Amana NDG7800AWW, NDG5800AWW, NDG2330AWW Installation Guide

Exhaust System Materials

CONNECT

DRYER TO

BgmLT BETTER THAN mTHAS TQ B_"

EXHAUST

SYSTEM

Secure all joints with clamps or duct

tape. DO NOT use sheet metal

screws or other fastening means

which extend into the duct to attach

Installation

Instructions

Gas Dryer

Keep instructions for future

reference. Be sure manual

stays with dryer.

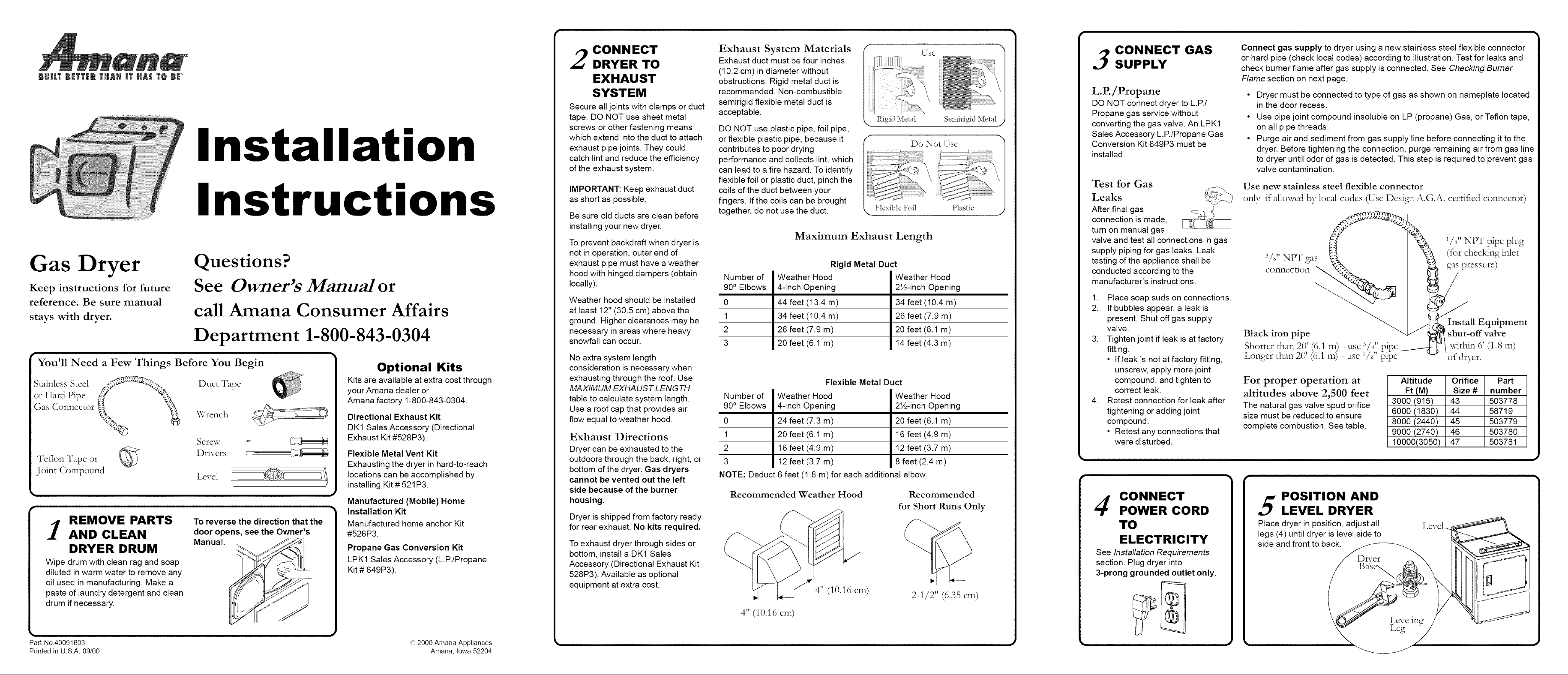

You'll Need a Few Things Before You Begin

Stainless Steel

or Hard Pipe

Gas Connector

Teflon Tape or

Joint Compound

REMOVE PARTS

AND CLEAN

DRYER DRUM

Part No.40091603 ¢, 2000 Amana Appliances ,_

Printed in US.A. 09/00 Amana, Iowa 52204

Questions?

