Amana P1113406S, P1113401S, P1113405S, AO27DGW, P1132514N Service Manual

...

Service

Double Gas Wall Ovens

Service Manual for

Amana

®

Models and manufacturing

numbers in this manual

AO27DG P1113401S

AO27DG P1113405S

AO27DGW P1113406S

AO27DG1/W1/DGK P1132514N

AO27D* P1132519N

AO27DG* P1132525N

PHO303UB P1132513N

PHO303UWW P1132513N

PHO303UK P1132513N

PHO103UB P1132503N

PHO203UWW P1132509N

This manual is to be used by qualified appliance

technicians only. Amana does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

RA233001

Revision 3

June 1998

Important Information

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service

technician who is familiar with the safety procedures required in the repair and who is equipped with the proper tools,

parts, testing instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE

APPROPRIATE SERVICE MANUAL BEFORE BEGINNING REPAIRS.

IMPORTANT NOTICES

IF REPAIRS ARE ATTEMPTED BY UNQUALIFIED PERSONS, DANGEROUS

WARNING

!

CONDITIONS (SUCH AS EXPOSURE TO ELECTRICAL SHOCK) MAY RESULT. THIS MAY CAUSE SERIOUS INJURY OR DEATH.

CAUTION

!

IF YOU PERFORM SERVICE ON YOUR OWN PRODUCT, YOU ASSUME RESPONSIBILITY FOR ANY

PERSONAL INJURY OR PROPERTY DAMAGE WHICH MAY RESULT.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

CONSUMER AFFAIRS DEPT. OR 1-319-622-5511

AMANA REFRIGERATION, INC. CALL and ask for

AMANA, IOWA 52204 Consumer Affairs

If outside the United States contact:

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

AMANA WILL NOT BE RESPONSIBLE FOR ANY INJURY OR PROPERTY

DAMAGE ARISING FROM IMPROPER SERVICE OR SERVICE PROCEDURES.

AMANA

ATTN: CONSUMER AFF AIRS DEPT .

AMANA, IOWA 52204, USA

Telephone: (319) 622-5511

Facsimile: (319) 622-2180

DANGER

!

WARNING

!

CAUTION

!

RA233001 Rev. 3 2

DANGER - Immediate hazards which WILL result in

severe personal injury or death.

WARNING - Hazards or unsafe practices which COULD

result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which COULD

result in minor personal injury or product or property damage.

Contents

Introduction

General Information ............................................................................................................................................... 5

Model Identification and Ordering Replacement Parts ........................................................................................... 5

Modern Maid Cooking Products Nomenclature...................................................................................................... 5

Amana Cooking Products Nomenclature .............................................................................................................. 5

Specifications and Features ................................................................................................................................... 6

Safety Precautions ................................................................................................................................................. 7

General........................................................................................................................ .................................... 7

Oven................................................................................................................................................................ 7

Safety Procedures ........................................................................................................................................... 7

Oven fires ........................................................................................................................................................ 7

Installation Instructions

Cabinet Opening .................................................................................................................................................... 8

Installation Requirement......................................................................................................................................... 8

Gas Connection ..................................................................................................................................................... 8

Pressure Testing .................................................................................................................................................... 8

Electrical Connection ............................................................................................................................................. 8

Place Oven in Opening .......................................................................................................................................... 9

Final Gas Connection............................................................................................................................................. 9

Testing for Leaks.................................................................................................................................................. 10

Adjusting the Bake Burner Flame Size................................................................................................................. 10

Broil Burner Flames ..............................................................................................................................................11

Pressure Regulator Conversion ............................................................................................................................1 1

Converting Bake Burners ..................................................................................................................................... 12

Converting Insta-Broil Burners ............................................................................................................................. 12

Oven Removal and Replacement ........................................................................................................................ 13

General Use and Oven Controls

Maintenance ........................................................................................................................................................ 14

Oven Doors ................................................................................................................................................... 14

Replacing Oven Light .................................................................................................................................... 14

Removing Oven Bottom................................................................................................................................. 14

Adjusting Oven Temperature ......................................................................................................................... 14

Clock and Timer Instructions................................................................................................................................ 15

Baking.................................................................................................................................................................. 15

Automatic Baking........................................................................................................................................... 15

Delayed Baking.............................................................................................................................................. 15

Broiling ................................................................................................................................................................. 16

Insta-Broil Cooking Area................................................................................................................................ 16

Operating the Broiler...................................................................................................................................... 16

Self-Cleaning ....................................................................................................................................................... 16

Cancel Remaining Cleaning Time.................................................................................................................. 16

