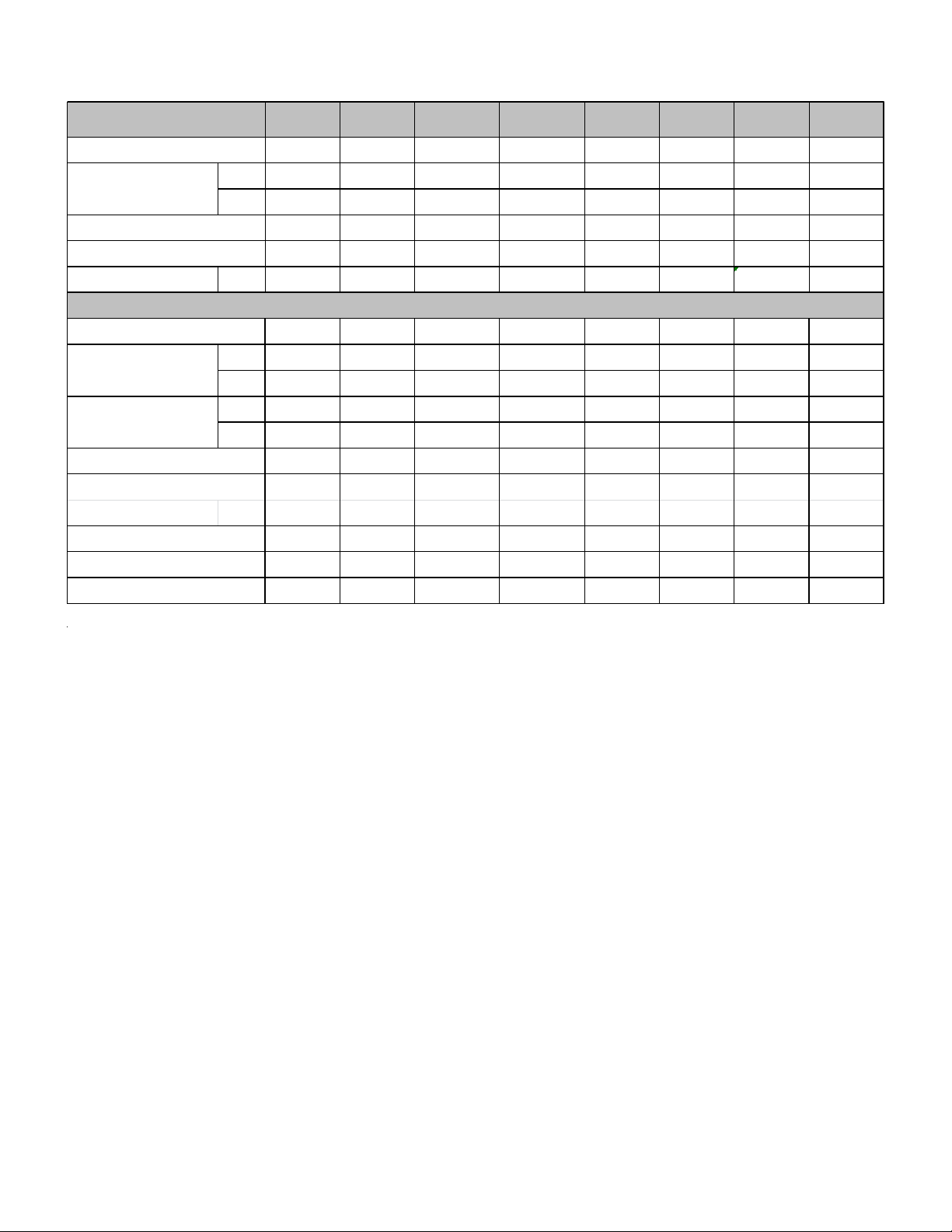

SPECIFICATIONS

ELECTRIC HEAT PERFORMANCE

PTC***(E,F,G) & PTH***(E,F) Models

DRY***(E, G) Models

Voltage

Electric

Heater Size

(kW)

No. of

Stages

Nominal Heating (BTU/h)

@ 230V @ 208V @ 265V

Tota l

Watts

6

Total

Amps

Min. Circuit

Ampacity²

MOD

(amps)

4

Pow er Cord

230/208V 2.5 1 8,500 6,800 - - 2,570 / 2,115 11.2 / 10.1 14.0 15 6-15 P

230/208V 3.5 1 12,000 9,900 - - 3,570 / 2,935 15.5 / 14.1 19.4 20 6-20 P

230/208V 5 1 17,100 14,000 - - 5,070 / 4,160 22.1 / 20.0 27.5 30 6-30 P

265V 2.5 1 - - - - 8,500 2,570 9.7 12.1 15 7-20 P

265V 3.7 1 - - - - 12,600 3,770 14.2 17.8 20 7-20 P

265V 5 1 - - - - 17,100 5,070 19.2 23.9 25 7-30 P

Notes:

¹ All 265-vol t models must use an Amana® brand sub-base (PTSB4* *E) or an Amana ® br and hard-wire kit (PT PWHWK4 ) .

² Minimum branch c ircuit am pacity ratings conform to the National El ec tric Code; however, local codes sh ould apply.

³ Minimum v ol tag e on 230/208-v olt models is 197 volts; m aximum is 253 volts.

Minimum voltage on 265 - v ol t models is 239 v olts; maxi m um is 292 v ol ts.

4

Over current protect i on fo r al l units w i thou t el ectri c heaters is 15 amps. Over curr ent pro tection on 265-vol t mode l s m ust be car tridge-style time-delay

fus es (included and fact ory-inst al led on all Amana® brand 265-v olt chassis).

5

Heati ng capacity and efficiency based on u ni t oper ation without condensate pump; un i t a utomatic al l y swi tches to el ectri c heat at approximately 24°F outdoor ambient.

6

Total watts for 15,000 BTU/h model s; s ubtra ct 20 watt s for PT 07/09/12

7

Specify two-digit heater kW size to complete model number.

8

R-41 0A r efr i gerant used in all sy stems.

9

All units meet or e xceed ASH R AE 90.1 standards.

10

All units l es s than 250 volts hav e a Leak C urr ent De tector Interru pter (LCDI) po we r cord and m eet UL 484 standard s.

EER - Energy Efficiency Ratio per The Air -Conditioning,

Heating, and Refrigeration Institute (AHRI) T est

Procedures and Canadian Standards Association

(CSA) T est Procedures.

COP - Coefficient of Performance per AHRI Test

Procedures

9

SPECIFICATIONS

(

HEAT PUMP - PTH

Model ¹, 6, 8,

Voltage ¹, ³

Capacity (BTU/h)

9

PTH E SERIES

PTH

073E**AXXX

230 / 208 230 / 208 230 / 208 230 / 208 265 265 265 265

7,600 / 7,500 9,000 / 8,900 11,500 / 11,100 14,000 / 13,900 7,500 9,000 11,500 14,000

PTH

093E**AXXX

PTH

123E**AXXX

PTH

153E**AXXX

PTH

074E**AXXX

PTH

094E**AXXX

PTH

124E**AXXX

PTH

154E**AXXX

10

Amps

10

Watts

EER 11.3 / 11.4 11.1 / 11.1 10.2 / 10.1 9.6 / 9.5 11.6 11.1 10.0 9.7

Unit without Electric Heater

Min. Circuit Am ps ², 4,

CFM (Cool/Wet Coil)

CFM (Dry Coil)

Ventilated Air, CFM (Fan Only)*

Ventilated Air, CFM

(Compressor & Fan)* 6* 6* 6* 6* 6* 6* 6* 6*

Dehum idification (Pints/Hr.)

Net Weight (lbs.)

Ship Weight (lbs.)

10

High 290 290 290 340 290 290 290 340

Low 264 264 264 314 264 264 264 314

High 310 310 310 360 310 310 310 360

Low 282 282 282 332 282 282 282 332

3.5 / 3.5 4.1 / 4.1 5.6 / 5.6 7.0 / 7.0 3.0 3.6 4.8 6.0

675 / 660 810 / 800 1,125 / 1,100 1,460 / 1,465 645 810 1,150 1,445

4.2 4.9 6.8 8.5 3.6 4.4 5.9 7.4

65* 65* 65* 65* 65* 65* 65* 65*

1.7 2.2 3.6 4.4 1.7 2.2 3.6 4.4

108 112 115 126 108 112 115 125

123 127 132 143 123 127 132 142

* Actual vent C FM p er formance will var y due to applicat ion and instal l ation conditions.

Notes:

¹ All 265-vo lt mo dels must use an Am a na® brand s ub-bas e (PT SB4**E) or a n Amana® brand hard-wir e kit (PTP W H WK4).

² Minimum Ci r cuit Ampacity (MC A) r atings conform to the N ational Electric Code; howeve r, local c odes should apply.

Minimum vo ltage on 230/208-vo l t models is 197 v olts ; maximum is 253 v olts .

³ Minimum voltage on 265-volt models is 239 volts; maximum is 292 volt s.

4

Overcur r ent protection fo r all units without electric heaters is 15 amps. Overcurrent protecti on on 265-vol t models m ust be cartridge-style time-delay fuses

incl uded and factory-installed on al l Ama na® bra nd 265-volt ch assis). S e e he ater p e rformance for total MCA.

5

Heatin g capa city and ef ficiency based on un i t operation without condens ate pum p; unit automaticall y swi tch es to el ectric heat at approximately 24°F outdoor am bient.

6

Specify two-digit heater kW size to complete model nu mber.

7

R-410A refrigerant used in all systems.

8

All units meet o r exc eed ASHRAE 90.1 standards.

9

All units less than 250 volts have a Leak Current Detec tor Interrupter (LCDI ) power cord and m ee t UL 484 standa r ds.

10

Refer to electr i c heat performance da ta fo r total MCA and r ecommend ed over current pr otection. Am ps and W att s notation ref ers to compressor only.

EER - Energy Efficiency Ratio per The Air -Conditioning,

Heating, and Refrigeration Institute (AHRI) T est

Procedures and Canadian Standards Association

(CSA) T est Procedures.

COP - Coefficient of Performance per AHRI Test

Procedures

10

SPECIFICATIONS

(

HEAT PUMP - PTH

Model ¹, 6, 8,

Voltage ¹, ³

Capacity (BTU/h) 11,500 / 11,300 11,600

Amps

Watts

EER 10.3 / 10.3 10.3

Unit without Electric Heater

Min. Circuit Amps ², 4,

CFM (Cool/Wet Coil)

CFM (Dry Coi l)

Ventilated Air, CFM (Fan Only)*

Ventilated Air, CFM

Dehum idification (Pints/Hr.)

Net Weight (lbs.)

Ship Weight (lbs.)

9

10

10

10

High 290 290

Low 264 264

High 310 310

Low 282 282

(Compressor & Fan)* 6* 6*

PTH

123F**AXXX

230 / 208 265

5.6 / 5.6 4.8

1,125 / 1,095 1,125

7.0 6.0

65* 65*

3.6 3.6

115 115

132 132

PTH

124F**AXXX

PTH F SERIES

* Actual vent C FM p er formance will var y due to applicat ion and instal l ation conditions.

Notes:

¹ All 265-vo lt mo dels must use an Am a na® brand s ub-bas e (PT SB4**E) or a n Amana® brand hard-wir e kit (PTP W H WK4).

² Minimum Ci r cuit Ampacity (MC A) r atings conform to the N ational Electric Code; howeve r, local c odes should apply.

Minimum vo ltage on 230/208-vo l t models is 197 v olts ; maximum is 253 v olts .

³ Minimum voltage on 265-volt models is 239 volts; maximum is 292 volt s.

4

Overcur r ent protection fo r all units without electric heaters is 15 amps. Overcurrent protecti on on 265-vol t models m ust be cartridge-style time-delay fuses

incl uded and factory-installed on al l Ama na® bra nd 265-volt ch assis). S e e he ater p e rformance for total MCA.

5

Heatin g capa city and ef ficiency based on un i t operation without condens ate pum p; unit automaticall y swi tch es to el ectric heat at approximately 24°F outdoor am bient.

6

Specify two-digit heater kW size to complete model nu mber.

7

R-410A refrigerant used in all systems.

8

All units meet o r exc eed ASHRAE 90.1 standards.

9

All units less than 250 volts have a Leak Current Detec tor Interrupter (LCDI ) power cord and m ee t UL 484 standa r ds.

10

Refer to electr i c heat performance da ta fo r total MCA and r ecommend ed over current pr otection. Am ps and W att s notation ref ers to compressor only.

EER - Energy Efficiency Ratio per The Air -Conditioning,

Heating, and Refrigeration Institute (AHRI) T est

Procedures and Canadian Standards Association

(CSA) T est Procedures.

