Page 1

120-Volt Electric

120-Volt Electric

Compact Dryer

Use and Care Guide

Para una versión de estas instrucciones en español, visite www.amana.com

Table of Contents

DRYER SAFETY ......................................................................... 2

INSTALLATION INSTRUCTIONS ............................................... 4

USING YOUR DRYER .............................................................. 10

DRYER CARE ........................................................................... 12

TROUBLESHOOTING .............................................................. 13

WARRANTY .............................................................................. 15

ASSISTANCE OR SERVICE ..................................BACK COVER

Compact Dryer

par le dessus guide

d’utilisation et

d’entretien

Table des matières

SÉCURITÉ DE LA SÉCHEUSE ................................................ 16

INSTRUCTIONS D’INSTALLATION ......................................... 18

UTILISATION DE LA SÉCHEUSE ............................................ 24

ENTRETIEN DE LA SÉCHEUSE .............................................. 26

DÉPANNAGE ............................................................................ 27

GARANTIE ................................................................................ 30

ASSISTANCE OU SERVICE ............... COUVERTURE ARRIÈRE

W10773366A

W10773375A-SP

Page 2

Dryer Safety

2

Page 3

3

Page 4

Installation Instructions

Tools and Parts

Tools needed

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listed here.

Flat-blade screwdriver Tin snips (new vent

installations)

Level Vent clamps

Parts needed

Check local codes, existing electrical supply and venting, and

see “Venting Requirements” and “Electrical Requirements” before

purchasing parts.

■ Mobile home installations require metal exhaust system

hardware.

For information on ordering, please refer to “Assistance or

Service” on the back cover. You may also contact the dealer

from whom you purchased your dryer.

Location Requirements

Adjustable wrench that opens

to 1" (25 mm) or hex-head

socket wrench

Caulking gun and compound

(for installing new exhaust vent)

Parts supplied

Remove parts package from the dryer drum. Check that all parts

listed are included.

Cycle control knob Start button

You will need

■ A location that allows for proper exhaust installation. See

“Venting Requirements.”

■ A 120-volt, 60-Hz., AC only, 15- or 20-amp circuit.

■ A grounded electrical outlet located within 2 ft (610 mm) of

either side of the dryer. See “Electrical Requirements.”

■ A sturdy floor to support the dryer weight (dryer and load)

of 115 lbs (52 kg). The combined weight of a companion

appliance should also be considered.

■ A level floor with a maximum slope of 1" (25 mm) under

entire dryer.

Do not operate your dryer at temperatures below 45ºF (7ºC). At

lower temperatures, the dryer might not shut off at the end of an

automatic cycle. Drying times can be extended.

The dryer must not be installed or stored in an area where it will

be exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes, or

sleeping quarters. Contact your local building inspector.

Casters (4) Cord brackets (2) and

screws (2)

4

Page 5

Installation Clearances

AB

(25 mm)

(305 mm)

(305 mm)

A B

C

(76 mm)

(76 mm)

The location must be large enough to allow the dryer door to

open fully.

Dryer Dimensions

Front View

3

*20

/4"

(527 mm)

31"

(787 mm)

3

/4"

3

/4"

1

(44 mm)

(606 mm)

Side View

36"

(914 mm)

237/8"

20

(527 mm)

Minimum spacing for recessed area and

closet installation

The following dimensions shown are for the minimum spacing

allowed when the dryer is to be operated with, or without, the

Stack Stand Kit. To purchase a Stack Stand Kit, see “Assistance

or Service.”

■ Additional spacing should be considered for ease of

installation and servicing.

■ Additional clearances might be required for wall, door, and

floor moldings.

■ For closet installation with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings

are acceptable.

■ Companion appliance spacing should also be considered.

Recessed or closet installation - Dryer only

14"*

(356 mm)

18"* (457 mm)

51/2"*

(140 mm)

1"

(25 mm)

1"

13/4"

(44 mm)

Back View

1

3

/2"

(89 mm)

1

/4"

29

(743 mm)

13/4"

(44 mm)

(303 mm)

”

11

A. Side view - closet or confined area

B. Recessed area

*Most installations require a minimum 5½" (140 mm) clearance

behind the dryer for the exhaust vent with elbows. See “Venting

Requirements.”

Recessed or closet installation - Stacked

12"*

12"*

(25 mm)

51/2"

(76 mm)

48 in. *

(309.7 cm )

DRYER

24 in. *

WASHER

1"

1"

(25 mm)

1"*

(25 mm)

(154.8 cm )

A. Recessed area

B. Side view - closet or confined area

C. Closet door with vents

2

3"*

2

2

2

3"*

Mobile Home - Additional Location Requirements

31/4"

(83 mm)

This dryer is suitable for mobile home installations. The

installation must conform to the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction and

Safety, Title 245, HUD Part 280) or Standard CAN/CSA-Z240 MH.

Mobile home installations require:

7

/8"

■ Metal exhaust system hardware, which is available for

purchase from your dealer.

■ Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such as a

nearby window) should be at least twice as large as the dryer

exhaust opening.

5

Page 6

Electrical Requirements

■ 120 Volt, 60 Hz, AC only, 15- or 20- amp fused electrical

supply is required.

■ A time-delay fuse or circuit breaker is recommended.

Check that the fuse or circuit breaker matches the rating

of your line.

■ It is also recommended that a separate circuit serving only

this dryer be provided.

■ Do not use an extension cord.

Venting

Venting Requirements

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

Dryer exhaust must not be connected into any gas vent, chimney,

wall, ceiling, attic, crawlspace, or a concealed space of a

building. Only rigid or flexible metal vent shall be used

for exhausting.

GROUNDING INSTRUCTIONS

■

For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualied electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not t the outlet, have a proper outlet

installed by a qualied electrician.

SAVE THESE INSTRUCTIONS

4" (102 mm) heavy metal exhaust vent

■ Only a 4" (102 mm) heavy metal exhaust vent and clamps

may be used.

■ Do not use plastic or metal foil vent.

Rigid metal vent:

■ Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

■ Must be fully extended and supported in final dryer location.

■ Remove excess to avoid sagging and kinking that may result

in reduced airflow and poor performance.

■ Do not install in enclosed walls, ceilings, or floors.

■ The total length should not exceed 7¾ ft. (2.4 m).

NOTE: If using an existing vent system, clean lint from entire

length of the system and make sure exhaust hood is not plugged

with lint. Replace plastic or metal foil vents with rigid metal

or flexible metal vents. Review “Vent System Chart” and, if

necessary, modify existing vent system to achieve best drying

performance.

6

Page 7

C

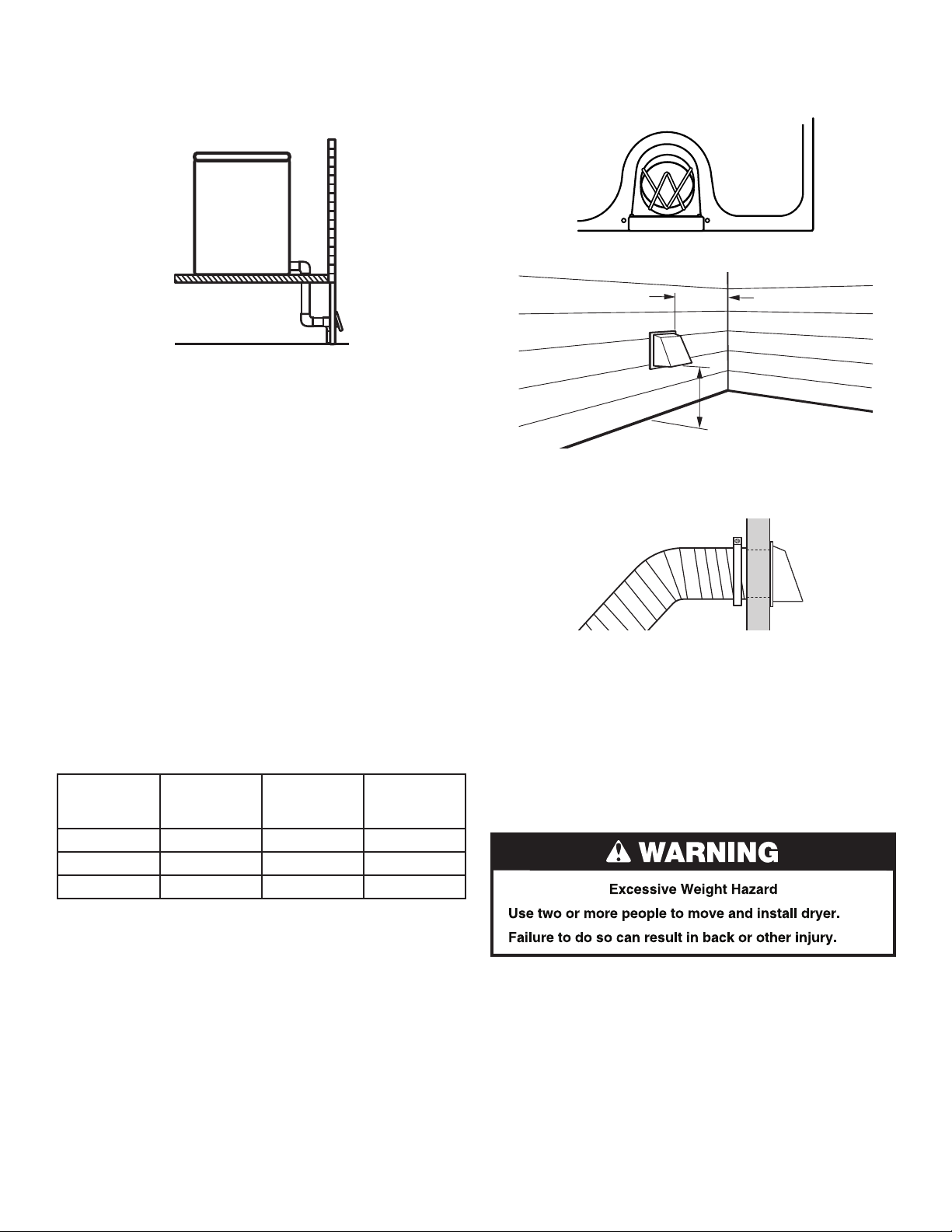

Exhaust hoods:

■ Must be at least 12" (305 mm) from ground or any object

that may obstruct exhaust (such as flowers, rocks, bushes,

or snow).

