Page 1

®

P

ACKAGE

H

EAT

P

UMP

INSTALLATION INSTRUCTIONS

Installer: Affix literature adjacent to the unit.

Part No. 10730420

Printed in USA

is a trademark of Maytag Corporation and is used under

license to Goodman Company, L.P. All rights reserved.

*NOTE: Please contact your distributor or our website

for the applicable product data book referred to in this

Goodman Company, L.P.

1810 Wilson Parkway • Fayetteville, Tennessee 37334

www.amana-hac.com

2000-2004 Goodman Company, L.P.

Effective: July 2004

Page 2

SAFETY INSTRUCTIONS

RECOGNIZE SAFETY SYMBOLS, WORDS, AND LABELS

The following symbols and labels are used throughout this manual to indicate immediate or potential safety hazards. It is the owner’s and

installer’s responsibility to read and comply with all safety information and instructions accompanying these symbols. Failure to heed

safety information increases the risk of personal injury, property damage, and/or product damage.

WARNING

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

CAUTION - Hazards or unsafe practices which COULD result in minor or moderate personal injury, product damage, property damage.

WARNING

O AVOID PROPERTY DAMAGE, PERSONAL INJURY OR DEATH, DO NOT USE THIS UNIT IF ANY PART HAS BEEN UNDER WATER. IMMEDIATELY CALL A

T

QUALIFIED SERVICE TECHNICIAN TO INSPECT THE FURNACE AND TO REPLACE ANY PART OF THE CONTROL SYSTEM AND ANY GAS CONTROL HAVING BEEN

UNDER WATER.

WARNING

O PREVENT PROPERTY DAMAGE, PERSONAL INJURY OR DEATH DUE TO IMPROPER INSTALLATION, ADJUSTMENTS, ALTERATIONS, SERVICE OR MAINTENANCE,

T

CONSULT THIS MANUAL, THE SERVICE MANUAL, A QUALIFIED INSTALLER OR A SERVICE AGENCY.

WARNING

HIS PRODUCT CONTAINS OR PRODUCES A CHEMICAL(S) WHICH MAY CAUSE DEATH OR SERIOUS ILLNESS AND WHICH ARE KNOWN BY THE STATE OF

T

ALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

C

ATTENTION INSTALLING PERSONNEL

As a professional installer you have an obligation to know the product better than the customer. This includes all

safety precautions and related items.

Prior to actual installation, thoroughly familiarize yourself with this Instruction Manual. Pay special attention to all safety

warnings. Often during installation or repair it is possible to place yourself in a position which is more hazardous than

when the unit is in operation.

Remember, it is your responsibility to install the product safely and to know it well enough to be able to instruct a

customer in its safe use.

Safety is a matter of common sense...a matter of thinking before acting. Most dealers have a list of specific good

safety practices...follow them.

The precautions listed in this Installation Manual are intended as supplemental to existing practices. However, if there

is a direct conflict between existing practices and the content of this manual, the precautions listed here take

precedence.

2

Page 3

GENERAL INFORMATION

TO THE INSTALLER

Before installing this unit please read this manual and the Product

Data Book applicable to your model* to familiarize yourself on the

specific items which must be adhered to such as maximum external

static pressure to unit, air temperature rise, minimum or maximum

CFM and motor speed connections.

TO THE OWNER

It is important to complete the owner registration card and mail it

immediately. This will assist us in contacting you if any service or

warranty information should change in the future. When completing

the registration card, be sure to include the Model, Manufacturing

and Serial Numbers, plus the installation date.

The warranty certificate is also supplied with the unit. Read the warranty carefully and note what is covered. Keep the warranty certificate in a safe place so you can find it if necessary.

If additional operating instructions are required, call the dealer where

the purchase was made. Keep this literature in a safe place for future reference.

UNIT PLACEMENT

WARNING

O PREVENT POSSIBLE EQUIPMENT DAMAGE, PROPERTY DAMAGE, PERSONAL

T

INJURY OR DEATH, THE FOLLOWING BULLET POINTS

WHEN INSTALLING THE UNIT.

MUST BE OBSERVED

ALL INSTALLATIONS:

Ground Level Installations Only:

• When the unit is installed on the ground adjacent to the

building, a level concrete (or equal) base is recommended.

Prepare a base the same physical size as the unit or slightly

larger and 3 inches thick.

• The base should also be located where no runoff of water

from higher ground can collect in the unit.

Rooftop Installations Only:

• To avoid possible personal injury or property damage, the

roof must have sufficient structural strength to carry the

weight of the unit(s) and snow or water loads as required by

local codes.

• If horizontal air delivery is used, the unit may be installed

directly on wood floors or on Class A, Class B, or Class C

roof covering material.

• To avoid possible personal injury, a safe, flat surface for

service personnel must be provided.

• If vertical air discharge is used and the unit is installed on

combustible flooring or class A, B, or C roofing material,

then the Amana® brand roof curb (PRC06A1 or PRC08A1)

is required.

This unit is approved only for an outdoor installation. To assure

that your unit operates safely and efficiently, it must be installed,

operated, and maintained in accordance with these installation and

operating instructions, all local building codes and ordinances.

The heating and cooling capacities of the unit should be greater than

or equal to the design heating and cooling loads of the area to be

conditioned. The loads should be calculated by an approved method

or in accordance with A.S.H.R.A.E. Guide or Manual J - Load Calculations published by the Air Conditioning Contractors of America.

Obtain from:

American National Standards Institute

1430 Broadway

New York, NY 10018

TRANSPORTATION DAMAGE

All units are securely packed in shipping containers tested according to International Safe Transit Association specifications. The carton should be checked upon arrival for external damage. If damage

is found, a request for inspection by carrier agent should be made in

writing immediately.

The unit should be carefully inspected upon arrival for damage and

bolts or screws which may have loosened in transit. In the event of

damage, the consignee should:

1. Make notation on delivery receipt of any visible damage to

shipment or container.

2. Notify carrier promptly and request an inspection.

3. In case of concealed damage, carrier should be notified as

soon as possible-preferably within 5 days.

4. File the claim with the following supporting documents within

the 9 month statute of limitations.

a. Original Bill of Lading, certified copy, or indemnity bond.

b. Original paid freight bill or indemnity in lieu thereof.

c. Original invoice or certified copy thereof, showing trade and

other discounts or reductions.

d. Copy of the inspection report issued by carrier

representative at the time damage is reported to the carrier.

The carrier is responsible for making prompt inspection of

damage and for a thorough investigation of each claim.

The distributor or manufacturer will not accept claims from

dealers for transportation damage.

NOTE: When inspecting the unit for transportation damage, remove

all packaging materials. Recycle or dispose of the packaging material according to local codes.

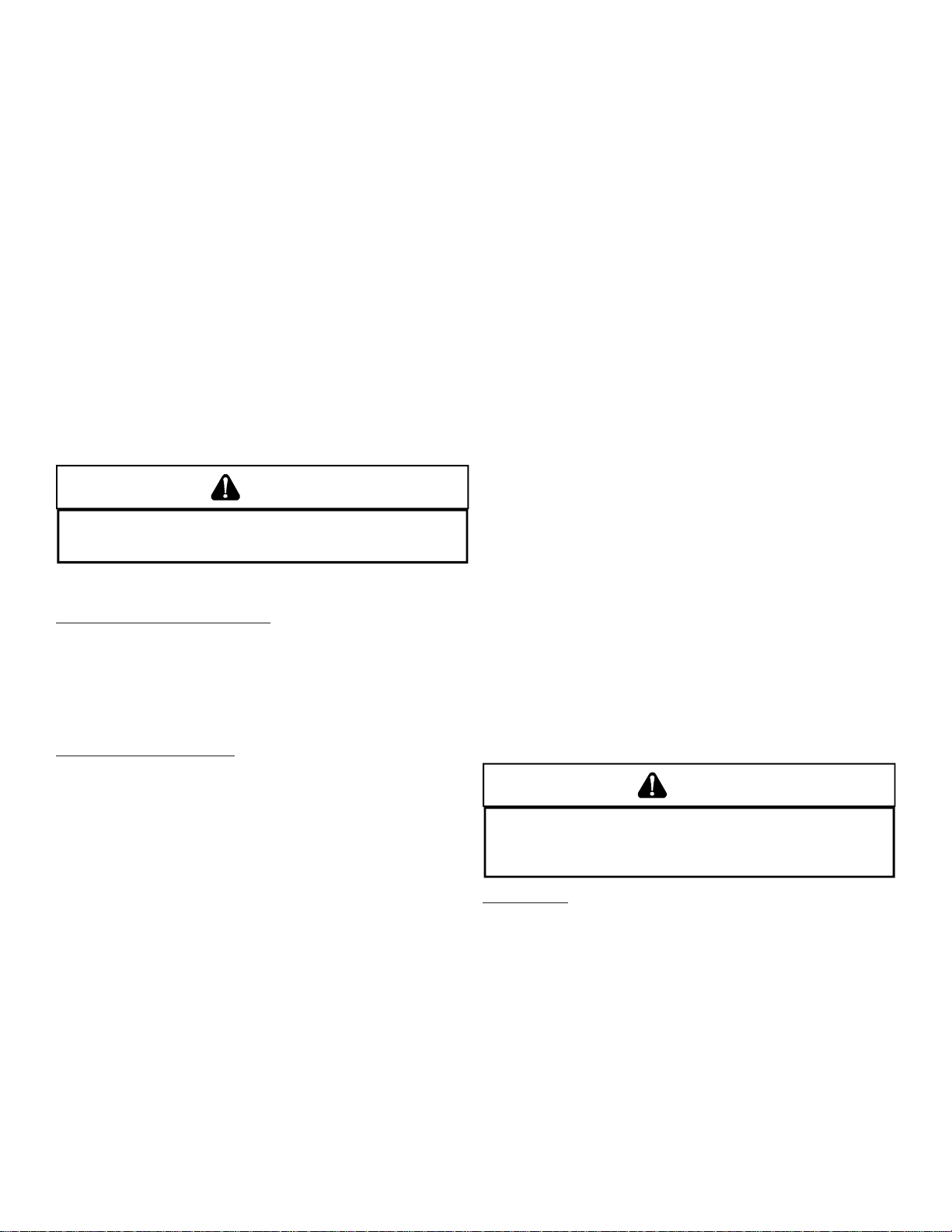

RIGGING AND HANDLING

WARNING

O PREVENT PROPERTY DAMAGE, THE UNIT SHOULD REMAIN IN AN UPRIGHT

T

POSITION DURING ALL RIGGING AND MOVING OPERATIONS.

