Page 1

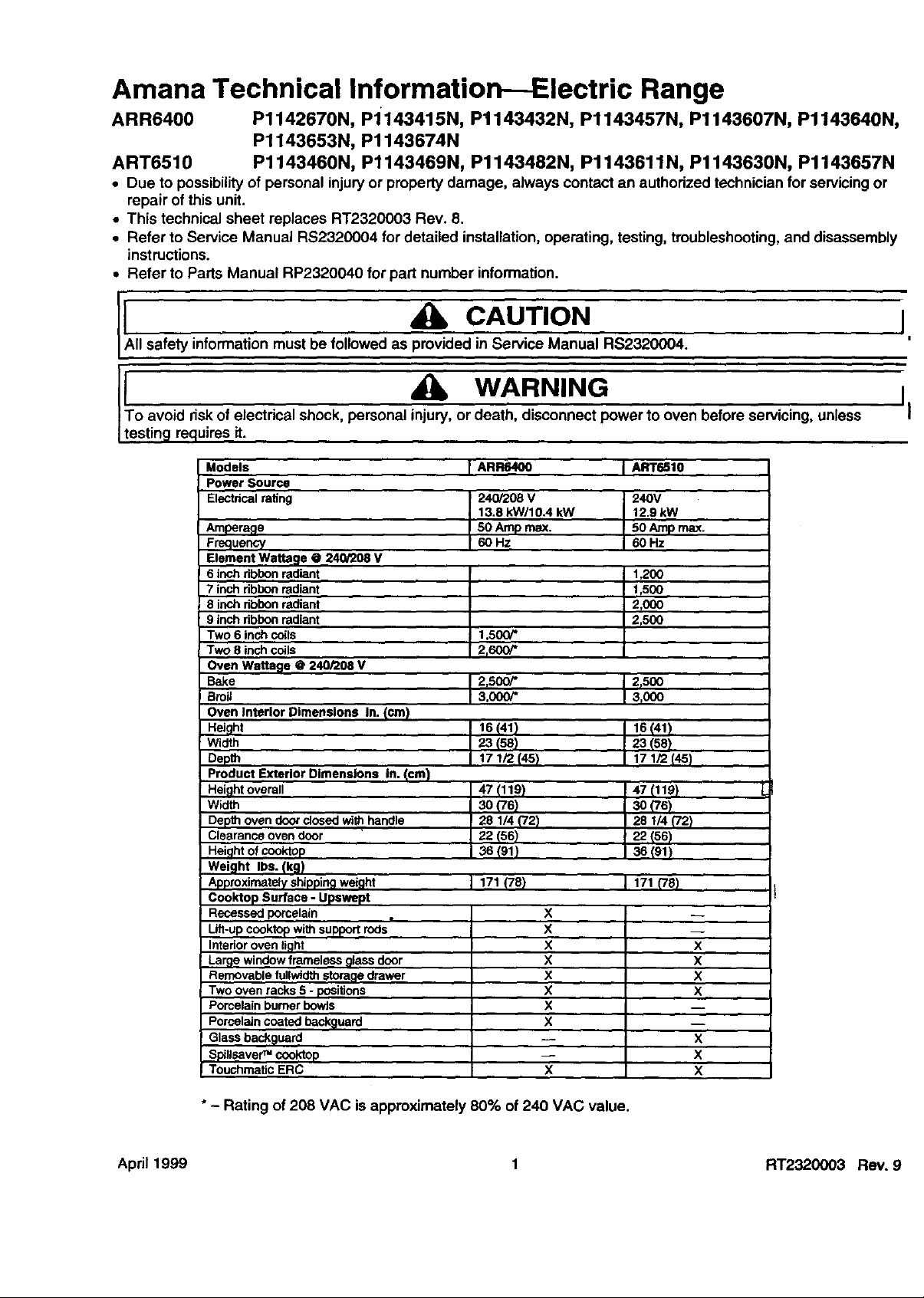

Amana Technical Information Electric Range

ARR6400 P1142670N, Pi143415N, P1143432N, P1143457N, P1143607N, P1143640N,

P1143653N, P1143674N

ART6510 P1143460N, P1143469N, P1143482N, P1143611N, P1143630N, P1143657N

• Due to possibilityof personal injuryor property damage, always contact an authorized technician for servicing or

repair of this unit.