Delayed Self-Cleaning ................................................................................................................................... 16

Canceling Remaining Cleaning Time............................................................................................................. 17

Test Procedures

Oven Thermostat ................................................................................................................................................. 18

Selector Switch .................................................................................................................................................... 18

Sail Switch ........................................................................................................................................................... 19

Momentary Door Latch Switch ............................................................................................................................. 19

Door Latch Solenoid............................................................................................................................................. 20

Top and Rear Latch Switches............................................................................................................................... 20

Clean Relay.......................................................................................................................................................... 21

Thermal Fan Switch ............................................................................................................................................. 21

Fan Motors........................................................................................................................................................... 22

Electronic Clock Timer ......................................................................................................................................... 22

Timer Tests – Switch Contact Operations ............................................................................................................ 22

3 RA233001 Rev . 3

Bake and Broil Ignitors ......................................................................................................................................... 24

Indicator Lights..................................................................................................................................................... 25

Oven Light Switch ................................................................................................................................................ 25

Troubleshooting Procedures

Oven Operation.................................................................................................................................................... 26

Self-Clean Operation............................................................................................................................................ 28

Oven Door............................................................................................................................................................ 29

Fan Motor............................................................................................................................................................. 30

Oven Light............................................................................................................................................................ 30

Disassembly Instructions

Control Panel Glass ............................................................................................................................................. 31

Electronic Clock ................................................................................................................................................... 31

Control Panel Mounting Bracket........................................................................................................................... 31

Oven Light Switch ................................................................................................................................................ 31

Indicator Light ...................................................................................................................................................... 31

Selector Switch .................................................................................................................................................... 31

Oven Thermostat ................................................................................................................................................. 31

Power Cord .......................................................................................................................................................... 31

Door Hinge.............................................................................................................................................................32

Compression Door Hinge .......................................................................................................................................32

Oven Door (Model A027DG) ...................................................................................................................................32

Frameless Door Disassembly ................................................................................................................................32

Broil Gas V alve ......................................................................................................................................................32

Bake Gas V alve .....................................................................................................................................................32

Gas Manifold .........................................................................................................................................................33

Control Panel Flueway ...........................................................................................................................................33

Lower Oven Flue ....................................................................................................................................................33

Upper Oven Flue ....................................................................................................................................................33

Sail Switch ............................................................................................................................................................33

Fan Motor ..............................................................................................................................................................33

Thermal Fan ..........................................................................................................................................................33

Oven Light .............................................................................................................................................................34

Oven Light Socket .................................................................................................................................................34

One Piece Oven Light Bulb/Oven Light Socket ......................................................................................................34

Pressure Regulator ................................................................................................................................................34

Shut-Off V alve ........................................................................................................................................................34

Momentary and Door Lock Switch .........................................................................................................................34

Door Lock ..............................................................................................................................................................35

Door Lock Solenoid ...............................................................................................................................................35

Lower Oven Door Lock ...........................................................................................................................................35

Lower Oven Momentary and Door Lock Switch ......................................................................................................35

Lower Oven Door Lock Solenoid ............................................................................................................................36

Broil Ignitor ............................................................................................................................................................36

Broil Burner ...........................................................................................................................................................3 6

Oven Burner Ignitor ................................................................................................................................................36

Oven Burner...........................................................................................................................................................36

Oven Liner .............................................................................................................................................................36

Wiring Diagrams and Schematics

Operation Diagrams ........................................................................................................................................ 37-40

Schematic – All Models........................................................................................................................................ 41

Wiring Diagram for AO27DG, PHO103 and PHO203 .......................................................................................... 42

Wiring Diagram for AO27DG1 and PHO303 ........................................................................................................ 43

RA233001 Rev. 3 4

Introduction

General Information

This manual provides complete instructions and suggestions for handling, installing and servicing Amana

double gas wall ovens.

The directions, information and warnings in this

manual are developed from experience with, and careful testing, of the product. If the unit is installed according to the manual, it will operate properly and will require minimal servicing. A unit in proper operating order ensures the customer all the benefits provided by

clean, modern gas cooking.

This manual contains all the information needed by authorized Amana service technicians to install and ser-

Amana Cooking Products Nomenclature

AO27DG1/W1

Amana

Product Group

G - Gas Range

R - Electric Range

K - Cooktop

CO - Convection Wall

Oven

O - Wall Oven

DG1 -Downdraft

DH - Downdraft

Halogen Cartridge

DS - Gas or Elec-

G - Gas on Glass

H - Halogen

Product Type

Gas Cooktop,

1 pc Grate

Electric

Cooktop, Op-

tional

tric Downdraft

Slide-In

Range

Cooktop,

Sealed Burners

Smoothtop

Range, 1 Dual

2H - Halogen

R - Electric

S - Gas Range,

T - Radiant

2T - Radiant

vice Amana double gas wall ovens. There may be,

however, some parts which need further explanation.