LIFTING AND MOVING WHEN A CRANE IS USED, PLACE THE UNIT IN AN

ADEQUATE CABLE SLING.

IMPORTANT: If using bottom discharge with roof curb, ductwork

should be attached to the curb prior to installing the unit. Ductwork

dimensions are shown in Amana® brand roof curb installation instructions.

Refer to the Roof Curb Installation Instructions for proper curb installation. Curbing must be installed in compliance with the National

Roofing Contractors Association Manual.

NOTE: Lower unit carefully onto roof mounting curb. While rigging

unit, center of gravity may cause condenser end to be lower than

supply air end.

O FACILITATE

T

*NOTE: Please contact your distributor or our website for the applicable product data book referred to in this manual.

3

Page 4

(

Fork Lift From

Back Of Unit

blower section, to allow splicing-in of field-installed wiring, or connect to terminal strip in unit control box.

See the unit wiring diagram for electrical connections.

C/X G Y R O W1 W2 EROOM THERMOSTAT

Rigging

DUCT CONNECTIONS

HORIZONTAL AIRFLOW INSTALLATIONS

(24, 30, 36, 42 AND PHB48 MODELS)

Two three-inch collar connections and two square flanges are shipped

with the unit. The collar connections are located in the return air

opening of the unit. The square flanges are inside the unit blower

compartment. The square flanges can be used for either connecting 16x16 ductwork to the unit or used with a Horizontal Duct Cover

kit (CHK001A).

To install the collar connections, remove the two collars, reverse and

snap them back into place in the outlet and inlet openings. Be sure

the flanges are to the outside of the unit. Secure with screws provided.

OUTDOOR UNIT

PH__C02E

ROOM THERMOSTAT

OUTDOOR UNIT

PH__C02E

C/X G Y R O W W1 W2

Wiring shown is for D9945804 (THSMEC1H2BA) thermostat.

C/X G Y R O W2 E

C/X G Y R O W W1 W2

Wiring shown is for 10636701(THSADC1H2BA) or

10636 702 (THSMDC1H2B A) therm ostat

PHD60 TWO-STAGE

Yellow No. 20 W ire in Blower S ection

ROOM THERMOSTAT

OUTDOOR UNIT

PHD60C02E

(HEATER KIT CONTROL BOX)

NOTE: If Electric Heater Kit is not installed or low voltage connection is made

in unit contro l box, connect as follows.

ROOM THERMOSTAT

OUTDOOR UNIT

PHD60C02E

(CO NTRO L BOX)

C G Y2 Y1 R O W1 W2 W3

C/X G Y R O W W1 W 2

Wiring shown is for

1213412 (1F95-371) thermostat.

C G Y2 Y1 R O W1 W2 W3

C G Y Y1 R O W

Wiring shown is for 1213412 (1F95-371) thermostat.

HORIZONTAL AIRFLOW INSTALLATIONS

(PHD48/60 and PHB60 models only)

These units are equipped with 14x14 square supply and return air

openings for horizontal air flow. The openings are flanged for ease

of duct connection. A 16x16 Horizontal Duct Cover kit (CHK001A)

can be used with the clips provided with the unit.

THERMOSTAT PLACEMENT

Thermostat should be mounted 5 feet above the floor, on a vibration

free inside wall in a room or a hallway that has good air circulation.

Movement of air should not be obstructed by furniture, door, draperies, etc. The thermostat should not be mounted where it will be affected by drafts, hot or cold water pipes or air ducts in walls, radiant

heat from fireplace, lamps, the sun, television, etc. Consult the Instruction Sheet packaged with thermostat for mounting instructions.

WARNING

SHOCK HAZARD

ISCONNECT ALL ELECTRICAL POWER BEFORE ELECTRICALLY CONNECTING

D

OR SERVICING THI S UNIT.

BEFORE WORKING ON THIS PRODUCT CAN CREATE A HAZARD LEADING TO

PERSONAL INJURY AND/OR DEATH.

AILURE TO DISCONNECT THE ELECTRICAL POWER

F

!

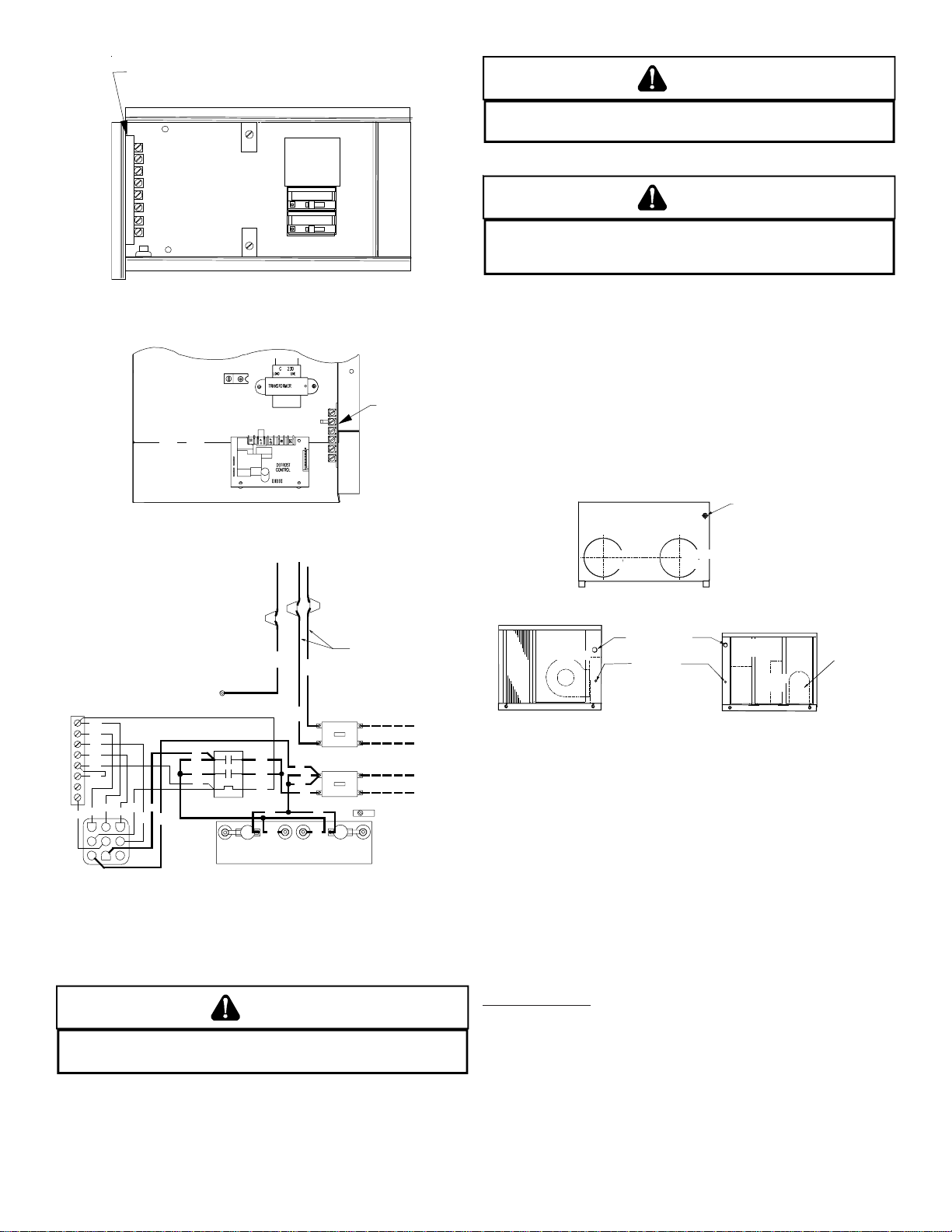

THERMOSTAT WIRING

When an electric heater is installed, the thermostat wiring will be

made at the heater accessory box.

If a unit is installed without electric heaters, the low voltage wiring to

the blower section can be cut, either in the control box area or in the

ROOM THERMOSTAT

OUTDOOR UNIT

PH__CC2E

OUTDOOR UNIT

PH__CC2E

C/X G Y R O W1 W2 E

C/X G Y R O W W1 W 2

Wiring shown is for D9945804 (THSMEC1H2BA) thermostat.

C/X G Y R O W2 EROOM THERMOSTAT

C/X G Y R O W W1 W2

Wiring shown is for 10636701(THSADC1H2BA) or

10636702

THSMDC1H2BA) thermostat

Typical Thermostat and Unit 24 Volt Wiring Hoo2kup

ELECTRICAL CONNECTIONS

NOTE: The units are designed for operation on 60 Hz current and at

the voltages shown on the rating plate. All internal wiring in the unit is

complete. For the PHB**CC and PHD**CC units, the power supply

connection for the heater and unit will be at the circuit breaker in the

heater control box. For all others, the power supply may be brought

into the contactor (refer to unit wiring diagram supplied with unit).

Ensure 24 volt wiring is connected between the unit control panel

and the room thermostat. See the following figures for low voltage

field connection.

4

Page 5

Low Voltage

T

Terminal Strip

CG YR W W1

CAUTION

O AVOID PROPERTY DAMAGE OR PERSONAL INJURY DUE TO FIRE, USE

T

ONLY COPPER CONDUCTORS.