COP - Coefficient of Performance per AHRI Test

Procedures

11

SPECIFICATIONS

(

HEAT PUMP - PTH

Model ¹, 6, 8,

Voltage ¹, ³

Capacity (BTU/h)

9

PTH G SERIES

PTH

073G**AXXX

230 / 208 230 / 208 230 / 208 230 / 208 265 265 265 265

7,600 / 7,600 9,000 / 9,000 12,000 / 12,000 14,200 / 14,200 7,600 9,100 12,000 14,200

PTH

093G**AXXX

PTH

123G**AXXX

PTH

153G**AXXX

PTH

074G**AXXX

PTH

094G**AXXX

PTH

124G**AXXX

PTH

154G**AXXX

10

Amps

10

Watts

EER 11.7 / 11.7 11.5 / 11.5 10.7 / 10.7 9.7 / 9.7 11.7 11.5 10.7 9.7

Unit without Electric He ater

Min. Circuit Amps ²,

CFM (Cool/Wet Coil)

CFM (Dry Coil)

Ventilated Air, CFM (Fan Only)*

Ventila ted Air, CFM

(Compressor & Fan)* 40* 40* 40* 40* 40* 40* 40* 40*

Dehumidification (Pints/Hr.)

Net Weight (lbs.)

Ship Weight (lbs.)

4, 10

High 340 330 340 390 340 330 340 390

Low 245 245 245 340 245 245 245 340

High 370 360 370 410 370 360 370 410

Low 270 270 270 370 270 270 270 370

3.9 / 3.9 4.2 / 4.2 5.8 / 5.8 7.0 / 7.0 3.1 3.7 5.0 6.1

650 / 650 785 / 785 1,125 / 1,100 1,465 / 1,445 650 790 1,120 1,465

4.7 5.1 7.1 8.5 3.8 4.5 6.1 7.4

65* 65* 65* 65* 65* 65* 65* 65*

1.7 2.2 3.6 4.4 1.7 2.2 3.6 4.4

108 112 115 126 108 112 115 125

123 127 132 143 123 127 132 142

* Actual vent C FM p er formance will var y due to applicat ion and installation condi tions.

Notes:

¹ All 265-vo lt mo dels must u se an Am ana® brand s ub-base (P TSB4**E) or an Amana® br and hard-wire kit (PTPWHWK4).

² Minimum Ci r cuit Ampacity (MC A) r atings conform to the N ational Electric Code; howeve r , loc al codes s hould apply.

Minimum vo ltage on 230 /208-vol t models is 197 v ol ts; maximum is 253 v ol ts.

³ Minimum voltage on 265-volt models is 239 volts; maximum is 292 volt s.

4

Overcur r ent protection fo r all units without electric heaters is 15 amps. Overcurrent protection on 265-volt models must be cartridge-style time-delay fuses

incl uded and factory-installed on al l Ama na® brand 265-vol t chassis). S e e he ater p e rformance for total MCA.

5

Heatin g capa city and ef ficiency based on unit operation witho ut condens ate pum p; unit automaticall y swi tches to el ectr ic heat at approxim ately 24°F outd o or ambi ent.

6

Specify two-digit heater kW size to complete model nu mber.

7

R-410A refrigerant used in all systems.

8

All units meet o r exc eed ASHRAE 90.1 standards.

9

All units less than 250 volts have a Leak Current Detec tor Interrupter (LCDI) p ow er cord and m ee t UL 484 standa r ds.

10

Refer to electr i c heat perfor m anc e data for to tal MCA and recommended overcurrent protection. Am ps and W att s notation ref ers to compressor only.

EER - Energy Efficiency Ratio per The Air -Conditioning,

Heating, and Refrigeration Institute (AHRI) T est

Procedures and Canadian Standards Association

(CSA) T est Procedures.

COP - Coefficient of Performance per AHRI Test

Procedures

12

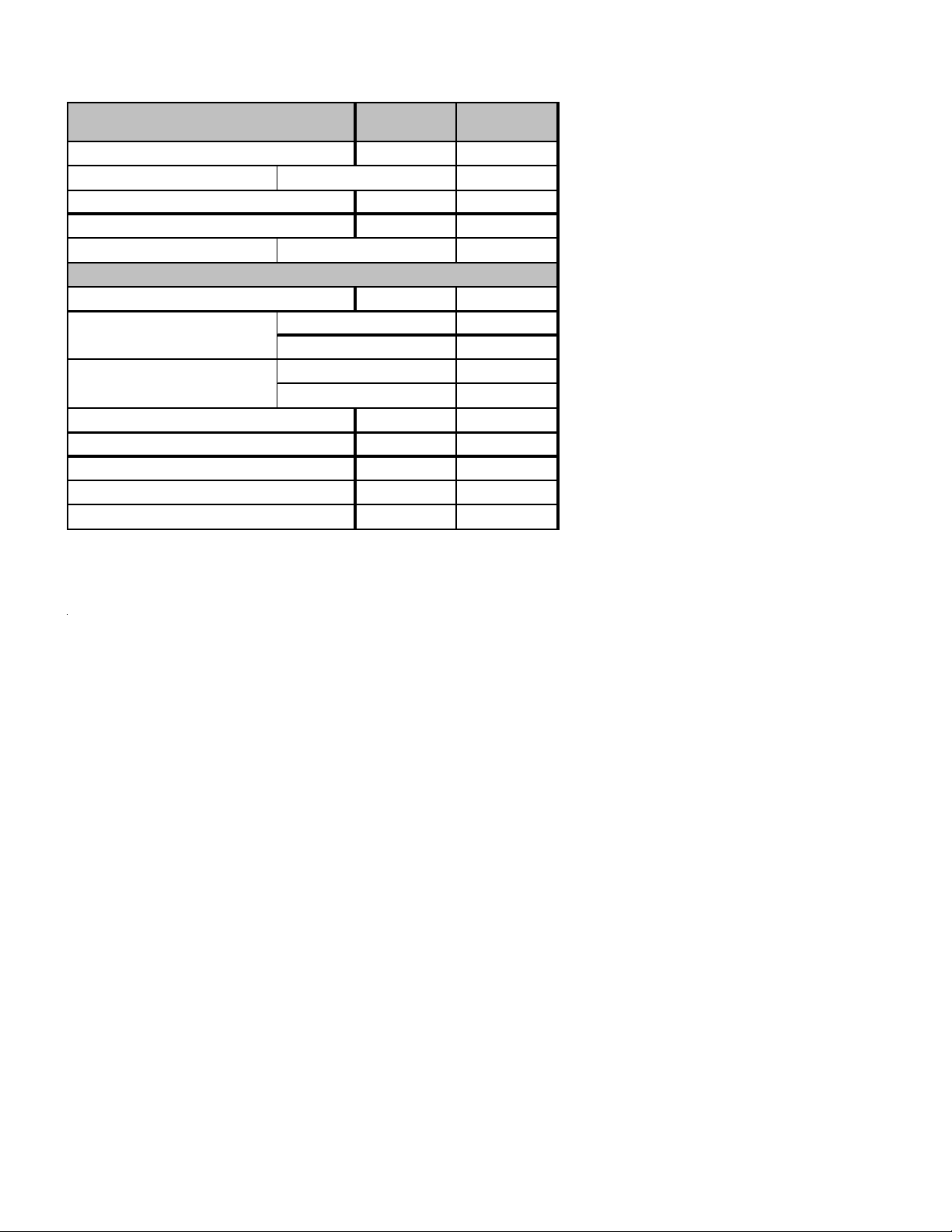

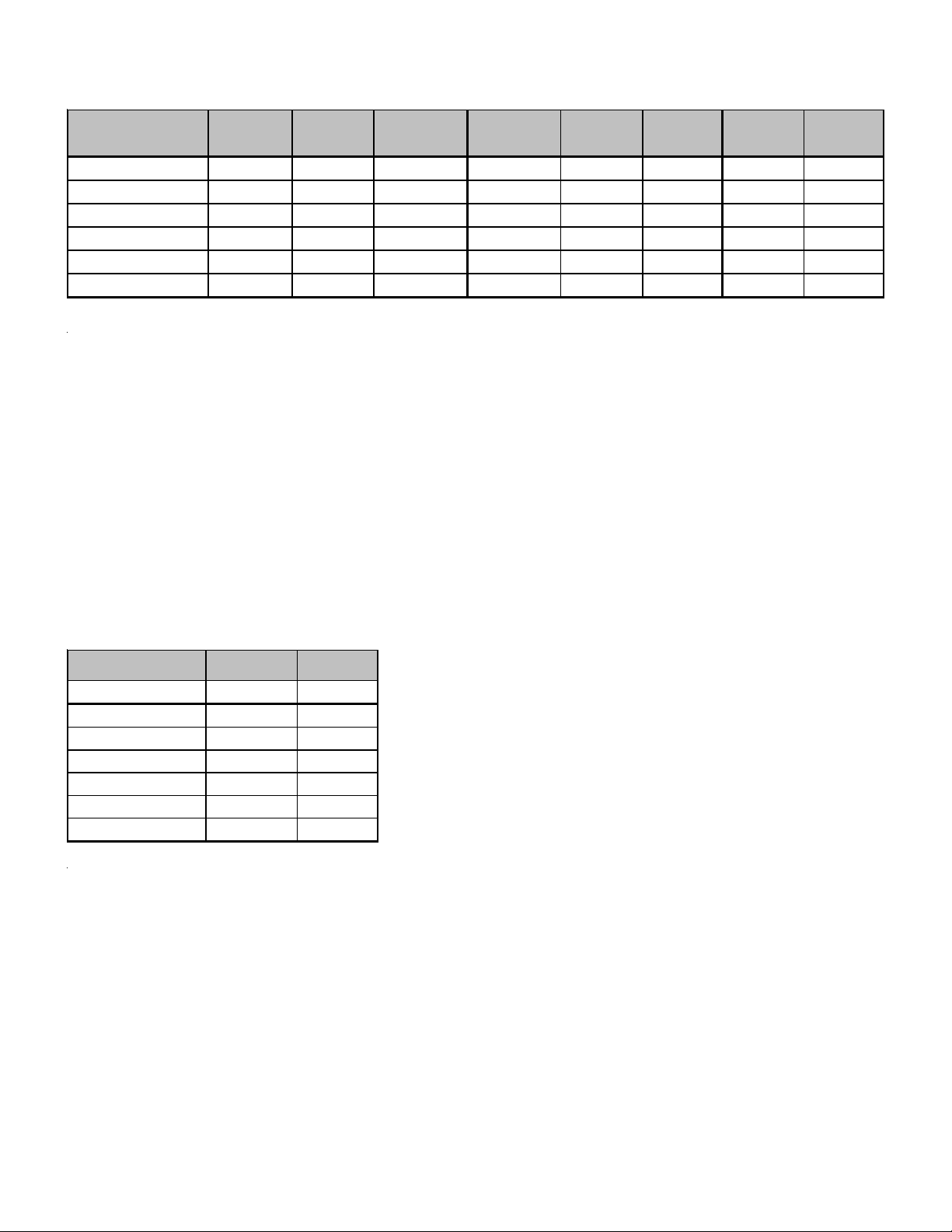

SPECIFICATIONS

(

(

HEAT PUMP HEATING DATA

PTH E SERIES

Heating Capacity¹

Voltage ¹, ³

5

BTU/h

10

Amps

10

Watts

5

COP

PTH

073E**AXXX

230 / 208 230 / 208 230 / 208 230 / 208 265 265 265 265

6,800 / 6,800 8,300 / 8,100 10,900 / 10,500 13,500 / 13,300 6,800 8,200 11,000 13,500

3.5 / 3.5 4.1 / 4.1 5.6 / 5.6 7.0 / 7.0 3.0 3.6 4.8 6.0

605 / 605 735 / 720 1040 /1020 1365 / 1345 585 730 1040 1365

3.3 / 3.3 3.3 / 3.3 3.1 / 3.1 2.9 / 2.9 3.4 3.3 3.1 2.9

PTH

093E**AXXX

PTH

123E**AXXX

PTH

153E**AXXX

PTH

074E**AXXX

PTH

094E**AXXX

PTH

124E**AXXX

PTH

154E**AXXX

CFM (Dry) 310 310 310 360 310 310 310 360

COP = Coefficiency of Performance; per AHRI Test Procedures, units are rated for capacities and efficiencies.

Not es:

¹ All 2 65-volt mo d els m ust use an A m ana® bra nd su b- base (P TSB4**E) or an Amana® brand hard-wire ki t (PTPWHWK4).

² Minimum C ircuit Ampacity (MCA) r atings conform to th e N ational Elec tric Code; however, local cod es should apply.

Minimum voltage on 230/208-volt models is 197 volts; maximum is 253 volts.

³ Minimum voltage on 265-v o l t models is 239 volts; ma xim um is 292 vol ts.

4

Overcurren t protection for all unit s without ele ctric heaters is 15 a m ps. Overcurrent protection on 265-volt m o dels must be cartri dge-style time-delay fuses

included and factory-installed on all Am ana® brand 265-vol t chassi s). See heater performan ce for total MCA.