Amana maintains a toll-free technical support line to

answer questions from authorized service technicians.

The number is 1-800-AMANA99.

Model Identification and

Ordering Replacement Parts

A unit’s model and manufacturing numbers are recorded

on its rating label. The rating label is located on the

upper door frame. It can be seen by opening the upper

oven door. Before ordering parts, write down the correct

model and manufacturing numbers from the rating label.

This avoids incorrect shipments and delays. Please refer

to the parts catalog when ordering replacement parts.

Color

Door

Element

Smoothtop

Cooktop, 2

Halogen Elements,1 Dual

Roughtop

Range, Calrod

Elements

Sealed Burners

Smoothtop

Range

Smoothtop

Range or

Cooktop, 1

Dual Element

Features

Range Features - Variable

Cooktop Width

• 30 = 30"

• 35 = 35"

• 300 = 30", reduced

depth (20-1/4")

Wall Oven Width/Fuel

• 24SE2 = 24" Single

Electric (2.9 cu. ft.

oven), Soft Look Trim

• 27SE = 27" Single Electric (3.3 cu. ft. oven)

• 27DG = 27" Double Gas

(Two 3.3 cu. ft. ovens)

No Designator - Ebony

K - Chrome Top

L - Almond

LG - Almond, Glass

W(1*) - Whi te

WW - White on White

E(1*) - Ebony

* Enhancements: Electric Variable Intensity

System, Gas One Piece

Grates

Product Group

D - Dishwasher

F - Electric Product

G - Refrigerator

K - Cooktop

M - Microwave Oven

P - Gas Product

X - Kit or Accessory

Modern Main Cooking Products Nomenclature

Product Type

BR - Backguard Kit

DC - Electric

Single/

Double Con

vection Wall

Oven, SelfClean

DO - Electric Com

bination

Wall Oven,

Self- Clean

DU - Electric Slide-

In Range,

Self-Clean

PHO303UK

ET - Electric

Cooktop (Coil

or

Downdraft)

GO - Gas Wall Oven,

Manual Clean

GT - Gas Cooktop

HO - Double Gas

Wall Oven,

Self- Clean

HU - Gas Slide-In

Range, Self-

Clean

KO - Gas Wall Oven,

Continuous

Clean

Series

Variable

Features

Variable

Fuel

N - Natural Gas

Only

U - Universal (Set

for natural gas)