ON ON

W2

O

Low Voltage Connection

Heater Kit Control Box

Low Voltage

Terminal Strip

Low Voltage Connection

Unit Control Box

T2

T1

TO CO NTACTOR

BK

CB2

CB1

RD

OL

L2

FIELD

CONNECTIO N

L1

208/240 VAC

ø

1

L2

USE COPP ER

CONDUCT ORS

ONLY-75°C MIN

L1

208/230 VAC 1

HERMOSTAT

C

G

Y

R

W

W1

W2

O

0R

BU

GY

YL

RD

BR

BR

GYBURD

123

456

789

BR

YLBKVT

BK

BK

BK

BR

GND-75

5

3

SEQUENCER #1

4

BK

1

BK

BU

OL

GN

RD

VT

RD

RD

BK

RD

BK BK

10KW

Field Connection

Refer to the unit wiring diagram (see back of manual) for electrical

connections. When installed, the unit must be electrically grounded

in accordance with local codes or in the absence of local codes, with

the National Electrical Code, ANSI/NFPA No. 70, and/or the CSA

C22.1 Electrical Code, if an external source is utilized.

WARNING

O AVOID THE RISK OF ELECTRICAL SHOCK, WIRING TO THE UNIT MUST BE

T

POLARIZED AND GROUNDED.

CAUTION

O PREVENT IMPROPER AND DANGEROUS OPERATION DUE TO WIRING

T

ERRORS, LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING

CONTROLS.

ERIFY PRO PER OPERATION AFTER SERVICING.

V

The best protection for the wiring is the lowest rated fuse or circuit

breaker which will supply power to the unit during normal operation

without nuisance trips. Such a device will provide maximum circuit

protection. DO NOT EXCEED THE MAXIMUM OVERCURRENT

DEVICE SIZE SHOWN ON UNIT DATA PLATE.

All line voltage connections must be made through weatherproof

fittings. All exterior power supply and ground wiring must be in approved weatherproof conduit. Low voltage wiring from the unit control panel to the thermostat requires coded cable.

FLEXIBLE WIRING SETUP

Line and low voltage wiring must enter the unit as shown.

REAR VI EW

ELECTRICAL

LOW

VOLTAGE

RETURN

AIR

SIDE VIEW

HEATER

KIT

BLOWE R

SUPPLY

AIR

For knockout locations, see dimension drawing in the Product Data

Book applicable to your model* . Use the Single Point wiring kit to

add further flexibility to the installation wiring.

UNIT VOLTAGE

ø

The unit transformer is factory connected for 230V operation. If the

unit is to operate on 208V, reconnect the transformer primary lead

as shown on the unit wiring diagram.

ELECTRICAL

SIDE VIEW

ELECT.

CONTROL

BOX

EVAP

COIL

COMPR ESSOR

AIR CIRCULATION AND FILTERS

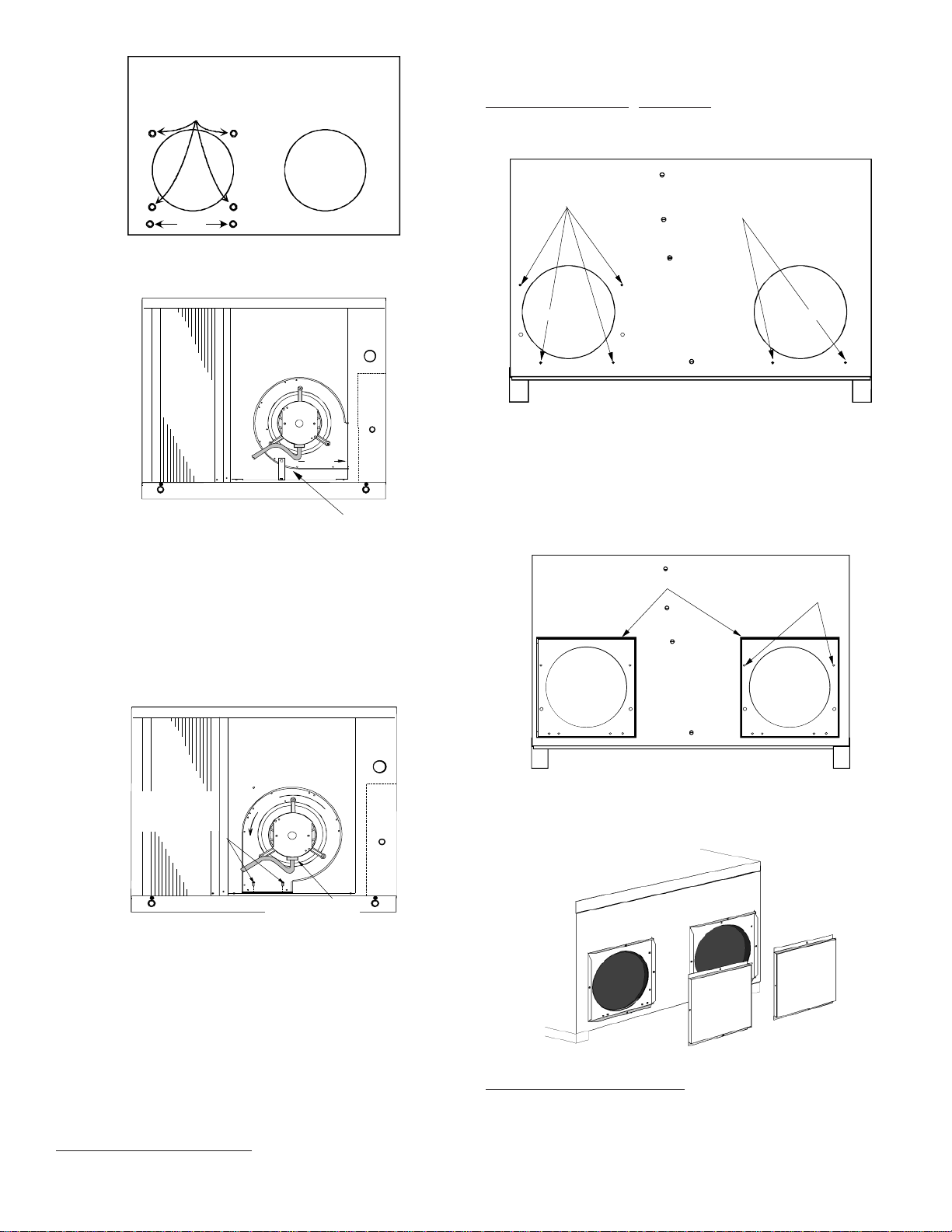

DOWNSHOT AIRFLOW CONVERSION

Units are shipped from the factory ready for horizontal airflow. These

units can be easily converted from horizontal to downshot airflow

delivery. If conversion to vertical airflow is necessary, proceed as

follows:

Blower Rotation

1. Cut insulation around bottom openings and remove panels

from the bottom of the unit, saving the screws holding the

panels in place.

2. From the rear of the unit, remove the four (4) screws securing

the blower assembly in place and loosen the two (2) screws

directly below the duct opening.

*NOTE: Please contact your distributor or our website for the applicable product data book referred to in this manual.

5

Page 6

Remove

Loosen

Duct Removal

3. Remove the clamp securing the blower assembly to the

bottom of the unit. Discard clamp and screws.

Airflow

}

{

Remove

Clamp Removal

5. Rotate the blower assembly 90° clockwise, setting the blower

assembly outlet on the panel removed from bottom of the

unit.

Ensure the blower motor is oriented with the motor wires

at the bottom. This keeps condensate from puddling

inside the blower motor and causing motor failure. If

the motor is not oriented correctly, loosen the motor belly

band and rotate the motor to the correct position, then

retighten the motor belly band.

require that cover clips (included with the unit) be installed to ensure a secure fit of the Horizontal Duct Covers.

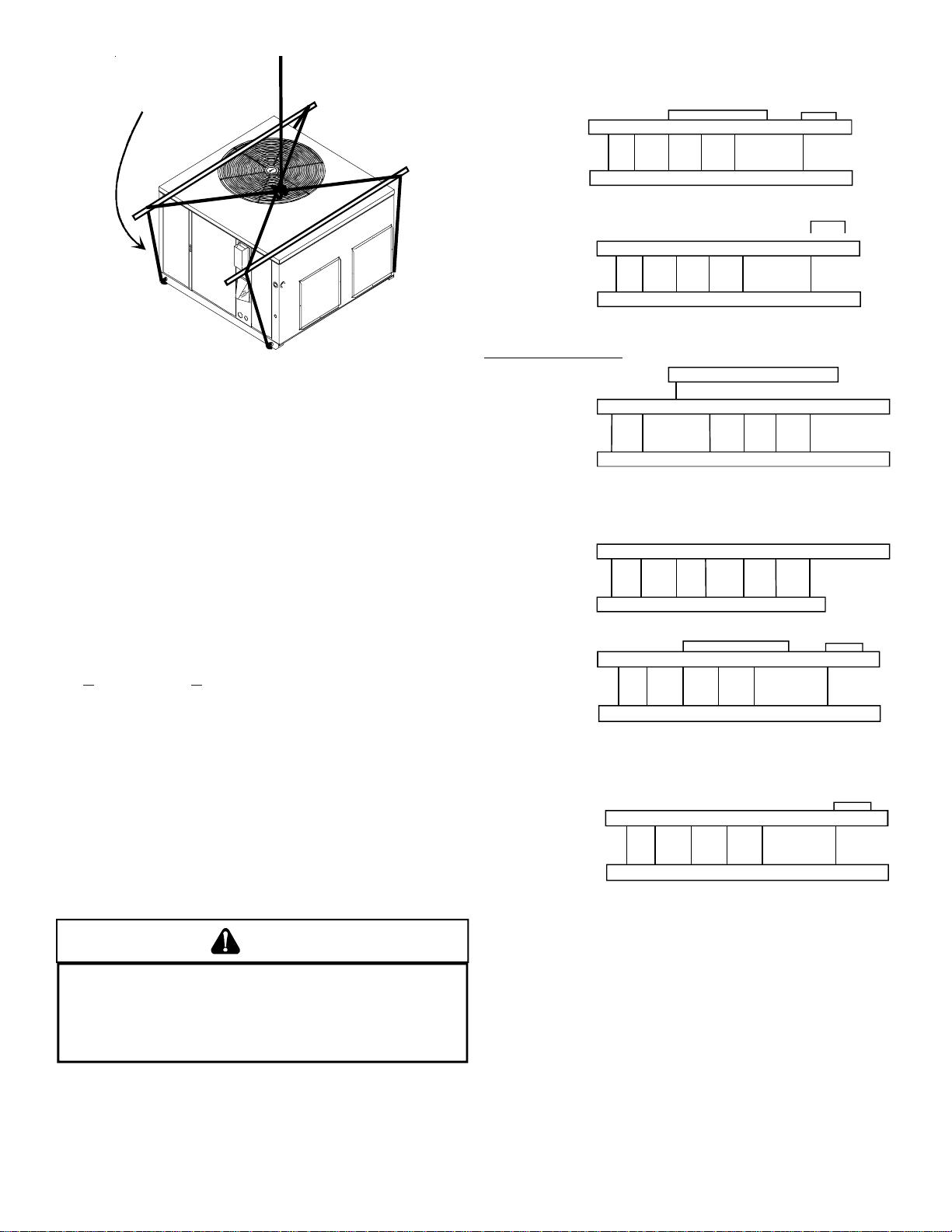

24, 30, 36, 42 AND PHB48 Models:

1. Remove and set aside the four (4) supply air side screws.

2. Remove and set aside the two (2) return air side screws.

REMOVE

SCREWS

REMOVE

SCREWS

RETURN AIRSUPPLY AIR

Supply Air Side Screws Removal

3. Center flange bracket and unit openings. Attach flange

brackets to the unit using the removed screws in Step 1.

Retighten screws.

4. Drill two 1/8” diameter holes on the return air side as

indicated in the figure below.

5. Secure the return air side flange bracket with the two (2)

self-tapping screws included with the unit.

FLANGE BRACKETS

SUPPLY AIR RETURN AIR

Drill 2-1/8"

Dia. holes

Install Screws

Removed From

Back Panel

w

o

l

f

r

i

A

Motor Leads MUST

exit at bottom

Vertical Blower Assembly

6. Secure the blower assemblyy with screws removed in step

1.

HORIZONTAL DUCT COVER INSTALLATION

The second step in the downshot airflow conversion is to install Horizontal Duct Covers. Horizontal Duct Covers are an accessory, and

can be purchased from your authorized dealer. The kit number is

CHK001A.

PHB/PHD Models 24, 30, 36, 42, and PHB48 require that the supply and return air openings be converted to square. Flanges are

shipped with these units to complete this conversion.

Models PHD48/60 and PHB60 supply and return air openings are

square and do not require a flange conversion. They do, however,

Flange Bracket Installation

6. Align the horizontal duct covers over the flange brackets

just installed and secure with screws included in the

Horizontal Duct Cover kit.

Horizontal Duct Cover Alignment

PHD48/60 and PHB60 Models:

1. Install cover clips (included with unit) on the inner flange

sides using existing flange hole.

2. With self-drilling screws provided, attach clips to the unit.

6

Page 7

CLIPS

SELF-DRILLING

SCREWS

Cover Clip Installation

3. Attach 16x16 horizontal covers using screws provided with

kit to the outer duct opening flange and cover clip holes.

4. Secure the center of the top flat cover flange to the unit

using a self-drilling screw included with the unit.

Even though a return air filter is not supplied with this unit, there

must be a means of filtering all return air.

Refer to the following table or the Product Data Book applicable to

your model* for filter size information.

RATED

MODEL

DISPOSABLE

FILTER (ft

PERMANENT

2)1

FILTER (ft

2)2

COOLING

AIRFLOW

(CFM)

PHB 24C02* 3.0 1.5 850

PHB 30C02* 3.4 1.7 960

PHB 36C02* 4.0 2 1170

PHB 42C02* 4.5 2.3 1350

PHB 48C02* 5.5 2.8 1550

PHB 60C02* 6.5 3.3 1750

PHB 24CC2* 3.0 1.5 850

PHB 30CC2* 3.4 1.7 960

PHB 36CC2* 4.0 2 1170

PHD24C02* 3.0 1.5 810

PHD30C02* 3.4 1.7 1020

PHD36C02* 3.0 1.5 1100

PHD42C02* 3.4 1.7 1200

PHD48C02* 5.5 2.8 1550

PHD60C02* 6.5 3.3 1750

Horizontal Duct Cover Installation

DUCTWORK

Duct systems and register sizes must be properly designed for the

C.F.M. and external static pressure rating of the unit. Ductwork should

be designed in accordance with the recommended methods of Air

Conditioning Contractors of America Manual D (Residential) or

Manual Q (Commercial). All ductwork exposed to the outdoors must

include a weatherproof barrier and adequate insulation.

A duct system should be installed in accordance with Standards of

the National Board of Fire Underwriters for the Installation of Air Conditioning, Warm Air Heating and Ventilating Systems. Pamphlets No.

90A and 90B.

The warm air supply duct from the unit through a wall fabricated of

combustible material may be installed without clearance. However,

minimum clearances for the unit must be observed (see appendix in

back of manual).

The outlet duct should be provided with an access panel.

For vertical airflow, the ductwork should be attached to the roof curb

prior to installing the unit. Ductwork dimensions are shown in the

Amana ® PRC roof curb installation manual.

If desired, supply and return duct connections to the unit may be

made with flexible connections to reduce possible unit operating

sound transmission.

FILTERS

PHD24CC2* 3.0 1.5 810

PHD30CC2* 3.4 1.7 1020

PHD36CC2* 4.0 2 1100

1

Based on a face veloc ity of 300 f t./min.

2

Based on a face velocity of 600 ft./min.

If using the Over/Under Transition Kit, the filter(s) may be located in

the return air duct(s) or return air filter grille(s). Filters installed external to the unit should be sized in accordance with their manufacturer

recommendations. A throwaway filter must be sized for a maximum

face velocity of 300 feet per minute.

FILTER INSTALLATION

Important: When installing a filter, the air flow arrows on the filter

must point toward the circulating air blower.

CONDENSATE DRAIN

CONDENSATE DRAIN CONNECTION

An external condensate drain trap is required with this unit. See

your distributor for details. For proper unit operation, the trap must

be filled either before a cooling startup or during a unit “cycle-off”

after 20 minutes of running on first cycle. This drain can be extended using 3/4” PVC piping.

WARNING

O AVOID PROPERTY DAMAGE, PERSONAL INJURY OR DEATH, DISCONNECT

T

ELECTRICAL POWER BEFORE REMOVING FILTERS.

WITHOUT A FILTER INSTALLED BECAUSE DUST AND LINT WILL BUILD UP ON

INTERNAL PARTS RESULTING IN LOSS OF EFFICIENCY, EQUIPMENT DAMAGE

AND POSSIBLE FIRE.

*NOTE: Please contact your distributor or our website for the applicable product data book referred to in this manual.

EVER OPERATE FURNACE

N

7

Page 8

1-1/2" Minimum

drop at outlet

90° ELL

Condensate

Drain Trap

2-1/2" of

3/4" PVC

Figure 13 - Condensate Drain Connection

NORMAL SEQUENCE OF OPERATION

OPERATING INSTRUCTIONS

1. Turn ON the electrical power supply to the unit.

2. Place the room thermostat selector switch in the COOL or

HEAT position (or AUTO if available, and if automatic

changeover from cooling to heating is desired).

3. Set the room thermostat to the desired temperature.

MAINTENANCE

WARNING

O AVOID PERSONAL INJURY OR DEATH DUE TO ELECTRICAL SHOCK,

T

DISCONNECT ELECTRICAL POWER BEFORE PERFORMAING ANY

MAINTENANCE.

NOTE: There is a fan delay on initial power to unit before the low

voltage board resets and is operational.

1. Thermostat calls for heating or cooling. The compressor and

outdoor fan are energized.

2. Approximately 10 seconds later, the indoor fan starts.

3. The unit will deliver heating or cooling to the conditioned

space until the thermostat is satisfied.

NOTE: PHD60 TWO-STAGE COOLING

If the room temperature is 4°F higher than thermostat

setpoint, the indoor fan will run at high speed, and the

compressor at full load. If the room temperature is within

2°F of thermostat setpoint; the indoor fan will shift to low

speed and the compressor will unload to a lower capacity.

4. The compressor and outdoor fan will be de-energized when

the thermostat opens.

5. The indoor fan continues to run for approximately 60 seconds

after the thermostat is satisfied. This allows additional cooling

from the indoor coil to be transferred to the conditioned

space. Then, the indoor fan stops.

STARTUP AND ADJUSTMENT

WARNING

REPLACING OR CLEANING FILTER

A return air filter is not supplied with this unit; however, there must be

a means of filtering all of the return air. The filter(s) may be located in

the return air duct(s), or return air filter grille(s). Consult with your

installing dealer for the actual location of the return air filter(s) for

your unit.

Dirty filters are the most common cause of inadequate heating or

cooling performance. Filter inspection should be made at least every two months; more often if necessary because of local conditions

and usage.

Dirty throwaway filters should be discarded and replaced with a new,

clean filter. Dirty permanent filters should be washed with water, thoroughly dried and sprayed with a filter adhesive before being reinstalled. (Filter adhesives may be found at many hardware stores.)

Permanent filters should last several years; however, should one

become torn or uncleanable, it should be replaced.

MAINTAINING CABINET FINISH

Use a fine grade automotive wax on the cabinet finish to maintain

the finish’s original high luster. This is especially important in areas

with high ultraviolet radiation.

CLEAN OUTSIDE COIL (QUALIFIED SERVICER ONLY)

The coil with the outside air flowing over it should be inspected annually and cleaned as frequently as necessary to keep the finned

areas free of lint, hair and debris.