See Owner's Manual or

call Amana Consumer Affairs

Department 1-800-843-0304

Optional Kits

Duct Tape

Wrench

Screw

Drivers

Level

Kits are available at extra cost through

your Amana dealer or

Amana factory 1-800-843-0304.

Directional Exhaust Kit

DK1 Sales Accessory (Directional

Exhaust Kit #528P3).

Flexible Metal Vent Kit

Exhausting the dryer in hard-to-reach

locations can be accomplished by

installing Kit # 521P3.

Manufactured (Mobile) Home

Installation Kit

Manufactured home anchor Kit

#526P3.

Propane Gas Conversion Kit

LPK1 Sales Accessory (LP./Propane

Kit # 649P3).

exhaust pipe joints. They could

catch lint and reduce the efficiency

of the exhaust system.

IMPORTANT: Keep exhaust duct

as short as possible.

Be sure old ducts are clean before

installing your new dryer.

To prevent backdraft when dryer is

not in operation, outer end of

exhaust pipe must have a weather

hood with hinged dampers (obtain

locally).

Weather hood should be installed

at least 12" (30.5 cm) above the

ground. Higher clearances may be

necessary in areas where heavy

snowfall can occur.

No extra system length

consideration is necessary when

exhausting through the roof. Use

MAXIMUM EXHAUST LENGTH

table to calculate system length.

Use a roof cap that provides air

flow equal to weather hood.

Exhaust Directions

Dryer can be exhausted to the

outdoors through the back, right, or

bottom of the dryer. Gas dryers

cannot be vented out the left

side because of the burner

housing.

Dryer is shipped from factory ready

for rear exhaust. No kits required.

To exhaust dryer through sides or

bottom, install a DK1 Sales

Accessory (Directional Exhaust Kit

528P3). Available as optional

equipment at extra cost.

Exhaust duct must be four inches

(10.2 cm) in diameter without

obstructions. Rigid metal duct is

recommended. Non-combustible

semirigid flexible metal duct is

acceptable.

DO NOT use plastic pipe, foil pipe,

or flexible plastic pipe, because it

contributes to poor drying

performance and collects lint, which

can lead to a fire hazard. To identify

flexible foil or plastic duct, pinch the

coils of the duct between your

fingers. If the coils can be brought

together, do not use the duct.

f --,

Maximum Exhaust Length

Rigid Metal Duct

Number of

90° Elbows

0

1

2

3

Number of

90° Elbows

0

1

2

3

NOTE: Deduct 6 feet (1.8 m) for each additional elbow.

Recommended Weather Hood Recommended

4" (10.16 cm)

Weather Hood

4-inch Opening

44 feet (13.4 m)

34 feet (10.4 m)

26 feet (7.9 m)

20 feet (6.1 m)

Flexible Metal Duct

Weather Hood

4-inch Opening

24 feet (7.3 m)

20 feet (6.1 m)

16 feet (4.9 m)

12 feet (3.7 m)

4" (10.16 cm)

Weather Hood

2½-inch Opening

20 feet (6.1 m)

Weather Hood

2½-inch Opening

20 feet (6.1 m)

['se

Semirigid Metalj'-. Rigid Metal

Do Not _se

34 feet (10.4 m)

26 feet (7.9 m)

14 feet (4.3 m)

16 feet (4.9 m)

12 feet (3.7 m)

8 feet (2.4 m)

for Short Runs Only

2-1/2" (6.35 cm)

CONNECT GAS

SUPPLY

L.P./Propane

DO NOT connect dryer to LP./

Propane gas service without

converting the gas valve. An LPK1

Sales Accessory L.R/Propane Gas

Conversion Kit 649P3 must be

installed.

Test for Gas

Leaks

After final gas

connection is made,

turn on manual gas

valve and test all connections in gas

supply piping for gas leaks. Leak

testing of the appliance shall be

conducted according to the

manufacturer's instructions.

1. Place soap suds on connections.

2. If bubbles appear, a leak is

present. Shut off gas supply

valve.

3. Tighten joint if leak is at factory

fitting.

• If leak is not at factory fitting,

unscrew, apply more joint

compound, and tighten to

correct leak.

4. Retest connection for leak after

tightening or adding joint

compound.

• Retest any connections that

were disturbed.

i

CONNECT

POWER CORD

TO

ELECTRICITY

Connect gas supply to dryer using a new stainless steel flexible connector

or hard pipe (check local codes) according to illustration. Test for leaks and

check burner flame after gas supply is connected. See Checking Burner

Flame section on next page.

