Page 1

Service Instructions

ACCESSORIES MANUAL

R-22 Package Terminal

Air Conditioners & Heat Pumps

All Models and Manufacturing Numbers For R-22 Amana® Brand Units

This manual is to be used by qualified, professionally trained HVAC technicians only.

Goodman does not assume any responsibility for property damage or personal injury

due to improper service procedures or services performed by an unqualified person.

is a registered trademark of Maytag Corporation or its related companies and is used under

license to Goodman Company, L.P., Houston, TX. All rights reserved.

RS4900003r2

December 2010

© 2001, 2010 Goodman Company, L.P.

Page 2

Table of Contents

When Ordering Parts .................................................................................................................................................... 3

Circuit Breaker Kit......................................................................................................................................................... 4

Condensate Drain Kit .................................................................................................................................................... 6

Condensate Removal Pump .........................................................................................................................................10

Condenser Baffles ........................................................................................................................................................13

Curtain Guard...............................................................................................................................................................14

Duct Kit........................................................................................................................................................................16

Electric Heat ................................................................................................................................................................22

Escutcheon - Hydronic Remote....................................................................................................................................27

Escutcheon - Remote ..................................................................................................................................................28

Fuse Kit .......................................................................................................................................................................29

Hard Wire.....................................................................................................................................................................31

Hydronic Heat ..............................................................................................................................................................33

Hydronic Transformer ...................................................................................................................................................42

Keylock........................................................................................................................................................................43

Power Disconnect Switch ............................................................................................................................................44

Remote T emperature Sensor ........................................................................................................................................46

Subbase ......................................................................................................................................................................48

Remote Thermostat High Fan Kit .................................................................................................................................51

Right Hand Subbase Conversion ..................................................................................................................................53

IMPORTANT INFORMATION

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service

technician who is familiar with the safety procedures required in the repair and who is equipped with the proper tools,

parts, testing instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE

APPROPRIATE SERVICE MANUAL BEFORE BEGINNING REPAIRS. FOLLOW CAREFULLY ALL CAUTIONS

AND WARNINGS IN THE SERVICE MANUAL.

IMPORTANT NOTICES FOR CONSUMERS AND SERVICERS

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

HIGH VOLTAGE

D

ISCONNECT ALL POWER BEFORE

SERVICING

M

ULTIPLE POWER SOURCES MAY BE PRESENT

AILURE TO DO SO MAY CAUSE PROPERTY

F

DAMAGE

OR

INSTALLING THIS UNIT

,

PERSONAL INJURY OR DEATH

.

.

.

2

Page 3

WARNING

THIS AIR CONDITIONE R IS NOT ME ANT TO PROV IDE

UNATTENDED COOLI NG OR LIFE S UPPORT FO R

PERSONS OR AN IMALS WHO ARE UNABL E TO

REACT TO THE FAILURE OF THIS PRODUCT.

THE FAILURE OF AN UNATTENDED AIR CONDITIONER MAY RESUL T IN EX TREM E HEAT IN THE CON DITIONED SPACE CAUSING OVERHEATING OR

DEATH OF PERSONS OR ANIMALS.

PRECAUT IONS MUST BE TAKE N TO WARN OF OR

GUARD AGAINST SUCH AN OCCURENCE.

CAUTION

G

OODMAN WILL NOT BE RESPONSIBLE FOR ANY

OR

INJURY

IMPROPER

I

F YOU PERFORM SERVICE ON YOUR OWN

PRODUCT

PERSONAL INJURY OR PROPERTY DAMAGE

ANY

WHICH

PROPERTY DAMAGE ARISING FROM

SERVICE OR SERVICE PROCEDURES

,

YOU ASSUME RESPONSIBILITY FOR

MAY RESULT

.

WARNING

.

When Ordering Parts

All product model and serial nameplates carry an additional number called the

manufacturing number. It is possible to have one or more like products with the

same model number, but that a portion of the parts would not be interchangeable.

The manufacturing number has been added to the product to assist the

service department in identifying any given product.

It is extremely important when looking up service repair parts in the parts list,

or when requesting service information, that the manufacturing, model and

serial numbers be used to properly identify the product.

To locate an authorized servicer, please consult your telephone book or the dealer

from whom you purchased this product. For further assistance, please contact:

CONSUMER INFORMATION LINE -

AMANA® BRAND PRODUCTS TOLL FREE

1-877-254-4729 (U.S. only)

email us at: customerservice@goodmanmfg.com

fax us at: (713) 856-1821

(Not a technical assistance line for dealers.)

Outside the U.S., call 1-713-861-2500.

(Not a technical assistance line for dealers.)

Your telephone company will bill you for the call.

3

Page 4

ACCESSORY INST ALLA TIONS

Circuit Breaker Kit

HIGH VOLTAGE

ISCONNECT ALL POWER BEFORE

D

WIRING

SOURCES

SO

INJURY

HE UNIT

T

CONNECT ALL POWER TO THIS UNIT

ALL

LOCAL

LOCATION

MUST COMPLY WITH ALL APPLICABLE CODES

THE SUBBASE

MAY BE PRESENT

MAY CAUSE PROPERTY DAMAGE, PERSONAL

OR

DEATH

“OFF”

WIRING MUST COMPLY WITH APPLICABLE

AND NATIONAL CODES

OF

FUSED DISCONNECT SWITCH(ES

CAUTION

USE

COPPER CONDUCTORS

ELECTRICAL

TYPES

VANIC CORROSION, OVERHEATING AND RESUL

TANT EQUIPMENT FAILURE

OF

CONNECTIONS

CONDUCTORS MAY RESULT IN GAL

. M

ULTIPLE POWER

. F

AILURE TO DO

.

SWITCH DOES NOT DIS

.

. T

YPE AND

ONLY

. THE

FOR

USE OF OTHER

.

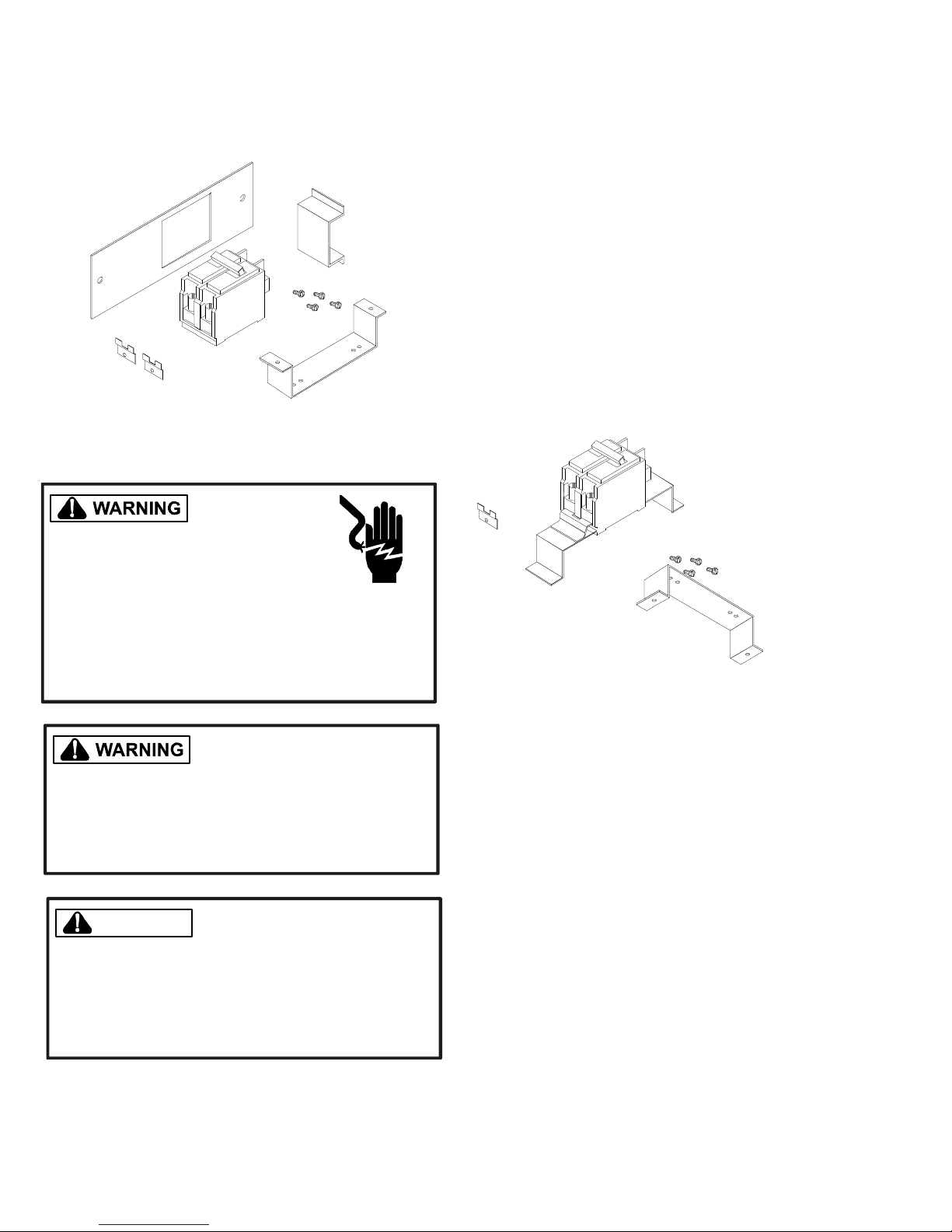

Description

The circuit breaker kit provides POWER ON/OFF and current overprotection function at the unit. The circuit breaker

kit contains the appropriate circuit breaker, replacement

access cover for the high voltage section of the subbase,

mounting bracket and clips, and required hardware. Select

circuit breaker kits according to unit amperage.

Installation

1. Check circuit breaker for manufacturers name. Select

mounting holes in mounting bracket to match part as

indicated in the following figure (GE and Westinghouse

use outer holes). Secure one of the two small mounting

clips to the mounting bracket. Do not fully tighten the

mounting screw at this time.

-

2. Position the circuit breaker on the mounting bracket so

that the locking tabs on the small clip (installed in Step

1) hold the circuit breaker on the mounting bracket.

3. Install the second small clip on the mounting bracket,

locking the circuit breaker on the mounting bracket.

Tighten both mounting screws securely.

)

.

-

-

4. Disconnect electrical power to the unit (if already wired).

5. Remove access cover from subbase.

6. Position the entire circuit breaker assembly in the subbase as shown in Figure 2. Using the two screws provided, secure the assembly to the subbase back wall in

the subbase high voltage section. The large compression connections should be on the left (“ON” to the left,

“OFF” to the right).

7. Connect the line voltage to the large compression terminals (left of breaker). Connect subbase wiring to the

smaller compression connections (right of breaker). If a

ground lug is provided, ground the lug to the unit.

8. Install the circuit breaker guard and the replacement

access cover for the high voltage section. Install the

assembly over the circuit breaker handle using the two

screws removed from the original access cover.