O PREVENT PERSONAL INJURY OR DEATH, ALWAYS DISCONNECT THE

T

ELECTRICAL POWER BEFORE INSPECTING OR SERVICING THE UNIT.

OF THE COMPRESSOR PROTECTION DEVICES RESET AUTOMATICALLY,

THE CONTACTOR AND OUTDOOR FAN MAY BE ENERGIZED WHEN RESET.

INCE ALL

S

WARNING

HIS UNIT MUST NOT BE USED AS A "CONSTRUCTION HEATER" DURING THE

T

FINISHING PHASES OF CONSTRUCTION ON A NEW STRUCTURE.

USE MAY RESULT IN PREMATURE FAILURE OF THE UNIT DUE TO EXTREMELY

LOW RETURN AIR TERMPERATURES AND EXPOSURE TO CORROS IVE OR V ERY

DIRTY ATMOSPHERES.

HIS TYPE OF

T

COMPRESSOR PROTECTION DEVICES

This package heat pump unit compressor includes components which

are designed to protect the compressor against abnormal operating

conditions.

CONDENSER AND EVAPORATOR MOTORS

Bearings on the evaporator motor and the condenser motor are permanently lubricated. No additional oiling is required.

WARNING

O AVOID PERSONAL INJURY OR DEATH DUE TO ELECTRIC SHOCK, DO NOT

T

REMOVE ANY INTERNAL COMPARTMENT COVERS OR ATTEMPT ANY

ADJUSTMENT.

CAUTION

LWAYS VERIFY PROPER OPERATION AFTER SERVICING.

A

8

Page 9

ACCESSORIES

Horizontal Duct Covers (CHK001A)

Single Point Power Connections (SPK**A)

Roof Curb - Heat Pump (PRC06A1)

Roof Curb - Universal (PRC08A1)

Over-Under to Side by Side (PDTROU4A)

Over-Under to Side by Side (PDTROU6A)

Additional accessories, as described above, can be purchased to fit

specific application needs. Accessories can be ordered by the part

numbers in the table and each accessory includes its own separate

instructions.

REPLACEMENT PARTS

Refer to the description in the Parts Catalog when ordering any part.

Be sure to provide the unit model, manufacturing, and serial numbers with the order.

NOTE: Details for installing and wiring electric heater kits and single

point wiring kits are contained in the installation instructions for these

accessories.

9

Page 10

WARNING

PHB[24-36]C02*

L1

GND

208/230 VAC 1Ø

FIELD CONNECTI ON

GND

VT-7

LINE

TRANSFORMER

COM

MOVE RD6 WIRE FROM TRANSFORMER

FOR PROPER OPERATION ON 208 VOLT THE

FOLLOWING CHANGE MUST BE MADE:

208 VOLT INSTALLATION

L2

°C MIN

ONLY-

75

CONDUCTORS

USE COPPER

31

RD

VT

62

L2

L1T1

CONTACTOR (CC)

T2

RD-27

BU-1

VT-20

RD-10

GY-8

COMPRESSOR

VT

Ø WIRING

1

20

BU

VT-62

RD-6

RELAY

SWITCH

COOLING

GY-9

VT-14

208

230

LOAD

GY-9

BU-23

NO NC

COM

G

C

XFMR-C

XFMR-R

R

VT-18

BK-26

RD-24

OR-28

RD-33

RD-11

VT-14(COMMON)

RD-24(COOL)

BU-23(H EAT)

WH-7

MED HI

LOW

HI

COMMON

MED LOW

2

3

4

1

5

6

AIR

(ACB)

BLOWER

CIRCULATION

BR

BR

(CAP)

CAPACITOR

230 TERMINA L TO 208 TERMINAL .

BK-24

BK-13

(DT)

DEFROST

THERMOSTAT

(RS)

SOLEN OID

REVERSING

CS

R

RD

10

RD

23

1

3

YL

12

FAN H ERM

COM

RD-27

CAPACITOR

BR-11

31

HEAT

RELAY

ELECTRIC

2

4

5

BK-27

FAN

O.D.

RD-31

VT

MOTOR

16

RD-22

5

G

5

-

Y

T

S

E

C

Y

O

O

W

2

R

R

D

F

T

BR-21

RD-13

YL-27

OR-49

T

0

3

1

0

6

0

9

BU-34

BOARD

DEFROST

DF1

DF2

WH WHITE

GY GRAY

BR BROWN

BU BLUE

RD RED

COLO R CODE

YL YELLOW

VT VIOLET

OR ORANGE

22303301 REV. 1

GN GREEN

30

90

60

HI VOLTAGE

HI VOLTAGE FIELD

LOW VOL TAGE

LOW VOL TAGE FIELD

BK BLAC K

TEST

TEST

ALTE RNATE

CONFIGURATION

T

S

E

T

0

3

0

6

0

9

DETAIL 1

HIGH HIGH

HIGH HIGH

HIGH HIGH

MED

MED

MED

HIGH

HIGH

HIGH

MED

MED

MED

HIGH

HIGH

HIGH

LOW

LOW

LOW

G

BU-1

W

O

ELECTR IC HEAT BL OWER TAP

Y

R

C

A

BK-19

BK-20

YL-27

VT-18

OR-49

BR-21

BK-26

PIN 4

PIN 5

PIN 6

PIN 7

PIN 8

PIN 9

A

GY-70

BU-34

RD-13

TO

PIN 1

PIN 2

PIN 3

HEATER

4

321

6598

KIT

ALTERNATE UNIT POWER REFRIGERANT

ACCESSORY INSTALLATION INSTRUCTIONS.

HEATER ACCESSORIES. SEE HEATER

LEADS MAY BE USED WITH ELEC TRIC

GN

RD

BK

7

VIEW A-A

MED

MED

MED

LOW

LOW

LOW

LOW

LOW

LOW

PHCB05C1 PHCB10C1 PHCB15C1 PHCB20C1

MED

MED

MED

LOW

LOW

LOW

DOWN HORIZ DOWN HORIZ DOWN HORIZ DOWN HORIZ

LOW

BLOWER

COOLING

SPEED TAP

MODEL

NUMBER

MED-LOW

MED-HIGH

PHB24C02**

PHB30C02**

PHB36C02**

230/208

HEATER

ELECTRIC

SEQ

NO#1

ELECTR IC

HEAT

ELECTRIC

RELAY

WOY

R

GEC

W1

W2

KIT

HEATER

SEQ

NO#1

TO PREVENT PROPERTY DAMAGE, PERSONAL INJURY OR DEATH, DISCONNECT ELECTRICAL POWER TO THIS FURNACE BEFORE

SERVICING OR PERFORMING MAINTENANCE.

HEAT RELAY

TO HEAT ER KIT

DFT

DF1

DF2

R

Y

C

TERMINAL B OARD

DT

RRW2 O O Y

BOARD

DEFROST

O

906030

10

G

RELAY

SWITCH

W

COOLING

XFMR R

R

XFMR C

C

G

COMMON

CC

RS

C

T

S

E

T

24V

230/208

CAP

ACB

HI

LO

MD LO

MD HI

TAP

HEAT

2

4

5

HEAT

RELAY

ELECTRIC

TAP

OD

COOLING

NO

NC

COM

RELAY

SWITCH

COOLING

FAN

FAN

CAP

T2

C

COMP

R

S

CAP

COM

START

HERM

RELAY

521START

CAP

CC

T1

L2

208/230 VAC 1Ø

WARNING :DISCONNE CT POWER BEF ORE SERVI CING.

USE COPPE R CONDUCTO RS ONLY

L1

Page 11

WARNING

PHB[42-48]C02**

L1

GND

208/230 VAC 1Ø

FIELD CONNECTION

GND

VT-7

LINE

TRANSFORMER

COM

MOVE RD6 WI RE FROM TRANS FORMER

FOR PROPER OPERATION ON 208 VOLT THE

FOLLOWING CHANGE MUST BE MADE:

208 VOLT INSTALLATION

L2

ONLY-

75°C MIN

CONDUCTORS

USE COPPER

31

RD

VT

62

L2

L1T1

T2

CONTACTOR (CC)

RD-27

YL\BK

VT-20

RD-10

GY-8

1Ø WIRING

COMPRESSOR

VT

20

BU

VT-62

RD-6

RELAY

SWITCH

COOLING

GY-9

VT-14

208

230

LOAD

GY-9

CAPACITOR

230 TERMINAL TO 208 TERMINAL.

BU-23

RD-11

VT-14(COMMON)

RD-24(COOL)

BU-23(HEAT)

MED

LOW

HI

COMMON

3

2

4

1

5

6

AIR

(ACB)

BLOWER

CIRCULATION

BR

BR

(CAP)

NO NC

COM

G

C

XFMR-C

XFMR-R

R

VT-18

BK-26

RD-24

RD-33

LOW

SWITCH

PRESSURE

OR-28

WH-7

YL\BK

BK-24

BK-13

(DT)

DEFROST

THERMOSTAT

(RS)

SOLENOID

REVERSING

CS

R

RD

10

RD

23

1

3

YL

12

FAN H ERM

COM

RD-27

CAPACITOR

BR-11

31

HEAT

RELAY

ELECTRIC

2

4

5

BK-27

FAN

O.D.