1 - 120 Volts,

60 Hz.

2 - 240 Volts,

60 Hz.

Color

W - White

WW - White on White

WW1 - White on White/1

pc. grate

B - Black

B1 - Black/1pc grate

L - Almond

K - Chrome Top

D - Black Glass

5 RA233001 Rev . 3

Introduction

-

-

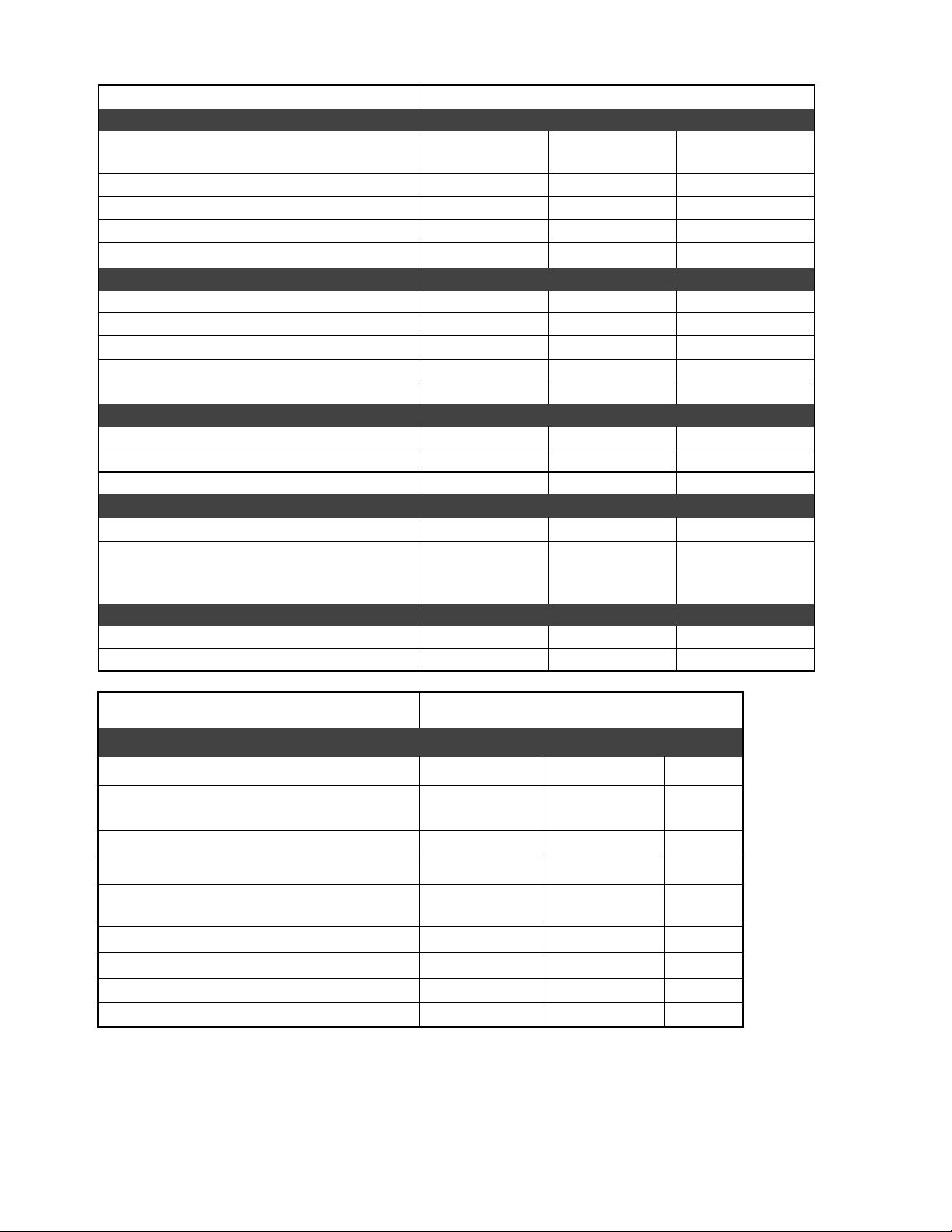

Specifications Models

AO27DG1/W1

Oven Interior Dimensions (Door Closed)

Height (cm) 16" (41) 16" (41) 16" (41)

Width (cm) 19-1/4" (49) 19-1/4" (49) 19-1/4" (49)

Depth (cm) 18-5/8" (47) 18-5/8" (47) 17" (43)

Oven Exterior Dimensions

Height (cm) 54-5/8" (139) 54-5/8" (139) 54-1/2" (138)

Width (cm) 26-5/8" (68) 26-5/8" (68) 27" (69)

Depth - oven door closed with handle (CM ) 24-3/4 (63) 24-3/4 (63) 27-1/2" (70)

Clearance - oven door (cm ) 16-1/2" (42) 16-1/2" (42) 20" (51)

Oven (BTU's - Nat./LP)

Upper and Lower Bake 15,500/14,000 15,500/14,000 15,500/14,000

Upper and Lower Broil 12,000/12,000 12,000/12,000 12,000/12,000

Electrical Requirements

120VAC, 60Hz, 3

Electrical

Wire, Single

Phase, 15 AMP

PHO303, 203 &

103

120VAC, 60Hz, 3

Wire, Single

Phase, 15 AMP

AO27DG

120VAC, 60Hz, 3Wire, Single

Phase, 15 AMP

Weight

Approxi mate Shipping (kg) 309lbs. (140) 309lbs. (140) 309lbs. (140)

Features Models

AO27DG1/W1 PHO303 A027DG

3.3 Cu. Ft. Porcelain Self-Cleaning Upper

and Lower Oven

Electronic Clock/Timer X X X

Insta-Broil Broiling System X X X

Removable Counterbal anc ed Glass Oven

Door W ith Window

Interior Oven Li ght X X X

Two Oven Racks - Each Oven X X X

Porcelai n B r oiler Pan and Grid X X X

Natural or LP Gas Operation X X X

XXX

XXX

RA233001 Rev. 3 6

Introduction

Safety Precautions

General

1. The oven must be installed and properly grounded

by a qualified installer or service technician.

2. Never use the oven for heating a room.

3. Do not store items on the oventop. Items stored on

the oventop can become hot and melt.

4. Wear proper apparel. Loose-fitting garments

should never be worn while using the oven.

5. Gasoline, or other flammable vapors or liquids and

combustible materials should not be stored near

the oven. They may ignite, causing a fire.