4

Page 5

ACCESSORY INST ALLA TIONS

5

Page 6

ACCESSORY INST ALLA TIONS

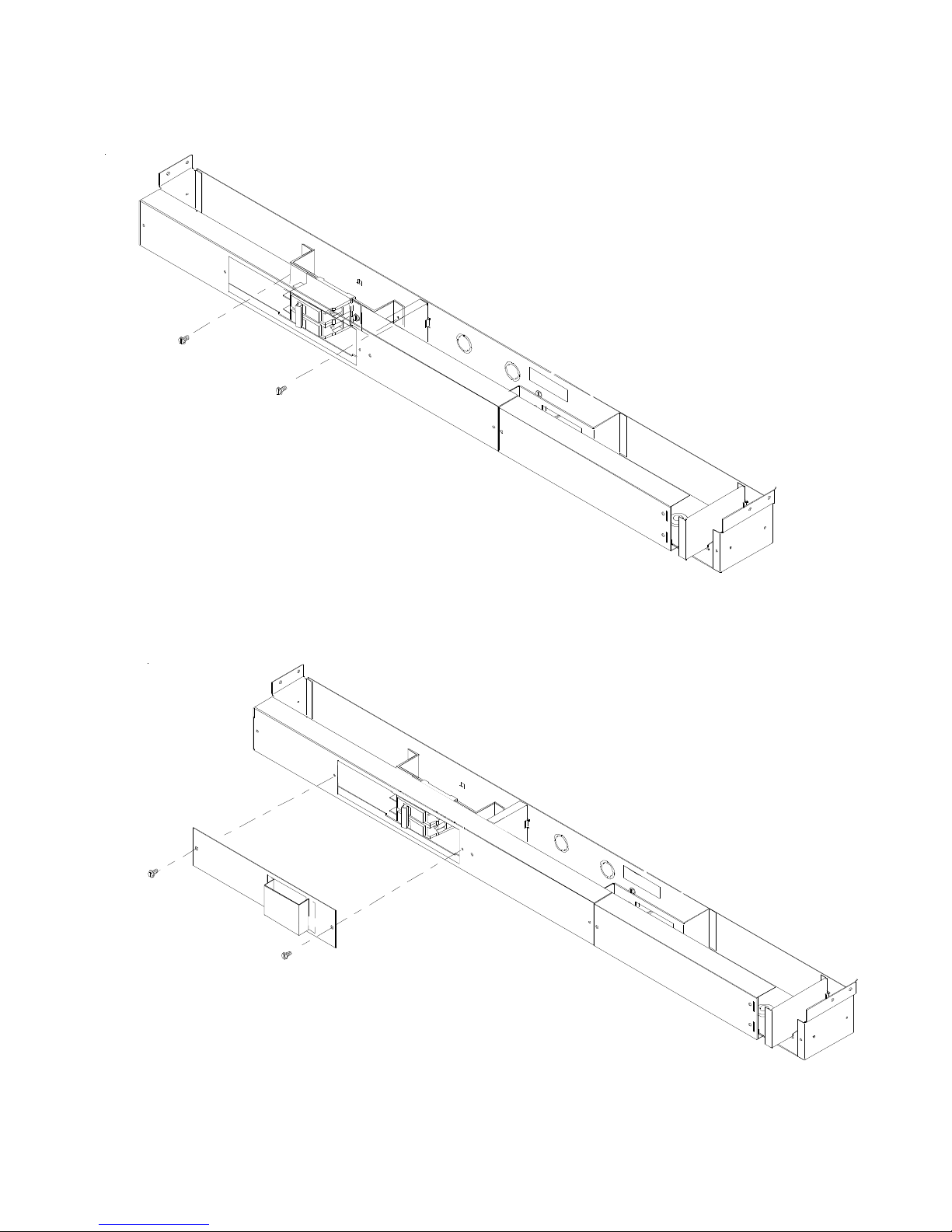

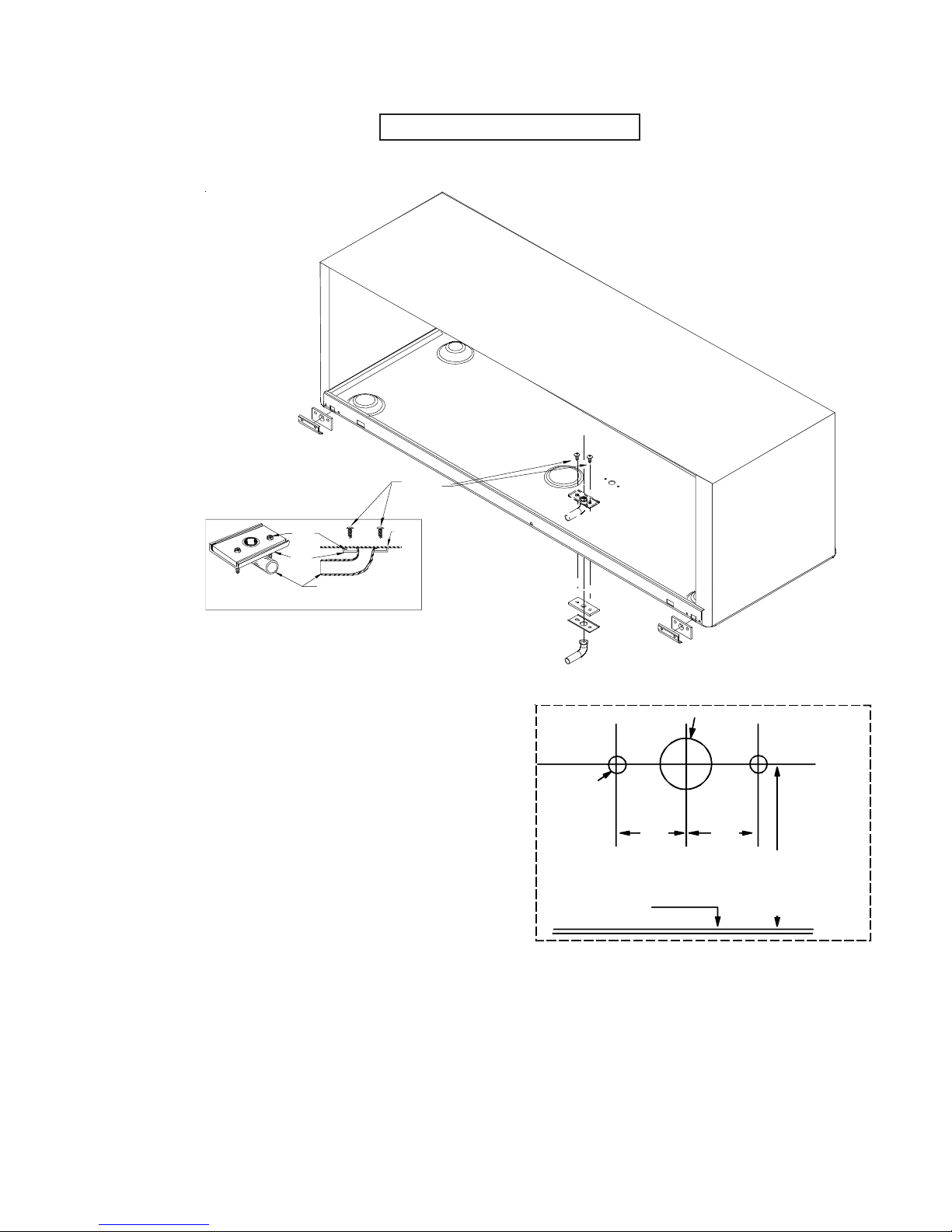

Condensate Drain Kit - DK900-*

1/2" DRAIN FITTING

BLANK-OFF

PLATE C

QTY: 2

DRAIN FITTING

PLATE B

DRAIN FITTING

Figure 1

PLATE D

GASKET A

GASKET E FOR

PLATE D

QTY: 2

Installation for Outdoor Use

The drain components for outdoor use must be installed before the wall sleeve condenser grille.

1. Remove the rear enclosure panel and the sleeve stiffener. These items can be removed from the inside of

the building.

2. Insert the 1/2” drain fitting in the opening of gasket A

and plate B. Secure this assembly into the holes located on the rear of the wall sleeve using two of the

Phillips mounting screws provided.

Figure 2

3. Place the remaining gasket A on the back of blank-off

plate C and secure the assembly to the left rear of wall

sleeve with the remaining Phillips mounting screws provided.

Description

This kit is used to control condensate from the unit. Condensate water drains from the chassis into the sleeve during

normal heat pump operation and during times of high humidity when the unit is in cooling operation. The drain kit allows

the condensate from the outdoor and indoor coils to be routed

to a suitable area. It can be installed for either outdoor or

indoor use. For outdoor use, the condensate can be drained

from either the right- or left-hand side of the wall sleeve. Local

codes will determine the proper condensate disposal. For

indoor use, the drain components must be installed on the

bottom of the wall sleeve and connected to a drain system

inside the building.

NOTE: This drain kit serves only as a link between the unit

and field-supplied condensate drain system. Installing the

kit without connecting it to a drainage system will result in

inadequate condensate removal, possible leakage and

corrosion.

ALGAECIDE: Some algaecide products may cause damage to the unit basepan or coils and should not be used.

Contact your sales representative when considering the use

of a commercial algaecide.

Figure 3

If unit chassis installed right away

Install the grille to wall sleeve with hardware provided. See

grille installation instructions.

If unit chassis is not installed right away

Replace the rear enclosure panel in the wall sleeve to pro-

tect the inside of the building from weather damage.

6

Page 7

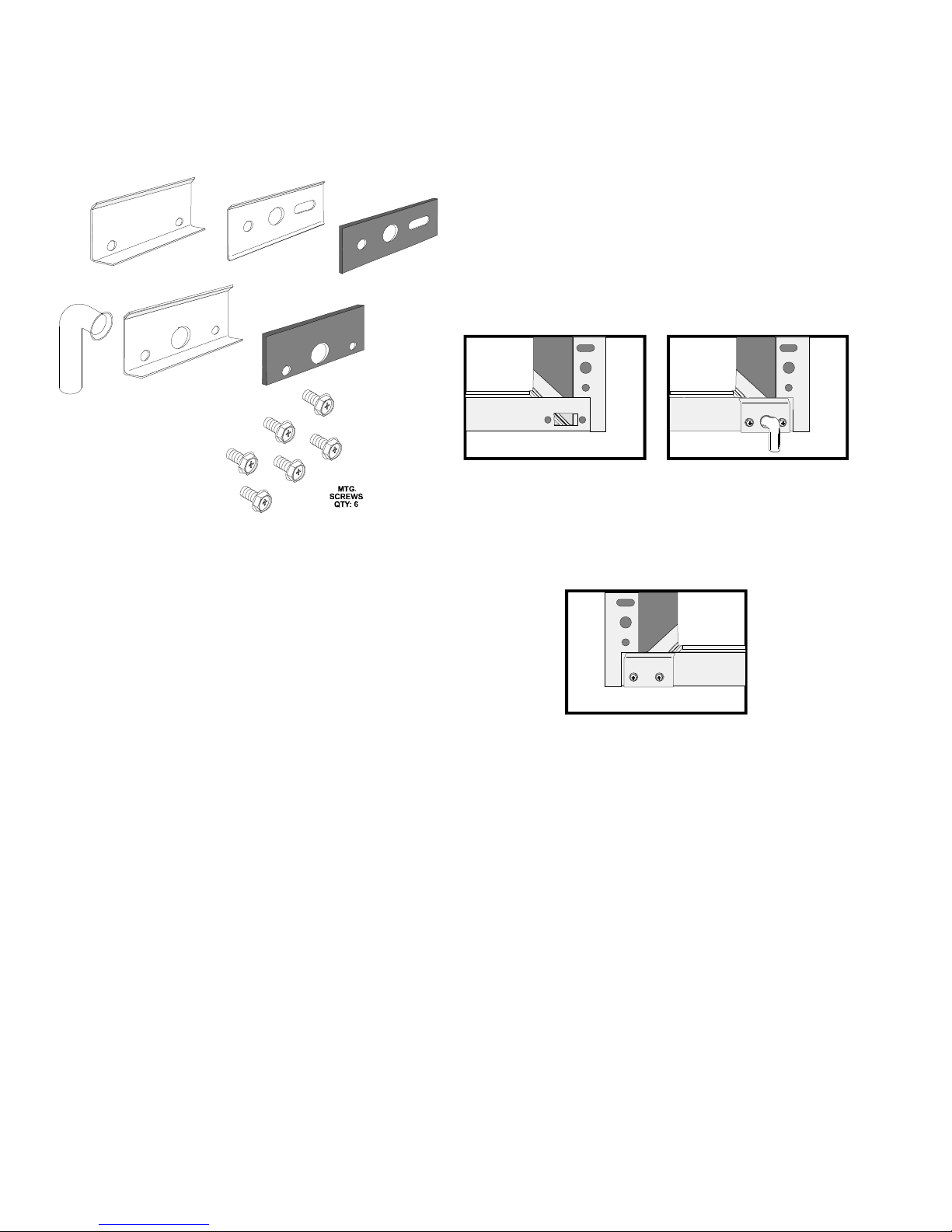

ACCESSORY INST ALLA TIONS

SLEEVE OVERFLOW PORT

DO NOT CLOSE UP THIS PO RT

GASKET (2)

SEE DETAIL A

BLANK-OFF PLATE (2)

Figure 4

The components of the wall sleeve drain kit for indoor use

are shown in the detail of the figure above. These compo-

nents must be installed prior to the installation of the

wall sleeve.

1. Locate an area on the wall sleeve that will be inside the

room when the sleeve is installed. If a subbase is installed, locate the kit a minimum of 3 1/2” from the front

flange of the wall sleeve. This clearance will provide

adequate clearance for the subbase.

2. Cutout the template in Figure 5. Using this template,

locate and drill the drain kit holes as close to the outside wall as possible.

3. Using detail A in Figure 4 as a guide, assemble the

gasket (E), drain fitting plate (D), and 1/2” drain fitting

together. Install the assembly into the drilled holes and

secure using the two slotted mounting screws included

in the kit. Be sure drain tube is not restricted.

NOTE: If the drain fitting is not connected to an indoor

drainage system immediately after the wall sleeve is

installed; plug the hole with cork (not included) to prevent indoor water damage in case it rains

4. Install a 1/2” ID tube or hose (not included) on the drain

fitting and interconnect it to the drain system inside of

the building. Ensure that there are no kinks or traps in

tube or hose. Kinks or traps can cause improper drainage.

5. Install the two blank-off plates C and gaskets A on the

outdoor portion of the wall sleeve as shown in Figure 4.

These components can be installed after the sleeve is

secured in the wall opening just prior to the installation

of the condenser grille and chassis.

.500" DIA.

.156” DIA.