Recommended Style:

Louvered hood Box hood

Acceptable Style:

Angled hood

Elbows

45° elbows provide better airflow than 90° elbows.

Good Better

Plan Vent System

Choose your exhaust installation type

Recommended exhaust installations:

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

A

B

A. Exhaust hood

B. Flexible metal or rigid metal vent

C. Elbow

Alternate installations for close clearances:

Venting systems come in many varieties. Select the type best

for your installation. Two close-clearance installations are shown.

Refer to the manufacturer’s instructions.

Clamps

■ Use clamps to seal all joints.

■ Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into the interior of the

duct, because they can catch lint. Do not use duct tape.

Improper venting can cause moisture and lint to collect

indoors, which may result in:

Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

Housecleaning problems and health problems.

A B

A. Over-the-top installation

(also available with one offset elbow)

B. Periscope installation

NOTE: The following kits for close clearance alternate

installations are available for purchase. For information on

ordering, see “Assistance or Service.”

■ Over-the-Top Installation:

Part Number 4396028

■ Periscope Installation (for use with dryer vent to wall vent

mismatch):

Part Number 4396037 - for mismatch of 0" (0 mm) to

18" (457 mm)

Part Number 4396011 - for mismatch of 18" (457 mm) to

29" (737 mm)

Part Number 4396014 - for mismatch of 29" (737 mm) to

50" (1.27 m)

7

Page 8

Special provisions for mobile home installations:

The exhaust vent must be securely fastened to a noncombustible

portion of the mobile home structure and must not terminate

beneath the mobile home. Terminate the exhaust vent outside.

Determine vent path

■ Select the route that will provide the straightest and most

direct path outdoors.

■ Plan the installation to use the fewest number of elbows

and turns.

■ When using elbows or making turns, allow as much room

as possible.

■ Bend vent gradually to avoid kinking.

■ Use the fewest 90° turns possible.

Install Vent System

1. Before installing the vent system, be sure to remove the wire

exhaust guard that is located at the exhaust outlet.

2. Install exhaust hood.

12" min.

(305 mm)

12" min.

(305 mm)

Install exhaust hood and use caulking compound to seal

exterior wall opening around exhaust hood.

3. Connect vent to exhaust hood.

Determine vent length and elbows needed for

best drying performance

■ Use the “Vent System Chart” below to determine type of vent

material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specified in

the Vent system chart. Exhaust systems longer than those

specified will:

■ Shorten the life of the dryer.

■ Reduce performance, resulting in longer drying times and

increased energy usage.

The “Vent System Chart” provides venting requirements that will

help to achieve the best drying performance.

Vent System Chart

Number of

90º turns or

elbows

0

1

2

Type of vent Box or

louvered

hoods

Rigid metal 36 ft (11 m) 26 ft (7.9 m)

Rigid metal 26 ft (7.9 m) 16 ft (4.9 m)

Rigid metal 16 ft (4.9 m) 6 ft (1.8 m)

Angled

hoods

Vent must fit inside exhaust hood. Secure vent to exhaust

hood with 4" (102 mm) clamp. Run vent to dryer location.

Use the straightest path possible. See “Determine vent path”

in “Plan Vent System.” Avoid 90º turns. Use clamps to seal

all joints. Do not use duct tape, screws, or other fastening

devices that extend into the interior of the vent to secure vent,

because they can catch lint.

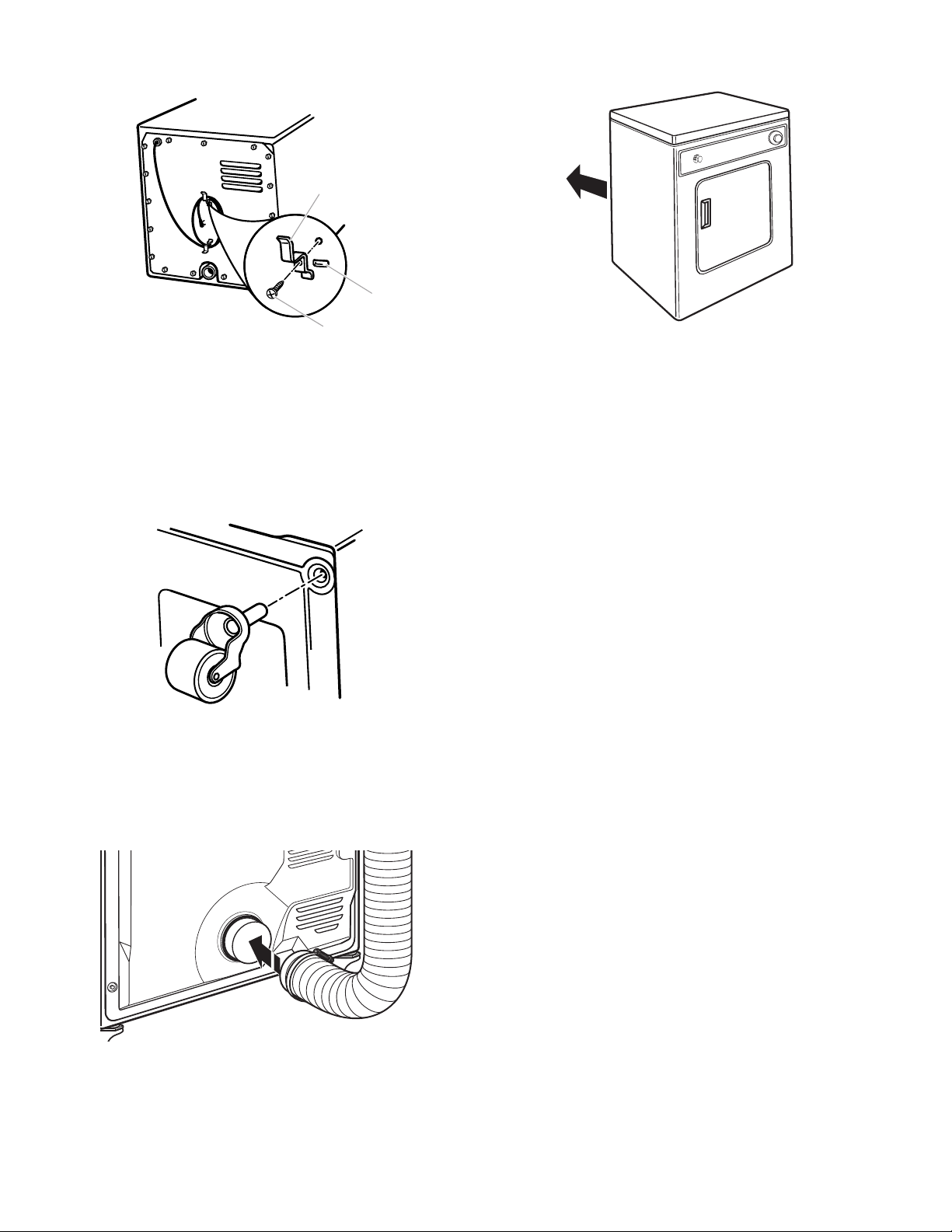

Install Cord Bracket and Casters

Do not move dryer into its final location until the following steps

have been performed.

Install cord bracket

1. Remove tape from the power cord and the rear panel.

8

Page 9

2. Insert cord brackets into slotted holes in rear panel and

B

C

secure with screws provided.

A

2. Move dryer into its final location. Avoid crushing or kinking

the vent.

A .Cord bracket

B. Slotted hole

C. Screw

NOTE: Power supply cord may be wrapped around the brackets

for storage convenience when dryer is not in use.

Install casters

1. To avoid damaging floor, use a large flat piece of cardboard

from dryer carton. Place cardboard under entire back edge

of the dryer.

2. Firmly grasp dryer body and gently lay dryer on cardboard.

3. Screw casters into dryer base at four corners and

tighten securely.

4. Set the dryer upright. In doing so, be certain that the dryer

does not roll away from you.

Connect Vent

1. Connect vent to exhaust outlet.

3. Once exhaust vent connection is made, remove cardboard.

Complete Installation

1. Check that all parts are now installed. If there is an extra part,

go back through the steps to see what was skipped.

2. Check that you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. Check dryer’s final location. Be sure vent is not crushed

or kinked.

5. Check that dryer is on a level surface.

6. Plug into a grounded 3 prong outlet.

7. Remove film on the console and any tape remaining on dryer.

Remove tape from lint screen (located on inside back wall

of dryer).

8. Read “Dryer Use.”

9. Wipe dryer drum interior thoroughly with a damp cloth to

remove any dust.