• This technical sheet replaces RT2320003 Rev. 8.

• Refer to Service Manual RS2320004 for detailed installation, operating, testing, troubleshooting, and disassembly

instructions.

• Refer to Parts Manual RP2320040 for part number information.

CAUTION

MI safety information must be followed as provided in Service Manual RS2320004.

[ WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless

testing requires it.

Models I ARR6400 I ART6510

I Power Source

Electrical rating 240/208 V 240V

Amperage

Frequency

Element Wattage @ 240/208 v

6 inch ribbon radiant

7 inch ribbon radiant

8 inch ribbon radiant

9 inch ribbon radiant

Two 6 inch coils

Two 8 inch coils

Oven Wattage @ 240/208 V

Bake

Broil

Oven Interior ,Dimensions In. (cm)

Height

Width

Depth

Product Exterior Dimensions In. (cm)

Height overall

Width

Depth oven door dosed with handle "

Clearance oven door

Height of cooktop

Weight Ibs. (kg)

Approximately shipping wel'ght

Cook'top Surface - Upswept

Recessed porcelain

Lilt-up cooktop with support rods

Interior oven light

La_e window frameless glass door

Removable fullwidth storage drawer

Two oven racks 5 - positions

Porcelain burner bowie

Porcelain coated baek_luard

Glass back_luard

S_llsaver TM cooktop

Touchmatic ERC

13.8 kW/10.4 kW 12,9 kW

50 Amp max. 50 Amp max.

60Hz 60Hz

1,200

t r500

2_000

2,500

1,500/*

2,600/*

2t500/* 2r500

3000/* 3r000

16 (41} 16 (41)

2"3(58) 23 (58)

t7 1/2 (45) 17 1/2 (45)

47(119) 47(110)

s0_76) 30(76)

20 1/4{72) 28 1/4('/2)

22(56) 22(56)

36(91) 36(91)

171 (78) 171 _78)

X

X

x

X

x

X

X

X

X

X

X

X

X

X"

X

X

I

!

II

"- Rating of 208 VAC is approximately 80% of 240 VAC value.