MTG. HOLES

(2)

.687"

INSID E ED GE OF

FRONT SLEEVE FLANGE

.687"

Figure 5

7

Page 8

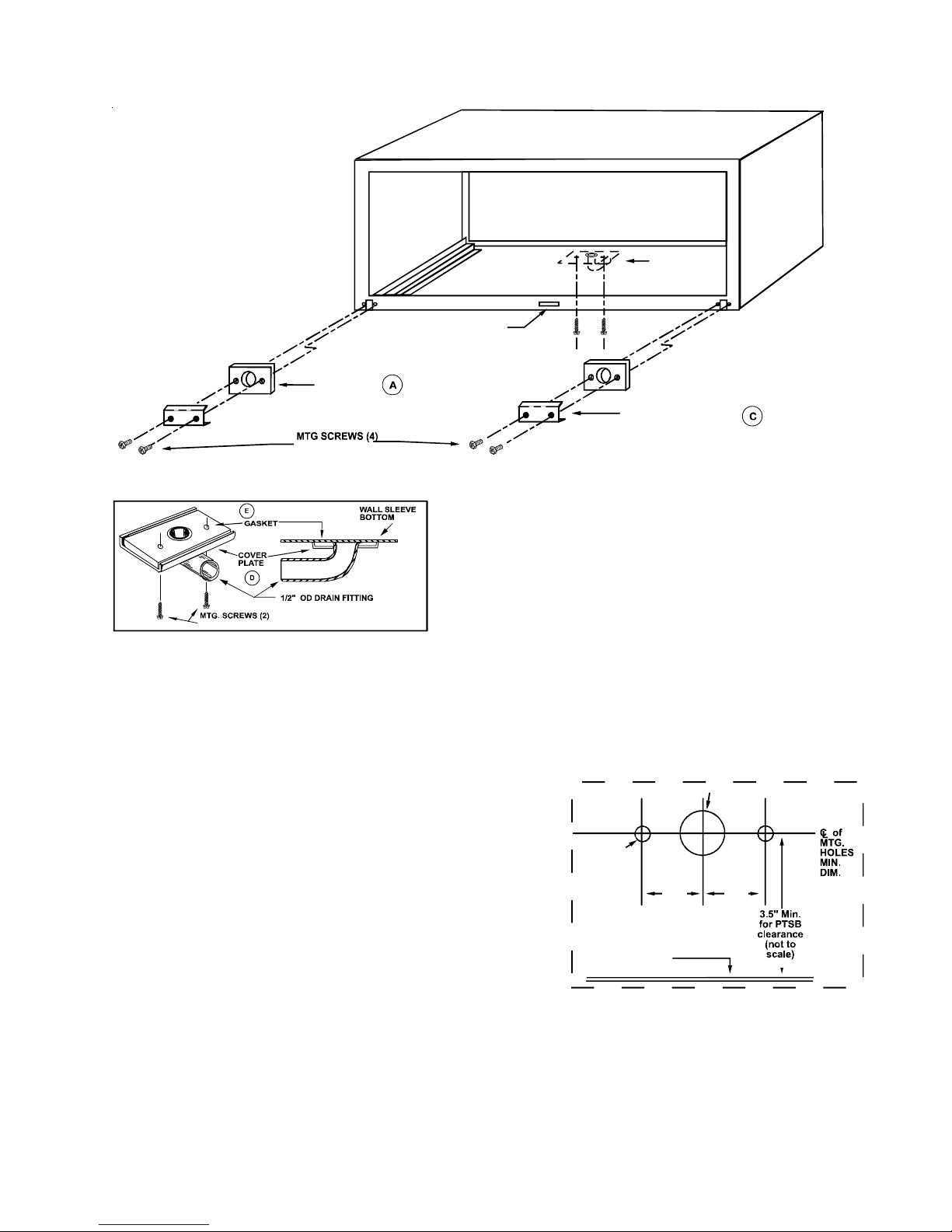

ACCESSORY INST ALLA TIONS

Condensate Drain Kit - DK900*

(Combination Drain Kit...for outdoor or indoor sleeve drainage.)

The installation and servicing of the equipment should be done by qualified experienced technicians.

Description

This kit is used to control condensate from the unit. Condensate water drains from the chassis into the sleeve

during normal heat pump operation and during times of

high humidity when the unit is in cooling operation. The

drain kit allows the condensate from the outdoor and

indoor coils to be routed to a suitable area. It can be

installed for either outdoor or indoor use. For outdoor use,

the condensate can be drained from either the right- or lefthand side of the wall sleeve. Local codes will determine the

proper condensate disposal. For indoor use, the drain

components must be installed on the bottom of the wall

sleeve and connected to a drain system inside the building.

Outdoor

Drain

Fitting

Indoor

Mtg. Screws

Qty: 2

Indoor

Drain Fitting

Gasket

Outdoor

Mtg. Screws

Qty: 4

Indoor

Drain

Fitting

Indoor

Drain Fitting

Plate

NOTE: This drain kit serves only as a link between the unit

and field-supplied condensate drain system. Installing the

kit without connecting it to a drainage system will result in

inadequate condensate removal, possible leakage and

corrosion.

ALGAECIDE: Most algaecide products will cause damage to the unit basepan or coils and should not be used.

Contact your sales representative for the recommended

algaecide pan treatment for your unit.

Installation for Outdoor Use

The drain components for outdoor use must be installed

before the wall sleeve condenser grille.

1. Remove the rear enclosure panel and the sleeve

stiffener. NOTE: These items can be removed from

the inside of the building.

2. Install the outdoor drain fitting and one of the outdoor

drain fitting gaskets over one of the drain holes on the

rear of the wall sleeve using two of the provided

outdoor mounting screws.

3. Cover and seal the remaining drain hole using the

remaining outdoor drain gasket, blank-off plate and

outdoor screws.

If unit chassis installed right away

Install the condenser grille to wall sleeve with hardware

provided. See condenser grille installation instructions.

If unit chassis is not installed right away

Replace the rear enclosure panel in the wall sleeve to

protect the inside of the building from weather damage.

Blank-Off

Plate Qty: 2

Outdoor

Drain Fitting

Gasket Qty: 2

Drain Kit Components

Outdoor Drain Fitting Installation

8

Blank-Off Installation

Page 9

ACCESSORY INST ALLA TIONS

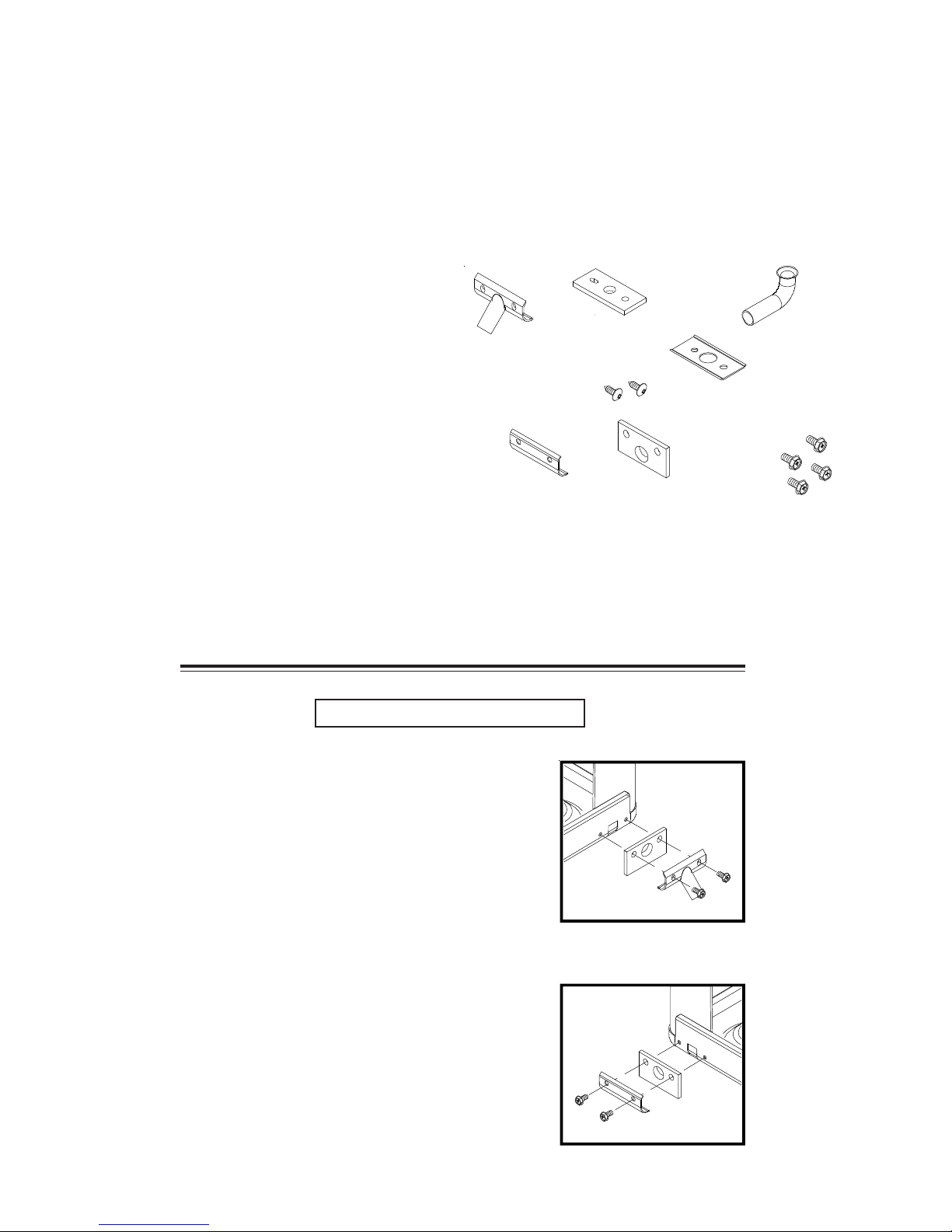

Installation for Indoor Use

The components of the wall sleeve drain kit for indoor use are shown in figure below. These components must be

installed prior to the installation of the wall sleeve.

MTG.

SCREWS (2)

WALL

DRAIN

GASKET

DRAIN

FITTING

PLATE

SLEEVE

BOTTOM

Detail A

1. Locate an area on the wall sleeve that will be inside the

room when the sleeve is installed. If a subbase is

installed, locate the kit a minimum of 3 1/2” from the

front flange of the wall sleeve. This clearance will

provide adequate clearance for the subbase.

2. Cutout the template shown to the right. Using this

template, locate and drill the drain kit holes as close to

the outside wall as possible.

3. Using detail A (above) as a guide, assemble the drain

gasket, drain fitting plate, and indoor drain fitting together. Install the assembly into the drilled holes and

secure using the two indoor mounting screws provided. The screws must be inserted INSIDE the wall

sleeve.and TOP driven down into the drain fitting plate.

Ensure drain tube is not restricted. Cover the two

screw heads with a good quality outdoor caulking (not

supplied) for additional corrosion protection.

NOTE: If the drain fitting is not connected to an indoor

drainage system immediately after the wall sleeve is

installed; plug the hole with cork (not included) to

prevent indoor water damage in case it rains.

4. Install a 1/2” ID tube or hose (not included) on the drain

fitting and interconnect it to the drain system inside of

the building. Ensure that there are no kinks or traps in

tube or hose. Kinks or traps can cause improper

drainage.

5. Install the two drain blank-off plates and outdoor drain

gaskets on the outdoor portion of the wall sleeve as

shown in the figure above. These components can be

installed after the sleeve is secured in the wall opening

just prior to the installation of the condenser grille and

chassis.

.500" DIA.

.187" DIA.

MTG. HOLES

(2)

.687"

INSIDE EDGE OF

FRONT SLEEVE F LANGE

.687"

Template

Due to policy of continual product

improvement, the right is reserved to

change specifications and design

without notice.

3.5" Min.

for PTSB

clearanc e

(not to

scale)

C of

L

MTG.

HOLES

MIN.

DIM.

9

Page 10

ACCESSORY INST ALLA TIONS

Condensate Removal Pump

HIGH VOLTAGE

ISCONNECT ALL POWER BEFORE

D

SERVICING

ULTIPLE POWER SOURCES MAY BE PRESENT

M

AILURE TO DO SO MAY CAUSE PROPERTY

F

DAMAGE

Description

The internal condensate pump serves as an effective means

for disposing of condensate generated during heat pump

operation by transferring it to the indoor coil. The warm coil

surface and the warm room air help in evaporation of the

condensate while adding humidity to the room. As with any

equipment of this type, the addition of this kit will decrease

the sensible heating capacity of the unit. This kit is not

intended for use in seacoast or corrosive environments.

NOTE: Under extreme high humidity conditions, the internal

condensate pump may not be able to dispose of all the condensate produced, and condensate would then drip from the

outside of the wall sleeve. If this condensation is unacceptable, then a drain system (including factory approved drain

kit for the wall sleeve) should be installed.

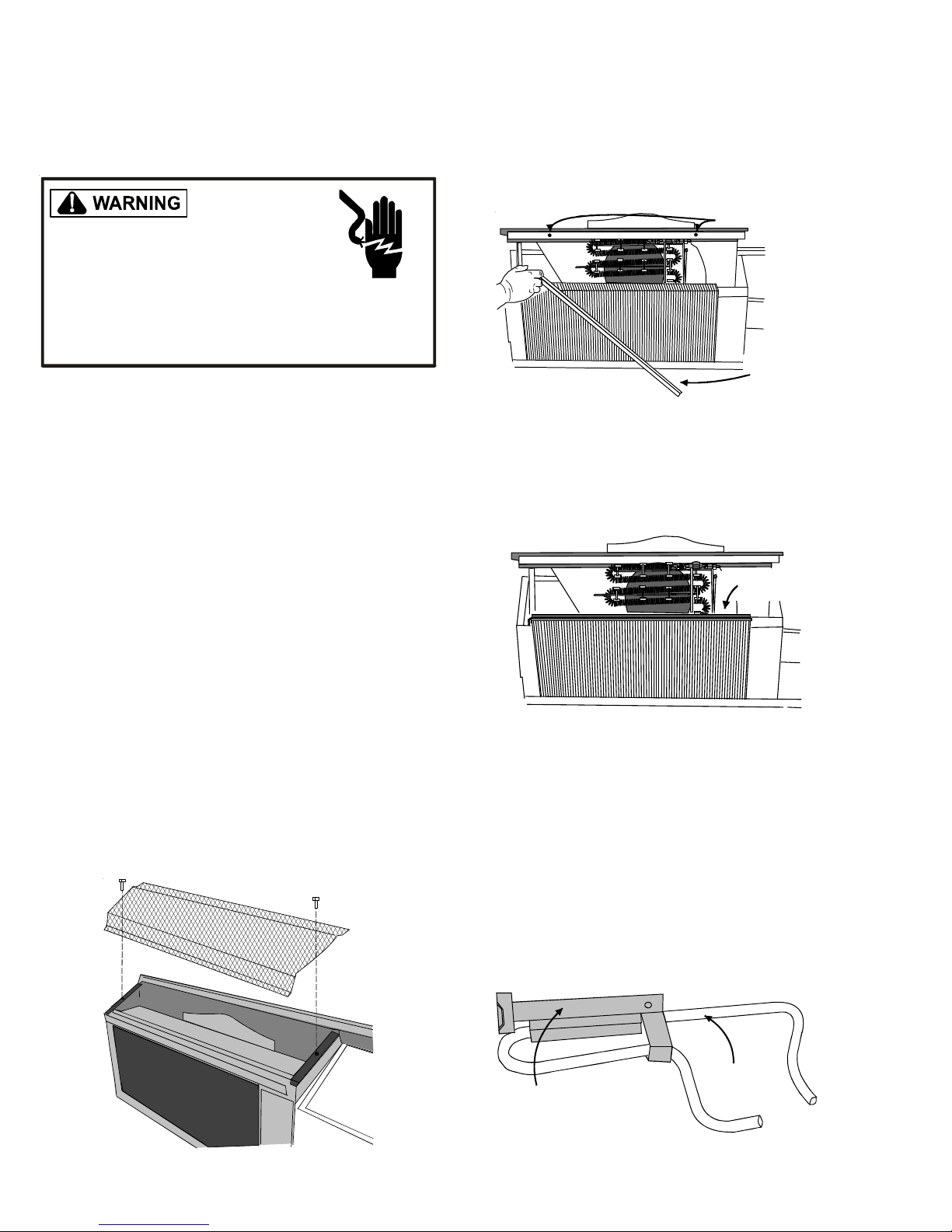

1. Remove front by rotating bottom outward and then lifting

up and out from chassis.