10. To test the dryer, set the dryer on a full heat cycle (not an air

cycle) for 20 minutes and start the dryer.

If the dryer will not start, check the following:

■ Controls are set in a running or “On” position.

■ Start button has been firmly pressed.

■ Dryer is plugged into a grounded 3 prong outlet.

■ Household fuse is intact and tight, or circuit breaker has

not tripped.

■ Dryer door is closed.

11. When the dryer has been running for 5 minutes, open the

dryer door and feel for heat. If you feel heat, cancel cycle and

close the door.

If you do not feel heat, check the following:

■ Controls are set on a heated cycle, not an air cycle.

NOTE: You may notice an odor when dryer is first heated. This

odor is common when the heating element is first used. The odor

will go away.

Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure the vent is

clean. Dryer vent must fit over dryer exhaust outlet and inside

exhaust hood. Check that vent is secured to exhaust hood

with a 4" (102 mm) clamp.

9

Page 10

Using Your Dryer

Starting Your Dryer

WARNING: To reduce the risk of fire, electric shock, or injury to

persons, read the IMPORTANT SAFETY INSTRUCTIONS before

operating this appliance.

Before using your dryer, wipe the dryer drum with a damp cloth

to remove dust from storing and shipping.

1. Clean the lint screen before each load. See “Cleaning the

Lint Screen.”

2. Load clothes loosely into the dryer and close the door. Do not

pack the dryer. Allow space for clothes to tumble freely.

3. Turn the Cycle Control knob to the recommended cycle for the

type of load being dried. Use the Perm Press Energy Preferred

Automatic Setting to dry most heavyweight and medium

weight loads. See “Drying, Cycle, and Temperature Tips.”

4. Press START.

Stopping and Restarting

You can stop your dryer anytime during a cycle.

To stop your dryer:

Open dryer door or turn Cycle Control knob to OFF.

NOTE: The Cycle Control knob should point to an Off

area when dryer is not in use.

To restart your dryer:

1. Close the door.

2. Select a new cycle and temperature (if desired).

3. Press the START button.

10

Page 11

Loading

Load clothes loosely into the dryer. Do not overload the dryer.

Allow space for clothes to tumble freely. The following chart

shows the maximum load you can place in your compact dryer.

Expect longer drying times.

Heavy work clothes

Delicates

Towels

Mixed load

Knits

Perm Press

2 pair of pants, 3 work shirts

1 camisole, 2 slips, 4 undergarments,

1 set of sleepwear, 1 half slip

9 bath towels; or 6 bath towels,

3 hand towels, 6 washcloths

2 pillowcases, 1 T-shirt, 2 shirts,

1 pair slacks

2 slacks, 2 shirts; or 3 dresses

6 shirts; or 2 double sheets &

2 pillowcases; or 2 singles sheets &

2 pillowcases

Drying, Cycle, and Temperature Tips

Select the correct cycle and temperature for your load.

Your dryer tumbles the load without heat during the last few

minutes of all cycles to make the load easier to handle.

Drying tips

■ Follow care label directions when they are available.

■ If desired, add a fabric softener sheet. Follow package

instructions.

■ Remove load from the dryer as soon as tumbling stops to

reduce wrinkling. This is especially important for permanent

press, knits, and synthetic fabrics.

Cycle and temperature tips

■ Dry most loads using the Energy Preferred setting.

■ Use a no heat (air) setting for rubber, plastic, or heat-

sensitive fabrics.

■ Line-dry bonded or laminated fabrics.

NOTE: If you have questions about drying temperatures for

various loads, refer to the care label directions.

Air Dry

Use this cycle for items that require drying without heat, such

as rubber, plastic and heat-sensitive fabrics. See the chart for

examples of items that can be dried using an air cycle.

Type of Load Time*

Foam rubber - pillows,

padded bras, stuffed toys

Plastic - shower curtains,

tablecloths

Rubber-backed rugs 40 - 50

Olefin, polypropylene, sheer

nylon

*(Minutes). Reset cycle to complete drying, if needed.

When using an air cycle

■ Check that coverings are securely stitched.

■ Shake and fluff pillows by hand periodically during cycle.

■ Dry item completely. Foam rubber pillows are slow to dry.

20 - 30

20 - 30

10 - 20

Time Dry Cycle

Use this cycle to complete drying if items are still damp after the

automatic cycle.

Time Dry is also useful for:

■ Heavyweight items and work clothes that require a long

drying time.

■ Lightweight items, such as lingerie, blouses and knits that

require a short drying time.

For damp dry, turn the Cycle Control knob to 30 minutes or less.

End of Cycle Signal

The dryer sounds a signal to let you know when the cycle is

finished. The signal is not adjustable and cannot be turned off.

The signal is helpful when you are drying permanent press,

synthetics and other items that should be taken out as soon as

the dryer stops.

Cycles

Auto Dry

This automatic cycle shuts off the dryer when the Auto Moisture

Sensing feature determines the selected dryness level has been

reached. The Cycle Control knob does not move until the load is

almost dry. After the cool down, the knob automatically turns to

an Off area and tumbling stops.

Dry most loads using the Energy Preferred setting. Drying time

with an Auto Dry cycle varies according to the type of fabric, size

of load, and temperature setting.

■ If the load is drier than you like, select a setting closer to Less

Dry the next time you dry a similar load.

■ If the load is not as dry as you like, complete drying using the

Time Dry cycle. The next time you dry a similar load, select a

setting closer to Very Dry.

How Auto Moisture Sensing Works

With Auto Moisture Sensing, the dryness of the load is

determined by two metal strips (sensors) located on the inside

of the dryer. The metal strips help detect the amount of moisture

left in the clothes as they pass. When there is moisture left in

the clothes, the Cycle Control knob will not advance. As clothes

begin to dry, the amount of water left in the clothes decreases,

and the timer advances through the remainder of the cycle. When

the selected dryness level is reached, the dryer goes into a cool

down period of up to 5 minutes.

11

Page 12

Dryer Care

Cleaning the Dryer Location

Keep dryer area clear and free from items that would obstruct the

flow of combustion and ventilation air.

Cleaning the Lint Screen

Every load cleaning

The lint screen is located inside the dryer drum, on the back wall.

Clean it before each load. A screen blocked by lint can increase

drying time.

To clean:

1. Open the door and pull the lint screen straight out.

To wash:

1. Roll lint off the screen with your fingers.

2. Wet both the lint screen cover and body with hot water.

3. Wet a nylon brush with hot water and liquid detergent.

Scrub lint screen cover and body with the brush to remove

residue buildup.

4. Rinse with hot water.

5. Thoroughly dry lint screen body and cover with a clean towel.

Replace in dryer.

Cleaning the Dryer Interior

To clean dryer drum:

1. Make a paste with powdered laundry detergent and very

warm water.

2. Apply paste to a soft cloth.

OR

Apply a liquid, nonflammable household cleaner to the stained

area and rub with a soft cloth until all excess dye is removed.

3. Wipe drum thoroughly with a damp cloth.

4. Tumble a load of clean cloths or towels to dry drum.

NOTE: Garments that contain unstable dyes, such as denim blue

jeans or brightly colored cotton items, may discolor the dryer

interior. These stains are not harmful to your dryer and will not

stain future loads of clothes. Dry unstable dye items inside-out to

avoid transfer of dye.

2. Squeeze body of lint screen lightly while pulling off the cover.

3. Roll lint off the screen with your fingers. Do not rinse or wash

screen to remove lint. Wet lint is hard to remove.

4. Replace cover on lint screen body. Push the lint screen firmly

back into place and close the door.

IMPORTANT:

■ Do not run the dryer with the lint screen loose, damaged,

blocked, or missing. Doing so can cause overheating and

damage to both the dryer and fabrics.

As needed cleaning

Laundry detergent and fabric softener residue can build up on the

lint screen. This buildup can cause longer drying times for your

clothes, or cause the dryer to stop before your load is completely

dry. The screen is probably clogged if lint falls off the screen.

Clean the lint screen with a nylon brush every 6 months, or more

frequently if it becomes clogged due to a residue buildup.

Removing Accumulated Lint

From Inside the Dryer Cabinet

Lint should be removed every 2 years, or more often, depending

on dryer usage. Cleaning should be done by a qualified person.

From the Exhaust Vent

Lint should be removed every 2 years, or more often, depending

on dryer usage.

Vacation and Moving Care

Vacation Care

Operate your dryer only when you are at home. If you will be on

vacation or not using your dryer for an extended period of time,

you should:

1. Unplug dryer or disconnect power.

2. Clean lint screen. See “Cleaning the Lint Screen.”

Moving Care

1. Unplug the power supply cord.

2. Use tape to secure dryer door.

12

Page 13

Troubleshooting

First try the solutions suggested here or visit our website at www.amana.custhelp.com -

In Canada www.amanacanada.ca for assistance and to possibly avoid a service call.

If you experience Possible Causes Solution

Dryer Operation

Dryer will not run Door not closed completely. Make sure the dryer door is closed completely.

Press and hold the START button

2–5 seconds.

Household fuse is blown or circuit

breaker has tripped.

Incorrect power supply. Electric dryers require 120-volt power supply.

Wrong type of fuse. Use a time-delay fuse.

Incorrect power supply. Electric dryers require 120-volt power supply.