VT

RD-31

MOTOR

16

RD-22

5

G

5

-

Y

T

S

E

C

Y

O

O

W

2

R

R

D

F

T

BR-21

RD-13

YL-27

OR-49

T

0

3

1

0

6

0

9

BU-34

BOARD

DEFROST

DF1

DF2

22303901 REV. 1

BR BROWN

COLOR CODE

YL YELLOW

906030

WH WHITE

GY GRAY

BU BLUE

RD RED

LOW VOLTA GE

LOW VOLTAGE FIELD

HI VOLTAGE

HI VOLTAGE FIELD

OR ORANGE

VT VIOLET

GN GREEN

BK BLAC K

TEST

TEST

ALTERNATE

CONFIGURATION

T

S

E

T

0

3

0

6

0

9

DETAIL 1

MED

MED HIGH HIGH

LOW LOW MED

MED MED

LOW

G

W

O

ELECTRIC HEAT BLOWER TAP

Y

R

C

A

BK-19

BK-20

VT-18

OR-49

YL-27

BR-21

BK-26

PIN 4

PIN 5

PIN 6

PIN 7

PIN 8

PIN 9

A

GY-70

BU-34

RD-13

TO

PIN 1

PIN 2

PIN 3

HEATER

4

6598

321

KIT

ALTERNATE UNIT POWER REFRIGERANT

ACCESSORY INSTALLATION INSTRUCTIONS.

HEATER ACCESSORIES. SEE HEATER

LEADS MAY BE USED WITH ELECTRIC

GN

RD

BK

COOLING

7

VIEW A-A

LOW

MED

MED

PHCB07C1 PHCB10C1 PHCB15C1 PHCB20C1

BLOWER

SPEED TAP

MODEL

NUMBER

MED

LOW LOW

DOWN HORIZ DOWN HORIZ DOWN HORIZ DOWN HORIZ

MED

LOW

PHB42C02**

PHB48C02**

230/208

HEATER

ELECTRIC

SEQ

NO#1

ELECTR IC

ELECTRIC

HEAT

RELAY

WO Y

R

GEC

W1

W2

KIT

HEATER

SEQ

NO#1

TO PREVENT PROPERTY DAMAGE, PERSONAL INJURY OR DEATH, DISCONNECT ELECTRICAL POWER TO THIS FURNACE BEFORE

SERVICING OR PERFORMING MAINTENANCE.

HEAT RELAY

TO HEAT ER KIT

DFT

DF1

DF2

R

Y

C

TERMINAL B OARD

DT

RRW2 O O Y

BOARD

DEFROST

O

906030

11

G

RELAY

SWITCH

W

COOLING

XFMR R

R

XFMR C

C

G

COMMON

24V

230/208

LPS

CC

RS

C

T

S

E

T

CAP

ACB

HI

LO

MED

TAP

HEAT

2

4

5

HEAT

RELAY

ELECTRIC

TAP

OD

COOLING

NO

NC

COM

RELAY

SWITCH

COOLING

FAN

FAN

CAP

T2

C

COMP

R

S

CAP

COM

START

HERM

RELAY

521START

CAP

CC

T1

L2

WARNING :DISCONNE CT POWER BE FORE SERVI CING.

208/230 VAC 1Ø

USE COPPE R CONDUCT ORS ONLY

L1

Page 12

WARNING

PHB60 / PHD48C02**

L1

GND

208/230 VAC 1Ø

FIELD CONNECTION

GND

VT-7

LINE

TRANSFORMER

COM

MOVE RD6 WIRE FR OM TRA NSFORME R

FOR PROPER OPERATION ON 208 VOLT THE

FOLLOWING CHANGE MUST BE MADE:

208 VOLT INSTALLATION

L2

°C MIN

ONLY-

75

CONDUCTORS

USE COPPER

RD

31

1Ø WIRING

COMPRESSOR

62

VT

20

L2

L1T1

T2

CONTACTOR (CC)

RD-27

YL/BK

VT-20

GY-8 VT

RD-10

RD-6

GY-9

VT-14

208

230

LOAD

GY-9

VT-14

RD-31

INDUCTOR (OPTIONAL)

230 TERMINA L TO 208 TERM INAL.

24

BK

(DT)

DEFROST

THERMOST AT

8

GY

RD

33

BLOWER

BK

19

BK

BK

13

CUT TO

ENABLE

DEHUMID IFY

A

BCD

HEAT

A

BCD

COOL

( )+(-)

NORM

ADJUST

INTERFACE

20

(RS)

SOLENOID

REVERSING

TEST

A

CS

R

RD

10

VT

SWIT CH (L PS)

LOW PRESSURE

YL/BK

YL-27

YL-27

2

1

2

YL

12

FAN H ERM

COM

RD-27

CAPACITOR

BR-11

62

BR-21

BR-21

RD-13

RD-13

OR-49

OR-49

Y2

Y/

G

C

C

R3

R2

O

EM/W

W1

BK-27

FAN

O.D.

VT

16

C

C

Y

Y

O

O

O

O

W

W

2

2

R

R

R

R

D

D

F

F

T

T

DF1

DF1

G

G

W

W

O

O

Y

Y

R

R

C

C

MOTOR

E

E

T

T

T

T

S

S

0

0

3

3

1

0

0

6

6

0

0

9

9

BOARD

BOARD

DEFROST

DEFROST

DF2

DF2

A

20424101 REV. 3

BU-34

BU-34

BR BROWN

COLOR CODE

YL YELLOW

906030

DETAIL 2

WH WHITE

GY GRAY

BU BLUE

RD RED

LOW VOLTA GE

LOW VOLTAGE FIELD

HI VOLTAGE

HI VOLTAGE FIELD

OR ORANGE

VT VIOLET

GN GREEN

BK BLAC K

TEST

TEST

ALTERNATE

T

0

0

0

A

CONFIGURATION

S

E

T

3

DETAIL 1

6

9

B

C

D

(HEAT)

CFM

1650

B

1850

C

2000

D

1450

A

(COOL)

CFM

1350

1550

1750

1950

A

B

C

D

RD-31

AIR

(ACB)

BLOWER

CIRCULATION

D

E

E

C

H

N

U

U

A

T

M

B

T

I

D

L

O

E

I

F

Y

N

T

(

(

-

O

E

)

)

+

A

S

R

D

T

M

J

U

S

T

D

C

B

A

C

O

O

L

D

C

B

A

H

E

A

T

BLOW ER

INTERF ACE

T

I

K

T

R

E

Y

C

RWO

G

E

AIR

(ACB)

BLOWER

TO PREVENT PROPERTY DAMAGE, PERSONAL INJURY OR DEATH, DISCONNECT ELECTRICAL POWER TO THIS FURNACE BEFORE

SERVICING OR PERFORMING MAINTENANCE.

CIRCULATION

INDUCTOR (OPTIONAL)

SEE DETAIL 2

PIN 7

PIN 8

PIN 9

2

Y

Y

/

G

C

2

C

1

R

3

R

2

O

W

2

/

E

M

W

1

A

E

T

H

O

KIT

W1

W2

DFT

HEATER

DF1

DF2

GY-70

OR-49

YL-27

BU-34

RD-13

BR-21

TO

PIN 1

PIN 2

PIN 3

PIN 4

PIN 5

PIN 6

R

C

TERMINAL B OARD

DT

RRW2 O O Y

BOARD

DEFROST

12

4

7

321

6598

KIT

HEATER

O

W

Y

RS

C

T

90

60

30

VIEW A-A

G

LPS

CC

S

E

T

GN

RD

BK

ALTERNATE UNIT POWER REFRIGERANT

HEATER ACCESSORIES. SEE HEATER

LEADS MAY BE USED WITH ELECTRIC

COMMON

24V

230/208

OD

ADJUST

(+)

(-)

L2

RELAY

521START

208/230 VAC 1Ø

CAP

START

CC

T1

L1

TEST

WARNING :DISCONNE CT POWER BE FORE SERVI CING.

USE COPPE R CONDUCT ORS ONLY

ACCESSORY INSTALLATION INSTRUCTIONS.

FAN

COM

CAP

FAN

NORM

T2

C

COMP

S

R

CAP

HERM

Page 13

PHD[24-36]C02**

L2

L1

GND

WARNING

ONLY-

208/230 VAC 1Ø

208/230 VAC 1

FIELD CONNECTION

L2

T2

CONTACTOR (CC)

T1 L 1

GND

USE COPPER

75°C MIN

CONDUCTORS

31

RD

VT

62

RD-27

YL\BK

VT-20

RD-10

GY-8

VT-62

VT-7

R

1Ø WIRING

COMPRESSOR

VT

20

BU

SC

YL

12

10

RD

RD

31

HEAT

23

RELAY

ELECTRIC

1

2

5

3

RD-31

4

RD-22

RD-6

NCNO

RELAY

SWITCH

GY-9

VT-14

208

LINE

TRANSFORMER

COM

230

LOAD

GY-9

BU-23

RD-24

RD-33

RD-11

VT-14(COMMON)

RD-24(COOL)

BU-23(HEAT)

COOLING

COM

G

C

XFMR-C

R

XFMR-R

VT-18

BK-26

OR-28

WH-7

BR-21

YL-27

C

Y

O

O

W

2

R

R

D

F

T

RD-13

OR-49

G

W

O

Y

LOW

LOW

MED HI

HI

COMMON

MED LOW

2

3

1

4

5

6

AIR

(ACB)

BLOWER

CIRCULATION

BR

BR

(CAP)

MOVE RD6 WI RE FROM TRANS FORMER

230 TERMINAL TO 208 TERMINAL.

FOR PROPER OPERATION ON 208 VOLT THE

FOLLOWING CHANGE MUST BE MADE:

208 VOLT INSTALLATION

YL\BK

SWITCH

PRESSURE

BK-24

BK-13

BK-19

BK-20

(DT)

DEFROST

THERMOSTAT

(RS)

SOLENOID

REVERSING

R

C

A

VT-18

YL-27

OR-49

BK-26

BR-21

RD-13

PIN 9

PIN 8

PIN 7

PIN 6

PIN 5

PIN 4

PIN 3

HERMFAN

RD-27

CAPACITOR

COM

WH WHITE

GY GRAY

BR BROWN

BU BLUE

RD RED

COLOR CODE

LOW VOLTA GE

LOW VOLTAGE FIELD

HI VOLTAGE

HI VOLTAGE FIELD

BR-11

BK-27

FAN

O.D.