5

Heating capacity an d efficiency base d on uni t operation without co nden s a te pump; unit automati cally switches to e lect ric heat at approximately 24°F outdoor ambie n t.

6

Sp ecify two-digi t heater kW size to complete model numbe r.

7

R-410A refrigerant used in all sys tems.

8

All units m eet or exceed ASH RAE 90.1 standards.

9

All u nits less than 2 50 volts have a Leak Current Detector Interrupter (LCDI) power cord and m eet UL 484 standar ds.

10

Refer to electric h eat pe r formance data for total MCA and r ecommended overcurrent protection. Amps and Watts notation refer s to compresso r only.

PTH F SERIES

Heating Capacity¹

Voltage ¹, ³

5

BTU/h

10

Amps

10

Watts

5

COP

PTH

123F**AXXX

230 / 208 265

10,900 / 10,500 11,000

5.6 / 5.6 4.8

1040 /1020 1040

3.1 / 3.1 3.1

C FM (Dry) 310 310

C O P = Coeffi c iency of P er fo rmanc e ; pe r AH R I Test Pr ocedur e s , un i t s ar e rated for c a pa c i ti es a n d effic iencie s .

Not es:

¹ All 2 65-volt mo d els m ust use an A m ana® bra nd su b- base (P TSB4**E) or an Amana® brand hard-wire ki t (PTPWHWK4).

² Minimum C ircuit Ampacity (MCA) r atings conform to th e N ational Elec tric Code; however, local cod es should apply.

Minimum voltage on 230/208-volt models is 197 volts; maximum is 253 volts.

³ Minimum voltage on 265-v o l t models is 239 volts; ma xim um is 292 vol ts.

4

Overcurren t protection for all unit s without ele ctric heaters is 15 a m ps. Overcurrent protection on 265-volt m o dels must be cartri dge-style time-delay fuses

included and factory-installed on all Am ana® brand 265-vol t chassi s). See heater performan ce for total MCA.

5

Heating capacity an d efficiency base d on uni t operation without co nden s a te pump; unit automati cally switches to e lect ric heat at approximately 24°F outdoor ambie n t.

6

Sp ecify two-digi t heater kW size to complete model numbe r.

7

R-410A refrigerant used in all sys tems.

8

All units m eet or exceed ASH RAE 90.1 standards.

9

All u nits less than 2 50 volts have a Leak Current Detector Interrupter (LCDI) power cord and m eet UL 484 standar ds.

10

Refer to electric h eat pe r formance data for total MCA and r ecommended overcurrent protection. Amps and Watts notation refer s to compresso r only.

PTH

124F**AXXX

13

SPECIFICATIONS

HEAT PUMP HEATING DATA

PTH G SERIES

Voltage ¹, ³

5

BTU/h

10

Amps

10

Watts

5

COP

Model

PTH

073G**AXXX

230 / 208 230 / 208 230 / 208 230 / 208 265 265 265 265

6,800 / 6,800 8,300 / 8,100 11,500 / 11,300 13,800 / 13,600 6,800 8,300 11,400 13,700

3.9 / 3.9 4.2 / 4.2 5.8 / 5.8 7.0 / 7.0 3.1 3.7 5.0 6.1

585 / 570 715 / 700 1085 /1035 1350 / 1330 570 715 1080 1340

3.4 / 3.5 3.4 / 3.4 3.1 / 3.2 3.0 / 3.0 3.5 3.4 3.1 3.0

PTH

093G**AXXX

PTH

123G**AXXX

PTH

153G**AXXX

PTH

074G**AXXX

PTH

094G**AXXX

PTH

124G**AXXX

PTH

154G**AXXX

CFM (Dry) 370 360 370 410 370 360 370 410

COP = Coefficiency of Per form a nce; per AHRI Test Pr oc e dures , u nit s a r e rate d f or capacities and efficienc ies.

Not es:

¹ All 265-volt models must use an Amana® brand sub-base (PTSB4**E) or an Amana® brand hard-wire kit (PTPWHWK4).

² Minimum C i rcuit A m p acity (MC A) ratings con form to the Nat i onal Elec tri c Code; however, local cod es should apply.

Minimum voltage on 230/208-volt models is 197 volts; maximum is 253 volts.

³ Minimum voltage on 265-vol t models is 239 volts; ma xi mum is 292 volts.

4

Overcurren t protection for a ll un its without electric heat er s is 15 amps. Ov er current protection on 265-volt mod els must be cartridge-style time-delay fuses

(incl uded and factory-installed on all Amana® brand 265-volt chassis). See heater performance for total MCA.

5

Heating capacity an d efficiency based on u nit operation without condensate pump; unit automatically switches to electric heat at approximately 24°F outdoor ambie nt.

6

Specify two-digit heater kW size to complete model number.

7

R-410A refrigerant used in all sys tems .

8

All units meet or exceed ASHRAE 90.1 standards.

9

All units l e ss than 250 volt s have a Leak Current Detector Int errupter (LCDI) power cord and m eet UL 484 st andards .

10

Refer t o electr ic heat perform ance data fo r tota l MCA and recommended ove rcurrent pro tection. Amps and Watts no tatio n r efers to compressor only.

EER - Energy Efficiency Ratio per The Air -Conditioning,

Heating, and Refrigeration Institute (AHRI) T est

Procedures and Canadian Standards Association

(CSA) T est Procedures.

COP - Coefficient of Performance per AHRI Test

Procedures

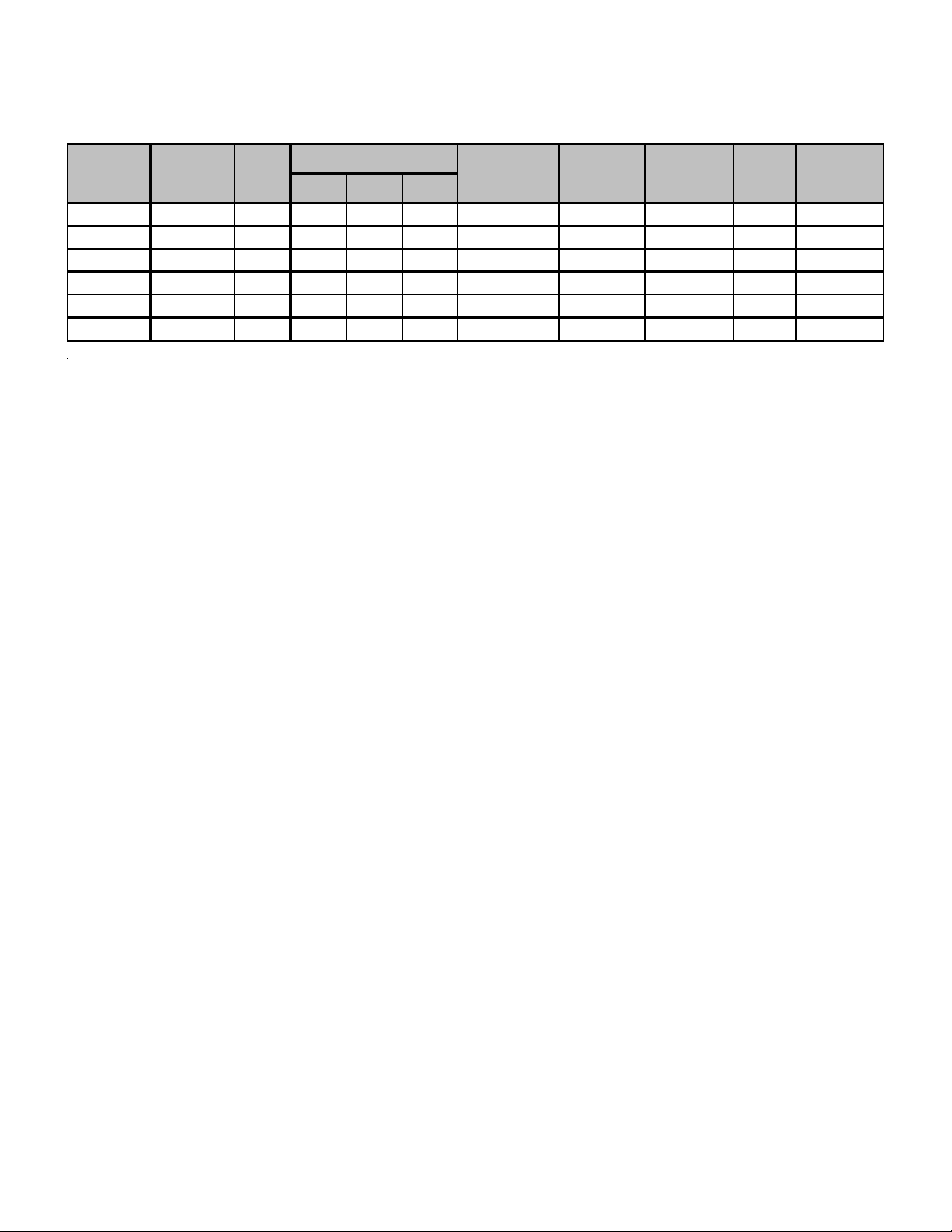

PTH G SERIES

ELECTRIC HEAT PERFORMANCE

Voltage

Electric

Heater Size

(kW)

No. of

Stages

Nominal Heating (BTU/h)

@ 230V @ 208V @ 265V

Total

Watts

6

Total

Amps

Min. Circuit

Ampacity²

230/208V 2.5 1 8,500 6,800 - - 2,570 / 2,115 11.2 / 10.1 14.1 15 6-15 P

230/208V 3.5 1 12,000 9,900 - - 3,570 / 2,935 15.5 / 14.1 19.5 20 6-20 P

230/208V 5 1 17,100 14,000 - - 5,070 / 4,160 22.1 / 20.0 27.6 30 6-30 P

265V 2.5 1 - - - - 8,500 2,570 9.7 12.2 15 7-20 P

265V 3.7 1 - - - - 12,600 3,770 14.2 17.9 20 7-20 P

265V 5 1 - - - - 17,100 5,070 19.2 23.9 25 7-30 P

Notes:

¹ All 265-vol t models must use an Amana® bran d s ub-bas e (P TSB4* *E) or an Amana® brand hard-wire k it (PTPWHWK4 ) .

² Minimum branch circuit ampacity ratings conform to the National Electric Code; however, local codes should apply.

³ Minimum v ol tag e on 230/208-v olt models is 197 volts; m ax i m um is 253 volts.

Minimum voltage on 265 - v ol t models is 239 volts ; maxi m um is 292 v ol ts.

4

Over current protect i on fo r al l units w i thou t electr i c heaters i s 15 amps. Overcurrent protec tion on 265-vol t mode l s m ust be car tridge-style time-delay

fus es (incl uded and factory-installed on al l Am ana® brand 265-vol t chas s is).

5

Heati ng capacity and efficiency based on u ni t oper ation wit hout condensate pump; un i t a utomatic al ly switch es to elec tric heat at approximately 24°F outdoor ambient.

6

Total watts for 15,000 BTU/h model s; s ubtra ct 20 watt s for PT 07/09/12

7

Specify two-digit heater kW size to complete model number.

8

R-41 0A r efr i gerant used in all sy stems.

9

All units meet or e xceed ASHRAE 90.1 standards.

10

All units l ess than 250 volts hav e a Leak Cur r ent Detector Interrupter (LCDI) power c or d and meet UL 484 s tandar ds.

EER - Energy Efficiency Ratio per The Air -

Conditioning, Heating, and Refrigeration

Institute (AHRI) T est Procedures and

Canadian Standards Association (CSA)

T est Procedures.