Timer does not

noticeably advance

Unusual Noise

Thumping noise Dryer hasn’t been used in a while. This is normal. The thumping sound should diminish after a few

Rattling or vibrating noise A small object caught between the

Dryer set to Timed or Air Dry The timer moves slowly and continuously for the time setting.

Dryer set to Auto Dry The timer moves only when the clothing is mostly dry. See “How

edges of dryer drum.

Dryer isn’t properly leveled. The dryer may vibrate if not properly installed. Check the

Clothing is balled up in dryer. When balled up, the load will bounce, causing the dryer to

Press and hold the START button 2–5 seconds.

There is be a household fuse or circuit breaker for the dryer.

Check that the fuse is intact and tight, or that the circuit breaker

has not tripped. Replace the fuse or reset the circuit breaker. If

the problem continues, call an electrician.

Check with a qualified electrician.

Check with a qualified electrician.

Auto Moisture Sensing Works” in “Dryer Use.”

minutes of use.

Check the front and rear edges of the drum for small objects.

Clean out pockets before laundering.

levelness of the dryer. All four casters should be in firm contact

with the floor.

vibrate. Separate the load items and restart the dryer.

Dryer Results

NOTE: The compact dryer operates at a lower wattage. Expect longer drying times.

Clothes are not drying

satisfactorily or drying

times are too long

Lint screen is clogged with lint. Clean lint screen before each load.

The exhaust vent or outside exhaust

hood is clogged with lint, restricting

air movement.

Run the dryer for 5–10 minutes. Hold your hand under

the outside exhaust hood to check air movement. If you

do not feel air movement, clean exhaust system of lint

or replace exhaust vent with heavy metal or flexible metal vent.

See “Venting.”

13

Page 14

Troubleshooting

First try the solutions suggested here or visit our website at www.amana.custhelp.com -

In Canada www.amanacanada.ca for assistance and to possibly avoid a service call.

If you experience Possible Causes Solution

Dryer Results

Clothes are not drying

satisfactorily or drying

times are too long (cont.)

Cycle time is too short The sensor cycle is ending early. Change the dryness level setting on sensor cycles. Increasing

Lint on load Lint screen is clogged with lint. Clean lint screen before each load.

Stains on load Improper use of fabric softener. Add dryer fabric softener sheets at the beginning of the cycle.

Stains on drum Loose dyes in clothes. Drum stains are caused by dyes in clothing (usually blue jeans).

Loads are wrinkled The load was not removed from dryer

Odors Recent painting, staining, or

The exhaust vent is not the

correct length.

The exhaust vent diameter is not the

correct size.

The dryer is not level. Clothes not contacting the moisture sensors during Automatic

The Air Dry temperature setting has

been selected.

The load is too large and heavy

to dry quickly.

Fabric softener sheets are blocking

the lint screen cover.

The dryer is located in a room with

temperature below 45ºF (7ºC).

The dryer is located in a closet. Closet doors must have ventilation openings at the top

The load may not be contacting the

sensor strips on Sensor Cycles.

at the end of the cycle.

The dryer was tightly packed. Dry smaller loads that can tumble freely.

varnishing in the area where your

dryer is located.

Dryer being used for the first time. The new electric heating element may have an odor. The odor

Check that the exhaust vent is not too long or has

too many turns. Long venting will increase drying times.

See “Venting.”

Use 4" (102 mm) diameter vent material.

cycles. Check the levelness of the dryer. All four casters should

be in firm contact with the floor.

Select the correct temperature for the types of garments being

dried. See “Cycles.”

Separate the load to tumble freely.

Use only one fabric softener sheet, and use it only once.

Proper operation of dryer cycles requires temperatures above

45ºF (7ºC).

and bottom of the door. The front of the dryer requires a

minimum of 1” (25 mm) of airspace, and, for most installations,

the rear of the dryer requires 5½” (140 mm). See “Location

Requirements.”

Check the levelness of the dryer. All four casters should be in

firm contact with the floor.

or decreasing the dryness level will change the amount of

drying time in a cycle. If loads are consistently ending too early,

see “Cycles.”

Fabric softener sheets added to a partially dried load can stain

your garments.

These will not transfer to other clothing.

Refer to garment care label instructions. Dry clean only garments

are not recommended.

Ventilate the area. When the odors or fumes are gone from the

area, rewash and dry the clothing.

will be gone after the first cycle

Accessories

Part Number Accessory

49971 Compact dryer stand - white

For ordering information, see “Assistance or Service” on the back page.

14

Page 15

ATTACH YOUR RECEIPT HERE. PROOF OF PURCHASE IS REQUIRED

usthelp.com

AMANA®

MAJOR APPLIANCE

LIMITED WARRANTY

TO OBTAIN WARRANTY SERVICE.

Please have the following information available when you call the

Customer eXperience Center:

■ Name, address and telephone number

■ Model number and serial number

■ A clear, detailed description of the problem

■ Proof of purchase including dealer or retailer name and address

IF YOU NEED SERVICE:

1. Before contacting us to arrange service, please determine whether your product requires repair. Some

questions can be addressed without service. Please take a few minutes to review the Troubleshooting or

Problem Solver section of the Use and Care Guide, scan the QR code on the right to access additional

resources, or visit http://amana.custhelp.com.

2. All warranty service is provided exclusively by our authorized Amana Service Providers

direct all requests for warranty service to:

Amana Customer eXperience Center

In the U.S.A., call 1-800-843-0304. In Canada, call 1-800-807-6777.

If outside the 50 United States or Canada, contact your authorized Amana dealer to determine whether another warranty applies.

ONE YEAR LIMITED WARRANTY

WHAT IS COVERED WHAT IS NOT COVERED

For one year from the date of purchase, when

this major appliance is installed, operated and

maintained according to instructions attached to

or furnished with the product, Amana brand of

Whirlpool Corporation or Whirlpool Canada LP

(hereafter “Amana”) will pay for Factory Specified

Replacement Parts and repair labor to correct

defects in materials or workmanship that existed

when this major appliance was purchased, or at

its sole discretion replace the product. In the

event of product replacement, your appliance will

be warranted for the remaining term of the

original unit's warranty period.

YOUR SOLE AND EXCLUSIVE REMEDY UNDER

THIS LIMITED WARRANTY SHALL BE

PRODUCT REPAIR AS PROVIDED HEREIN.

Service must be provided by a Amana

designated service company. This limited

warranty is valid only in the United States or

Canada and applies only when the major

appliance is used in the country in which it was

purchased. This limited warranty is effective from

the date of original consumer purchase. Proof of

original purchase date is required to obtain

service under this limited warranty.

1. Commercial, non-residential, multiple-family use, or use inconsistent with published user,

operator or installation instructions.

2. In-home instruction on how to use your product.

3. Service to correct improper product maintenance or installation, installation not in

accordance with electrical or plumbing codes or correction of household electrical or

plumbing (i.e. house wiring, fuses or water inlet hoses).

4. Consumable parts (i.e. light bulbs, batteries, air or water filters, preservation solutions, etc.).

5. Defects or damage caused by the use of non-genuine Amana parts or accessories.

6. Conversion of products from natural gas or L.P. gas.

7. Damage from accident, misuse, abuse, fire, floods, acts of God or use with products not

approved by Amana.

8. Repairs to parts or systems to correct product damage or defects caused by unauthorized

service, alteration or modification of the appliance.

9. Cosmetic damage including scratches, dents, chips, and other damage to the appliance

finishes unless such damage results from defects in materials and workmanship and is

reported to Amana within 30 days.

10. Discoloration, rust or oxidation of surfaces resulting from caustic or corrosive environments

including but not limited to high salt concentrations, high moisture or humidity or exposure

to chemicals.

11. Food or medicine loss due to product failure.

12. Pick-up or delivery. This product is intended for in-home repair.

13. Travel or transportation expenses for service in remote locations where an authorized

Amana servicer is not available.

14. Removal or reinstallation of inaccessible appliances or built-in fixtures (i.e. trim, decorative

panels, flooring, cabinetry, islands, countertops, drywall, etc.) that interfere with servicing,

removal or replacement of the product.

15. Service or parts for appliances with original model/serial numbers removed, altered or not

easily determined.

The cost of repair or replacement under these excluded circumstances shall be borne by

the customer.

. In the U.S. and Canada,

http://amana.c

DISCLAIMER OF IMPLIED WARRANTIES

IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. Some states and provinces do not allow

limitations on the duration of implied warranties of merchantability or fitness, so this limitation may not apply to you. This warranty gives you

specific legal rights, and you also may have other rights that vary from state to state or province to province.

DISCLAIMER OF REPRESENTATIONS OUTSIDE OF WARRANTY

Amana makes no representations about the quality, durability, or need for service or repair of this major appliance other than the representations

contained in this warranty. If you want a longer or more comprehensive warranty than the limited warranty that comes with this major appliance,

you should ask Amana or your retailer about buying an extended warranty.

LIMITATION OF REMEDIES; EXCLUSION OF INCIDENTAL AND CONSEQUENTIAL DAMAGES

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN. AMANA

SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some states and provinces do not allow the exclusion or limitation

of incidental or consequential damages, so these limitations and exclusions may not apply to you. This warranty gives you specific legal rights, and

you also may have other rights that vary from state to state or province to province.

11/14

15

Page 16

Sécurité de la sécheuse

16

Page 17

17

Page 18

Instructions d’installation

Outillage et pièces

Outils nécessaires

Rassembler les outils et pièces nécessaires avant d’entreprendre

l’installation. Lire et observer les instructions fournies avec

chacun des outils de la liste ci-dessous.