2. Unplug and remove the PTAC chassis from the

wallsleeve. Move the chassis where the front and back

of the chassis can be easily accessed.

3. Remove the discharge screen by unscrewing two screws

holding the screen to the blower panel. Set screen aside.

OR

INSTALLING THIS UNIT

,

PERSONAL INJURY OR DEATH

.

.

.

4. Lift the blower panel approximately 10 inches by unscrewing two screws holding the blower panel to the

chassis and lift upward being careful not to pinch heater

wires.

Mounting Screw

Holes

Condensate

Tube

5. Using the short leg of the condensate tube push out the

1/2 inch diameter knockout on the back wall of the

styrofoam scroll. The condensate tube should protrude

through the partition panel by 1-3/4 inches. Rotate the

condensate tube so the tube lays flat on the coil.

Condensate

Tube

6. Orient the condensate tube on the coil so when the blower

panel is lowered the condensate tube fits snugly into

the raised embossment of the blower panel.

7. Make sure the holes in the condensate tube are facing

downward toward the evaporator coil.

8. Lower the blower panel over the condensate tube and

screw the blower panel to the chassis with the existing

screws. Replace the discharge screen and screw the

screen to the blower panel with the existing screws.

9. Using the overflow tube holder and the overflow tube,

hold the tube with the metal holder and screw the holder

to the partition panel with the provided 1/2 inch #8 screw.

10

Tube

Holder

Page 11

ACCESSORY INST ALLA TIONS

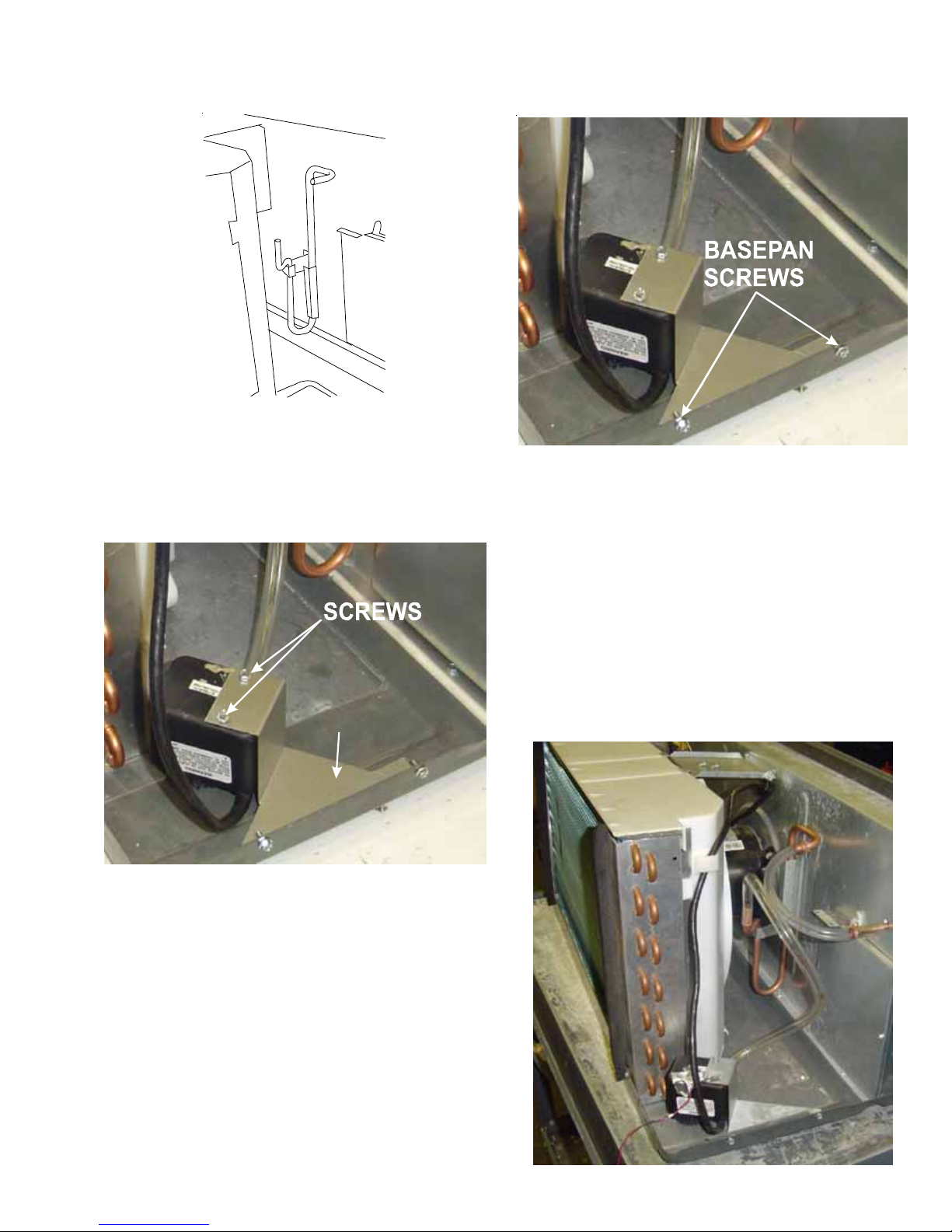

10. Place the pump bracket onto the top of the pump and

screw the pump bracket to the pump with the provided

two (2) 1/2 inch #8 screws so that the bracket is secure

against the pump.

PUMP

12. Remove the protective adhesive backing from the plastic U clip and mount the U clip to the plastic condenser

shroud in approximately the position shown.

13. Attach the p-clamp to the brace with the screw provided (see figure below.

14. Place one of the hose clamps over one end of the 16

inch vinyl hose. Place the same end over the barbed

discharge tube of the pump assembly. Place a hose

clamp on the other end of the 16 inch hose. Place this

same end over the shorter leg of the overflow tube and

secure the hose with the hose clamp.

BRACKET

11. Orient the pump in the back left corner of the basepan

and screw the pump bracket to the basepan with the

provided two 1/2 inch #8 screws.

11

Page 12

ACCESSORY INST ALLA TIONS

15. Place a hose clamp over one end of the 11 inch long

hose. Push this same end over the longer leg of the

overflow tube and secure with the hose clamp. Place

another hose clamp over the other end of the 11 inch

hose. Push this same end over the condensate tube

protruding out from the back of the partition panel and

secure with the hose clamp.

16. Route the condensate pump cord through the U clip on

the condenser shroud, through the p-clamp attached to

the brace, and then through the hole in the panel where

the compressor wires are routed through the panel.

NOTE: The permagum may have to be removed to feed

the wires through the panel, make sure wires have no

slack and replace the permagum back into place to prevent air leaks.

SCREW

SCREW

N

O

3

2

1

SCREW

Back Of Escutcheon

Transformer

Mounting Holes

Relay Mounting

Holes

holes provided in the panel. (See figure above.)

20. Mount the relay in one of the three relay mounting holes

in the control panel making sure that the threaded stud

is in the smaller hole and the metal tab is in the adjacent larger hole. Screw the provided nut onto the threaded

stud from the opposite side of the control panel.

21. Disconnect the RD33, VT12, and BK19 wires from the

control board and connect the YL5 (where RD33 was

connected), YL3 (where VT12 was connected), and YL1

(where BK19 was connected). Connect RD33 to the

piggyback terminal of YL5, VT12 to the piggyback terminal of YL3, and BK19 to the piggyback terminal of

YL1. Make sure the OR8 wire is connected from the #6

terminal of the relay to 24 volt terminal of the transformer.

22. For 208 volt applications move the WH6 wire terminal

from the 240 volt terminal of the transformer to the 208

terminal of the transformer.

23. Units that have a Power Vent or Power Door Kit already

installed in the chassis should refer to the proper wiring

schematic for proper wiring of the condensate pump kit.

Use the second set of transformer holes to mount the

transformer.

24. Units that have a 2 stage heater already installed in the

chassis should refer to the proper wiring schematic for

proper wiring of the condensate pump kit.

25. Units that have a Power Vent or Power Door Kit and a

two stage heater already installed in the chassis should

refer to the proper wiring schematic for proper wiring of

the condensate pump kit.

26. Install the basepan drain plug into the basepan drain

hole by pushing it up into the drain hole from the bottom

of the basepan. This will defeat the thermostatic controlled drain valve. The basepan drain is located left of

the outside coil (as viewed from the back of the unit).

NOTE: When using a condensate removal pump, extra care

must be taken to keep the basepan clean and free of algae

or fungus. Failure to do so may result in the failure of the

condensate removal system.

19. Using two #8 screws that are provided, screw the transformer to the control panel in the transformer mounting

12

Page 13

ACCESSORY INST ALLA TIONS

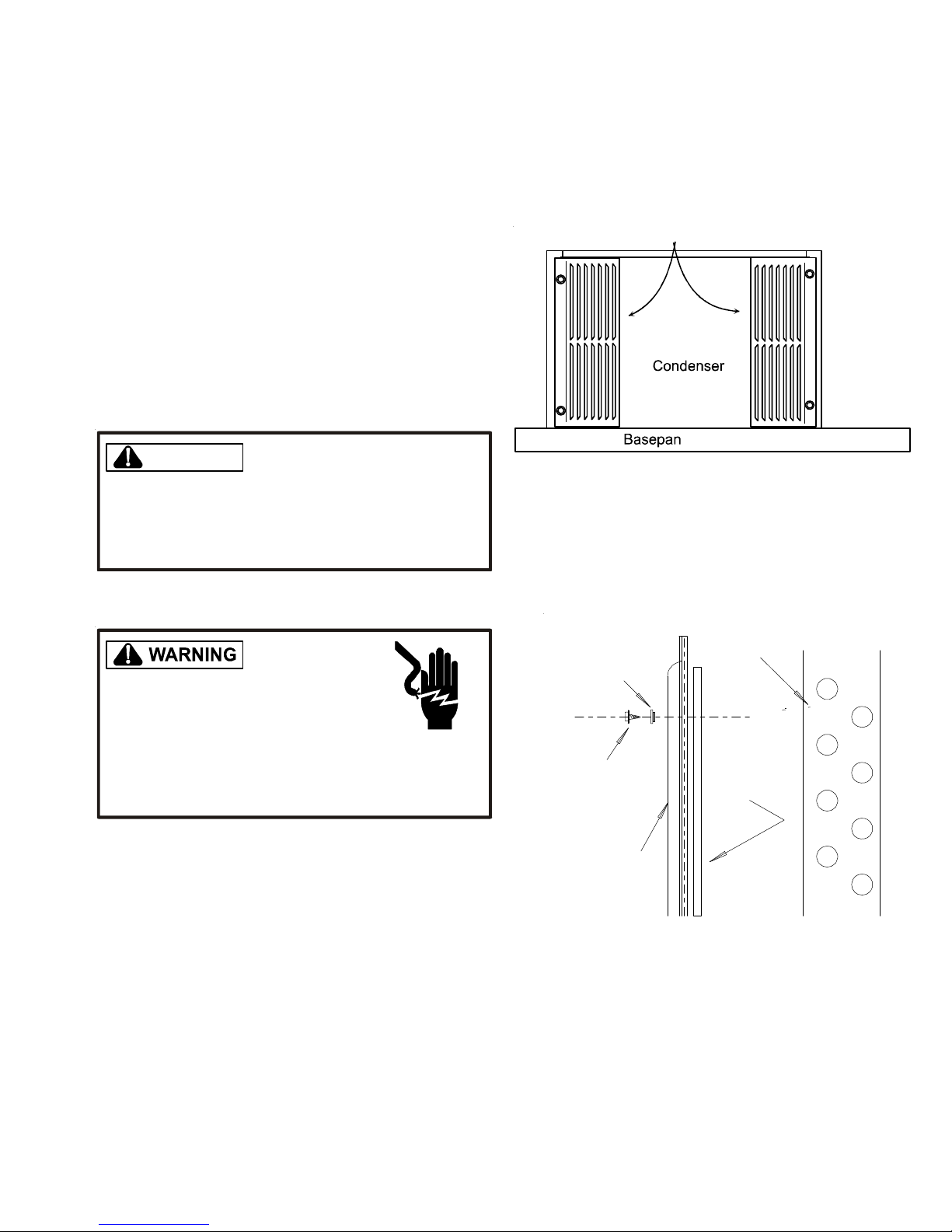

Condenser Baffles

Description

The condenser baffle kit is required when replacing an existing package terminal unit and the original outdoor grille is

not made by the same manufacturer. These baffles are required to deflect discharge air away from the inlet, preventing recirculation of hot condenser air.