• Dryer must be connected to type of gas as shown on nameplate located

in the door recess.

• Use pipe joint compound insoluble on LP (propane) Gas, or Teflon tape,

on all pipe threads.

• Purge air and sediment from gas supply line before connecting it to the

dryer. Before tightening the connection, purge remaining air from gas line

to dryer until odor of gas is detected. This step is required to prevent gas

valve contamination.

Use new stainless steel flexible connector

only if allowed by local codes (Use Design A.G.A. certified connector)

,_Y_","_'_

,_ I_)_ ,,

_/,,-'_,,, (, ] _5, (for checking inlet

/8 _NI'I has _a

connection _ {,,_ I _ ". * "

Black iron pipe _ ent

Shorter than 20' (6.1 m) _ pipe _ _/within 6 (1.8 m)

Lon(*er than 20' :6 1 m_ _/2" PiPe "--'-- ¢_A _,,9"

• -- _ I _ _as pressure)

v • a- ' /_ pp orurver.

For proper operation at

altitudes above 2,500 feet

The natural gas valve spud orifice

size must be reduced to ensure

complete combustion. See table.

POSITION AND

LEVEL DRYER

Place dryer in position, adjust all

legs (4) until dryer is level side to

side and front to back.

I "£% 1/8 NlYF pipe plug

_).1 - -

Altitude

Ft (M)

3000 (915)

6000 (1830)

8000 (2440)

9000 (2740)

10000(3050)

Orifice

Size #

43

44

45

46

47

Level.

Pa_

number

503778

58719

503779

503780

503781

Drier

B,'fse_

I

Leveling

Leg

Important Safety Information Installation Requirements Installation Checks and Adjustments

Install

About Ground Wires

In the event of an electrical short circuit, a

ground wire reduces the risk of electric

shock by providing an escape wire for the

electric current.

Standard accepted color coding for ground

wires is green or green with a yellow

stripe.

Grounding wires and wires colored like

grounding wires are NOT to be used as

current carrying conductors.

l li WARNING ]

To avoid risk of personal injury or

death:

• Do not allow children to play on or

in the appliance. Close

supervision of children is

necessary when the appliance is

used near children.

I WARNING I

To avoid injury or death due to

suffocation, remove door to dryer

compartment before appliance is

removed from service or discarded.

Save These Instructions

Part No.40091603

Printed in US.A. 09/00

Grounding Instructions

Dryer must be grounded. Dryer is equipped with a cord having a grounding

conductor and a 3-prong grounding plug. The three-prong grounding plug on

the power cord should be plugged directly into a polarized three-slot grounded

receptacle rated 110/120V AC (alternating current) 15 Amps.

WARNING I

To avoid risk of personal injury or death due to electrical shock:

• Disconnect electrical power to •

unit before servicing.

• Ground appliance properly. •

• Check with a qualified •

electrician if you are not sure

this appliance is properly

grounded, or that it has enough

electrical power to operate the

dryer.

• All wiring and grounding must

conform with the latest edition

of the National Electric Code,

ANSt/NFPA 70, or the Canadian

Electrical Code, CSA C22.1, •

and such local regulations as

might apply. •

• DO NOT ground to gas line.

To avoid death, personal injury or property damage, from fire or

explosion, information in this manual must be followed exactly:

• Do not store or use gasoline

or other flammable vapors

and liquids in the vicinity of

this or any other appliance.

• DO NOT use plastic pipe, foil

pipe, or flexible plastic pipe

to exhaust the dryer.

• Never install flexible duct in

concealed spaces, such as

a wall or ceiling.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor's phone. Follow

the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

• Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

DO NOT ground to cold water

pipe.

DO NOT pinch power cord.

DO NOT modify plug on power

cord. tf plug does not fit

electrical outlet, have proper

outlet installed by qualified

electrician.

DO NOT have a fuse in the

neutral or ground circuit. A fuse

in the neutral or ground circuit

could result in an electrical

shock.

DO NOT use an extension cord

with this appliance.

DO NOT use an adapter plug

with this appliance.

Dryer must be exhausted to

the outdoors. DO NOT

exhaust dryer air into a

window well, gas vent,

chimney or enclosed,

unventilated area, such as

an attic, wall, ceiling, crawl

space under a buidling or

concealed space of a

building.