Tournevis à lame plate Cisaille de ferblantier

(pour l’installation d’un

nouveau conduit)

Pièces nécessaires

Consulter les codes locaux, les “Exigences concernant

l’évacuation” et les “Spécifications électriques”, vérifier

l’alimentation électrique et le circuit d’évacuation existants,

avant d’acheter les pièces nécessaires.

■ Pour les installations en résidence mobile, le circuit

d’évacuation nécessite des matériaux métalliques.

Pour connaître le processus de commande, consulter la

section “Assistance ou service” sur la couverture arrière.

Vous pouvez aussi contacter le marchand chez qui vous avez

acheté la sécheuse.

Exigences d’emplacement

Niveau Brides de conduit

Clé à molette avec ouverture

jusqu’à 1" (25 mm) ou clé à

douille hexagonale

Pistolet à calfeutrage et

composé de calfeutrage

(pour l’installation d’un

nouveau conduit

d’évacuation)

Pièces fournies

Retirer le sachet de pièces du tambour de la sécheuse.

Vérifier que toutes les pièces énumérées sont présentes.

Bouton de commande

des programmes

Bouton Start

(mise en marche)

Il vous faudra

■ Un emplacement permettant une évacuation appropriée.

Voir “Exigences concernant l’évacuation”.

■ Un circuit de 120 volts, 60 Hz, CA seulement, 15 ou

20 ampères.

■ Une prise électrique avec liaison à la terre située à moins

de 2 pi (610 mm) de l’un des côtés de la sécheuse.

Voir “Spécifications électriques”.

■ Un plancher robuste pour supporter la sécheuse avec un

poids total (sécheuse et charge) de 115 lb (52 kg). Il faut

aussi prendre en compte le poids combiné d’un appareil

ménager voisin.

■ Un plancher de niveau ayant une pente maximale de

1" (25 mm) sous l’ensemble de la sécheuse.

Ne pas faire fonctionner la sécheuse à des températures

inférieures à 45ºF (7ºC). À des températures inférieures,

la sécheuse risque de ne pas s’arrêter à la fin d’un programme

automatique. Les durées de séchage risquent alors

d’augmenter.

La ne doit pas être installée ou remisée dans un endroit où elle

sera exposée à l’eau et/ou aux intempéries.

Vérifier les spécifications des codes. Certains codes limitent

ou interdisent l’installation des sécheuses dans un garage,

un placard, une résidence mobile ou une chambre à coucher.

Contacter l’inspecteur en bâtiments local.

Roulettes (4) Supports du cordon (2)

et vis (2)

18

Distances de dégagement à respecter

L’emplacement doit être assez grand pour permettre d’ouvrir

complètement la porte de la sécheuse.

Page 19

Dimensions de la sécheuse

(89 mm)

AB

(25 mm)

A B

C

Vue de face

Vue latérale

(914 mm)

36"

237/8"

(606 mm)

3

20

/4"

(527 mm)

3

*20

/4"

(527 mm)

31"

(787 mm)

3

/4"

1

(44 mm)

■ Prévoir davantage d’espace pour faciliter l’installation et l’entretien.

■ Un espace supplémentaire peut être requis pour les moulures

de porte et de plancher et pour les plinthes.

■ Pour installation dans un placard avec porte, on doit prévoir

des ouvertures minimums d’entrée d’air en haut et en bas

de la porte. Les portes à claire-voie offrant des ouvertures

équivalentes de passage de l’air sont acceptables.

■ Il faut aussi prendre en compte l’espace requis entre les

appareils voisins.

Installation dans un encastrement ou un placard –

sécheuse seulement

14"*

(356 mm)

18"* (457 mm)

51/2"*

(140 mm)

1"

(25 mm)

1"

A. Vue latérale – placard ou endroit exigu

B. Zone d’insertion

*La plupart des installations requièrent un espace minimum de

5½" (140 mm) derrière la sécheuse pour le conduit d’évacuation

avec coudes. Voir “Exigences concernant l’évacuation”.

13/4"

Vue arrière

1

3

/2"

1

/4"

29

(743 mm)

13/4"

(44 mm)

(303 mm)

Dégagement minimal pour une installation

dans un encastrement ou un placard

Les dimensions suivantes indiquent l’espacement minimum

autorisé lorsque la sécheuse doit être utilisée avec ou sans

nécessaire de superposition. Pour acheter un nécessaire de

superposition, voir “Assistance ou service”.

117/8"

31/4"

(83 mm)

Installation dans un encastrement ou un placard – superposition

12"*

12"*

(25 mm)

51/2"

(76 mm)

48 in. *

(309.7 cm )

DRYER

24 in. *

WASHER

1"

1"

(25 mm)

1"*

(25 mm)

(154.8 cm )

A. Encastrement

B. Vue latérale – placard ou endroit exigu

C. Porte du placard avec grilles d’aération

2

2

2

2

3"*

(76 mm)

3"*

(76 mm)

Résidence mobile – Spécifications additionnelles

concernant l’emplacement

Cette sécheuse peut être installée dans une maison mobile.

L’installation doit satisfaire les critères de la Manufactured Home

Construction and Safety Standard, Titre 24 CFR, partie 3280

(anciennement Federal Standard for Mobile Home Construction and

Safety, Titre 245 HUD, partie 280) ou de la Norme CAN/CSA-Z240MH.

Autres critères à respecter pour une installation en

résidence mobile :

■ Un système d’évacuation en métal qui peut être acheté chez

votre marchand.

■ Il faut prendre des dispositions spéciales dans les maisons

mobiles pour l’apport d’air de l’extérieur dans la sécheuse.

L’ouverture (telle qu’une fenêtre à proximité) devrait être au moins

deux fois plus grande que l’ouverture de décharge de la sécheuse.

19

Page 20

Spécifications électriques

■ Une source d’alimentation de 120 V, 60 Hz, CA uniquement,

de 15 ou 20 ampères et protégée par fusible est nécessaire.

■ On recommande d’utiliser un fusible ou un disjoncteur

temporisé. Vérifier que le fusible ou le disjoncteur

correspond aux caractéristiques de la ligne électrique.

■ Il est également recommandé de raccorder l’appareil sur un

circuit distinct exclusif à cet appareil.

■ Ne pas utiliser de rallonge.

INSTRUCTIONS DE LIAISON À LA TERRE

Pour une sécheuse reliée à la terre et connectée par

un cordon :

Cette sécheuse doit être reliée à la terre. En cas de mauvais

fonctionnement ou de panne, la liaison à la terre réduira le

risque de choc électrique en offrant au courant électrique un

acheminement d'évacuation de moindre résistance. Cette

sécheuse est alimentée par un cordon électrique comportant

un conducteur relié à la terre et une che de branchement

munie d'une broche de liaison à la terre. La che doit être

branchée sur une prise appropriée qui est bien installée et

reliée à la terre conformément à tous les codes et règlements

locaux.

AVERTISSEMENT : Le raccordement incorrect de

cet appareil au conducteur de liaison à la terre peut susciter

un risque de choc électrique. En cas de doute quant à la

qualité de liaison à la terre de la sécheuse, consulter un

électricien ou un technicien ou un personnel qualié. Ne pas

modier la che de branchement fournie avec la sécheuse;

si la che ne correspond pas à la conguration de la prise de

courant, demander à un électricien qualié d'installer une

prise de courant appropriée.

CONSERVEZ CES INSTRUCTIONS

20

Évacuation

Exigences concernant l’évacuation

AVERTISSEMENT : Pour réduire le risque d’incendie,

cette sécheuse doit ÉVACUER L’AIR À L’EXTÉRIEUR.

IMPORTANT : Observer les dispositions de tous les codes et

règlements en vigueur.

Le conduit d’évacuation de la sécheuse ne doit pas être raccordé

à une évacuation de gaz, une cheminée, un mur, un plafond,

un grenier, un vide sanitaire ou un vide de construction. Seul un

conduit d’évacuation métallique rigide ou souple doit être utilisé

pour le système d’évacuation.

Conduit d’évacuation en métal lourd de 4" (10,2 cm)

■ Utiliser uniquement un conduit d’évacuation en métal lourd de

4" (10,2 cm) et des brides de serrage.

■ Ne pas utiliser de conduit de plastique ou de métal très mince.

Conduit métallique rigide :

■ Recommandé pour une performance de séchage idéale afin

d’éviter tout écrasement ou déformation.

Conduit métallique flexible : (Acceptable uniquement si son

accès reste facile pour le nettoyage)

■ Doit être entièrement déployé et soutenu à l’emplacement

d’installation final de la sécheuse.

■ Enlever tout excès de conduit flexible pour éviter tout

affaissement et déformation susceptible de réduire la capacité

d’évacuation et le rendement.

■ Ne pas installer le conduit métallique flexible dans des cavités

fermées de mur, plafonds ou planchers.

■ La longueur totale ne doit pas dépasser 7¾ (2,4 m).

REMARQUE : Lors de l’utilisation d’un système d’évacuation

existant, nettoyer et éliminer la charpie sur toute la longueur du

système, et veiller à ce que le clapet d’évacuation ne soit pas

obstrué par de la charpie. Remplacer tout conduit de plastique

ou en aluminium par un conduit métallique rigide ou souple.

Consulter à nouveau le tableau des systèmes d’évacuations et

modifier le système d’évacuation existant au besoin pour obtenir

un meilleur séchage.