VT

5

G

5

-

Y

T

0

0

0

DF1

DF2

MOTOR

16

S

E

T

3

1

6

9

BOARD

DEFROST

A

4

7

GY-70

BU-34

TO

PIN 2

PIN 1

123

89

5

6

KIT

HEATER

BU-34

VIEW A-A

YL YELLOW

OR ORANGE

VT VIOLET

GN GREEN

22304001 REV. 1

90

BK BLAC K

TEST

TEST

30

60

ALTERNATE

CONFIGURATION

T

S

E

T

0

3

0

6

0

9

DETAIL 1

HIGH

HIGH

HIGH HI GH

MED

MED

MED

HIGH

HIGH

HIGH

MED

MED

MED

HIGH

HIGH

HIGH

MED HIGH HIGH

MED

MED

ELECTRIC HEAT BLOWER TAP

ACCESSORY INSTALLATION INSTRUCTIONS.

ALTERNATE UNIT POWER REFRIGERANT

HEATER ACCESSORIES. SEE HEATER

LEADS MAY BE USED WITH ELECTRIC

GN

BK

RD

MED

PHCB05C1 PHCB10C1 PHCB15C1 PHCB20C1

MED

DOWN HORIZ DOWN HORIZ DOWN HORIZ DOWN HORIZ

BLOWER

COOLING

SPEED TAP

MODEL

NUMBER

LOW

MED

LOW

LOW

MED

LOW LOW

MED

LOW

MED

LOW

MED

LOW

LOW

MED-LOW

MED-HIGH

PHD36C02**

PHD24C02**

PHD30C02**

230/208

HEATER

ELECTRIC

SEQ

NO#1

ELECTR IC

ELECTRIC

HEAT

RELAY

WO Y

R

GEC

W1

W2

KIT

HEATER

SEQ

NO#1

TO PREVENT PROPERTY DAMAGE, PERSONAL INJURY OR DEATH, DISCONNECT ELECTRICAL POWER TO THIS FURNACE BEFORE

SERVICING OR PERFORMING MAINTENANCE.

HEAT RELAY

TO HEAT ER KIT

DFT

DF1

DF2

R

Y

C

TERMINAL B OARD

DT

RRW2 O O Y

BOARD

DEFROST

13

O

906030

G

RELAY

SWITCH

W

COOLING

XFMR R

R

XFMR C

C

G

COMMON

24V

230/208

LPS

CC

RS

C

T

S

E

T

CAP

ACB

HI

LO

MD HI

MD LO

TAP

HEAT

2

4

5

HEAT

RELAY

ELECTRIC

TAP

OD

COOLING

NO

NC

COM

RELAY

SWITCH

COOLING

FAN

FAN

CAP

T2

C

COMP

R

S

CAP

COM

START

HERM

RELAY

521START

CAP

CC

T1

L2

WARNING :DISCONNE CT POWER BE FORE SERVI CING.

208/230 VAC 1Ø

USE COPPE R CONDUCT ORS ONLY

L1

Page 14

WARNING

PHD42C02**

L1

GND

Ø

208/230 VAC 1

FIELD CONNECTION

GND

VT-7

TRANSFORMER

COM

MOVE RD6 WIRE FROM TRANSFORMER

FOR PROPER OPERATION ON 208 VOLT THE

FOLLOWING CHANGE MUST BE MADE:

208 VOLT INSTALLATION

L2

ONLY-

75°C MIN

USE COPPER

CONDUCTORS

VT

L2

L1

CONTACTOR (CC)

T2

T1

GY-8

RD

31

62

RD-27

YL/BK

VT-20

RD-10

Ø WIRI NG

1

COMPRESSOR

VT

20

RD-6

GY-9

VT-14

208

LINE

230

LOAD

GY-9

VT-14

RD-31

230 TERMINAL TO 208 TERMINAL.

BK

24

BK

19

20

BK

(DT)

DEFROST

THERMOSTA T

8

GY

RD

33

CUT TO

ENABLE

DEHUMID IFY

BLOWER

INTERFACE

BK

13

(RS)

SOLENOID

REVERSING

ABC

D

HEAT

ABC

D

COOL

( )+(-)

NORM

TEST

ADJUST

A

CS

R

RD

10

VT

LOW PRESSURE

SWITC H (L PS)

YL/BK

YL-27

YL-27

2

1

2

YL

12

FAN HER M

COM

RD-27

CAPACITOR

BR-11

62

BR-21

BR-21

RD-13

RD-13

OR-49

OR-49

Y2

Y/

G

C

C

R3

R2

O

EM/W

W1

BK-27

FAN

O.D.

VT

16

C

C

Y

Y

O

O

O

O

W

W

2

2

R

R

R

R

D

D

F

F

T

T

DF1

DF1

G

G

W

W

O

O

Y

Y

R

R

C

C

MOTOR

T

T

S

S

E

E

T

T

0

0

3

3

0

0

6

6

1

0

0

9

9

BOARD

BOARD

DEFROST

DEFROST

DF2

DF2

A

WH WHITE

GY GRAY

BR BROWN

BU BLUE

RD RED

COLOR CODE

20473501 REV. 0

VT VIOL ET

YL YELLOW

OR ORANGE

GN GREEN

30

30

90

90

60

60

S

T

0

3

0

6

0

BU-34

BU-34

9

HI VOLT AGE

HI VOLT AGE FIELD

LOW VOLT AGE

LOW VOLT AGE FIELD

BK BLACK

TEST

TEST

TEST

TEST

ALTERNATE

CONFIGURATION

E

T

DETAIL 1

A

B

C

D

(HEAT)

CFM

900

1100

1200

1300

A

B

C

D

(COOL)

DETAIL 2

CFM

800

1000

1200

1400

A

B

C

D

AIR

(ACB)

BLOWER

CIRCULATION

D

E

E

C

H

N

U

U

A

M

T

B

T

I

D

L

O

E

I

F

Y

N

T

(

(

O

E

)

)

A

+

R

S

D

T

M

J

U

S

T

D

C

B

A

C

O

O

L

D

C

B

A

H

E

A

T

BLOWER

INTERFA CE

T

I

K

T

R

E

WOY

GEC

R

AIR

(ACB)

BLOWER

TO PREVENT PROPERTY DAMAGE, PERSONAL INJURY OR DEATH, DISCONNECT ELECTRICAL POWER TO THIS FURNACE BEFORE

SERVICING OR PERFORMING MAINTENANCE.

CIRCULATION

SEE DETAIL 2

PIN 7

PIN 8

PIN 9

Y/Y2

G

2

C

1

C

R3

R2

O

EM/W2

W1

A

E

T

H

O

KIT

W1

W2

DFT

HEATER

DF1

DF2

GY-70

OR-49

YL-27

BU-34

RD-13

BR-21

TO

PIN 1

PIN 2

PIN 3

PIN 4

PIN 5

PIN 6

R

C

TERMINAL BOA RD

DT

RRW2 O O Y

BOARD

DEFROST

14

4

65987

321

KIT

HEATER

O

W

Y

RS

C

T

90

60

30

VIEW A-A

G

LPS

CC

S

E

T

GN

RD

BK

ALTERNATE UNIT POWER REFRIGERANT

LEADS M AY BE USED WITH ELEC TRIC

HEATER ACCESSORIES. SEE HEATER

COMMON

24V

230/208

OD

ADJUST

(+)

(-)

L2

RELAY

521START

CAP

START

CC

T1

L1

TEST

208/230 VAC 1Ø

WARNING:DISCONNECT POWER BEFORE SERVICING.

USE COPPE R CONDUCTOR S ONLY

ACCESSORY INSTALLATION INSTRUCTIONS.

FAN

COM

CAP

FAN

NORM

T2

C

COMP

R

S

CAP

HERM

Page 15

WARNING

PHD60C02**

L1

GND

208/230 VAC 1Ø

FIELD CONNECTION

GND

VT-7

LINE

TRANSFORMER

COM

VT-14

MOVE RD6 WI RE FROM TRA NSFORME R

THE FOLLOWING CHANGE MUST BE MADE:

FOR PROPER OPERATION ON 208 VOLT

208 VOLT INSTALLATION

L2

°C MIN

ONLY-

75

USE COPPER

CONDUCTORS

RD

VT

62

L2

L1T1

T2

CONTACTOR (CC)

BU

YL/BK

31

RD-27

YL-10

VT-20

RD-10

1Ø WIRING

COMPRESSOR

VT

20

YL-29

2ND

STAGE

DEFR

RELAY

3

RD-6

208

230

LOAD

SWIT CH (L PS)

LOW PRESSURE

BK-

40

DISCH

T'STAT

BK-

40

GY-9

GY-9

VT-14

RD-31

INDUCTOR (OPTIONAL)

230 TERMINAL TO 208 TERMINAL.

5

4

2

1

BU

BK

COMPR SOLENOID (CS)

(DT)

DEFROST

THERMOST AT

8

GY

RD

33

BR-21

24

BK

19

BK

BK

13

20

(RS)

SOLENOID

REVERSING

YL-37

CUT TO

ENABLE

DEHUMID IFY

A

BCD

HEAT

A

BCD

COOL

( )+(-)

TEST

NORM

ADJUST

BLOWER

INTERFACE

CS

R

RD

10

VT

2ND

STAGE

COOL

RELAY

YL-10

YL-29

YL-29

YL

12

FAN H ERM

COM

RD-27

CAPACITOR

BR-11

62

123

5

OR-49

4

YL-47

YL-27

BR-21

BR-21

RD-13

RD-13

OR-49

OR-49

BK-27

FAN

O.D.