April 1999 1 RT2320003 Rev. 9

Page 2

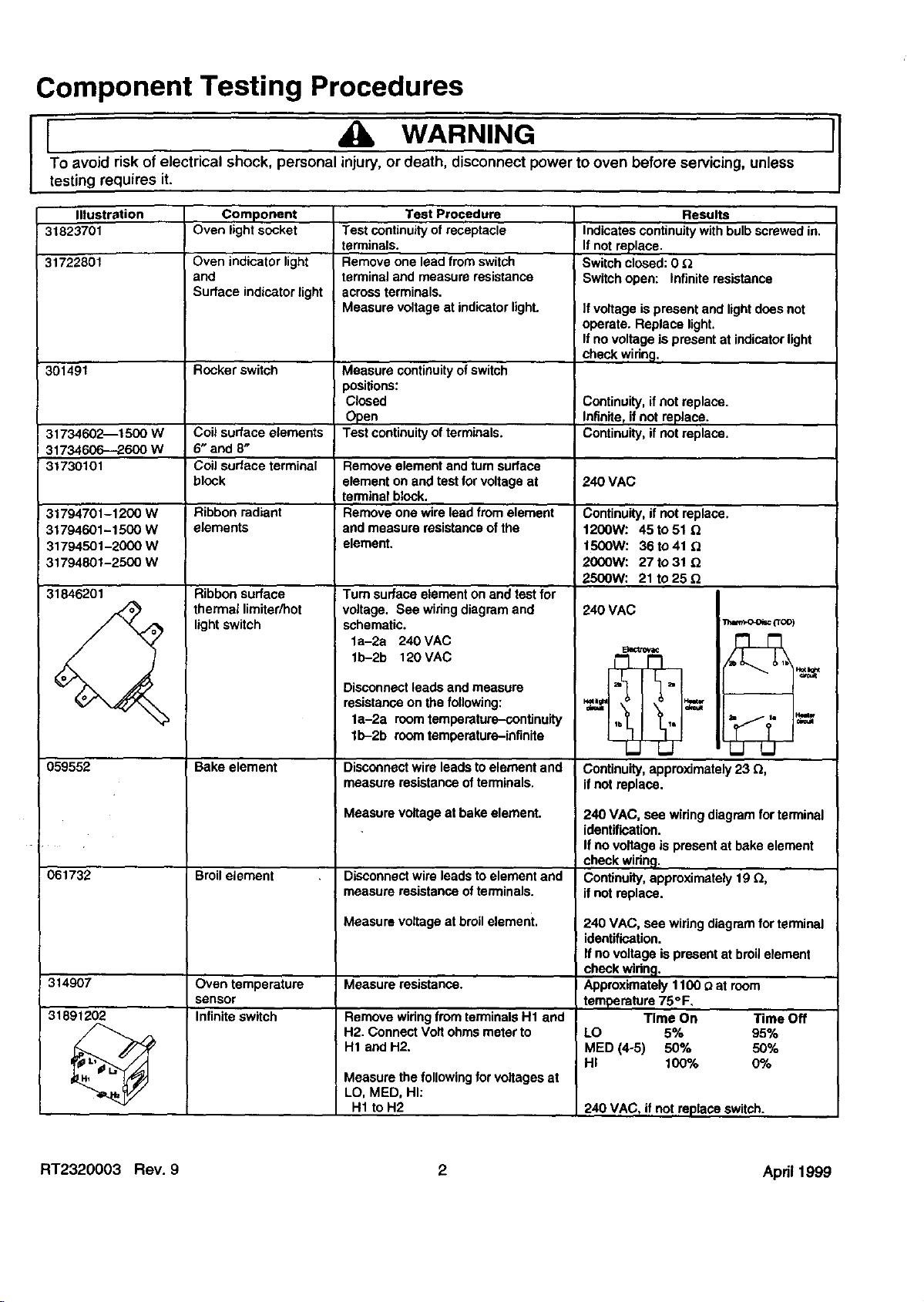

Component Testing Procedures

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless

f WARNING

testing requires it.

'1

nlustration

31823701

31722801

301491

31734606--2600 W 6" and 8"

31730101 Coilsurface terminal Remove element and turn surface

31794701-1200 W Ribbon radiant Remove one wire lead from element Continuity,if not replace.

31794601-1500 W elements and measure resistanceof the 1200W: 45 to 51

31794501-2000 W element, t50OW: 36 to 41

31794801-2500 W 200OW: 27 to 31

31846201

Component

Oven light socket

Oven indicator light

and

Surface indicator light

Rocker switch

block element on and test for voltage at 240 VAC

Ribbon surface

thermal limiter/hot

lightswitch

Test continuityof receptacle

terminals.

Remove one lead from switch

terminal and measure resistance

acrossterminals.

Measure voltage at indicatorlight.

Measure continuityofswitch

positions:

Closed

Open

Test continuityofterminals.

terminal block.

Tum surface element on and test for

voltage. See wiring diagram and

schematic.

la-2a 240 VAC

lb-2b 120 VAC

Test Procedure

Results

Indicates continuitywith bulbscrewed in.

If not replace.

Switchclosed: 0

Switchopen: Infinite resistance

]f voltage is present and lightdoes not

operate. Replace light.

If no voltage is present at indicatorlight

checkwidng.

Continuity, if not replace.

Intinife,if notreplace.

Continuity, if notreplace.31734602--1500 W Coil surface elements

2500W: 21 to 25

240 VAC

Etectmv_

059552

061732

314907

31891202

I Bake element

Broil element

Oven temperature

sensor

Infinite switch

Disconnect leads and measure

resistanceon the following:

la-2a roomtemperature-continuity

lb-2b room temperature-infinite

Disconnectwire leads to element and

measure resistance of terminals.

Measure voltage at bake element.

Disconnectwire leads to element and

measure resistance of terminals.

Measure voltage at broilelement.

Measure resistance.

Remove wiring fromterminalsH1 and

H2. Connect Volt ohms meter to

H1 and H2.

Measure the followingfor voltages at

LO, MED, HI:

H1 to H2

Continuity,approximately 23 Q,

ifnot replace.

240 VAC, see wiring diagram forterminal

identification.

Ifno voltage is presentat bake element

check widng.

Continuity, approximately 19 £_,

if not replace.