COP - Coefficient of Performance per AHRI

T est Procedures

MOD

(amps)

4

Power Cord

14

PROPER INSTALLATION

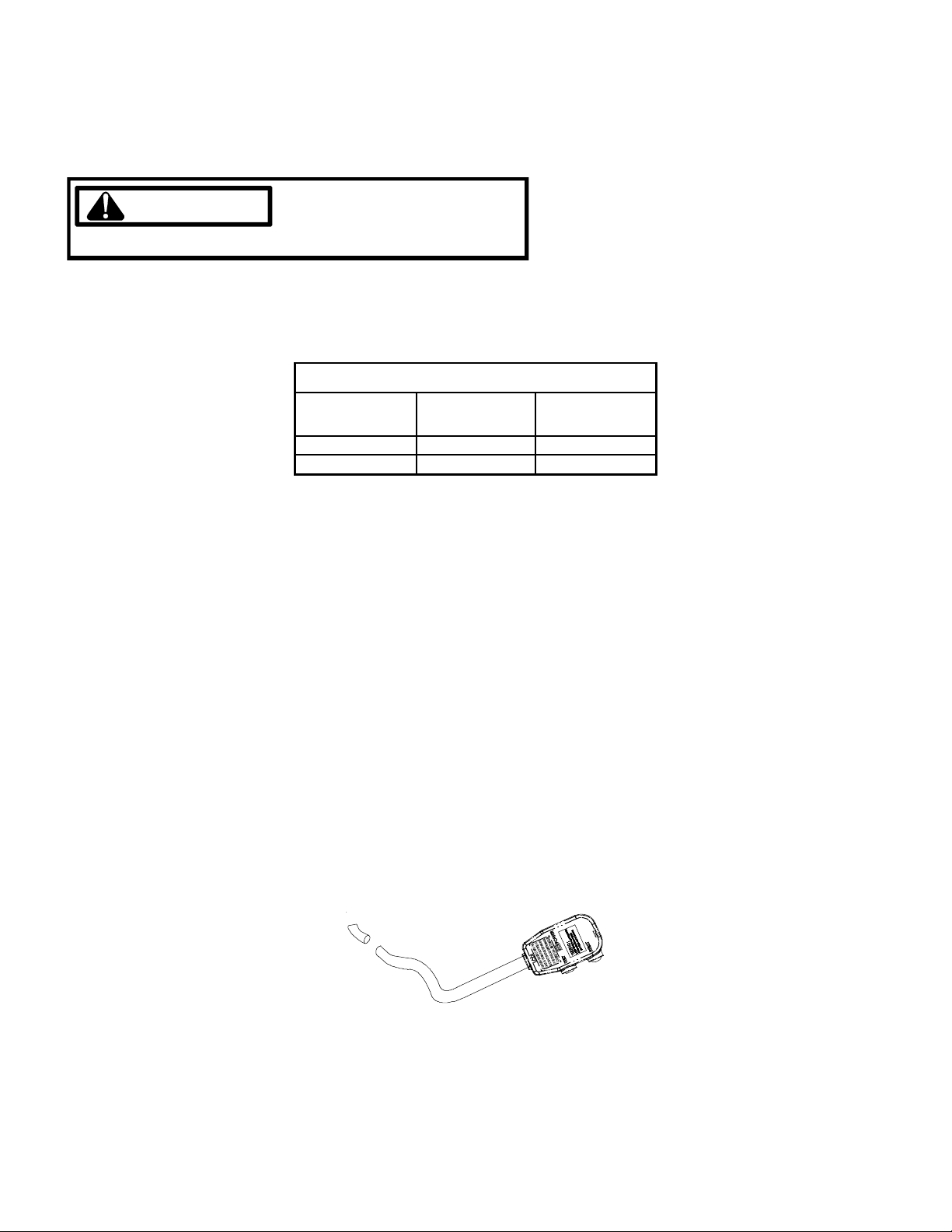

OPERATING VOLTAGES

WARNING

USE EXTREME CAUTION WHEN CHECKING HIGH VOLTAGE.

Use a voltmeter, check the voltage at the outlet.

The reading must be within the minimums and maximums shown below for the operating voltage.

Operating Voltages

Operating Voltage Minimum Voltage Maximum Voltage

230/208 197 253

265 238 291

NOTE:

1. All 265 volt models must use subbase or hard wire kit.

2. Minimum branch circuit ampacity ratings conform to the National Electric Code. However, local codes should apply

if in conflict.

3. Minimum voltage on 230/208 volt models is 197 volts; maximum is 253 volts. Minimum on 265 volts is 238 volts;

maximum is 291 volts.

4. Overcurrent protection for all units without electric heaters is 15 amps. Overcurrent protection on 265 volt models

must be cartridge-style time delay fuses (included and factory installed on chassis).

5. Heating capacity and efficiency is based on unit operation without condensate pump. Unit automatically switches to

electric heat at 25° F outdoor coil temperature.

6. Total watts for 15,000 BTUH models; subtract 30 watts for PT*12*E**** and 70 watts for PT*07/09*E****.

7. Please specify 2-digit heater kW size to compete model number.

8. Total amps for 12,000 and 15,000 BTUH models; subtract 0.2 amps for PT*07/09*E****.

• LCDI or AFCI Power Cords - Underwrites Laboratories and the National Electric Code (NEC) now require power cords

that sense current leakage and can open the electrical circuit to the unit on units rated at 250 volts or less. In the

event that unit does not operate, check the reset button located on or near the head of the power cord as part of

the normal troubleshooting procedure.

LCDI Power Cord

15

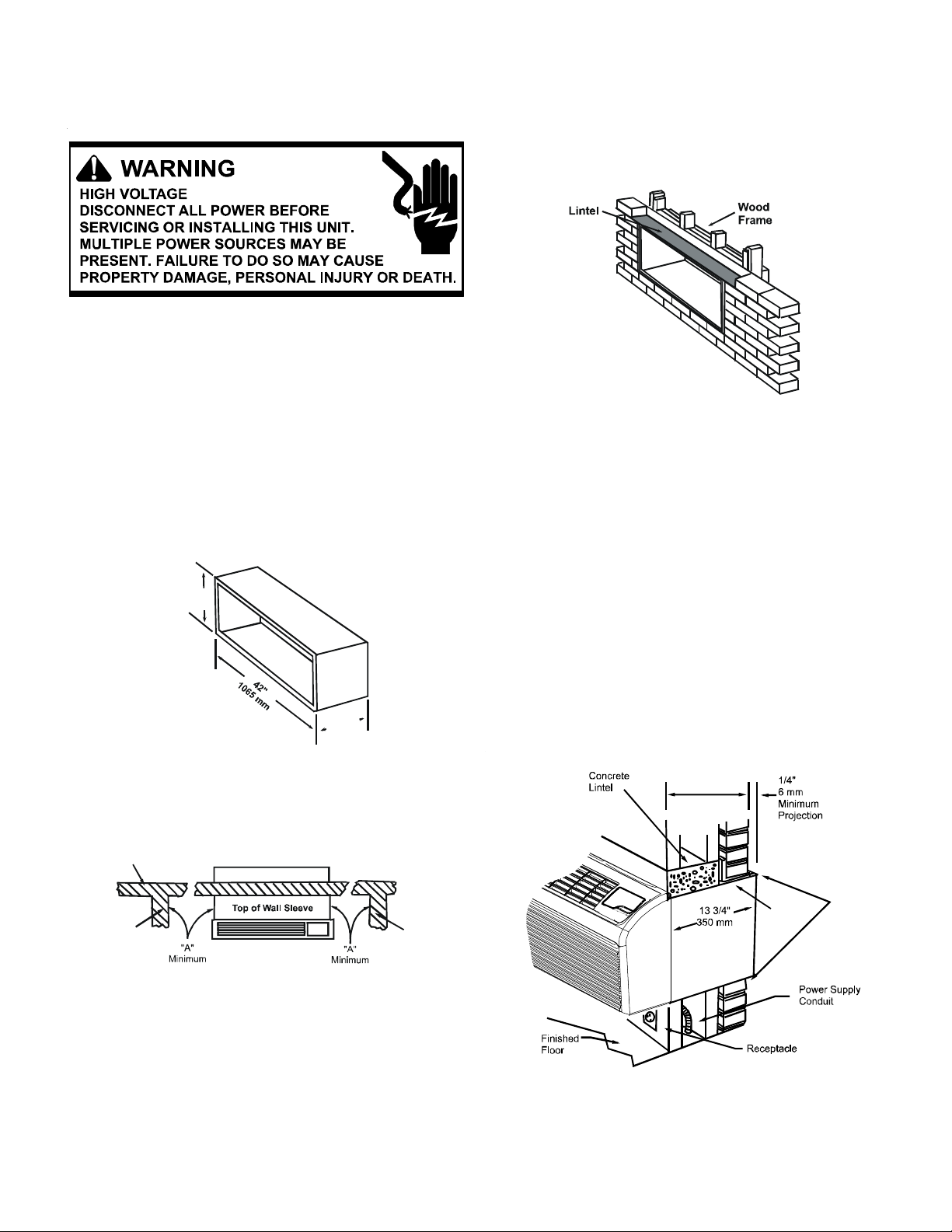

PROPER INSTALLATION

A

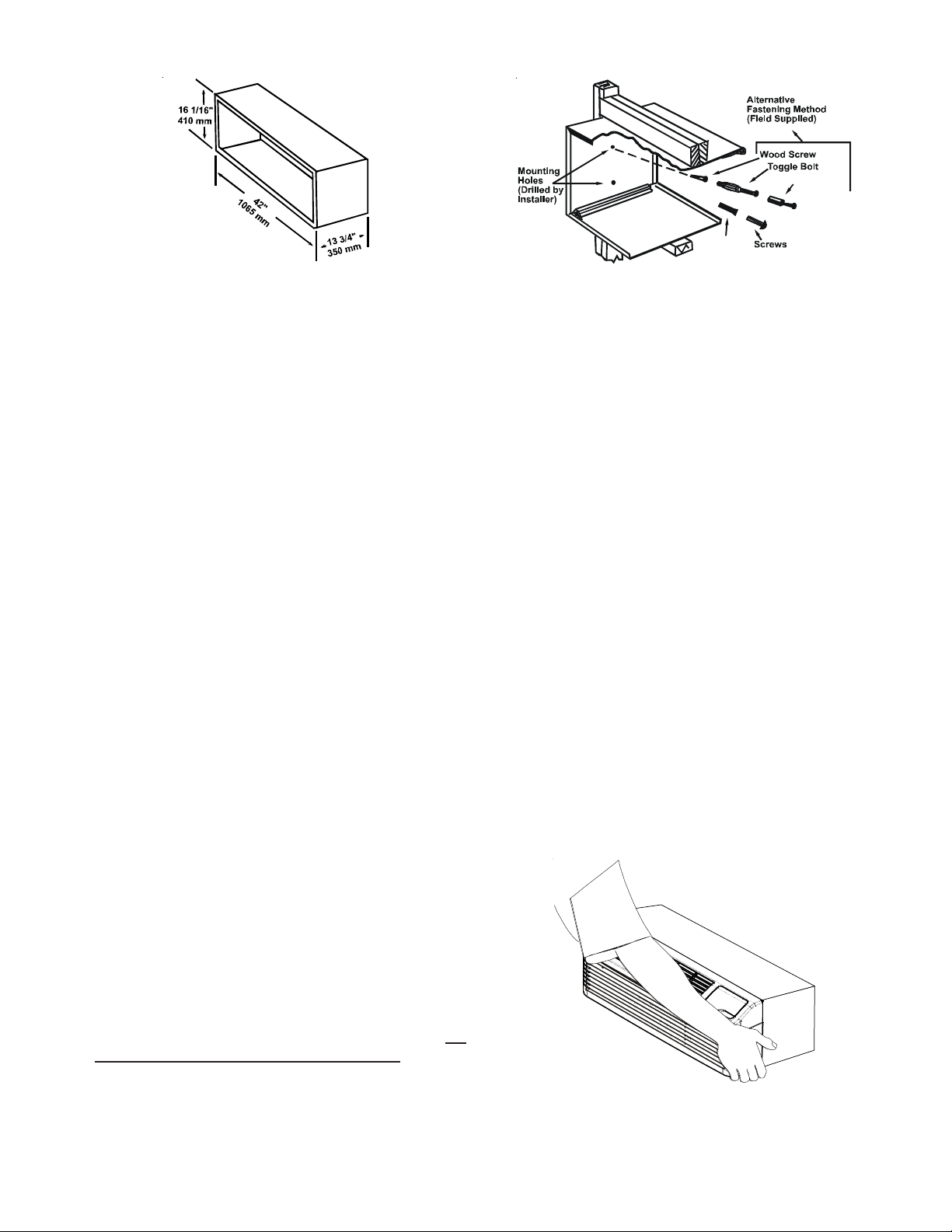

WALL SLEEVE INSTALLATION

The wall sleeve must be installed before the air conditioner

or heat pump chassis can be set in place. Read the instructions thoroughly before proceeding.

Pre-installation Considerations

Before proceeding with the sleeve installation, ensure the

following guidelines for locating the wall opening and sleeve

are met:

• The wall opening must be the correct size. See the figures below for wall sleeve Dimensions and minimum

wall opening size.

1

1

6

6

1

/

"

4

m

0

1

m

"

4

/

3

3

1

m

m

0

5

Wall Receptacle Within 58" From

Bottom R ight Side Corner on

208/230 VAC Units Only

3

• If installed in a concrete or masonry wall, a lintel must

be provided in the wall opening for support. Do not use

the wall sleeve as a lintel. See Framing with Lintel

Figure for a typical lintel construction.

Framing with Lintel

• When installed in the opening, the wall sleeve must be

horizontally level from side to side and pitched (one

quarter bubble in the sight glass) to the outside. DO

NOT INSTALL LEVEL (FRONT TO BACK) OR SLOPE THE

WALL SLEEVE TOWARD THE ROOM.

• The installer must determine and supply the mounting

bolts and/or screws to attach the wall sleeve to the

sides of the wall opening. Make sure the wall opening is

adequate for strong support.