This kit is intended to be used with outdoor grilles having

horizontal louvers. If the outdoor grille has vertical louvers,

contact the manufacturer of the package terminal unit.

NOTE: This kit is not to be used when the outdoor grille is

provided by the original manufacturer of the package terminal unit.

CAUTION

TO

PREVENT DAMAGE TO THE UNIT DUE TO

RESTRICTED

OR

DEFLECTORS OF ANY KIND FROM THE

OUTDOOR

AIR FLOW, REMOVE ANY BAFFLES

GRILLE

.

Installation

1. Locate the baffles on the condenser coil flange as shown.

Position the louvers to direct the air toward the center

as the air leaves the coil.

Condenser Baffles

2. Using the screws and shoulder washers provided, secure the grille to the condenser flange. NOTE: Be sure

to install the gasket between the grille and the flange as

shown.

HIGH VOLTAGE

ISCONNECT ALL POWER BEFORE

D

SERVICING

ULTIPLE POWER SOURCES MAY BE PRESENT

M

AILURE TO DO SO MAY CAUSE PROPERTY

F

DAMAGE

OR

INSTALLING THIS UNIT

,

PERSONAL INJURY OR DEATH

.

.

CONDENSER

FLANGE

SHOULDER

WASHER

.

SCREW

BAFFLE

GASKET

GASKET

13

Page 14

ACCESSORY INST ALLA TIONS

PTCB10B Curtain Guard

Description

The PTAC PTCB10B Kit is a curtain guard kit that redirects the

airflow of the PTAC unit to provide added comfort. Each kit

contains 10 guards. Before installing this kit, ensure that the

correct kit has been ordered and received for your unit.

This curtain guard has been designed to work in most curtain

applications, but may NOT work in some applications. If you

are unsure if the curtain guard will work in YOUR application,

please contact your Amana® brand PTAC sales person for assistance before you order guards for the entire property.

IMPORTANT NOTE: This kit is designed for models with R-22

refrigerant and should NEVER be used on models using R410A refrigerant.

Below are two ways to determine if your unit requires PTCB10B

kit:

1. Check the underside of the guard next to the side tab for

specific guard/unit compatibility statement. See Figure 1

for location of this statement:

“Install on units with serial numbers starting with 0304******

and less than 1001******”

IMPORT ANT NOTE: Do NOT remove curtain guard until front

is removed from unit. Trying to uninstall the curtain guard

before removing the cabinet front may cause the curtain guard

to break.

1. Position the curtain guard over the cabinet front (tab side

down) so the left and right side tabs on the guard line up

with the 2nd horizontal louver on each side of the cabinet

front. Make sure the 2 middle tabs on the curtain guard

are positioned over the 2nd and 4th vertical louvers on

the cabinet front. Gently snap the left side of the curtain

guard onto the 2nd horizontal louver of the cabinet front

and then gently snap the tab on the right side of the

cabinet front into place. See Figure 1. DO NOT FORCE

CURT AIN GUARD INTO PLACE.

Check here to verify

curtain guard and unit’s compatibility.

2. If your unit’s model number contains LETTERS B, C or D for

the 7th digit (i.e. PTH123

D35AR), PTCB10B is the correct kit

to use (see note below for “A” series information).

If your unit’s model number contains the letter “E” for the

7th digit, DO NOT USE THIS KIT. The correct curtain guard

kit for these units is PTCB10E.

NOTE: Use of the incorrect part may cause the guard to break

and it will not be replaced by Goodman. If you are in doubt

about which kit is needed, please contact your sales representative.

Attach s ide tabs

to 2nd Horizontal Louver

on the left & ri ght sides

of the cabinet front

“

I

n

Figure 1

s

t

a

l

l

o

n

u

n

i

t

s

w

i

t

h

s

e

r

i

a

l

n

u

m

b

e

r

s

s

t

a

r

t

i

n

g

w

i

t

h

0

3

0

4

*

*

*

*

*

*

a

n

d

l

e

s

s

t

h

a

n

1

0

0

1

*

*

*

*

*

*

”

14

Page 15

ACCESSORY INST ALLA TIONS

2. After tabs are secure on the left and right side horizontal

louvers, gently slide the two middle tabs along the bottom of the 2nd & 4th vertical louvers and snap in place.

DO NOT FORCE CURTAIN GUARD INTO PLACE.

When installed, the tabs should point towards the outside of the unit. See Figure 2.

Figure 2

See Figures 3 and 4 for views of correctly installed curtain

guard.

Side Tabs attached on 2nd Horizontal Louver

2nd Louver

View of R-22 Model with Curtain Guard Installed Correctly.

3. T o remove the curt ain guard, remove cabinet front from

the chassis. Rotate the cabinet front so the back of the

cabinet is facing you. Depress the tabs of the curtain

guard while gently pulling the guard away from the front.

4th Louver

Figure 4

2nd Vertical Louver 4th Vertical Louver

Tabs

snapped

into p lace

Figure 3

15

Page 16

ACCESSORY INST ALLA TIONS

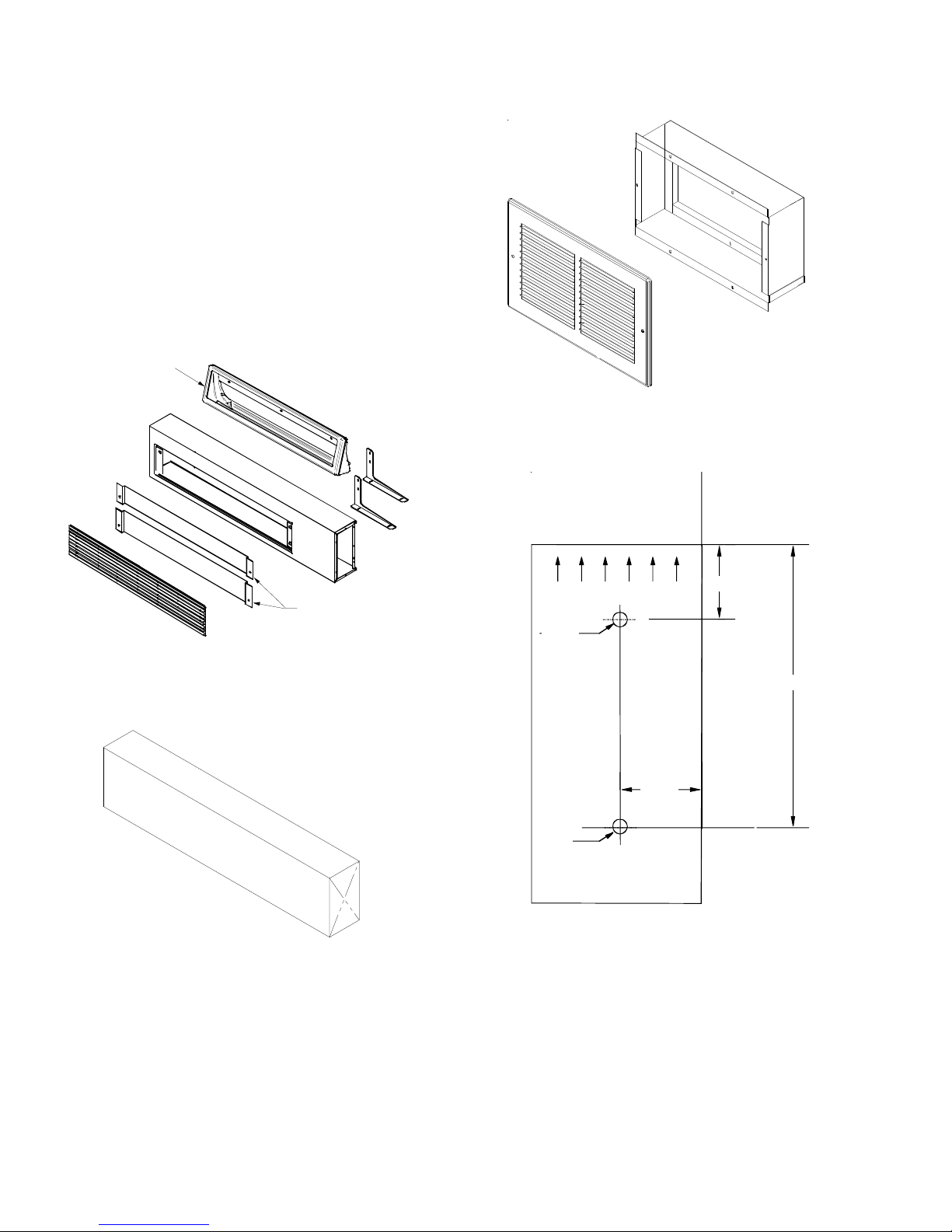

Duct Kit

Description

Extends air distribution to an adjoining room.

Kit Contents

The kit consists of a main duct for the room of origin and an

extension duct to reach the adjoining room, and terminal

duct. NOTE: All required hardware is provided within kit.

TRANSITION

*

*

*

*

Terminal Duct Kit - TDK02B

*

*

*

*

BAFFLES

Main Duct Kit - MDK02*

Extension Duct Kit -EDK02B

5/8"

TOP

Ø 1/8"

2 3/8"

11/16"

Ø 1/8"

Hole Placement Template

16

Page 17

ACCESSORY INST ALLA TIONS

10"

5"

1/2"

18-3/8"

3-1/4" MIN

TRANSITION

UNIT FRONT

7-1/2"

BOTTOM OF

WALL SLEEVE

END OF

DUCT

EXTENSION

INNER WALL

CUT-OUT

1-3/8" MIN

(FOR DUCT KIT)

WALL SLEEVE

2-3/4" MIN

(FOR SUBBASE KIT)

SUBBASE KIT

OUTSIDE

WALL

FLOO R LINE

MDK INSTALLATION INSTRUCTIONS

Disconnect power source before removing the chassis.

PRE-ASSEMBLY (Transition/Front)

1. If the cabinet front is screwed to the chassis, remove the

screw located behind the inlet grille. Pull the inlet grille

forward from the top of the grille to access two screws.

Figure 1.

2. Remove cabinet front from chassis by tilting the bottom

of the front forward, lifting slightly up and forward.

20-1/2" MAX

1/4" MIN

FRONT MOUNTING

HOLE

Figure 1 - Cabinet Front Removal

3. Disengage discharge grille from cabinet front by removing four pal nuts from under the front.

17

Page 18

ACCESSORY INST ALLA TIONS

4. Place transition in air discharge opening of cabinet front

and secure with the provided U-clip. See Figures 2 & 3.

TRANSITION

AIR DISCHARGE

OPENIN G

CABINET

FRONT

Figure 2

PRE-ASSEMBLY

(Wall Sleeve) Hole Dimension and Placement

1. Unplug and remove chassis from wall sleeve. Drill two

1/8” holes on left and right sides of wall sleeve in proper

locations (see template on page 2).

2. Install chassis back into wall sleeve.

3. Install transition/front assembly on to chassis. Make sure

top of cabinet front catches metal flange on chassis.

WALL

2-3/8"

11/16"

5/8"

1/8" HOLES

SLEEVE

INDOOR

`

U-CLIP

Figure 3

5. Using 1/8” drill bit, pre-drill holes in front using the actual

transition as a template. Fasten with three screws. Do

not overtighten. Figure 4.

Figure 4

18

WALL

SLEEVE

1/8" HOLES

5/8"

2-3/8"

11/16"

INDOOR

Figure 5 - Wall Sleeve Hole Placement

NOTE: If there is not enough clearance between sleeve and

partition wall to drill the holes, layout and drill the holes from

inside the sleeve.

MDK ASSEMBLY

Determine if the duct is to be extended to the right of the unit

(where controls are located) or to the left of the unit (opposite the controls). Figure 6.

For left side extensions remove the main duct end cap and

reinstall on the right end of the duct. Using the four painted

sheet metal screws, secure the two mounting brackets to

the main duct.

Page 19

ACCESSORY INST ALLA TIONS

Two mounting slots are provided in each bracket. To mount

extension on right side, adjust bracket so the screws are in

left side of bracket slots; for mounting extension on the left,

adjust brackets so the screws are in right side of slots.

On right side extensions shift the brackets to the right. For

left side extensions shift the brackets to the left.

DISCHARGE

AIR GRILLE

AIR BAFFLE

SUPPORT

BRACKETS

RIGHT SHIFT

Figure 6 - Mounting Brackets installation

AIR BAFFLE INSTALLATION INSTRUCTIONS

1. Determine amount of air desired at main duct and at extension duct. Using the table provided, select the appropriate baffle.

BAFFLE DIMENSIONS

Small 3 11/16" x 31 3/4" 80% 20%

Large 4 5/16" x 31 3/4" 65% 35%

Table 1

2. Place baffle on grille support brackets on main duct. Ensure the two extruded holes of the baffle are on top of the

front bracket holes.

3. Install discharge air grille on top of the air baffle. Secure

the grille to the duct with pal nuts (provided) by reaching

through the opening in the bottom of the duct. See figure

7.

LEFT SHIFT

AIRFLOW

MAIN DUCT EXT. DUCT

Figure 7 - Air Grille Inst allation

4. Place main duct assembly on the transition. Secure the

brackets to the wall sleeve with four #10 hex head screws.