240 VAC, see wiringdiagram for terminal

identification.

If novoltage is present at broilelement

checkwidng.

Approximately1100 _ at room

temperature 75°F.

Time On Time Off

LO 5% 95%

MED (4-5) 50% 50%

HI 100% 0%

240 VAC, if notreplace switch.

RT2320003 Rev. 9 2 Apd11999

Page 3

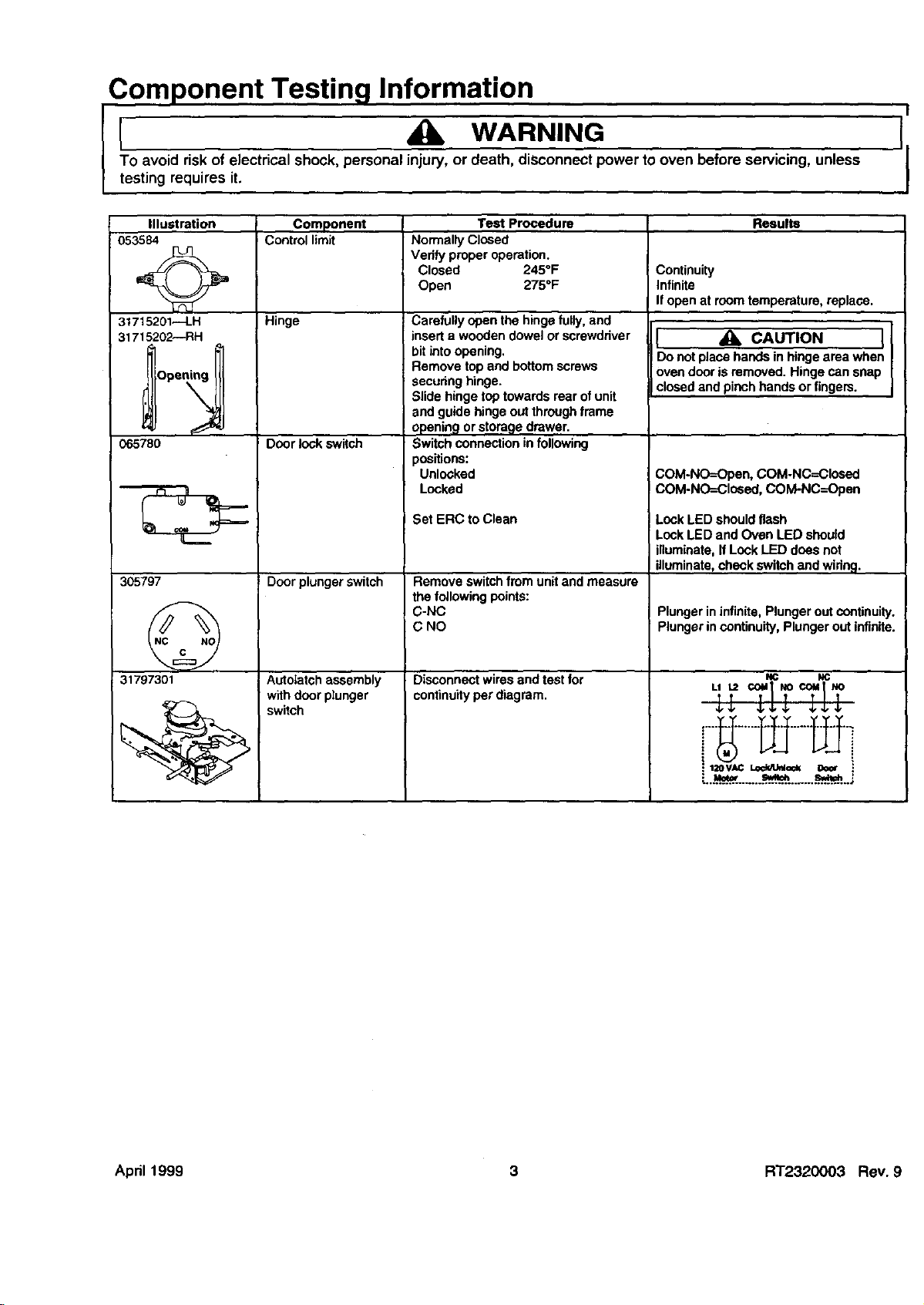

Component Testing Information

To avoid risk of electrical shock, personal injury, or death, diSconnect power to oven before servicing, unless

I I WARNING

testing requires iL

I

Illustration

053584

31715201--LH

31715202--RH

065780

305797

Component Test Procedure Results

Control limit Normally Closed

Verify proper operation.