• The installer must provide adequate sealing and insulation around the sleeve after it is installed (air and water tight). See Block and Brick Veneer Installation Figure for one of many types of constructions.

13 1/2" (340 mm)

Maximum

(No Ac ce s so ries)

Wall Sleeve Dimensions

Outside

Wall

Caulk Top,

Bottom, and

Both Sides

Internal

Adjacent

Wall

Allow Front Clearance (See Table 1)

Internal

djacent

Wall

Steel

Lintel

Minimum Unit Clearances

• The wall sleeve will need to be installed with minimum

clearances to the floor and adjacent walls. Minimum

projections of the sleeve into and out of the room will

also have to be met. See Minimum Unit Clearances and

Minimum Interior and Exterior Projections Figures as

well as Minimum Clearances and Projections table for

details.

16

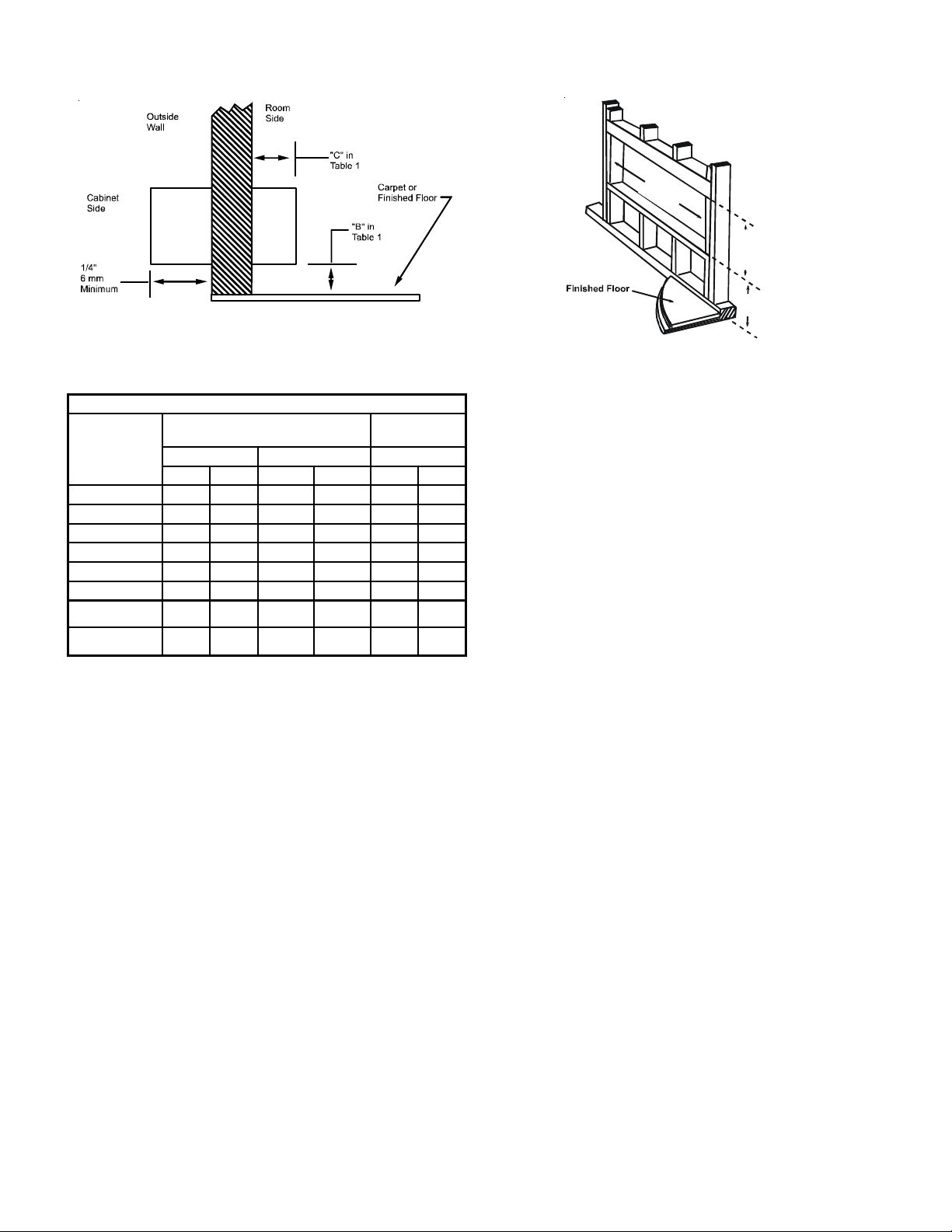

Block and Brick Veneer Installation

PROPER INSTALLATION

Minimum Interior and Exterior Projections

MINIMUM CLEARANCES AND PROJECTIONS

Minimum

Option

in. mm in. mm in. mm

Wall Sleeve Only 3 75 0 0 0 0

Subbase Kit 3 75 3 1/4 85 2 3/4 70

Leveling Legs Kit 3 75 3 75 2 50

Duct Kit 3 75 0 0 1 3/8 35

Drain Kit 3 75

Hard Wire Kit 3 75 1 1/4 30 0 0

Hydronic Heat Kit

"A" Series

Hydronic Heat Kit

"J" Series

1

If inside mounted then B = 1 1/2 inches (40 mm).

2

To achieve a flush fit between the hydronic front and the finished

9 230

6 150 0 0 2 1/2 65

Clearances

ABC

1

0

0 to 3 1/4

3

1

0

0 to 85

wall, Dimension “C” must be between 3” and 3 1/8”. If this dimension is more than 3 1/8” there will be a gap between the front and

the wall. This gap could permit occupant access to hydronic lines or

other dangerous parts.

3

This dimension can be from 0” to 3-1/4”, but cannot exceed 3-1/4”.

If this dimension exceeds 3-1/4”, the skirt around the front will not

reach the floor.

• For installations in walls deeper than 13-1/2 inches,

special care is necessary to prevent problems with rain

water, condensate drainage and intake/discharge air.

Under these circumstances, careful job site analysis and

precautions are required. You must consult with your

Sales Representative and receive approval before attempting such installations.

• If used, a 230/208 volt wall receptacle must be located

within 58 inches of the lower right sleeve corner. Extension cords must not be used with the unit. See the

note on Wall Sleeve Dimensions Figure.

Minimum

Projection

00

3

32 752

4

2

1

1

0

/

4

7

"

M

5

i

m

n

i

m

m

u

m

m

"

m

u

4

/

m

1

m

i

5

6

n

1

i

1

4

M

Dimension "B"

in Table 1

Minimum Wall Opening Dimensions

When 230/208 volt units are to be installed, the power supply may be either cord connected or permanent wiring. Permanent wiring may be done through the accessory hard wire

junction box, or the accessory subbase.

When 265 volt units are to be installed, the power supply

must be permanent wiring. Permanent wiring may be done

through the accessory hard wire junction box, or the accessory subbase. An exposed cord connection on 265 volt

units is not permitted.

The subbase accessory includes leveling legs. If added wall

sleeve support is required and the subbase is not to be used

as an accessory, leveling leg kit may be installed.

Drain Kit

An indoor/outdoor drain kit is available as an accessory

item. When a drain kit is to be installed, do so before installing the wall sleeve in the wall. See the drain kit for

actual installation instructions.

Subbase, Leveling Legs, Main Duct, and Hydronic Heat

Kits

Installation of these kits requires drilling of mounting holes

on both sides of the wall sleeve. The minimum required

clearance distance between the wall sleeve and wall is shown

in Minimum Clearances and Projections Table. If the distance between wall sleeve and wall will be at or near the

minimum clearance distance, mount these kits on the sleeve

before installing the sleeve in the wall. The kit installation

instructions are included with the accessory kits.

17

PROPER INSTALLATION

Wall Receptacle Within 58" From

Bottom R ight Side Corner on

208/230 VAC Units Only

Wall Sleeve Dimensions

Outside Enclosure Panel Removal

The sleeve stiffener must be taken out before the enclosure panel can be removed from the sleeve.

The enclosure panel can be removed by folding the four

flaps up and downward and manipulating the front ends of

the top plus bottom towards the center. The entire panel

can be pulled out diagonally from one side.

Install the wall sleeve condenser air grille by using the screws

and holes provided.

Installation (WS900B or WS900D)

After the wall opening is checked and approved for location, size, and clearances, complete the following to install

the wall sleeve.

NOTE: Check with Amana® Brand Technical Service when a

chassis is installed in any wall sleeve not supplied by

Goodman.

1. Remove the outside enclosure panel from the wall sleeve.

2. Slide the wall sleeve into the wall opening. Do not distort the cabinet shape to fit the wall opening. The unit

chassis must fit snugly and uniformly into the wall

sleeve.

3. Locate the sleeve within the range of minimum projections, as shown in Minimum Wall Opening Dimensions

and Minimum Interior and Exterior Projections Figures,

so both sides are at least the minimum projection from

the wall.

4. Check the level of the wall sleeve. For proper drainage,

the sleeve should be level from side to side and onequarter bubble in the sight glass sloping to the outside.

5. Two holes will need to be drilled in both sides of the

wall sleeve for mounting into the wall. Drill holes of

proper size and in the proper location so the screws will

engage into strong supporting members of the wall. DO

NOT DRILL THROUGH BOTTOM OF SLEEVE. The following figure shows possible fastening methods.

Expansi on

Anchor Bolt

Plastic

Anchor

Attaching Wall Sleeve to Opening

6. Check the level of the wall sleeve and adjust if necessary.

7. Caulk or seal around the outside of the entire sleeve.

8. If the unit chassis will not be installed immediately,

replace the enclosure panel on the outside opening of

the sleeve. This will prevent weather damage to the

building interior.

9. Recycle or dispose of packaging materials per local

codes.

OUTDOOR GRILLE

An outside grille must be installed to direct air flow for proper

unit operation and also protect the outdoor coil. The grille

must be installed before installing the chassis. Refer to the

Installation Instructions supplied with the outdoor grille kit

for a complete description of the installation procedure.

This model requires either a Stamped Grille Kit (Model SGK-

-B) or an Architectural Grille Kit (Model AGK--B). When replacing an old chassis with an existing grille, please check

with your sales representative to determine if the new chassis should be used with the old outdoor grille. An improper

outdoor grille can decrease cooling or heating capacity, increase energy usage and shorten compressor life.

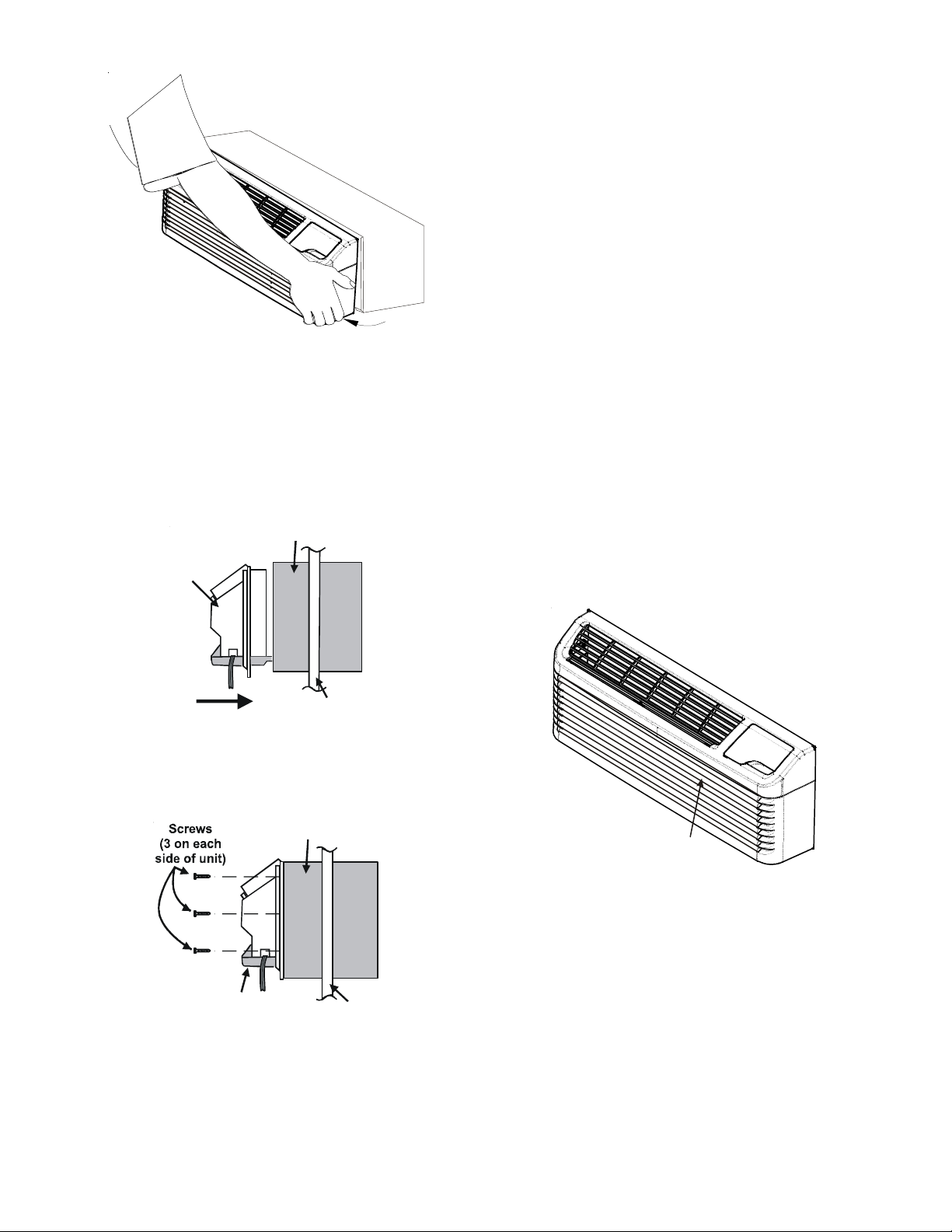

FRONT REMOVAL

1. Grasp the cabinet front as shown.

18

2. Pull the bottom of the cabinet front away from the chassis until the retaining clips disengage.

PROPER INSTALLATION

3. Lift the cabinet front off the chassis. Reverse this procedure to reinstall the cabinet front.

CHASSIS INSTALLATION

1. Remove the cabinet front from the chassis as described

in Front Removal.