(,, 2000 Amana Appliances

Amana, Iowa 52204

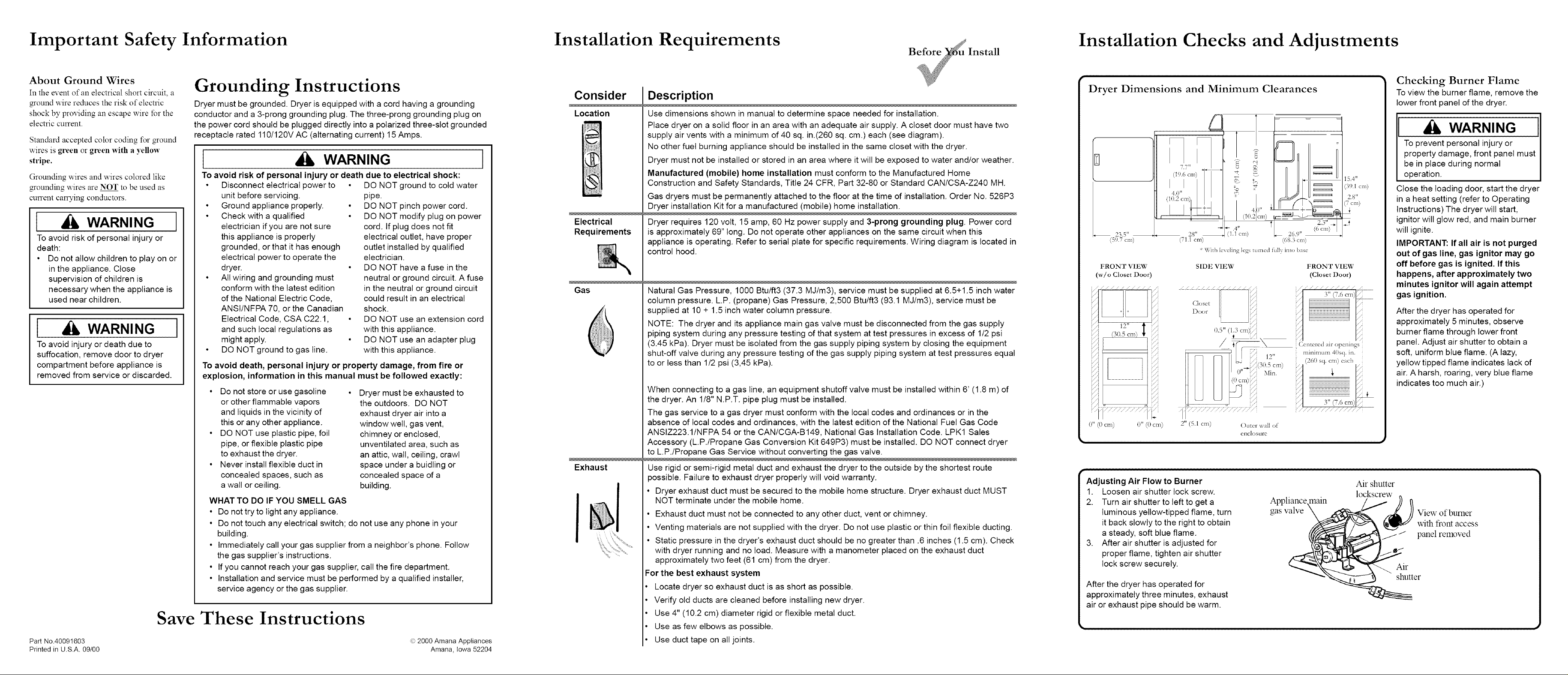

Consider

Location

i

Electrical

Requirements

Gas

Exhaust

Description

Use dimensions shown in manual to determine space needed for installation.

Place dryer on a solid floor in an area with an adequate air supply. A closet door must have two

supply air vents with a minimum of 40 sq. in.(260 sq. cm.) each (see diagram).

No other fuel burning appliance should be installed in the same closet with the dryer.

Dryer must not be installed or stored in an area where it will be exposed to water and/or weather.

Manufactured (mobile) home installation must conform to the Manufactured Home

Construction and Safety Standards, Title 24 CFR, Part 32-80 or Standard CAN/CSA-Z240 MH.

Gas dryers must be permanently attached to the floor at the time of installation. Order No. 526P3

Dryer installation Kit for a manufactured (mobile) home installation.