6. Use only dry potholders. Using damp potholders on

hot surfaces may result in steam burns. Do not let

a potholder touch an element. Do not use a towel

or a bulky cloth as a potholder.

7. Do not leave children unattended in an area where

the oven is in use.

8. Never sit, stand or lean on any part of the oven.

Oven

1. Use care when opening the oven door. Let hot air

or steam escape before removing or replacing

food.

2. Do not heat unopened food containers in the oven.

Buildup of pressure may cause a container to

burst.

3. Keep the oven vent ducts unobstructed.

4. Place oven racks in desired position while oven is

cool. If a rack must be moved while the oven is hot,

use a dry potholder.

5. Do not use aluminum foil to line the oven bottom.

Aluminum foil can cause a fire and will seriously

affect baking results.

6. Do not touch the interior surfaces of the oven during or immediately after use. Do not let clothing or

other flammable materials contact bake or broil elements. Although these surfaces may be dark in

color, they can still be hot enough to burn.

7. Other oven areas can become hot enough to cause

burns, such as vent openings, window, oven door

and oven racks.

8. Do not use oven cavities for storage space.

9. Do not drape towels or other materials on the oven

door handle. These items may contact an element

or become too hot and ignite.

10. Do not use aluminum foil to cover the broiler grid.

The foil can trap grease on top of the grid, causing

it to ignite.

11. Do not attempt to clean the gasket located on the

inside of the oven door. Cleaning the gasket may

cause damage. This gasket is required to seal the

oven.

Safety Procedures

Due to the nature of cooking, fires can occur as a result of overcooking or excessive grease. Use the following procedures to extinguish a fire in the unlikely

event one occurs:

Oven Fires

1. Do not open oven door.

2. Turn all controls to

3. As an added precaution turn off electricity at main

circuit breaker or fuse box.

4. Allow food or grease to burn itself out in oven.

WARNING

!

If smoke or fire persist, call the local fire department.

OFF

.

7 RA233001 Rev . 3

Installation Instructions

Cabinet Opening

Prepare the opening for the oven in a wall cabinet 25

inches wide by 54 inches high by 23-3/4 inches deep.

The bottom of the cabinet opening must be 12-1/2

inches above the floor.

The bottom of the opening must be level and square for

proper installation. The opening must completely enclose the unit. Any openings must be sealed before installation.

Gas Connection

The gas supply pipe should be 1/2-inch rigid pipe or an

AGA or CGA design approved flexible connector. Use a

pipe joint compound resistant to the action of propane

gas on all male threads.

The manual shut-off valve must be installed in an accessible location outside the oven. The customer should

know how and where to turn off the gas supply.

Assemble the supply line up to the union as shown in

the following illustration.

Cabinet Cutout

Installation Requirement

The oven is shipped from the factory set for use with

natural gas. It may be converted for use with LP gas.

Instructions to convert to LP use are found on

pages 11-13.

The installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1-latest edition; in Canada CAN/CGAB149.1 or -B149.2.

If the oven is installed in a mobile home, the installation

must conform with the Manufactured Home Construction and Safety Standards, Title 24CFR, Part 3280 (formerly the Federal Standard for Mobile Home Constructions and Safety, Title 24, HUD Part 280) or, when such

standard is not applicable, the Standard for Manufactured Home Installations, ANSI A225.1/NFPA 501A, or

with local codes. When installed in mobile housing in

Canada, the installation must conform with CSA Standard Z240.4-1 for gas-equipped mobile housing and with

local codes.

RA233001 Rev . 3 8

Gas Supply Connection

When using a flexible connector, the connections

should be made as shown replacing only the 1/2-inch

rigid pipe with the flexible connector.

Do not attach the supply line to the regulator until the

electrical connection has been made. The supply line

connection can only be made after the unit is placed in

the cabinet opening.

Pressure Testing

The oven and its individual shut-off valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psig (3.5 kPa).

The gas supply pressure for testing the regulator setting

must be seven inches WCP for natural gas and 11

inches WCP for LP gas. The maximum supply pressure

for the oven must not exceed 14 inches WCP.

Electrical Connection

When the appliance is installed, it must be electrically

grounded in accordance with local codes, or in the absence of local codes, with the current National Electrical Code, ANSI/NFPA 70, or in Canada, CSA Standard

Installation Instructions

C22.1, Canadian Electric Code, Part 1. In Canada, the

installation must conform with CSA standards Z240.6.1

electrical requirements for mobile homes.

The wiring diagram is located behind the control panel

taped to the side of the oven near the gas pressure regulator.