2. Insert the chassis into the wall sleeve.

Wall Sleeve

Chassis

4. Secure the chassis to the wall sleeve using three screws

on each side of the chassis to ensure a proper seal between the chassis and the wall sleeve. The screws are

supplied in a plastic bag which is attached to the power

cord.

IMPORTANT NOTES:

1. The unit is equipped with a rubber grommet mounted

compressor. These grommets are factory set and require no adjustment.

2. If a standard subbase is used, be sure the right hand

subbase cover is removed before the chassis is installed

in the sleeve.

3. Check the indoor and outdoor grilles for obstructions to

air flow. The unit must be located where curtains, furniture, trees, shrubs or other objects do not block the

air flow to and from the unit. If air is obstructed and/or

deflected back into the unit, the air conditioner’s compressor may cycle on and off rapidly. This could damage the compressor and void the warranty.

Front Mounting Holes - Two mounting holes are provided to

give the owner the option of securing the front to the chassis. The mounting holes are located behind the intake grille.

The owner must supply two 1/2 inch long #8 sheet metal

screws per unit. The two screws must be removed before

the front can be removed.

Slide Chassis In

Outside

Wall

3. Slide the chassis into the wall sleeve until the chassis

flanges contact the front edge of the wall sleeve.

Wall Sleeve

Chassis

Outside

Wall

Front Mounting Screw

accessed

through louv er s.

Front Mounting Screws

19

PROPER INSTALLATION

SPECIFICATIONS

WIRING

CAUTION

TO AVOID PROPERTY DAMAGE, PERSONAL INJURY

OR DEATH DUE TO ELECTRICAL SHOCK:

• DO NOT USE AN EXTENSION CORD WITH THIS UNIT.

• USE ONLY COPPER CONDUCTORS.

• WIRING TO THE UNIT MUST BE PROPERLY POLAR-

IZED AND GROUNDED.

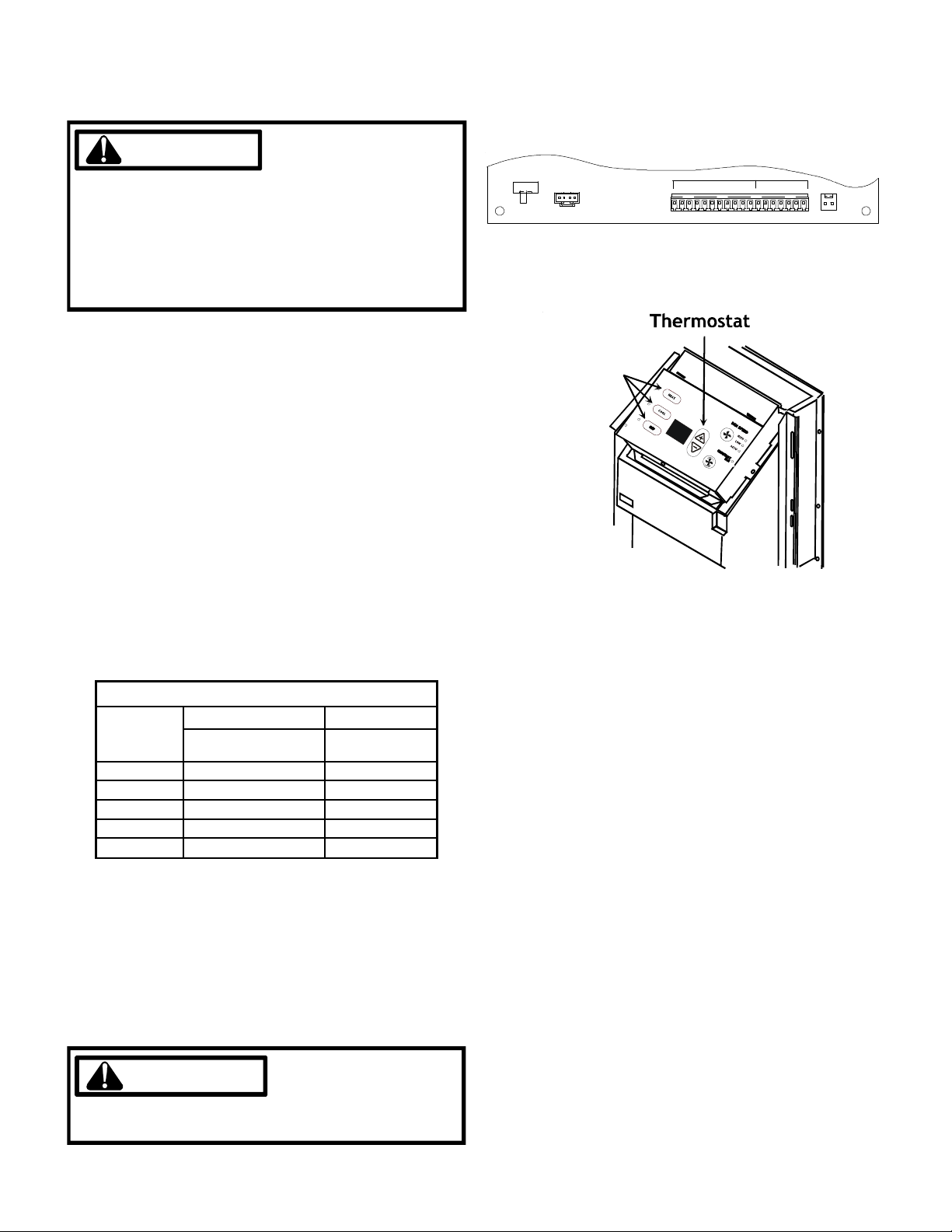

OPERATING CONTROLS

Users Controls

Two rotary knobs controlling temperature and operational

SW2

M1

ON / OFF

MASTER SWIT CH

P10

COM A

DS1 DS2 MS1 MS2 EH IN LS FD1 FD2 TF- TF + C R G L W2 Y/W1 B GH

P12

REMOTE THERMOSTATAUXILIARY

P13

IAT

BLACK

M2

Cord connection to a wall socket is not permitted for 265volt units. All 265-volt units must be hard wired using the

hard wire kit or make use of the plug-in receptacle in the

standard subbase.

Heaterless Units

If a heaterless unit is ordered, field provisions must be made

for supplemental heat if desired. Refer to the Installation

Instructions supplied with the heater kit for a complete description of the installation procedures. All 208/230 volt

heaterless units are shipped with a 15 Amp power cord and

all heaterless 265 volt units are shipped with a 20 Amp power

cord.

When adding a heater kit to a unit, the power cord supplied

with the heater kit must be used in place of the power cord

supplied with the unit. The following table specifies power

cord rating requirements for the various heater kits.

POWER CORD REQUIREMENTS

Heater Size

(kW)

1.5 15 20

2.5 15 20

3.5 20 Not Applicable

3.7 Not Applicable 20

530 30

230/208 Volt Units 265 Volt Units

Power Cord Rating

(amp)

Power Cord Rating

(amp)

NOTE: Heaterless units are shipped with an auxiliary data

label on the front side of the mid-partition panel. If an

electric heater kit is field installed, the installer must mark

the appropriate box on the label to indicate the electric

heater capacity. If no heater is installed, the box labeled

“None” must be marked. Refer to the unit nameplate for

over current protection data.

Mode

Switches

Master Switch

The master switch disconnects power to all of the system

components. When this switch is in the off position, the

compressor, fan motor, reversing valve, and electric resistance heater will all be de-energized.

REMOTE/STANDARD

The remote/standard configuration is used to change the

control of the unit from the standard on board controls in

the standard mode, to a remote wall mounted thermostat

in the remote mode. For remote control configuration settings, refer to Configuration Settings.

Fan Cycle Configuration

The fan cycle configuration sets the operational mode of

the fan. In the ON position, the fan will run continuously

whenever the unit is in the heat or cool mode. In the AU

position, the fan will cycle on and off with the compressor

or electric heater when the unit is in the cool or heat mode.

Remote Control Inputs

The C, R, G, (GL for low fan speed or GH for high speed fan

on W2, Y/W1 and B terminals provide control inputs for a

remote wall mounted thermostat. See following illustra-

tion.

CAUTION

DO NOT INSTALL A 5kW HEATER KIT IN ANY 7,000

OR 9,000 BTU CHASSIS.

20

PROPER INSTALLATION

18 Pin Connector

IMPORTANT NOTE: Disconnect power to the unit and/or

turn the Master Switch on the control board to OFF when

connecting or altering wiring to any terminal. Failure to do

so may result in shorting the fuse or damaging the control

board.

Front Desk Control

The FD1 and FD2 provide control inputs for a front desk

switch. Shorting across these two terminals will disable

unit operation. The only control function which will remain

active when these terminals are shorted is freeze protection. Any switch which will produce a short circuit across

these two terminals can be used as a front desk switch.

The contact resistance of the switch, when closed, must be

less than 200 ohms for the front desk feature to operate

properly.

The following table shows the maximum wire length and

corresponding gage size for installation of a front desk

switch.

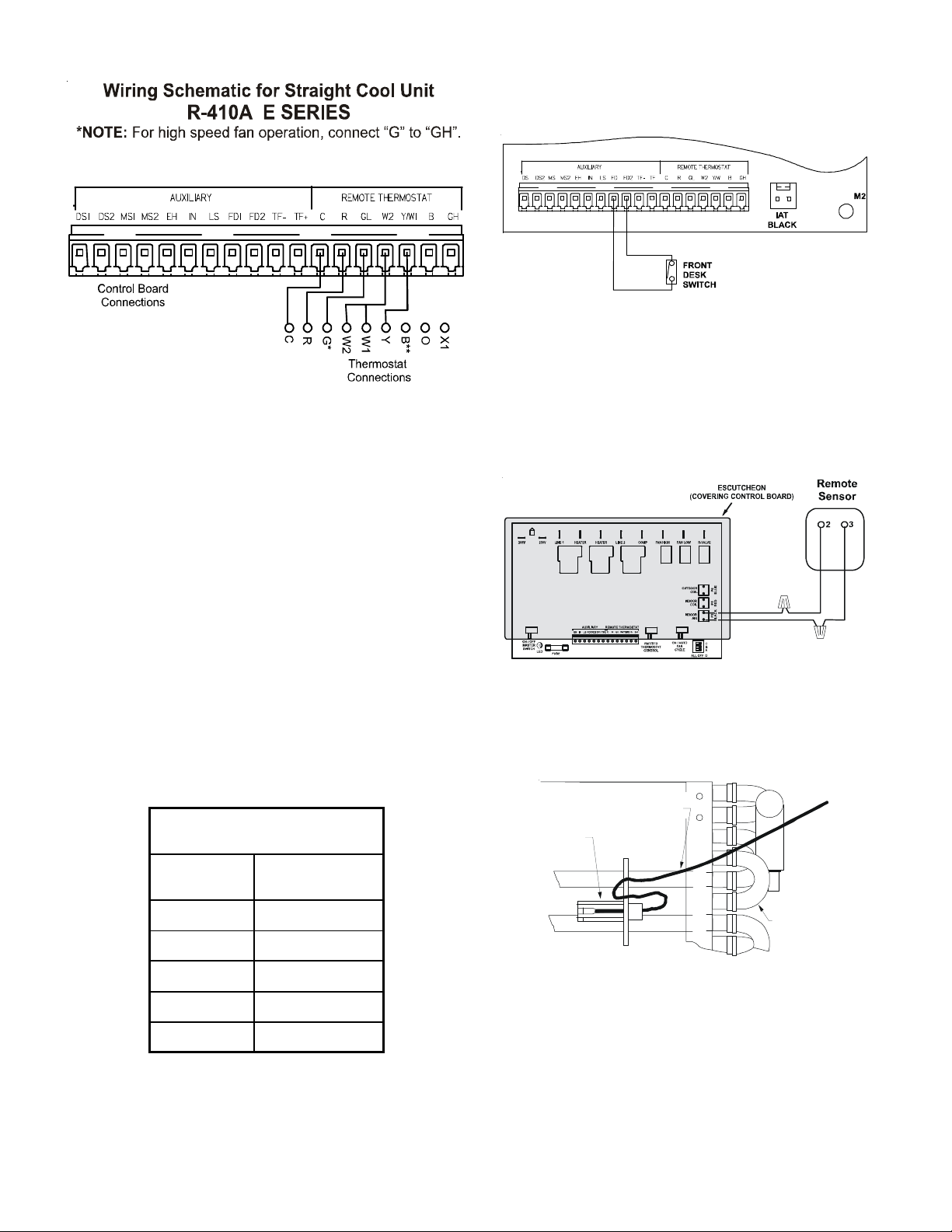

The figures below shows a wiring schematic for connecting

the front desk switch to the unit.