Figure 8. Do not apply pressure on top of duct dur-

ing this installation!

M

D

K

A

S

S

E

M

B

L

Y

T

R

A

N

S

IT

I

O

N

Figure 8

MDK Installation Onto T ransition Assembly

5. Install two Phillips head screws into the top flange of the

main supply duct at extension duct connection. Do not

tighten screws. Leave space for one thickness of the

duct sheet metal between screw head and main duct

flange. Figure 9.

19

Page 20

ACCESSORY INST ALLA TIONS

Figure 9 - Main Supply Duct Top Flange

IMPORTANT NOTE: Total length of duct extension

assembly, including field supplied duct between main and

extension duct, should not exceed 15 effective feet (according

to ASHRAE standards). For additional dimensions, refer to

Main Duct and Duct Extension Dimensions illustration.

7. Measure from the end of the main duct where the extension duct will be connected to the hole in the wall. If

necessary cut the extension duct to a length where the

cut end protrudes into the wall’s inner space and one

inch from the adjoining room’s wall surface.

8. Insert the extension duct into the opening in the wall.

Install the extension duct by placing the slotted flange

over the two screws in the main duct. Using two #8 round

Phillips head screws, mount bottom of extension duct to

mounting bracket through the bracket slot (see Main

Supply Duct T op Flange illustration).

NOTE: The EDK02B can be cut into two sections and used

with two MDK02s if the needed length does not exceed

21-1/4”.

6. In the room where the main duct kit is attached to the

chassis, cut a hole in the wall at the same height from

the floor that the main duct is located. Cut the hole 1/8”

larger than the width and height (10” x 5”) dimensions of

the extension duct.

42-27/32" 6" TO 42-1/2"

AIR FLOW

BRACKET

5"

TRANSITION

DUCT

MAIN DUCT

DUCT EXTENSION

BRACKET

MINIMUM

5"

BOTH SIDES

PARTITION

WALL

DUCT

TERMINATION

KIT

AIR FLOW

1" to

adjoining

wall

surface

Figure 10 - Main Duct and Duct Extension Dimensions

20

Page 21

ACCESSORY INST ALLA TIONS

TDK INSTALLATION INSTRUCTIONS

IMPORTANT NOTE: ANY FIELD-SUPPLIED GRILLE,

MUST HAVE FIXED LOUVERS THAT CANNOT BE

CLOSED.

The sheet metal collar of the terminal duct kit must be

mounted in the wall of the adjoining room opposite the room

where the main duct kit is attached to the PTAC chassis.

1. Cut a hole in the wall of the adjoining room such that the

hole is centered on the extension duct that is currently

in the wall of the opposite room. Figure 1 1. See wall hole

dimensions illustration for sheet metal collar. Figure 12.

11-1/2”

GASKET

Figure 12 - Sheet Metal Collar

3. Center the metal grille over the sheet metal collar and

use two #8 screws (provided) to attach the grille to the

metal collar . Figure 13.

6-1/4"

Figure 1 1 - Wall Hole Dimension

2. Insert the sheet metal collar into the wall so that the

flanges will mount flush to the wall after the collar is

pushed all the way into the wall. While pushing the collar

into the wall make sure the extension duct is inside the

collar. Use four #8 screws to att ach metal collar to wall.

USE

TWO

#8 SCREWS

Figure 13 - Metal Grille

21

Page 22

ACCESSORY INST ALLA TIONS

Electric Heat

Description

The supplemental electric heater kits described in this

manual are available for field installation on heaterless models of packaged air conditioners and heat pumps.

Unit power cords are factory installed for heater kits up to 15

amps on 230/208 volt units and 20 amps on 265 volt units.

When a 20 (230/208 volt units), 25, or 30 amp heater kit is

installed, the corresponding power cord is supplied with the

heater kit.

NOTE: The incoming electrical power on 230/208 volt units

is not fuse protected unless a fuseholder kit has been either

factory or field installed.

Power Cord Installation (HK335E, HK350E, HK450E)

HIGH VOLTAGE

D

ISCONNECT ALL POWER BEFORE

SERVICING

M

ULTIPLE POWER SOURCES MAY BE PRESENT

F

AILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE

OR

INSTALLING THIS UNIT

,

PERSONAL INJURY OR DEATH

.

.

.

Unit Preparation

NOTE: The unit power cord is shown in Figure 1. The power

cord plug configurations are shown in Figure 3.

1. Remove the unit front by tilting the bottom of the front

outward and then lift the front straight up.

2. Remove the control knobs on the control panel cover by

pulling upward on the knobs. Remove the escutcheon.

3. Remove the control panel cover by removing the two

screws holding the control panel cover. Tilt the control

panel forward to gain access to the wires.

Power Cord

4. The incoming electrical power on all 265 volt units is

fuse protected. On all kits, except the 5 kW kit, replace

the fuse with the fuse supplied with the kit. On 5 kW

heater kits replace the existing fuseholder with the

fuseholder (with fuse) supplied with the kit.

1. If the unit has a power cord, remove the power cord

clamp located near the bottom right of the chassis.

Right Side

Power

Cord

Of Unit

Incoming

Power

Opening

Control

Panel

Power Co rd Clamp

Incoming Power Opening

2. On 230/208 volt units disconnect the ribbed lead from

the C terminal on the capacitor and the smooth lead

from LINE 2 terminal on the control board and the green

ground wire from the partition panel. Discard both the

cord and the cord clamp.

22

Page 23

ACCESSORY INST ALLA TIONS

On 265 volt units disconnect the ribbed lead from the C

terminal on the capacitor and the smooth lead from the

fuseholder and the green ground wire from the partition

panel. Discard both the cord and the cord clamp.

3. Push about 20 inches of the power cord shipped in the

kit through the incoming power opening.

4. Secure the cord to the partition panel using the power

cord clamp and #8 screw shipped in the kit.

XX

LINE1 LINE 2 COMP FAN

Ribbed Wire

BK18 on LINE 2 with fuse shown

connected is for 265 volt units. For

BK18

230/208 volt units, connect power

cord to LINE 2.

Control Panel

Capacitor

HIGH

FAN

LOW

R-VAL VE

Power Cord Connections

5. Connect the ribbed lead to the C terminal on the capacitor.

6. On 230/208 volt units connect the smooth lead to LINE

2 terminal on the control board.

On 265 volt units connect the smooth lead to the

fuseholder.

7. Connect the power cord’s green ground wire to the partition panel using the ground screw provided in the kit.

8. If the unit is mounted on a subbase with a power receptacle, remove the right front cover plate of the subbase,

connect the plug end of the power cord into the subbase

power receptacle, and route the cord up out of the subbase through the cord slot in the right side of the subbase. Replace the subbase right front cover panel.

Subbase Power Cord

Electric Heater Installation.

CAUTION

TO

AVOID CUTS FROM SHARP EDGES OF SHEET

METAL, USE GLOVES

IMPORTANT NOTE: To prevent component failure, do

not install HK350E or HK450E (5 Kw) heater kits into

7,000 or 9,000 BTU air conditioners (PTC07, PTC09) or

heat pumps (PTH07, or PTH09).

1. Remove the two mounting screws holding the screen

above the indoor coil in place. Remove the screen.

2. Remove the two screws holding the blower inlet panel in

place. Lift the blower inlet panel out of the unit and set

aside.

.

3. Attach heater to the blower inlet panel with two #8 screws

provided with the kit

23

Page 24

ACCESSORY INST ALLA TIONS

#8 Screw

#8 Screw

4. While placing the blower inlet panel back into the chassis, insert the heater wires through the clip and into the

hole located on the mid partition panel.

Clip

Outdoor Section

Heater Wires

Control Panel

For single Stage Heaters Follow Step 6 then skip to

Step 16.

6. Connect brown 34 and brown 35 heater wires to the 1/4

inch terminals on the control board marked HEATER.

5. Lower the blower inlet panel down into the chassis.

Secure the blower inlet panel to the chassis with the

screws removed in Step 1 and replace the screen removed in Step 2.

24

Single Stage Heater Schematic

For two stage heaters Follow Steps 7 through 15

7. Mount the heater relay supplied with the heater kit to

the middle section of the control panel. Place the studs

on the heater relay through the respective holes on the

control panel and tighten the nut onto the threaded stud.

NOTE: All wiring required for this kit is preconnected to the

heater relay or the heater assembly.

Page 25

ACCESSORY INST ALLA TIONS

A

Relay Mounted

Inside of Control

Panel

Control Panel

8. After disconnecting the BK16 wire from the FAN HIGH

terminal on the control board, connect it to the heater

relay 3 terminal.

9. On the LINE 1 terminal of the control board:

A. Disconnect the RD33 wire.

B. Connect VT19 from the heater relay A terminal.

C. Reconnect the RD33 wire to the piggyback terminal

of VT19.

10. Connect BR34 from the heater 34 terminal to the HEATER

terminal next to the LINE 1 terminal on the control board.

11. Connect VT17 from the heater relay 6 terminal to the

HEATER terminal next to the LINE 2 terminal on the

control board.

12. Connect BR35 from the heater 35 terminal to the

HEATER terminal next to the piggyback terminal of VT17

on the L2 terminal on the control board.

13. Connect VT18 from the heater relay B terminal (as

shipped from the factory) to the FAN HIGH terminal on

the control board.

14. On the LINE 2 terminal of the control board:

A. Disconnect the power wire (BK18 on 265 volt units,

power cord on the 230/208 volt units).

B. Connect VT20 from the heater relay 5 terminal.

C. Reconnect the power wire to the piggyback terminal

of VT20.

BR34

BR35

BR36

Two Stage Heater

Wire Connections

15. Connect wire BR36 from the heater 36 terminal to the

heater relay 4 terminal.

1

4

3

5

6

B

36

35

HEATERHEATER

2 Stage Heater Schematic

6. Find the auxiliary “electric heater” data plate label on the

PTAC unit near the serial plate. Check mark the appropriate box on the data plate to indicate data for the heater

installed in the unit.

17. Replace the control panel, control panel cover, escutcheon plate and the unit front.

25

Page 26

ACCESSORY INST ALLA TIONS

Electric Electrical Heater kW Heater Total Total Mini mum Overcurrent

Heater 230/208 V BTU/HR Watts Amps Circuit Protection**

Size (kW) Ord. No. Stage 1 Stage 2 230V 208V 230V 208V 230V 208V Ampacity

1.5 HK315E 1.5/1.2 - 5100 4100 1580 1280 7.1 5.8 8.8 15A

2.5 HK325E 2.5/2.0 - 8500 6800 2580 2080 11.5 11.5 14.2 15A

3.5 HK335E 3.5/2.9 - 12000 9900 3580 2980 15.8 15.8 19.6 20A

5.0* HK350E 3.5/2.9 1.5/1.2 17100 14000 5080 4180 22.3 22.3 27.8 30A

*On two stage heater kit “High Heat” = both stages ON; “Low Heat” = stage 1 on only.

**Recommended field supplied time delay fuses or HACR type circuit breaker.

230/208 Volt Electric Heater and Power Cord Data

Electric Electrical Heater kW Heater Total Total Minimum Overcurrent

Heater 230/208 V BTU/HR Watts Amps Circuit Protection**

Size (kW) Ord. No. Stage 1 Stage 2 265V 265V 265V Ampacity

1.5 HK415E 1.5 - 5100 1580 6.3 7.7 15A

2.5 HK425E 2.5 - 8500 2580 9.9 12.3 15A

3.7 HK435E 3.7 - 12600 3780 14.5 18 20A

5.0* HK450E 3.5 1.5 17100 5080 19.4 24.1 25A

*On two stage heater kit “High Heat” = both stages ON; “Low Heat” = stage 1 on only.

**Recommended field supplied time delay fuses or HACR type circuit breaker.

265 Volt Electric Heater and Power Cord Data

LISTED ACCESSORIES - PACKAGE TERMINAL AIR CONDITIONER

AUXILIARY HEATERS - 230/208 VOLT

INSTALLER TO MARK HEATERS INSTAL LED:

NONE

HEATER HEATER MAX MIN. CIR. MAX. FUSE

KW P/N AMPS AMPACITY SIZE

1.5/1.2 20252001 7.1 8.8 15

2.5/2.0 20252002 11.5 14.2 15

3.5/2.9 20252003 15.8 19.6 20

5.0/4.1 20257501 22.3 27.8 30

(SA5810)

230/208 Volt Electric Heat Auxiliary Data Label

LISTED ACCESSORIES - PACKAGE TERMINAL AIR CONDITIONER

AUXILIARY HEATERS - 265 VOLT

INSTALLER TO MARK HEATERS INSTAL LED:

NONE

HEATER HEATER MIN. CIR. CIRCUIT MAX. FUSE

KW P/N AMPACITY BRKR. SIZE

1.5 20252006 7.7 15 15

2.5 20252007 12.4 15 15

3.7 20252008 18.1 N/A 20

5.0 20257502 24.2 N/A 25

(SA5810)

26

265 Volt Electric Heat Auxiliary Data Label

Page 27

ACCESSORY INST ALLA TIONS

Escutcheon - Hydronic Remote

Description

This kit provides an attractive replacement escutcheon, allowing the removal of control knobs and graphics no longer

required when a wall thermostat is used to control the unit.

R

T

O

Z

F

O

M

N

E

O

C

Standard Escutcheon

THIS UNIT IS CONTROLLED BY

WALL MOUNTED THERMOSTAT

Low

Heat

High

Heat

Fan

Only

High

Cool

Off

Low

Cool

O

R

F

T

M

Z

O

O

C

N

E

B-Nut

4. Reaching below the hydronic top, remove the extensions

from the chassis by pulling the extensions off the control shafts. Pull the extensions out of the hydronic top.