The receptacle should be checked by an authorized

electrician to make sure it is properly grounded. This

should be a 120 volt, 60hz, properly grounded, threeprong receptacle protected by a 15-amp circuit breaker

or time delay fuse.

The power supply cord on double gas wall ovens is

equipped with a three-prong (grounding) plug for protection against shock hazard. It should be plugged into a

properly grounded receptacle.

If there is any doubt as to whether the wall receptacle is

properly grounded, the customer should have it checked

by an authorized service electrician. Where a standard

two-prong wall receptacle is encountered, it is the personal responsibility and obligation of the customer to

have it replaced with a properly grounded three-prong

wall receptacle.

Before the final gas connection is made and the oven is

position, the electrical supply cord should be plugged

into the receptacle. Do not turn the power on at the main

circuit breaker until the final gas connection is made. In

the event of a power failure, the oven cannot be operated.

DANGER

!

To avoid the risk of electrical shock or fire, a threewire grounded conductor system must be used.

Relying upon the gas line for ground may result in

fire or expose persons to the risk of electric shock as

well as erratic control operation.

the cabinet. Do not pinch the power cord.

6. Locate the holes in the oven frame. Drill 1/8-inch

pilot into the cabinet front and secure the oven using

the four screws provided.

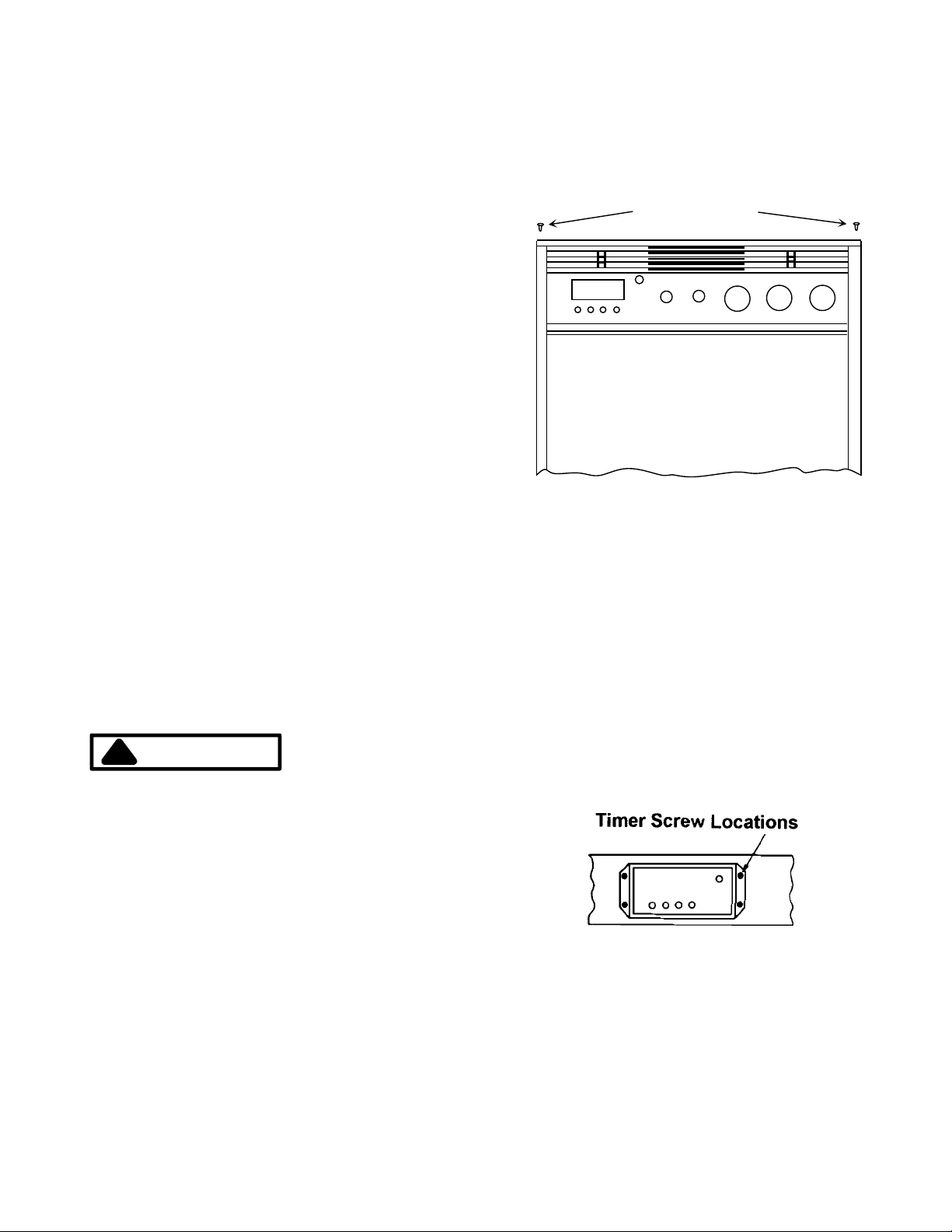

Oven Screw Locations

Screw Location

Final Gas Connection

The electrical supply should be turned off at the main

circuit breaker before attempting to make the final gas

connection.