1 1 1 + 1

Front Desk Switch Wiring Schematic

IMPORTANT NOTE: Do not apply 24VAC across these ter-

minals. Applying 24VAC to these terminals will result in failure of the control board. Shorting these terminals to any

other terminals may also result in control board failure.

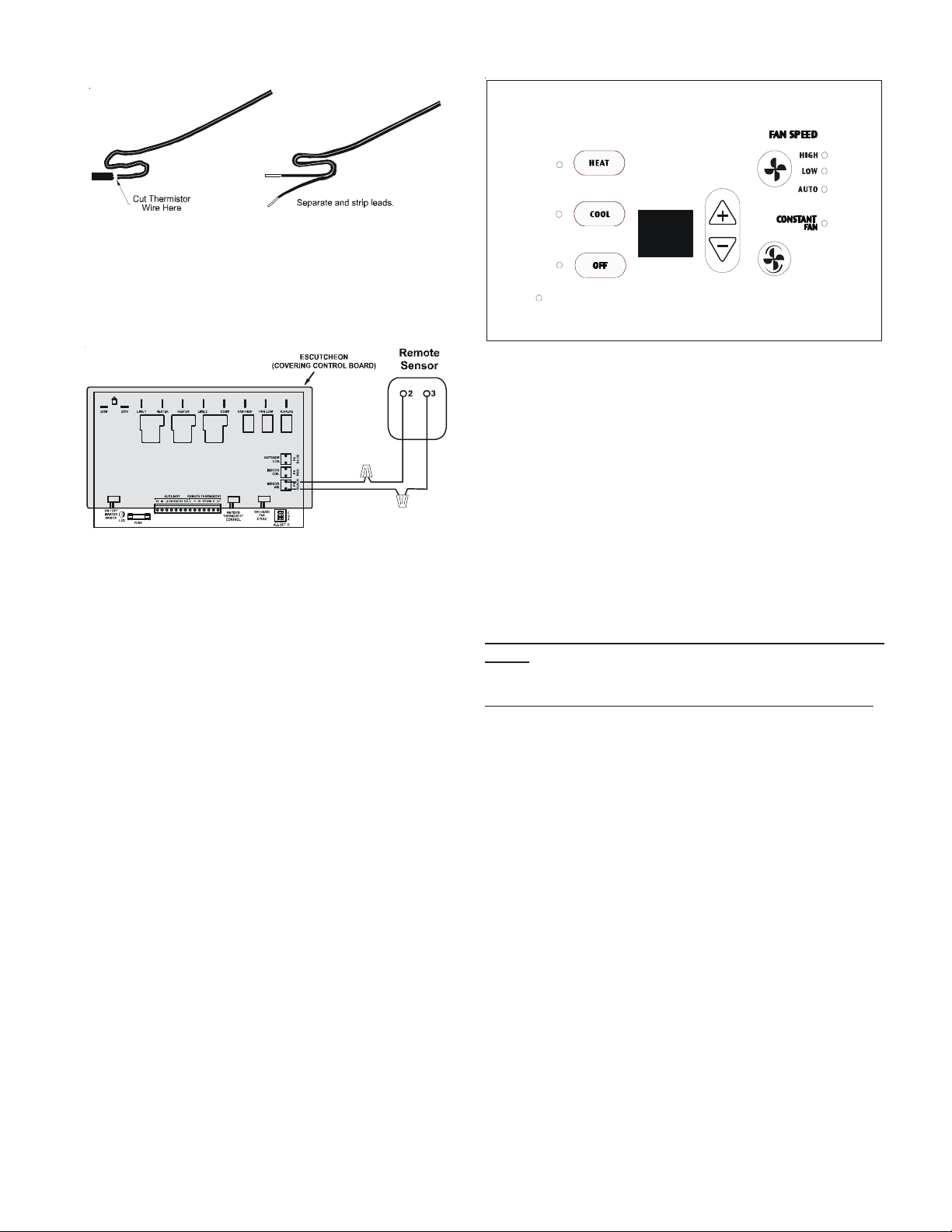

Remote Temperature Sensing

1. Remove indoor ambient thermistor from plastic holder

on indoor coil.

MAXIMUM WIRE LENGTH

FOR FRONT DESK SWITCH

Wire Size

(AWG)

#24 400

#22 600

#20 900

#18 1500

#16 2000

Maximum

Length Allowed

(ft)

Indoor Ambient

Thermistor

Plastic

Holder

Indoor Coil

2. Cut off end of thermistor, separate leads 1” back from

cut and strip 1/2” of insulation from each lead.

21

PROPER INSTALLATION

3. Wire nut the stripped leads to the two sensor wires

running from terminals 2 and 3 on the remote temperature sensor base .

User Controls

Thermostat Setting

Pressing the COOL thermostat control and the up or down

arrows will provide a cooler room temperature, respectively. Pressing the HEAT thermostat control and the up or

down arrow keys will provide a warmer room temperature.

Fan Speed

4.Place the mode switch in the “OFF” position. Reestablish power to the unit. The remote temperature will

automatically activate.

NOTE: Ensure the mode switch is in the OFF position before

electrical power is applied to the unit. If the mode switch is

not in the OFF position when electrical power is applied to

the unit, the random restart feature will activate causing a

two to four minute start-up delay.

NOTE: Freeze protection temperatures will be sensed by

the remote temperature sensing device and not at the PTAC

unit (sensed at the PTAC unit when a remote thermostat is

used).

Temperature Limiter

The temperature limiting feature can reduce energy costs

by controlling the maximum temperature available in heating and the minimum temperature available in cooling. While

approximate temperature settings are shown below, actual

room temperature will vary slightly.

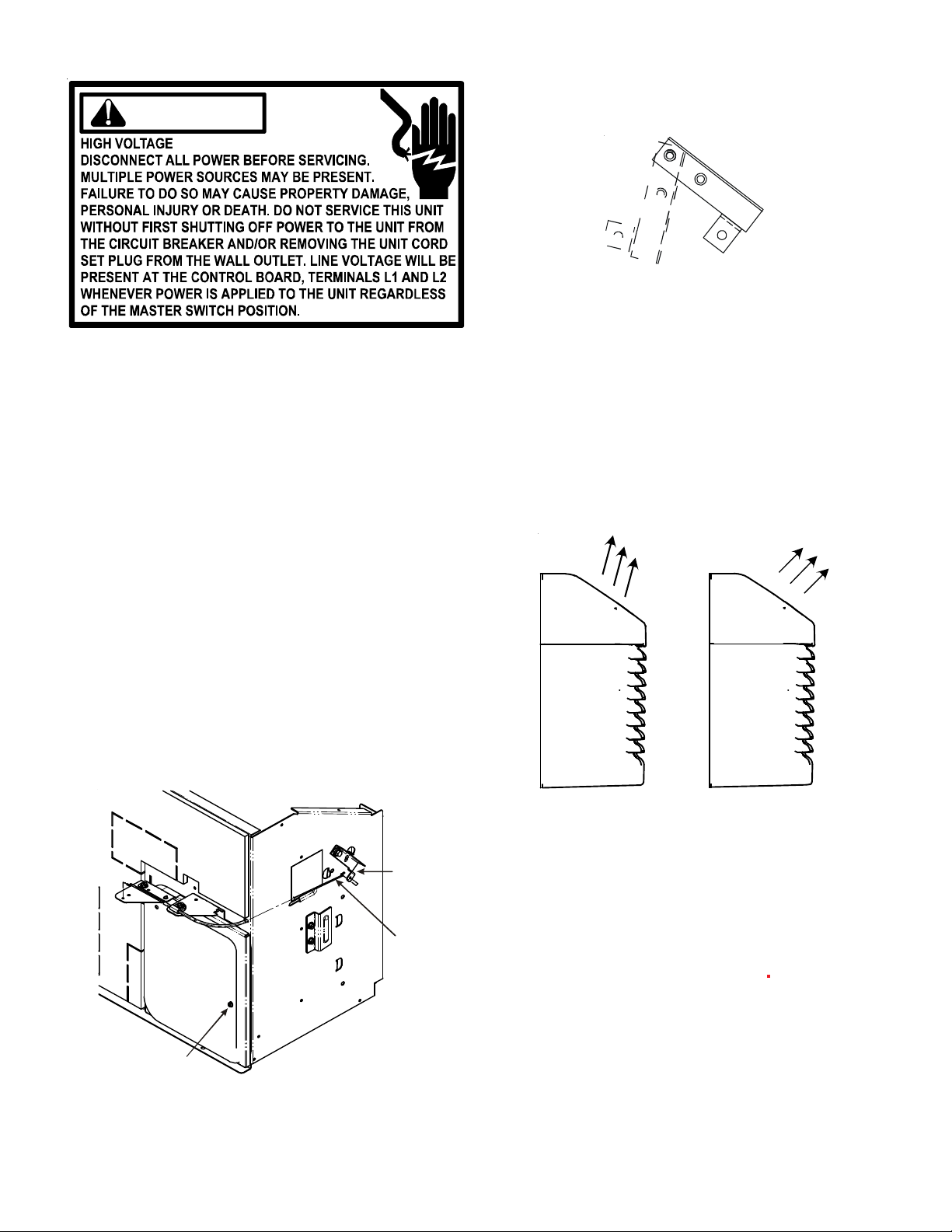

Users Controls "Digital Touch Pad"

A seven button touch key pad located behind the control

door controls both temperature and operation mode. The

key pads can be used alone or in combination.

The fan speed touch key will deliver high, low or auto fan

speed to circulate room air. NOTE: The AUTO selection will

not be available if a fan speed is selected without COOL or

Heat selection.

Fan Operation HIGH or LOW with HEAT or COOL mode selected - The selected fan speed shall run in the selected

speed.

Fan Operation AUTO with HEAT or COOL mode selected The fan will run in low and high speed. The changes in fan

speed are automatic. See "Configuration Settings" section

for further details.

Diagnostic Light

The green diagnostic light located in the lower left hand

corner of the touchpad and indicates operation warnings.

This light usually indicates that either the filter or coils need

cleaning. Please refer to the Maintenance and Cleaning

section for the proper cleaning procedure. If this light is

still on after cleaning, please refer to the Diagnostic & Sta-

tus Report section for assistance.

Additional Control Inputs

The control inputs provide additional unit control and features. To access these control inputs, the cabinet front

must be removed (see Front Removal).

Master Switch

The master switch disconnects power to all of the system

components. When this switch is in the off position, the

compressor, fan motor, reversing valve, and electric resistance heater will all be de-energized.

22

PROPER INSTALLATION

WARNING

Rotate the vent control lever to either open or close the

damper.

Remote Control Inputs

The C, R, GL, W2, Y/W1, B/O, and GH terminals provide

control inputs for a “manufacturer-approved” remote wall

mounted thermostat. The “B” terminal can be configured

to become “O” if needed see Configuration Settings For

remote control thermostat operation, refer to the Remote

Thermostat Operation section.

Vent Control

NOTE: Vent control is only used on units with the power

vent or power vent door kit not installed.

The vent control allows fresh air to be drawn into the conditioned area. This fresh air can provide ventilation when the

blower is operating, but it will increase the heating or cooling load and operating costs.

To obtain access to the vent control, remove the cabinet

front (see Front Removal). Remove the shipping screw (if

installed) from the vent door. Then remove the label (if

present) from over the vent control lever on the left side of

the chassis.

Vent

Open

Vent

Closed

HYDRONIC HEAT INSTALLATIONS

To avoid the risk of freezing the steam or water coil during

prolonged shut down periods, the vent door must be left

closed when the outdoor temperature might fall below freezing or a power door kit must be installed.