VT

16

BU-34

C

C

Y

Y

O

O

O

O

W

W

2

2

R

R

R

R

D

D

F

F

T

T

DF1

DF1

MOTOR

S

S

E

E

T

T

T

T

0

0

3

3

1

0

0

6

6

0

0

9

9

BOARD

BOARD

DEFROST

DEFROST

DF2

DF2

Y1

G

G

W

GY-10

YL

27

Y2

Y/

G

C

2

C

1

R3

R2

O

2

EM/W

W1

W

O

O

Y2

R

R

C

C

Y1

20484301 REV. 3

BU-34

BU-34

BR BROWN

COLOR CODE

YL YELLOW

906030

DETAIL 2

WH WHITE

GY GRAY

BU BLUE

RD RED

LOW VOLTA GE

LOW VOLTAGE FIELD

HI VOLTAGE

HI VOLTAGE FIELD

OR ORANGE

VT VIOLET

GN GREEN

BK BLAC K

TEST

TEST

ALTERNATE

T

0

0

0

A

CONFIGURATION

S

E

T

3

DETAIL 1

6

9

B

C

D

(HEAT)

CFM

1650

B

1850

C

2000

D

1450

A

(COOL)

CFM

1350

1550

1750

1950

A

B

C

D

A

RD-31

AIR

(ACB)

BLOWER

CIRCULATION

D

E

E

C

H

N

U

U

A

T

M

B

T

I

D

L

O

E

I

F

Y

N

T

(

(

-

O

E

)

)

+

A

S

R

D

T

M

J

U

S

T

D

C

B

A

C

O

O

L

D

C

B

A

H

E

A

T

BLOW ER

INTERF ACE

Y

RWO

AIR

(ACB)

TO PREVENT PROPERTY DAMAGE, PERSONAL INJURY OR DEATH, DISCONNECT ELECTRICAL POWER TO THIS FURNACE BEFORE

SERVICING OR PERFORMING MAINTENANCE.

BLOWER

CIRCULATION

2

T

I

K

T

R

A

E

E

H

O

W1

W2

C

G

E

INDUCTOR (OPTIONAL)

YL-20

SEE DETAIL 2

Y

Y

/

2

G

C

2

C

1

R

3

R

2

O

W

/

E

M

W

1

PIN 7

PIN 8

PIN 9

Y1

T

KIT

DFT

HEATER

DF1

DF2

A

GY-70

OR-49

YL-29

BU-34

RD-13

BR-21

TO

PIN 1

PIN 2

PIN 3

PIN 4

PIN 5

PIN 6

R

C

TERMINAL B OARD

DT

RRW2 O O Y

BOARD

DEFROST

15

4

7

321

6598

KIT

HEATER

O

W

Y2

RS

C

T

90

60

30

VIEW A-A

G

Y1

DT

CC

LPS

COOL RELAY

2ND STAGE

S

E

T

GN

RD

BK

ALTERNATE UNIT POWER REFRIGERANT

HEATER ACCESSORIES. SEE HEATER

LEADS MAY BE USED WITH ELECTRIC

2ND STAGE

DEFROST RELAY

24V

CS

2ND

STAGE

DEFR

RELAY

OD

230/208

ADJUST

(+)

(-)

L2

RELAY

521START

208/230 VAC 1Ø

CAP

START

CC

T1

L1

COOL

STAGE

RELAY

TEST

WARNING :DISCONNE CT POWER BE FORE SERVI CING.

USE COPPE R CONDUCT ORS ONLY

ACCESSORY INSTALLATION INSTRUCTIONS.

FAN

COM

CAP

FAN

NORM

T2

C

COMP

S

R

CAP

HERM

2ND

Page 16

PHB[24-36]CC2**

WARNING

GND

WH WHITE

GY GRAY

BR BROWN

BU BLUE

RD RED

T1

COLO R CODE

T2

YL YELLOW

VT VIOL ET

OR ORANGE

22304101 REV. 0

°C MIN

ONLY-

75

USE COPPER

CONDUCTORS

RD

31

VT

62

L2T2

L1

T1

CONTACTOR (CC)

GND

VT-7

RD-6

GY-9

VT-14

208

LINE

TRANSFORMER

COM

230

LOAD

GY-9

BU-23

RD-27

BU-1

VT-20

RD-10

GY-8

NC

NO

COM

G

C

XFMR-C

XFMR-R

R

RD-24

RD-33

Ø WIRING

COMPRESSOR

1

VT

20

23

BU

VT-62

RELAY

SWITCH

COOLING

VT-18

BK-26

OR-28

CS

R

RD

10

RD

1

3

YL-27

YL

12

31

HEAT

RELAY

ELECTRIC

2

5

RD-22

BR-21

RD-13

RD-31

4

C

Y

O

O

W

2

R

R

D

F

T

OR-49

FAN HER M

COM

BR-11

BK-27

VT

16

5

G

5

-

Y

T

S

E

T

0

3

0

6

0

9

DF1

DF2

RD-27

CAPACITOR

FAN

O.D.

MOTOR

1

BOARD

DEFROST

GN GREEN

906030

BU-34

HI VOLT AGE

HI VOLT AGE FIELD

LOW VOLTAGE

LOW VOLTAGE FIELD

BK BLACK

TEST

TEST

ALTE RNATE

CONFIGURATION

T

S

E

T

0

3

0

6

0

9

DETAIL 1

RD-11

VT-14(COMM ON)

RD-24(COOL)

BU-23(HEAT)

MED HI

LOW

HI

COMMON

MED LOW

3

2

4

1

5

6

AIR

(ACB)

BLOWER

CIRCULATION

BR

BR

(CAP)

CAPACITOR

MOVE RD6 WIRE FROM TRANSFORMER

230 TERMINA L TO 208 TERMINAL .

FOR PROPER OPERATION ON 208 VOLT THE

FOLLOWING CHANGE MUST BE MADE:

208 VOLT INSTALLATION

TO PREVENT PROPERTY DAMAGE, PERSONAL INJURY OR DEATH, DISCONNECT ELECTRICAL POWER TO THIS FURNACE BEFORE

SERVICING OR PERFORMING MAINTENANCE.

WH-7

BK-24

(DT)

DEFROST

THERMOST AT

BK-13

16

G

BU-1

W

O

Y

R

C

A

BK-19

BK-20

(RS)

SOLEN OID

REVERSING

OR-49

YL-27

VT-18

BR-21

BK-26

PIN 4

PIN 5

PIN 6

PIN 7

PIN 8

PIN 9

A

GY-70

BU-34

RD-13

TO

PIN 1

PIN 2

PIN 3

HEATER

4

65

987

321

KIT

VIEW A-A

Page 17

PHD[24-36]CC2**

GND

WH WHITE

GY GRAY

BR BROWN

BU BLUE

RD RED

T1

COLOR CODE

T2

YL YELLOW

OR ORANGE

22304201 REV. 0

90

60

ONLY-

75°C MIN

USE COPPER

CONDUCTORS

L2

L1

T2

CONTACTOR (CC)

T1

GND

31

RD

VT

62

RD-27

YL\BK

VT-20

RD-10

GY-8

VT-62

VT

COMPRESSOR

BU

1 Ø WIRING

20

RD

23

10

R

31

RD

1

3

SC

HEAT

ELECTRIC

2

4

5

YL

12

RELAY

RD-31

VT-7

RD-22

RD-6

NC

RELAY

SWITCH

COOLING

GY-9

VT-14

208

LINE

TRANSFORMER

COM

230

LOAD

GY-9

BU-23

NO

COM

G

C

XFMR-C

R

XFMR-R

VT-18

BK-26

RD-24

RD-33

OR-28

BR-21

YL-27

C

Y

O

O

W

2

R

R

D

F

T

RD-13

OR-49

HERMFAN

RD-27

CAPACITOR

COM

BR-11

BK-27

FAN

O.D.

VT

5

G

5

-

Y

T

0

0

0

MOTOR

16

S

E

T

3

6

1

9

BU-34

BOARD

DEFROST

DF1

DF2

LOW VOLTA GE

LOW VOLTAGE FIELD

HI VOLTAGE

HI VOLTAGE FIELD

VT VIOLET

GN GREEN

BK BLAC K

TEST

TEST

30

ALTERNATE

CONFIGURATION

T

S

E

T

0

3

0

6

0

9

DETAIL 1

RD-11

VT-14(COMMON)

RD-24(COOL)

BU-23(HEAT)

WH-7

G

W

O

Y

R

MED HI

LOW

HI

COMMON

MED LOW

2

3

4

1

5

6

AIR

(ACB)

BLOWER

LOW

CIRCULATION

BR

(CAP)

CAPACITOR

MOVE RD6 WI RE FROM TRANS FORMER

230 TERMINAL TO 208 TERMINAL.

FOR PROPER OPERATION ON 208 VOLT THE

FOLLOWING CHANGE MUST BE MADE:

208 VOLT INSTALLATION

PRESSURE

BR

BK-24

BK-13

YL\BK

SWITCH

A

BK-19

BK-20

(DT)

DEFROST

THERMOSTAT

(RS)

SOLENOID

REVERSING

C

A

4

VT-18

YL-27

OR-49

BK-26

PIN 9

PIN 8

PIN 7

PIN 6

GY-70

BR-21

RD-13

BU-34

TO

PIN 5

PIN 4

PIN 3

KIT

PIN 2

PIN 1

HEATER

78956123

VIEW A-A

ACCESSORY INSTALLATION INSTRUCTIONS.

ALTERNATE UNIT POWER REFRIGERANT

HEATER ACCESSORIES. SEE HEATER

LEADS MAY BE USED WITH ELECTRIC

GN

BK

RD

17

Page 18

CLEARANCES

e

WARNING

TO AVOID PROPERTY DAMAGE, PERSONAL INJURY OR DEATH

TO FIRE, CLEARANCES TO COMBUSTIBLE SURFACES LISTED

DUE

SHOWN MUST BE OBSERVED.

AS

for Servicing

Recommended

24" Clearance

(Condenser End)

36" Side

Clearance

36"

Maximum

Overhang

48" M inimu m

Overhang

Vinyl Coated

Canvas

Connections

Insulat

Return

Duct

Minimum 9" Clearance

to Combustibl es

36" Clearance for

Service Required

0" Min imu m

Clearance to

Combustibles

Insulated

Supply

Duct

18

Page 19

19

Page 20

20

2000-2004 Goodman Company, L.P.

Effective: July 2004

Loading...

Loading...