Page 21

C

Évents pour conduit d’évacuation :

■ Doit se trouver à au moins 12" (30,5 cm) du plancher ou de

tout objet susceptible d’obstruer l’ouverture d’évacuation

(tels des fleurs, des pierres, des buissons ou de la neige).

Styles recommandés :

Planification des circuits de conduits

Choisir un type de système d’évacuation

Installations d’évacuation recommandées :

Les installations typiques consistent à acheminer le conduit

d’évacuation à l’arrière de la sécheuse. D’autres installations

sont possibles.

A

Type persienne Type boîte

Style acceptable :

Type incliné

Coudes

Les coudes à 45° permettent une meilleure circulation de l’air

que les coudes à 90°.

Bon

Meilleur

Brides de serrage

■ Utiliser des brides pour sceller tous les joints.

■ Le conduit d’évacuation ne doit pas être connecté ou fixé

avec des vis ou avec tout autre dispositif de serrage qui se

prolonge à l’intérieur du conduit, car ils peuvent retenir la

charpie. Ne pas utiliser de ruban adhésif pour conduit.

B

A. Clapet d’évacuation

B. Conduit métallique flexible ou rigide

C. Coude

Autres installations avec dégagement réduit :

Il existe de nombreux systèmes d’évacuation. Choisir le

système qui convient le mieux à votre installation. Deux

installations à dégagement réduit sont illustrées. Voir les

instructions du fabricant.

Une mauvaise évacuation de l'air peut causer de

l'humidité et une accumulation de charpie à l'intérieur de

la maison, ce qui peut provoquer :

Dommages par l'humidité aux boiseries, meubles, peinture,

papier-peint, tapis, etc.

Problèmes de nettoyage dans la maison et problèmes

de santé.

A B

A. Installation au-dessus de la sécheuse

(également disponible avec un coude décalé)

B. Installation de périscope

REMARQUE : On peut acheter les trousses suivantes pour

les installations où le dégagement est réduit. Pour des

renseignements sur la commande, voir la section “Assistance ou

service”.

■ Installation au-dessus de la sécheuse :

Pièce numéro 4396028

■ Installation avec périscope (pour utilisation en cas de

non-concordance de la bouche de décharge de la sécheuse

avec la bouche d’évacuation murale) ;

Pièce numéro 4396037 – Non-concordance de 0" (0 mm) à

18" (457 mm)

Pièce numéro 4396011 – Non-concordance de 18" (457 mm)

à 29" (737 mm)

Pièce numéro 4396014 – Non-concordance de 29" (737 mm)

à 50" (1,27 m)

21

Page 22

Dispositions spéciales pour les installations dans une

maison mobile

Le système d’évacuation doit être solidement fixé à une section

non combustible de la structure de la maison mobile et ne doit

pas se terminer en dessous de la maison mobile. Acheminer le

conduit d’évacuation vers l’extérieur.

Déterminer l’itinéraire d’acheminement

du conduit

■ Choisir l’itinéraire d’acheminement vers l’extérieur qui sera le

plus direct et le plus rectiligne.

■ Planifier l’installation pour introduire le nombre minimal de

coudes et de changements de direction.

■ Si des coudes ou changements de direction sont utilisés,

prévoir autant d’espace que possible.

■ Plier le conduit graduellement pour éviter de le déformer.

■ Utiliser le moins possible de changements de direction à 90°.

Installation du conduit d’évacuation

1. Avant d’installer le conduit d’évacuation, s’assurer de

retirer le protecteur en fil métallique qui est situé à la sortie

d’évacuation.

2. Installer le clapet d’évacuation.

12" min.

(305 mm)

12" min.

(305 mm)

Installer le clapet d’évacuation et utiliser un composé de

calfeutrage pour calfeutrer le côté extérieur de l’ouverture

murale autour du clapet d’évacuation.

3. Raccorder le conduit d’évacuation au clapet.

Déterminer la longueur du conduit et les

coudes nécessaires pour la meilleure

performance de séchage

■ Utiliser le tableau des systèmes d’évacuation ci-dessous

pour déterminer le type de composants et les combinaisons

acceptables.

REMARQUE : Ne pas utiliser un conduit de longueur

supérieure à la valeur spécifiée dans le tableau des systèmes

d’évacuation. Si la longueur du circuit est supérieure à la

valeur spécifiée dans le tableau, on observera :

■ Une réduction de la longévité de la sécheuse.

■ Une réduction du rendement, avec temps de séchage

plus longs et une plus grande consommation d’énergie.

Le tableau des systèmes d’évacuation fournit les exigences

d’évacuation qui vous aideront à atteindre la meilleure

performance de séchage.

Tableau des systèmes d’évacuation

Nombre de

changements

de direction

à 90° ou

coudes

0

1

2

Type de

conduit

d’évacuation

Métallique

rigide

Métallique

rigide

Métallique

rigide

Hottes

d’évacuation

de type

boîte ou à

persiennes

36 pi (11 m) 26 pi (7,9 m)

26 pi (7,9 m) 16 pi (4,9 m)

16 pi (4,9 m) 6 pi (1,8 m)

Hottes

d’évacuation

inclinées

Le conduit doit être inséré à l’intérieur du manchon du

clapet. Fixer ensemble le conduit et le clapet avec une

bride de 4" (10,2 cm). Acheminer le conduit d’évacuation

jusqu’à l’emplacement de la sécheuse. Utiliser l’itinéraire

le plus rectiligne possible. Voir “Déterminer l’itinéraire

d’acheminement du conduit” dans “Planification du système

d’évacuation”. Éviter les changements de direction de 90º.

Utiliser des brides pour sceller tous les joints. Ne pas utiliser

de ruban adhésif pour conduit, de vis ou autres dispositifs de

fixation qui se prolongeraient à l’intérieur du conduit pour fixer

le conduit d’évacuation ; ceux-ci pourraient retenir la charpie.

Installation des supports du cordon et

des roulettes

Ne pas déplacer la sécheuse vers son emplacement final jusqu’à

que les étapes suivantes ont été effectuées.

22

Installation des supports du cordon

1. Retirer le ruban du cordon d’alimentation et du

panneau arrière.

Page 23

2. Insérer les supports du cordon dans les fentes du panneau

B

C

arrière et les fixer à l’aide des vis fournies.

A

2. Déplacer la sécheuse à son emplacement final.

Éviter d’écraser ou de déformer le conduit d’évacuation.

A. Support du cordon

B. Fente

C. Vis

REMARQUE : Le cordon d’alimentation peut être enroulé autour

des supports pour rangement lorsque la sécheuse n’est pas utilisée.

Installation des roulettes

1. Pour éviter d’endommager le plancher, utiliser un grand

morceau de carton plat à partir de l’emballage de la sécheuse.

Placer le carton sous tout le bord arrière de la sécheuse.

2. Saisir fermement le corps de la sécheuse, puis reposer la

sécheuse sur le carton avec précaution.

3. Visser les roulettes dans la base de la sécheuse aux quatre

coins et les serrer solidement.

4. Relever la sécheuse. S’assurer que la sécheuse ne se roule

pas loin de soi après l’avoir relevée.

Raccordement du conduit d’évacuation

1. Raccorder le conduit d’évacuation au clapet d’évacuation.

À l’aide d’une bride de fixation de 4" (102 mm), relier

le conduit d’évacuation à la bouche d’évacuation de la

sécheuse. Si on utilise le conduit d’évacuation existant,

s’assurer qu’il est propre. Le conduit d’évacuation doit être

fixé par-dessus la bouche d’évacuation de la sécheuse et à

l’intérieur du clapet d’évacuation. S’assurer que le conduit

d’évacuation est fixé au clapet d’évacuation à l’aide d’une

bride de fixation de 4" (102 mm).

3. Une fois que le raccordement du conduit d’évacuation est

réalisé, retirer le carton.

Achever l’installation

1. Vérifier que toutes les pièces sont maintenant installées.

S’il reste une pièce, passer en revue les différentes étapes

pour découvrir laquelle aurait été oubliée.

2. Vérifier la présence de tous les outils.

3. Éliminer/recycler tous les matériaux d’emballage.

4. Vérifier l’emplacement définitif de la sécheuse. S’assurer que

le conduit d’évacuation n’est pas écrasé ou déformé.

5. Vérifier que la sécheuse est sur une surface plane.

6. Brancher l’appareil sur une prise 3 alvéoles reliée à la terre.

7. Ôter la pellicule protectrice de la console et tout ruban adhésif

resté sur la sécheuse. Retirer le ruban du filtre à charpie

(situé sur l’intérieur de la paroi arrière de la sécheuse).

8. Lire “Utilisation de la sécheuse”.

9. Essuyer soigneusement l’intérieur du tambour de la sécheuse

avec un chiffon humide pour éliminer toute trace de poussière.

10. Pour tester le fonctionnement de la sécheuse, la régler sur

un programme de séchage complet (pas un programme

de séchage à l’air) de 20 minutes et mettre la sécheuse en

marche.

Si la sécheuse ne démarre pas, vérifier ce qui suit :

■ Les commandes sont réglées à la position de marche

ou “On”.

■ Le bouton Start (mise en marche) a été appuyé

fermement.

■ La sécheuse est branchée sur une prise à trois alvéoles

reliée à la terre.

■ Les fusibles du domicile sont intacts et serrés ;

le disjoncteur n’est pas déclenché.

■ La porte de la sécheuse est fermée.