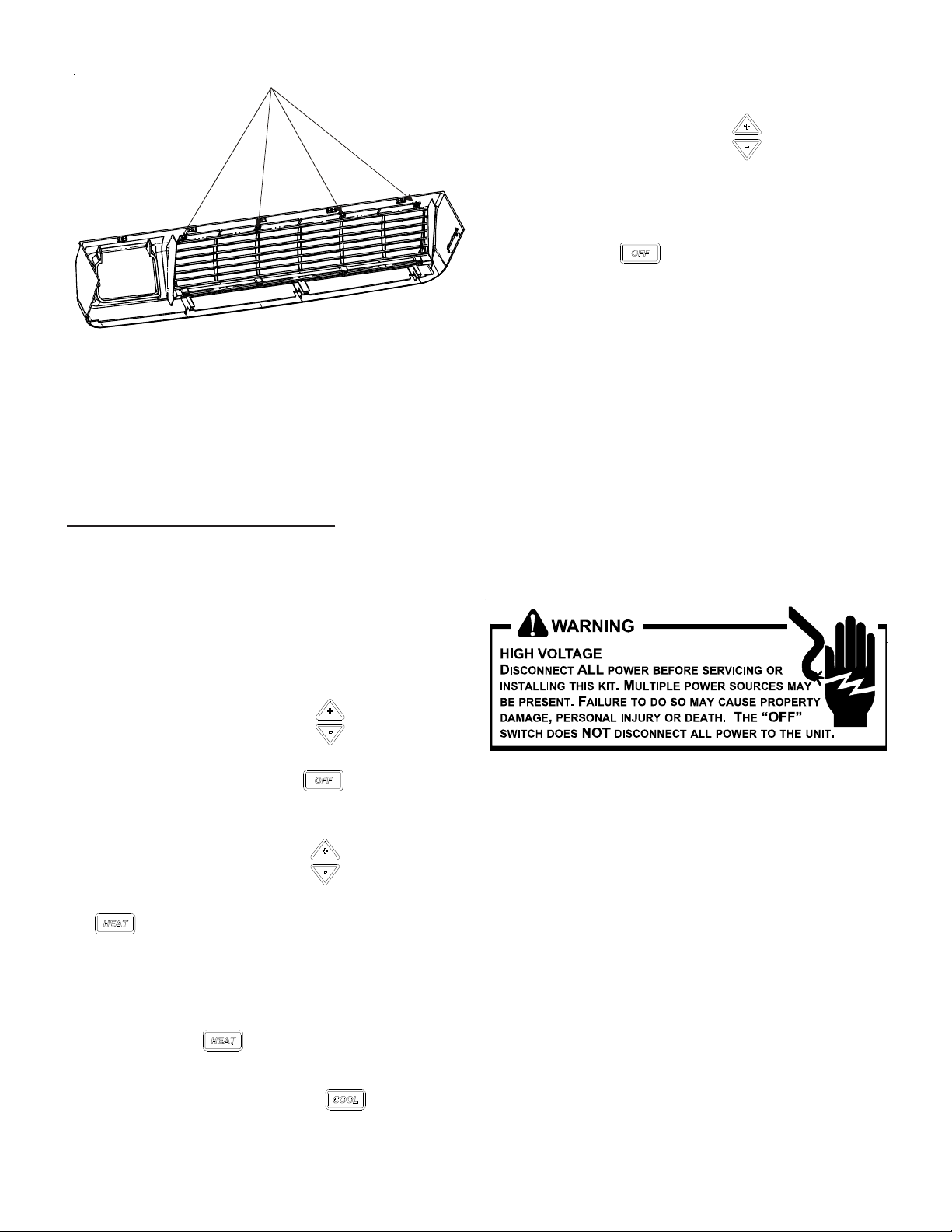

AIR DISCHARGE GRILLE

The discharge grille can be adjusted to expel air at either a

16° or 56° angle.

16°

Discharge

Air

56°

Discharge

Air

Vent Door

Shipping Screw

Vent

Control

Lever

Vent

Control

Discharge Grille Orientation Options

Use the following procedure to change the angle of the discharge air flow:

1. Remove the front cabinet (see Front Removal).

2. Position the front so that the backside is accessible.

Discharge Air Flow

3. Remove the four (4) screws which secure the discharge

air grille to the cabinet front.

23

PROPER INSTALLATION

Location of 4 Screws

4. Rotate the grille 180° end-for-end.

5. Reinstall the nuts securing the discharge air grille to

the cabinet front. Reinstall the cabinet front on the unit.

CONFIGURATION SETTINGS FOR R410A

E SERIES MODEL BOARDS

7 BUTTON TOUCH PAD WITH DISPLAY

The control can be configured to operate a wide range of

options. The options listed below with the * are the factory

default settings. If these are acceptable, then the unit does

not require any additional configuration and is fully operable. To configure the unit, first select the configuration

feature code setting and then an option code to change

from the factory default setting.

To enter configuration feature mode:

Once you have scrolled to the correct feature, then to

select the option code for your desired configuration,

press either the up or down key

the options of the selected feature code.

To exit configuration mode:

1. Press the OFF

mode will also exit if no keys are pressed for a period of two (2) minutes.

Refer to the Configuration Chart.

key. Configuration feature

to scroll through

Wireless Communications

PTAC models PT****B***M, N or P have the option to use a

wireless thermostat and door sensor. These features will

only work on the models listed above. The thermostat and /

or door sensor will require an antenna for communication

with the digital control board.

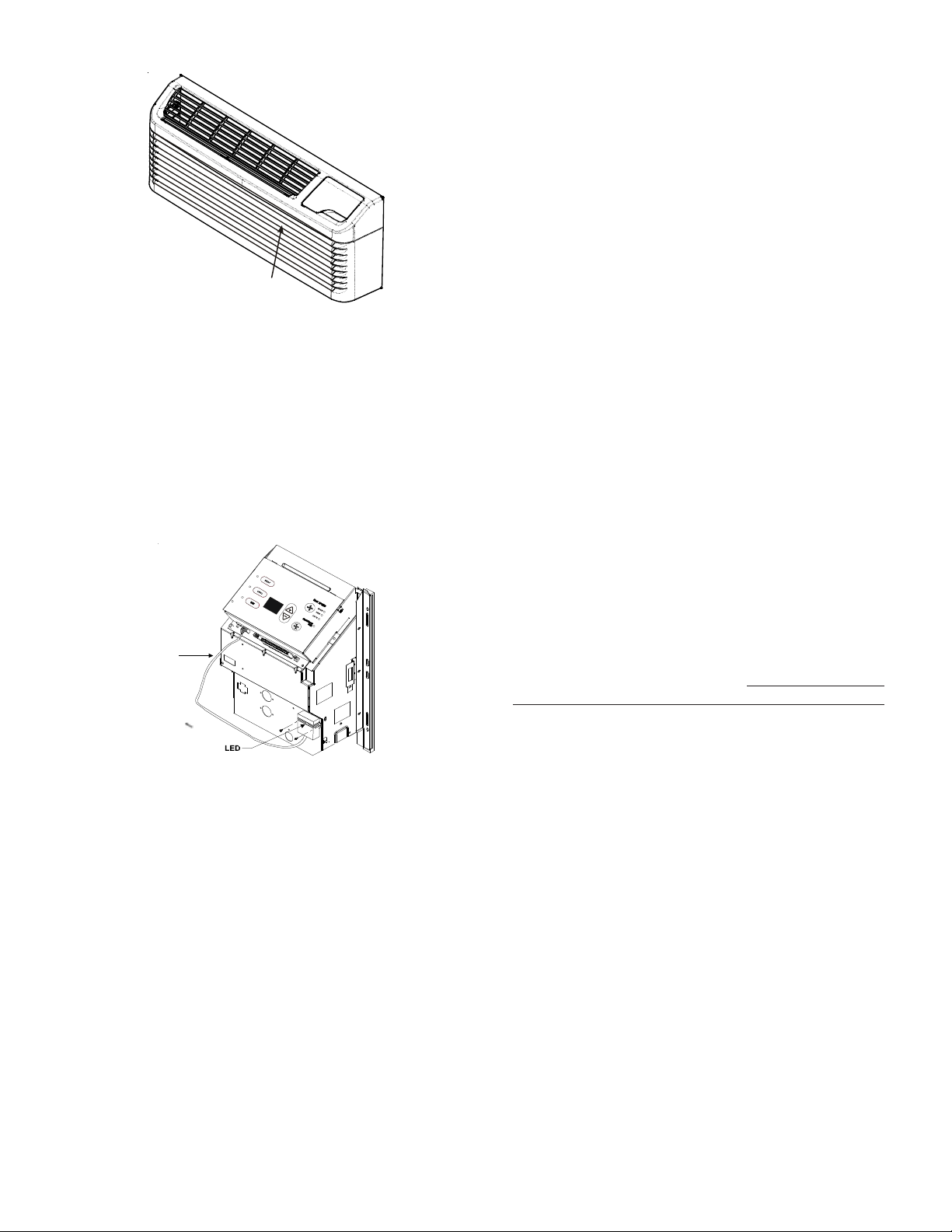

ANTENNA INSTALLATION FOR DT01* KIT

A DT01* antenna must be installed on the digital PTAC to

allow operation of either the DS01* remote RF thermostat

or a DD01* combination PIR motion sensor and door switch.

1. Press and hold the up and down arrow keys at the

same time and press the OFF key twice within

a two (2) second time frame. The display will indi-

cate - -., and then release the key and press the

key one time. The display will then alternate be-

tween C1 and 0.

To select a different configuration feature code,

press the HEAT key until the desired configu-

ration comes up. To scroll to a previously viewed configuration codes press the COOL key .

24

PREPARATION

1. Disconnect power to the unit by unplugging the power

cord at the wall outlet or subbase, or disconnect power

at the fuse box or circuit breaker.

2. If the cabinet front is screwed to the chassis, remove

the 1/4” screw (or screws). See following figure.

PROPER INSTALLATION

Front Mounting Screw

accessed

through louvers.

3. Remove cabinet front from chassis by tilting the bottom of the front forward, lifting slightly up and forward.

4. Mount the antenna as high up on the control panel as

possible and as far to the right as possible in a location

that will not interfere with the reinstallation of the PT AC

polymer room front. Mark holes for screw location. Remove antenna housing and drill two 1/8” holes where

marked. Some units may have the holes already predrilled in the correct location.

Wire

DT01* Mounting

5. Remove antenna cable and route cable through opening

in bottom of antenna housing.

6. Mount antenna housing with two screws as shown in

figure. (NOTE: The Amana® brand logo should be in the

lower right hand corner).

7. Plug wire harness from antenna into connector on the

control board to the right of the master switch, being

careful not to bend and/or break the wires when you

connect the cable to the PT AC. Gently push the connector into place by pushing on the edge of the connector

with your thumb nails. Avoid pushing directly on the

wires.

8. Restore power to the PT AC unit.

9. Reinstall the polymer room cover .

NOTE: The LED must be oriented at the top of the antenna

housing (the Amana® brand logo will be on the lower right)

for proper unit operation.

THERMOSTAT INSTALLATION FOR DS01E KIT

NOTE: A DT01* must be installed on the digital PTAC unit for

the DS01* to be operable.

Skip these steps if not installing.

1. Select thermostat mounting location about five feet

above the floor, on an inside wall, out of direct sunlight, away from sources of radiant heat (lamps, fireplaces, heating and air conditioning equipment, etc.),

away from windows or door to the outside, and avoid

areas with poor air circulation. If the PIR in the thermostat is to be used with a DD01* device as a 2nd motion sensor , point the thermostat towards the area where

you are requiring additional motion sensing.

Ensure location is out of the path of foot traffic where

a person might accidentally bump into the thermostats

and damage the device.

2. R emove thermostat from mounting plate by pulling apart

at the bottom of the thermostat about 1”, and slide

thermostat up to release from the top of the mounting

plate.

3. Place thermostat mounting plate against the wall at desired location and mark placement of mounting holes.

Make sure the UP arrow is pointing up on the mounting

plate.

4. If mounting in drywall, tap plastic anchors into wall. For

other surfaces, drill a 3/16” hole.

5. Screw mounting plate to the wall. DO NOT SNAP THERMOSTAT INTO PLACE UNTIL AFTER BINDING PROCESS.

See Binding Instructions.

6. Install four (4) AA batteries (included) into the back of

the thermostat. Terminals are marked “+” and “-” for

polarity.

NOTE: Do not install thermostat on wall plate until all configuration settings and binding processes have been completed.

WIRED POWER OPTION

1. If the option for wired power is used, the two thermostat wires (20 gauge minimum field supplied) can be

connected to the thermostat.

2. Route wires through the opening in the mounting plate.

3. Loosen set screws on wired terminal and insert wires

into the opening. Tighten set screws.

4. Connect wires at PTAC unit to terminal pins C and R.

The wire harness kit PWHK01C is required for this connection.

25

Loading...

Loading...