Closed 245°F Continuity

Open 275°F Infinite

If open at roomtemperature, replace.

Hinge

Door lock switch

Door plungerswitch

Carefully open the hinge fully, and

insert a wooden dowelor screwdriver

bitinto opening.

Remove top and bottom screws

: securing hinge.

Slide hinge top towards rear of unit

and guide hinge out throughframe

opening or storage drawer.

Switch connectionin following

positions:

Unlooked

Looked

;et ERC to Clean

Remove switchfrom unit and measure

the following points:

C-NC

C NO

I 4_ CAUTION II

Do notplace hands in hinge area when

Ovendooris removed. Hinge can snap

closed and pinch hands or fingers.

COM-NO=Open, COM-NC=Closed

COM-NO=Clceed, COM-NC--Open

Lock LED should flash

LookLED and Oven LED should

illuminate,If LockLED does not

illuminate,check switch and widng.

Plunger ininfinite, Plunger out continuity.

Plunger incontinuity, Plunger out infinite.

I

31797301

Autotatch assembly

withdoor plunger

switch

Disconnect wires and test for

continuityperdiagram

NC NC

__, ,_

,:....a_H.__.....___.o_ _.. ;

April 1999 3 RT2320003 Rev 9

Page 4

Component Testing Procedures

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless

I L WARNING

testing requires it.

IllustraUon

ERC3 Controlled

ERC3 Controlled

ERC3 Controlled

ERC3 Controlled

Component

ERC3 - Touchmatic

electronic range

control

Oven temperature

adjustment

Twelve hour off

Child lock out

Drive requirements

Based on a 60

second cycle.

F1---Shorted pad button.

F2---Oven cavity over temperature.

F3---Open circuitinoven temperature

sensor circuit.

F4_Shorted circuitin oven

temperature circuit.

F5--Defective watchdogcircuitin

contmL

F"/-_Failure of door lockswitchsensing

with door looked.

Fg--Failure of door lockswitching

sensingwith door unlocked.

DOOR--Look status is not sensed

within 20 seconds of energizing door

lookrelay.

Push BAKE pad.

Push SLEWpad until an oven

temperature greaterthan 500°F

displays.

I Immediately pushand hold BAKEpad

until"00" displays,approximately 5

seconds.

To decrease oventeroperatara (for a

cooler oven), Push SLEWpad until

negative numbersappear, Oven can be

adjustedfrom -05° to -35° ower. To

avoid over adjustingoven move

temperature -5° each time.

To increase oventemperature (for a

warmer oven), Push SLEWped until

positive numbersappear. Oven can be

adjusted from 5" to 35 ° higher. To avoid

over adjusting oven move temperature

5° each time.

Push OVEN CANCEL button.

Temperature adjustment willbe

retained even througha powerfailure.

Controlwillautomaticallycancel any

cookingoperationand remove all relay

ddves 12 hoursafter the last pad touch.

Controlinputfeatures willbe disabled

and display will indicate"OFF", when

BAKE and CLOCK are pushed

simultaneouslyand held for 5 seconds.

Controlwill returnto normal operat on

by repeatingthe procedure.

Bake

Broil

Clean

Stage 1

Stage 2

Lock light

Test Procedure

Results

Verify actuator operation.

Check sensorwidng, sensor, and

temperature limiter,

Check sensor resistanceand wiring.

Check sensor resistanceand widng.

Replace ERC3.

Check latch switchand door motor.

Check latch switchand door motor.

Vedfy operationof door latchswitches.

While increasingor decreasing oven

temperature, this does not affect self-

cleaningtemperature.

100% bake 10°1,broil

0O,_,bake 100% broil HI

0% bake 93% broil 5

0% bake 87% broil 4

0% bake 80% broil 3

0% bake 73% bmil 2

0% bake 57"/,,broil 1

Time controlled15 minutes 0% bake

100% broil.

Time controlled100% bake 10o/obroil.