The gas supply line assembled earlier must be connected to the pressure regulator on the oven. To gain

access to the pressure regulator, the control panel and

timer must be removed.

1. Remove knobs from the timer and control panel by

pulling them straight out.

2. Remove two screws securing control panel in place

as indicated in the illustration below.

Place Oven in Opening

Slide the oven on its cardboard shipping base to the

cabinet opening.

1. One person should lean the oven to the side.

2. A second person must remove the four screws from

the shipping base. Discard the screws and the shipping base.

3. Remove the oven doors by pulling them up and off

the oven.

4. One person should be positioned on each side of

the unit. Grasping the unit inside the lower oven and

on the bottom, lift it into the cabinet opening.

5. Plug in the power cord and push the oven back into

3. Remove four screws holding the timer in place.

4. Pull the timer forward and place it on the top oven

rack. There should not be any stress placed on the

harness connections.

5. Connect the supply line to the regulator using a

1/2-inch nipple, union and elbow. The supply line

should be accessed by reaching through the opening in the control panel area and through the upper

cabinet doors or removable panel. Use two

9 RA233001 Rev . 3

Installation Instructions

wrenches when tightening the connection. The

pressure regulator is die cast and will crack if too

much pressure is applied. Seal the connection with

an approved pipe joint compound.

WARNING

!

To avoid the risk of fire, personal injury or property

damage, do not overtighten the supply line to the

regulator. Overtightening the supply line can cause

the regulator to crack and leak gas.

Testing for Leaks

1. Turn on house gas supply.

2. Open the oven manual shut-off valve in gas supply

line.

3. Cover each gas connection with soap suds.

Bubbles indicate a leak.

4. If a leak is present, turn off the gas supply.

5. Tighten the joint or unscrew it completely and apply

additional pipe joint compound and retighten the

connection.

6. Retest each connection and repeat the above procedure until bubbles cease forming at the connections.

Outer Mantle - Dark Blue

Inner Cone - Blue-Green

Flame – Sectional View

1. Disconnect the electrical and gas supplies.

2. Remove the upper or lower oven door.

3. Remove screw under the plastic door latch knob.

Lift off the plastic knob (applies to upper oven only).

4. Remove three screws securing trim below oven

doors. Remove trim.

All factory fittings have been tested and tightened. Retest the factory fittings. If a leak is present, tighten the

fitting but do not add additional pipe joint compound.

Replace the timer and control panel by reversing steps

one through three under

nine.

WARNING

!

To avoid the risk of a fire, personal injury or property

damage, do not test for gas leaks with an open

flame. Do not apply pipe joint compound on factory

fittings.

Final Gas Connection

on page

Adjusting the Bake Burner Flame Size

The upper and lower ovens each have a bake burner.

The bake burner flame should have a glue-green inner

core and a dark blue outer mantle. The flame should be

clean and soft without yellow tips, blowing or lifting. The

flame should be 1/2-inch long (see following illustration). If the flame does not appear normal, adjust the air

shutter according to the following the directions.

Trim Removal

5. Loosen air shutter lock screw on bake burner. Close

the air shutter to decrease the amount of air to the

flame or open to increase the air amount. Retighten

lock screw.

Air Shutter

Lock Screw

RA233001 Rev . 3 10

Bake Burner

Installation Instructions

6. Reconnect electrical and gas supplies. Test flame

size and shape. If flame needs further adjustment,

repeat steps one through five.

7. When the flame is properly adjusted, verify air channel is in place, reassemble the trim and plastic door

knob latch.

Important Note: The air channel must be in place before operating the oven.

WARNING

!

To avoid the risk of electrical shock and personal

injury, do not attempt to insert anything in the

openings of the protective shield around the ignitor

coil. Do not attempt to clean this area.

Broil Burner Flames

There are two broiler burners, one in the top of each

oven. The broil burners will have a hazy or fuzzy appearance when in operation. This haze may be a maximum

of 3/8-inch thick and is normal for this type of burner.

examples.

Example One

1. Remove pressure regulator cap with a 7/8-inch

wrench.