11. Après 5 minutes de fonctionnement, ouvrir la porte de la

sécheuse et voir s’il y a de la chaleur. Si de la chaleur est

détectée, annuler le programme et fermer la porte.

Si la sécheuse n’est pas chaude à l’intérieur, vérifier ce

qui suit :

■ Les commandes sont réglées au programme de séchage

avec chaleur, pas au programme de séchage à l’air.

REMARQUE : Il est possible que la sécheuse dégage une

certaine odeur lorsqu’elle chauffe pour la première fois.

Cette odeur est normale lorsque l’élément chauffant est utilisé

pour la première fois. L’odeur disparaîtra.

23

Page 24

Utilisation de la sécheuse

Mise en marche de la sécheuse

AVERTISSEMENT : Pour réduire le risque d’incendie, de choc

électrique ou de blessures corporelles, lire les INSTRUCTIONS

IMPORTANTES DE SÉCURITÉ avant de faire fonctionner cet

appareil.

Avant d’utiliser la sécheuse, essuyer le tambour de la sécheuse

avec un linge humide pour enlever la poussière accumulée au

cours de l’entreposage et de l’expédition.

1. Nettoyer le filtre à charpie avant chaque charge.

Voir “Nettoyage du filtre à charpie”.

2. Charger les vêtements sans les tasser dans la sécheuse

et fermer la porte. Ne pas surcharger la sécheuse.

Prévoir suffisamment d’espace pour que les vêtements

puissent culbuter librement.

24

3. Tourner le bouton de commande de programme au programme

recommandé pour le type de charge à sécher. Utiliser le réglage

automatique Perm Press Energy Preferred (Énergie préférée

pour pressage permanent) pour sécher la plupart des charges

lourdes et de poids moyen. Voir “Conseils pour le séchage, les

programmes et la température”.

4. Appuyer sur START (mise en marche).

Arrêt et remise en marche

On peut arrêter la sécheuse à tout moment au cours d’un programme.

Pour arrêter la sécheuse :

Ouvrir la porte de la sécheuse ou tourner le bouton de

commande de programme à OFF (arrêt).

REMARQUE : Le bouton de commande de programme doit

pointer à Off (arrêt) lorsque la sécheuse n’est pas utilisée.

Pour remettre la sécheuse en marche :

1. Fermer la porte.

2. Sélectionner un nouveau programme et une nouvelle

température (si désiré).

3. Appuyer sur le bouton START (mise en marche).

Page 25

Chargement

Charger les vêtements dans la sécheuse sans les tasser. Ne pas

trop charger la sécheuse. Prévoir suffisamment d’espace pour

que les vêtements puissent culbuter librement. Le tableau suivant

montre la charge maximale que l’on peut placée dans la sécheuse

compacte. Prévoir des durées de séchage plus longues.

Vêtements de

travail épais

Delicates (articles

délicats)

Serviettes

Charge mixte

Tricots

Perm Press

(pressage

permanent)

2 pantalons, 3 chemises de travail

1 chemise de nuit, 2 combinaisons,

4 sous-vêtements, 1 pyjama, 1 jupon

9 serviettes de bain ; ou 6 serviettes de

bain, 3 serviettes à main, 6 débarbouillettes

2 taies d’oreiller, 1 t-shirt, 2 chemises,

1 pantalon léger

2 pantalons légers, 2 chemises ; ou 3 robes

6 chemises ; ou 2 grands draps et 2 taies

d’oreiller ; ou 2 draps une personne et

2 taies d’oreiller

Conseils pour séchage, programmes

et température

Choisir le programme et la température corrects pour la charge.

La sécheuse fait culbuter la charge sans chaleur au cours des

quelques dernières minutes de tous les programmes, ce qui

permet de saisir les charges plus facilement.

Conseils de séchage

■ Suivre les directives figurant sur l’étiquette lorsqu’elles

sont disponibles.

■ Si désiré, ajouter une feuille d’assouplissant de tissu.

Suivre les instructions figurant sur l’emballage.

■ Enlever la charge de la sécheuse aussitôt que le culbutage

cesse pour réduire le froissement. Cette action est

particulièrement importante pour les tissus à pressage

permanent, les tricots et les tissus synthétiques.

Conseils pour les programmes et la température

■ Sécher la plupart des charges en utilisant le réglage Energy

Preferred (éconergique).

■ Utiliser un réglage sans chaleur (à l’air) pour le caoutchouc,

le plastique ou les tissus sensibles à la chaleur.

■ Sécher sur une corde à linge les tissus doublés ou

multi-couches.

REMARQUE : Pour toute question concernant les températures

de séchage pour diverses charges, consulter les instructions sur

l’étiquette de soin.

Programmes

Auto Dry (degré de séchage automatique)

Ce programme automatique éteint la sécheuse lorsque la

fonction de détection automatique de l’humidité détermine

que le niveau de séchage sélectionné est atteint. Le bouton de

commande de programme ne se déplace pas tant que la charge

n’est pas presque sèche. Après la période de refroidissement,

le bouton tourne automatiquement à Off (arrêt) et le culbutage

cesse.

Sécher la plupart des charges en utilisant le réglage Energy

Preferred (éconergique). La durée de séchage avec un

programme automatique de séchage varie selon le type de tissu,

le volume de la charge et le réglage de la température.

■ Si la charge est plus sèche que l’on souhaite, sélectionner un

réglage plus proche de Less Dry (moins sec) pour le prochain

séchage d’une charge semblable.

■ Si la charge n’est pas aussi sèche que désiré, achever le

séchage en utilisant le programme de séchage minuté.

La prochaine fois que vous séchez une charge semblable,

choisir un réglage plus proche de Very Dry (très sec).

Comment fonctionne la caractéristique Auto Moisture

Sensing (détection automatique de l’humidité)

Avec le programme Auto Moisture Sensing (détection

automatique de l’humidité), le degré de séchage de la charge

est déterminé par deux bandes métalliques (capteurs) situées

à l’intérieur de la sécheuse. Les bandes métalliques aident à

“détecter” la quantité d’humidité restant dans les vêtements

au moment de leur passage. S’il reste de l’humidité dans les

vêtements, le bouton de commande de programme n’avance

pas. Au fur et à mesure du séchage, la quantité d’eau restant

dans les vêtements diminue et la minuterie avance pour la suite

du programme. Lorsque le degré de séchage sélectionné est

atteint, la sécheuse entre dans une période de refroidissement

pouvant durer jusqu’à 5 minutes.

Séchage à l’air

Utiliser ce programme pour les articles qui doivent être séchés

sans chaleur, tels que le caoutchouc, le plastique et les tissus

sensibles à la chaleur. Voir le tableau pour des exemples

d’articles qui peuvent être séchés au programme de séchage

sans chaleur.

Type de charge Durée*

Caoutchouc mousse – oreillers,

soutiens-gorges rembourrés,

jouets rembourrés

Plastique – rideaux de douche,

nappes

Tapis à endos de caoutchouc 40 - 50

Plastique oléfinique,

polypropylène, nylon diaphane

*(Minutes). Régler de nouveau le programme pour compléter le

séchage, si nécessaire.

Lors de l’utilisation du programme de séchage à l’air

■ Vérifier que les revêtements sont bien cousus.

■ Secouer et faire bouffer les oreillers à la main périodiquement

pendant le programme.

■ Sécher l’article complètement. Les oreillers en caoutchouc

mousse mettent du temps à sécher.

20 - 30

20 - 30

10 - 20

Programme de séchage minuté

Utiliser ce programme pour compléter le séchage si des articles

sont encore humides après le programme automatique.

Le séchage minuté est aussi utile pour :

■ Articles épais et vêtements de travail qui nécessitent un temps

de séchage prolongé.

■ Articles légers, tels que la lingerie, les chemisiers et les tricots

qui nécessitent une durée de séchage courte.

Pour le séchage humide ; tourner le bouton de commande de

programme à 30 minutes ou moins.

Signal de fin de programme

La sécheuse émet un signal sonore qui indique la fin du

programme. Le signal sonore n’est pas réglable et ne peut

être désactivé. Le signal est utile pour faire sécher des tissus à

pressage permanent, synthétiques et autres articles qui doivent

être enlevés de la sécheuse aussitôt qu’elle s’arrête.

25

Page 26

Entretien de la Sécheuse

Nettoyage de l’emplacement

de la sécheuse

Dégager l’emplacement de la sécheuse de façon à ce qu’il soit

libre de tout élément susceptible d’obstruer le débit d’air de

combustion et de ventilation.

Nettoyage du filtre à charpie

Nettoyage avant chaque charge

Le filtre à charpie se trouve à l’intérieur du tambour de la

sécheuse, sur la paroi arrière. Le nettoyer avant chaque charge.

Un filtre obstrué de charpie peut augmenter la durée de séchage.

Nettoyage :

1. Ouvrir la porte et retirer le filtre à charpie tout droit pour

le sortir.

Nettoyage :

1. Retirer la charpie du filtre en la roulant avec les doigts.

2. Mouiller le couvercle et le corps du filtre à charpie avec de

l’eau chaude.

3. Mouiller une brosse en nylon avec de l’eau chaude et du

détergent liquide. Frotter le couvercle et le corps du filtre à

charpie avec la brosse pour enlever l’accumulation de résidus.

4. Rincer à l’eau chaude.

5. Bien sécher le corps et le couvercle du filtre à charpie avec

une serviette propre. Le replacer dans la sécheuse.