On at the startof the clean cycle.

Off at approximately 400°F + 25°F.

'1

RT2320003 Rev. 9 4 Apd11999

Page 5

Wiring Diagram and Schematic

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless

[ WARNING

testing requires it.

I

I[NPERATURE CO. 9BIN 9SOCKET

SENSOR PLUG CAP

Lr SI IlK

B PIN I_C

I LOCK

u J\ $ I L

WB BU \ " I I

RU 2SOCKET

CIR OR

BOON

lATCH $I

VT VT

5TERNCONNECTOR

RELAY CONNECTIONS

(BR) (LI) (BA)

YL 2SOONBAKE

16

CA

ELECTRONICRANGE

CONTROL(E.R,C.)

J4- IOIERN CONNECTOR

OVENHIGHLIMIT

UOO0t

BROtL

_L

NO

OR

SURFAC[ ELEg [BES

R.F. R,R.

K2

12 LI

IOH1 A

IFACE Vl

EOR H

BACKCUARO IUOA NEON

SUHUACEELEKENTS

L,R. L.F.

18 IB 16 I

CA

CA CA Ok C

BU YL

SWITCH

R.R.

16CA BK

MAINTOP

_6CA RD _

_H CBASS]SCNO

10 HASSIS

_GROUNO

L_F_

(,,TG,K'

! El P

SURFACE

BE

LE'T

COLOR COLOR '

REO KO ROUGE

ORANC_O_

YElLO_ Y L JAUN_

GREE_ O_ VEBI

BLUE eu BLEU_U

WOL_) VT v_OlEl

BLACK BK NOIR

Re0H_ e_

NOTES:

I ALLINT[RNALN(RESAR_ 1BGA,)SB "C XLUNLESSOIBER()S[ NOTEO

2 ALLREPLAC[MENFIVIB[S MUSE HAVE SANE BALING AS

OBIG IKAI W liE[S,

_ S[[ S[BIAIPLAI[ FORINPUIVOLFAC[_AIIAO[ RATING,

40_NOT[BOPIlONAIEOUIPMEKIANDBELAI[OIVIRING ROE

SUPPII[O ON SOME MOO[IS

5,[LEN[NT WAFIAC[SVARY BYIIOOEL. REPLKCENENIELEMENTS

NUSI HAVE sag[ NKEIAG[ AS ORIGINALELEKENIS.

U.FOR RANGL INSTALLAIION,USECOPPER glUE ONLY.

).GROUNDSIRAPN01 US[G BOB FOUR VIIR[ INSIALLAEIOKS,

]

( ,,,.r_,, L,.', -ELECIRICALSHOCKHAZARO

I /_x w AKI_III_b DISCONNECTPOWER AIMAIN

i/LJ\ FUSE ORC_RCUII BREAKER BEFORE SERVICING

J/-JI_FAILURE TO DO SO COULD RESULI INSERIOUS

INJURY OR DEATH

April 1999 5 RT2320003 Rev. 9

CLEFL [NO $ RICHI ENO $ FLUOR,

FLUOR. FLUOR. LIGHT

LIC HE LlOHT SW IICH

UALLASE

BU_WH

-RSOUE DE CHOC ELECIRQUE

DANGER _)EBRANCHERL'ALIMENIATIONELECTRIQUE.

AVANT DI"NIRETENIR CETTE UNITE.

LEIRANQUE DE RESPECI DECETTE CONSIGNE POURRAIT

AVOIRCOI,II_ERESULTAT UNF BLESSURE GRAVE OU uORIELLE

ARFI6400

Page 6

Wiring Diagram and Schematic

I _lb WARNING

To avoid risk of electrical shock, personal injury, ordeath, disconnect power to oven before servicing, unless

testing requires it.

RED

ELI) _E_ { SUREAOENEOR

2600W

SUR[AC[

!500W

(NOIE _)

2600R

1500W

_TJan

RF I

KK I

E

L_ IL2 I

tl IL2 I

FLUOR.