2. Remove plastic insert from cap. Insert fits tightly in

cap.

3. Reverse plastic insert. Push firmly into hole in the

cap.

4. Verify insert fits tightly in hole. Do not disturb spring

in regulator body.

5. Replace cap in regulator body.

Important Note: The broil burner flames are not adjustable because the burners are equipped with a fixed orifice. The burners do not have air shutters.

Broil Burner Flame

Pressure Regulator Conversion

Several varieties of gas pressure regulators may equip

Amana and Modern Maid gas cooking products. All gas

pressure regulators perform the same function. In most

instances, universal pressure regulators are used in gas

cooking products. A universal regulator can be modified

to use either natural gas or liquefied petroleum (LP) gas

supplies.

Cooking products with universal pressure regulators are

set for a natural gas supply at the factory. Gas cooking

products can be connected to a natural gas supply without modifying the pressure regulator.

Example Two

1. Remove cap with screwdriver.

2. Remove insert.

3 Reverse insert and replace. “LPG10” is visible. Do

not disturb spring in regulator body.

4. Replace cap.

A universal pressure regulator, however, must be modified when connecting a gas cooking product to an LP

gas supply. How each type of universal pressure regulator is converted to LP use is illustrated in the following

Example Three

11 RA233001 Rev. 3

Installation Instructions

1. Remove cap marked “Nat.”

2. Reverse cap. “LP” now appears on cap.

3. Reinsert cap. Do not disturb spring beneath the

cap. Verify fiber washer is correctly placed between

cap the regulator body.

Important Note: Some models may not have

washers. If washer is not supplied, none is needed.

Example Four

1. Remove cap with screwdriver slot.

2. Reverse and replace cap. Verify “LPG10” is visible.

Do not disturb spring beneath cap.

Example Five

1. Remove cap with screwdriver slot.

2. Remove black insert marked “NAT” from cap. (Insert

fits tightly in cap.)

3. Reverse insert.

4. Replace in hole. Verify “LP” is visible. Verify that

insert is pressed firmly into shoulder. Do not disturb

spring in regulator body.

5. Replace cap in regulator body and tighten.

1. Remove cap with screwdriver slot.

2. Remove spring and washer. Washer will be at bottom of spring as illustrated below.

3. Reverse to bring washer to the top.

4. Reinstall spring and washer.

5. Tighten cap.

Converting Bake Burners

The bake burner is behind the horizontal trim on the

front of the unit below each oven door.

1. Remove oven doors by lifting them up and off the

unit.

2. Remove screw under the plastic door latch knob.

Lift off the plastic knob (applies to upper oven only).

3. Remove three screws securing the trim below the

oven doors. Remove the trim.

4. Locate the oven burner orifice hood. The orifice hood

is brass and protrudes into the oven burner air shutter.

5. Turn the orifice hood down onto the pin, approximately 1-1/2 to 2 turns. Do not overtighten the hood.

Overtightening may distort the hole.

6. Adjust the air shutters to a 11/16-inch opening.

7. Reassemble trim and latch knob. Check burners for

proper flame appearance.

Example Six

RA233001 Rev . 3 12

Important Note: The air channel must be in place before operating the oven.

Converting Insta-Broil Burners

The broil burner spuds must be changed from a natural

gas spud to an LP spud. Both upper and lower oven

broilers must be converted.

1. Remove screw securing broiler burner to the oven

cavity at the front of the burner.

2. Remove the burner by gently pulling to left and

down. Be careful not to damage ignitor. Spud will be

Installation Instructions

visible in the rear wall of oven.

3. Locate and remove the #59 LP gas spud wired to

the inlet pipe.

Gas Supply Connection

4. Use a 5/16-inch nut driver and remove the #52 natural gas spud from each oven. Save for future conversions. Wire the #52 natural gas spuds to the inlet

pipe.

5. Install the #59 LP spud in the orifice opening.

6. Reinstall the broiler burner using the screws removed in step 1.

The broil burner flames are not adjustable because the

burner is equipped with a fixed orifice. The burner does

not have an air shutter.

Bake burners are rated at 14,000 BTU for LP gas and

15,500 for natural gas. Broil burners are rated at 12,000

BTU for LP gas and 12,000 BTU for natural gas.

Oven Removal and Replacement

1. Turn off electrical and gas supplies.

2. Remove control panel and timer.

3. Disconnect gas connection.

4. Pull the oven forward out of the opening.

5. Unplug power cord.

6. Replace the oven using directions outlined earlier in

this section.

13 RA233001 Rev. 3

Loading...

Loading...