Dryer requires 120 volt, 15 amp, 60 Hz power supply and 3-prong grounding plug. Power cord

is approximately 69" long. Do not operate other appliances on the same circuit when this

appliance is operating. Refer to serial plate for specific requirements. Wiring diagram is located in

control hood.

Natural Gas Pressure, 1000 Btu/ft3 (37.3 MJ/m3), service must be supplied at 6.5+1.5 inch water

column pressure. LP. (propane) Gas Pressure, 2,500 Btu/ft3 (93.1 MJ/m3), service must be

supplied at 10 + 1.5 inch water column pressure.

NOTE: The dryer and its appliance main gas valve must be disconnected from the gas supply

piping system during any pressure testing of that system at test pressures in excess of 1/2 psi

(3.45 kPa). Dryer must be isolated from the gas supply piping system by closing the equipment

shut-off valve during any pressure testing of the gas supply piping system at test pressures equal

to or less than 1/2 psi (3,45 kPa).

When connecting to a gas line, an equipment shutoff valve must be installed within 6' (1.8 m) of

the dryer. An 1/8" N.P.T. pipe plug must be installed.

The gas service to a gas dryer must conform with the local codes and ordinances or in the

absence of local codes and ordinances, with the latest edition of the National Fuel Gas Code

ANSIZ223.1/NFPA 54 or the CAN/CGA-B149, National Gas Installation Code. LPK1 Sales

Accessory (LP./Propane Gas Conversion Kit 649P3) must be installed. DO NOT connect dryer

to LP./Propane Gas Service without converting the gas valve.

Use rigid or semi-rigid metal duct and exhaust the dryer to the outside by the shortest route

}ossible. Failure to exhaust dryer properly will void warranty.

• Dryer exhaust duct must be secured to the mobile home structure. Dryer exhaust duct MUST

NOT terminate under the mobile home.

• Exhaust duct must not be connected to any other duct, vent or chimney.

• Venting materials are not supplied with the dryer. Do not use plastic or thin foil flexible ducting.

• Static pressure in the dryer's exhaust duct should be no greater than .6 inches (1.5 cm). Check

with dryer running and no load. Measure with a manometer placed on the exhaust duct

approximately two feet (61 cm) from the dryer.

For the best exhaust system

Locate dryer so exhaust duct is as short as possible.

Verify old ducts are cleaned before installing new dryer.

Use 4" (10.2 cm) diameter rigid or flexible metal duct.

Use as few elbows as possible.

Use duct tape on all joints.

r

Dryer Dimensions and Minimum Clearances

fl

,%/

T-

4.o" /

(59.7 cm)

FRONT VIEW

(_/o Closet Door)

[//!

0" (0 cm) ( " (0 cm) 2" (5.1 cm) Outer vail o£

Adjusting Air Flow to Burner

1. Loosen air shutter lock screw.

2. Turn air shutter to left to get a

luminous yellow-tipped flame, turn

it back slowly to the right to obtain

a steady, soft blue flame.

3. After air shutter is adjusted for

proper flame, tighten air shutter

lock screw securely.

After the dryer has operated for

approximately three minutes, exhaust

air or exhaust pipe should be warm.

28"

(71.t cm) (68.3 cm)

• \Xith le_ cling le_zsturned i:ulR into base

SIDE VIEW FRONT VIEW

_4-

7

¢_ 4,0"

( 0.2 cm)

ei1closure

Appliance main

gas valve \

(Closet Door)

i_,4

(39.t cm)

2.8"

Air shutter

lockscrew _

• Checking Burner Flame

To view the burner flame, remove the

lower front panel of the dryer.

WARNING

To prevent personal injury or

property damage, front panel must

be in place during normal

operation.

Close the loading door, start the dryer

in a heat setting (refer to Operating

Instructions) The dryer will start,

ignitor will glow red, and main burner

will ignite.

IMPORTANT: If all air is not purged

out of gas line, gas ignitor may go

off before gas is ignited. If this

happens, after approximately two

minutes ignitor will again attempt

gas ignition.

After the dryer has operated for

approximately 5 minutes, observe

burner flame through lower front

panel. Adjust air shutter to obtain a

soft, uniform blue flame. (A lazy,

yellow tipped flame indicates lack of

air. A harsh, roaring, very blue flame

indicates too much air.)

View of burner

with front access

panel removed

_ Air

shutter

Loading...

Loading...