Nettoyage de l’intérieur de la sécheuse

Nettoyage du tambour de la sécheuse :

1. Préparer une pâte avec un détergent à lessive en poudre et de

l’eau très chaude.

2. Appliquer la pâte sur un linge doux.

OU

Appliquer un nettoyant liquide domestique ininflammable sur

la surface tachée et frotter avec un linge doux jusqu’à ce que

toute la teinture qui reste soit enlevée.

3. Essuyer complètement le tambour avec un linge humide.

4. Faire culbuter une charge de linge ou de serviettes propres

pour sécher le tambour.

REMARQUE : Les vêtements contenant des teintures instables,

tels que jeans en denim ou articles en coton de couleur vive,

peuvent décolorer l’intérieur de la sécheuse. Ces taches ne

sont pas nocives pour votre sécheuse et ne tacheront pas les

vêtements des charges futures. Faire sécher les articles à teinture

instable sur l’envers pour éviter le transfert de la teinture.

2. Pincer le corps du filtre à charpie légèrement tout en retirant

le couvercle.

3. Retirer la charpie du filtre en la roulant avec les doigts. Ne pas

rincer ni laver le filtre pour enlever la charpie. La charpie

mouillée s’enlève difficilement.

4. Replacer le couvercle sur le corps du filtre à charpie. Remettre le

filtre à charpie fermement en place et fermer la porte.

IMPORTANT :

■ Ne pas faire fonctionner la sécheuse avec un filtre à charpie

déplacé, endommagé, bloqué ou manquant. Une telle action

peut causer une surchauffe ou des dommages à la sécheuse

et aux tissus.

Nettoyage au besoin

Des résidus de détergent ou d’assouplisseur de tissu peuvent

s’accumuler sur le filtre à charpie. Cette accumulation peut

entraîner des temps de séchage plus longs, ou entraîner l’arrêt

de la sécheuse avant que la charge ne soit complètement sèche.

Si de la charpie tombe du filtre, le filtre est probablement obstrué.

Nettoyer le filtre à charpie avec une brosse en nylon tous les

6 mois ou plus fréquemment s’il devient obstrué par suite d’une

accumulation de résidus.

26

Retrait de la charpie accumulée

De l’intérieur de la caisse de la sécheuse

Retirer la charpie tous les 2 ans, ou plus souvent, selon

l’utilisation de la sécheuse. Le nettoyage doit être effectué par

une personne qualifiée.

À partir du conduit d’évacuation

Retirer la charpie tous les 2 ans, ou plus souvent, selon

l’utilisation de la sécheuse.

Précautions à prendre pour les

vacances ou le déménagement

Entretien avant les vacances

On ne doit faire fonctionner la sécheuse que lorsqu’on est

présent. Si l’utilisateur doit partir en vacances ou n’utilise pas la

sécheuse pendant une période prolongée, il convient d’exécuter

les opérations suivantes :

1. Débrancher la sécheuse ou déconnecter la source de

courant électrique.

2. Nettoyer le filtre à charpie. Voir “Nettoyage du filtre à charpie”.

Précautions à prendre avant un déménagement

1. Débrancher le cordon d’alimentation électrique.

2. Utiliser du ruban adhésif pour fixer la porte de la sécheuse.

Page 27

Dépannage

Essayer d’abord les solutions suggérées ici ou visiter notre site Web à www.amana.custhelp.com –

Au Canada, visiter www.amanacanada.ca pour assistance et pour éviter une visite de service.

Si vous rencontrez les

problèmes suivants

Fonctionnement de la sécheuse

La sécheuse ne

fonctionne pas

La minuterie ne

progresse pas

visiblement

Sons inhabituels

Bruit saccadé La sécheuse n’a pas été utilisée

Bruit de grattement ou

de vibration

La porte n’est pas bien fermée. S’assurer que la porte de la sécheuse est complètement fermée.

Appuyer sur le bouton START

(mise en marche) pendant 2 à 5

secondes.

Un fusible du domicile est grillé ou

le disjoncteur est ouvert.

Alimentation électrique incorrecte. Les sécheuses électriques nécessitent une alimentation électrique

Type de fusible incorrect. Utiliser un fusible temporisé.

Alimentation électrique incorrecte. Les sécheuses électriques nécessitent une alimentation électrique

La sécheuse est réglée sur Timed

Dry (séchage minuté) ou Air Dry

(séchage à l’air).

La sécheuse est réglée sur le

programme Auto Dry.

pendant un moment.

Un petit objet est coincé dans le bord

du tambour de la sécheuse.

L’aplomb de la sécheuse n’a pas été

correctement établi.

Les vêtements sont en boule dans la

sécheuse.

Causes possibles Solution

Appuyer sur le bouton START (mise en marche) pendant 2 à

5 secondes.

Il y a un fusible ou un disjoncteur pour la sécheuse. S’assurer

que le fusible est intact et serré ; ou que le disjoncteur n’est pas

déclenché. Remplacer le fusible ou réenclencher le disjoncteur. Si le

problème persiste, appeler un électricien.

de 120 V. Vérifier avec un électricien qualifié.

de 120 V. Vérifier avec un électricien qualifié.

La minuterie progresse lentement et de façon continue au cours de

la durée réglée.

La minuterie ne progresse que lorsque le linge est pratiquement

sec. Voir “Comment fonctionne la caractéristique Auto Moisture

Sensing (détection automatique de l’humidité)” dans “Utilisation de la

sécheuse”.

Ceci est normal. La bruit saccadé devrait s’atténuer après quelques

minutes d’utilisation.

Vérifier qu’il n’y a pas de petits objets coincés au niveau des rebords

avant et arrière du tambour. Vider les poches avant le lavage.

La sécheuse peut vibrer si elle n’est pas correctement installée.

Contrôler l’aplomb de la sécheuse. Les quatre roulettes doivent être

bien en contact avec le plancher.

Une charge en boule rebondit, ce qui fait vibrer la sécheuse. Séparer les

articles dans la charge et remettre la sécheuse en marche.

27

Page 28

Dépannage

Résultats de la sécheuse

REMARQUE : La sécheuse compacte fonctionne à faible puissance. Prévoir des durées de séchage plus longues.

Les vêtements ne

sèchent pas de

manière satisfaisante

ou le temps de

séchage est trop long

Le filtre à charpie est obstrué par

de la charpie.

Le conduit d’évacuation ou le

clapet d’évacuation à l’extérieur est

obstrué par de la charpie, ce qui

restreint le mouvement de l’air.

Le conduit d’évacuation ne

possède pas la bonne longueur.

Le conduit d’évacuation ne

possède pas le bon diamètre.

La sécheuse n’est pas d’aplomb.

Le réglage de température Air Dry

(séchage à l’air) a été sélectionné.

La charge est trop grosse et trop

lourde pour sécher rapidement.

Des feuilles d’assouplissant pour

tissu obstruent le couvercle du filtre

à charpie.

Nettoyer le filtre à charpie avant chaque charge.

Faire fonctionner la sécheuse pendant 5 à 10 minutes. Tenir la main sous

le clapet d’évacuation à l’extérieur pour vérifier le mouvement de l’air. Si

aucun mouvement d’air n’est perceptible, ôter la charpie présente dans

le système d’évacuation ou remplacer le conduit d’évacuation par un

conduit métallique lourd ou flexible. Voir “Évacuation”.

Vérifier que le conduit d’évacuation n’est pas trop long ou ne

comporte pas trop de changements de direction. Un long conduit

augmentera les durées de séchage. Voir “Évacuation”.

Utiliser un conduit de 4" (102 mm) de diamètre.

Les vêtements ne sont pas au contact des détecteurs d’humidité lors

du fonctionnement des programmes automatiques. Contrôler l’aplomb

de la sécheuse. Les quatre roulettes doivent être bien en contact avec

le plancher.

Choisir la bonne température en fonction du type de vêtements à

sécher. Voir “Programmes”.

Séparer la charge pour qu’elle culbute librement.

Utiliser seulement une feuille d’assouplissant pour tissu par charge

et l’utiliser une seule fois.

28

Page 29

Essayer d’abord les solutions suggérées ici ou visiter notre site Web à www.amana.custhelp.com –

Au Canada, visiter www.amanacanada.ca pour assistance et pour éviter une visite de service.

Si vous rencontrez les

problèmes suivants

Résultats de la sécheuse

Les vêtements ne

sèchent pas de

manière satisfaisante

ou le temps de

séchage est trop long

(suite)

La durée du

programme est trop

courte

Charpie sur la charge Le filtre à charpie est obstrué par

Présence de taches sur

le linge

Présence de taches sur

le tambour

Charges froissées La charge n’a pas été retirée de la

Odeurs

La sécheuse se trouve dans une

pièce où la température ambiante

est inférieure à 45°F (7°C).

La sécheuse est placée dans un

placard.

La charge n’est peut-être pas

en contact avec les bandes de

détection (pour les programmes de

détection).

Le programme de détection se

termine prématurément.

de la charpie.

Utilisation incorrecte de

l’assouplissant pour tissu.

Teintures instables sur les

vêtements.

sécheuse à la fin du programme.

Les vêtements sont tassés dans la

sécheuse.

Vous avez récemment employé de la

peinture, de la teinture ou du vernis

dans la pièce où votre sécheuse est

installée.

La sécheuse est utilisée pour la

première fois.

Causes possibles Solution

Le bon fonctionnement des programmes de la sécheuse nécessite