LIGHTS¥ _ TLUOR.LIGHT _ BALLAST

E_] YL (SURFACE) =

L_

,'0 T;o

_OVEN

LIGHT

SWITCH

$ STARTER

OVEN

:_ LIGHT

40W

SWITCH _e

BOOR

oJ2

BLACK

WHITE

(N)

;REENOrBARE

CHASS{S

GRBUNO

(FOUR W IRE

INSTALLATIONS

ONLY)

DRI

(L2)

_ GROUND

SERAR

NOT USEDFOR

tNSTALLATtORS

WH

J440

J4_

DOOR LOCK

wHMOTOR GROUNDSTRAP

RD FOUR"NIRE

J2-S

Vl BOOR LATCH

SWITCH

J2,4

G_I RANGE

CONDIIIONS

SHOWN:

"J2-5

{LEUENTSOTF

_)OOR UNLA[CHEB

II

AND CLOSEO

SCHEMATIC

CIRCUIT

WHEN LINE

BREAKNOI USED

ARR6400

35-51890601 49

RT2320003 Rev. 9 6 Apd11999

Page 7

Wiring Diagram and Schematic

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless

[ WARNING

testing requires it.

RD

[[_PE_T_E PIN g SOCKET st2 _2

_I60R DOOR CAP

SW BK OR SF? VT SF2

T

I4GA GN

)LIGHT

OULEUR

JAUNE

BLEU

NOIR

NOTES :

ALL INTERNAL W[RES ARE IBGA, 150"rC XL UNL[$S

O/HERWISE NOTED• SF2 IS SEW-2/SF2 2OO'rC.

2. ALL REPLACEktENT WIRES MUST HAVE SAME RATING AS

OR]G[NAL WIRES. MAIN /

3. SEE SERIAL PLAIE FOR INPUT VOUAGE/_/ATTACE RA]ING. TERMINAL I

• _OR (--)DENOTES OPTIONAL EQUIPMENT AND RELATED WIRING NOT BLOCK

SUPPLIED ON SOME MODELS.

5 _LEMENT WATTAGES VARY BY MODEL REPLACEMENT ELEMENTS

MUST HAVE SAME WATIAGE AS ORIGINAL ELEMENTS. _ POWER CO

6 FOR RANO_ ]NSIALLAT]ON, USE COPPER WIRE ONLY" _nIAGRAFA

7 GROUND STRAP NO1 USED FOR FOUR WIRE INSTALLATIONS

WARN I NC - ELECTRICAL SHOCK HAZARO - RISQUE DE CHOC EL_CTRIQUE

BLAN_ ,

DISCONNECT POWER AT MAIN DAN_ER- DEBRANCHER L'AL[MZNTATION ELECTRIQUE_

FUSE OR CIRCUIT BREAKER BEFORE SERVICING.

FAILURE TO DO SO COULD RESULT IN SERIOUS LE MANQUE DE RESPECT DE CETIE CONSIGNE P0URRAIF

INJURY OR DEATH AVOIR COMME RESULTAT UNE BLESSURE GRAVE 0U MORTELLE.

3R_(OVEN

(N)wH I

BK 14GA t_ !

(NOIE 7)

F--j_

(N

/

x

AVANT D'ENIRETENIR CETTE UNITE.

STRAP

GROUND

CHASSIS

RO

GND

ART6510

April 1999 7 RT2320003 Rev. 9

Page 8

Wiring Diagram and Schematic

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless

I _k WARNING II

testing requires it.

RED

(L1) (SEE NOTE 5)

RD

SURf

NEON (

RF

2500W

"LFLF

R

WH

LR

2OOOW

H1 q

LI

FLUOR. LIGHT

(SURFACE)

STARTER

_OVEN

LIGHT 40W

SENSOR ROT USED FOR

LF

120_

PLI[L2

DOOR

SWITCH

LOCK _GROUND

STRAP :

GROUND STRAP

FOUR WIRE

INSTALLATIONS

X_

_cuI1 WHEN tlNE

BR[AKNOT USED

RESISTER

J2-3 BARE

DOOR LATCH

SWITCH CHASSIS

RANGE

CONDITIONS

SHOWN:

-ELEMENTS OF,:" AND AT

ROOM TEMPERATURE

-DOOR UNLATCHED

AND CLOSED

SCHEMA1- I C

EN

GROUNO

(FOUR WIRE

INSIALLAT IONS

ONLY)

ART6510

RT2320003 Rev, 9 8 Apn11999

Loading...

Loading...