Hydronic Escutcheon

Extension Shafts

Hydronic Top

Control Board

Cover

Remote Escu tch eon

HIGH VOLTAGE

ISCONNECT ALL POWER BEFORE

D

SERVICING

ULTIPLE POWER SOURCES MAY BE PRESENT

M

AILURE TO DO SO MAY CAUSE PROPERTY

F

DAMAGE

Installation Instructions

1. Lift the cabinet front off the chassis.

2. Remove the unit control knobs by pulling the knobs off

the extension shafts.

3. Remove the b-nut mounting the extensions to the hydronic escutcheon.

OR

INSTALLING THIS UNIT

,

PERSONAL INJURY OR DEATH

.

.

5. After removing the backing, carefully place the remote

escutcheon over the hydronic escutcheon. Ensure the

escutcheon is firmly in place, without any air bubbles.

6. In the event the extension shafts may be needed, after

reassembling the B-nut and the extension shafts, tape

the extension shafts to the control board cover.

7. Replace the cabinet front.

.

27

Page 28

ACCESSORY INST ALLA TIONS

Escutcheon - Remote

Description

This kit provides an attractive replacement escutcheon, allowing the removal of control knobs and graphics no longer

required when a wall thermostat is used to control the unit.

R

T

O

Z

F

O

M

N

E

O

C

Standard Escutcheon

THIS UNIT IS CONTROLLED BY

WALL MOUNTED THERMOSTAT

Low

Heat

High

Heat

Fan

Only

High

Cool

Off

Low

Cool

2. Grasp the cabinet front as shown.

3. Pull the bottom of the cabinet front away from the chassis until the retaining clips disengage.

Remote Escu tch eon

HIGH VOLTAGE

D

ISCONNECT ALL POWER BEFORE

SERVICING

M

ULTIPLE POWER SOURCES MAY BE PRESENT

F

AILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE

Installation Instructions

1. Remove the two screws securing the front to the chassis. NOTE: Not all installations will use these screws.

OR

INSTALLING THIS UNIT

,

PERSONAL INJURY OR DEATH

Mounting Screws

Location

.

.

4. Lift the cabinet front off the chassis.

5. Remove the unit control knobs by pulling the knobs off

the control shafts.

Pull To Remove

Mode Switch Knob

Pull To Remove

Thermostat Knob

Escutcheon

.

6. Lifting the front edge of the escutcheon, slide the tabs at

the top of the escutcheon out of the retaining holes and

remove the escutcheon.

7. Replace the escutcheon with the one from this kit by

inserting the tabs at the top of the escutcheon into the

retaining holes and laying the escutcheon flat on the

control panel.

8. Replace the front by reversing steps 1 through 4.

9. Store the control knobs and escutcheon just removed

from the unit for reinstallation if the wall thermostat is no

longer used.

28

Page 29

ACCESSORY INST ALLA TIONS

Fuse Kit

ALL

WIRING MUST COMPLY WITH APPLICABLE

LOCAL AND NATIONAL CODES

LOCATION OF FUSED DISCONNECT SWITCH(ES

MUST COMPLY WITH ALL APPLICABLE CODES

F

AILURE TO FOLLOW THESE CODES COULD

RESULT IN OVERHEATING AND EQUIPMENT

FAILURE

.

. T

YPE AND

Fuse Holder Kit Installation (Without Subbase)

See page 27 for installation in a subbase.

BK-10

)

.

Fuse Holder Kit

Description

This optional fuse holder kit can be installed directly in the

chassis or in the optional subbase.

Fuse holder kits are available in 230/208 volt ratings. The

installer should supply time delay fuses at 15, 20, 25 or 30

amps in accordance with the “Maximum Overcurrent Protection” as listed on the unit nameplate. Fuses may be

purchased from the parts department.

Installation

The installation and servicing of the equipment referred to in

this booklet should be performed by qualified, experienced

technicians.

CAUTION

Fuseholder

Fuseholder

X X

Line 1 Heater Heater Line 2 Comp Fan

Electronic Board

RD-10

C

Capacitor

High

Fan

Rev.

Low

Valve

FH

Unit Electrical

Connector

Fuse Holder Diagram

Control Panel Installation

1. Remove front by rotating bottom outward and then lifting

up and out from chassis.

2. To gain access inside the control panel, after removing

the knobs and escutcheon, remove the two screws holding panel in position. Tilt control panel forward, being

careful not to pinch any wires.

3. As viewed from the front, remove both knockouts on the

control panel.

4. Insert two fuse holders from the front. The fuse holders

should be oriented so the quick-connect tabs are toward the center of the unit. Attach fuse holders using

the screws and nuts provided.

USE

COPPER CONDUCTORS

ELECTRICAL

TYPES

VANIC CORROSION, OVERHEATING AND RESUL

TANT EQUIPMENT FAILURE

CONNECTIONS

OF

CONDUCTORS MAY RESULT IN GAL

. THE

.

ONLY

FOR

USE OF OTHER

-

-

29

Page 30

ACCESSORY INST ALLA TIONS

Remove Two Screws

To Gain Access Inside

Control Panel

(One On Side Of Panel)

Fuse

Holder

Knockouts

2. Install the fuse holders using screws provided. The side

connector tab on the fuse holders should be towards

the left.

3. Connect a stripped BK-9 wire to the center of the quickconnect tab of the fuse holders. Wire nut the other end

of this wire to the black field connection wire (L2).

4. Connect the other stripped BK-9 wire to the quick-connect tab on the side of the same fuse holder. Wire nut

the other end to black subbase wire leading to receptacle.

Electrical

Receptacle

Fuseholder

BK-9

Control Panel

5. Remove both power cord leads, one lead from the capacitor and one from the electronic board.

6. Install one power cord lead on the center terminal of one

fuse holder.

7. Install the remaining power cord lead on the center terminal of the second fuse holder.

8. Connect BK-10 wire from the side terminal of one fuse

holder to the L2 terminal on the electronic board.

9. Connect RD-10 wire from the side terminal of the other

fuse holder to the common (C) terminal on the capacitor.

10. Tilt control panel back to original location, being careful

not to pinch any wires. Align the control panel with the

cover and screw panels into place with original screws.

Replace escutcheon and control knobs.

Fuse Holder Kit Installation (With Subbase)

See page 26 for installation in the control panel.

1. Remove both knockouts at the fuse holder location.

Fuseholder

Field Connection

Wiring

RD-9

Black

Red

Green

L2

L1

Fuse Holder Diagram

Subbase Installation

5. Connect the “stripped” RD-9 wire to the center quickconnect tab of the second fuse holder. Wire nut the

other end to the red field connection wire (L1).

6. Connect the other stripped RD-9 wire to the quick-connect tab on the side of the second fuse holder. Wire nut

other end to red subbase wire which leads to receptacle.

7. Insert time delay fuses into the fuse holders. Size all

fuses by the “Maximum Overcurrent Protection” shown

on the nameplate. Also refer to the serial plate on the

unit.

Fuse Holder

Knockouts

Leveling

Leg

Power Switch

Knockout

Subbase (Left Side)

30

Page 31

ACCESSORY INST ALLA TIONS

Hard Wire

Description

Hardwire Junction Box (Direct Wire Sub-Base)

The hardwire junction box kit is used to direct wire the unit

when it is not desirable to use the standard unit subbase or

the unit power cord. The junction box provides a protected

enclosure for electrical connections as required by some

electrical codes.

The hardwire junction box is intended to be mounted on the

floor or the adjacent wall.

The junction box is furnished with approximately 2-1/2 feet

of 1/2 inch flexible steel conduit and a metal box for securing the conduit to the unit cabinet at the incoming power

opening.

An optional 230/208V or 265V power switch assembly is

available for use with the hardwire junction box or subbase.

The switch provides a POWER ON/OFF function at the unit

as required by some electrical codes. A replacement junction box cover plate is provided with each switch kit. For

additional information, refer to the Power Switch Installation

Instructions.

Junction Box Kit Installation and Wiring Procedure

The installation and servicing of this equipment should be

performed by qualified, experienced technicians.

Electrical connections at the unit must be made after the

unit chassis is installed in the wall sleeve.

The installer must determine and supply the mounting components for attaching the junction box to the wall or floor.

CAUTION

USE

COPPER CONDUCTORS

ELECTRICAL

TYPES

VANIC CORROSION, OVERHEATING AND RESUL

TANT EQUIPMENT FAILURE

OF

CONNECTIONS

CONDUCTORS MAY RESULT IN GAL

ONLY

. THE

.

FOR

USE OF OTHER

-

-

ALL

WIRING MUST COMPLY WITH APPLICABLE

LOCAL

LOCATION

MUST COMPLY WITH ALL APPLICABLE CODES

F

RESULT

FAILURE

AND NATIONAL CODES

OF

FUSED DISCONNECT SWITCH(ES

AILURE TO FOLLOW THESE CODES COULD

IN

OVERHEATING AND EQUIPMENT

. T

YPE AND

.

)

.

1. Remove the cover plate from the junction box.

2. Mount the junction box to the wall or floor within 28

inches of the lower right corner of the wall sleeve.

Wall Sleeve

Ground Wire

With Eyelet

Terminal

Cover

Plate

28 Inches Max

Conduit

Power Leads

with Push

on Connectors

Metal Box

With Straight

Clamp

Mounting Hardwire Junction Box Kit

3. If a disconnect switch is to be used, make electrical

connections to it and mount the switch in the junction

box. Refer to the “Power Switch” Installation Instructions.

4. Remove control panel assembly by removing the two

screws holding control panel in place. Rotate panel forward.

5. Disconnect the power cord leads from all electrical connections including the ground wire.

6. Remove the power cord clamp and the power cord from

the unit.

7. For 230/208-volt units, remove and discard the white

lead from the wire assembly. For 265-volt units, remove

and discard the red lead from the wire assembly.

8. Remove the retaining ring from the threaded portion of

the straight conduit clamp. Insert the three wires into

the metal box through one of the two openings in the

box. Replace the hole cover grommet into the unused

hole to prevent objects from entering the box.

31

Page 32

ACCESSORY INST ALLA TIONS

9. Replace the retaining ring back on the conduit clamp

inside the metal box and tighten the ring securely.

10. Insert the three wires extending from the metal box into

the incoming power opening on the unit so that approximately 20 inches of the wires protrude through the opening.

11. Attach the metal box to the chassis with the two screws

provided.

12. Insert the wire tie into the 3/16 inch diameter hole located just above the incoming power opening. Tie all

wires together securely with the wire ties.

Control Panel

Base Pan

Junction Box

Metal Box Location

Right Side of

Chassis

Wire Tie

3/16 Inch

Diamenter

Hole

Electrical Supply

Wires

3. Connect the red lead to the common ( C ) terminal on

the capacitor.

4. Connect the ground wire to the partition panel where the

ground wire on the power cord was located. Use the

supplied green ground screw.

5. Connect the red lead in the wire assembly at the junction box to the red lead of the field power source.

6. Connect the black lead in the wire assembly at the junction box to the black lead of the field power source.

7. Connect the ground wire of the field power source to the

ground wire of the wire assembly at the junction box.

8. Install the junction box cover plate.

9. Reinstall the control panel assembly.

265 Volt Units

1. Remove and discard the red lead from the wire assembly.

2. Connect the black lead to the center terminal of the fuse

holder.

3. Connect the white lead to the common ( C ) terminal on

the capacitor.

4. Connect the ground wire to the partition panel where the

ground wire on the power cord was located. Use the

supplied green ground screw.

5. Connect the white lead of the wire assembly at the junction box to the white lead of the field power source.

6. Connect the black lead of the wire assembly at the junction box to the black lead of the field power source.

7. Connect the ground wire of the field power supply to the

ground wire of the wire assembly at the junction box.

8. Install the junction box cover plate.

9. Reinstall the control panel assembly.

Back of

Control Panel

Electrical Wiring Routing

208/230 Volt Units

1. Remove and discard the white lead from the wire assembly.

2. Connect the black lead to the line 2 terminal on the

control board.

32

Page 33

ACCESSORY INST ALLA TIONS

Hydronic Heat

Description

Where a central boiler is available, the Hydronic Kit can be

installed on the PTAC unit. This kit completely encloses all

plumbing and coils, but still allows easy access to controls.

In addition, the chassis can slide out for service without removing hydronic plumbing. Heating and cooling operations

are controlled by unit’s thermostat. Cooling operation is not

affected by the addition of the hydronic kit. Heat Pump models will operate on heat pump function down to the switchover

temperature before operating on hydronic heat. The electrical connections are plug-in type to assist in kit installation.

Freeze Protection

The hydronic kit has a factory installed freeze protection

thermostat which will allow a normally closed or normally

open water/steam valve to open when the thermostat senses

near freezing temperatures at the hot water or steam coil.

Once the temperature of the freeze thermostat rises above

58° F the water valve will return to normal mode operation.

Tools Required

1/4 Inch Electric Drill

1/8 Inch Diameter Drill Bit

Center Punch and Hammer

6 Foot Rule

Combination Square

1/4 Inch Nut Driver or Socket

5/16 Inch Nut Driver or Socket

Torch, Solder, Flux, etc.

Job Preparation

Before installing the hydronic kit, the following steps should

be complete:

1. Wall sleeve installed and completely sealed.

NOTE: The wall sleeve must be extending at least 3”

and no more than 3-1/8” past the finished interior wall in

order to properly install the hydronic kit.

2. Plumbing stub-outs complete.

3. Unit chassis uncrated but not installed and not yet con-

nected to electrical source.

4. A standard model chassis with an HTK3A or HTK4A kit

installed or a hydronic model chassis.

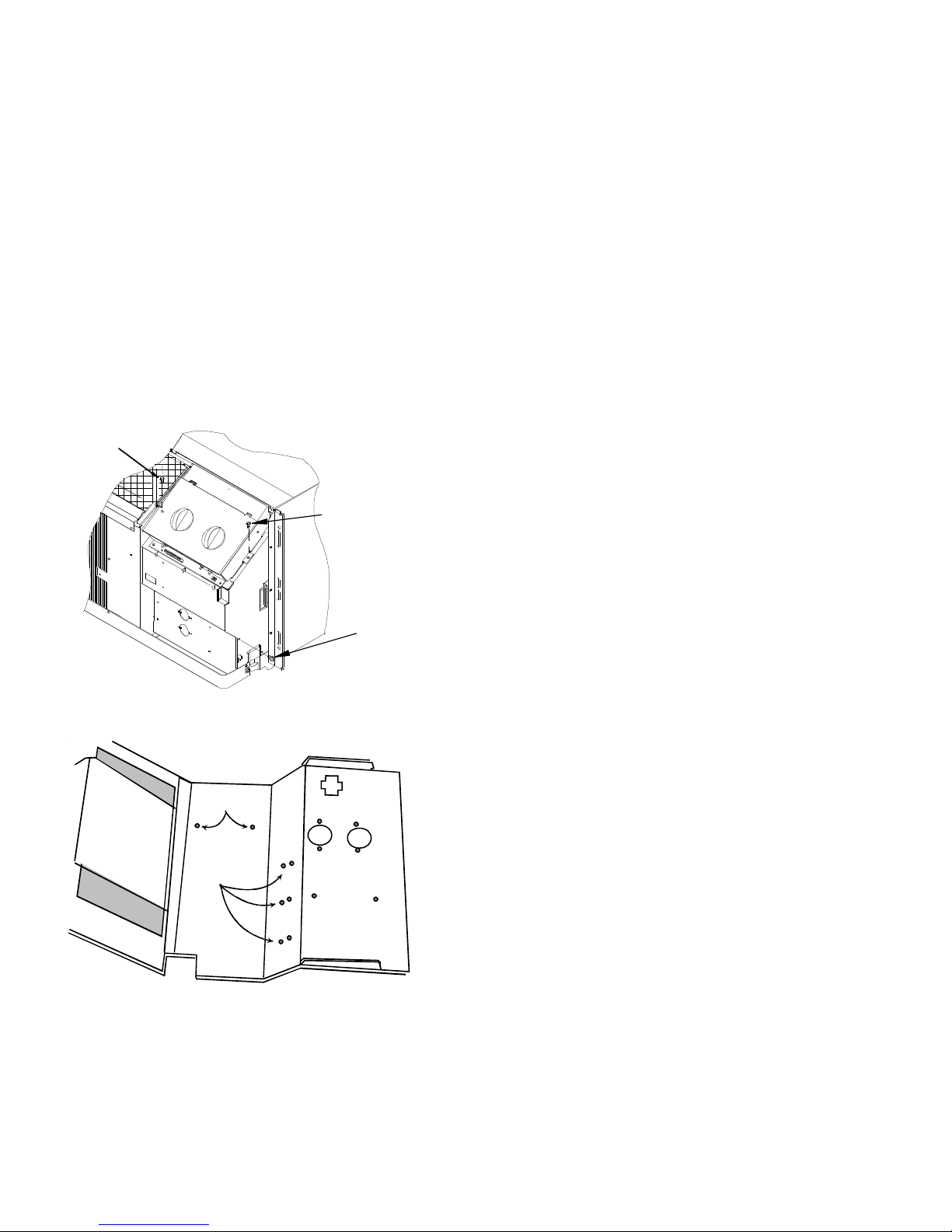

Installation

HIGH VOLTAGE

ISCONNECT ALL POWER BEFORE

D

SERVICING

ULTIPLE POWER SOURCES MAY BE PRESENT

M

AILURE TO DO SO MAY CAUSE PROPERTY

F

DAMAGE

Be sure to engage the services of a qualified water

treatment specialist to determine what water treatment, if any, is needed. The manufacturer will not

assume responsibility for equipment failures resulting from untreated or improperly treated water.

1. If the chassis is not a hydronic model chassis, remove

polymer front from chassis and discard. Install a HTK3A

or HTK4A kit as required.

2. Drill two 1/8” diameter holes on both sides of wall sleeve

as shown.

NOTE: If there is not enough room to drill holes from

the side then drill holes from inside the wall sleeve.

OR

INSTALLING THIS UNIT

,

PERSONAL INJURY OR DEATH

.

.

.

33

Page 34

ACCESSORY INST ALLA TIONS

V

Hydronic Heat Kit Application Data

Gal. Drop

per (psig) 200° F. EWT 180° F. EWT 200° F. EWT 180° F. EWT 200° F. EWT 180° F. EWT

Min. 2-Way Fan Speed Fan Speed Fan Speed Fan S peed Fan Speed Fan Speed

1.00 0.93 0.19 14910 13388 12639 11186 16945 14387 14257 12152 17858 15534 15049 13312

1.13 1.03 0.24 15216 13706 12898 11452 17360 14689 14607 12407 18276 15955 15401 13672

1.25 1.14 0.30 15500 13997 13139 11696 17745 14968 14930 12642 18666 16338 15729 14001

1.38 1.26 0.36 15762 14262 13361 11917 18099 15222 15228 12858 19025 16684 16032 14297

1.50 1.40 0.43 16003 14501 13565 12117 18423 15454 15501 13053 19356 16991 16311 14561

1.63 1.55 0.50 **16222 14714 13751 12295 18717 15661 15748 13228 19658 17261 16565 14792

1.75 1.71 0.58 16420 14900 13919 12450 18980 15845 15969 13384 19930 17494 16794 14991

1.88 1.89 0.66 16596 15061 14068 12584 19212 16006 16165 13519 20173 17689 16999 15158

2.00 2.10 0.76 16751 15195 14199 12696 **19268 16142 16212 13635 20387 17846 17179 15293

2.13 2.32 0.85 16884 15302 14312 12786 19586 16255 16479 13730 **20445 17965 17229 15395

2.25 2.57 0.96 16995 15384 14407 12854 19727 16345 16598 13806 20727 18047 17466 15465

2.38 2.84 1.07 17085 15439 14483 12900 19838 16410 16691 13861 20853 18091 17572 15503

2.50 3.14 1.18 17154 15467 14541 12924 19919 16452 16759 13897 20950 18110 17654 15508

2.63 3.48 1.30 17201 15470 14581 12926 19968 16471 16801 13912 21018 18125 17711 15520

2.75 3.85 1.43 17226 15505 14603 12956 19988 16580 16817 14004 21056 18140 17744 15545

** Based on ARI Rating Conditions of 70°F Entering Air Temp., 200°F Entering Water Temp and 180°F Leaving Water Temp. Max. Water Temperature

Pressure 7000 & 9000 BTUH Units 12000 BTUH Units 15000 BTUH Units

Coil

200°F. Max. Water Pressure - 200 Psig.

alve Hi Lo Hi Lo Hi Lo Hi Lo Hi Lo Hi Lo

Heating Capacity (Btu h )- Hot Water

34

Hydronic Heat Kit Application Data

Heating Capacity (Btuh) - Steam

Steam 7000 & 9000 BTUH Units 12000 BTUH Units 15000 BTUH Units

(psig) Fan Speed Fan Speed Fan Speed

Hi Low Hi Low Hi Low

2**

3

4

Maximum steam pressure 5 psig

**Based on ARI rating conditions of 70° F entering air temp. and 2 psig steam pressure

20,236 17,816 21,694 18,306 23,709 20,962

20,686 18,253 22,100 19,003 25,676 21,899

20,821 18,544 22,822 19,313 26,325 23,678

Water Valve Inlet/ Outlet Dimensions

Model Inlet Outlet

VW2WNOA 5/16" 5/16"

VW3WNOA 5/16" 5/16"

VW2WNCA 5/16" 5/16"

VW3WNCA 5/16" 5/16"

Steam Valve Inlet/ Outlet Dimensions

Model Inlet ( Inches) Outlet (Inches)

VS2WNOA 5/16" 5/16"

VS2WNCA 5/16" 5/16"

Page 35

ACCESSORY INST ALLA TIONS

r

r

r

Water Valve Pressure Drop

2-Way Valve 3-Way Valve Bypass 3-Way Valve

Wate

GPM (psig) GPM (psig) GPM (psig)

1.00 0.19 1.00 0.13 1.00 0.04

1.13 0.24 1.13 0.16 1.13 0.05

1.25 0.30 1.25 0.20 1.25 0.06

1.38 0.36 1.38 0.24 1.38 0.08

1.50 0.43 1.50 0.29 1.50 0.09

1.63 0.50 1.63 0.34 1.63 0.11

1.75 0.58 1.75 0.39 1.75 0.12

1.88 0.66 1.88 0.45 1.88 0.14

2.00 0.76 2.00 0.51 2.00 0.16

2.13 0.85 2.13 0.58 2.13 0.18

2.25 0.96 2.25 0.65 2.25 0.20

2.38 1.07 2.38 0.72 2.38 0.23

2.50 1.18 2.50 0.80 2.50 0.25

2.63 1.30 2.63 0.88 2.63 0.28

2.75 1.43 2.75 0.96 2.75 0.30

CV=2.3 CV=2.8 CV=5.0

Pressure Drop Wate

Pressure Drop Wate

Pressure Drop

Q = CV

Pd

Q = Flow in Gallons/Min

CV = Flow Coefficient of Valve

Pd = Pressure Drop (psig)

Dimensions of Complete Installation

3"

Top of Wal l Sleeve

10-13/16"

Bottom of Wall Sleeve

4-1/8"

e

v

e

e

l

S

l

l

a

W

Hydron ic Front

Toe Plate

0" - 3.0" Lo ng

PT AC Unit Wall Sleeve

5-1/2"

9-7/8"

Side View

Hydronic Air

Discharge

Unit Controls

Compartment

35

Top View

Page 36

ACCESSORY INST ALLA TIONS

Steam Plumbing Dimensions

(2 places)

3-1/2"

5-3/4"

1" x 1-1/2"

opening for piping

5-1/2"

1/2" I.D.

5/8" O.D.

5/8"

Steam Outlet

Connection

3-1/4"

1-7/8"

PTAC UNIT WALL SLEEVE

COIL

TOP VIEW OF C OIL LOCATION

(with t op grille and s heet metal r emoved)

1-1/2"

COIL

COIL

13-3/8"

1-1/2"

1-7/8"

3-1/4"

2-1/4 "

(2 places)

1" diameter

opening for piping

1/2" I.D.

5/8" O.D.

5/8"

Steam Inlet

Connection

Steam Outlet Connection

16-7/8"

16-3/4"

20-3/16"

COIL

1-1/2"

8-1/4"

Hydronic Air

Inlet

Steam Coil Position

2-1/8"

53"

FRONT VI EW

(unit with Hydronic Kit installed)

Steam Inlet Connection

COIL

1-1/2"

17-3/8"

Steam Trap (optional)

(

: Steam Trap may be

NOTE

installed on one or both

sides of Hyrdronic Unit)

SIDE VIEW SIDE VIEW

36

Page 37

ACCESSORY INST ALLA TIONS

Hot Water Plumbing Dimensions

5-1/2"

3-1/4"

3-3/8"

1-13/16"

1' 1-5/8"

1-13/16"

3-1/4"

5-11/18"

1"

1/2" I.D.

5/8" O .D.

1"

4-3/4"

2-3/4"

COIL

COIL

4' 5"

1-1/16"

1/2" I.D.

5/8" O.D.

2-1/8"

3-3/8"

1' 8-3/16"

1' 4-1/8"

0" TO 3"

Finished Floor

37

Page 38

ACCESSORY INST ALLA TIONS

Wall

3-1/4"

1/8" Hole s

2-1/4"

Indoor

Right

Side

Wall

Sleeve

Sleeve

1/8" Hole s

3-1/4"

5"

2-1/4"

Indoor

Left

Side

5. Remove the control knobs and metal escutcheon from

the control panel area of the chassis.

6. Remove the discharge screen from the chassis by removing the two screws holding the screen to the chassis.

7. Mount the transition to the chassis with supplied two 1/

2-inch #8 screws.

3. Unbox the hydronic kit and discard the packaging material. The cardboard packaging material should be recycled.

4. Mount the two support brackets to the bottom of the

hydronic top as shown with supplied four, 3/8-inch #8

screws.

Slide Brackets Before Tightening Screws

Rubber Splash

Shield

Move the brackets to the left so that screws are located

in right side of slot and tighten screws.

Transistion

8. Position the hydronic top with support brackets to the

wall sleeve and fasten the support brackets to the drilled

holes in the wall sleeve with supplied four 1/2-inch #10

screws.

38

Page 39

ACCESSORY INST ALLA TIONS

9. Place the chassis back into the wall sleeve and secure

chassis to wall sleeve. Be careful not to bind or pinch

the flexible shafts protruding from the bottom of the hydronic top assembly.

10. Place the ends of the flexible shafts protruding from the

hydronic top over the corresponding D shafts on the

chassis control board. Make sure the plastic inside the

flexible shaft fitting is mating with the flat surface of the

control board’s D shaft.

NOTE: The splash guard must be pushed against the

control panel.

Plastic

Insert

Skirt

2

"

-

D

2

8

6

-

3

"

/

4

"

Exterior

Wall

Hydronic

Front